Construction method for rapid hole alignment and posture adjustment of prefabricated stand column

A construction method and column technology, which is applied in the construction field of prefabricated columns to quickly align holes and adjust attitudes, can solve the problems of cumbersome hoisting process, low efficiency, and low precision control of column hoisting, and achieve low safety risks and reduce the number of times and time , Ensure that the error is controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

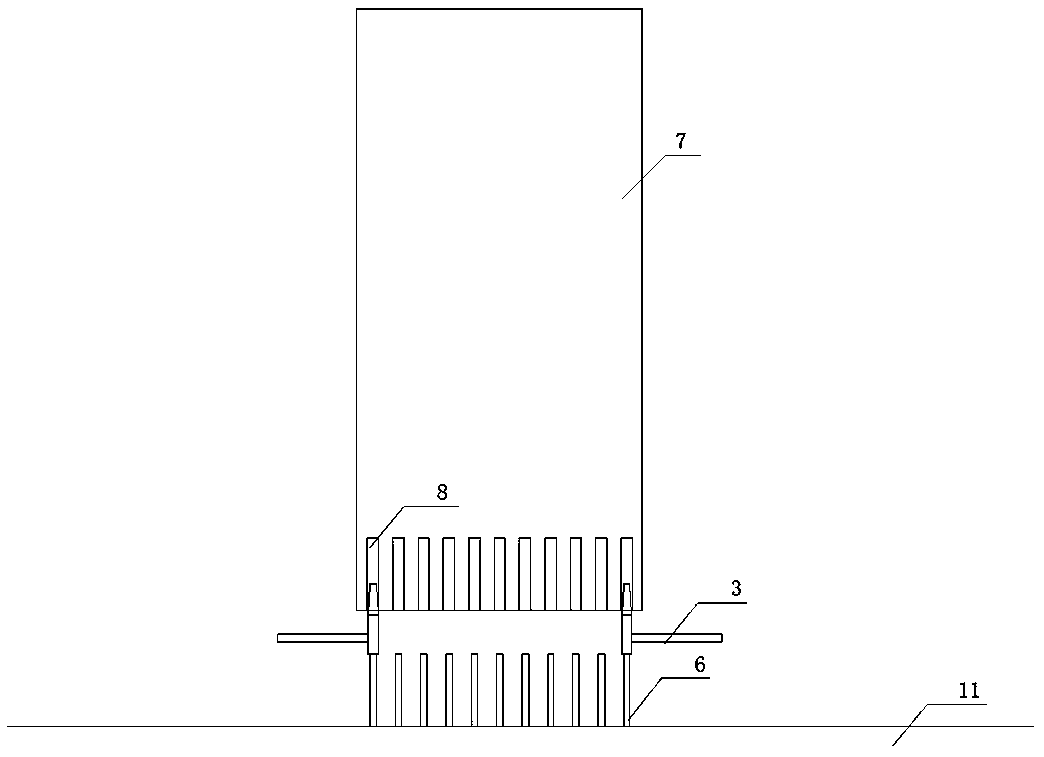

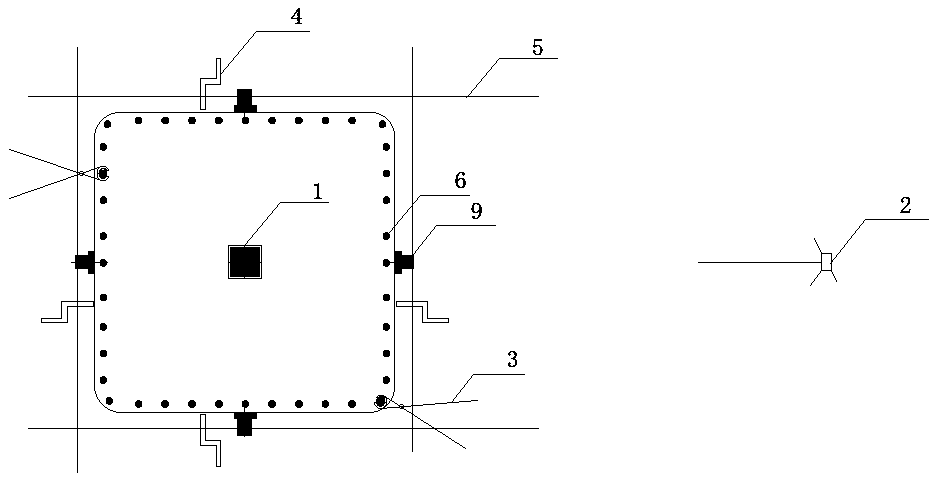

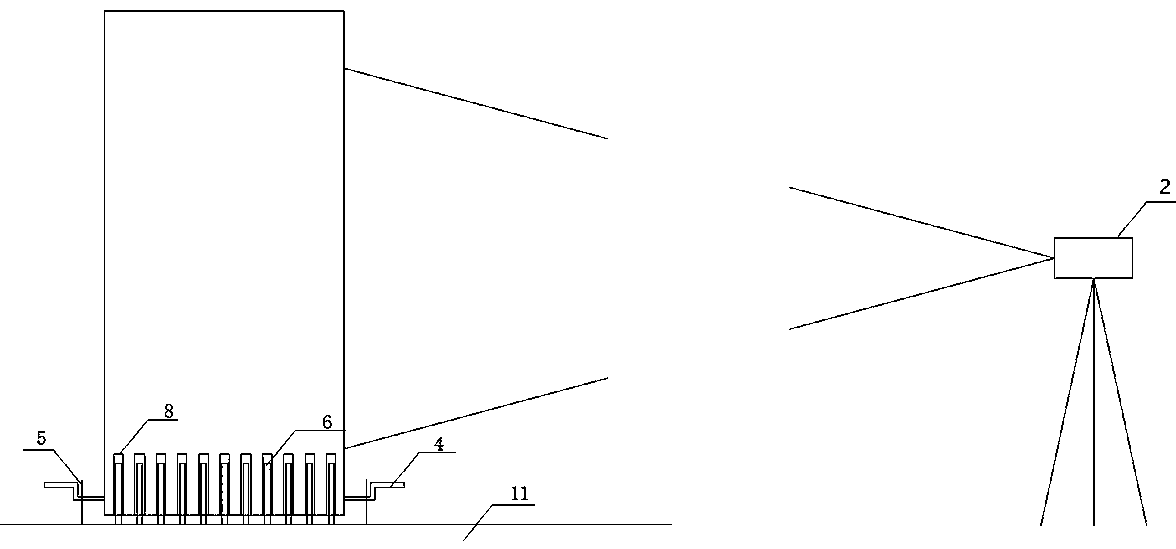

[0024] Embodiment: As shown in the figure, this embodiment specifically relates to a construction method for quickly aligning holes and adjusting attitude of a prefabricated column. 6 to level the top surface of the cap 11, and during the hoisting process, the pre-embedded sleeve 8 of the prefabricated column 7 is quickly aligned with the pre-embedded steel bar 6 on the hole cap 11 through the self-made guide tapered pliers 3, and then passed The azimuth adjuster 4 adjusts the plane position of the prefabricated column 7, and adjusts the verticality of the prefabricated column 7 by lifting the corbel 9 on the prefabricated column 7. Security Risk.

[0025] Such as Figure 1-6 As shown, a construction method for fast hole and posture adjustment of prefabricated columns in this embodiment includes the following steps:

[0026] (1) The prefabricated column 7 is prefabricated. In the prefabrication stage, a circle of vertical embedded sleeve 8 is embedded at the bottom of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com