Method for locking clamp on precision machine tool

A precision machine tool and fixture technology, applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of manpower tightening, damage to objects, etc., to increase the locking force, avoid virtual contact or insufficient locking force, Effect of Overcoming Virtual Contact or Slipping Phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in more detail below with reference to specific embodiments and accompanying drawings.

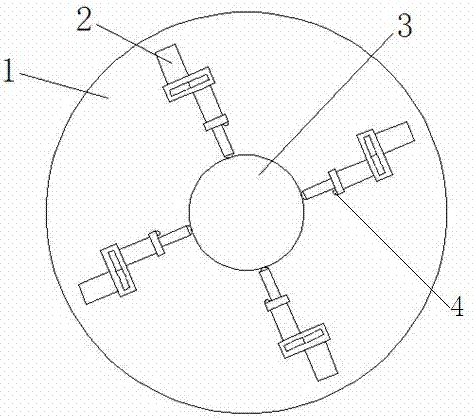

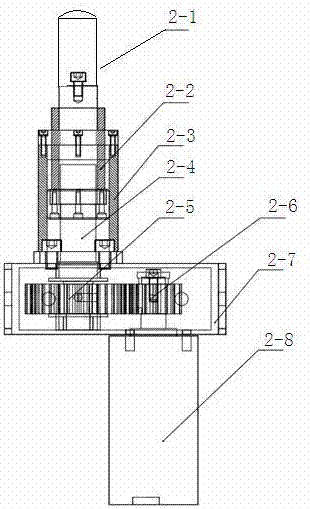

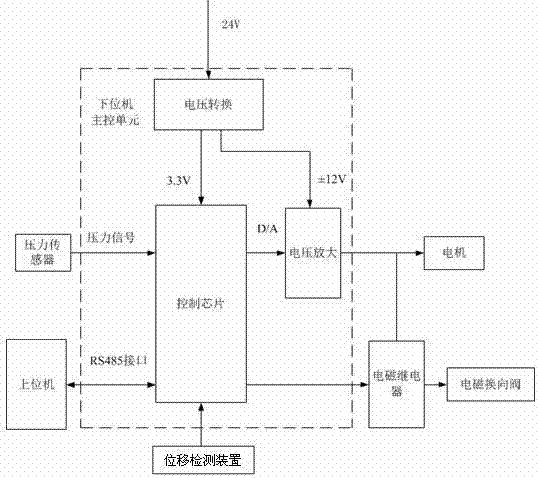

[0038] The invention discloses a clamp locking method based on the precision machine tool. The clamp is such as figure 1 As shown in the figure, it includes an electromagnetic chuck, a hydraulic oil device, a hydraulic propulsion mechanism, a displacement detection device, a pressure detection device and a lower computer, wherein, four hydraulic propulsion mechanisms are symmetrically arranged on the upper surface of the electromagnetic chuck along the circumference of the disk, and each hydraulic propulsion mechanism includes a pressure Rod, transition cylinder block, screw nut pair, driving gear, passive gear, gear box, hydraulic motor.

[0039]The pressure rod is connected to the transition cylinder block by bolts, and the transition cylinder block is embedded in the nut pair and fixed by the positioning pins, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com