Pre-gluing machine of bolt

A pre-glue machine and glue-coating technology, which is applied in the direction of coating and surface coating liquid devices, etc., can solve the problems of low production efficiency, unsuitable for multi-variety and small-batch production, poor glue quality, etc., and achieve production costs Reduced effect

Active Publication Date: 2010-09-01

FAWER AUTOMOTIVE PARTS

View PDF4 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention discloses a bolt pre-gluing machine with an axial gluing method to solve the problem of poor gluing quality and low production efficiency of the bolt pre-gluing machine with manual gluing and circumferential gluing methods in the prior art, and automatic bolt pre-gluing. Gluing line is expensive and not suitable for multi-variety and small-batch production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

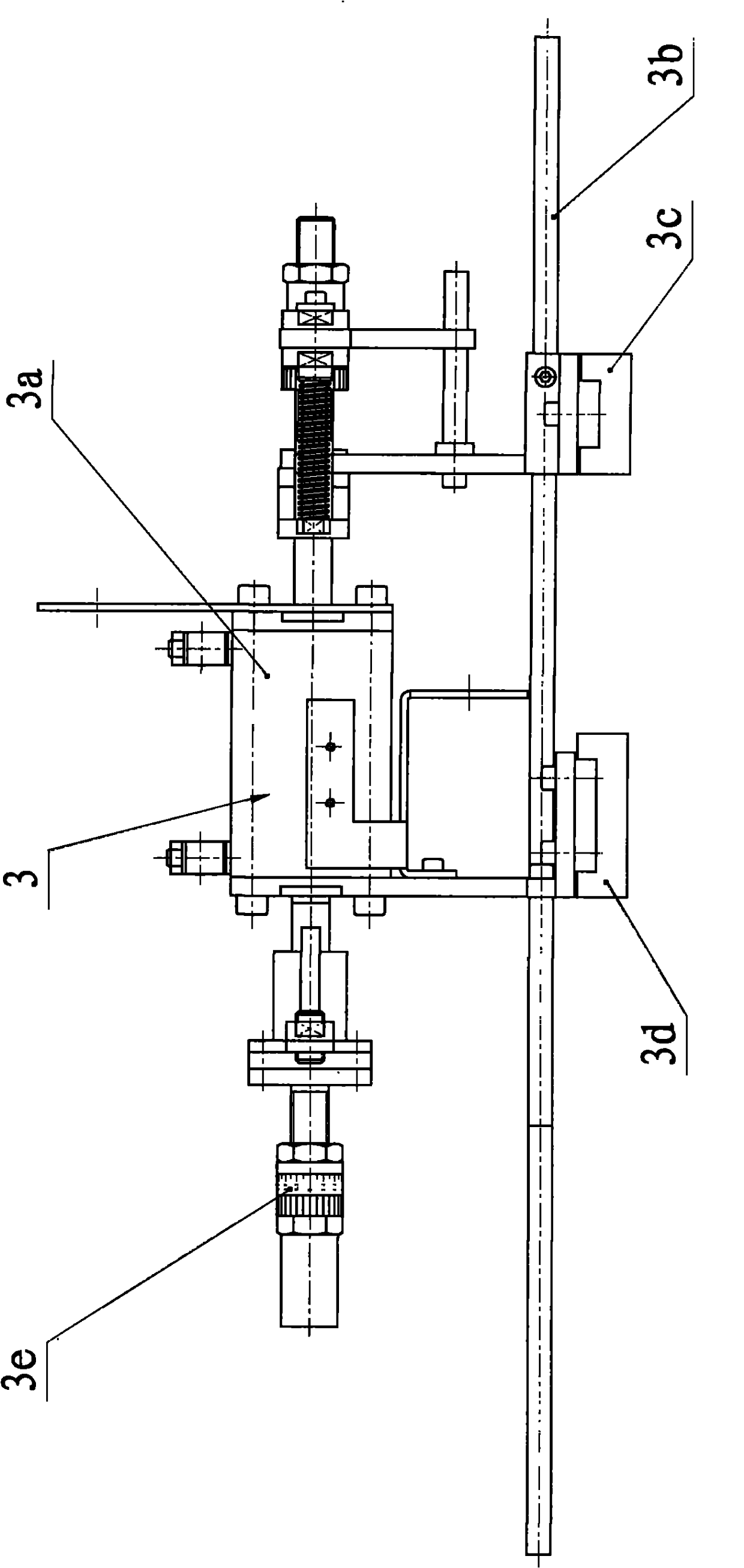

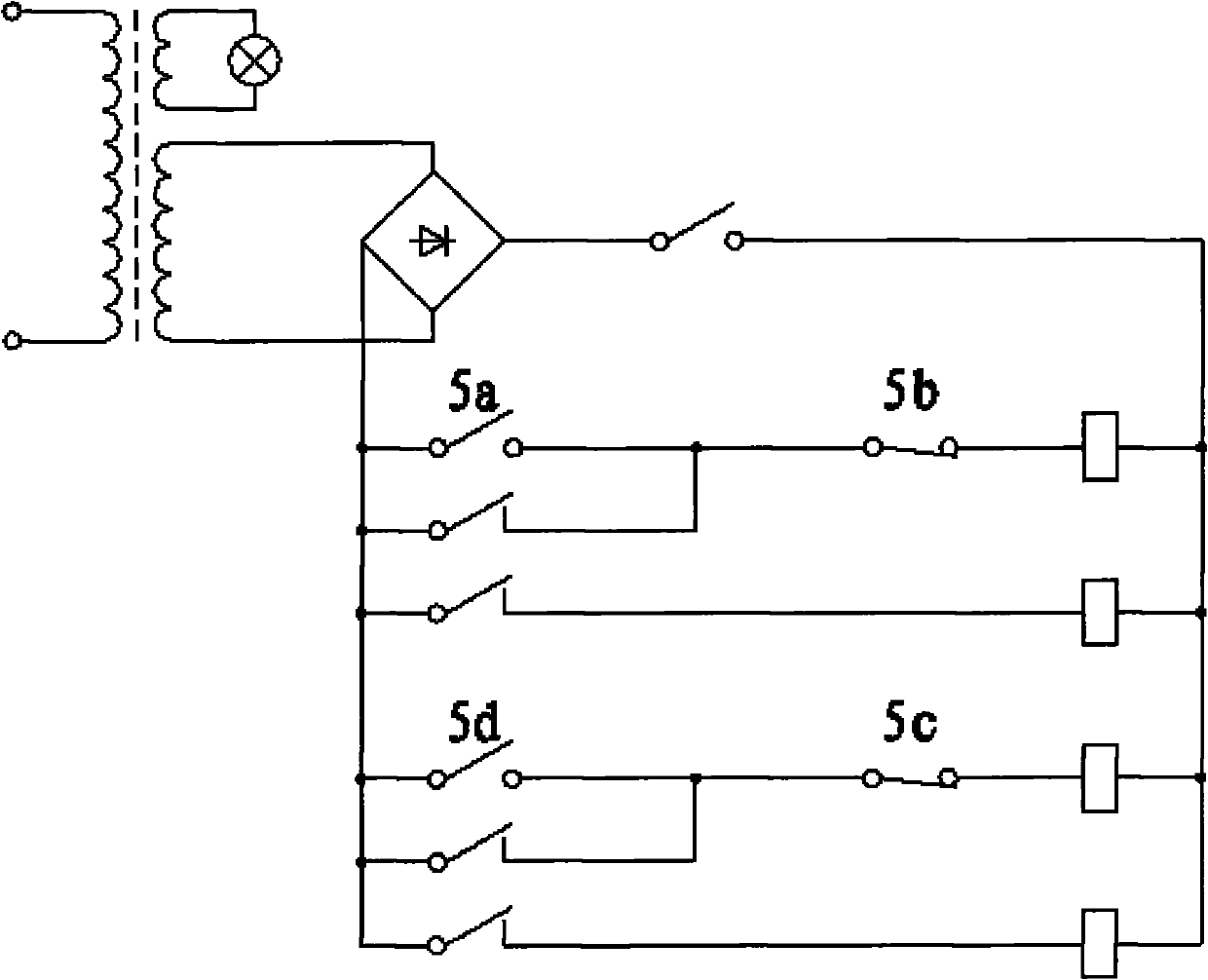

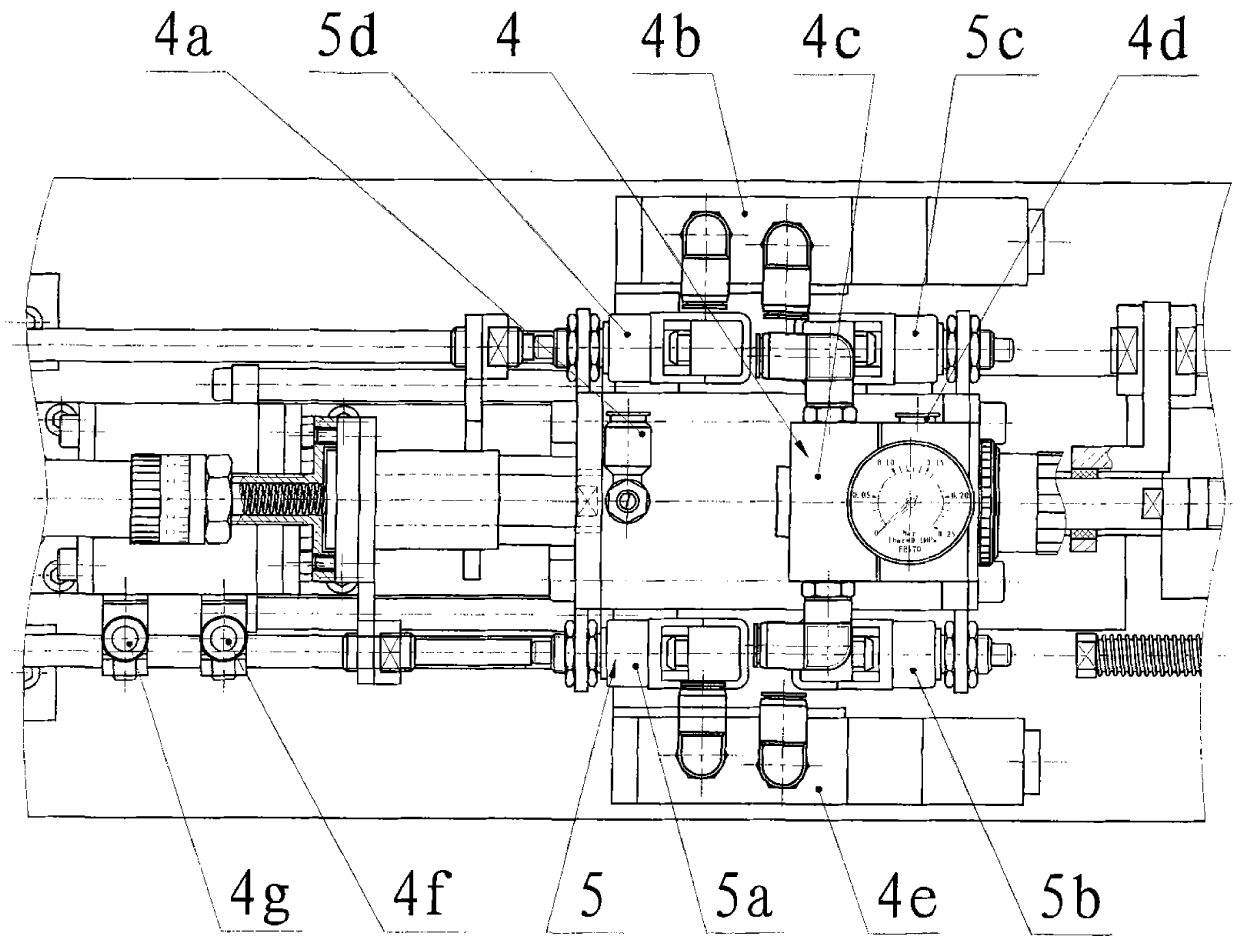

The invention discloses a pre-gluing machine of a bolt. The machine is characterized in comprising a gluing head, a gluing opening turning on-off mechanism, a pushing mechanism, an electric control device system, a glue storing cylinder and an adjusting component, wherein the glue storing cylinder is connected with a glue inlet of the gluing head; the gluing head comprises a baffle ring of an opening of a gluing cavity, a gluing cavity sleeve, a gluing cavity sleeve seat, a pushing rod, a gluing cavity, a gluing opening and a glue storing cavity; an annular gluing opening is formed between the baffle ring of the gluing cavity and the gluing cavity sleeve; the pushing mechanism and the gluing opening turning on-off mechanism respectively comprises a gas cylinder; the gluing opening turning on-off mechanism and the pushing mechanism are driven by the gas cylinders to realize the sequential linkage; the pushing rod gradually and axially pushes a bolt of a work piece; glue liquid is peripherally, axially and continuously injected among screw thread teeth of the bolt of the work piece from the gluing opening along the bolt of the work piece; and the adjusting component can adjust the action position of the pushing rod, the turning on-off position of the gluing opening, the opening width of the gluing opening, and the opening pressure of the gluing opening. The pre-gluing machine can peripherally, axially and fast inject the glue into an elastic die cavity, can evenly and exactly glue, guarantees the gluing length and position, and guarantees the quality.

Description

technical field The invention belongs to the technical field of mechanical engineering, and relates to a bolt pre-applying machine, which is particularly suitable for pre-applying thread-locking glue on various bolts. Background technique As we all know, the commonly used method of pre-applying thread-locking glue on the bolts by hand is of poor quality and cannot guarantee the expected locking performance, and the production efficiency is low, and the production cycle can generally only reach 4 seconds per piece. The traditional bolt pre-gluing machine adopts the circumferential gluing method, which mainly includes the following three types: the first is that the workpiece bolts are rolled and coated on the gluing plate with a certain width; the second is that the workpiece bolts are clamped on the Rotate on the rotating shaft, use a certain width glue brush or sheet to brush glue in the circumferential direction; the third is to roll the workpiece bolts and a certain thic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05C5/00B05C11/10B05C13/02

Inventor 王志宇

Owner FAWER AUTOMOTIVE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com