Fixed-length sensing device as well as automatic fixed-length cutting device and method of plastic-steel winding pipe

A technology of plastic-steel winding pipe and sensing device, which is applied in the direction of feeding device, automatic control device, measuring/indicating equipment, etc. It can solve the problem that the limit switch cannot be cut and sensed by the plastic-steel winding pipe to a fixed length, and the plastic-steel winding pipe cannot be automatically and fixedly Long cutting, affecting the production stability and continuity of plastic-steel winding pipe forming, to achieve the effect of maintaining stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

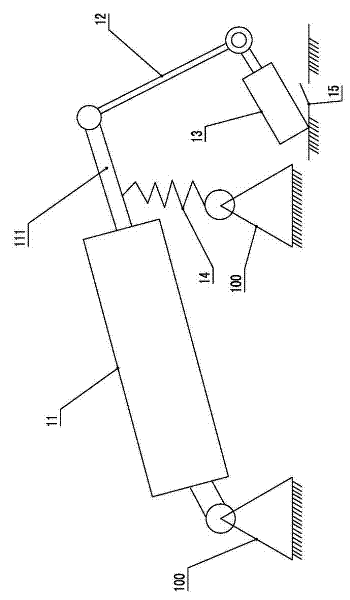

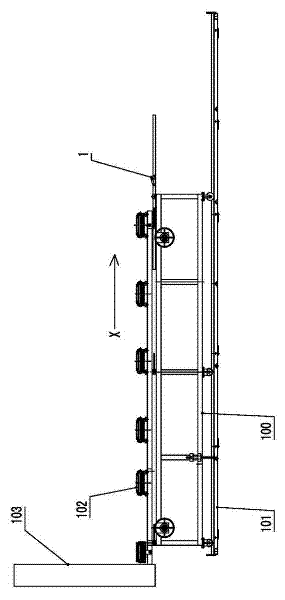

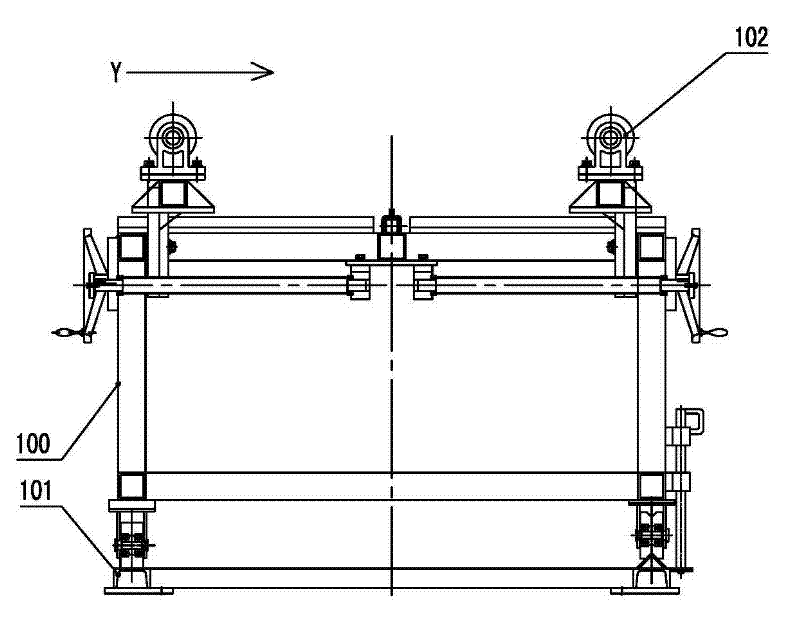

[0030] Figure 1 to Figure 4 The reference numerals in the drawing are: fixed-length sensing device 1; roller 11; roller shaft 111; connecting rod 12; limit switch trigger 13; return spring 14; limit switch 15; frame 100; 102; plastic-steel winding pipe forming extrusion part 103; limit starting position sensing proximity switch 21; starting position sensing proximity switch 22; end position sensing proximity switch 23; limit end position sensing proximity switch 24; stop position sensing proximity switch 31; longitudinal slide Table tracking position sensing proximity switch 32; cutting position sensing proximity switch 33.

[0031] Such as figure 1 As shown, a fixed-length sensing device includes a frame 100, a roller shaft 111, a connecting rod 12, a limit switch 15, a return spring 14, and a limit switch trigger part 13 that triggers the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com