Elastic floating support device for drawing and extending roller die of drawing and extending hydraulic press

A technology of floating support and hydraulic press, which is applied in the field of supporting devices for drawing roller molds, can solve the problems of lower production efficiency, large impact and vibration, and increased manual workload, so as to improve production quality, increase service life, and avoid being affected Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

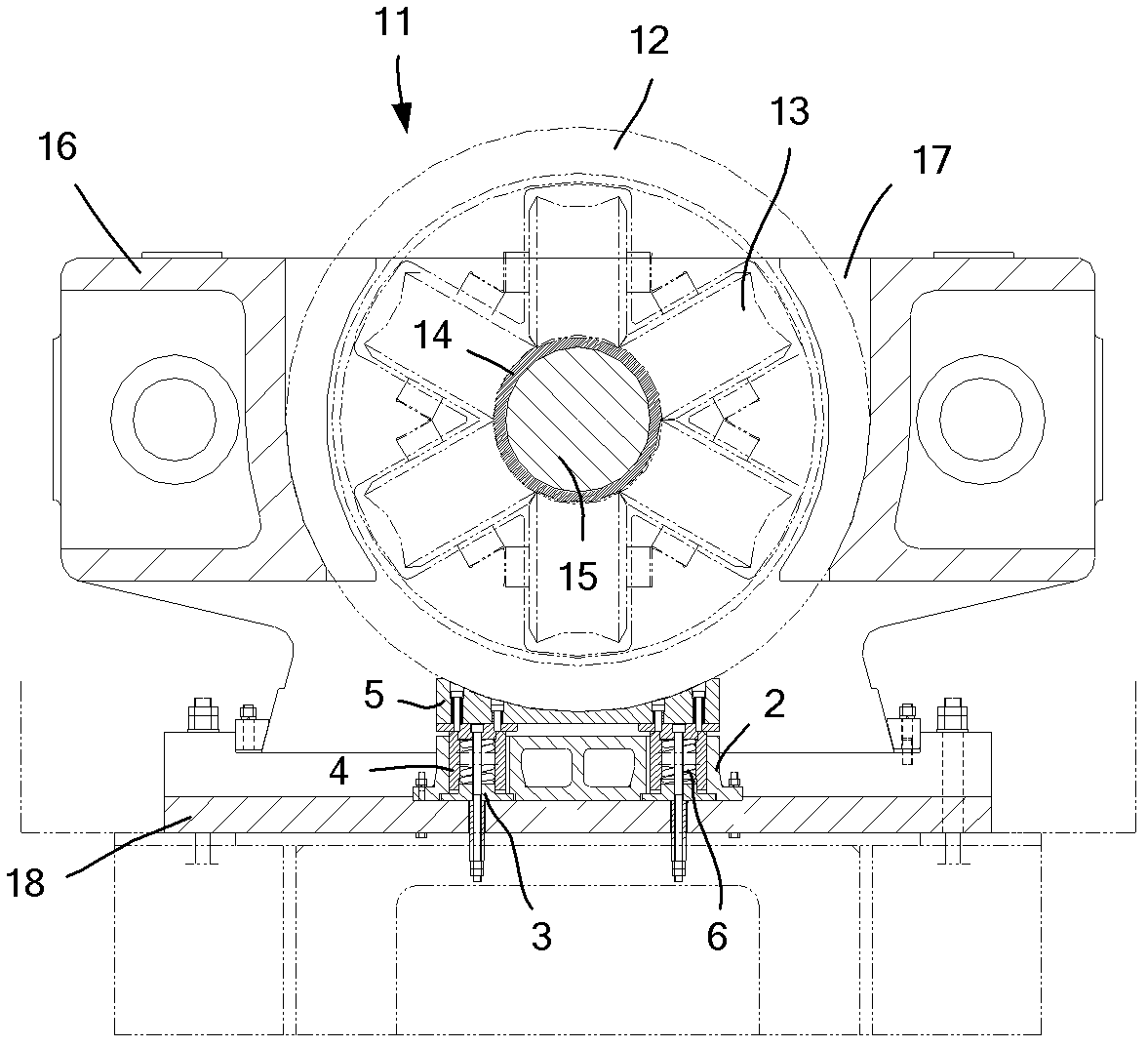

[0021] The use status of the present invention is as figure 1 As shown, the outside of the drawing roller mold 11 is a shell 12, and the inside is a rotating roller mold 13. The preform 14 is pushed to the top by the drawing mandrel 15, and drawn in the rotating roller mold 13. Both sides of drawing roller mold 11 are stuck in the arc groove 17 of front beam 16, and the lower end relies on the present invention that is fixedly installed on the front beam bottom plate 18 to support.

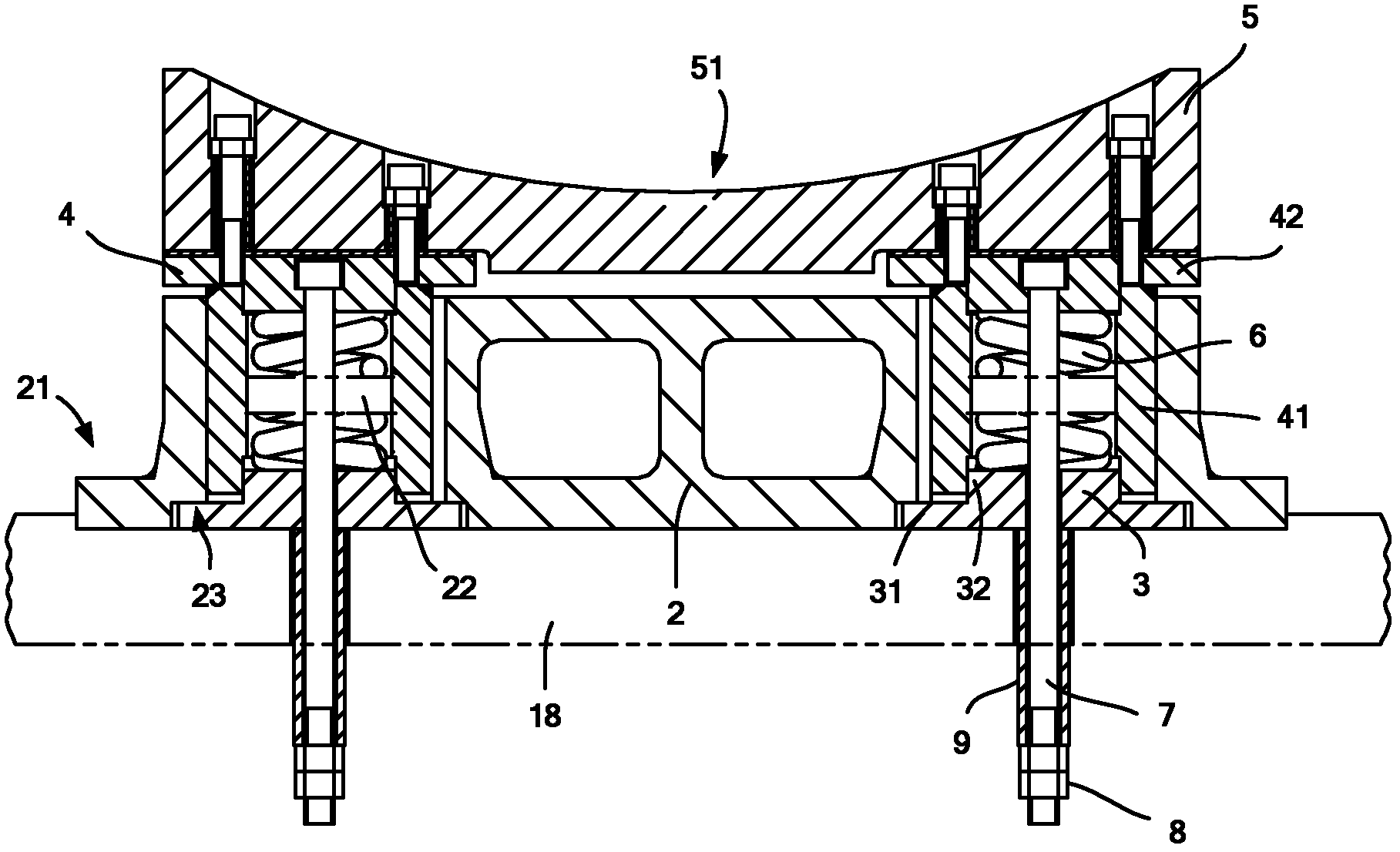

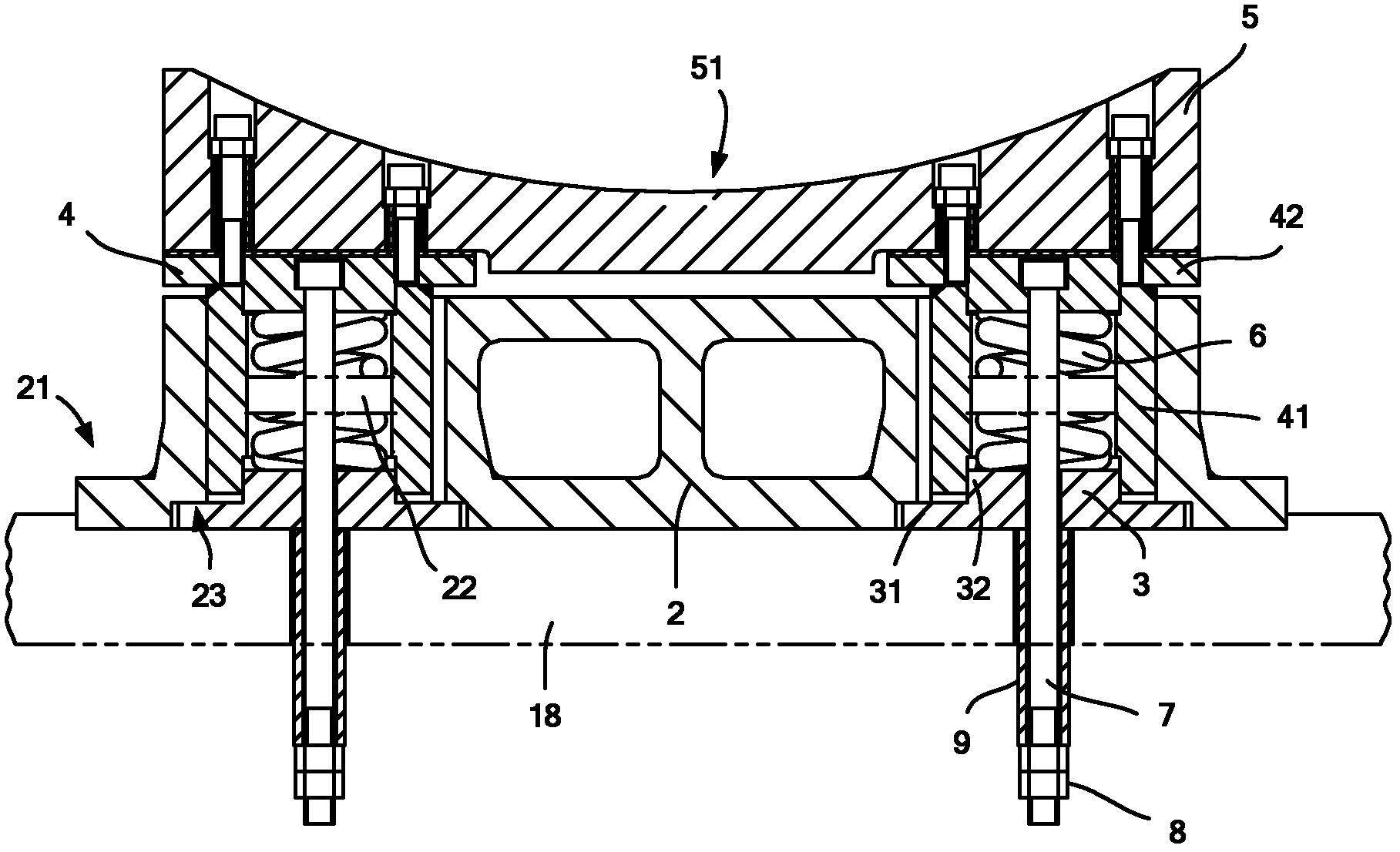

[0022] Such as figure 2 As shown, the present invention includes a base 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com