Stainless steel circular thin plate origin forming mechanism

A molding mechanism, stainless steel technology, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of upper mold and lower mold damage, easy adhesion to the lower mold, troublesome demoulding, etc., to achieve fast demoulding, Effect of reducing hard impact and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

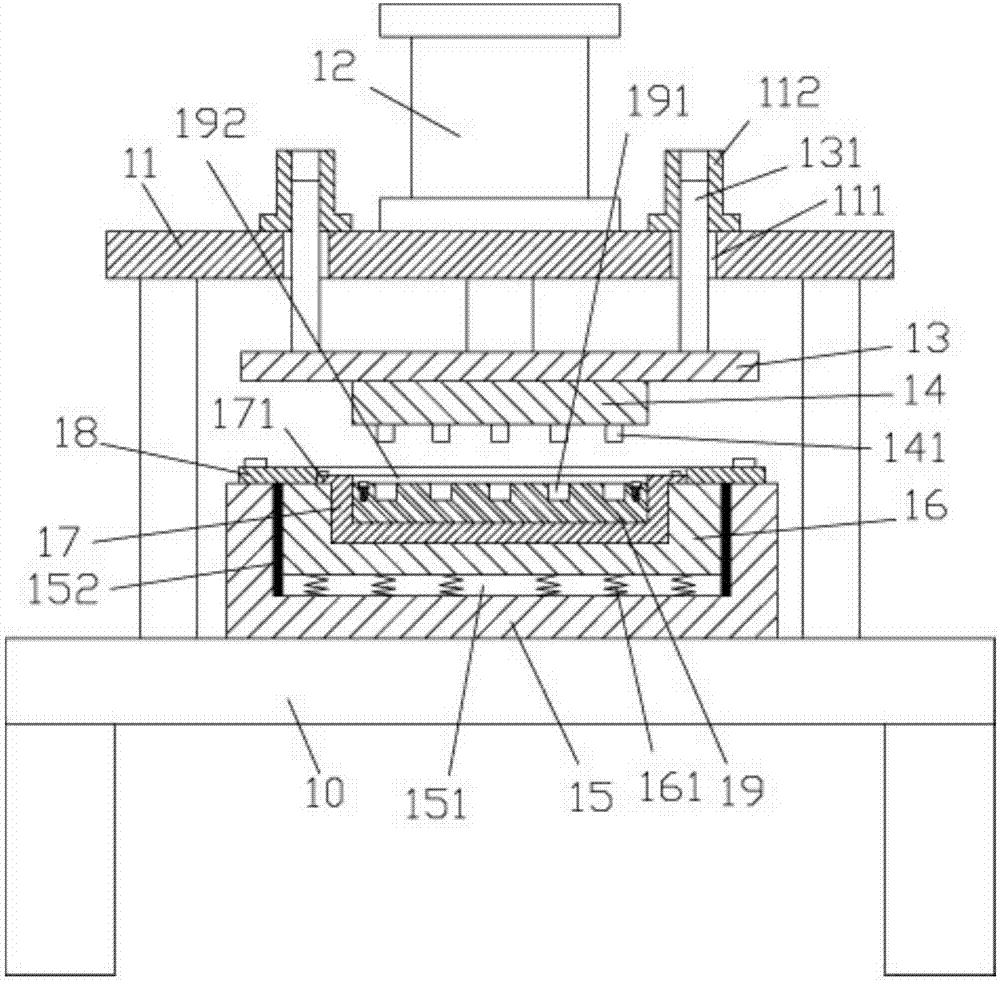

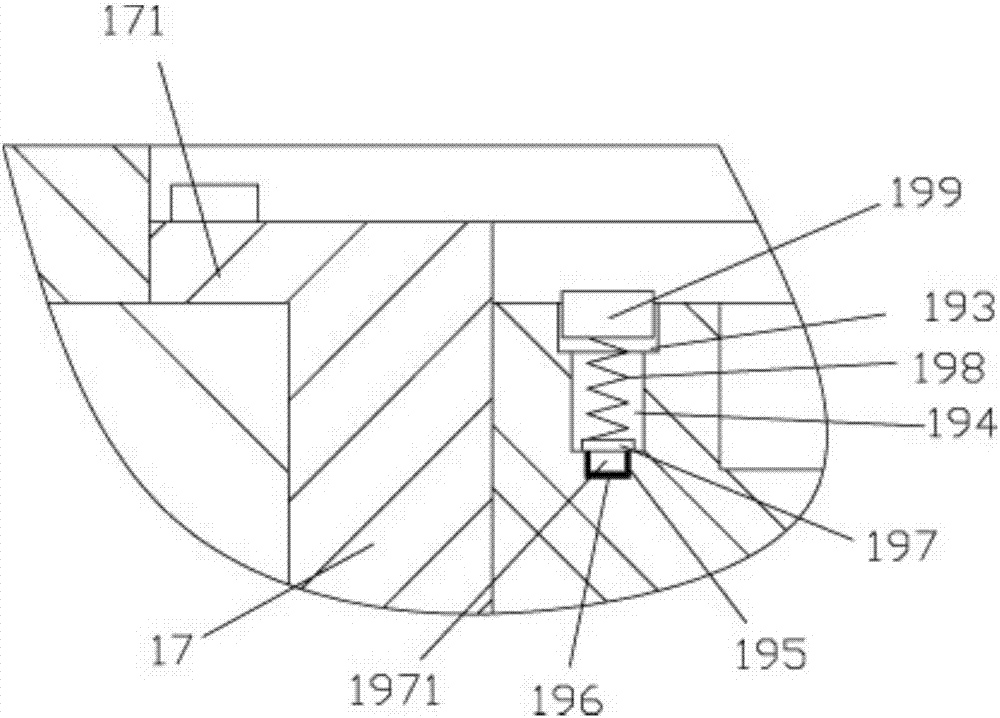

[0021] Examples, see as Figure 1 to Figure 2 As shown, a stainless steel circular sheet origin forming mechanism includes a frame 10, an upper support frame 11 is fixed on the top surface of the top plate of the frame 10, and a stamping cylinder 12 is fixed in the middle of the top surface of the top plate of the upper support frame 11. , the push rod of the punching cylinder 12 passes through the top plate of the upper support frame 11 and is fixed with the upper connecting plate 13, the middle of the bottom surface of the upper connecting plate 13 is fixed with the upper die 14, and the bottom surface of the upper die 14 is evenly distributed with a plurality of punching bumps 141 ;

[0022] The lower support block 15 is fixed on the top surface of the middle part of the top plate of the rack 10 , the middle part of the top surface of the lower support block 15 has a main groove 151 , the installation block 16 is inserted into the main groove 151 , and the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com