Patents

Literature

41results about How to "Simple form of exercise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

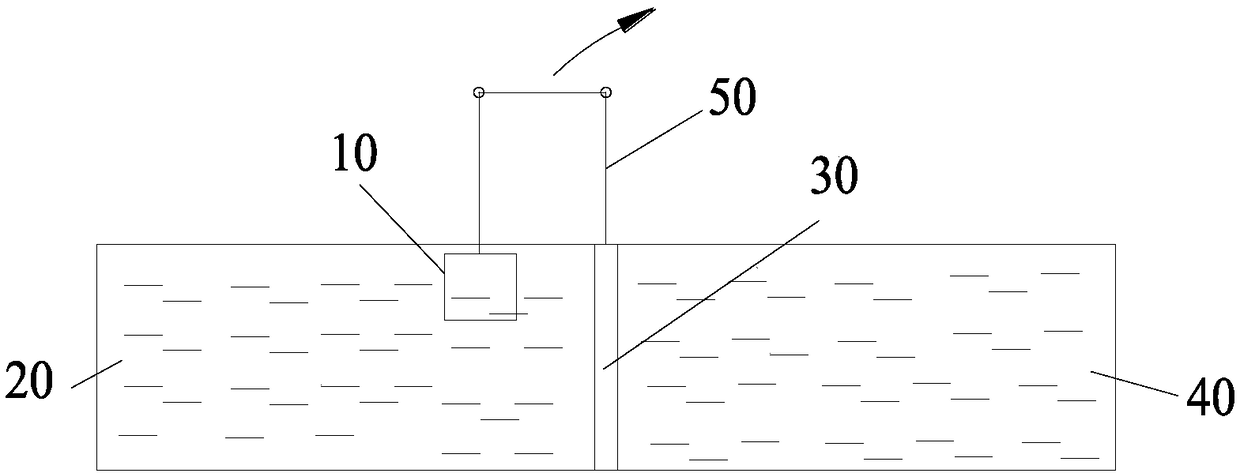

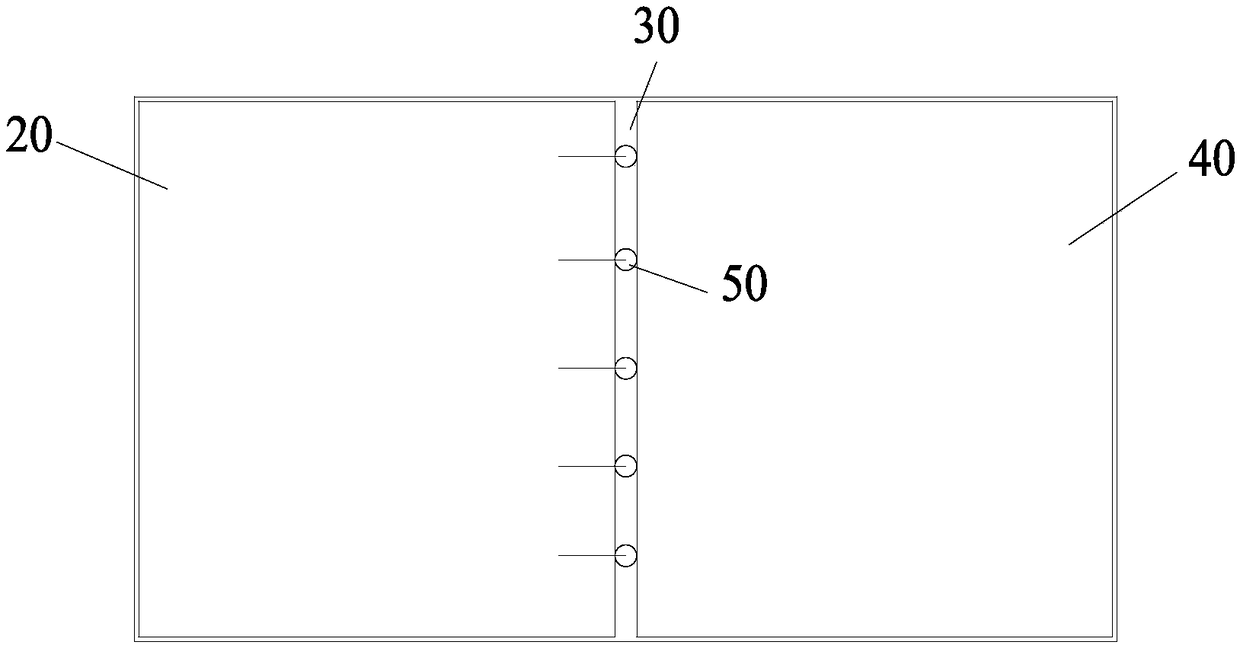

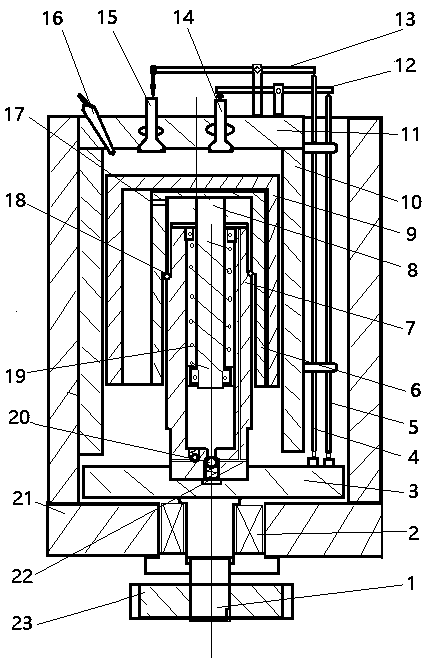

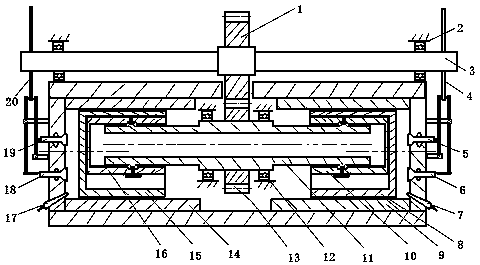

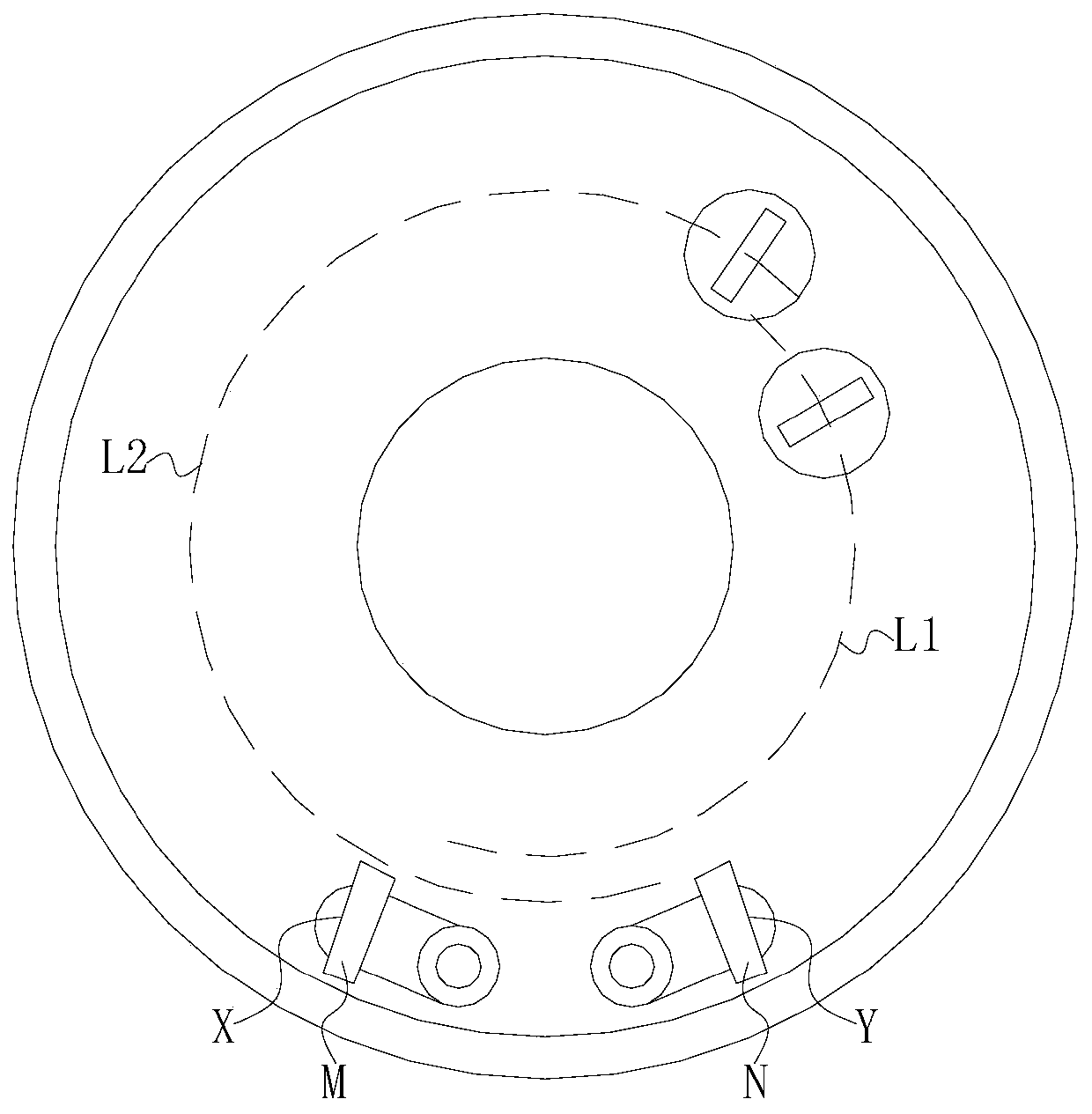

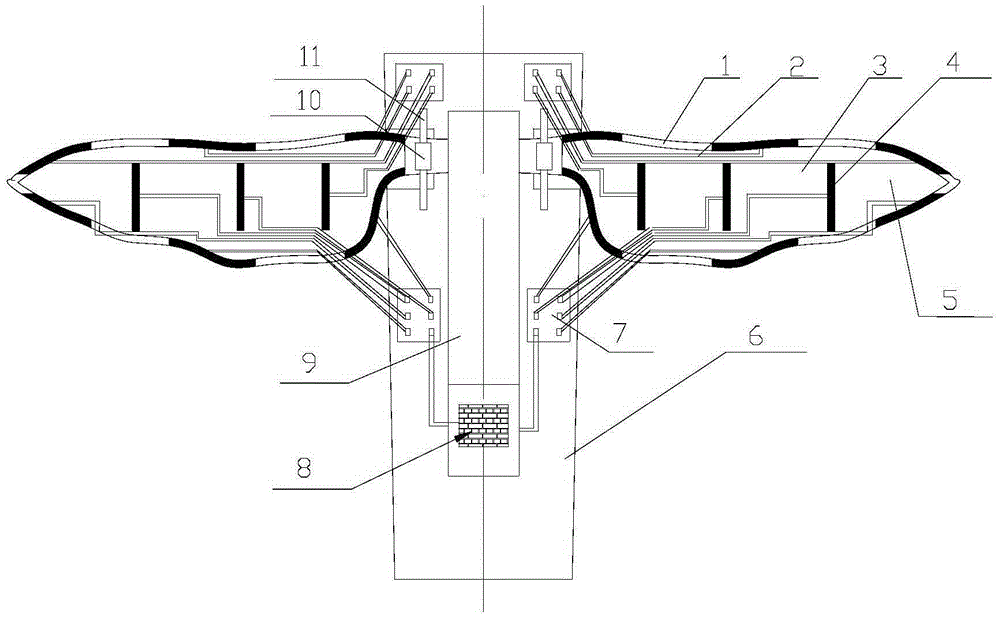

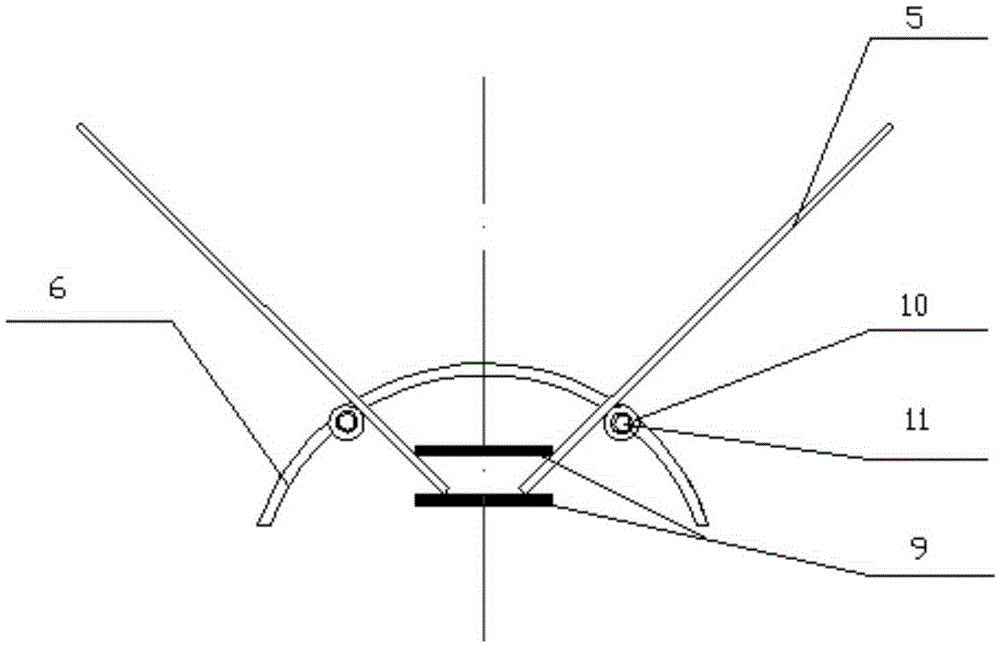

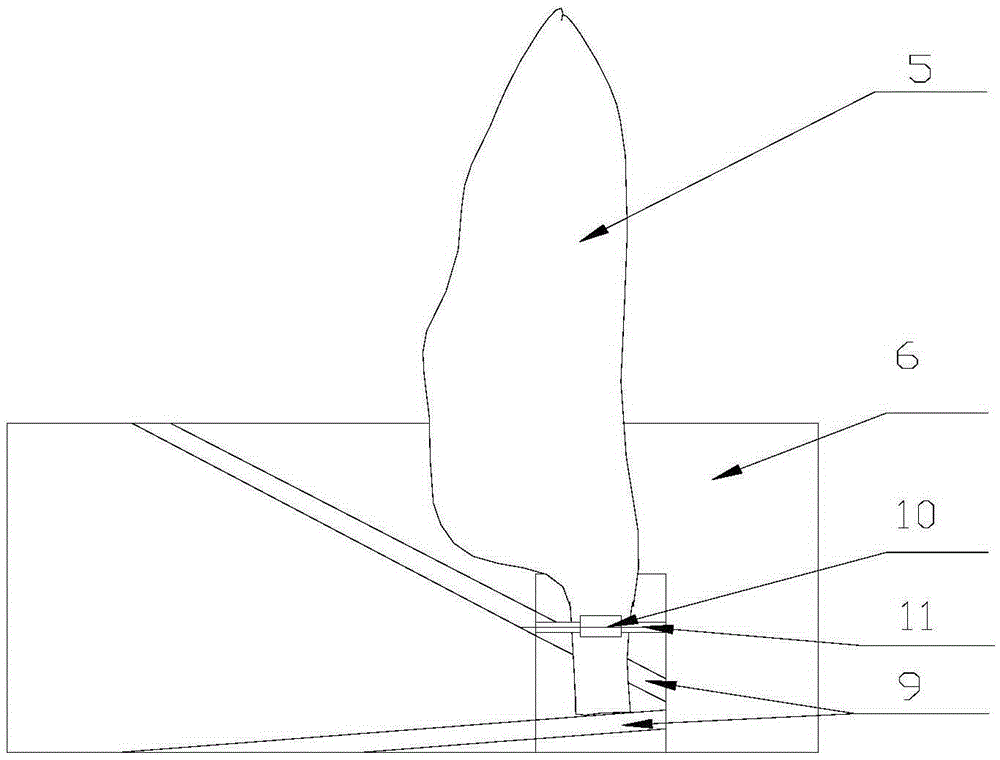

Source stirring electromagnetic reverberation chamber and stirring method thereof

InactiveCN104133126AImprove space utilizationLarge test areaElectrical testingField uniformityElectromagnetic reverberation chamber

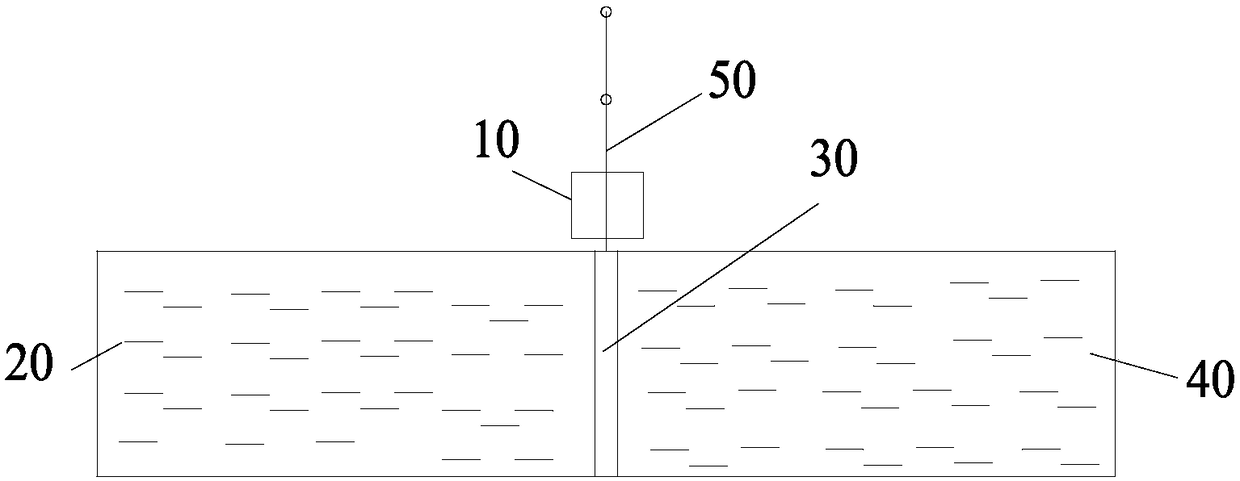

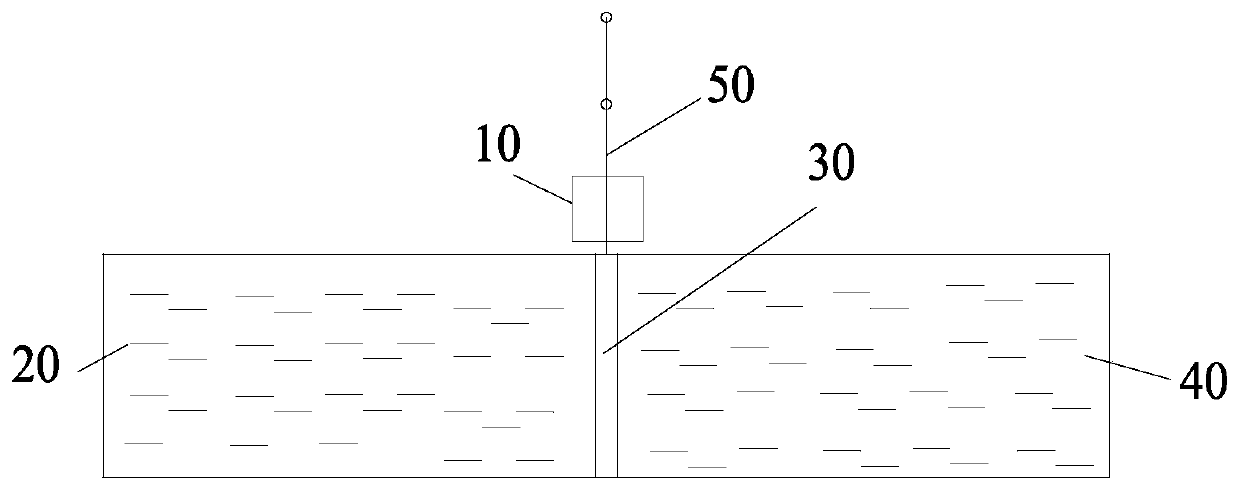

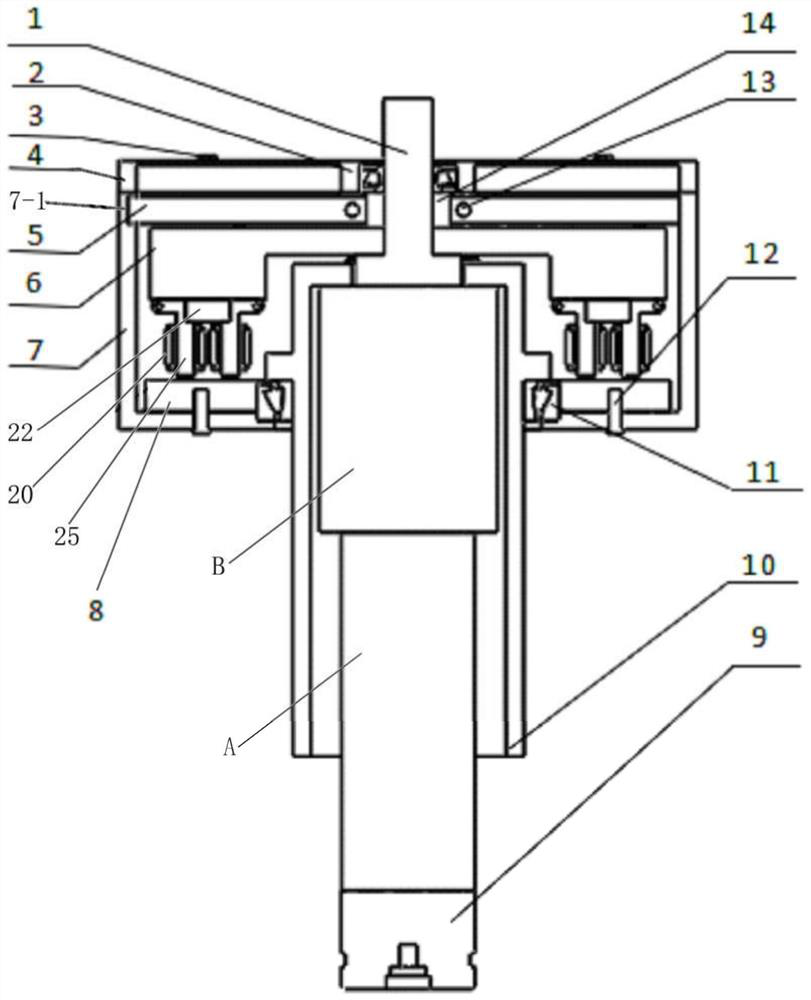

Disclosed are a source stirring electromagnetic reverberation chamber and a stirring method thereof. The reverberation chamber includes an electromagnetic shielding chamber, a source stirring device installed on the side wall of the electromagnetic shielding chamber, and the source stirring method used for describing installation, motion and control method of an transmitting antenna. Simultaneous change of the position and polarization direction of the transmitting antenna is realized through control of a rotating shaft to rotate. A drive device of the rotating shaft is installed at the outer side of the reverberation chamber and the rotating shaft which is installed on the inner wall of the reverberation chamber is driven to rotate through a changeover mechanism. The reverberation chamber realizes field uniformity in the reverberation chamber through rotation of a single antenna so that space utilization rate in the reverberation chamber is effectively improved and a source stirring reverberation chamber of the same volume can realize a larger test area; relative to an EUT of the same size, a source stirring reverberation chamber which is smaller in volume can be designed so that generation of high field intensity is better facilitated; and the reverberation chamber is also applicable to a condition in which a plurality of transmitting antennae are configured in a reverberation chamber to carry out source stirring.

Owner:陕西海泰电子有限责任公司

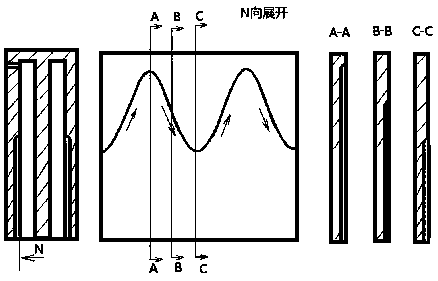

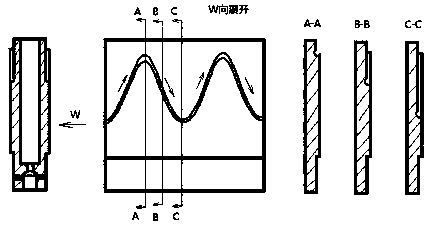

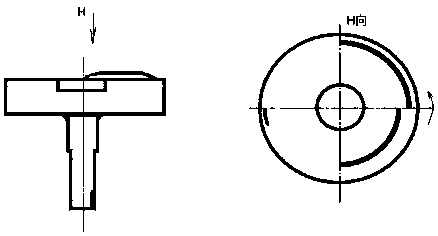

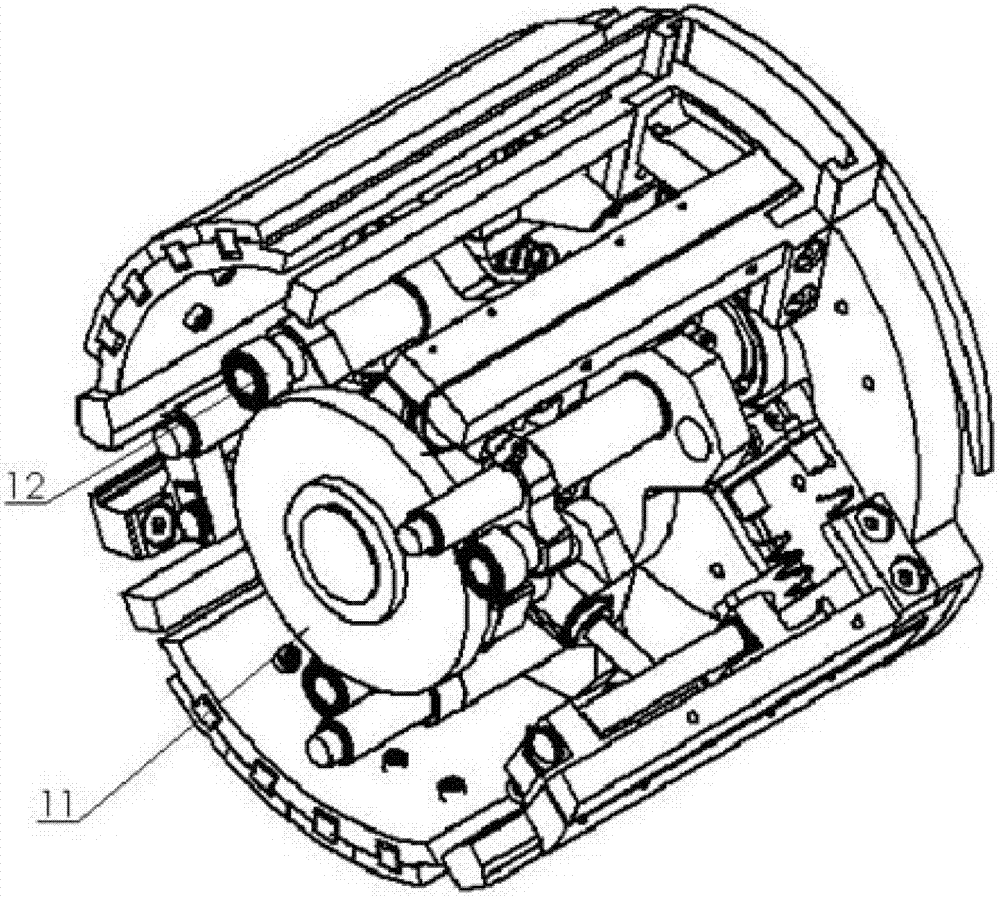

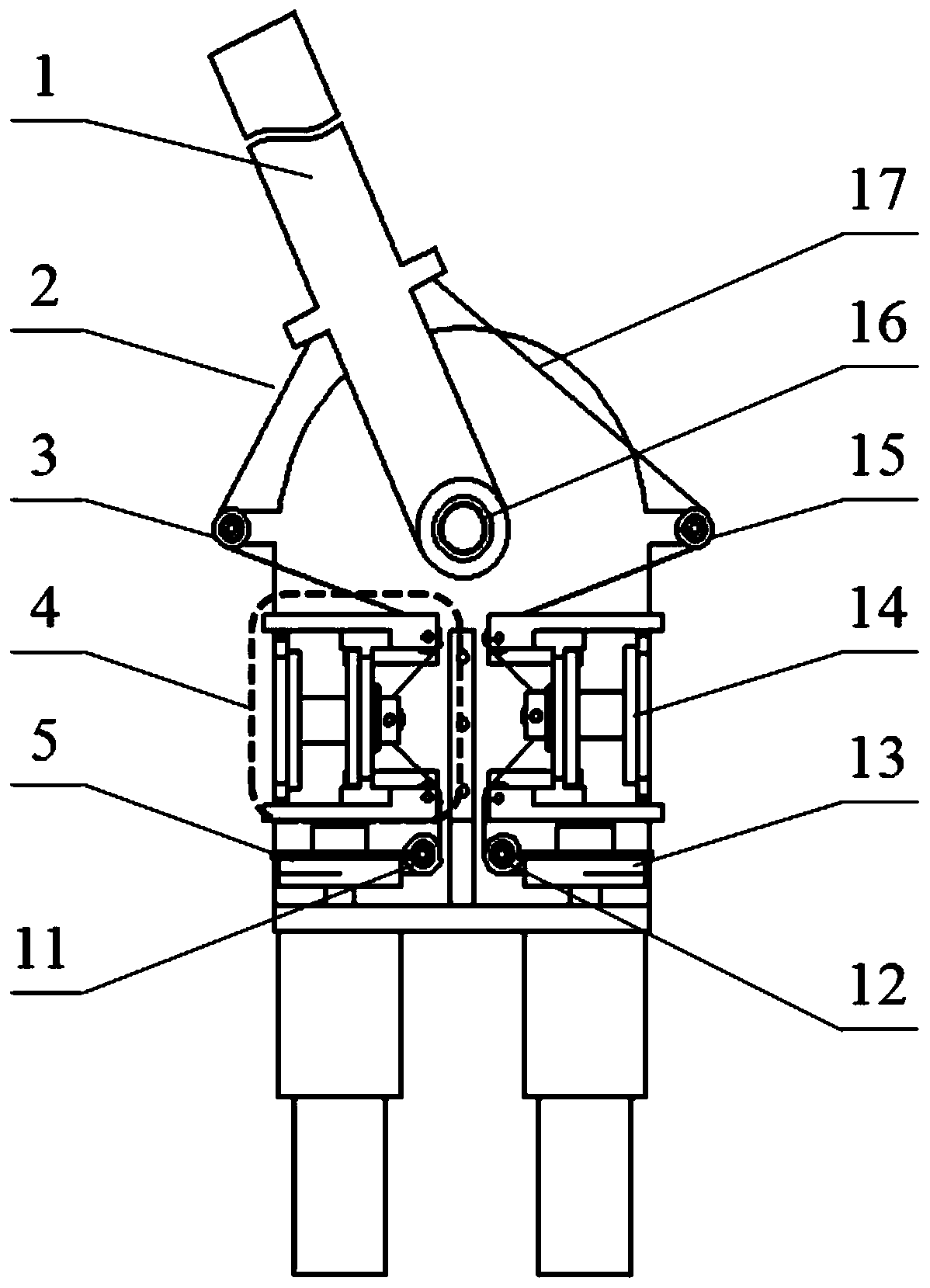

Reciprocating piston type internal combustion engine of crankless connecting rod mechanism

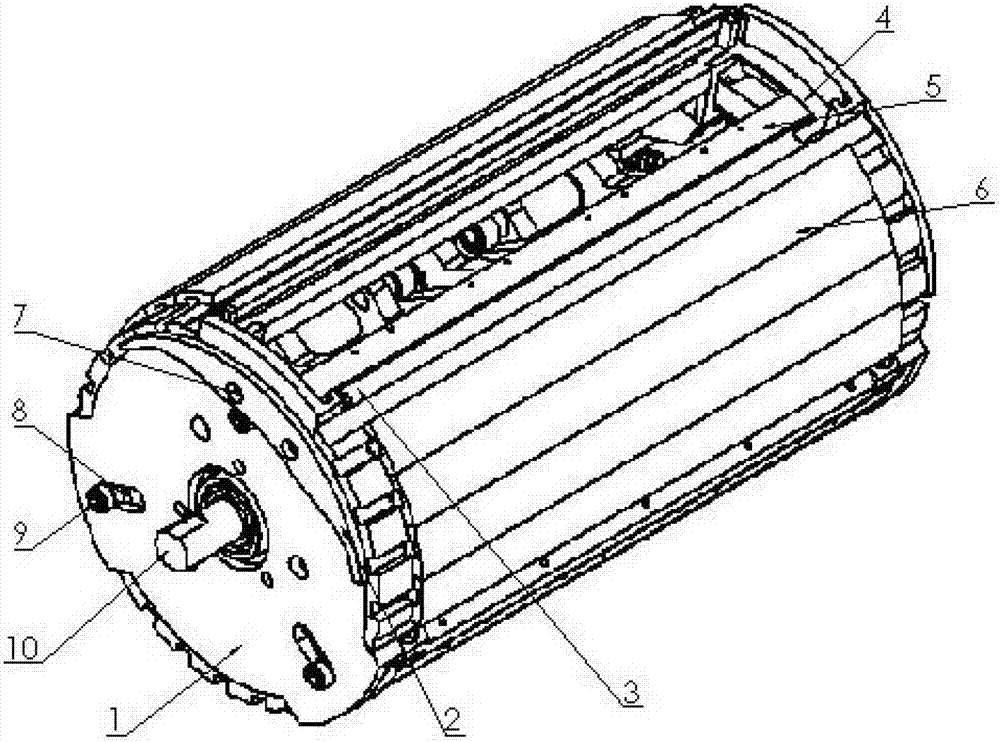

PendingCN109707509ASimple structureSimple form of exerciseValve drivesMachines/enginesCombustionBall bearing

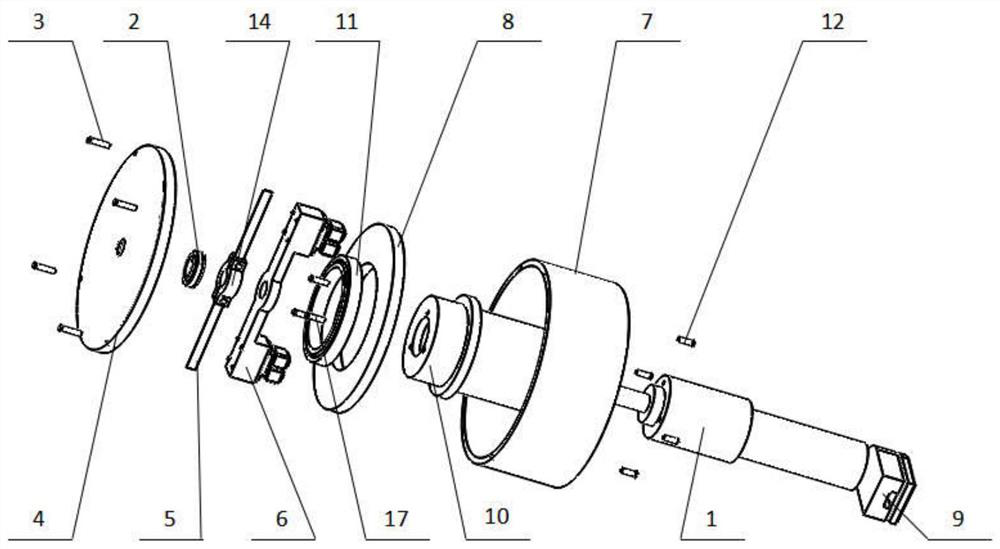

The invention discloses a reciprocating piston type internal combustion engine device of a crankless connecting rod mechanism, and belongs to the field of internal combustion engines. Aiming at the disadvantages of a traditional internal combustion engine that a crank structure is complex, material requirements are high, the processing difficulty is high, the force state in a same condition and movement status of a connecting rod are complex, and thus the complicated inertia effect and the noise are caused, according to the reciprocating piston type internal combustion engine device of a crankless connecting rod mechanism, a non-cage curved groove ball bearing is utilized to realize a function of reciprocating motion with a large swing, the non-cage curved groove ball bearing is designed with two cycles and four reciprocating travels per cycle of rotation, two push travels are correspondingly used for compression and exhaust, and the two return travels are correspondingly used for combustion working and an air intake travel. Compared with an internal combustion engine composed of a traditional crank connecting rod mechanism, the reciprocating piston type internal combustion engineof a crankless connecting rod mechanism has the following advantages that 1, all the moving parts are axisymmetric rotary parts with simple structures; 2, the motion form is simple, and only the rotary motion and reciprocating motion are included, and less noises are generated; and 3, the parts are low in processing requirements and are easy to manufacture.

Owner:NORTHWEST A & F UNIV

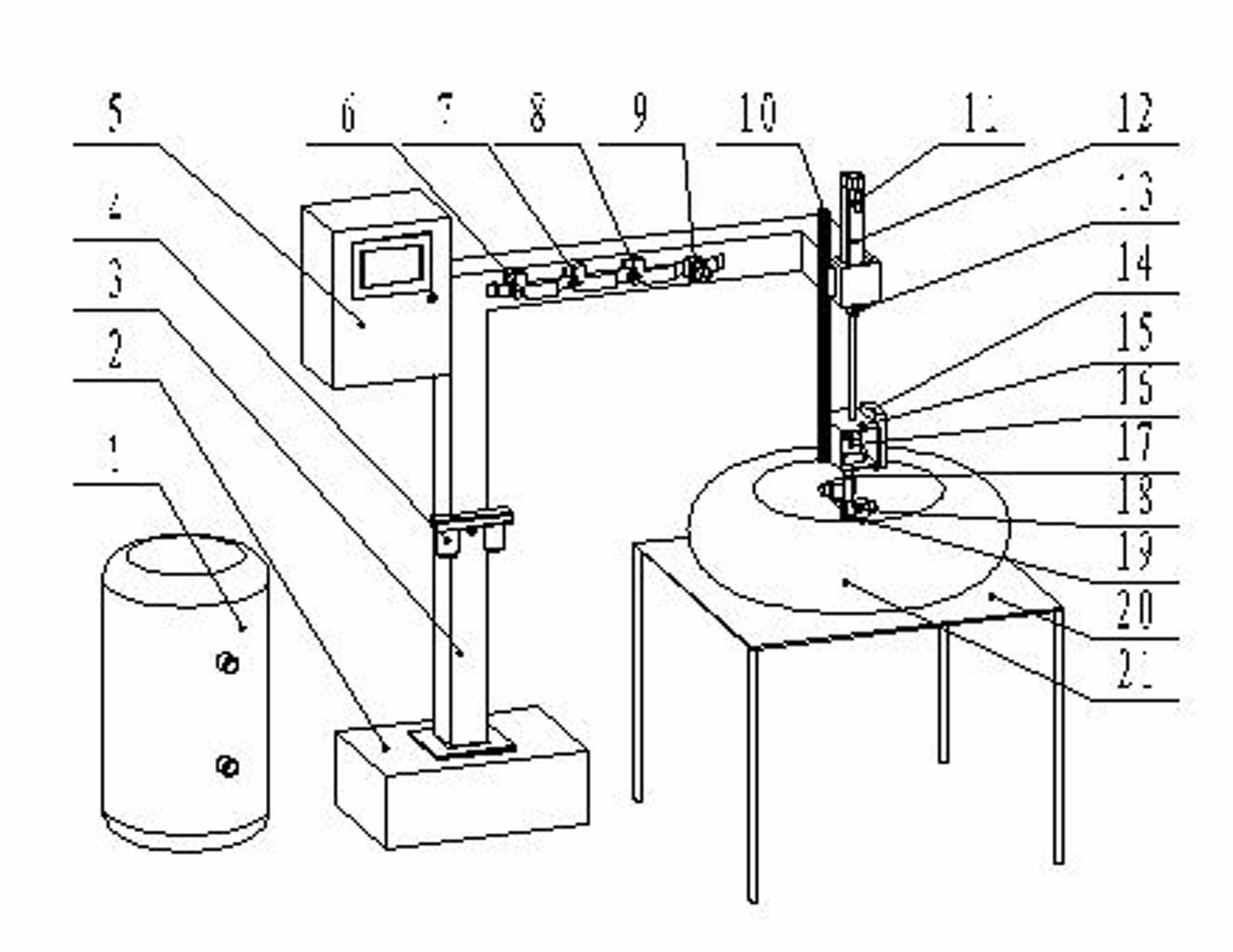

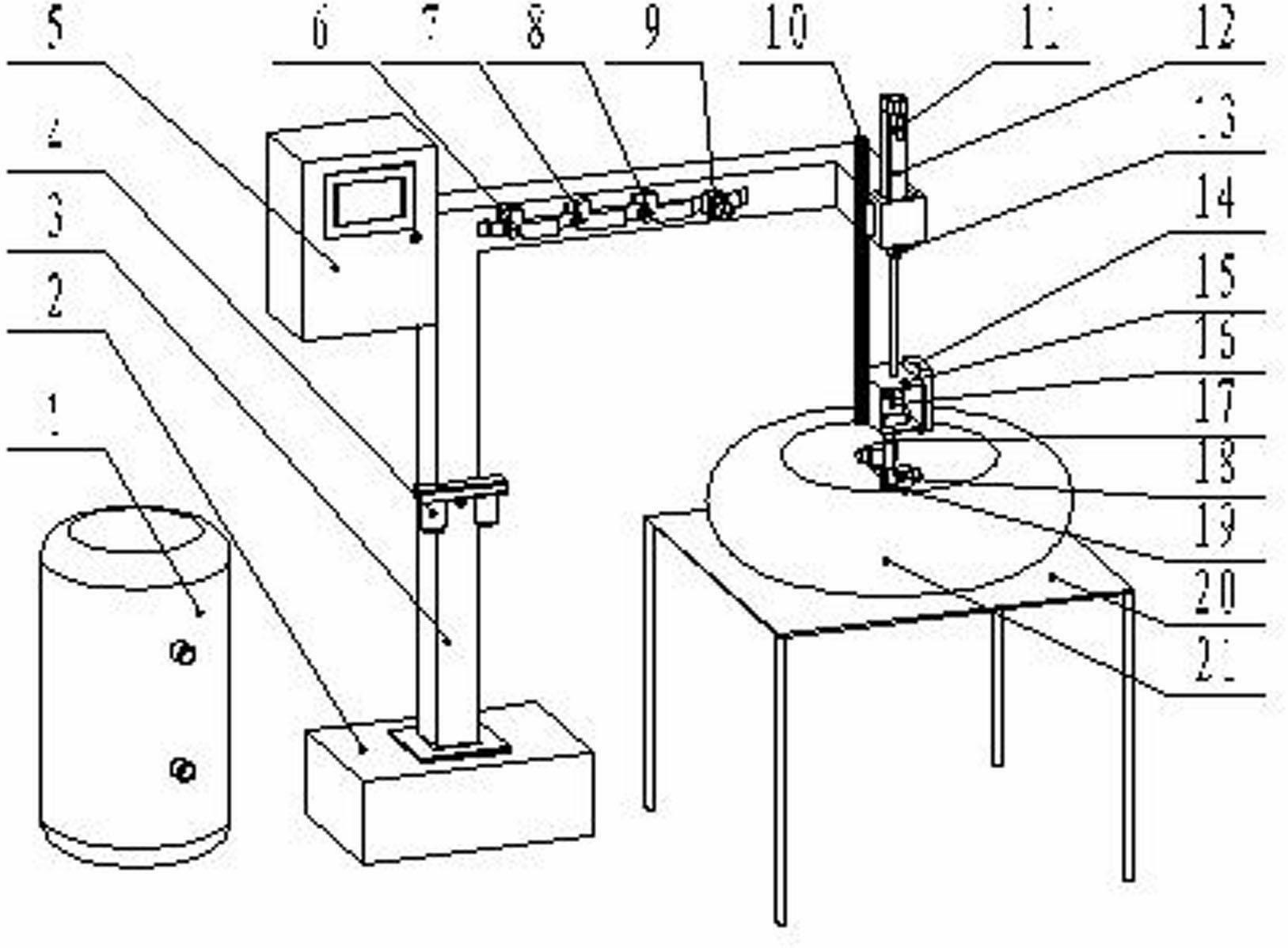

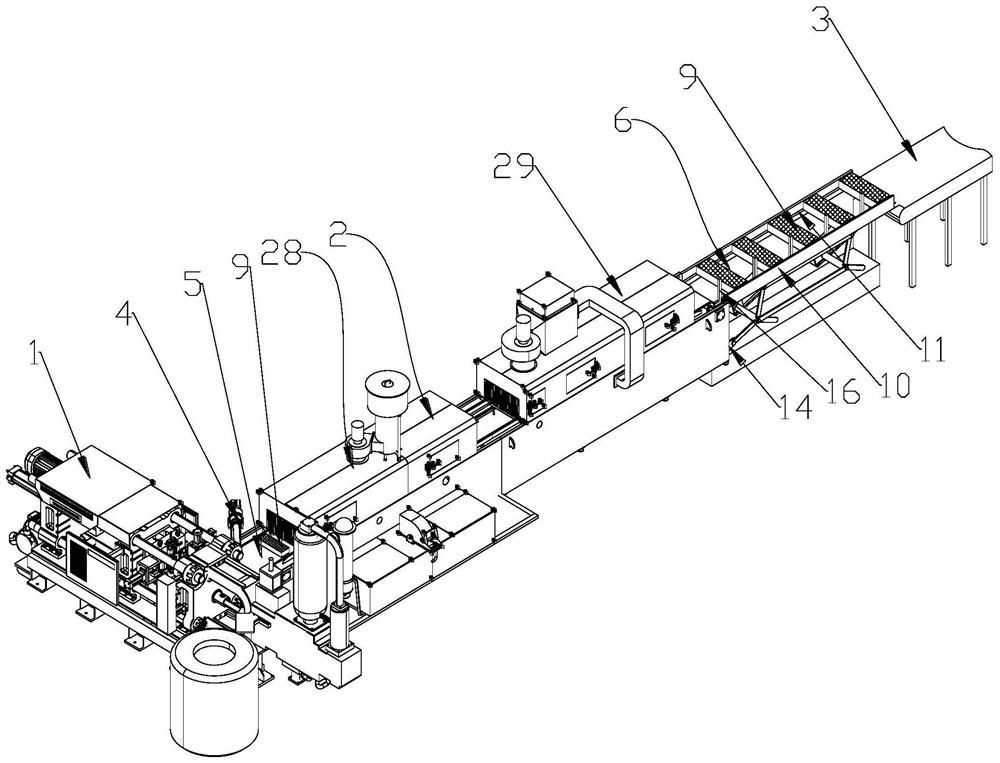

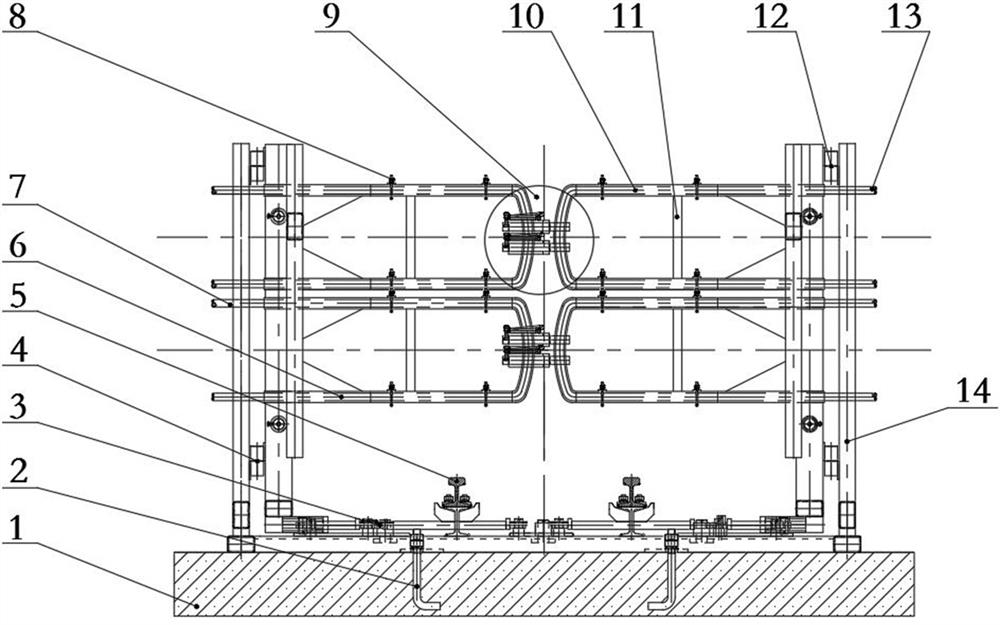

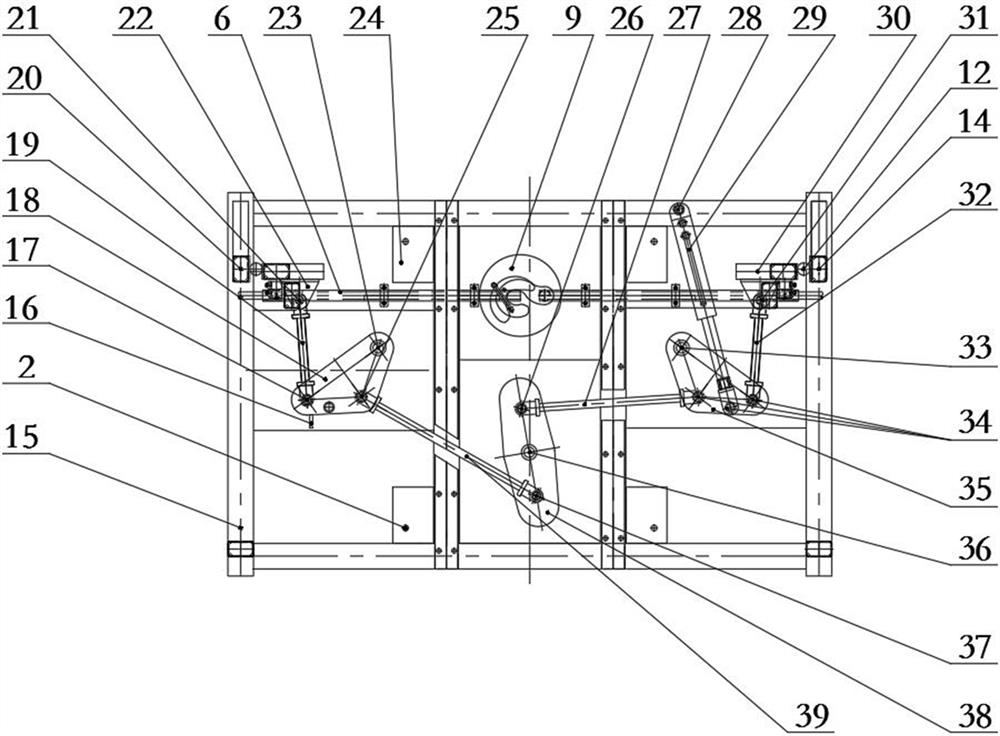

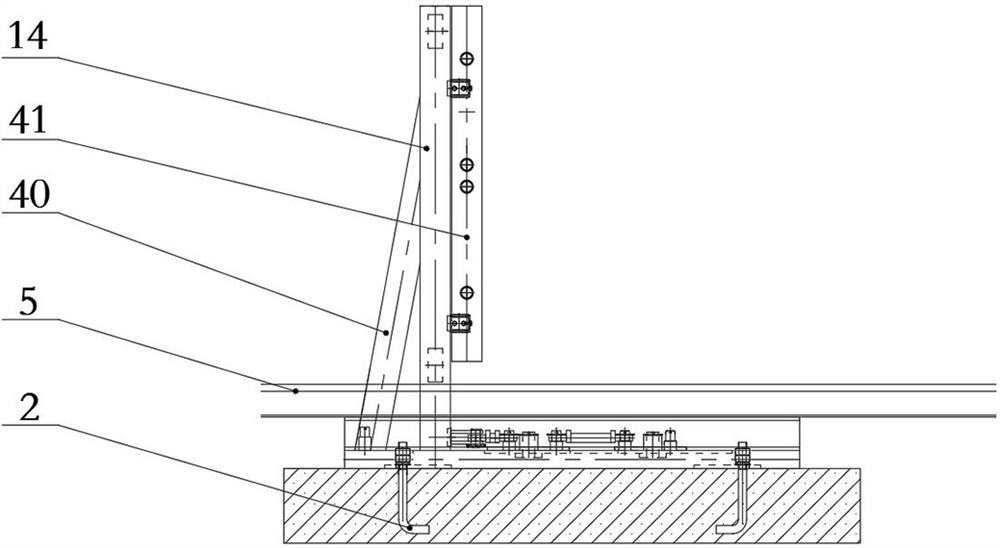

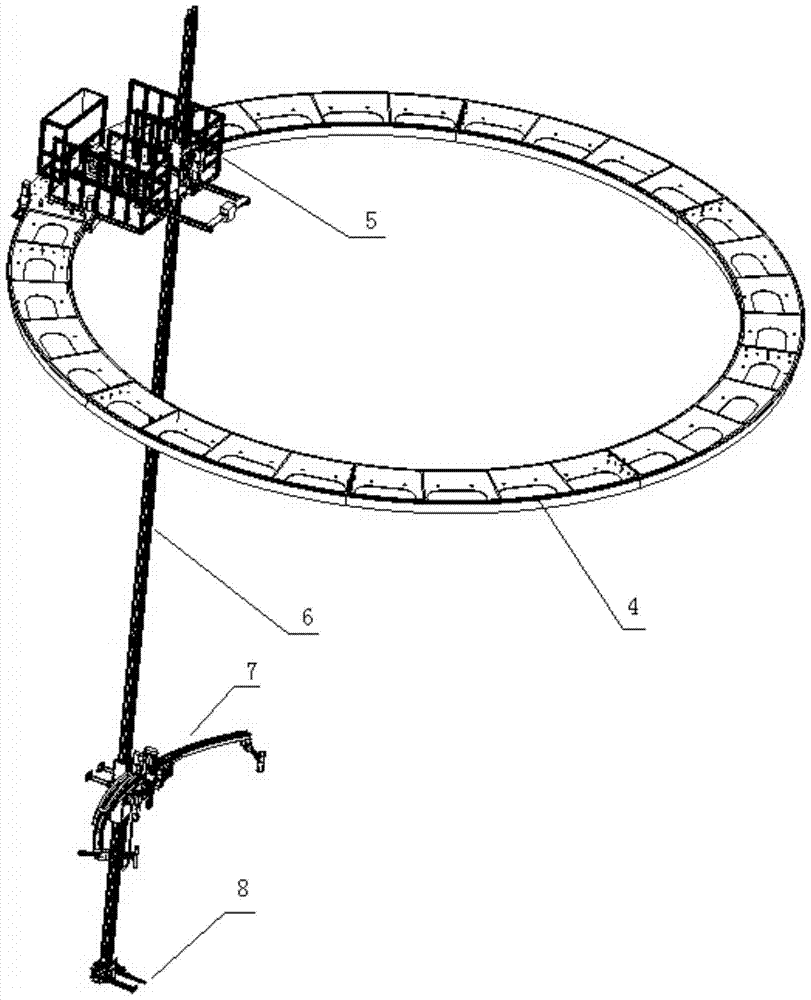

On-line coating machine of tire curing press

InactiveCN102327838AReduce labor intensityReduce the impactLiquid surface applicatorsSpraying apparatusProduction rateEngineering

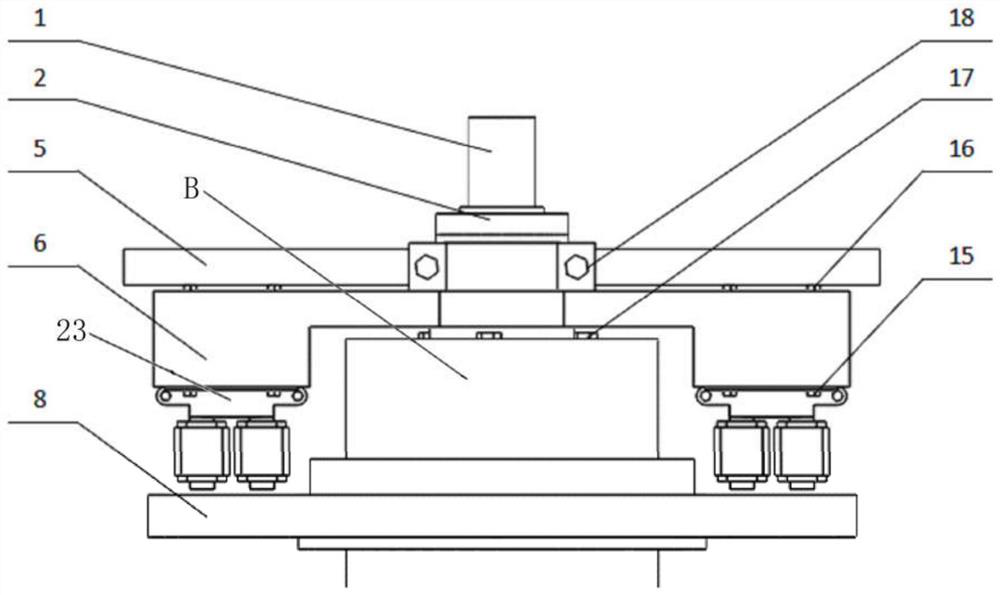

The invention discloses an on-line coating machine of a tire curing press. The on-line coating machine comprises a locating device, a support, a drive device, a spray device and a control device, wherein the locating device is used for locating a green tire; the support extends to the position right above the green tire locating center of the locating device; the drive device is arranged on the part, extending to be right above the locating device, of the support, and is provided with an elevating mechanism with an up-down adjustment function and a rotating mechanism which rotates around the vertical axis of the locating center; the spray device is equipped with a liquid path and is arranged on the drive end of the drive device so as to realize elevating and rotating actions; and the control device is connected with a control part of the drive device and a control part of the liquid path. By adopting the on-line coating machine, the production rate and the spraying uniformity are improved.

Owner:SHANDONG REIDA TECH GROUP

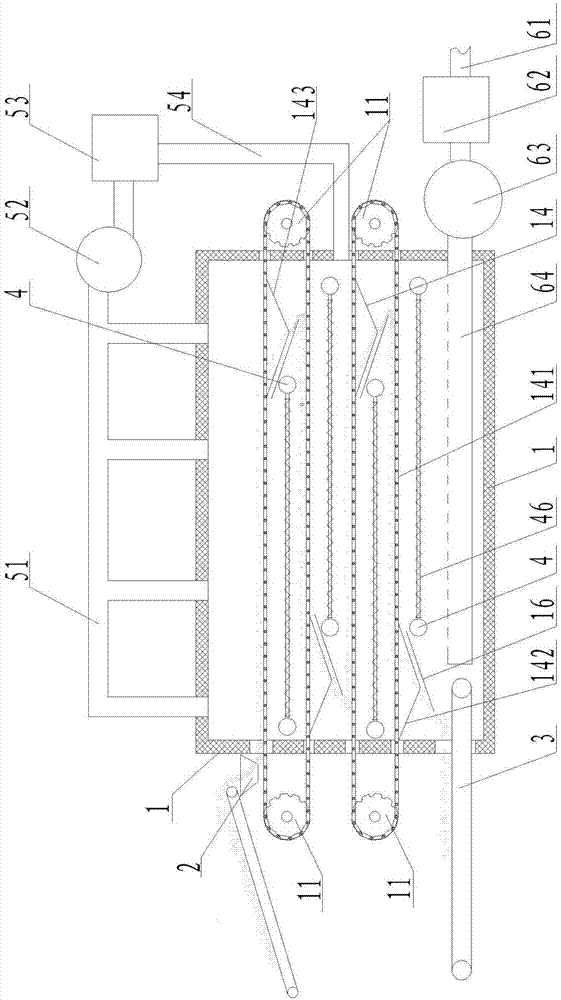

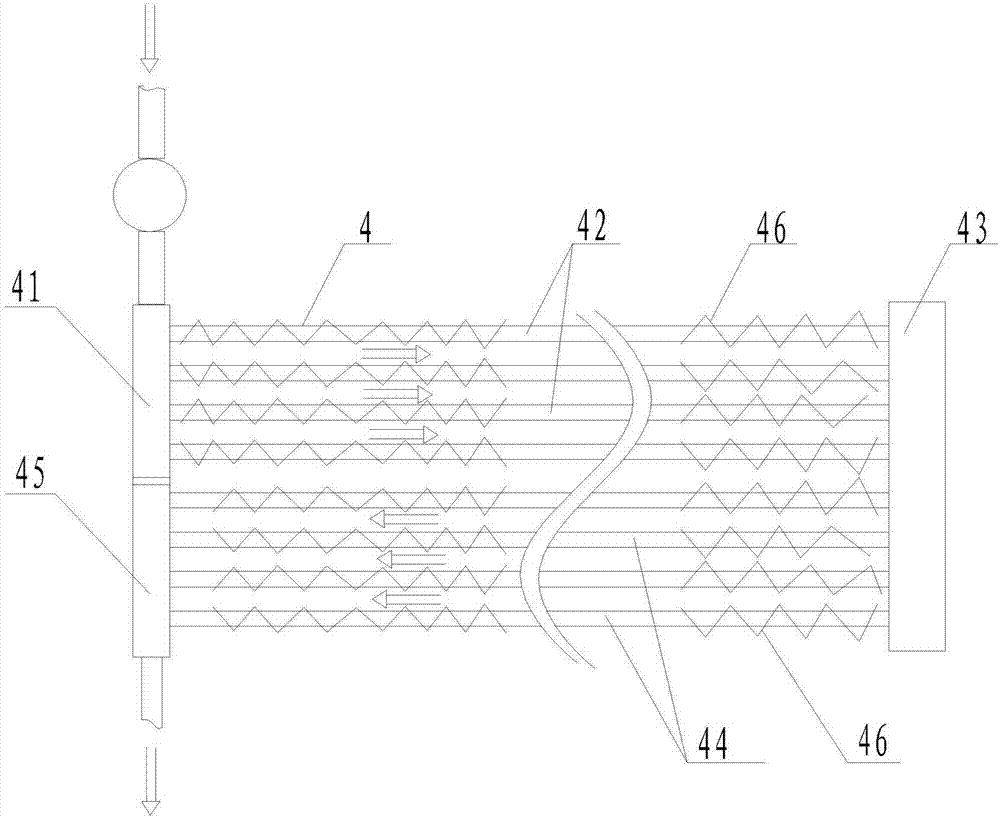

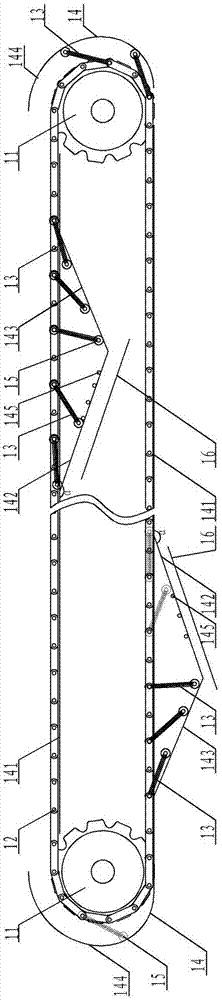

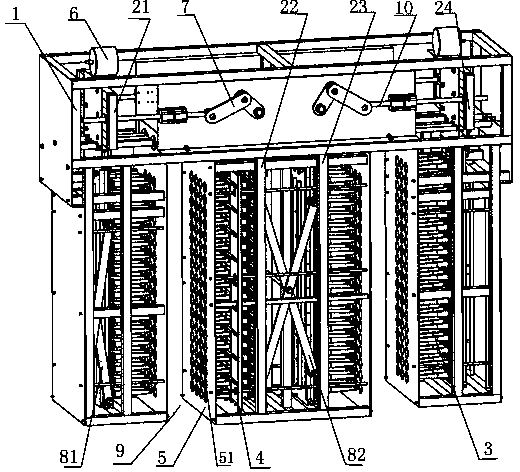

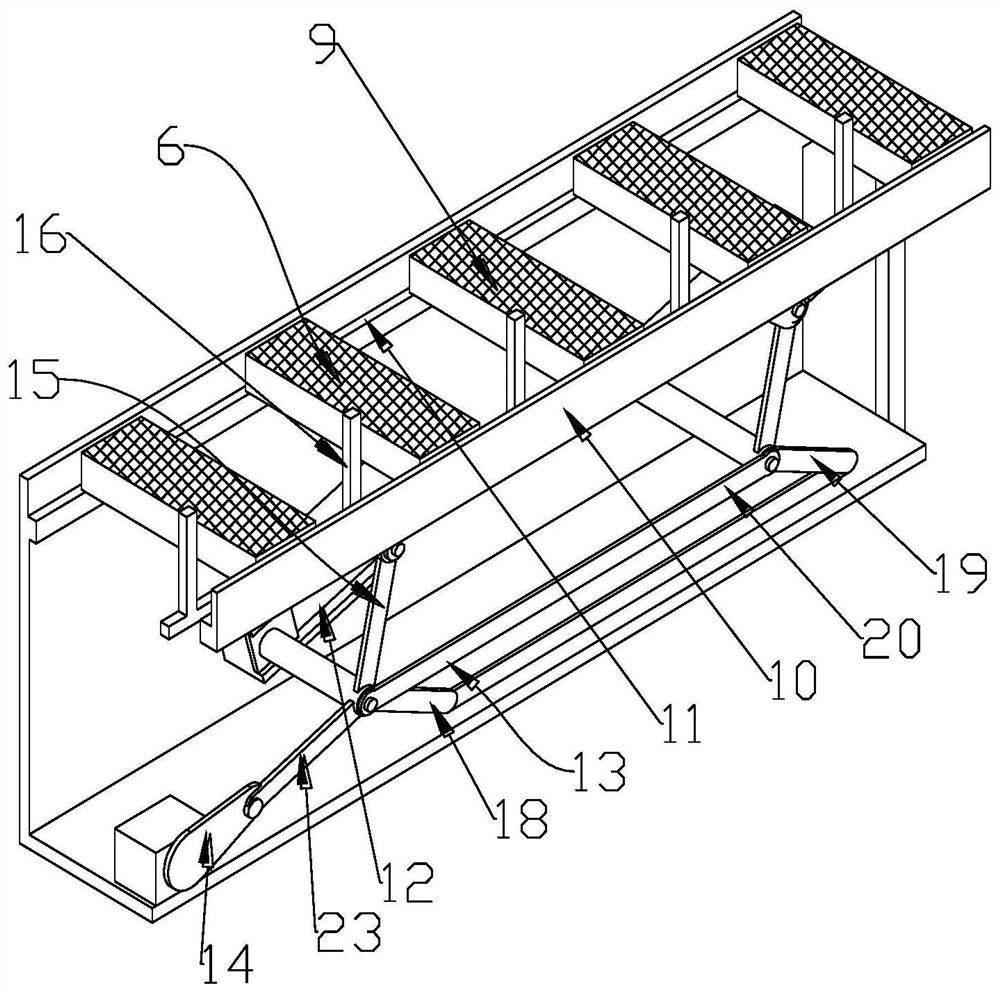

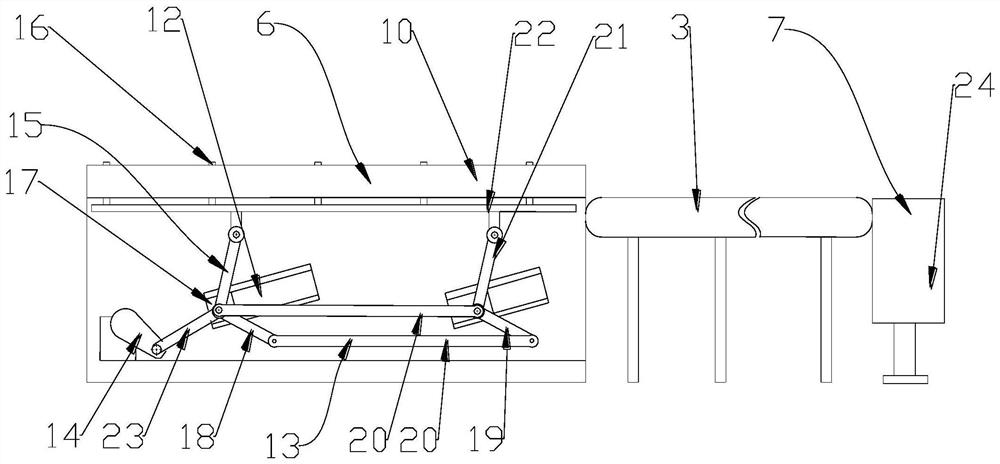

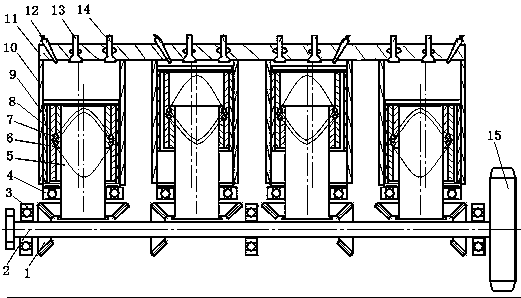

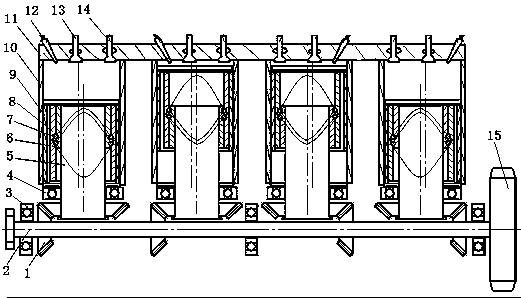

Horizontal type coal briquette drying machine

ActiveCN104748532ADry fastReduce energy consumptionDrying gas arrangementsDrying solid materialsCoal briquetteGrating

The invention relates to a horizontal type coal briquette drying machine. The horizontal type coal briquette drying machine comprises a drying cavity, a chain plate conveying mechanism arranged in the drying cavity, a feed hopper arranged on the top of the drying cavity, a discharging conveying belt arranged on one side of the bottom of the drying cavity, a heating system, an air circulating device and a tail gas recovery device. Coal briquettes make reciprocating motion in the chain plate conveying mechanism and fall layer by layer until the coal briquettes are dried by the discharging conveying belt and are conveyed out of the drying machine. The air circulating device separates water vapor and then conveys dry hot air back into the drying cavity, and the surfaces of the coal briquettes can be dried more quickly; furthermore, the tail gas recovery device leads flue waste gas of an oil furnace into the drying cavity so that waste heat utilization can further be increased, and the energy consumption of the entire drying finance is greatly lowered; in particular, a rigid grating plate can be guided by a guide rail to carry and dump the coal briquettes, the moving mode of the rigid grating plate is simple, in this way, the structure of the guide rail is made simple, the material falling section falls down slowly, the coal briquettes roll down evenly, the hard collision of the grating plate and other equipment is relieved, and the service life of the equipment is prolonged.

Owner:石家庄市矿区丰旺机械有限公司

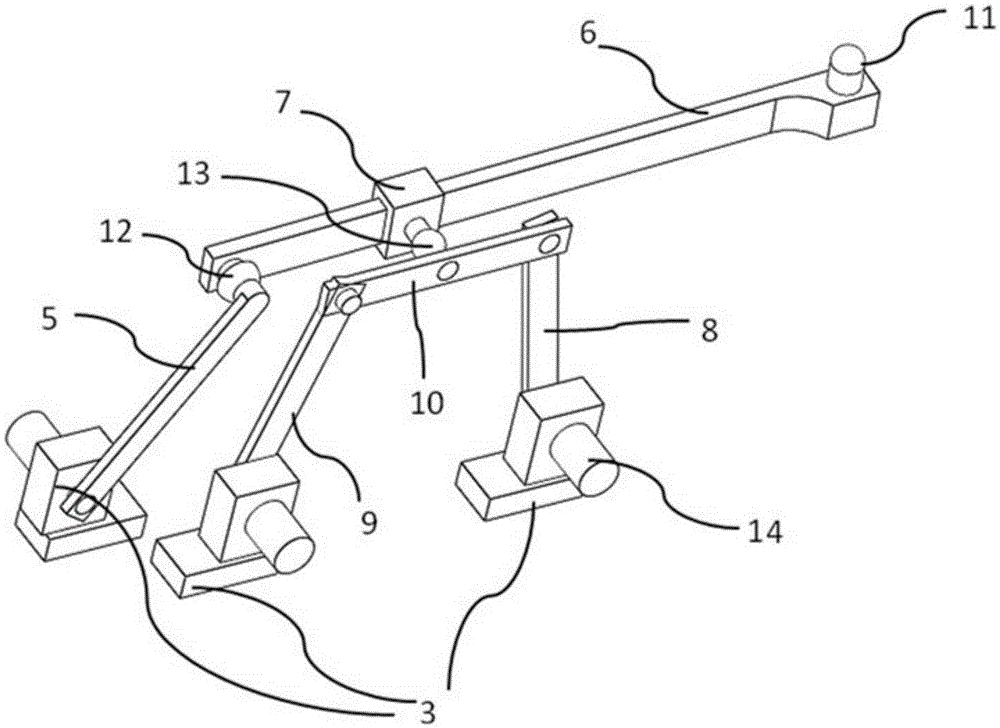

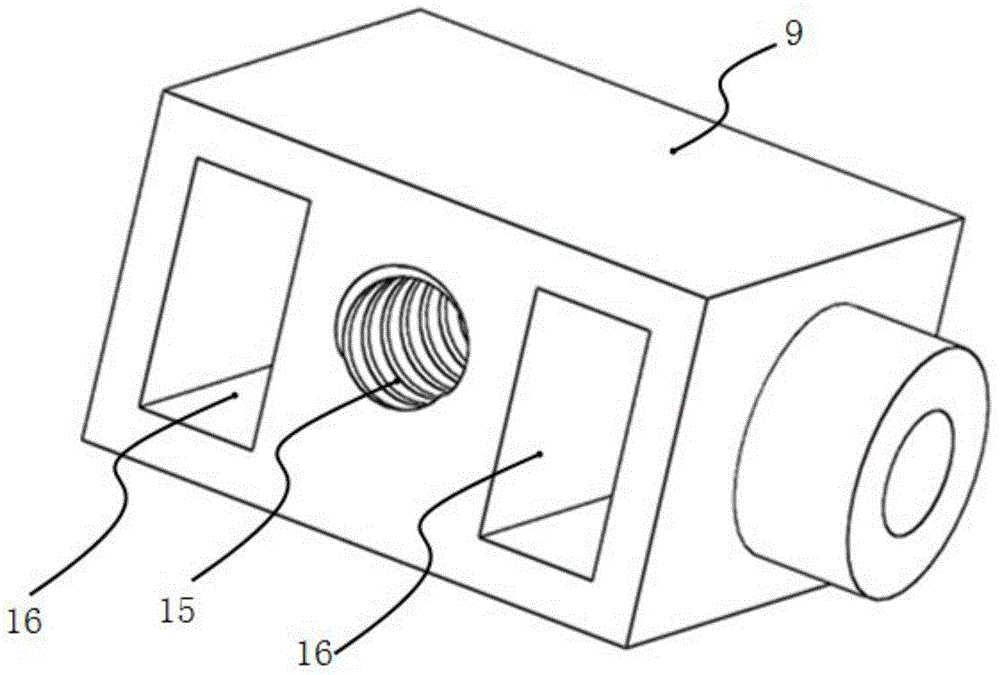

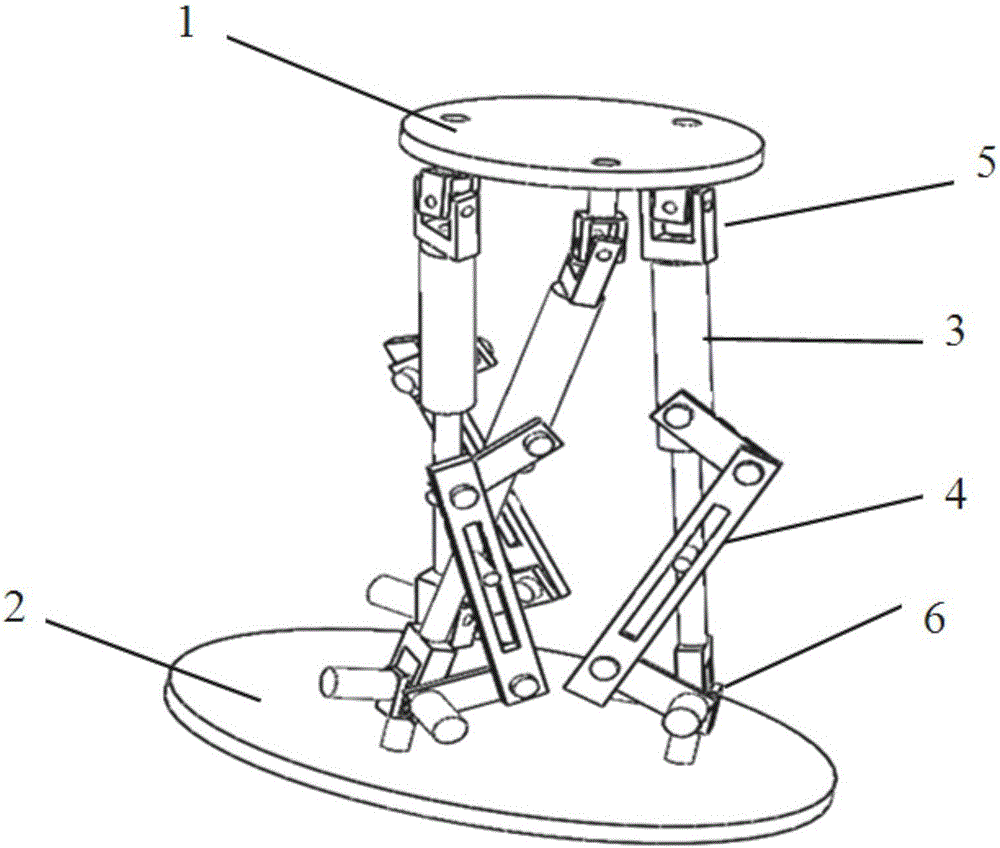

Three-branched-chain six-freedom-degree robot drive mechanism

InactiveCN104149084ASimple form of exerciseIncrease flexibilityProgramme-controlled manipulatorMachine toolSix degrees of freedom

The invention relates to a three-branched-chain six-freedom-degree robot drive mechanism which is mainly and technically characterized in that three branched chains identical in structure are arranged between a movable platform and a fixed platform, a fixed platform motor is arranged on a fixed platform motor support, and the fixed platform motor, second connection rods, first connection rods and the movable platform are sequentially connected; sliding guide rails are evenly distributed on the fixed platform in the circumferential direction, a guide rail top motor is arranged at the top end of each sliding guide rail, a screw rod is arranged in each sliding guide rail through a bearing, sliding blocks are arranged on the sliding guide rails in a sliding mode, and the middle portions of the sliding blocks are meshed with the screw rods in a spiral mode; connection sleeves are arranged on the outer sides of the sliding blocks and connected with the first connection rods in a sliding mode. The three-branched-chain six-freedom-degree robot drive mechanism is reasonable in design, has the advantages of being simple and reliable in structure, stable in movement of the movable platform, and the like, has good drive performance, robustness and bearing capacity, and can be applied to the fields of detection of machine tools and robots according to different needs.

Owner:HEBEI UNIV OF TECH

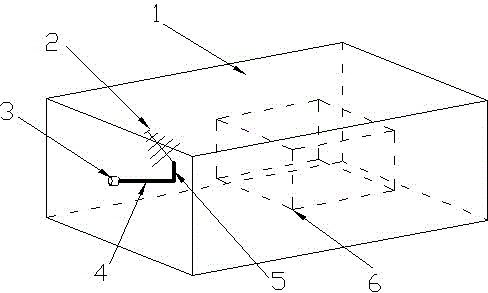

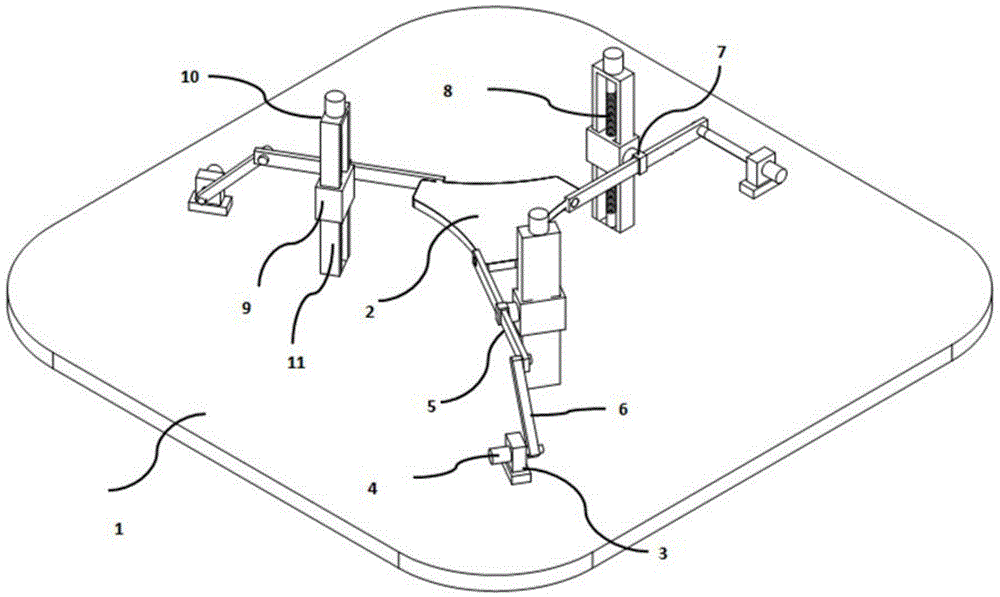

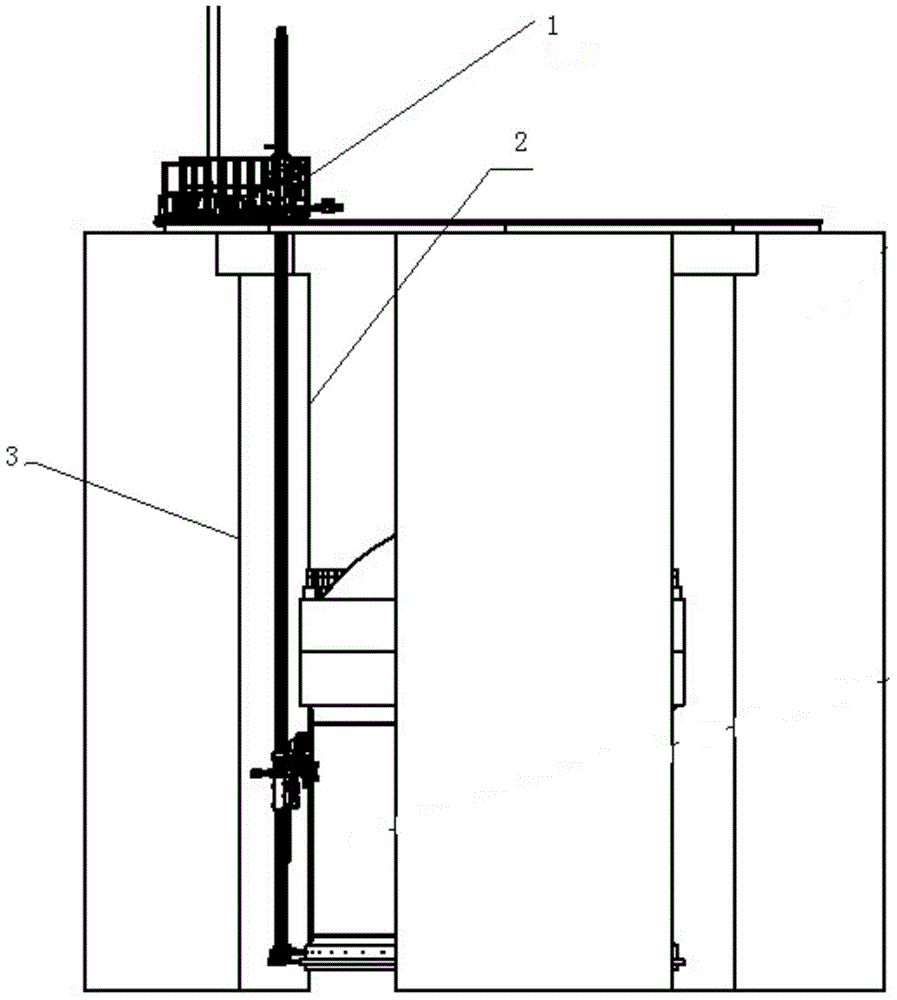

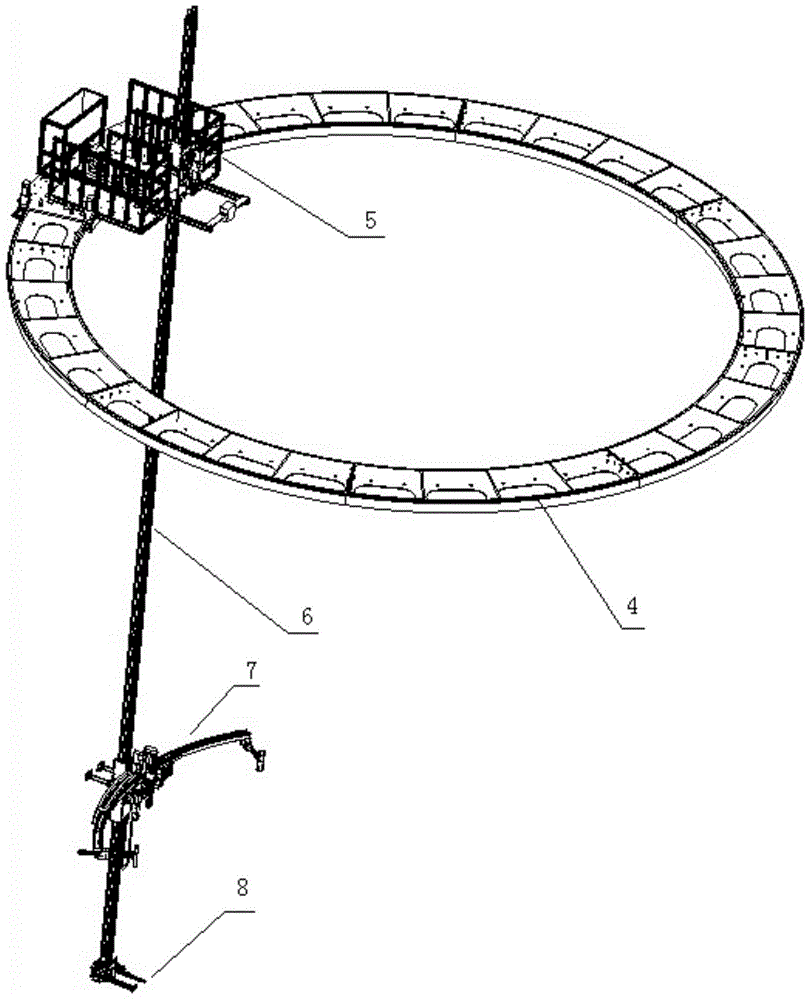

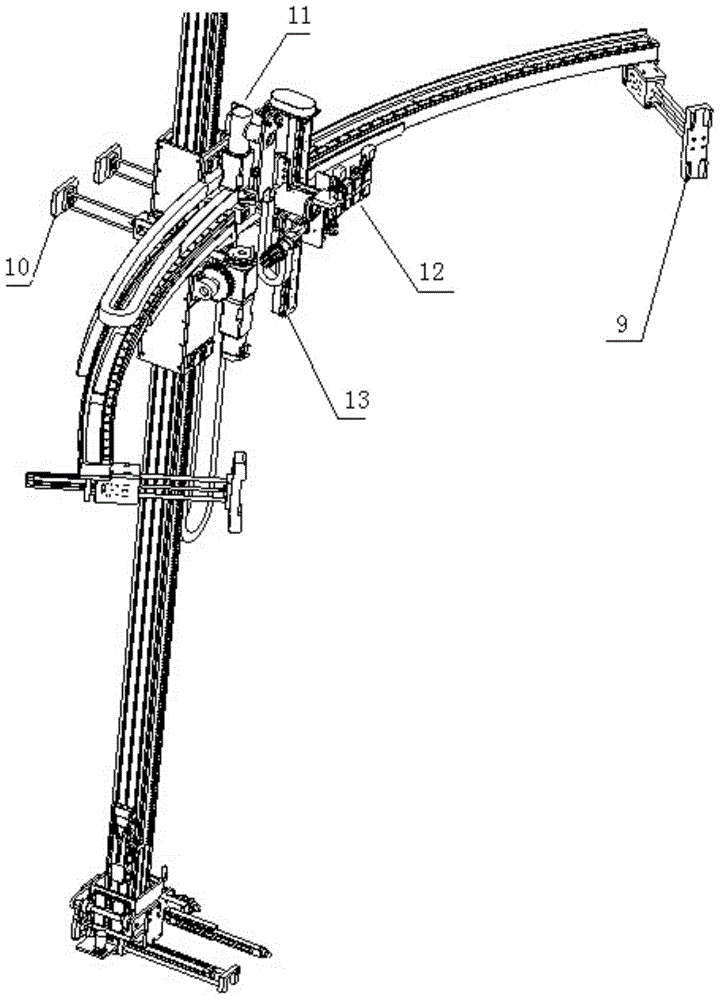

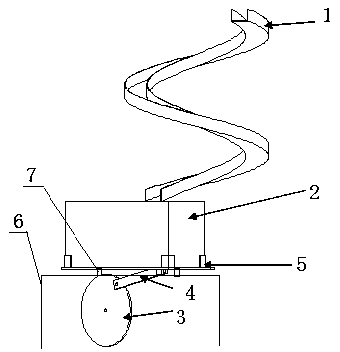

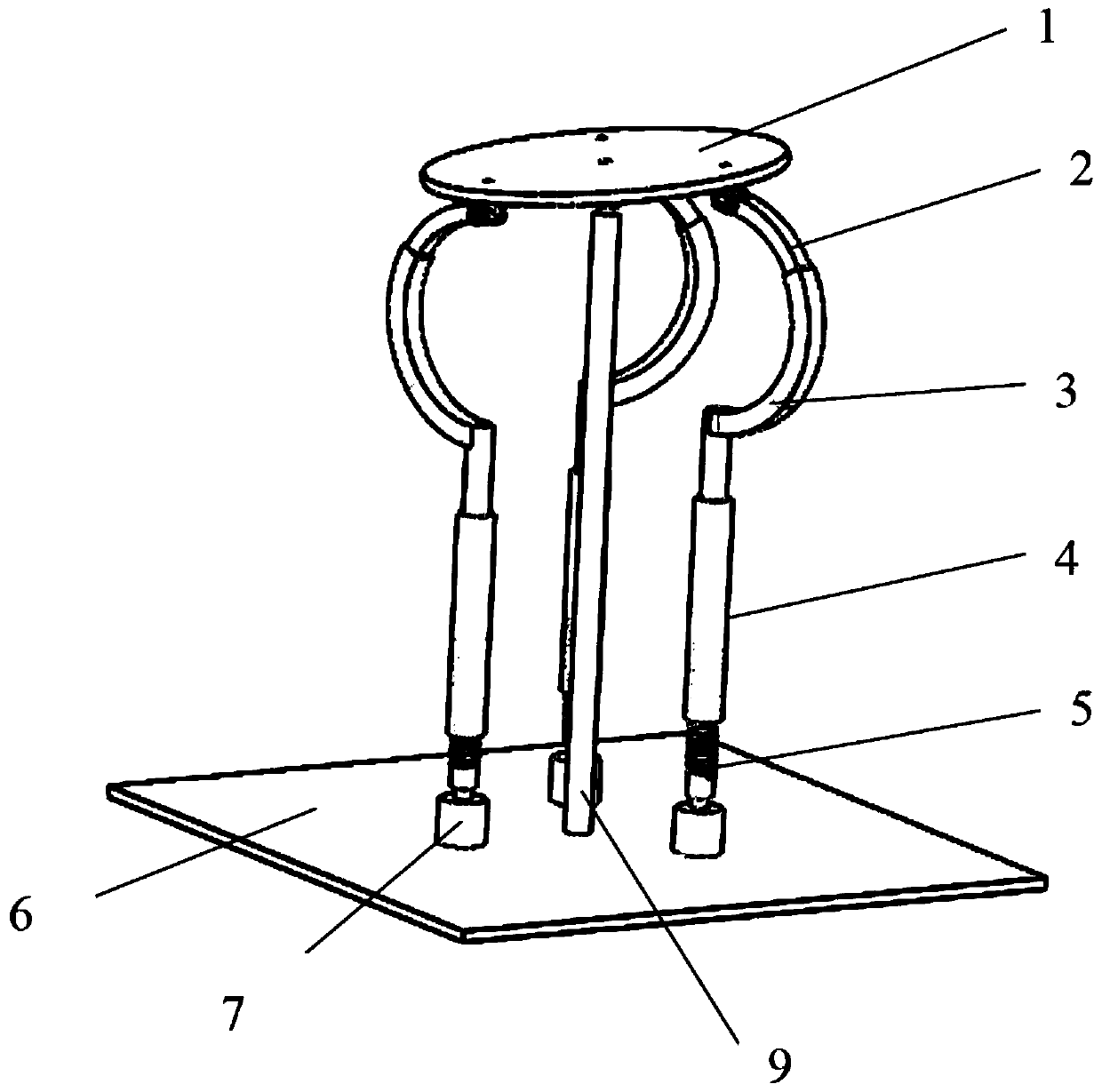

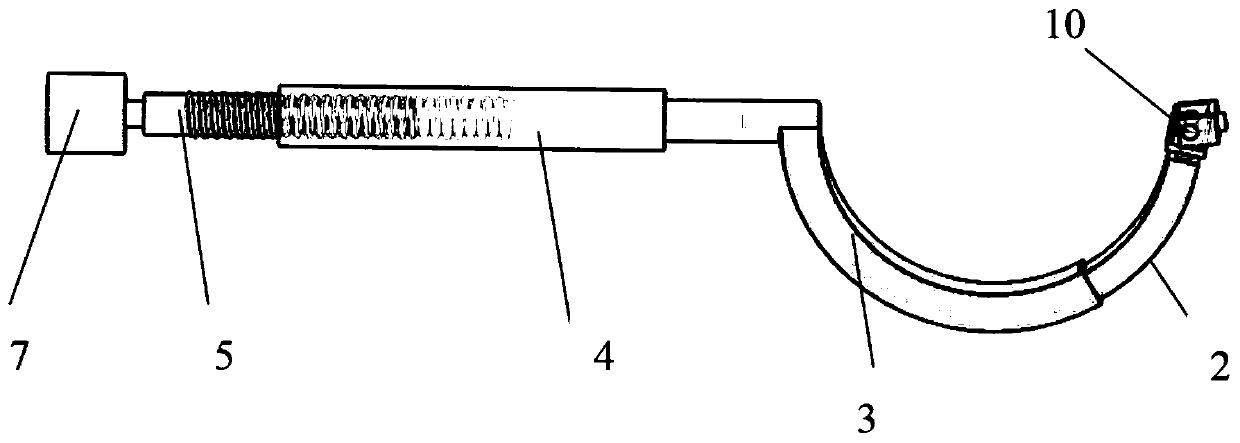

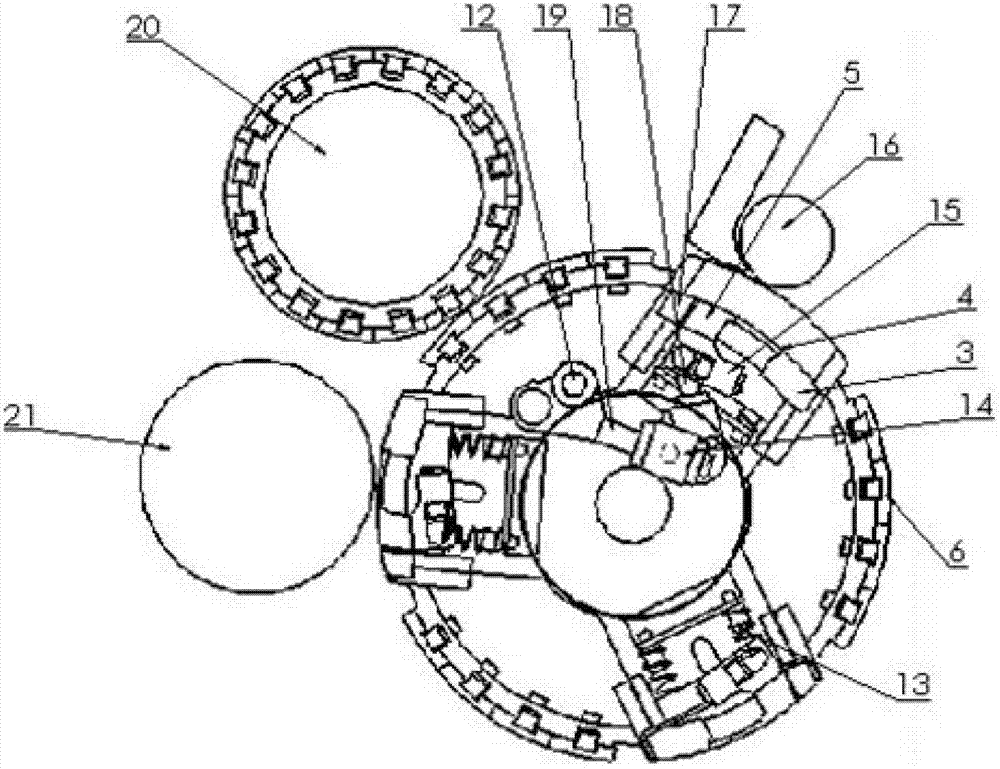

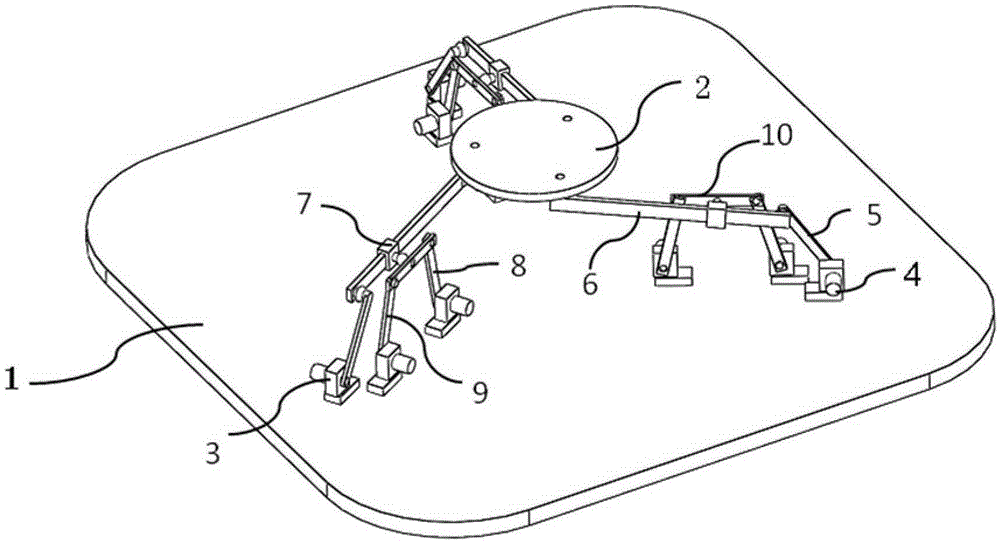

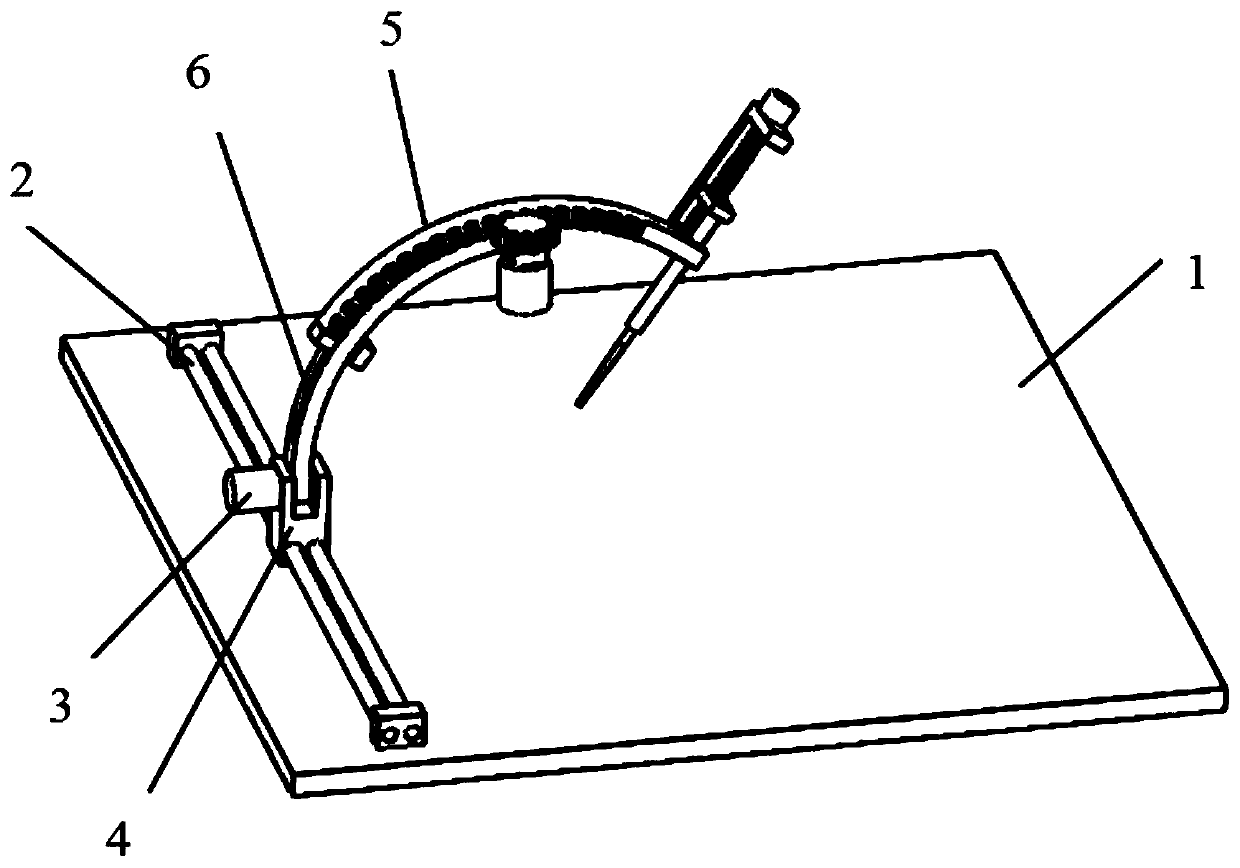

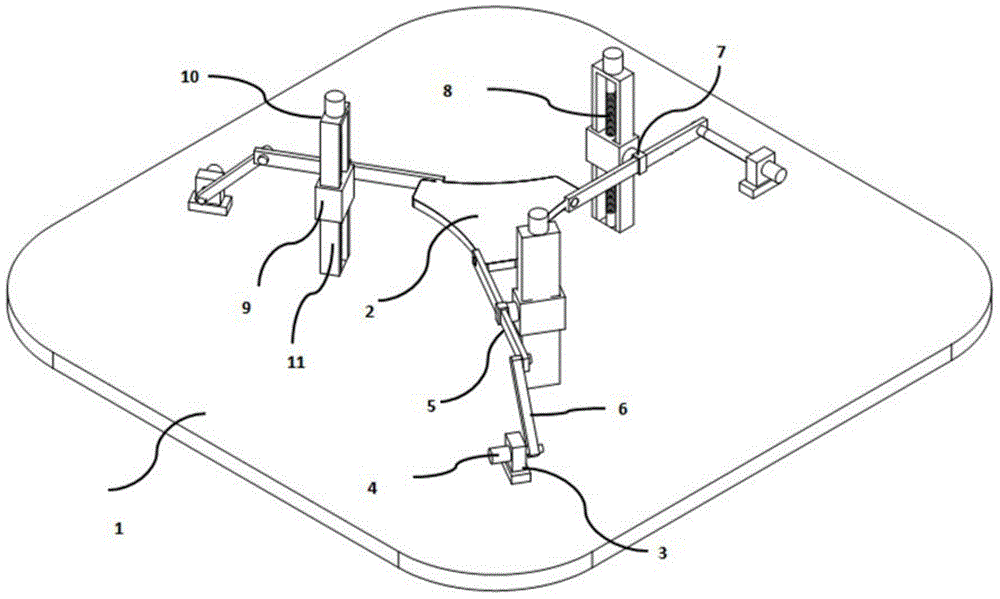

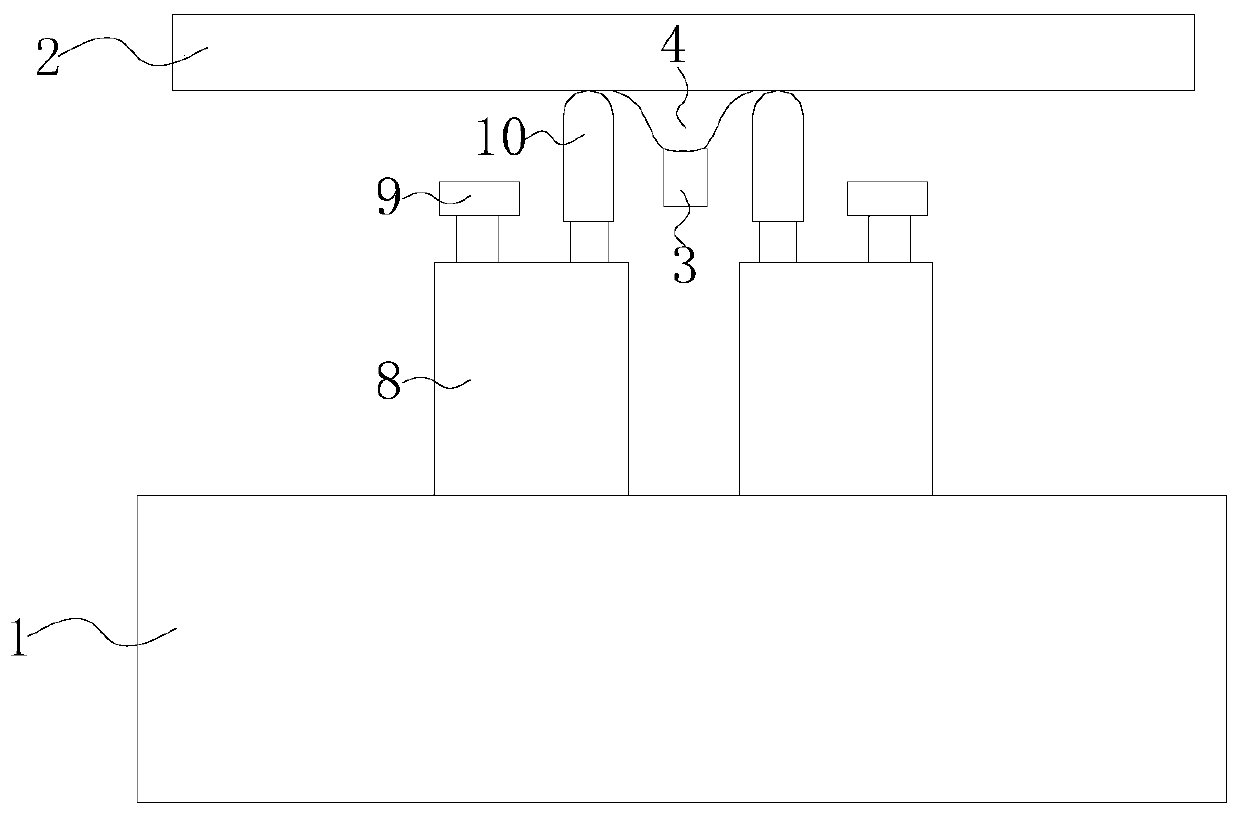

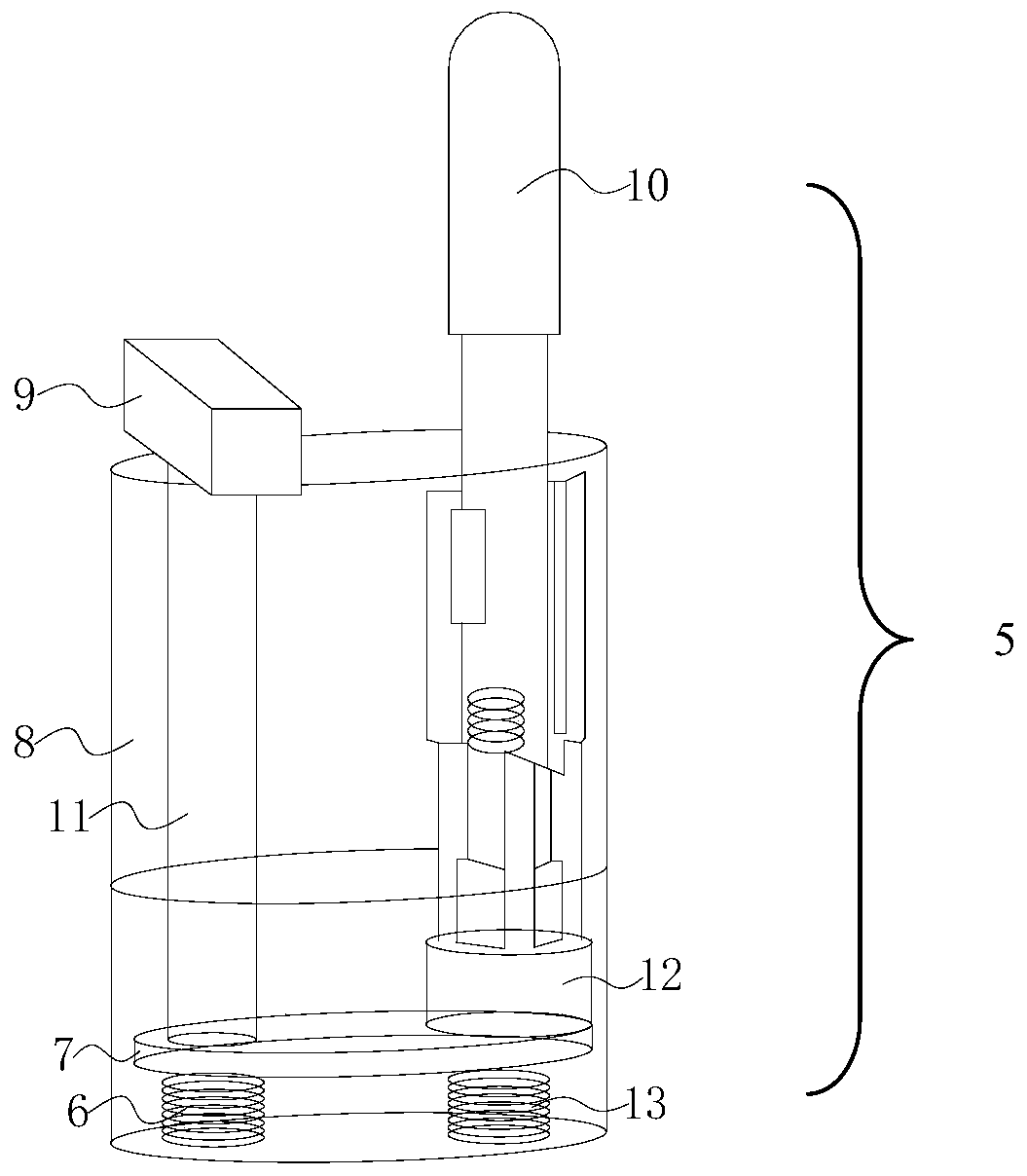

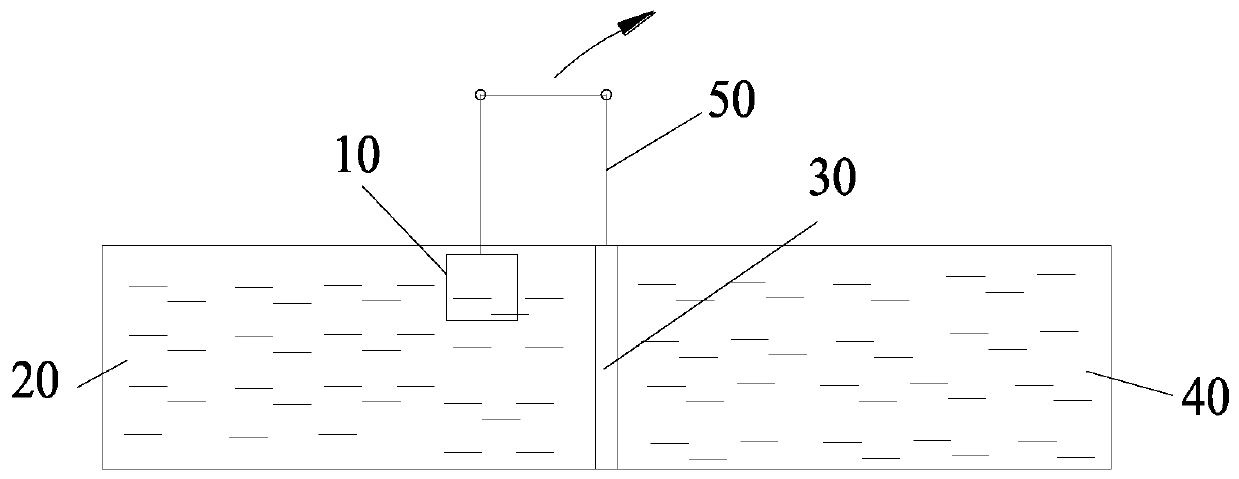

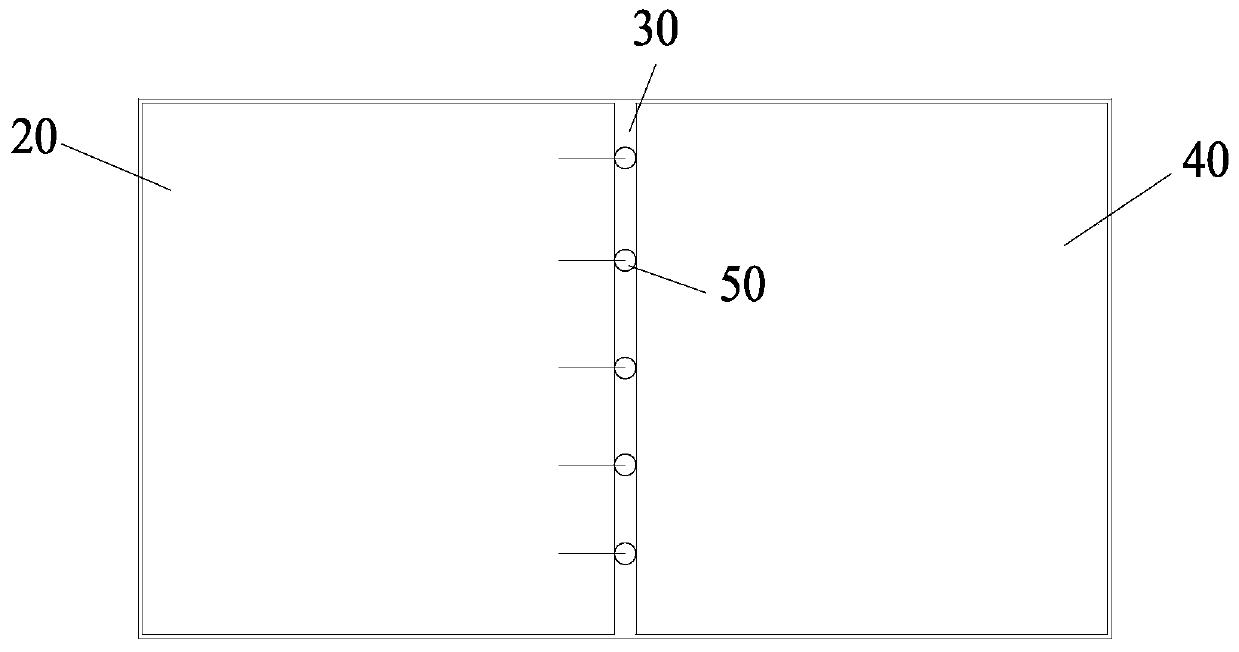

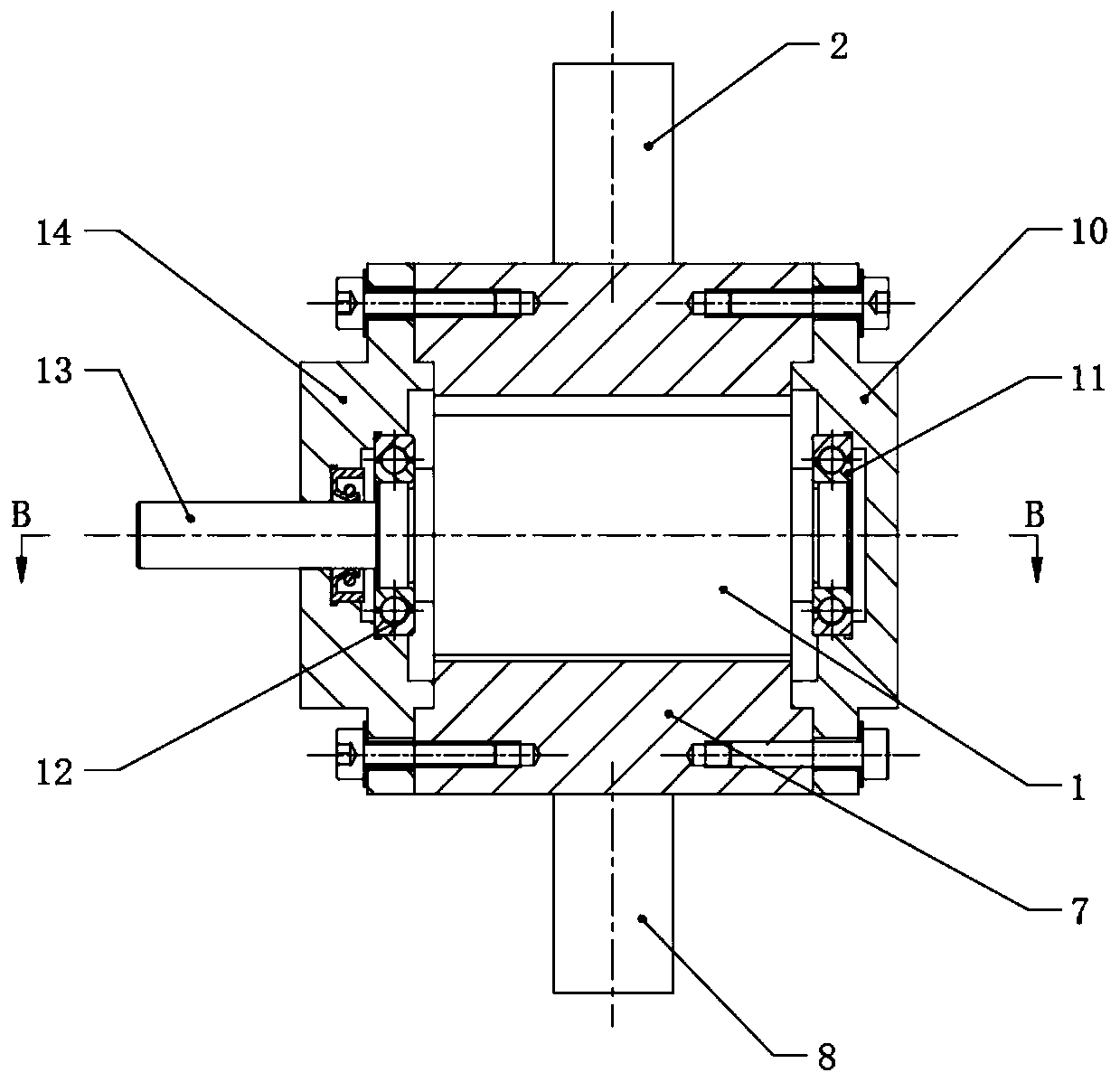

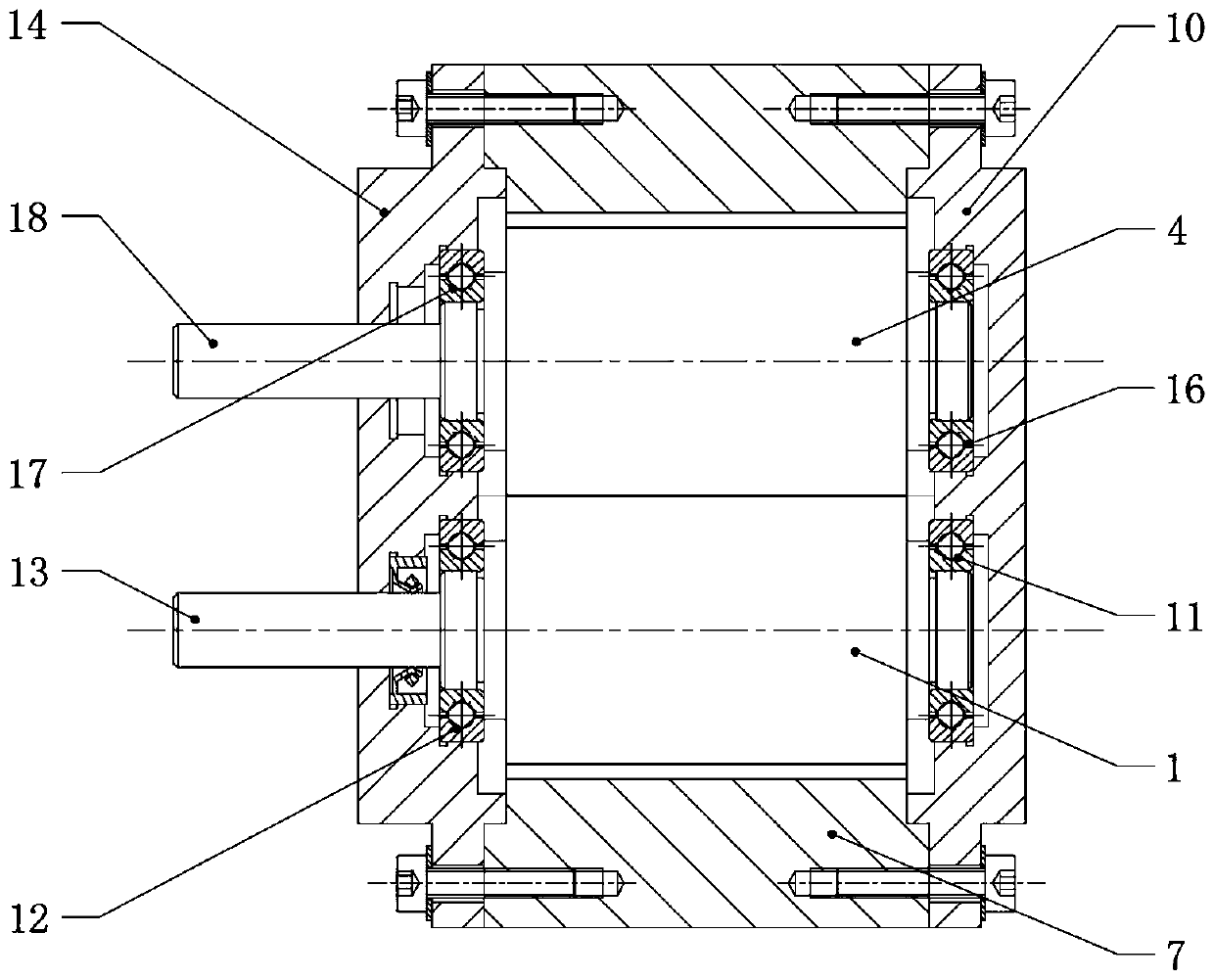

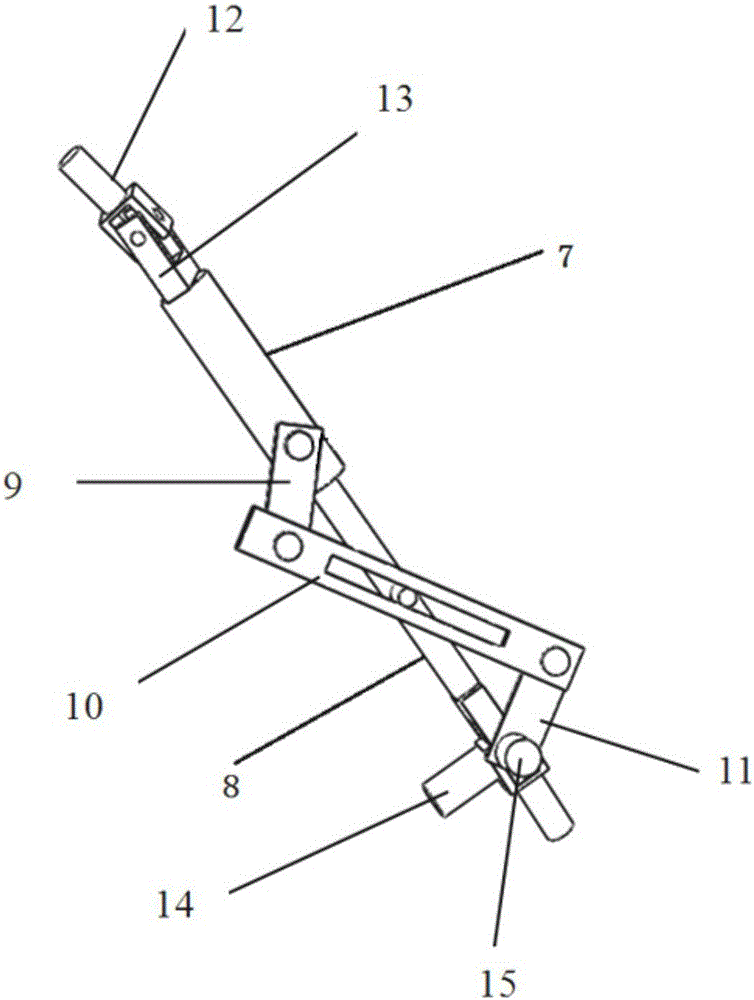

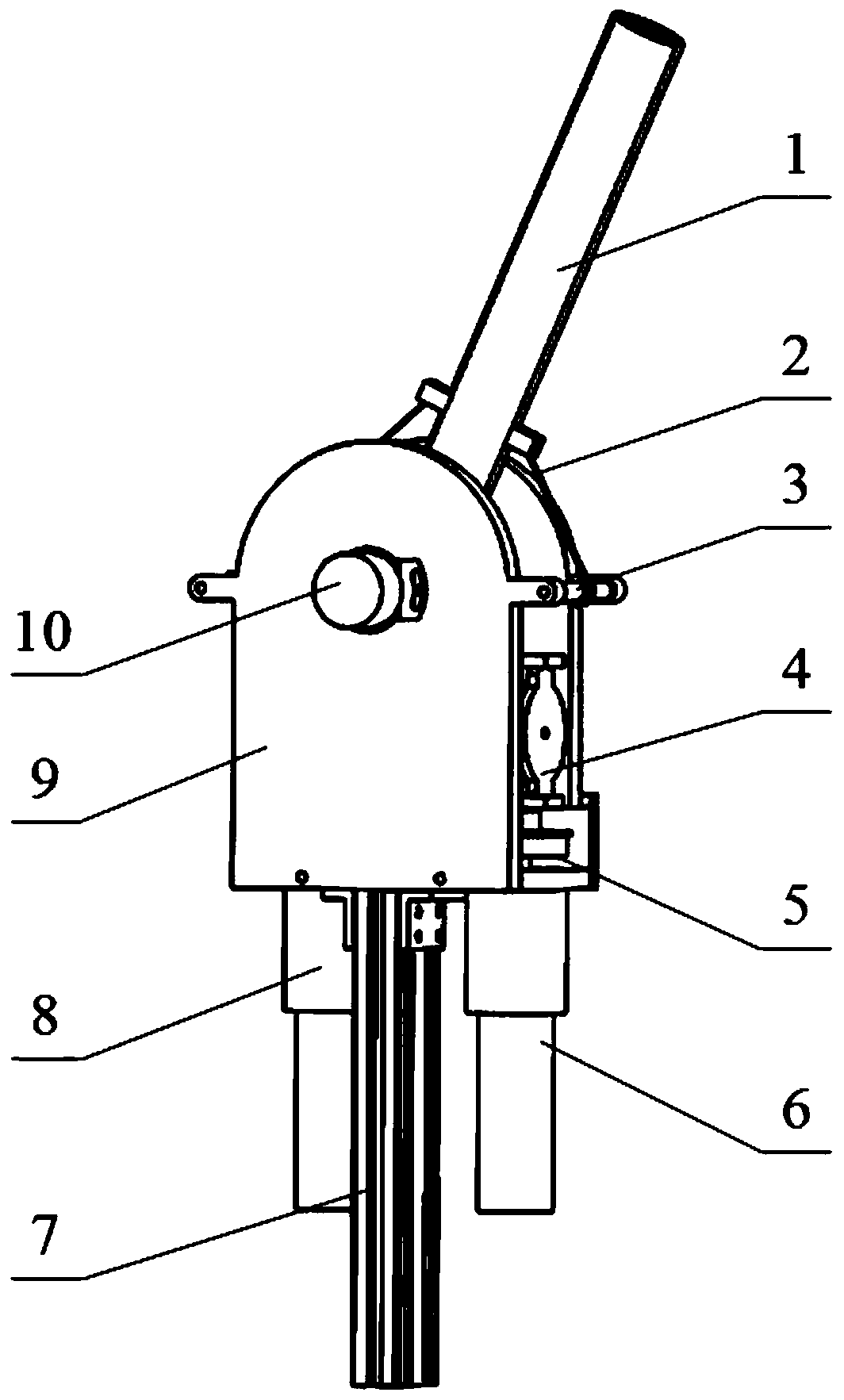

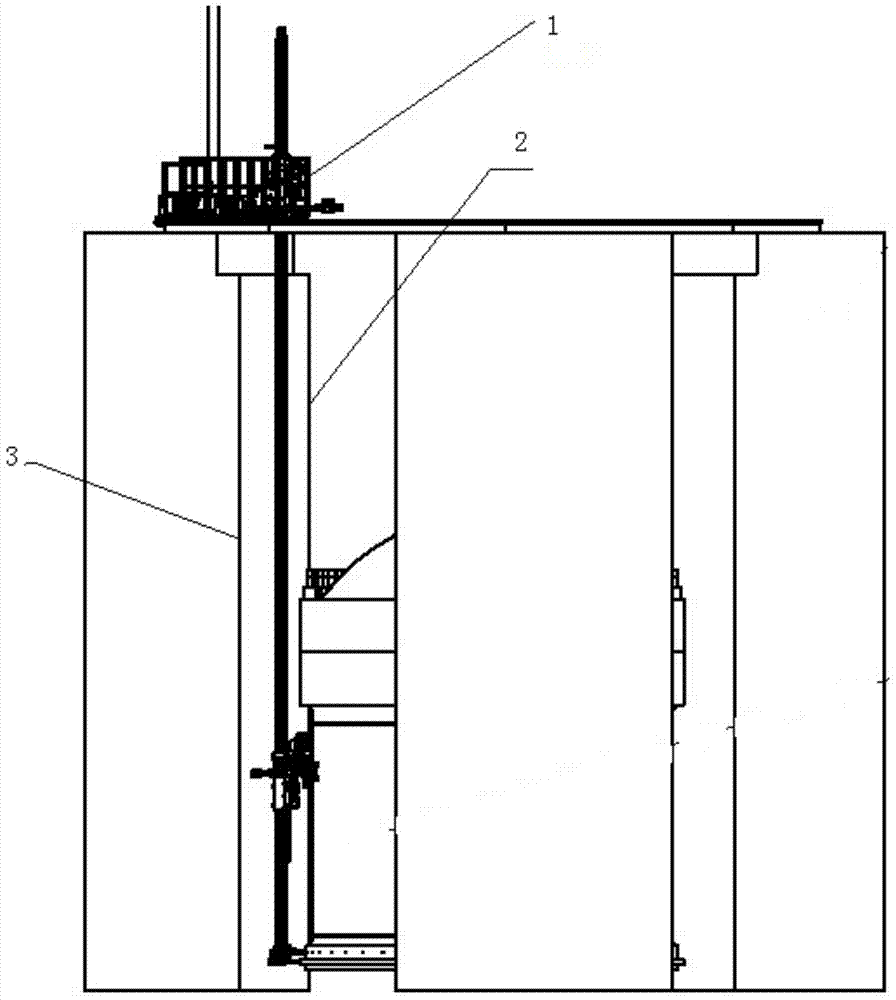

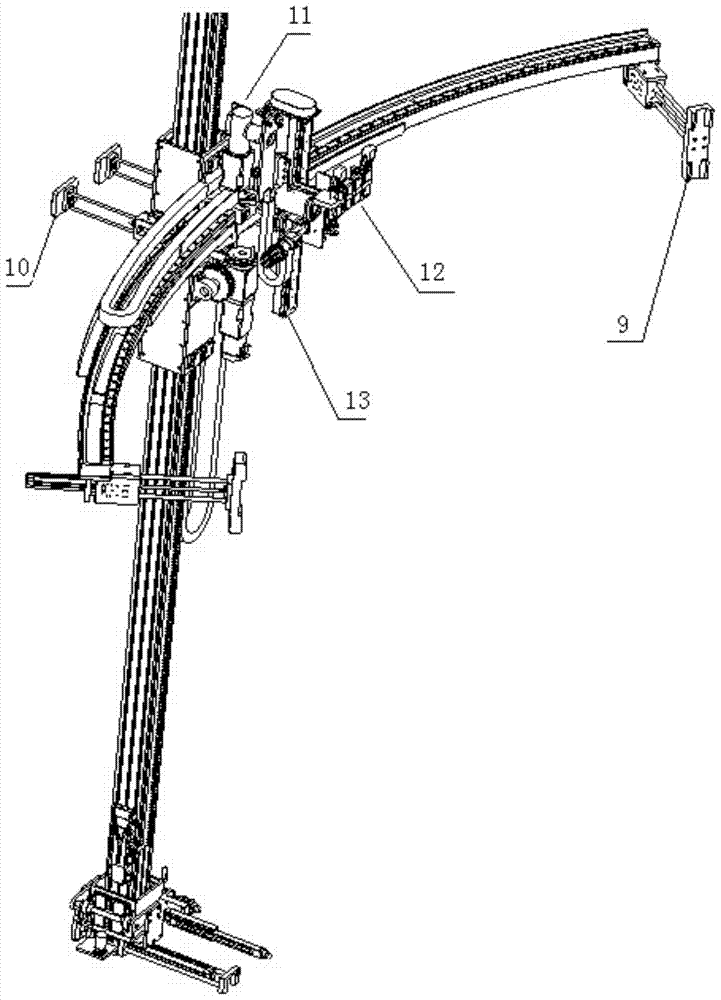

Detection apparatus for pressure vessel of high-temperature gas-cooled reactor

ActiveCN105810259ASimple form of exercisePrecise displacement controlNuclear energy generationNuclear monitoringEngineeringPressure vessel

The invention specifically relates to a detection apparatus for a pressure vessel of a high-temperature gas-cooled reactor, which belongs to the field of detection apparatuses for pressure vessels. The detection apparatus 1 is located between a pressure vessel outer barrel wall 2 and a cabin barrel wall 3 and comprises an annular guide rail 4, a rail-running trolley 5, a lifting bar 6, a two-shaft scanner 7 and a positioning pin pointing mechanism 8, wherein the annular guide rail 4 is a whole circular ring formed by splicing of a plurality of arc guide rails; the rail-running trolley 5 is located on the annular guide rail 4 and can move along the rail; and the lifting bar 6 is mounted on the rail-running trolley 5, and the lower end of the lifting bar 6 is provided with the positioning pin pointing mechanism 8 which can be fixed with a positioning pin hole located in the bottom of the pressure vessel. According to the invention, the lower end of the lifting bar 6 is provided with the positioning pin pointing mechanism 8 which can be fixed with the positioning pin hole located in the bottom of the pressure vessel.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Stepped horizontal spindle harvesting machine

A stepped horizontal spindle harvesting machine comprises a machine frame. At least one cotton picking channel is arranged on the machine frame, a cotton picking platform is arranged on at least one side of the cotton picking channel, a plurality of spindles are arranged on the cotton picking platform, a cotton doffing platform is arranged on a corresponding position of the cotton picking platform, and cotton doffing holes are formed in the cotton doffing platform. The spindles are matched with a plurality of cotton pushing tables on the cotton doffing platform to control toothed openings of the spindles to stretch out and draw out to pick cotton. The stepped horizontal spindle harvesting machine further comprises a rotation mechanism used for rotating the spindles, a moving mechanism used for moving the cotton picking platform, a cotton conveying device used for sucking cotton into a cotton storage box and a stepped walking mechanism used for enabling the stepped horizontal spindle harvesting machine to go forwards. The cotton picking platform and the cotton doffing platform are simple in moving mode, the mechanical structure is not complex, the failure rate is low, device maintenance cost is low, and if a set of cotton picking and doffing platform is arranged on the other side of the machine frame, cotton picking can be carried out on the two sides at the same time, and cotton picking efficiency can be improved in a multiplied mode.

Owner:SHANGHAI IT DRAGON COMP TECH

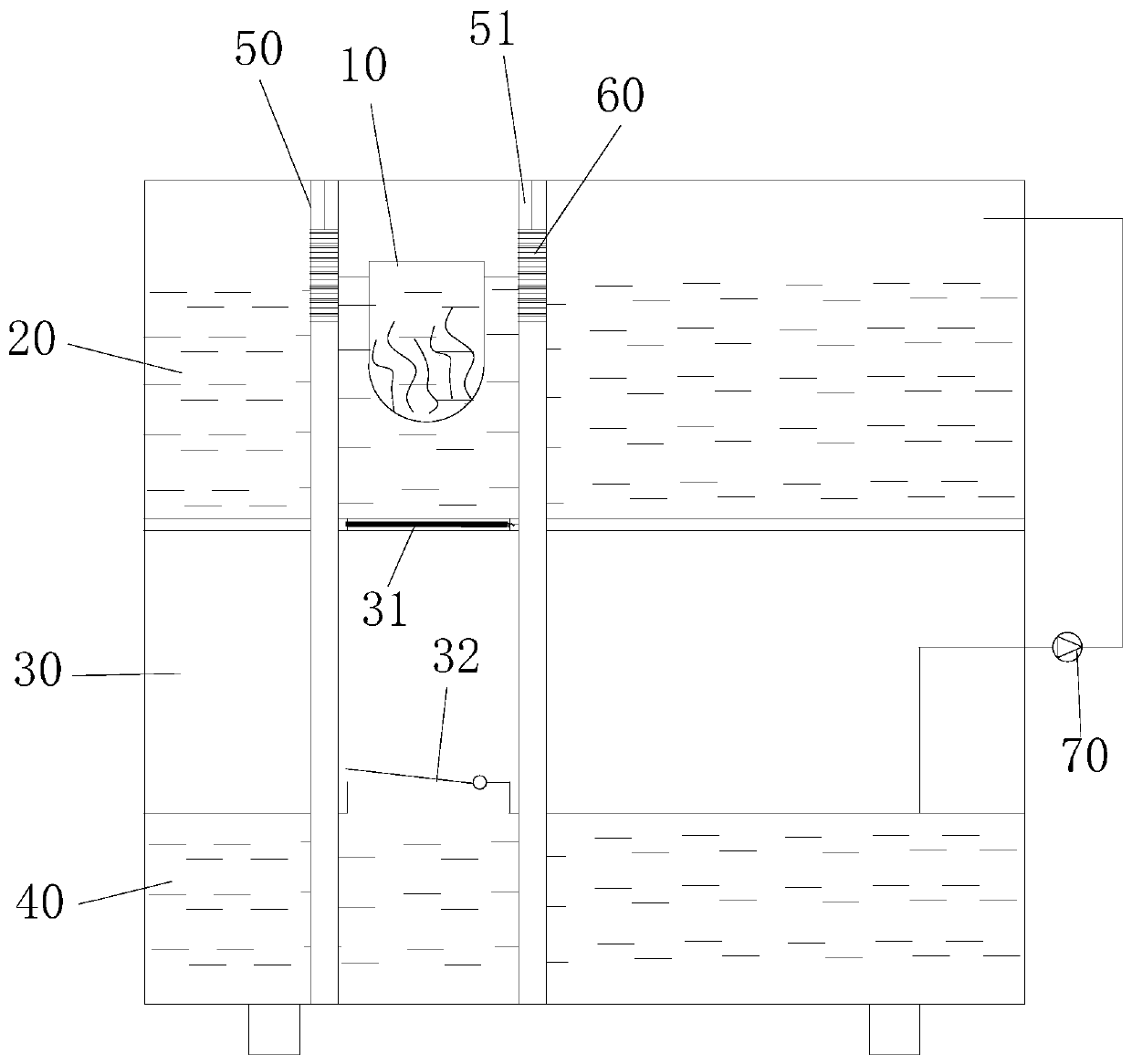

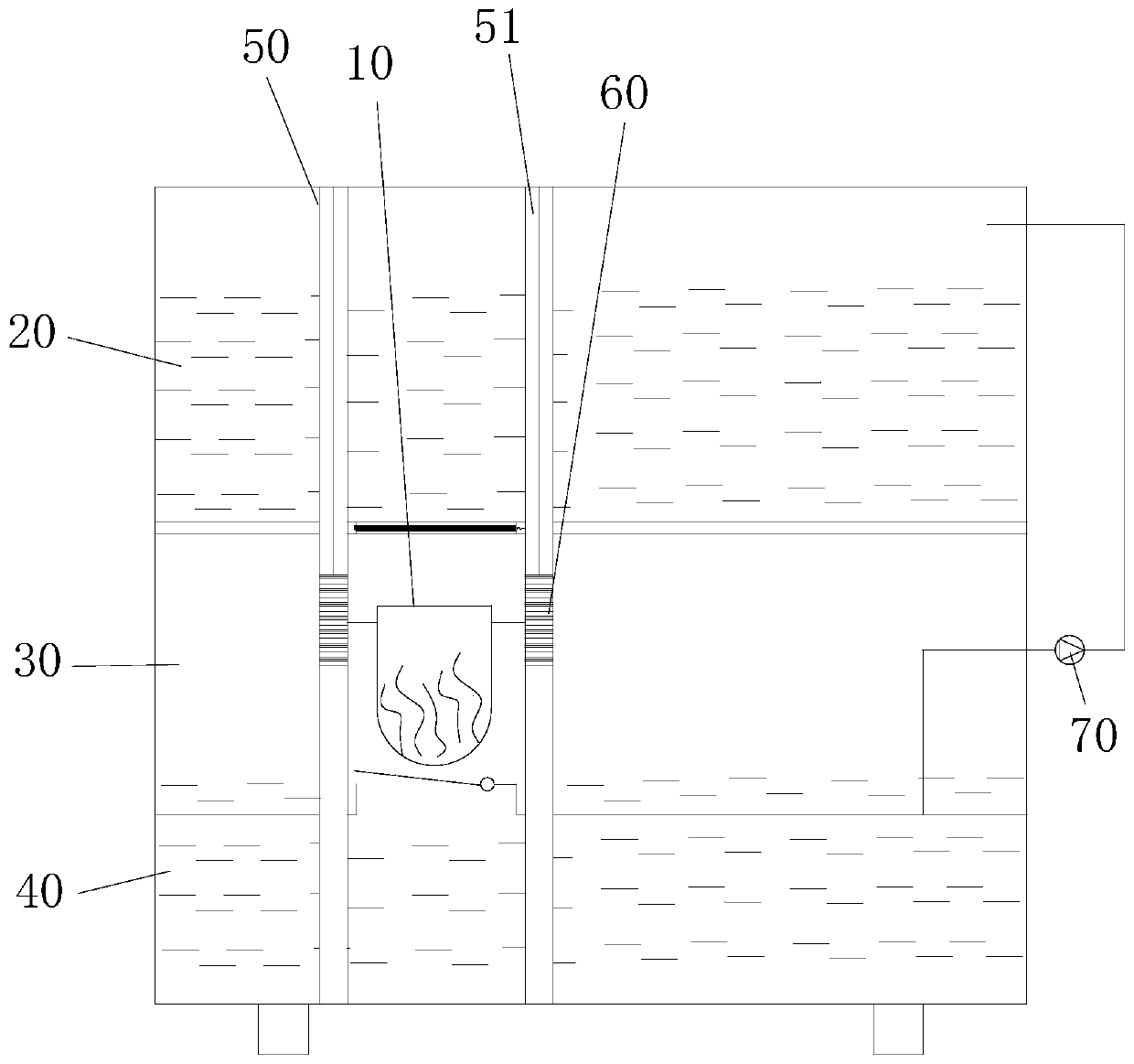

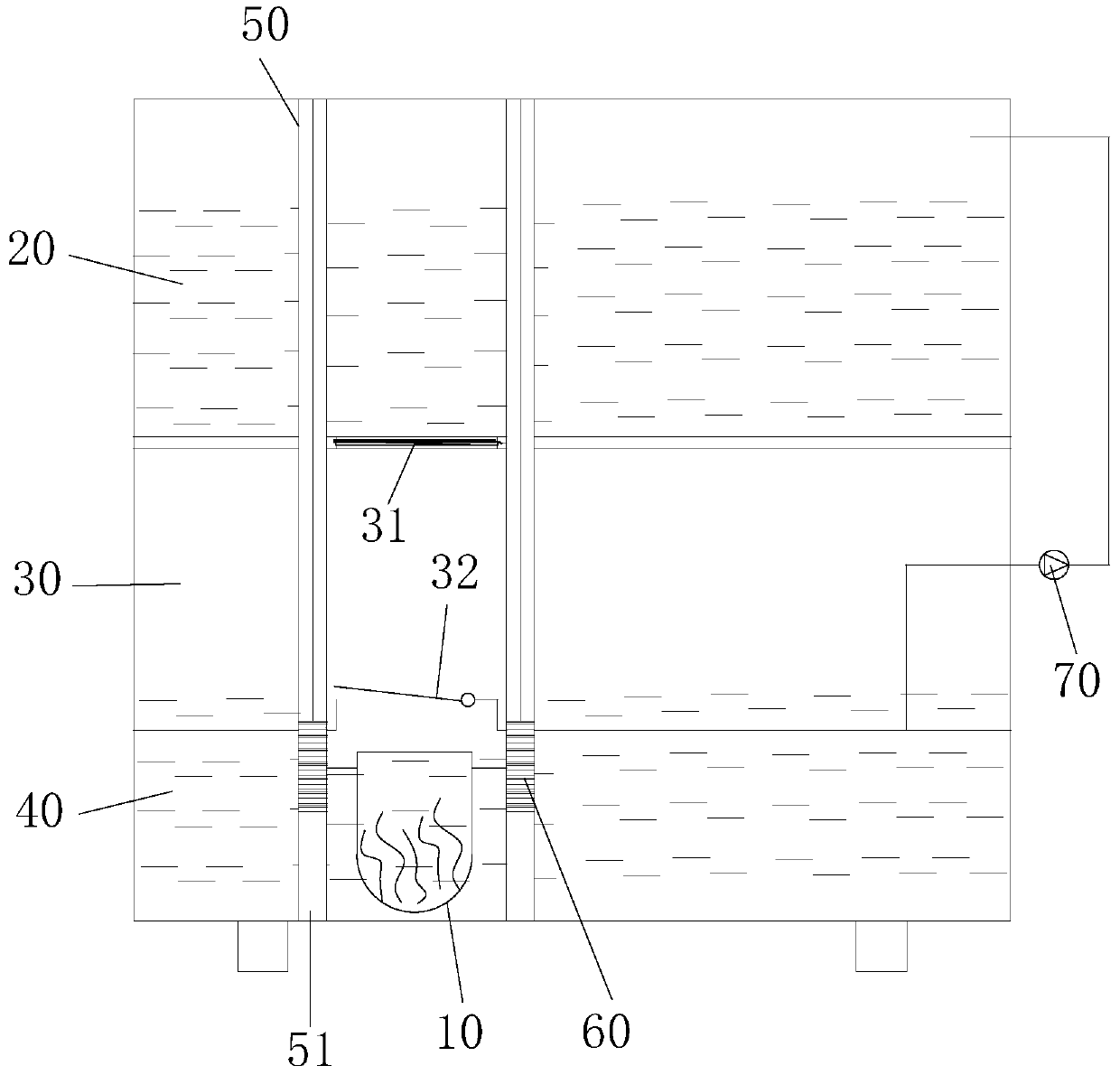

Noodle cooking device

ActiveCN108309024ASimple form of exerciseEasy to operateCooking insertsCooking vessel constructionsEngineeringMechanical engineering

The invention provides a noodle cooking device. The noodle cooking device comprises a noodle basket, a cooling water pool, a hot water pool, a conveying assembly and a power mechanism, wherein the conveying assembly is connected with the noodle basket and can drive the noodle basket to move between the cooling water pool and the hot water pool; the power mechanism is in driving connection with theconveying assembly, and the noodle basket is located in the hot water pool when noodles are cooked; when noodles are treated with cooling water, the noodle basket moves to the cooling water pool fromthe hot water pool under driving of the conveying assembly; when noodles needs to be heated again, the noodle basket moves to the hot water pool from the cooling water pool, and circulation is carried out through the mode till noodle cooking is completed. By means of the noodle cooking device, the problem that a noodle cooking device in the prior art is inconveniently used is solved.

Owner:珠海优特智厨科技有限公司

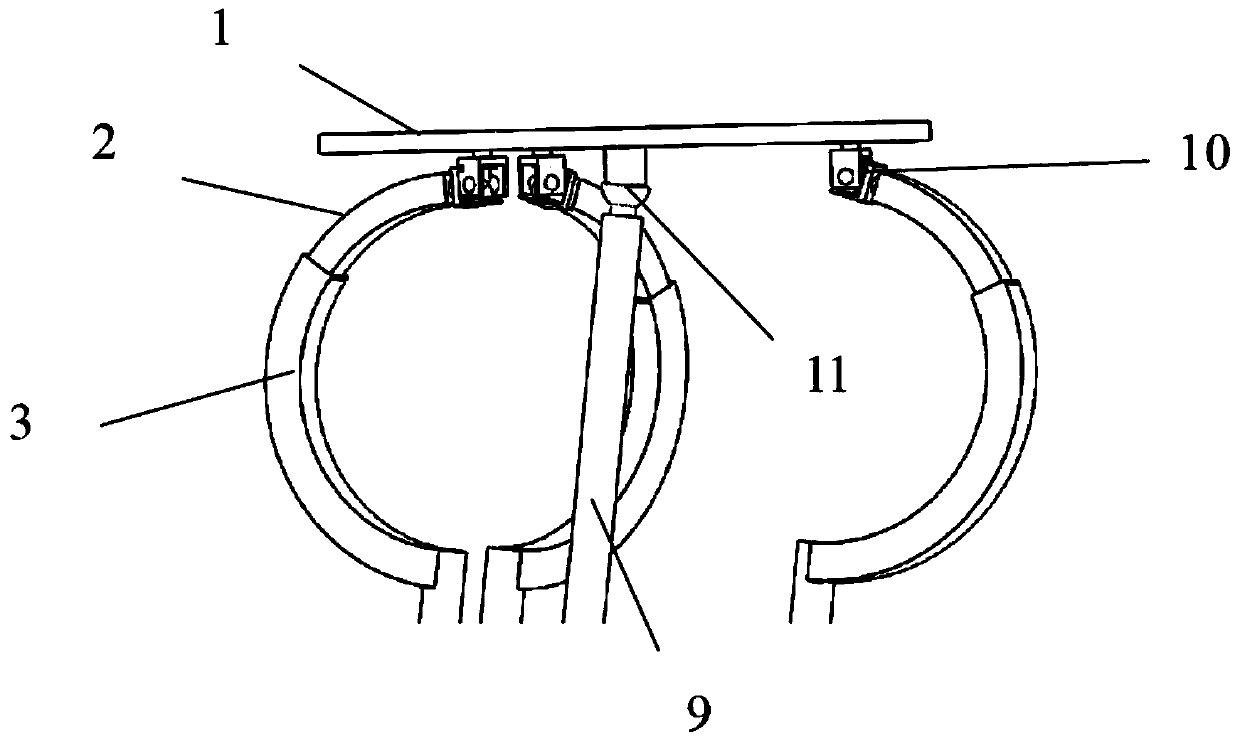

Three-degree-of-freedom parallel mechanism provided with arc-shaped sliding pairs

ActiveCN106903671AIncrease flexibilityGuaranteed accuracyProgramme-controlled manipulatorThree degrees of freedomEngineering

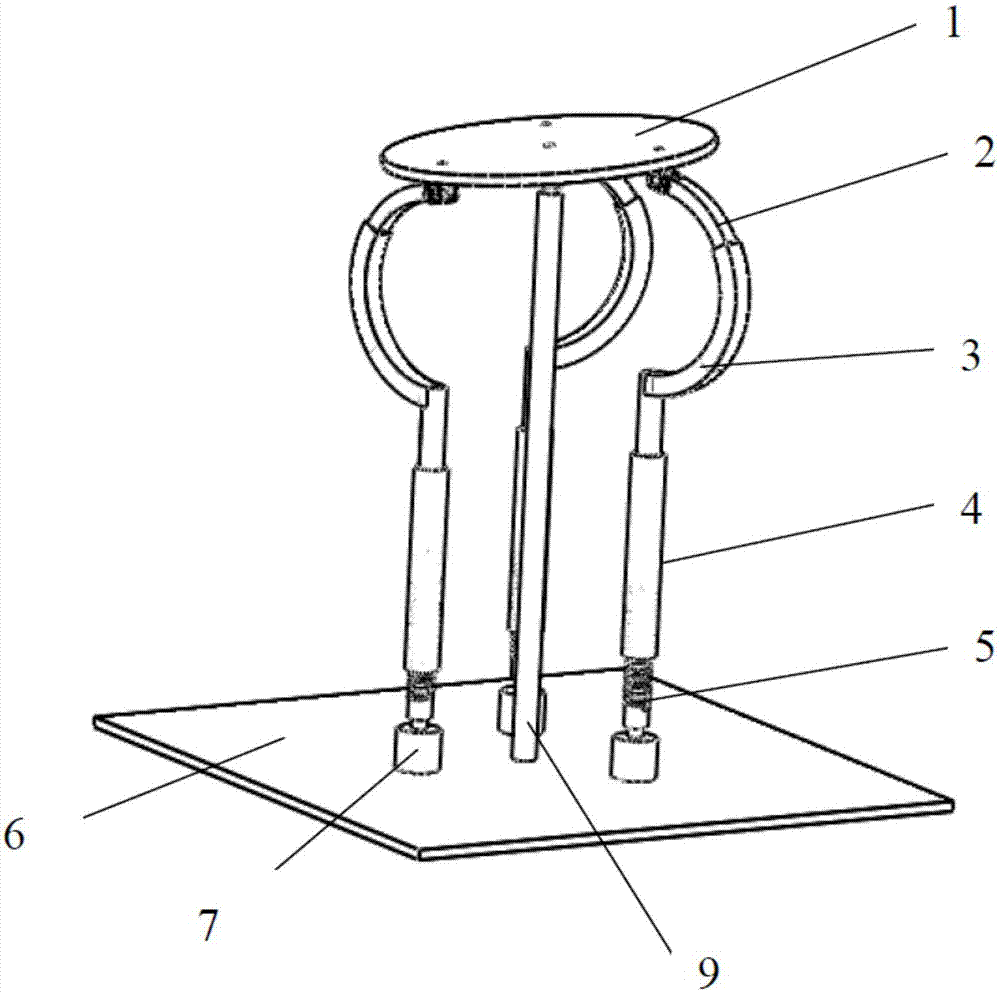

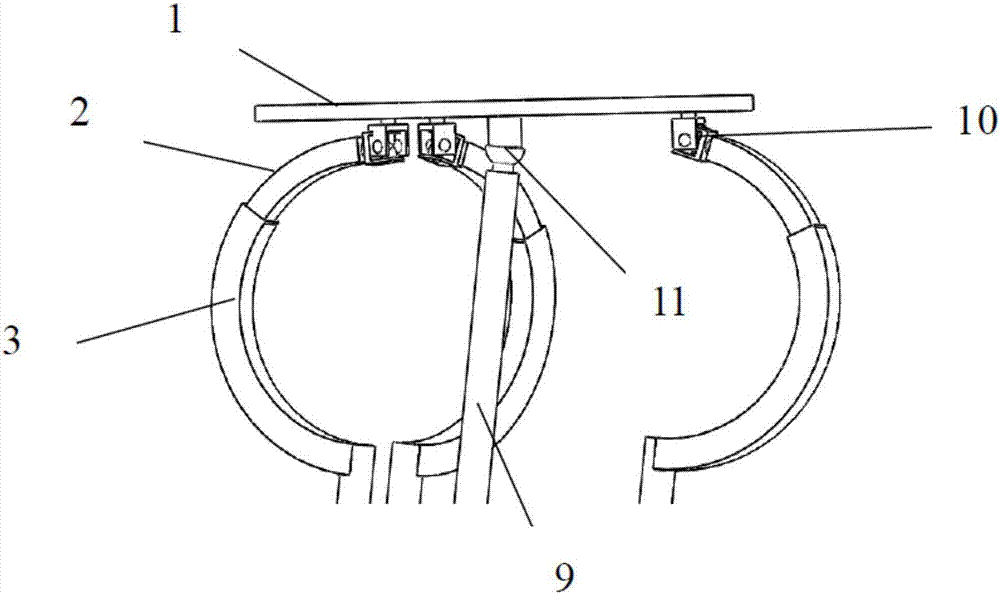

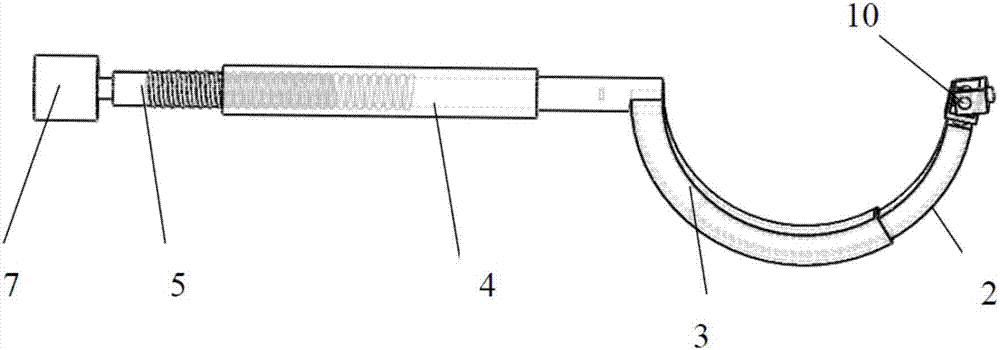

The invention discloses a three-degree-of-freedom parallel mechanism provided with arc-shaped sliding pairs. The three-degree-of-freedom parallel mechanism provided with the arc-shaped sliding pairs comprises a base, a movable platform, a restraining rod and three identical moving branched chains. The movable platform and the base are connected through the restraining rod. The movable platform has freedom degrees in three rotation directions relative to the restraining rod. The three moving branched chains are arranged symmetrically with the restraining rod as the center. Each moving branched chain comprises a lead screw assembly and one arc-shaped sliding pair. The lead screw assemblies are arranged on the base, and the arc-shaped sliding pairs are hinged to the movable platform. Each arc-shaped sliding pair comprises a lower arc-shaped connecting rod and an upper arc-shaped connecting rod, wherein the lower arc-shaped connecting rod and the upper arc-shaped connecting rod are connected in a nested mode, the lower arc-shaped connecting rod is driven by the corresponding lead screw assembly to move linearly in the axis direction of the lead screw assembly and to rotate around the axis of the lead screw assembly, the upper arc-shaped connecting rod is made to move along the arc-shaped track of the lower arc-shaped connecting rod accordingly, and one end of the upper arc-shaped connecting rod is hinged to the movable platform.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

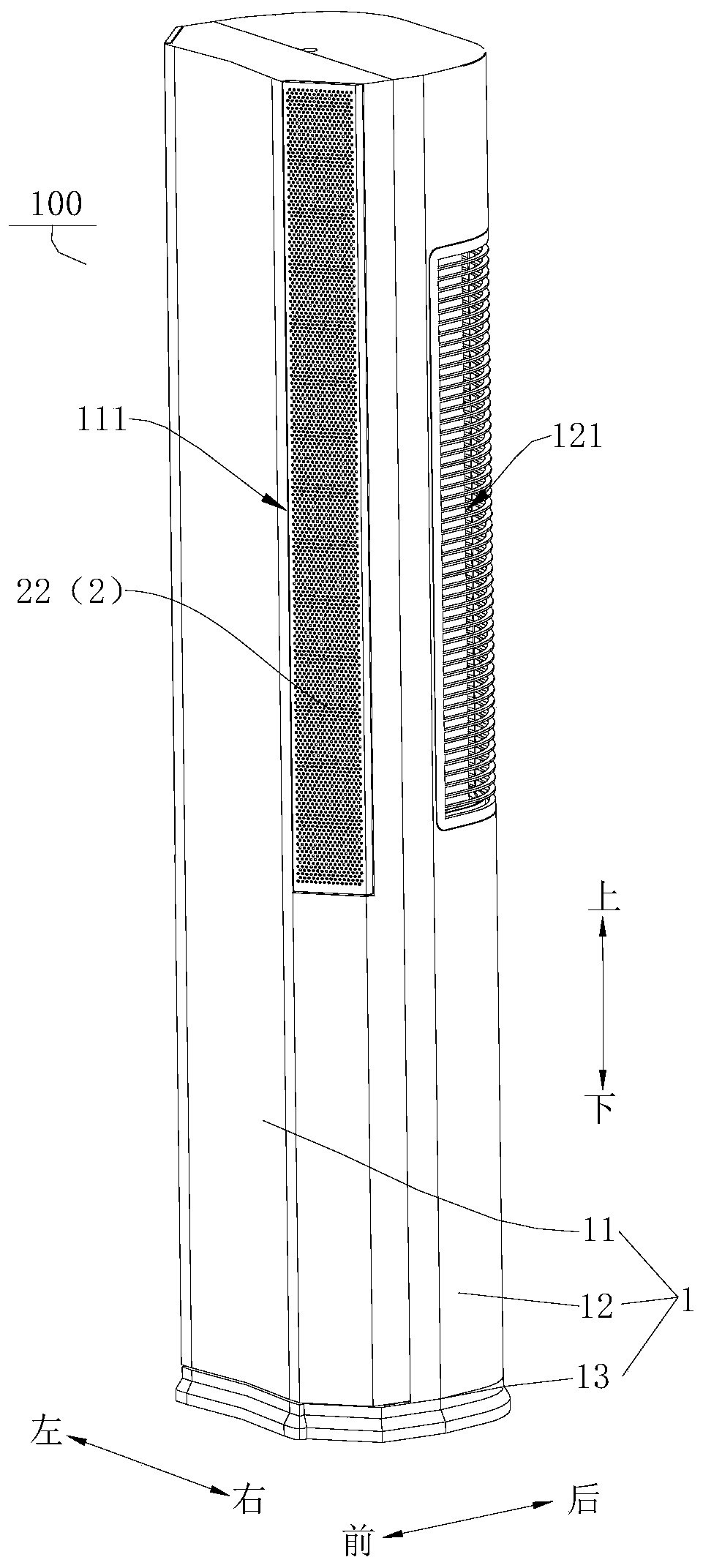

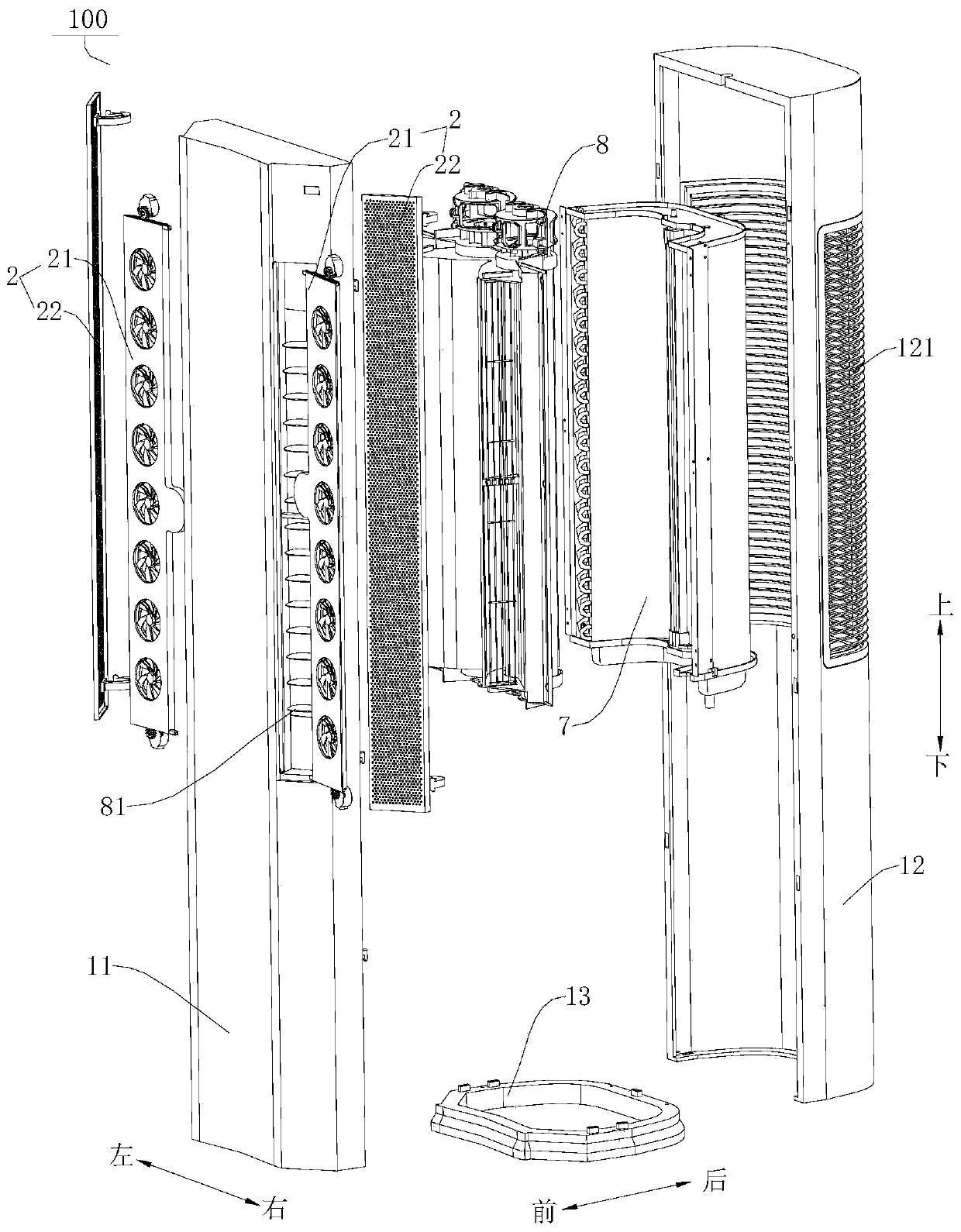

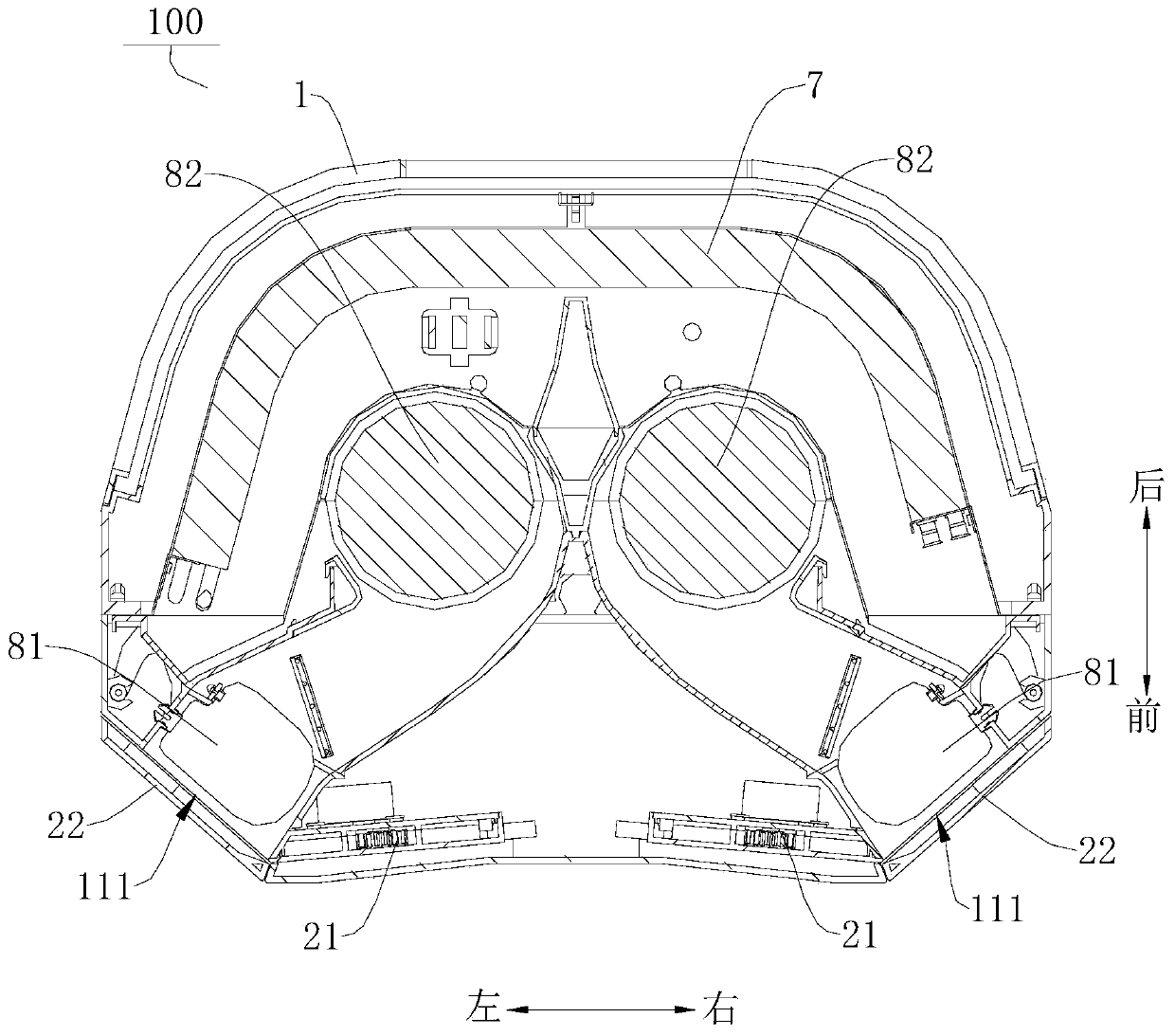

Cabinet-type air-conditioning inner unit and air conditioner with same

PendingCN111380106AIncrease air volumeImprove user experienceLighting and heating apparatusHeating and ventilation casings/coversEngineeringMechanical engineering

The invention discloses a cabinet-type air-conditioning inner unit and an air conditioner with the same. The cabinet-type inner unit comprises a shell body and an air dispersion assembly, wherein an air outlet is formed in the shell body; the air dispersion assembly comprises a first air guiding component and a second air guiding component, the first air guiding component is movably arranged on the shell body in the circumferential direction of the shell body, the second air guiding component is rotatably connected with the shell body, in the first no air sensing mode, at least part of the first air guiding component is located on the outer side of the air outlet, at least part of the second air guiding component is located on the outer side of the air outlet, an air supply space can be enclosed among the part of the first air guiding component located on the outer side of the air outlet, the part of the second air guiding component located on the outer side of the air outlet and a plane where the air outlet is located, and at least one of the first air guiding component and the second air guiding component is suitable for dispersing and flowing the air blown out from the air supply space. According to the cabinet-type air-conditioning inner unit, the air supply volume of the cabinet-type air-conditioning inner unit during air outlet with no air sensing can be increased, and meanwhile the control cost is low.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Automatic pipe connection and arranging device based on full-automatic winding machine

PendingCN107826887AAchieve receptionReceive and place in sequenceFilament handlingConveyor partsWinding machineReciprocating motion

The invention discloses an automatic pipe connection and arranging device based on a full-automatic winding machine. The device comprises a sand pipe sliding cannel used for containing a fine sand pipe, a pipe arranging box and a reciprocating movement mechanism. The pipe arranging box is located below the sand pipe sliding channel and used for containing the fine sand pipe sliding from the sand pipe sliding channel. The reciprocating movement mechanism is connected with the pipe arranging box and drives the pipe arranging box to do transverse reciprocating motion. The fine sand pipe can be well received and placed in sequence, the device is simple in structure and motion, good in stability, and free of frequent maintenance and overhaul, the working efficiency is improved, and the labor intensity of workers is lowered.

Owner:宜宾雅士德纺织有限公司

Energy-saving and environment-friendly high-strength cast aluminum alloy production line

InactiveCN113649556ASolve the problem that is easy to cause bumpsUntidy solutionCasting plantsCleaning using liquidsProduction lineMaterials science

The invention relates to the technical field of aluminum alloy casting, and provides an energy-saving and environment-friendly high-strength cast aluminum alloy production line. The energy-saving and environment-friendly high-strength cast aluminum alloy production line comprises casting equipment, surface treatment equipment and a first conveying belt which are sequentially arranged, wherein a mechanical arm is arranged between the casting equipment and the surface treatment equipment, the surface treatment equipment is provided with a second conveying belt, an arrangement assembly is arranged between the second conveying belt and the first conveying belt, a storage part is arranged behind the first conveying belt and provided with a plurality of storage grids, the storage grids are used for storing casting parts, a rack of the arrangement assembly is arranged between the second conveying belt and the first conveying belt, supporting edges are arranged on the two sides of the rack, the middles of the two supporting edges are hollow, the two supporting edges are used for supporting the casting parts, a driving part swings while driving a parallel four-connecting-rod to slide in an inclined sliding groove of the rack, an arranging rod swings along with the parallel four-connecting-rod, and protrusions are arranged on the arranging rod at intervals and used for pushing the casting parts. Through the above technical scheme, the problem that collision is likely to cause during casting part discharging is solved.

Owner:清苑县中久有色金属合金制造有限公司

A Three Degrees of Freedom Parallel Mechanism with Arc Moving Pair

ActiveCN106903671BIncrease flexibilityGuaranteed accuracyProgramme-controlled manipulatorThree degrees of freedomDegrees of freedom

The invention discloses a three-degree-of-freedom parallel mechanism provided with arc-shaped sliding pairs. The three-degree-of-freedom parallel mechanism provided with the arc-shaped sliding pairs comprises a base, a movable platform, a restraining rod and three identical moving branched chains. The movable platform and the base are connected through the restraining rod. The movable platform has freedom degrees in three rotation directions relative to the restraining rod. The three moving branched chains are arranged symmetrically with the restraining rod as the center. Each moving branched chain comprises a lead screw assembly and one arc-shaped sliding pair. The lead screw assemblies are arranged on the base, and the arc-shaped sliding pairs are hinged to the movable platform. Each arc-shaped sliding pair comprises a lower arc-shaped connecting rod and an upper arc-shaped connecting rod, wherein the lower arc-shaped connecting rod and the upper arc-shaped connecting rod are connected in a nested mode, the lower arc-shaped connecting rod is driven by the corresponding lead screw assembly to move linearly in the axis direction of the lead screw assembly and to rotate around the axis of the lead screw assembly, the upper arc-shaped connecting rod is made to move along the arc-shaped track of the lower arc-shaped connecting rod accordingly, and one end of the upper arc-shaped connecting rod is hinged to the movable platform.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Multi-cylinder internal combustion engine device

InactiveCN111120089ASimple form of exerciseReduce noiseValve drivesReciprocating piston enginesCrankPiston

The invention discloses a multi-cylinder internal combustion engine device, and belongs to the field of internal combustion engines. In order to overcome the defects that a crank of a traditional internal combustion engine is complex in structure, high in requirement for materials, high in machining difficulty, the inertia effect and noise are difficult to eliminate and the like, the invention designs the multi-cylinder internal combustion engine with the curved groove ball bearing mechanism replacing a crank-link mechanism. The crankshaft of a common internal combustion engine is replaced with a plurality of pairs of bevel gear shafts, an inner ring of the curved groove ball bearing mechanism is fixedly connected with a horizontal bevel gear, an outer ring is eccentrically and fixedly connected with a piston, reciprocating motion is formed in an air cylinder, and multi-cylinder reciprocating inertia is balanced. Compared with the prior art, the multi-cylinder internal combustion engine has the following advantages that 1, a motion form is simple, and the generated noise is low; 2, the inertia of reciprocating motion is counteracted, and vibration is small; 3, the part machining requirement is low, an existing engine structure is compatible, and the manufacturing is easy.

Owner:NORTHWEST A & F UNIV

Hasp split arrester and sports car protection device

PendingCN112373508AReduce actionSimple form of exercisePositive railway stopsLocked plateElectrical and Electronics engineering

The invention discloses a hasp split arrester and sports car protection device, only one locking movable component of a latch hook assembly is adopted, that is, a lock plate rotates around a pin shaft, the movement belongs to low pairs, the action links are few, the movement form is concise, and the probability of failure is greatly reduced. Meanwhile, the lock plate is specifically configured tobe divided into a first part located on the hook base side and a second part located on the hook head side with the overhead hole as the boundary, and the whole lock plate is equivalent to a lever. The first part shields part of the hook groove in the initial state, and when the first part is directly acted by the locked component, the lock plate rotates to cause the second part to gradually shield part of the hook groove, so the locked component is reversely restrained, and obviously, the action of the lock plate meets the requirements that the larger the dragging force of the locked component is, the tighter the locking is; and locking reliability is high.

Owner:泰安科创矿山设备有限公司

Combing machine cylinder structure with built-in nipper assemblies

The invention relates to a combing machine cylinder structure with built-in nipper assemblies. The combing machine cylinder structure comprises a cylinder shaft, a cylinder, cylinder end caps, the nipper assemblies and a cylinder card wire device, wherein the cylinder is movably sleeved on the cylinder shaft; the cylinder end caps are respectively fixed at two ends of the cylinder shaft; 1-4 nipper assemblies and the cylinder card wire device are peripherally distributed on the periphery of the cylinder uniformly; and each nipper assembly comprises a movable nipper, a fixed nipper, a nipper stretching and retracting mechanism, a nipper pressurizing mechanism and a nipper driving mechanism, the movable nipper is mounted on the nipper stretching and retracting mechanism and is connected with the nipper driving mechanism through the nipper pressurizing mechanism, and the fixed nipper is fixed on the nipper stretching and retracting mechanism. Combing and piecing modes finished in a narrow triangular region in the traditional combing process actions is changed into a mode that combing and piecing are simultaneously carried out on different portions of the surface of the periphery of the cylinder. After the cylinder rotates by a circle, a plurality of combing processes can be finished, and the combining efficiency of a combing machine is greatly improved. The combing machine cylinder structure is simple in motion mode, low in noise and suitable for popularization and application.

Owner:DONGHUA UNIV

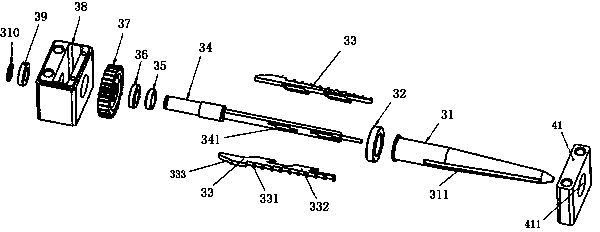

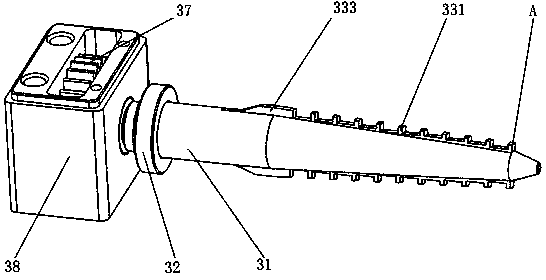

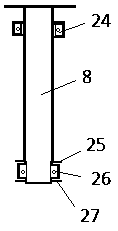

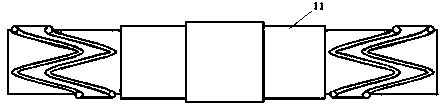

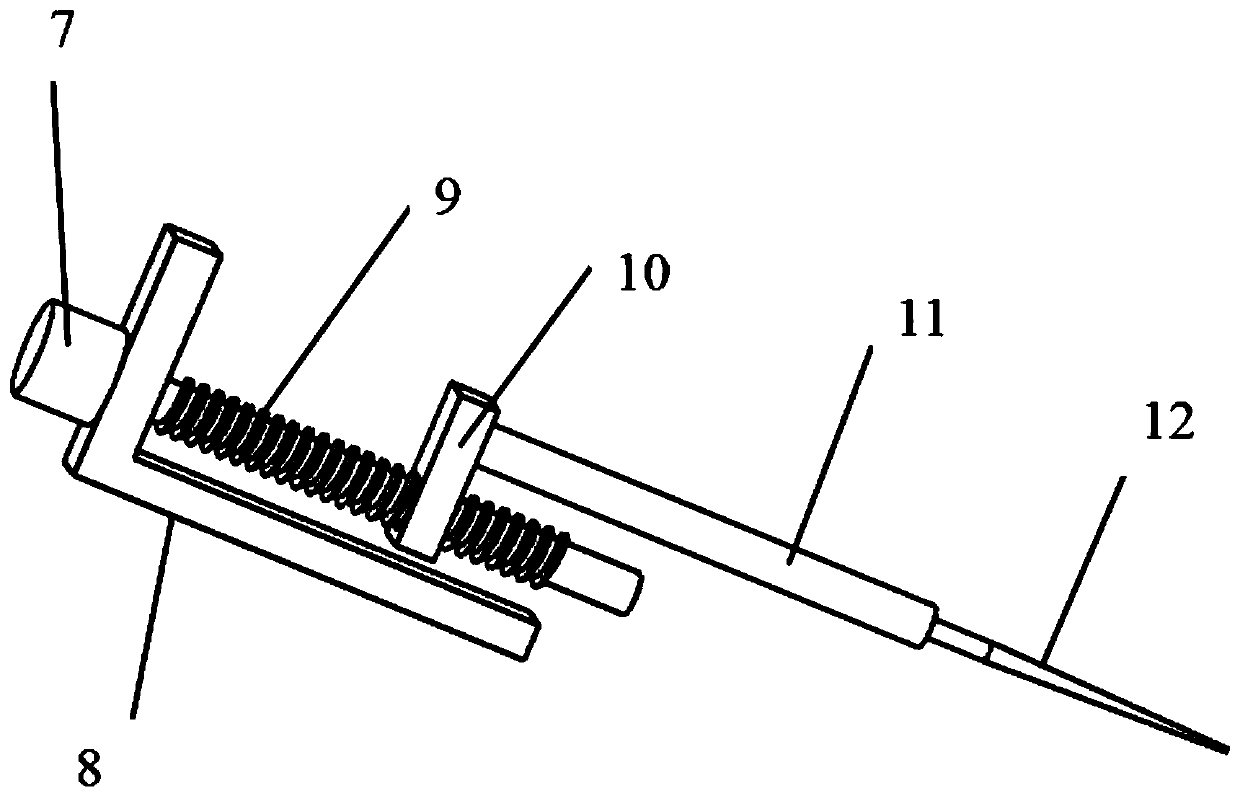

Reciprocating piston type internal combustion engine

PendingCN110159427ASports reliableSimple structureBearing componentsMachines/enginesBall bearingCombustion

The invention discloses a reciprocating piston type internal combustion engine device, and belongs to the field of internal combustion engines. In order to overcome the defects that a traditional internal combustion engine is complex in crank structure, high in material requirement, high in machining difficulty, capable of causing complex inertia effect and noise and the like, according to the reciprocating piston type internal combustion engine, the internal combustion engine which is characterized in that a rotating movement and reciprocating rectilinear movement switching mechanism is usedfor replacing a crank connecting rod mechanism is designed, wherein the rotating movement and reciprocating rectilinear movement switching mechanism is formed by a retainer-free curved groove ball bearing and a spring, once the retainer-free curved trench ball bearing rotates by one cycle, two-period circulations and four round strokes can be generated, the two extending strokes are used for compression and exhaust, and the two return strokes are used for combustion acting and suction stroke. Compared with the traditional internal combustion engine composed of the crank connecting rod mechanism, the reciprocating piston type internal combustion engine has the following advantages that 1, moving parts are all axisymmetric rotary parts, so that the structure is simple; 2, the movement form is simple and only comprises the rotating movement and the reciprocating movement, so that the generated noise is low; and 3, the machining requirements of the parts are low, so that manufacturing is easy.

Owner:NORTHWEST A & F UNIV

A three-branched six-degree-of-freedom robot

InactiveCN104608118BSimple form of exerciseAccuracy is easy to guaranteeProgramme-controlled manipulatorBall bearingDegrees of freedom

The invention relates to a three-branch six-degree-of-freedom robot. The three-branch six-degree-of-freedom robot is characterized in that three branched chains which are all with a same structure are arranged between a movable platform and a fixed platform, and each branched chain comprises a connecting rod motor, two connecting rods, a connecting sleeve and a four connecting rod component; one end of a first connecting rod is connected with the connecting rod motor, the other end of the first connecting rod is connected with a second connecting rod through a ball bearing pair, the second connecting rod is connected with the movable platform through another ball bearing pair, and the second connecting rod is connected with the connecting sleeve through a sliding pair; the four connecting rod component comprises an upper portion rod piece, two drive rods and two drive rod motors, the two ends of the upper portion rod piece are connected with the two drive rods respectively, the two drive rods are connected with the two drive rod motors respectively, and the upper portion rod piece is connected with the connecting sleeve through another ball bearing pair. The three-branch six-degree-of-freedom robot has the advantages that the structure is simple and reliable, the motion of the movable platform is stable, good drive capability, robustness and bearing capacity are achieved, and the three-branch six-degree-of-freedom robot can be applied to the fields of machine tools, robot detection and the like according to different requirements.

Owner:TIANJIN ZHIDA ROBOT

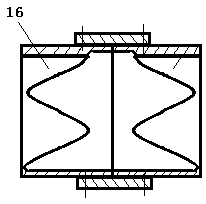

Double-cylinder internal combustion engine based on three-cycle curved groove ball bearing

The invention discloses a double-cylinder internal combustion engine based on a three-cycle curved groove ball bearing, and belongs to the field of internal combustion engines. In order to overcome the defect that a double-cylinder internal combustion engine curved groove of a two-cycle curved groove ball bearing is uneven in abrasion, the invention provides a double-cylinder internal combustion engine based on a three-cycle non-retainer curved groove ball bearing mechanism instead of a crank connecting rod mechanism. According to the double-cylinder internal combustion engine, two inner rings of the three-period non-retainer curved groove ball bearing are fixedly connected, and a gear pair is used for driving a gas distribution mechanism and an ignition (oil injection) mechanism to allow two sets of pistons to conduct opposite reciprocating motion, so that the reciprocating inertia of the two sets of pistons is automatically balanced, and meanwhile, curved grooves of different working pressures of the curved groove ball bearing can be interchanged alternately, thus improving abrasion uniformity. Compared with the prior art, the double-cylinder internal combustion engine based on the three-cycle curved groove ball bearing has the advantages of being 1, simple in motion form and uniform in the abrasion of the curved grooves; 2, small vibration due to the fact that the inertia of the reciprocating motion is automatically counteracted; and 3, low in requirements of part machining and easy to manufacture.

Owner:NORTHWEST A & F UNIV

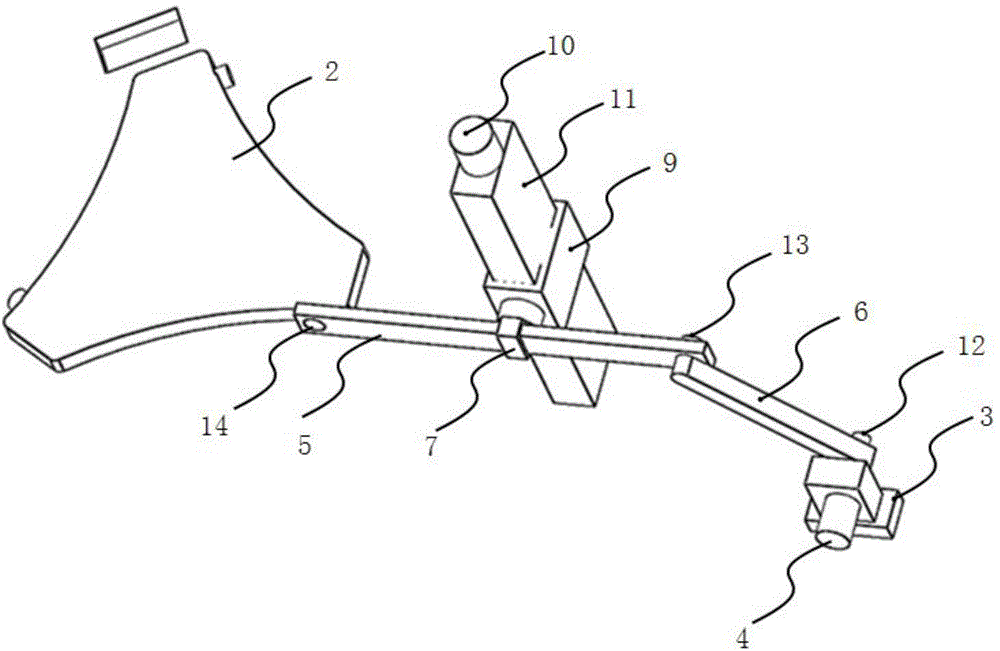

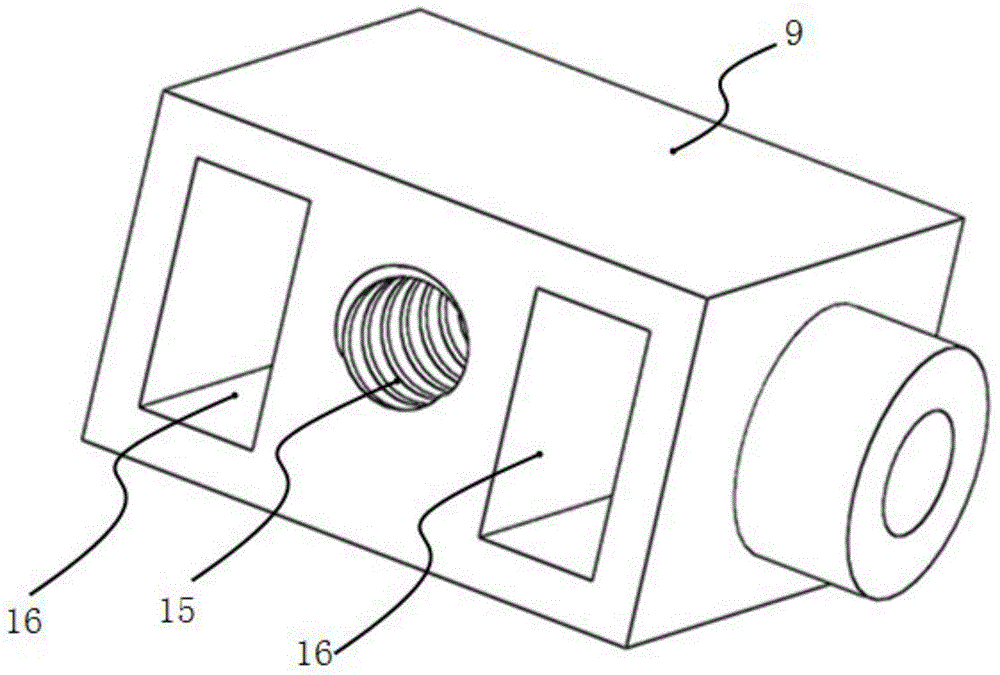

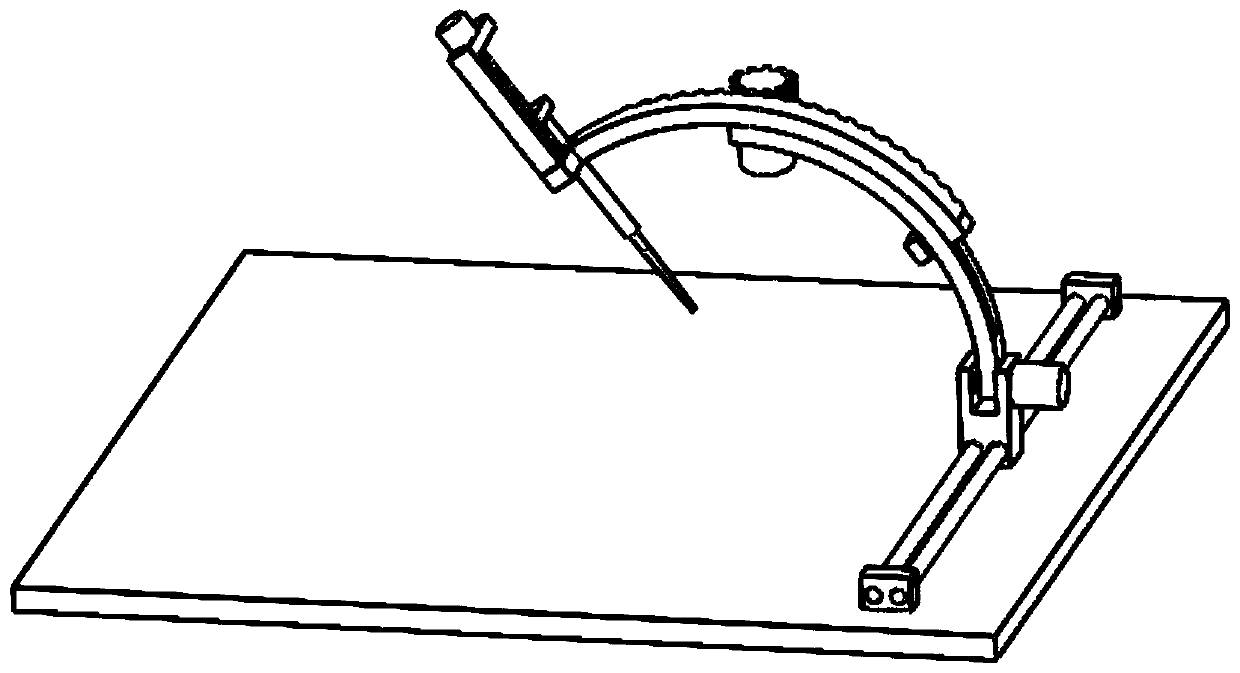

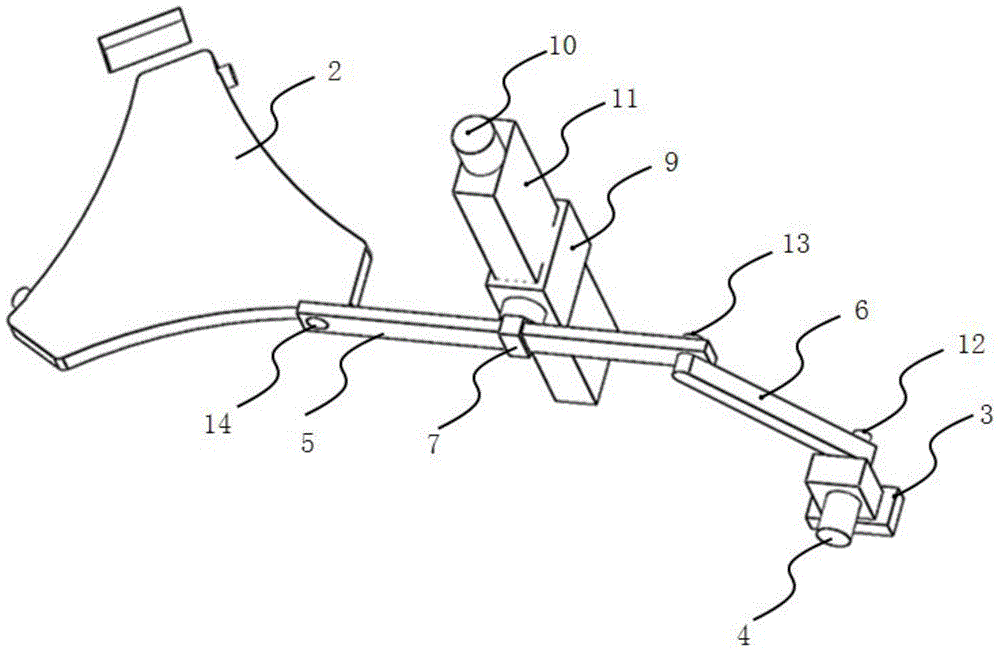

A surgical robot with arc-shaped moving joint

ActiveCN106344160BIncrease flexibilitySimple form of exerciseSurgical robotsSurgical robotEngineering

The invention relates to a surgical robot containing an arc-shaped moving pair. The surgical robot is characterized by comprising a fixed platform, a linear guide rail, a bottom driving motor, a movable sliding block, a lower arc-shaped connecting rod, an upper arc-shaped connecting rod and a tail-end executing device, wherein the linear guide rail is fixedly arranged on the fixed platform; the movable sliding block can move along the axial direction of the linear guide rail, the bottom driving motor is fixedly arranged on the movable sliding block, and an output shaft of the bottom driving motor is matched with the lower end of the lower arc-shaped connecting rod to drive the lower arc-shaped connecting rod to rotate around the output shaft of the bottom driving motor; the lower end of the upper arc-shaped connecting rod is connected with the lower arc-shaped connecting rod, and the upper end of the upper arc-shaped connecting rod is connected with the tail-end executing device; a long groove is arranged on the upper surface of the lower arc-shaped connecting rod, a middle-section driving motor is arranged at the upper end of the lower arc-shaped connecting rod, and an output shaft of the middle-section driving motor is connected with a gear; and a bulge is arranged at the lower end of the upper arc-shaped connecting rod and is matched with the long groove on the upper arc-shaped connecting rod, and the upper arc-shaped connecting rod is concentric to the lower arc-shaped connecting rod.

Owner:HEBEI UNIV OF TECH

A three-branched six-degree-of-freedom robot driving mechanism

InactiveCN104149084BSimple form of exerciseIncrease flexibilityProgramme-controlled manipulatorEngineeringMachine tool

The invention relates to a three-branched-chain six-freedom-degree robot drive mechanism which is mainly and technically characterized in that three branched chains identical in structure are arranged between a movable platform and a fixed platform, a fixed platform motor is arranged on a fixed platform motor support, and the fixed platform motor, second connection rods, first connection rods and the movable platform are sequentially connected; sliding guide rails are evenly distributed on the fixed platform in the circumferential direction, a guide rail top motor is arranged at the top end of each sliding guide rail, a screw rod is arranged in each sliding guide rail through a bearing, sliding blocks are arranged on the sliding guide rails in a sliding mode, and the middle portions of the sliding blocks are meshed with the screw rods in a spiral mode; connection sleeves are arranged on the outer sides of the sliding blocks and connected with the first connection rods in a sliding mode. The three-branched-chain six-freedom-degree robot drive mechanism is reasonable in design, has the advantages of being simple and reliable in structure, stable in movement of the movable platform, and the like, has good drive performance, robustness and bearing capacity, and can be applied to the fields of detection of machine tools and robots according to different needs.

Owner:HEBEI UNIV OF TECH

A mechanical limit mechanism and limit method for increasing motion stroke

The invention particularly relates to a mechanical limiting mechanism and method for increasing the movement stroke, and the mechanical limiting mechanism and method are wide in application range. Anarc-faced bumping block and a movement bumping block move under driving of a movement component, blocking bumping blocks are all in a descending state originally, and the arc-faced bumping block is firstly in contact with a slide rod of a first fixed bumping block component, so that the blocking bumping block of the first fixed bumping block component rises up; then, the arc-faced bumping block isin contact with a slide rod of a second fixed bumping block component, and the blocking bumping block of the second fixed bumping block component rises up; the movement bumping block and the blockingbumping block of the second fixed bumping block component are limited, the movement component retreats from a limiting area after conducting reverse movement to make contact with the slide rods of the two fixed bumping block components, so that the two blocking bumping blocks restore to be in the descending state, and limiting is achieved by limiting the movement of the movement component throughascending and descending of the blocking bumping blocks; and the movement range of the movement component can be intervened mutually without being influenced, and the application range is wide.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Noodle cooking device

ActiveCN108309024BSimple form of exerciseEasy to operateCooking insertsCooking vessel constructionsProcess engineeringThermal water

The invention provides a noodle cooking device. The noodle cooking device comprises a noodle basket, a cooling water pool, a hot water pool, a conveying assembly and a power mechanism, wherein the conveying assembly is connected with the noodle basket and can drive the noodle basket to move between the cooling water pool and the hot water pool; the power mechanism is in driving connection with theconveying assembly, and the noodle basket is located in the hot water pool when noodles are cooked; when noodles are treated with cooling water, the noodle basket moves to the cooling water pool fromthe hot water pool under driving of the conveying assembly; when noodles needs to be heated again, the noodle basket moves to the hot water pool from the cooling water pool, and circulation is carried out through the mode till noodle cooking is completed. By means of the noodle cooking device, the problem that a noodle cooking device in the prior art is inconveniently used is solved.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

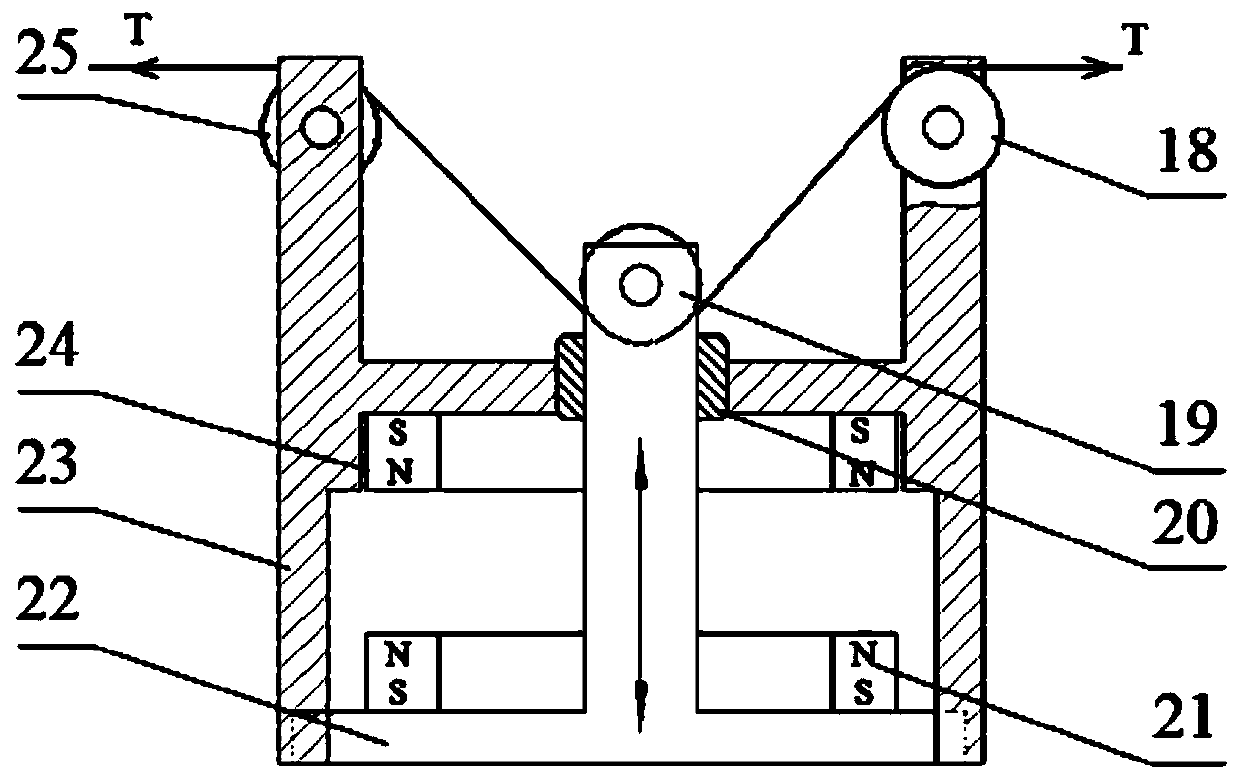

Variable stiffness joint for flexible robot based on hybrid electromagnet

The invention relates to a variable stiffness joint for a flexible robot based on a hybrid electromagnet. The variable stiffness joint comprises a motor, a hybrid electromagnet fixing shaft sleeve, the hybrid electromagnet, a joint shell, electrical pure iron and a motor supporting frame, wherein the hybrid electromagnet fixing shaft sleeve, the hybrid electromagnet and the electrical pure iron are located in the joint shell; and a joint stiffness adjusting portion adopts the combined action of the hybrid electromagnet and a spring piece, and has the advantages of being high in stiffness adjusting response speed, free of delay, free of lag and the like. The magnetic force and the stiffness are kept in a non-electrified state, and the energy-saving characteristic is achieved. Meanwhile, the characteristics of being simple in motion form, easy and convenient to manufacture, easy to operate and the like are achieved. The magnetic flux in a joint magnetic circuit system is jointly determined by currents in a permanent magnet and a magnet exciting coil (copper coil), so that the magnetic flux in the magnetic circuit system can be increased and decreased by changing the magnitude and the direction of the currents in the magnet exciting coil, that is, the joint stiffness is increased and decreased, and the joint stiffness change is nonlinear.

Owner:SHENYANG POLYTECHNIC UNIV

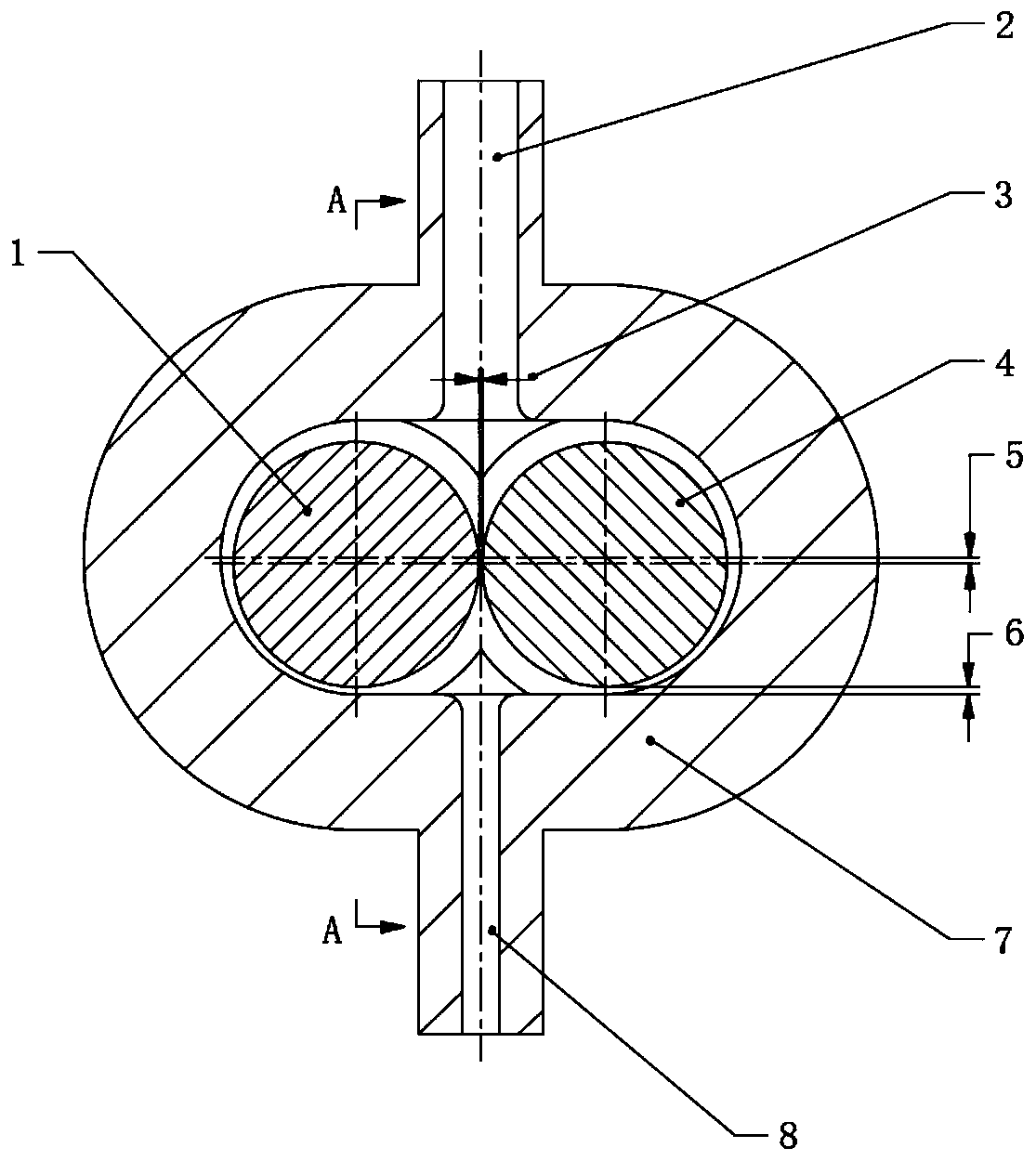

Non-impeller rotor valveless pump for artificial heart

PendingCN111420144ASimple form of exerciseCompact structureMedical devicesIntravenous devicesPhysicsImpeller

The invention provides a non-impeller rotor valveless pump for an artificial heart. The valveless pump comprises a pump shell, wherein the cross section profile of the inner wall surface of the shellis oblong, a first rotor and a second rotor are two cylinders with equal diameters, the first rotor and the second rotor are arranged in the pump shell in parallel, an eccentric distance is formed between the axis of the first rotor and the first axis of the inner wall of the shell, a first end cover and a second end cover are respectively arranged at two ends of the pump shell, a closed cavity isformed in the pump shell, two ends of the first rotor are supported on the first end cover and the second end cover through a first bearing and a second bearing, the first rotor can rotate freely, shoulders at two ends of the first rotor are pressed on inner rings of the first bearing and the second bearing respectively, and outer rings of the first bearing and the second bearing are pressed on the shoulders of the first end cover and the second end cover respectively, so that the axial positioning of the first rotor is realized. The valveless pump can realize the advantages of simple motionform, compact structure, good stress condition of parts and long service life.

Owner:HUAQIAO UNIVERSITY

Six-degree-of-freedom robot with three branch chains

InactiveCN105773582ASmooth motionThe overall structure is simple and reliableProgramme-controlled manipulatorEngineeringSix degrees of freedom

A six-degree-of-freedom robot with three branch chains consists of a moving platform, a fixed platform and three branch chains uniformly distributed for connecting the moving platform and the fixed platform, wherein each branch chain comprises a lower cross universal hinge, a support telescopic rod assembly and an upper cross universal hinge, sequentially connected from the fixed platform to the moving platform; the support telescopic rod assembly consists of a moving connecting rod and a support connecting rod, a plane connecting rod assembly is mounted among the upper hinge bases of the moving connecting rod, the support connecting rod and the lower cross universal hinge, and the plane connecting rod assembly consists of a lower connecting rod, a middle connecting rod and an upper connecting rod; the bottom end of the upper connecting rod is connected with the moving connecting rod through a hinge pin, and the bottom end of the lower connecting rod is connected with an output shaft of a second motor on an upper fork-shaped hinge base of the lower cross universal hinge; and a lower fork-shaped hinge base of the lower cross universal hinge is fixedly mounted on the fixed platform, a first motor is mounted on the lower fork-shaped hinge base of the lower cross universal hinge, and an output shaft of the first motor is connected with a cross hinge pin of the lower cross universal hinge.

Owner:HEBEI UNIV OF TECH

Noodle cooking device

ActiveCN108095545BSimple form of exerciseEasy to operateWater-bath cooking vesselsProcess engineeringThermal water

The invention provides a noodle cooker which comprises a noodle strainer, a hot water layer, an exchange layer and a cool water layer. A first gate normally closed is arranged between the hot water layer and the exchange layer; a second gate normally closed is arranged between the cool water layer and the exchange layer. During cooking, the noodle strainer stays in the hot water layer and noodle in the strainer is heated; during draining, the first gate is opened, the noodle strainer is moved to the exchange layer and then the first gate is closed; further, the noodle strainer is moved to thecool water layer after the second gate is opened so that noodle cooling is achieved; when people need to cook noodle again, people can move the noodle strainer to the hot water layer again, and repeatthe cycle until finishing cooking. With the noodle cooker, inconvenience in use of noodle cookers in the prior art is overcome.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

A biomimetic dragonfly flapping wing robot driven by ionomer-metal complexes

InactiveCN104229139BImprove transmission efficiencyImprove energy efficiencyOrnithoptersIonic polymer–metal compositesWing vein

The invention discloses an IPMC (Ionic Polymer Metal Composite) driven simulated dragonfly wing flapping robot and relates to a simulated wing flapping robot. The IPMC driven simulated dragonfly wing flapping robot is provided with wing veins, wing membranes, wing IPMC driving parts, wings, a robot body, circuit controllers, copper sheet electrodes, robot body IPMC driving parts and fixing shafts; the wing veins are arranged on the wings; the two wing IPMC driving parts are arranged on the wings; deformation of the wings is achieved due to change of the wing shapes; the two robot body IPMC driving parts are arranged at the bottom of the robot body; one ends of the robot body IPMC driving parts are fixed on the robot body and the other ends are arranged on wing root portions of the wings; the wings are hinged to the robot body which drives flapping of the wings; the copper sheet electrodes enable the circuit controllers and the wing IPMC driving parts or the circuit controllers and the robot body IPMC driving parts to be connected through leads; the circuit controllers, the robot body IPMC driving parts and the fixing shafts are arranged on a robot frame; fixing shaft holes in the wings are hinged to the fixing shafts to achieve rotation between the wings and the robot body.

Owner:XIAMEN UNIV

A permanent magnet variable stiffness flexible joint for robots

ActiveCN107639649BConstant stiffnessSimple form of exerciseJointsClassical mechanicsElectric machinery

The invention belongs to the technical field of flexible robots and proposes a permanent magnet variable stiffness flexible joint for robots, which can simulate the nonlinear variable stiffness muscle characteristics of bionic joints. The invention uses a permanent magnet variable stiffness mechanism as the stiffness adjustment component, and the rope as a force and motion transmission component. Its stiffness will change according to the change in the air gap between the permanent magnets. Through the action of the motor, rope winch and guide pulley, the control on both sides of the operator is realized. The decoupling of the force and position of the rope can achieve unchanged joint stiffness, only changing the joint angle, that is, adjusting the joint position under the condition of equal stiffness; it can also be achieved without changing the joint position, only changing the joint stiffness, according to different According to the working conditions, it can work under the corresponding set stiffness conditions. The invention is a permanent magnet variable stiffness flexible robot joint structure with simple motion form, simple manufacturing and simple operation.

Owner:NORTHEASTERN UNIV LIAONING

A high temperature gas-cooled reactor reactor pressure vessel inspection device

ActiveCN105810259BSimple form of exercisePrecise displacement controlNuclear energy generationNuclear monitoringReactor pressure vesselEngineering

The technology belongs to the field of pressure vessel inspection devices, and in particular relates to a high-temperature gas-cooled reactor pressure vessel inspection device. The inspection device 1 is located between the outer cylinder wall 2 of the pressure vessel and the cabin cylinder wall 3. The inspection device 1 includes a circular guide rail 4, a track running trolley 5, a lifting rod 6, a two-axis scanner 7, a positioning pin pointing mechanism 8, and a circular guide rail. 4 is a whole ring spliced by a plurality of arc guide rails; the track running trolley 5 is located on the circular guide rail 4 and can move along the track; a lifting rod 6 is installed on the track running trolley 5, and the lower end of the lifting rod 6 carries a positioning pin to point to the mechanism 8. It can be controlled and fixed with the positioning pin at the bottom of the pressure vessel. The lower end of the lifting rod 6 of the present invention carries a positioning pin pointing mechanism 8, which can be controlled and fixed with the positioning pin at the bottom of the pressure vessel.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com