On-line coating machine of tire curing press

A technology of tire vulcanization and coating machine, which is applied in the direction of coating, tire, and surface coating liquid device, etc., which can solve the problems of large influence of human factors and low efficiency of release agent, and achieve labor intensity reduction, rapid spraying, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

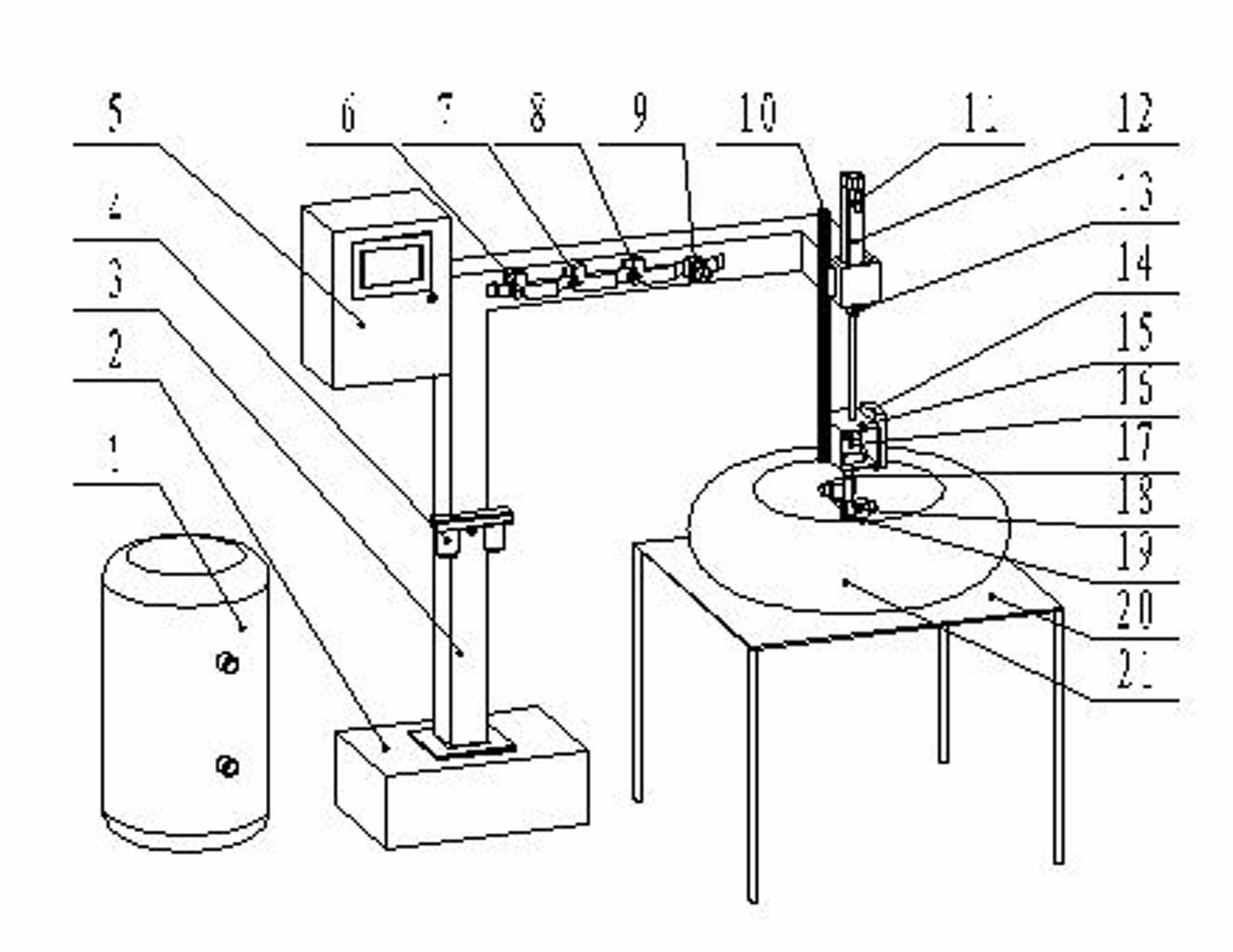

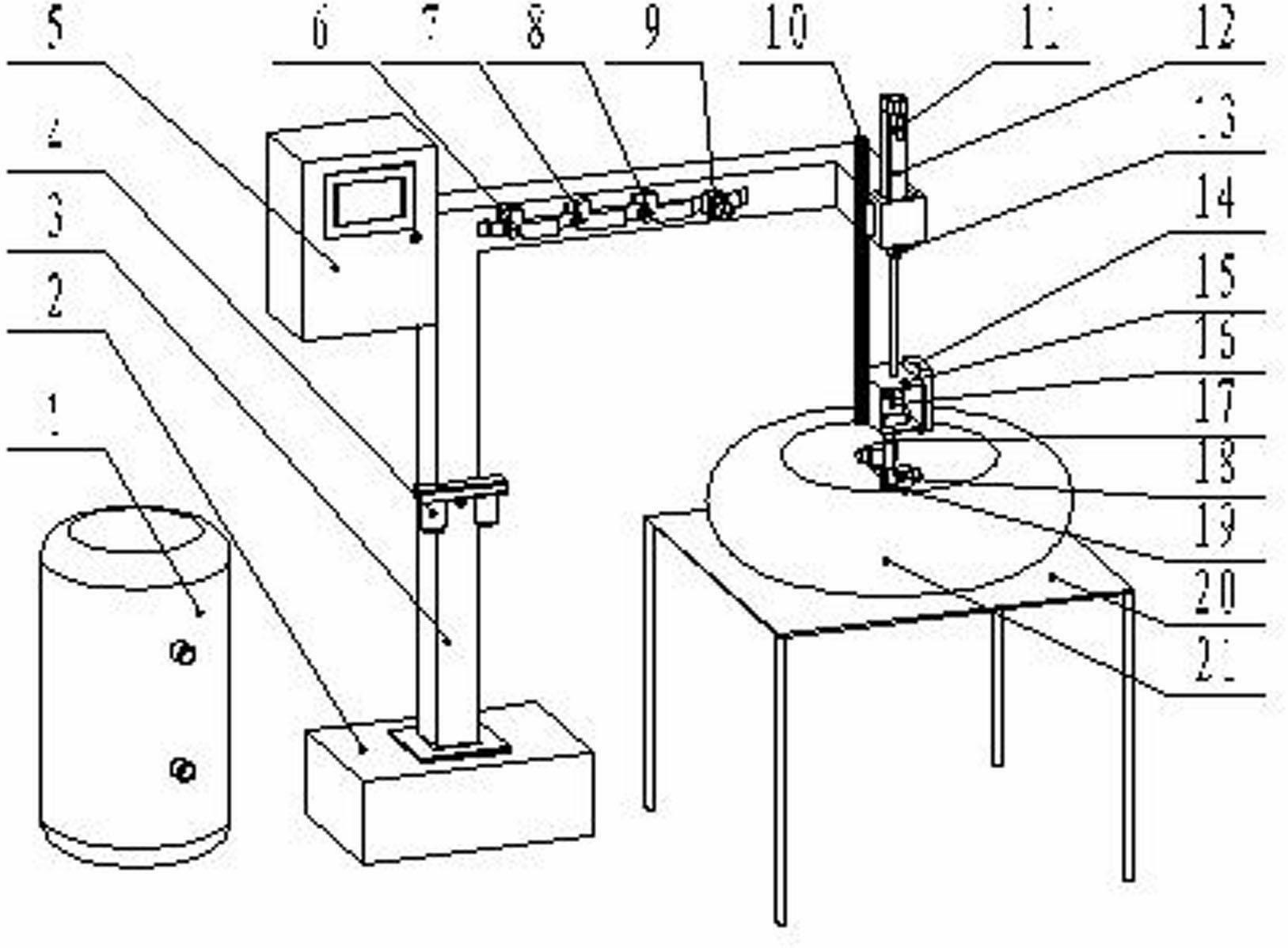

[0023] Refer to the attached figure 1 , which shows a tire vulcanizing machine online coating machine according to the present invention, its basic purpose is to realize a controllable up and down linear motion of the sprayer 18 and rotation around the linear motion direction, its basic structure is It includes:

[0024] A positioning device for positioning the tire embryo 21;

[0025] Bracket 3, extending directly above the tire embryo positioning center of the positioning device;

[0026] The driving device is arranged on the position where the support extends to the front of the positioning device, and has a lifting mechanism for up and down adjustment and a rotating mechanism for rotating around a vertical axis passing through the positioning center;

[0027] The sprayer 18 is equipped with a hydraulic circuit and is mounted on the driving end of the driving device to obtain lifting and rotating actions; and

[0028] A control device is connected to the control part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com