Patents

Literature

34results about How to "Precise displacement control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

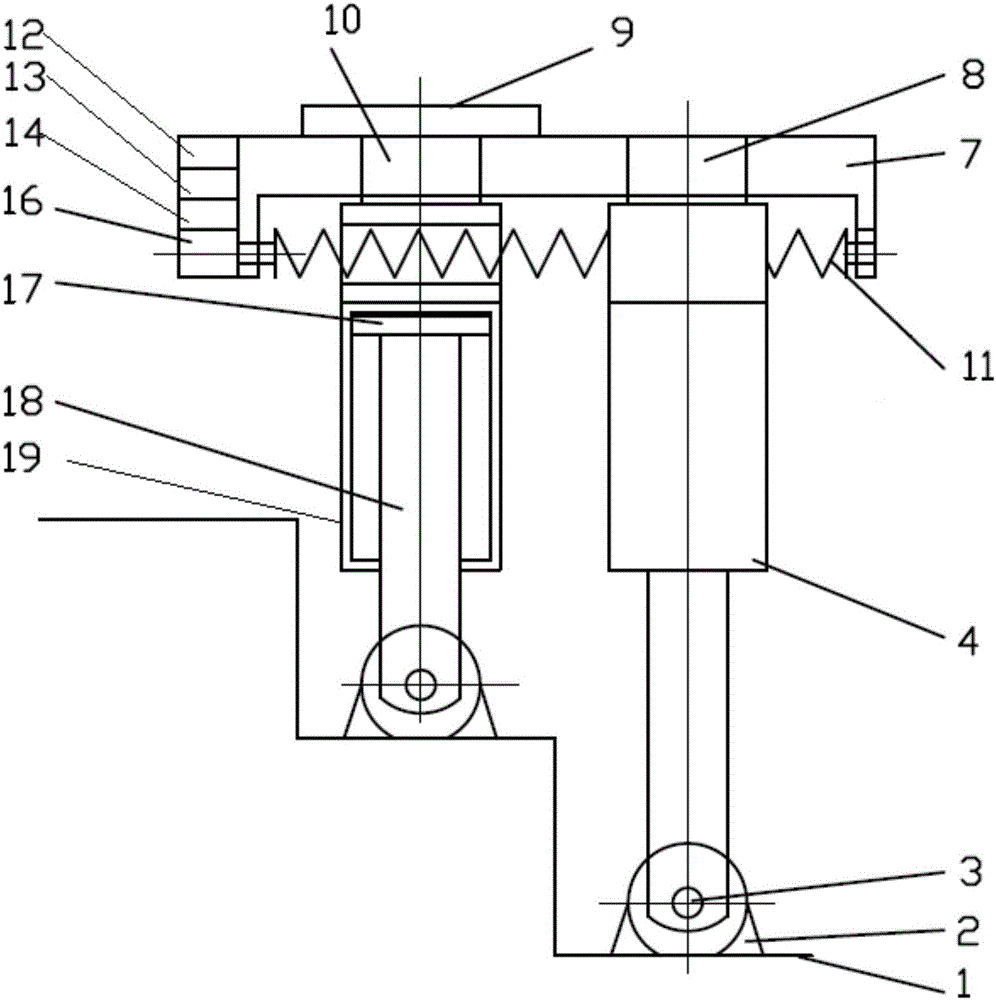

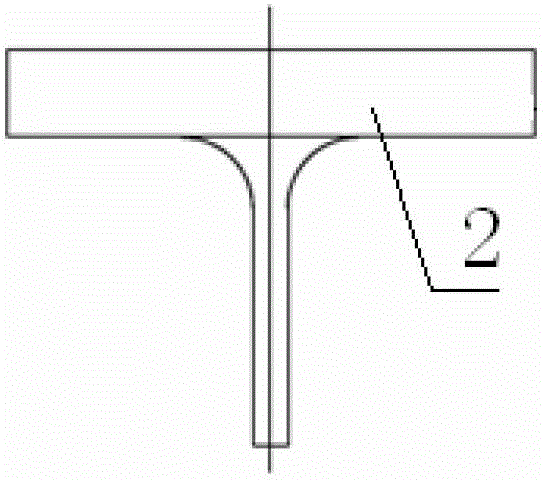

Permanent magnet type non-contact vibration exciter and excitation method thereof

InactiveCN101599339APrecise displacement controlIntegrity guaranteedSubsonic/sonic/ultrasonic wave measurementVibration testingPermanent magnet motorFerromagnetism

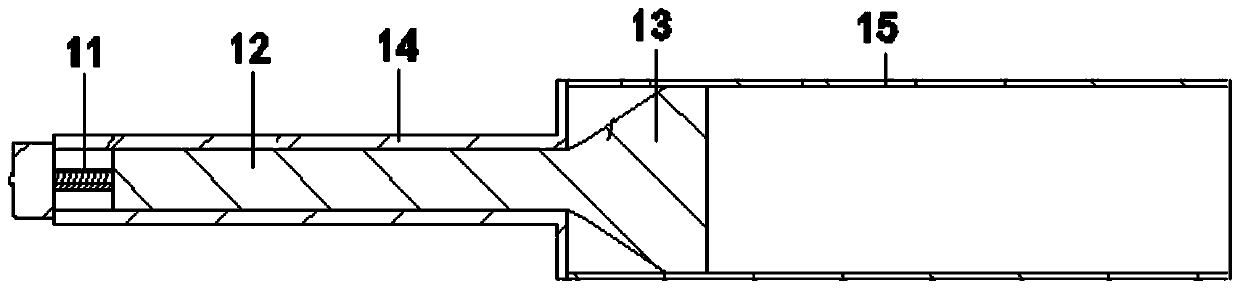

The invention discloses a permanent magnet type non-contact vibration exciter and an excitation method thereof; wherein the vibration exciter comprises a traditional vibration generator, a C type magnetic clamp, strong magnet blocks and armature blocks. A C type magnetic briquette is arranged on an electromagnetic vibration exciter, the two ends of the C type magnetic briquette are respectively provided with the strong magnet blocks and the armature blocks which are absorbed at the terminals of the strong magnet blocks. Actual displacement output of the armature block is sensed by a displacement sensor for feedback compensation, accurate displacement output is realized, and the aim of controlling exciting force is achieved. The invention has the advantages that the structure is simple, assembly and disassembly are convenient, processing is easy, and the vibration exciter can be used for excitation of a moving structure and can realize non-contact excitation on ferromagnetic metal structures, etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

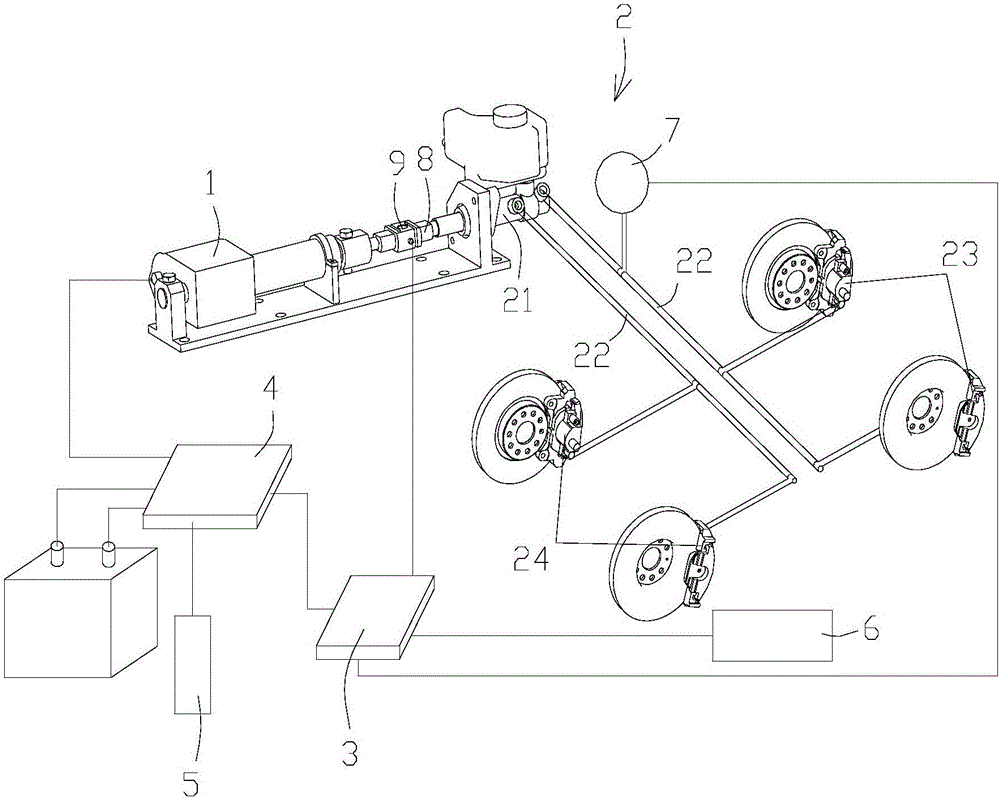

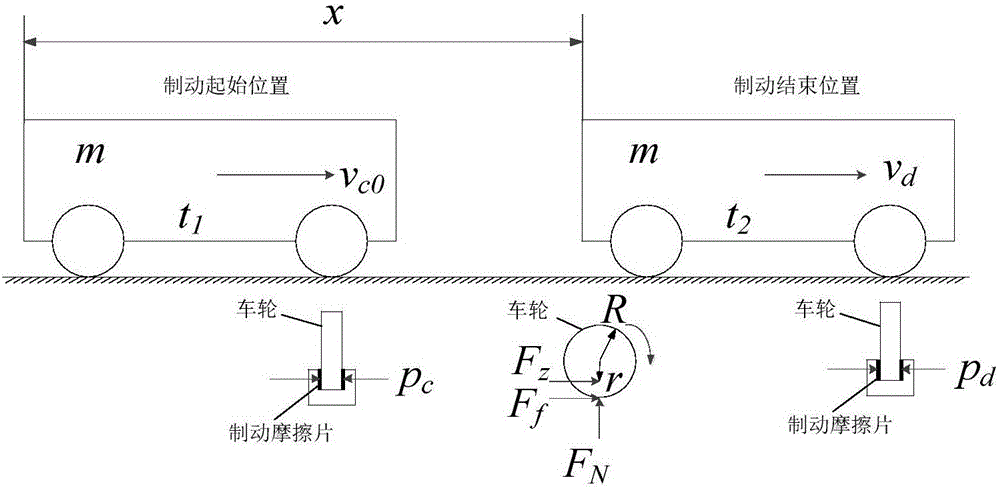

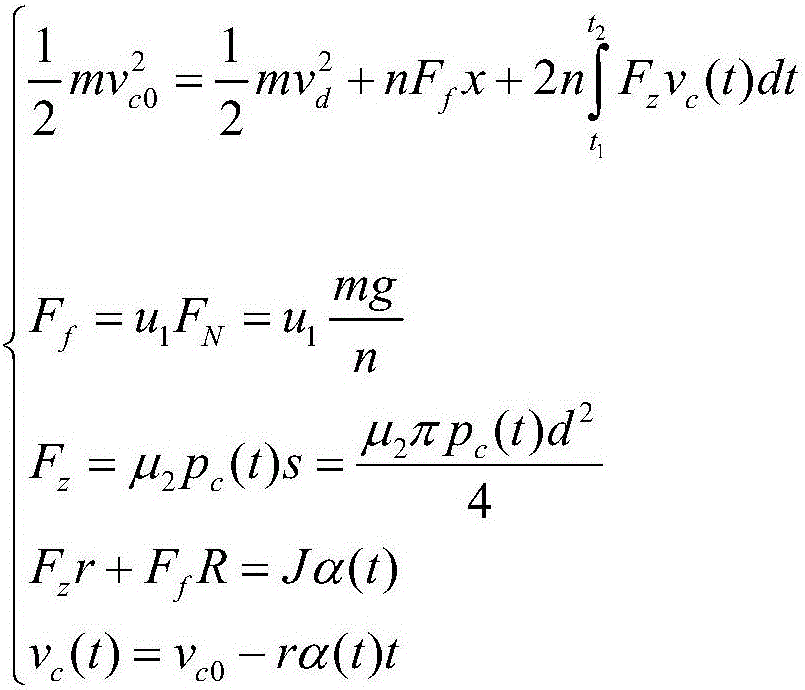

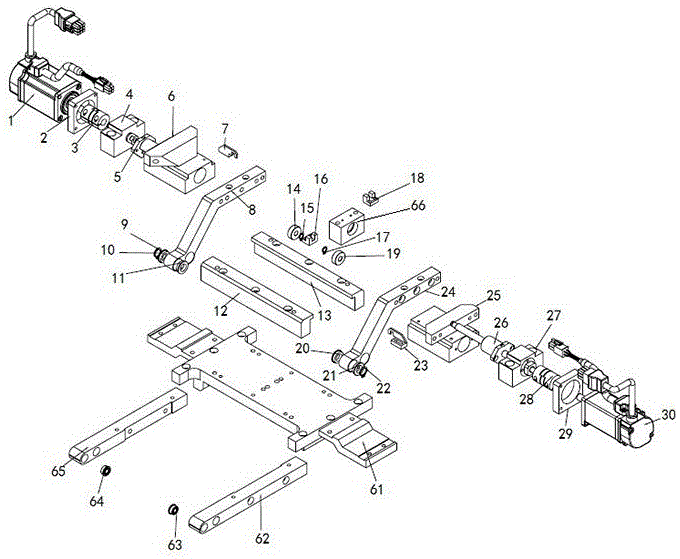

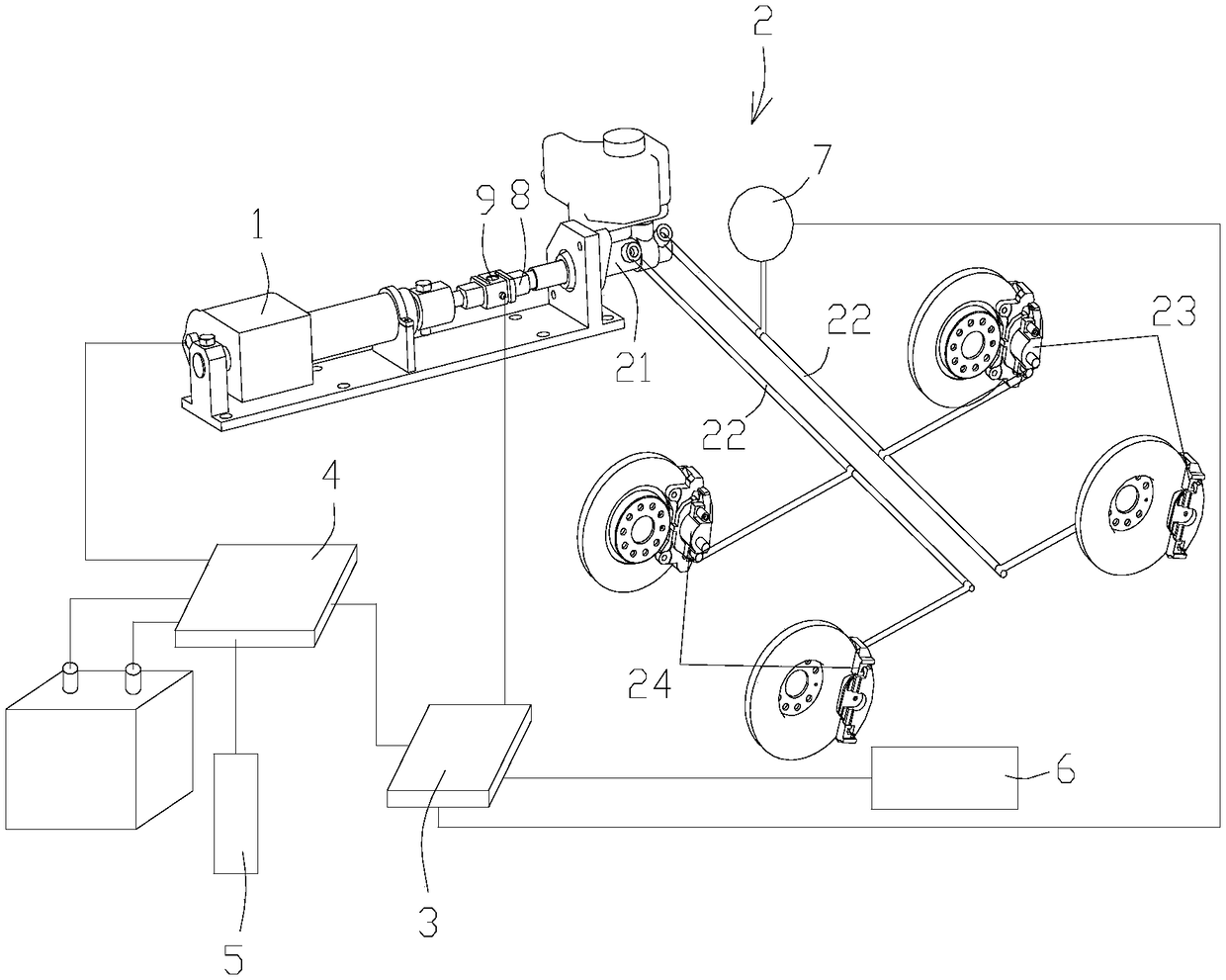

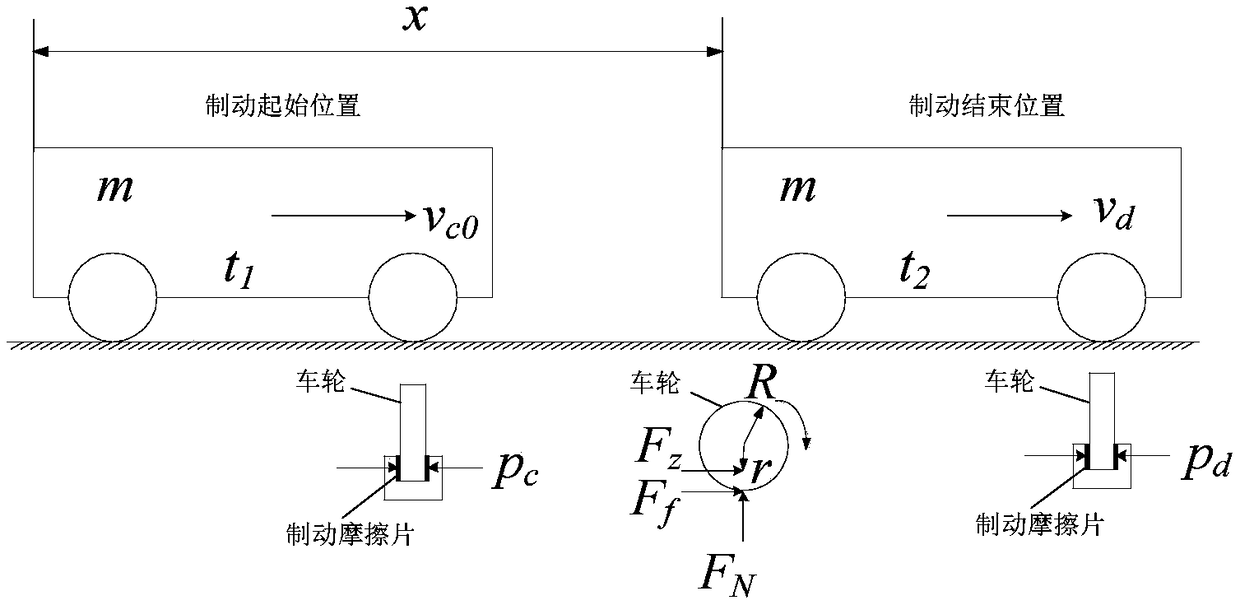

Unmanned vehicle braking control system and method

ActiveCN106740764ASimple structureImprove transmission efficiencyBraking action transmissionAutomatic initiationsWheel speed sensorControl system

The invention provides an unmanned vehicle braking control system and method. The unmanned vehicle braking control system comprises an electric cylinder, a braking pipeline system, a data collection card, a controller, a decision making layer, a wheel speed sensor for detecting vehicle speed and an oil pressure meter for detecting braking pressure of the braking pipeline system, the data collection card is used for collecting data of the wheel speed sensor and the oil pressure meter, the decision making layer sends an expected vehicle speed signal to the controller, and the controller is used for collecting data transmitted by the decision making layer and data of the oil pressure meter. Braking effect controllable in braking force is accurately realized by collecting current vehicle speed and current braking pressure, comparing them with expected vehicle speed and expected braking pressure and controlling extension and contraction of the electric cylinder.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

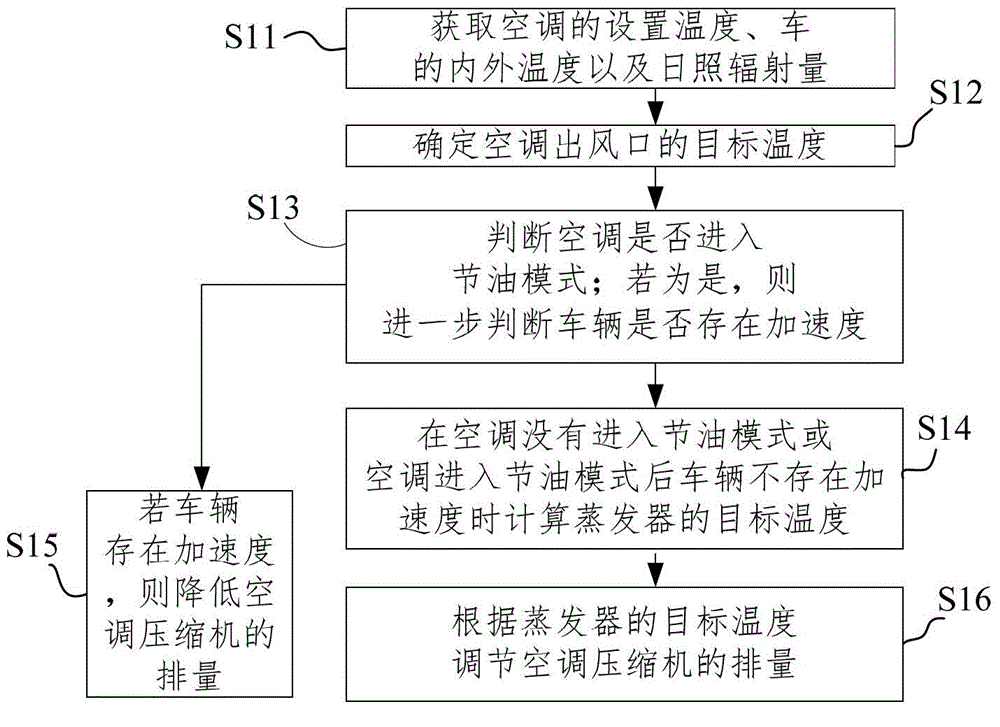

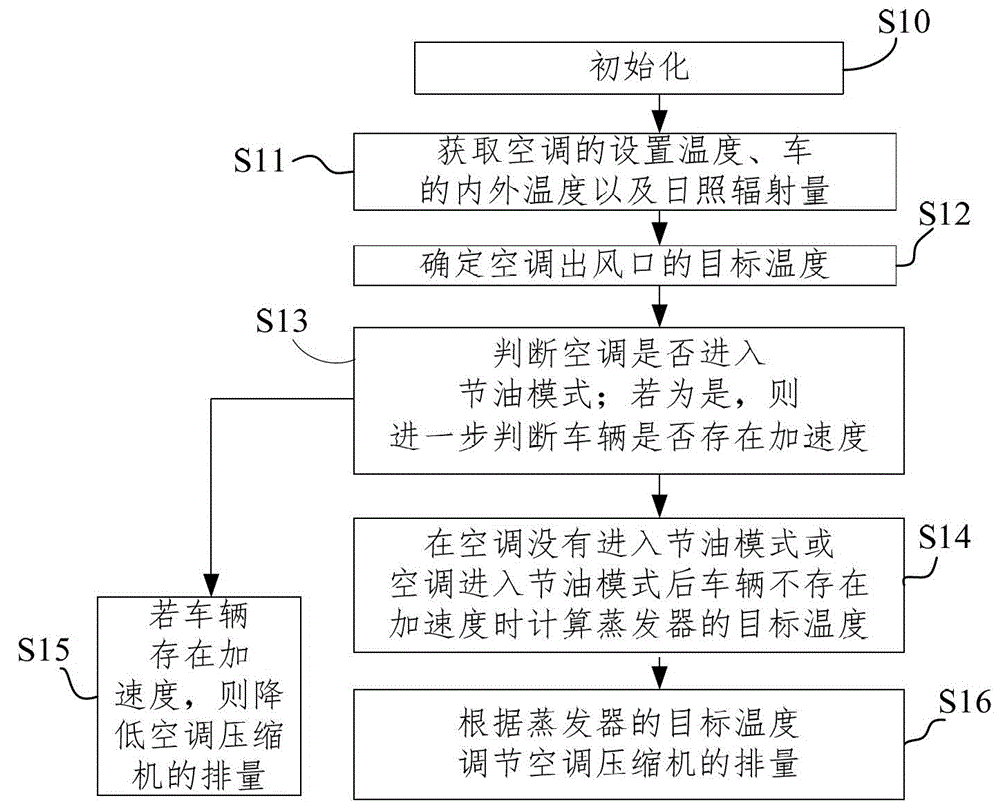

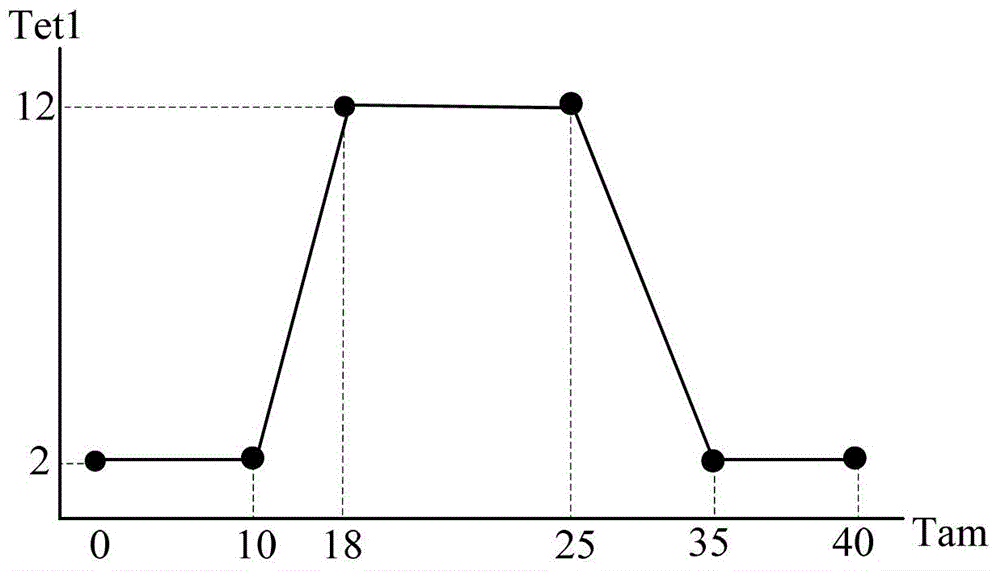

Control method and control system for vehicle air conditioner compressor

ActiveCN104417311AAccurate displacementReduce displacementAir-treating devicesVehicle heating/cooling devicesControl systemEvaporator

The invention provides a control method and a control system for a vehicle air conditioner compressor. The control method comprises the following steps: acquiring the set temperature of an air conditioner, the internal and external temperatures of a vehicle, and the sunshine radiation; determining a target temperature at the air outlet of the air conditioner according to the set temperature of the air conditioner, the internal and external temperatures of the vehicle, and the sunshine radiation; judging whether the air conditioner enters a fuel-saving mode or not; if so, further judging whether the vehicle has an acceleration, if so, lowering the displacement of the air conditioner compressor; if the air conditioner does not enter the fuel-saving mode or the vehicle does not have the acceleration after the air conditioner enters the fuel-saving mode, determining the target temperature of an evaporator according to the external temperature of the vehicle and the target temperature at the air outlet of the air conditioner; controlling the displacement of the air conditioner compressor according to the target temperature of the evaporator. By adopting the control method and the control system for the vehicle air conditioner compressor provided by the invention, the displacement of the air conditioner compressor is controlled more accurately.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

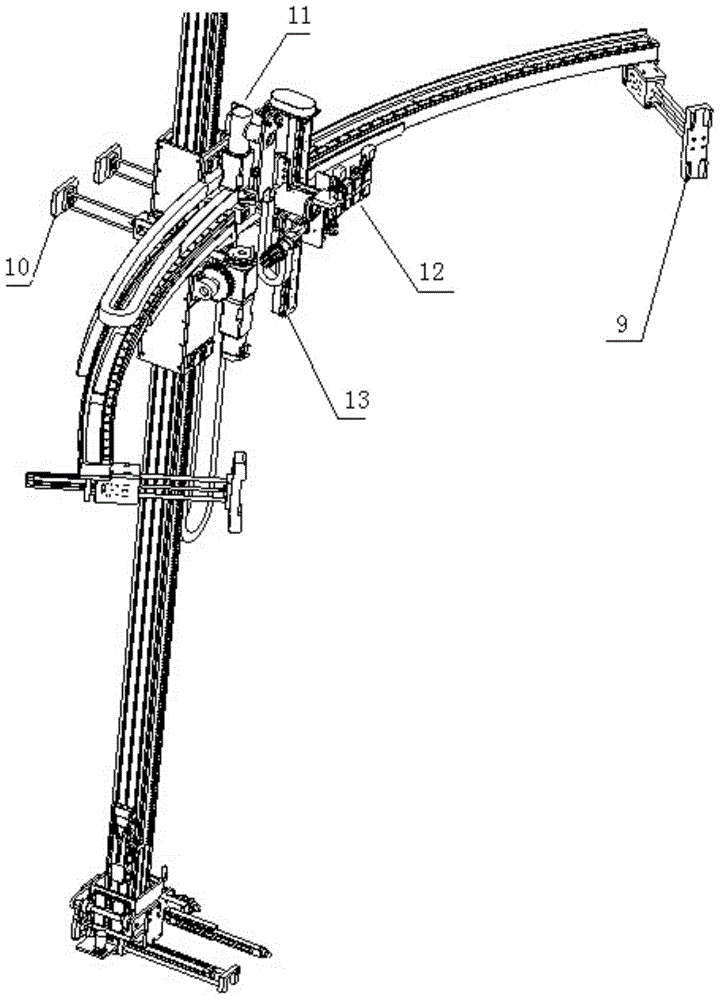

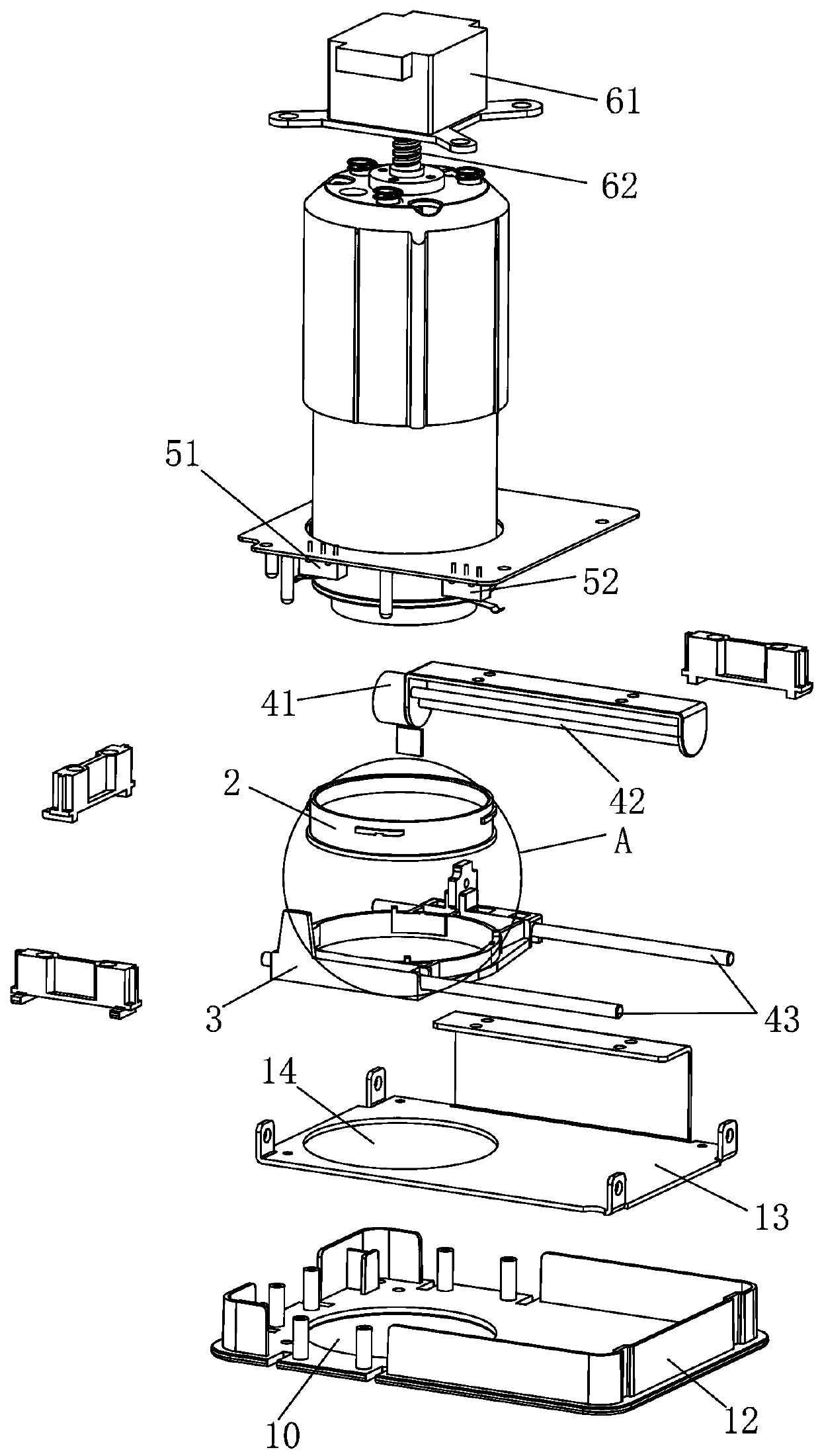

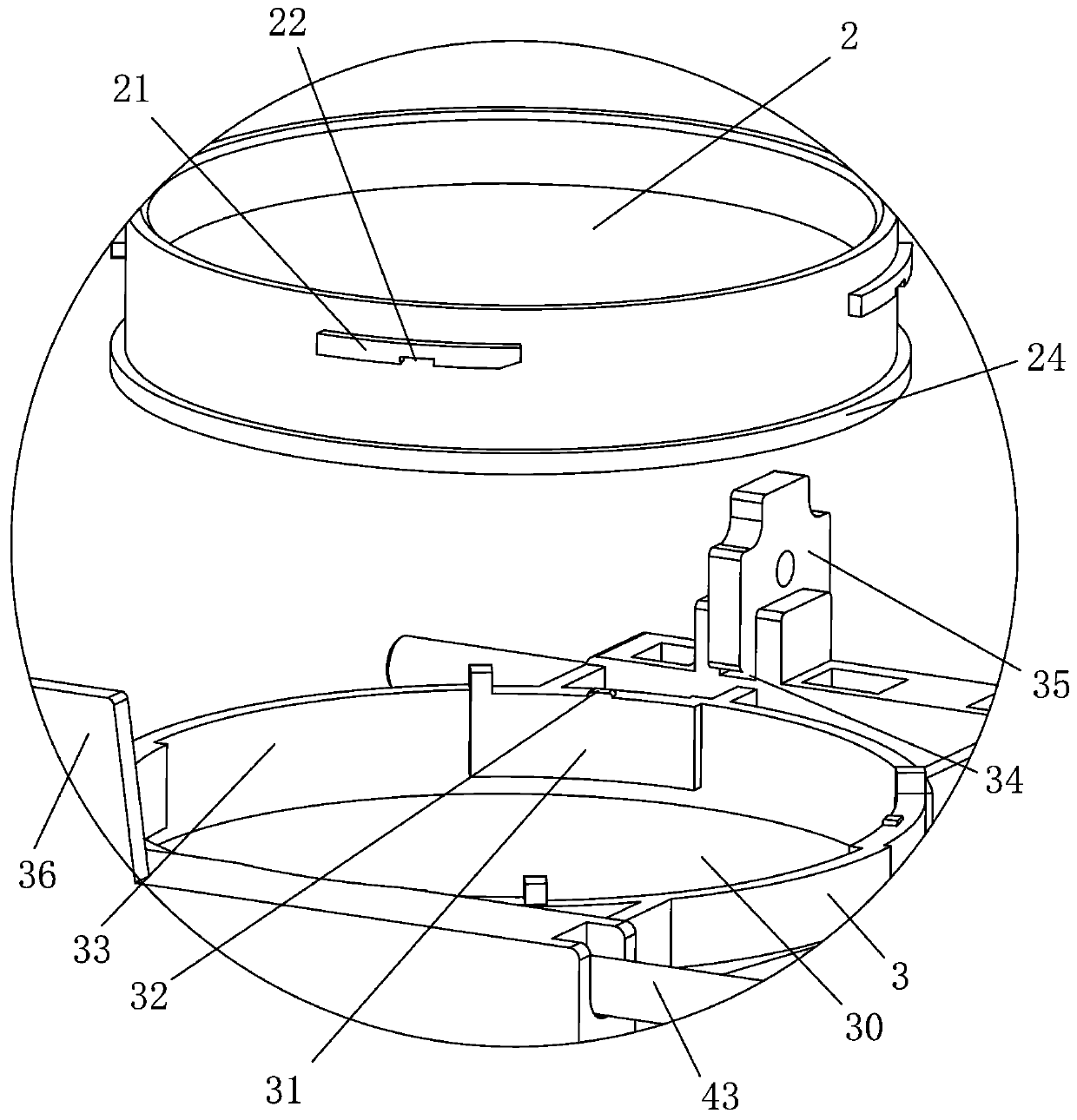

An electric stair-climbing robot

Owner:胡凌翔

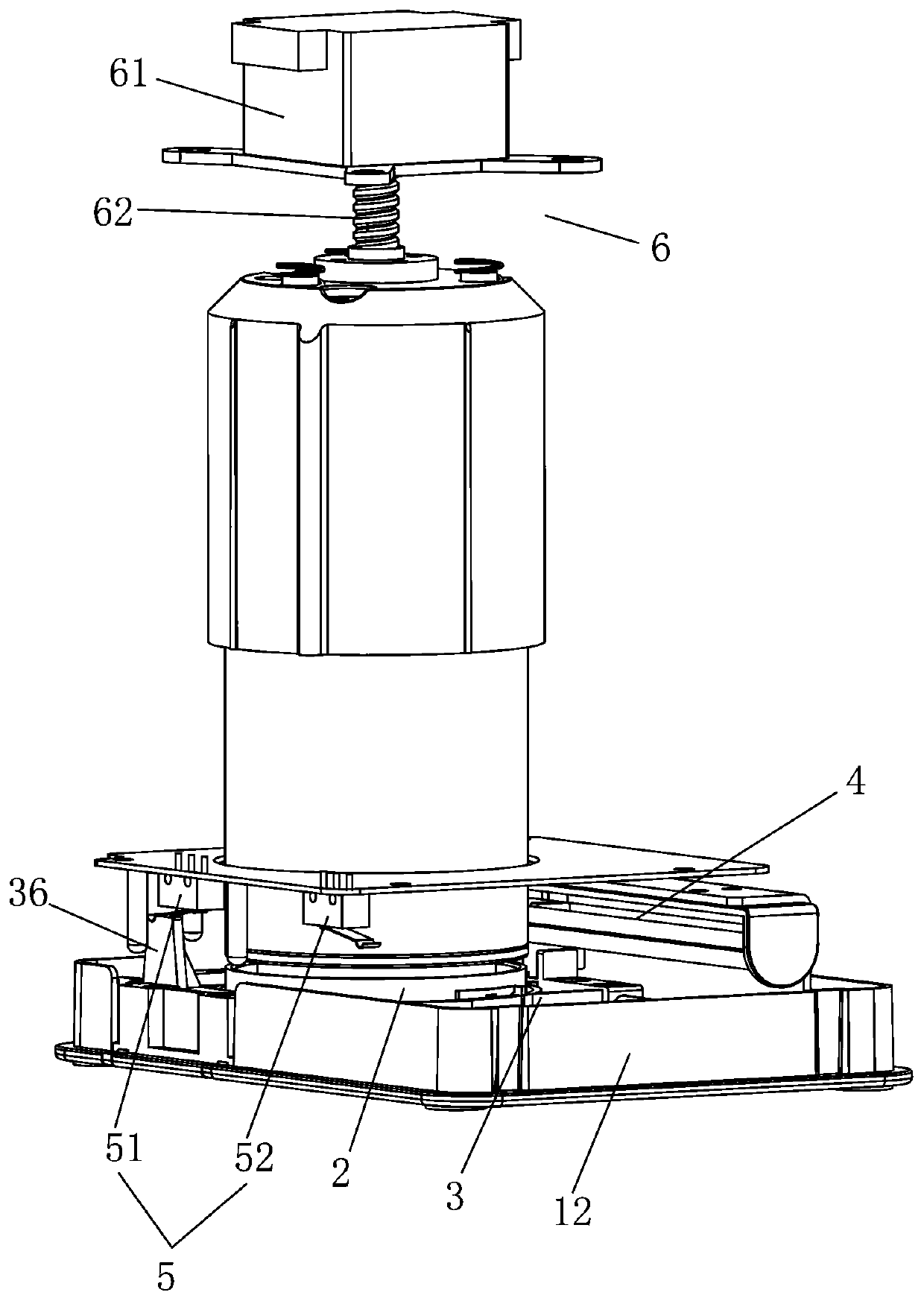

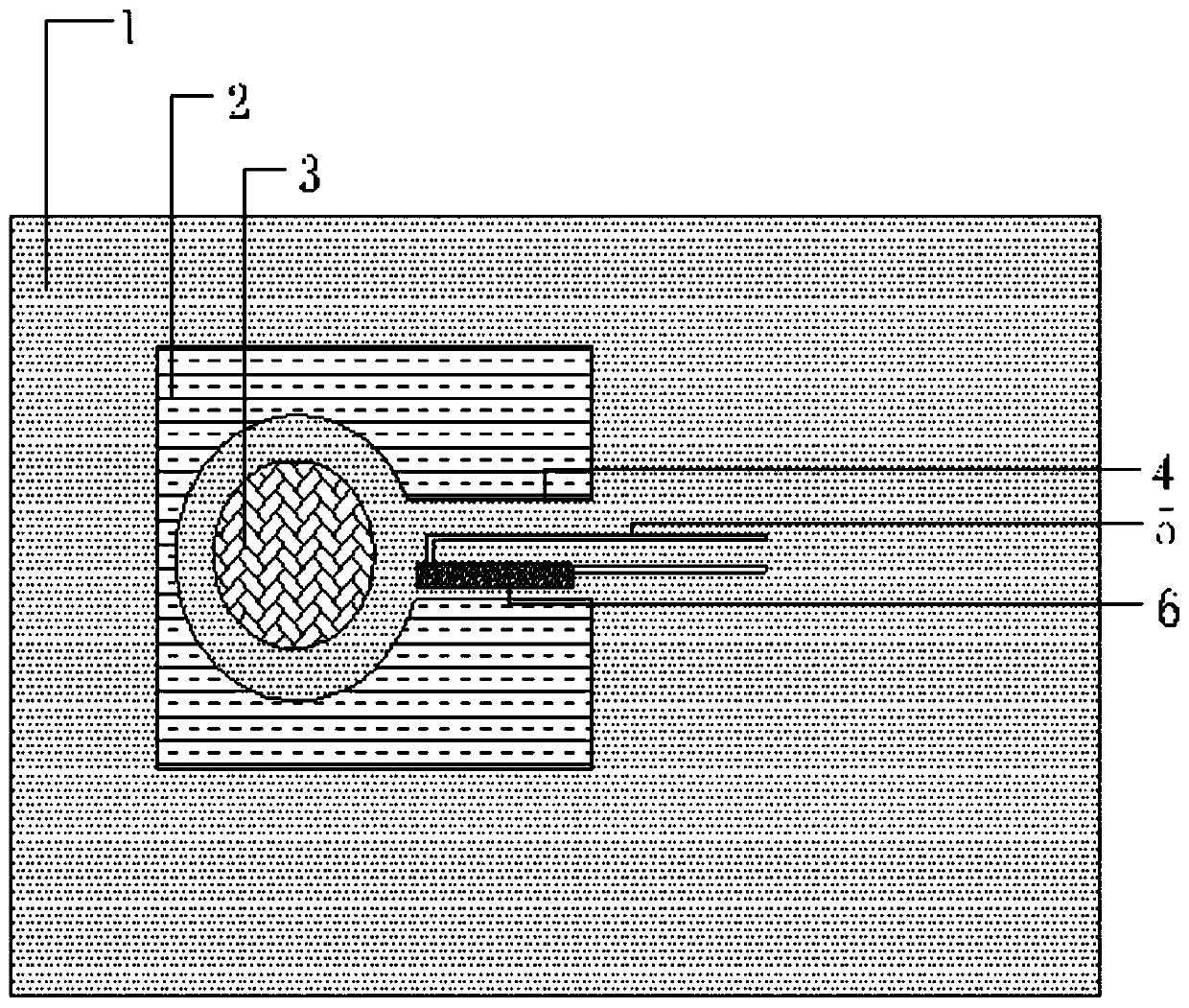

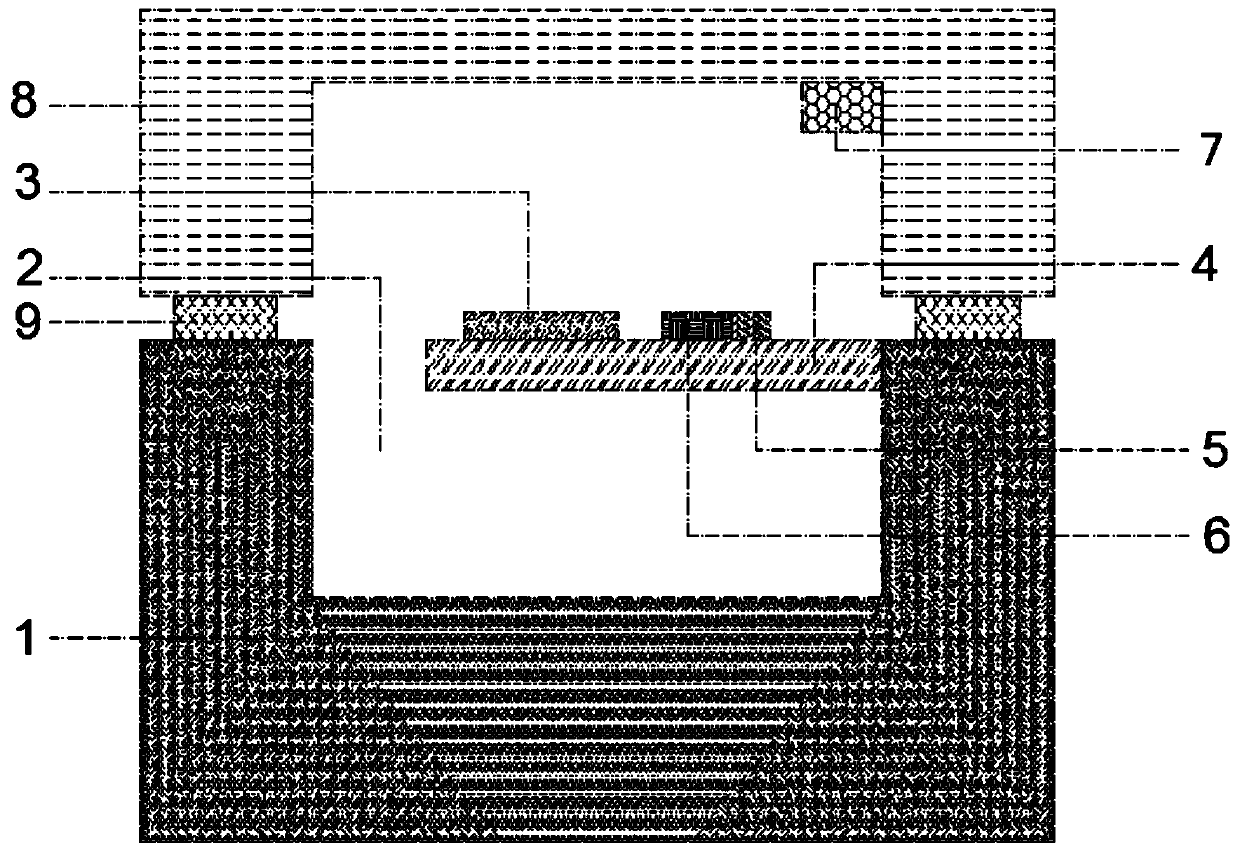

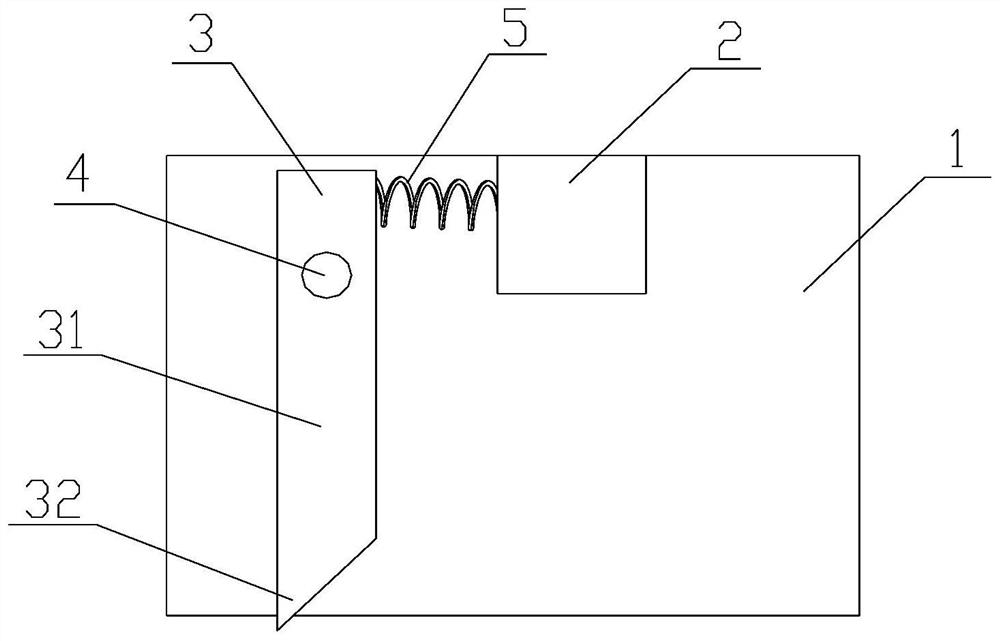

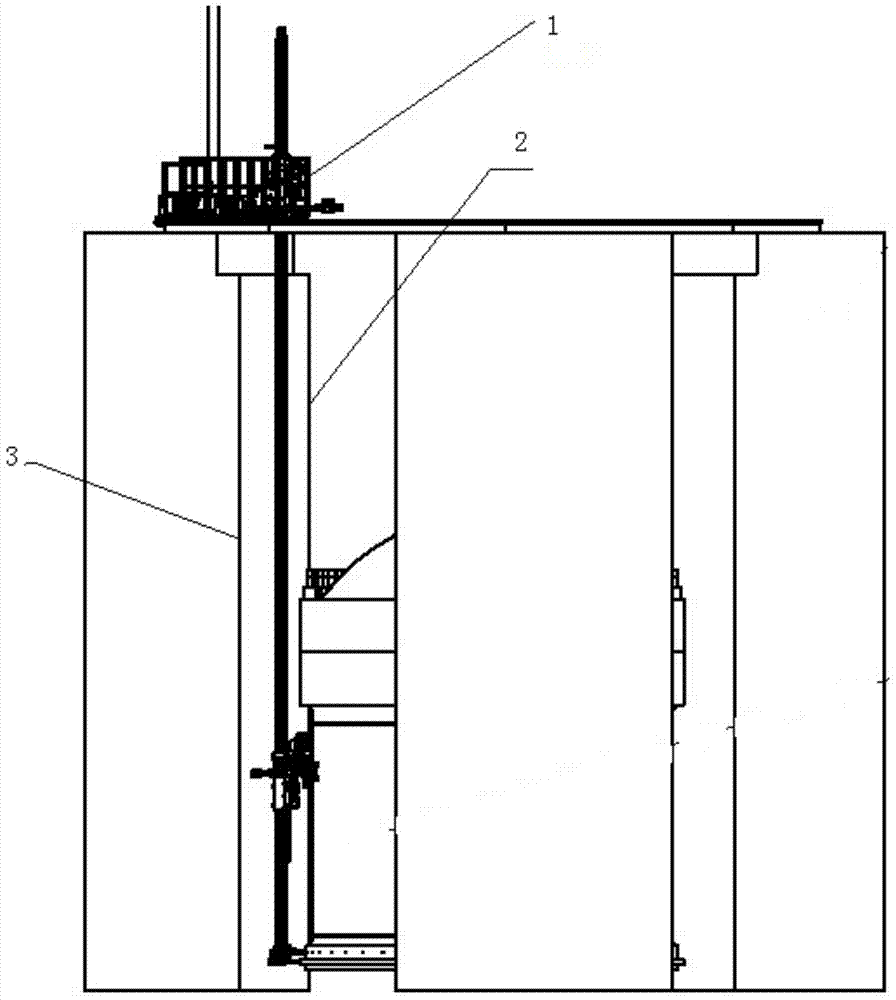

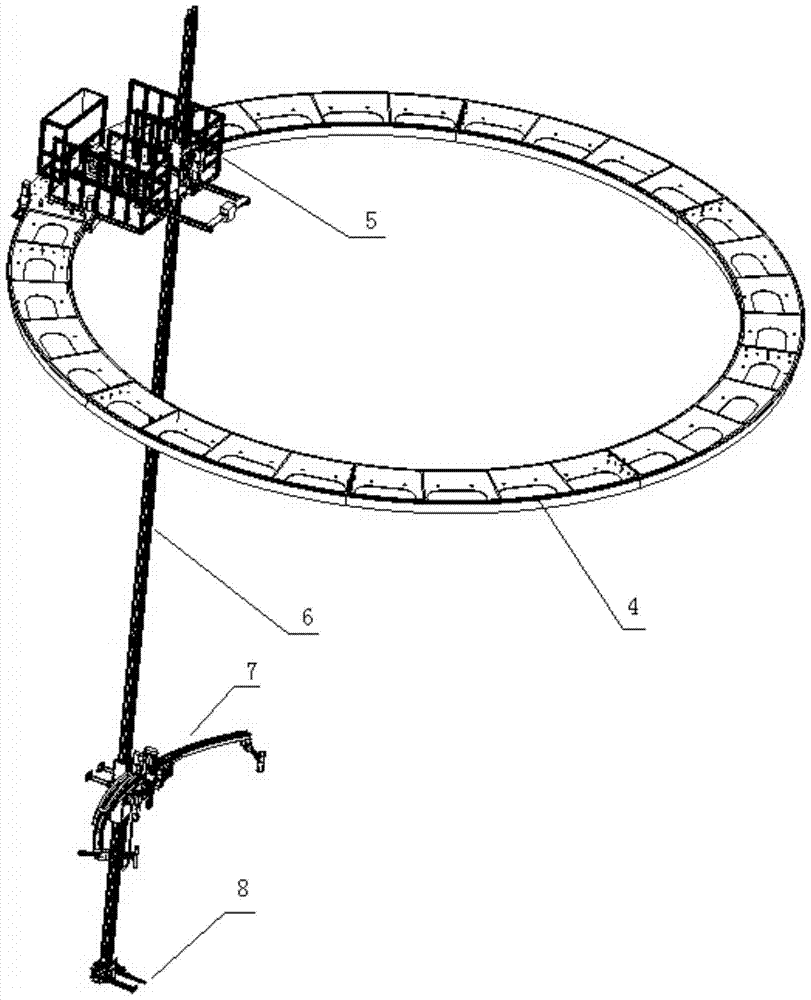

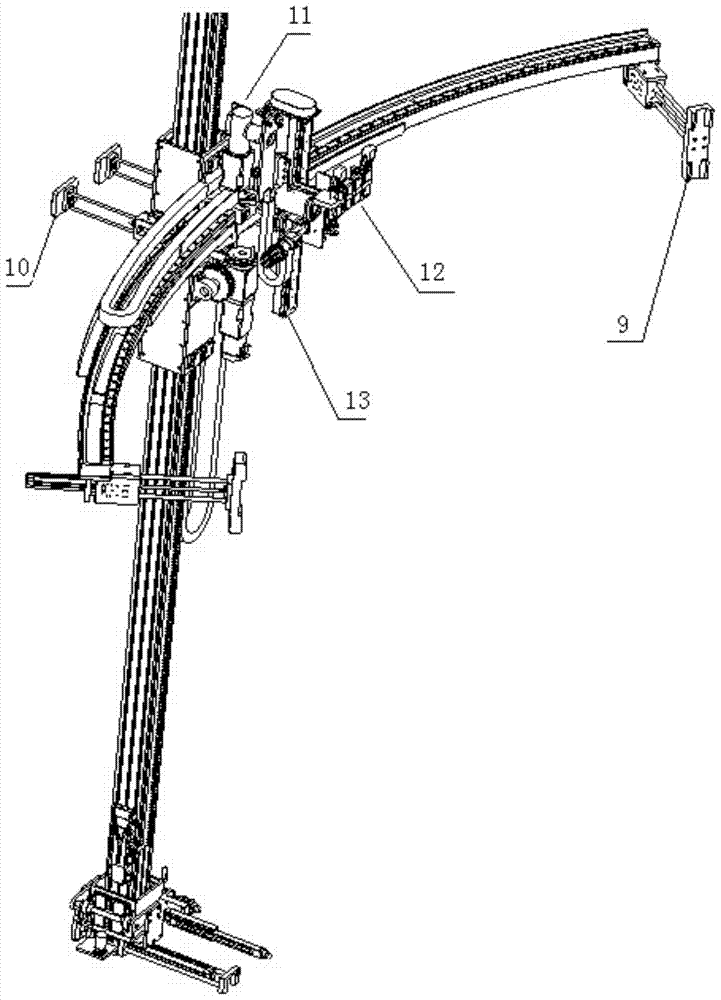

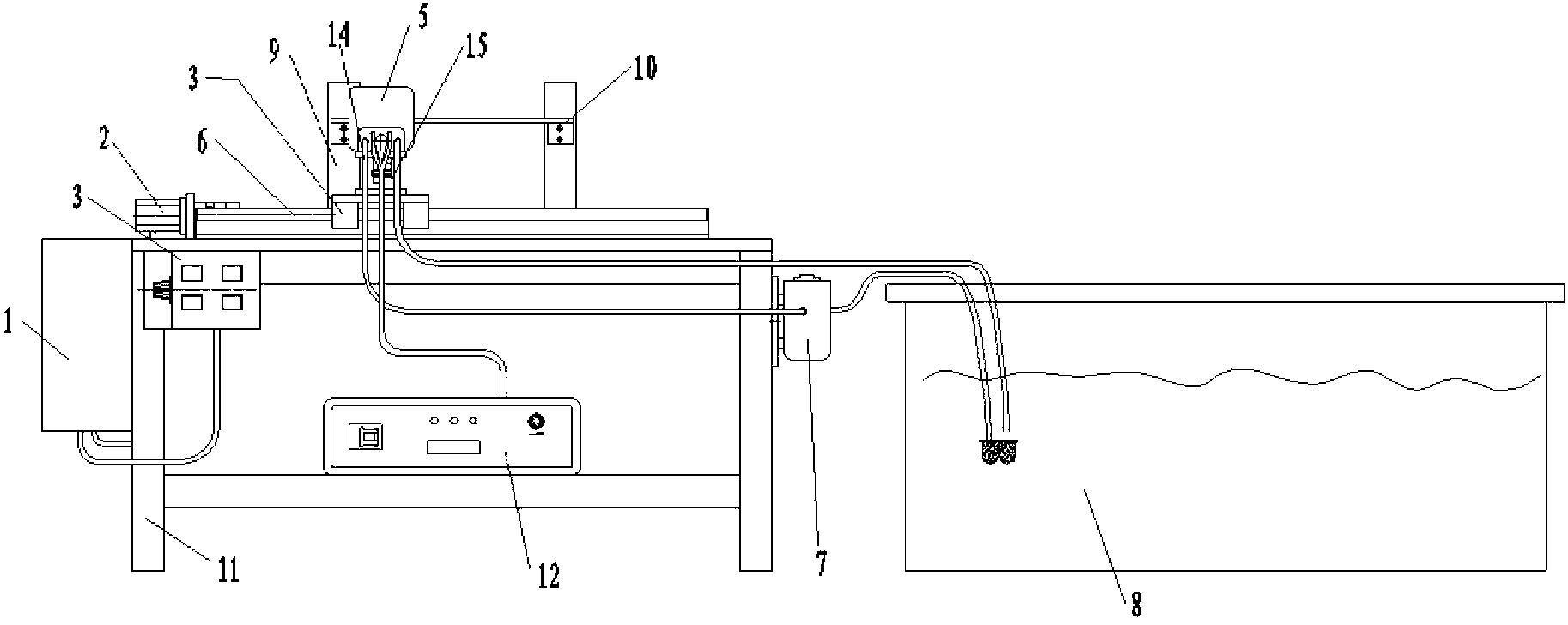

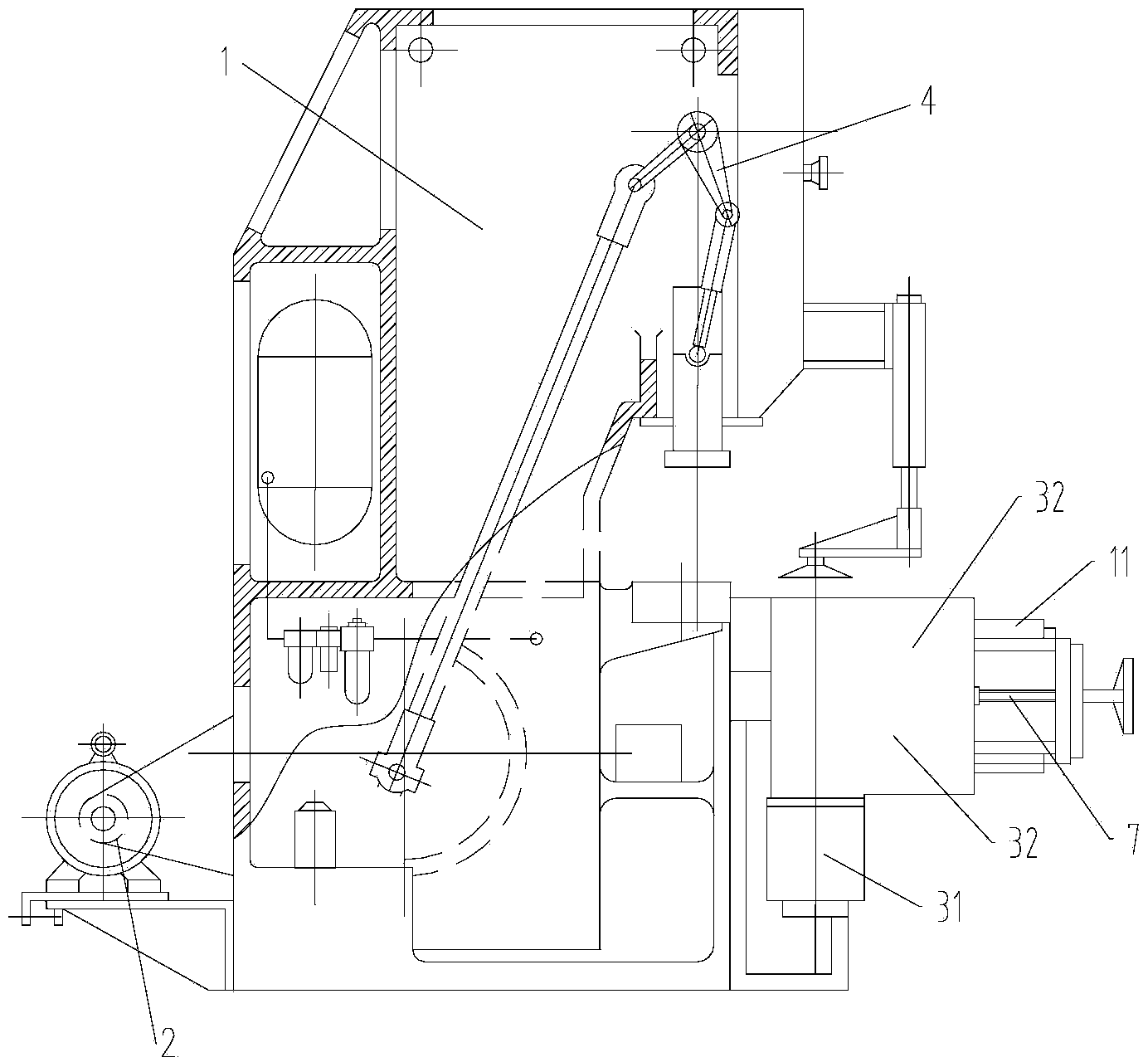

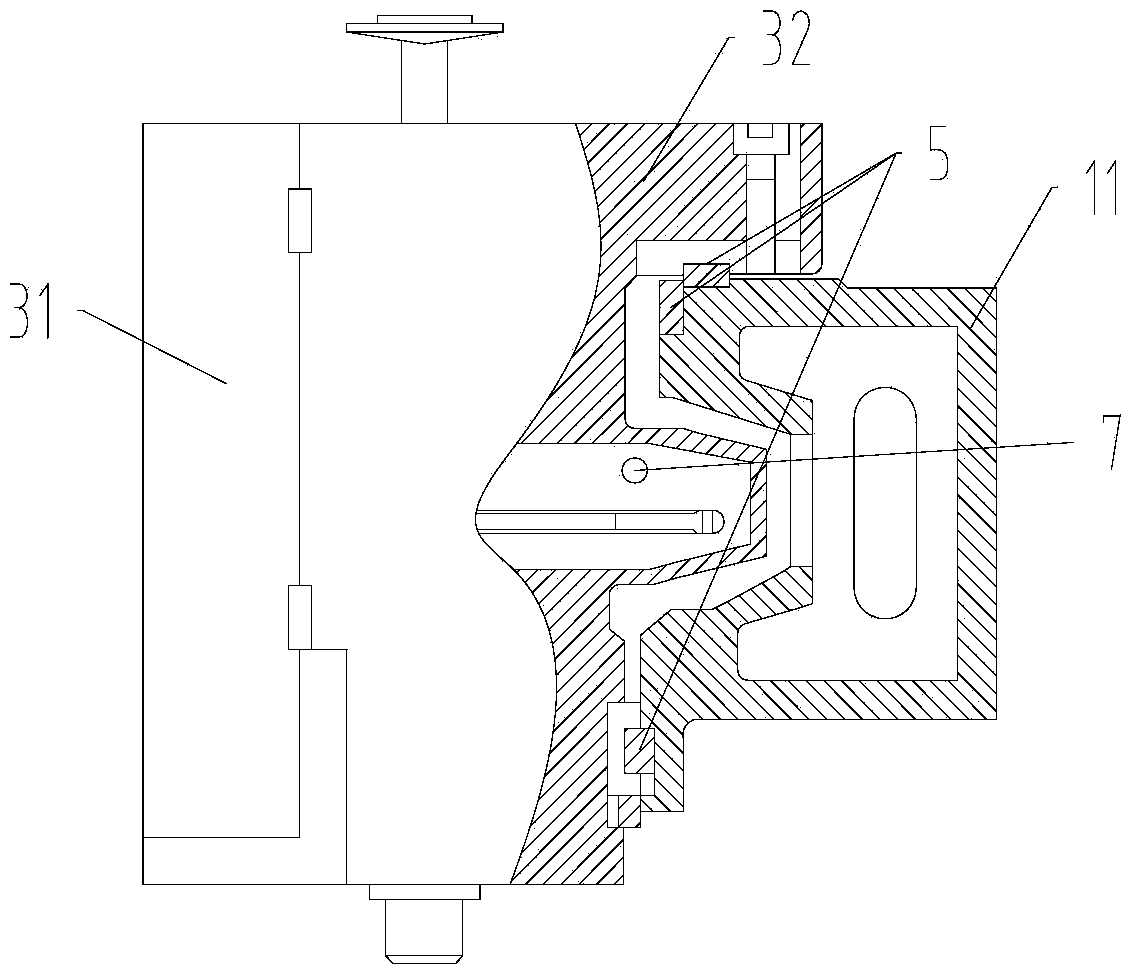

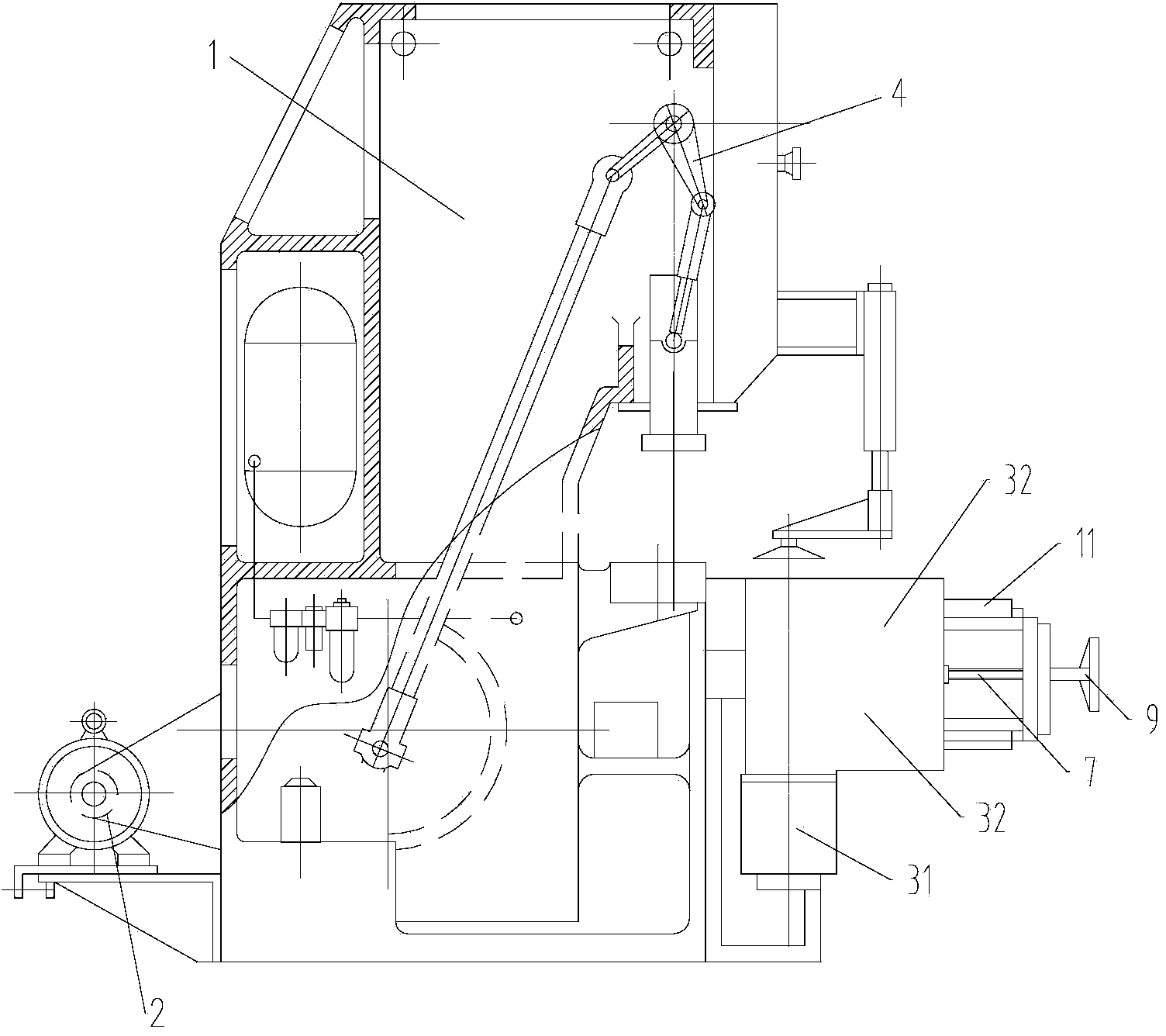

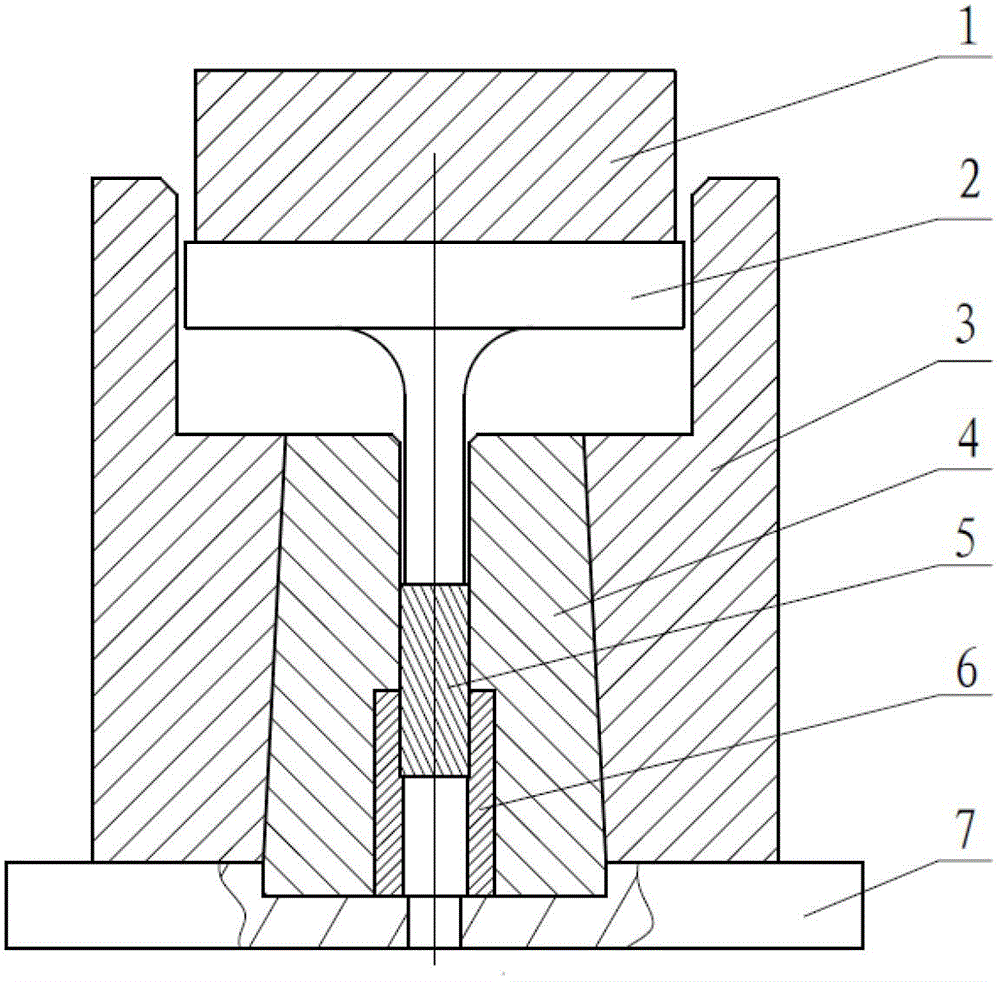

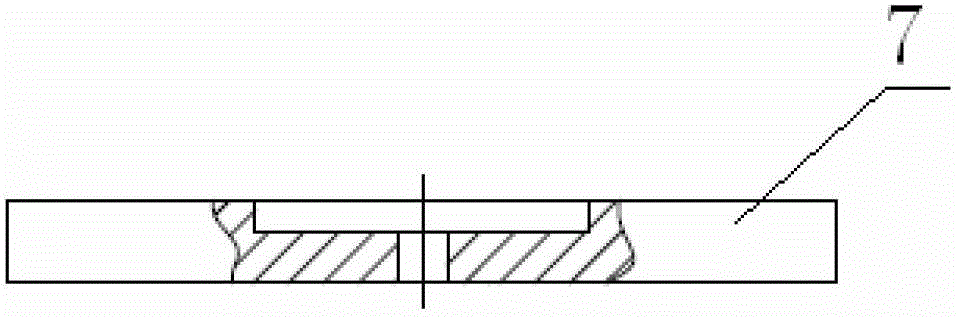

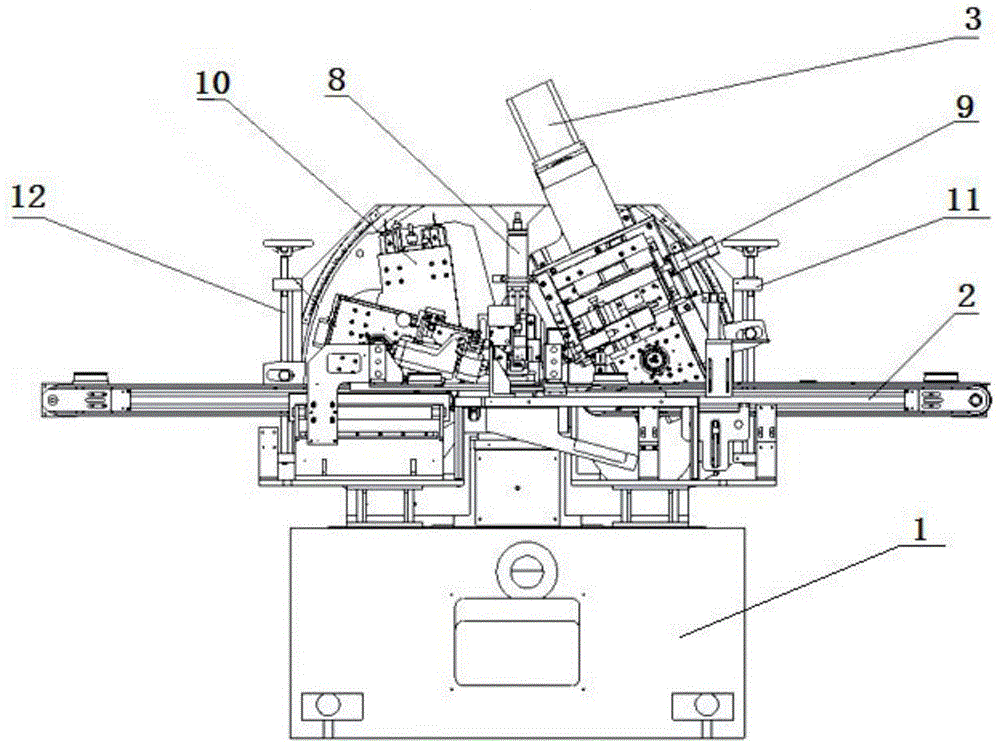

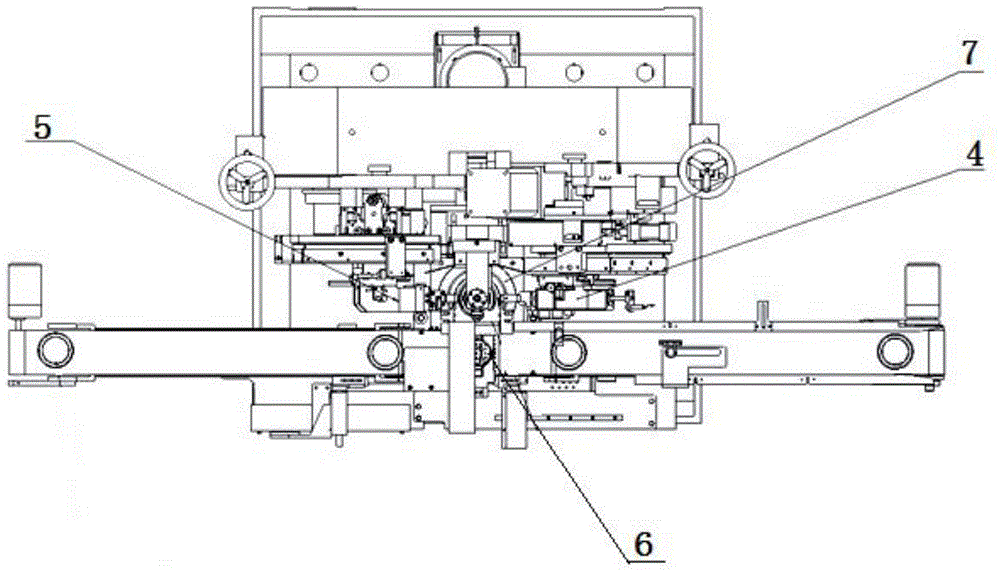

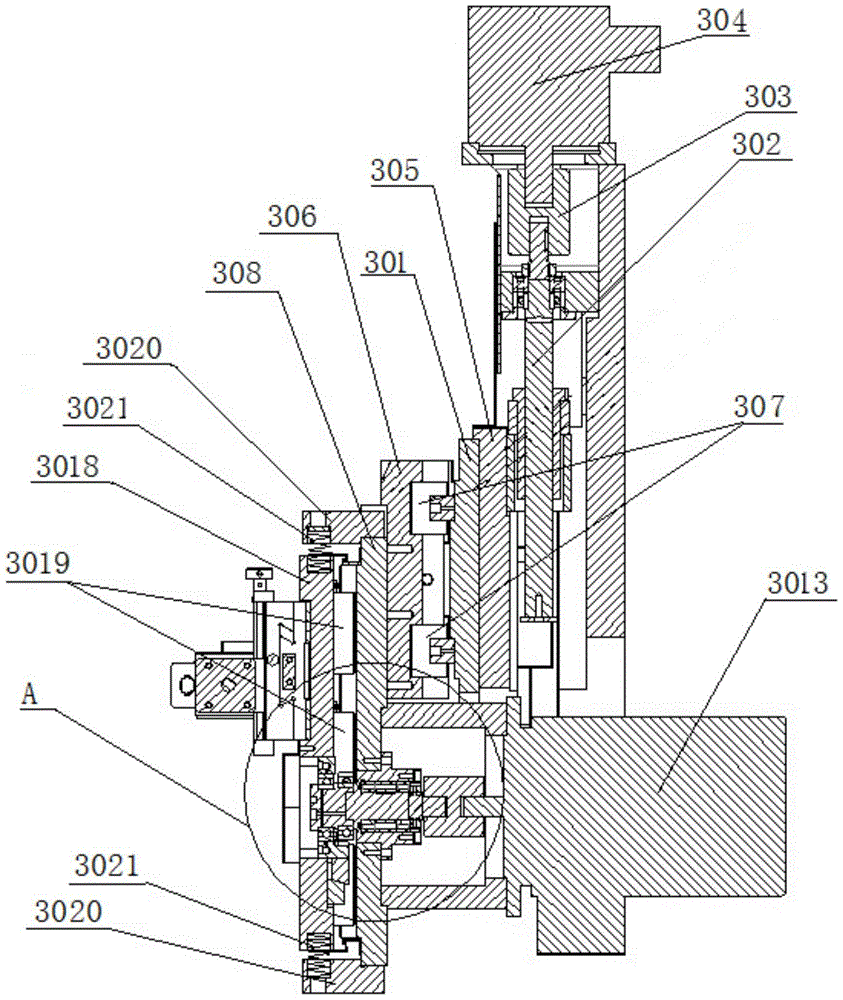

Detection apparatus for pressure vessel of high-temperature gas-cooled reactor

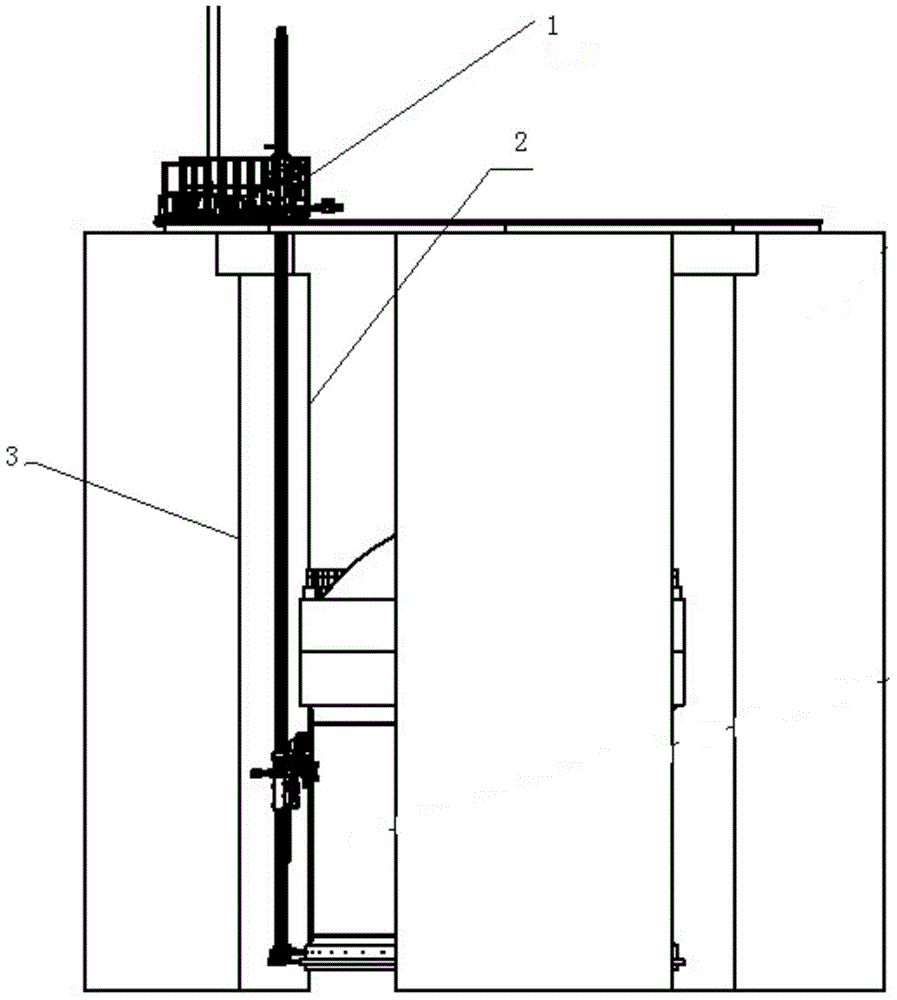

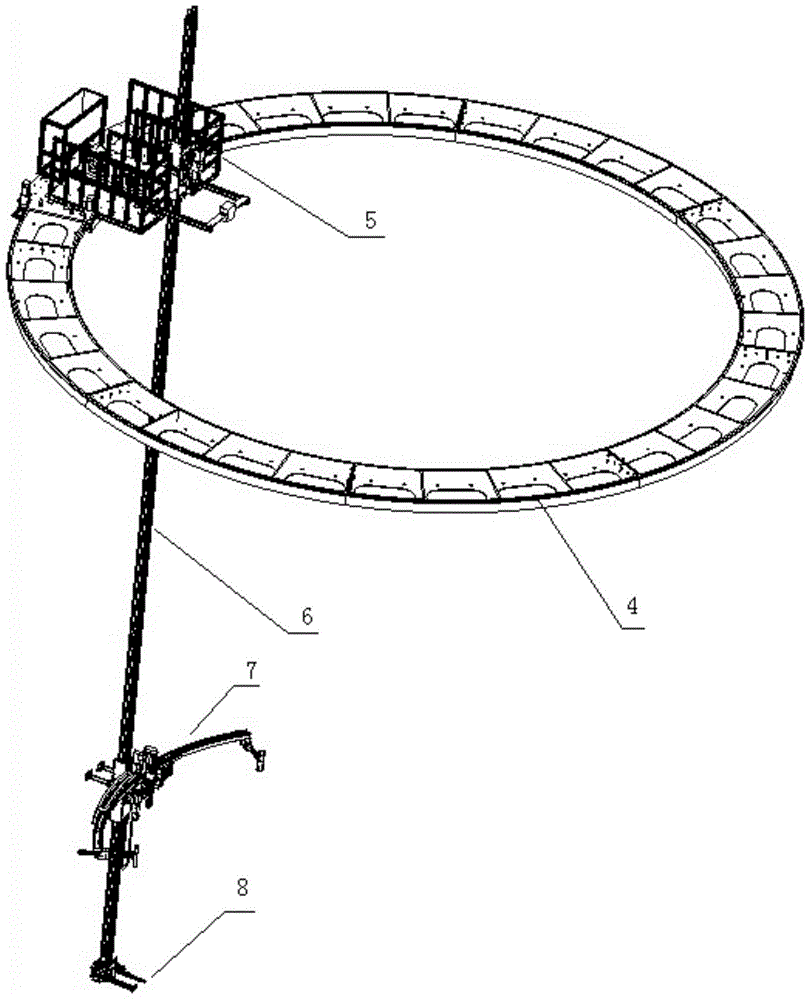

ActiveCN105810259ASimple form of exercisePrecise displacement controlNuclear energy generationNuclear monitoringEngineeringPressure vessel

The invention specifically relates to a detection apparatus for a pressure vessel of a high-temperature gas-cooled reactor, which belongs to the field of detection apparatuses for pressure vessels. The detection apparatus 1 is located between a pressure vessel outer barrel wall 2 and a cabin barrel wall 3 and comprises an annular guide rail 4, a rail-running trolley 5, a lifting bar 6, a two-shaft scanner 7 and a positioning pin pointing mechanism 8, wherein the annular guide rail 4 is a whole circular ring formed by splicing of a plurality of arc guide rails; the rail-running trolley 5 is located on the annular guide rail 4 and can move along the rail; and the lifting bar 6 is mounted on the rail-running trolley 5, and the lower end of the lifting bar 6 is provided with the positioning pin pointing mechanism 8 which can be fixed with a positioning pin hole located in the bottom of the pressure vessel. According to the invention, the lower end of the lifting bar 6 is provided with the positioning pin pointing mechanism 8 which can be fixed with the positioning pin hole located in the bottom of the pressure vessel.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

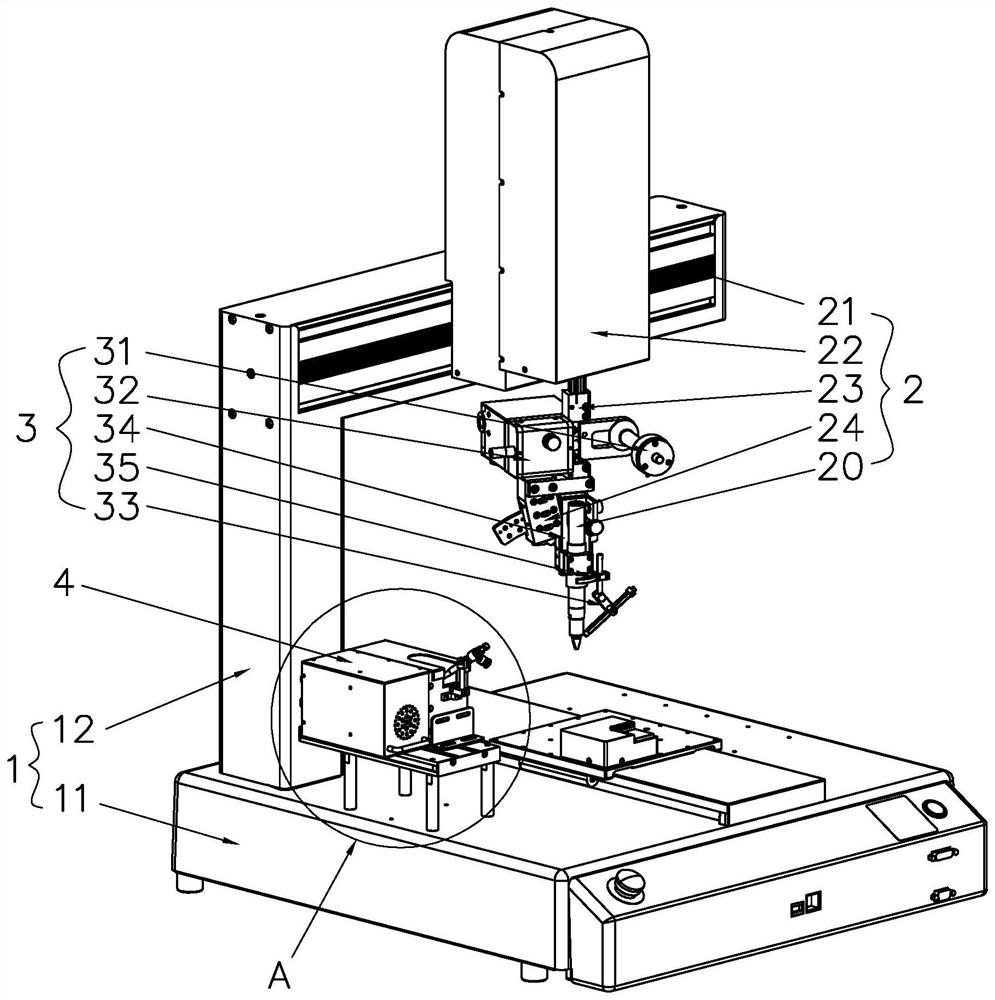

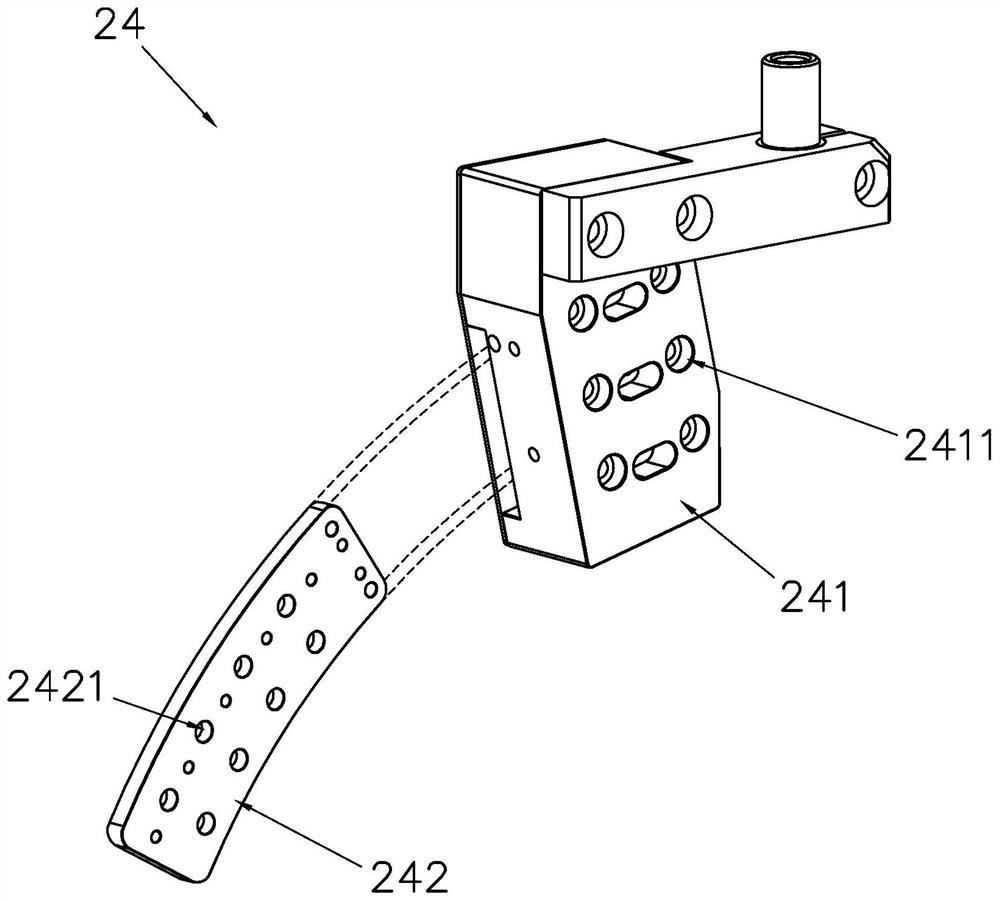

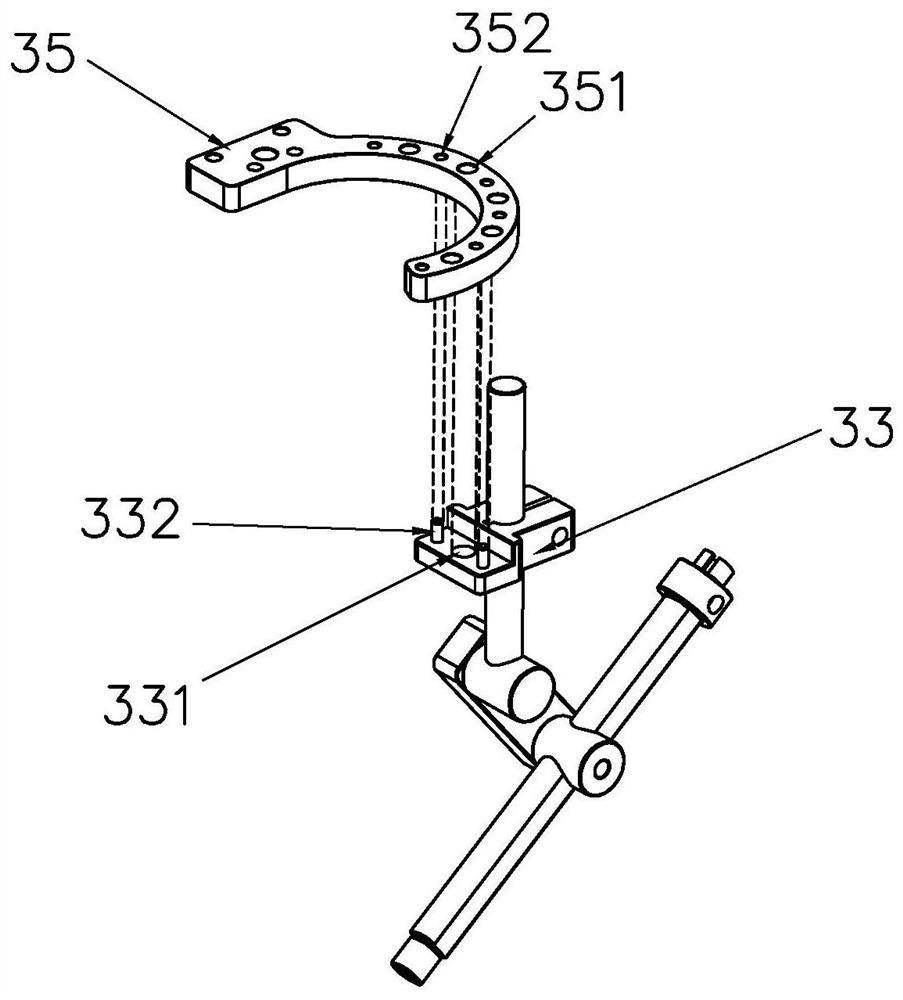

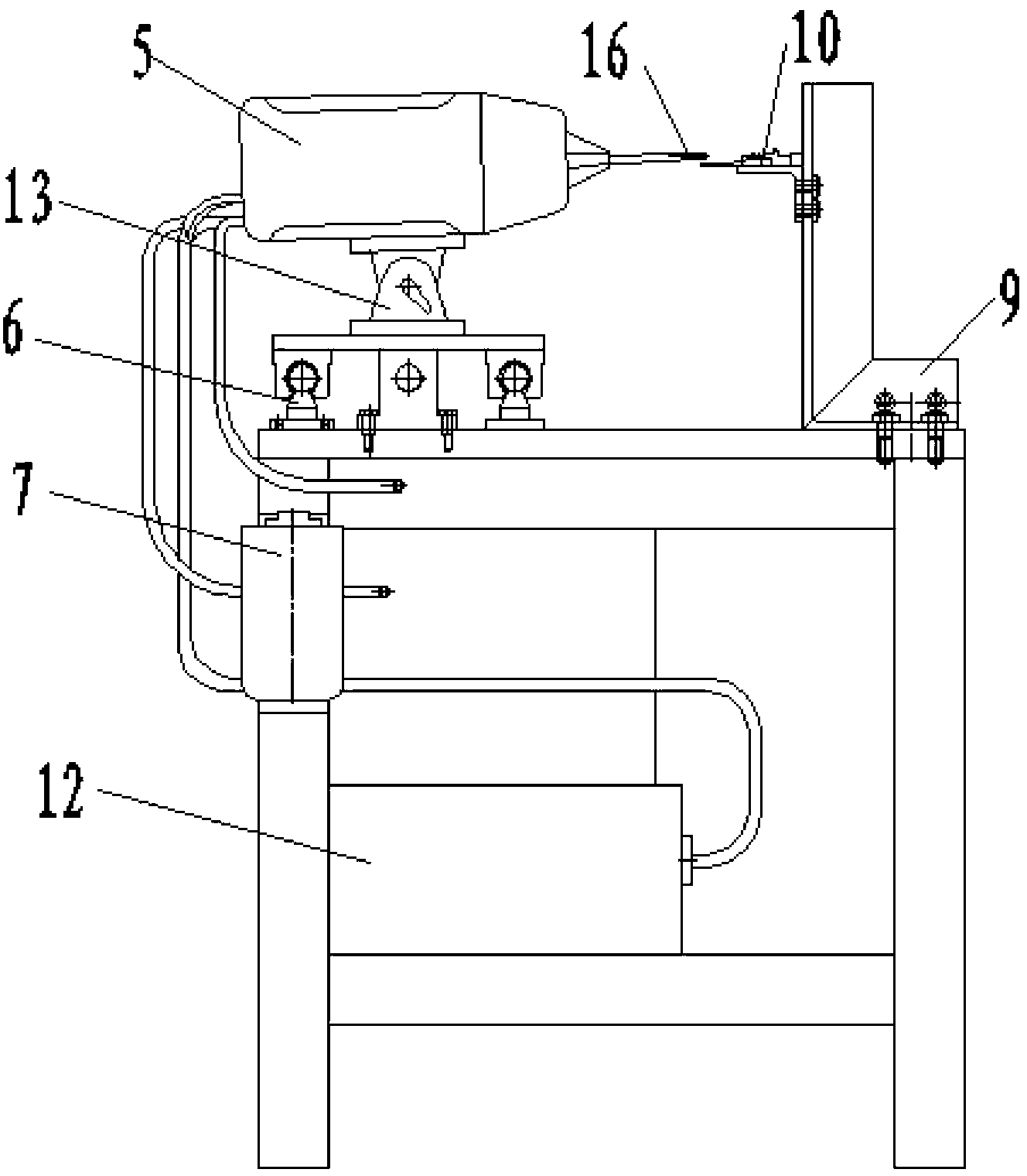

Automatic welding head contact type soldering device

PendingCN111715966APrevent splashWith negative pressure effectPrinted circuit assemblingCleaning using gasesSuction forceEngineering

The invention relates to an automatic welding head contact type soldering device and relates to the technical field of soldering equipment. The automatic welding head contact type soldering device comprises a rack and a soldering mechanism mounted on the rack; the soldering mechanism comprises a welding head arranged on the rack in a sliding manner; a cleaning mechanism is mounted on the rack andcomprises a cleaning box mounted on the rack and a negative pressure pump mounted on the cleaning box; the negative pressure pump is provided with a negative pressure end and a positive pressure end;a blowing cavity is formed in the cleaning box and is provided with a negative pressure opening communicating with the negative pressure end of the negative pressure pump; an air-jet piece is mountedin the blowing cavity; and a cleaning area capable of blowing to clean the welding head is arranged in the blowing cavity. During the cleaning process, the gas sprayed out by the air-jet piece blows off sundries on the welding head; the negative pressure pump generates suction force to the gas sprayed out by the air-jet piece to prevent the gas of the air-jet piece from overflowing out of the blowing cavity, and the cleaned sundries fall in the blowing cavity or is discharged via the positive pressure end of the negative pressure pump in a unified manner, so that the automatic welding head contact type soldering device can collect and treat the sundries from the welding head through blast cleaning in a unified manner.

Owner:深圳市嘉鸿宝科技有限公司

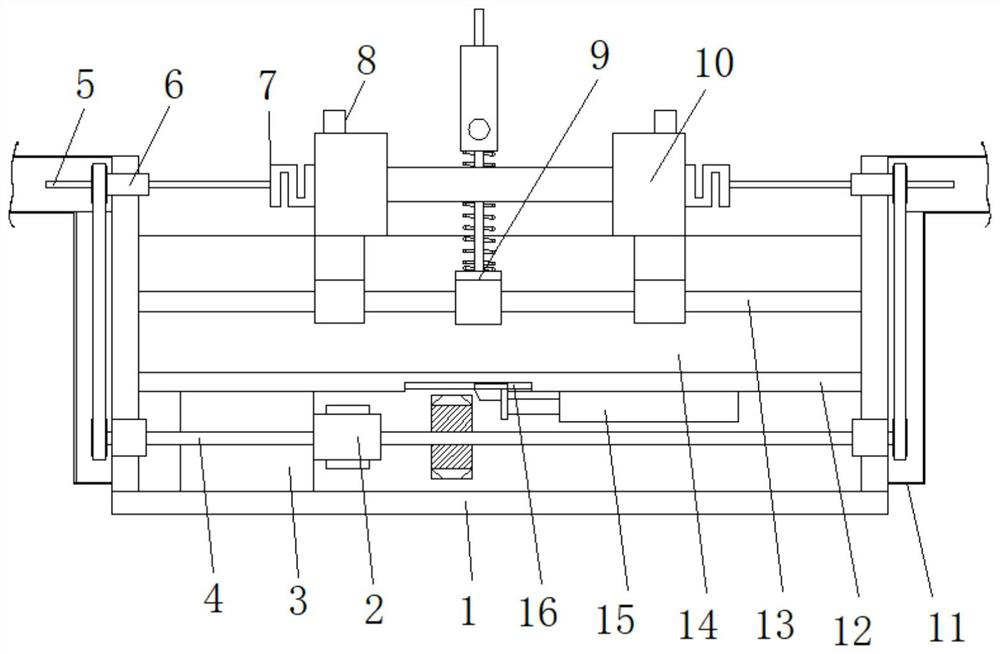

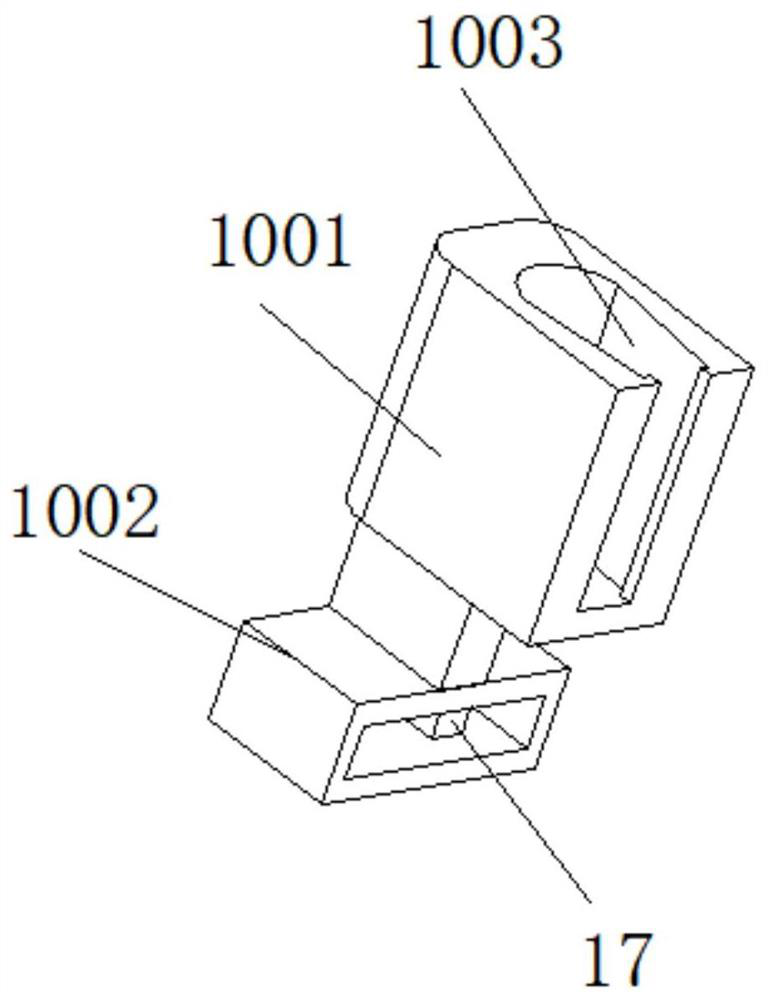

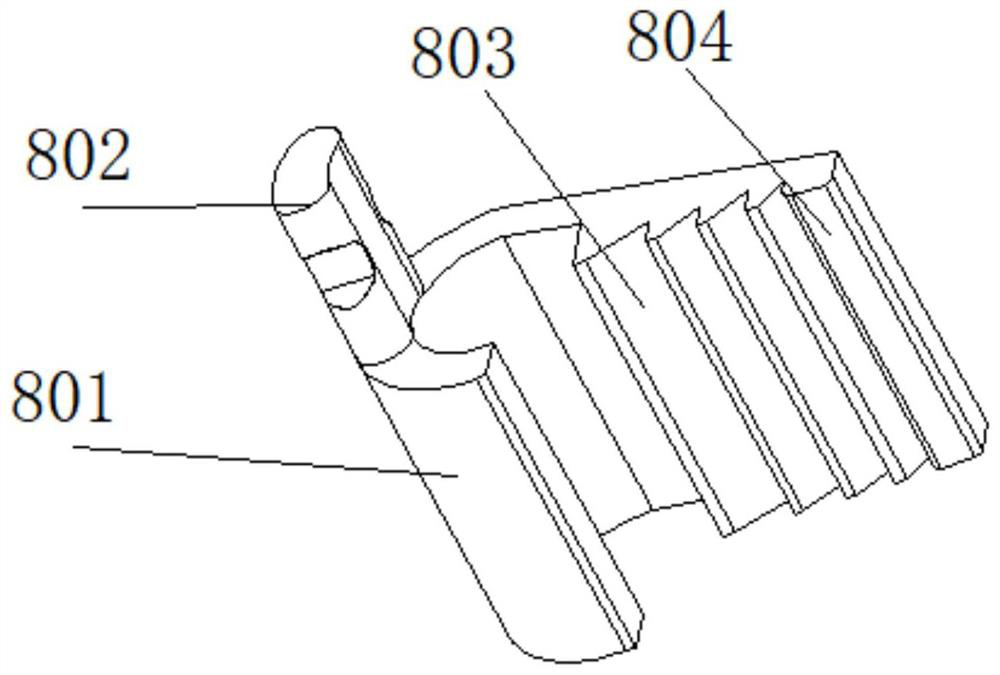

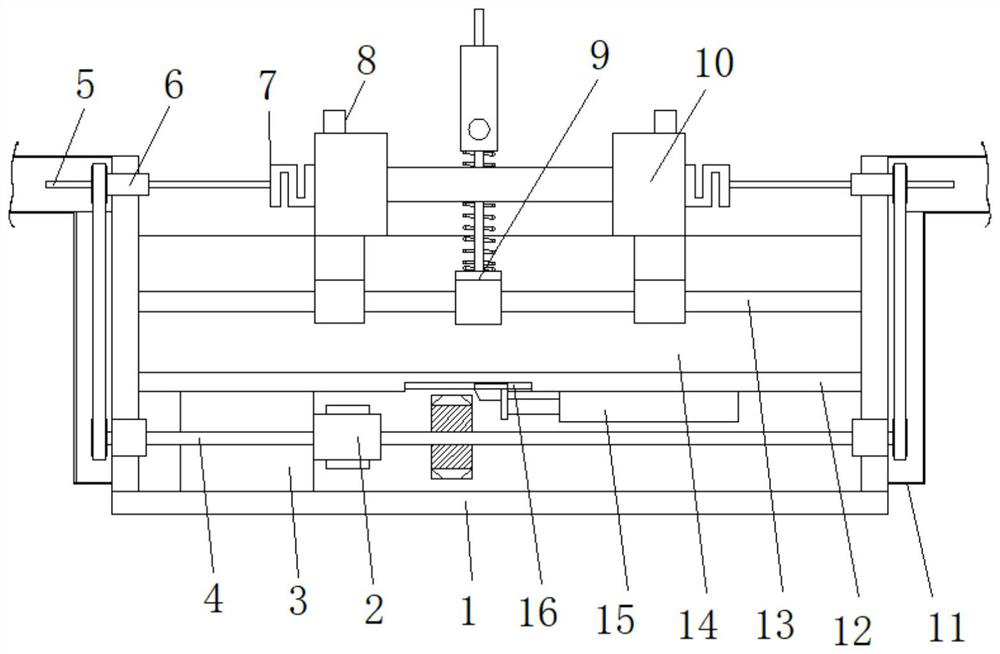

Large-scale multifunctional frozen soil-structure contact surface cyclic direct shearing instrument and its test operation method

ActiveCN102798575BEasy to controlPrecise displacement controlMaterial strength using steady shearing forcesTemperature controlConstant stress

The invention is a large multifunctional frozen soil-structure interface cyclic direct shear apparatus and a test operation method. The structure of the apparatus comprises a horizontal and vertical loading system, a horizontal and vertical displacement and a load sensor, a temperature control and refrigeration system, a temperature sensor, a data collecting and self-stabilizing system, a guide rail system, and a soil sample box and supports. The test operation method comprises the steps of: 1. Installing the interface steel of required roughness; 2. Applying normal boundary conditions to a soil sample; 3. Cooling the soil sample; and 4. When the temperature cools to a target temperature, performing a shearing to the frozen soil interface in a selected shearing speed, at the same time the date collecting system beginning to record the stress-strain relation of the frozen soil interface. The apparatus and the method are the advantageous in that: 1) accurate control of the interface temperature in the temperature range between 0 DEG C and -20 DGE C can be achieved; 2) three normal boundary conditions of constant stiffness, constant displacement and constant stress can be accurately applied; 3) interfaces of various roughness can be simulated; 4) two shear modes of cyclic shear and monotonic shear can be realized; and 5) the stress applying and displacement control are accurate.

Owner:NANJING FORESTRY UNIV

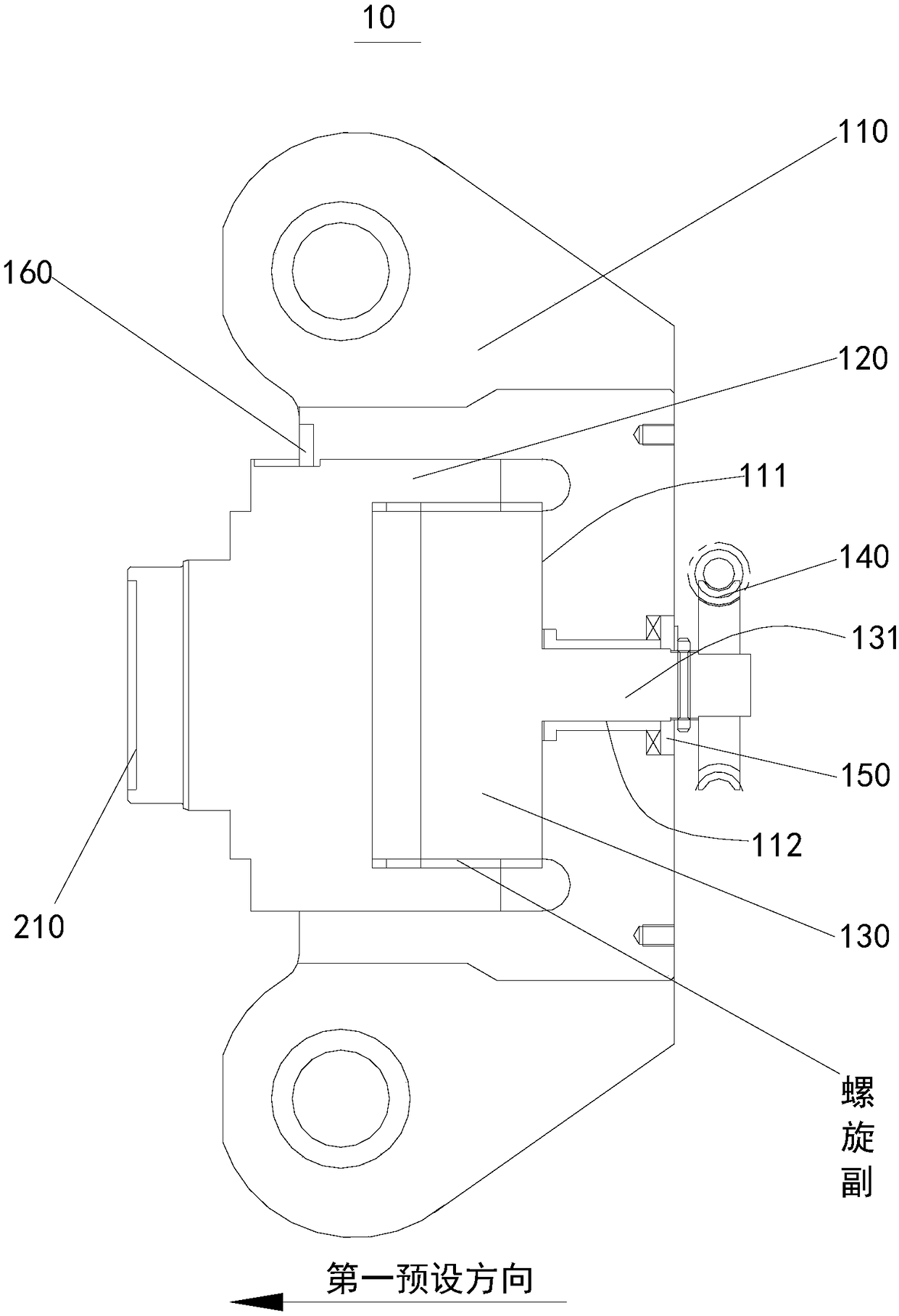

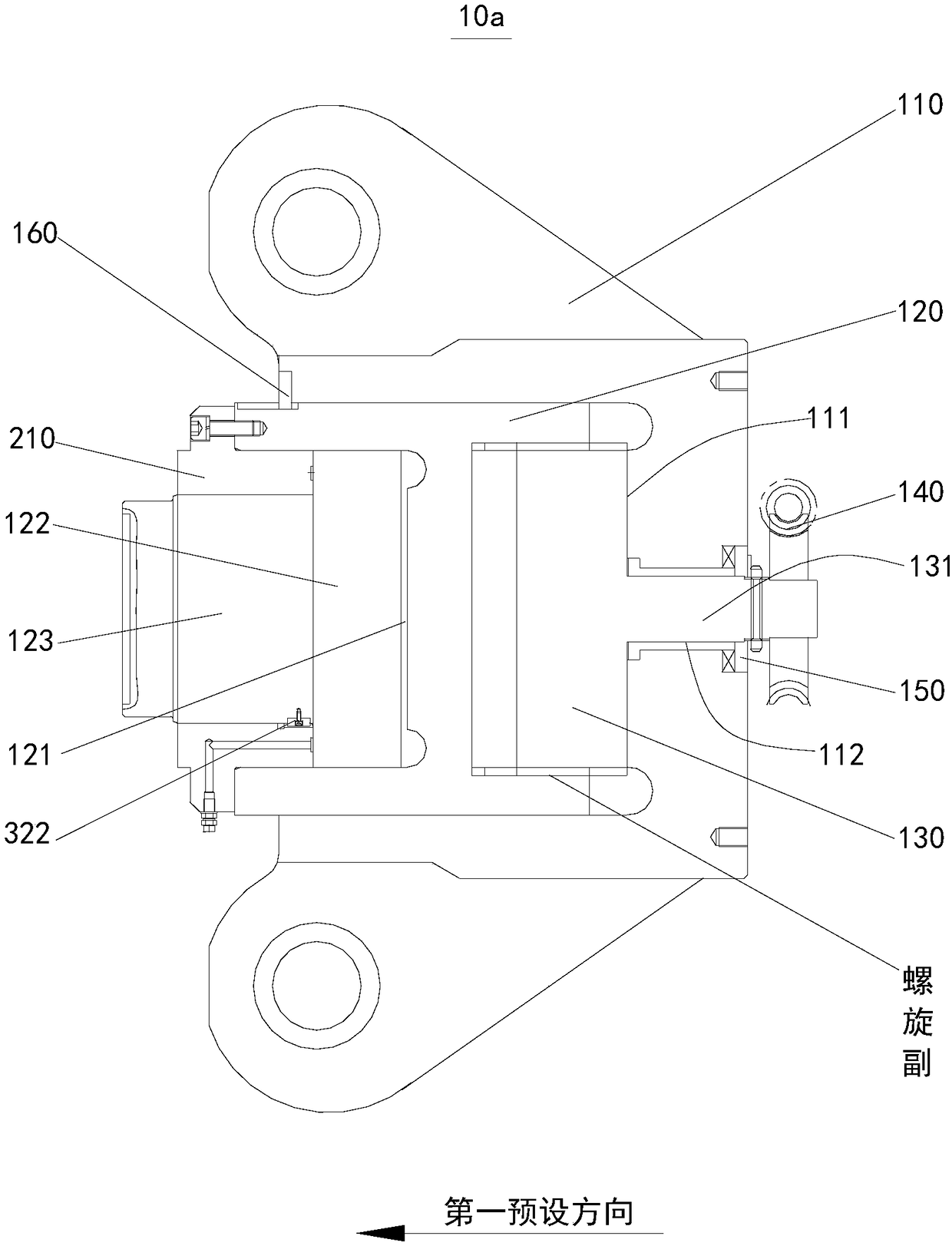

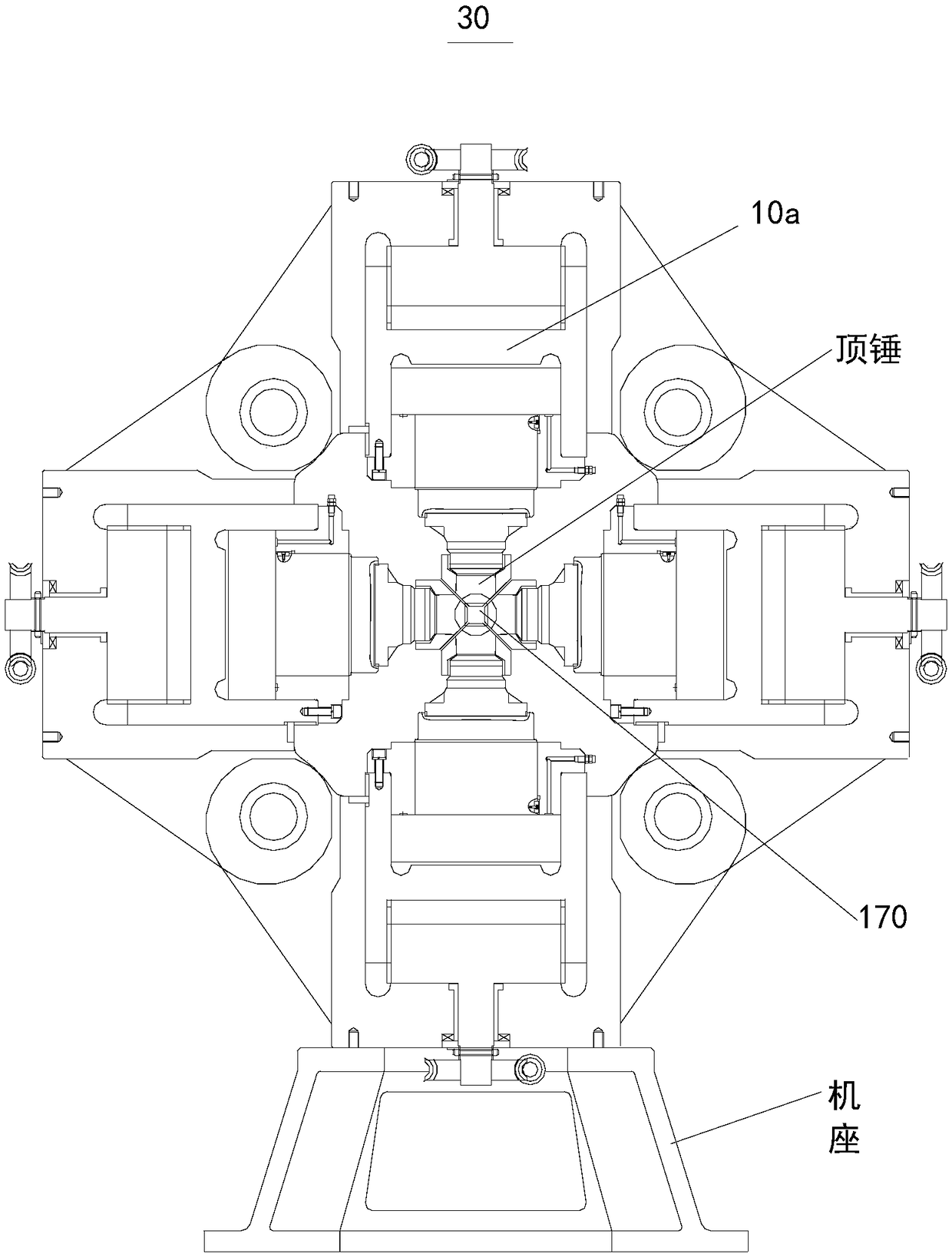

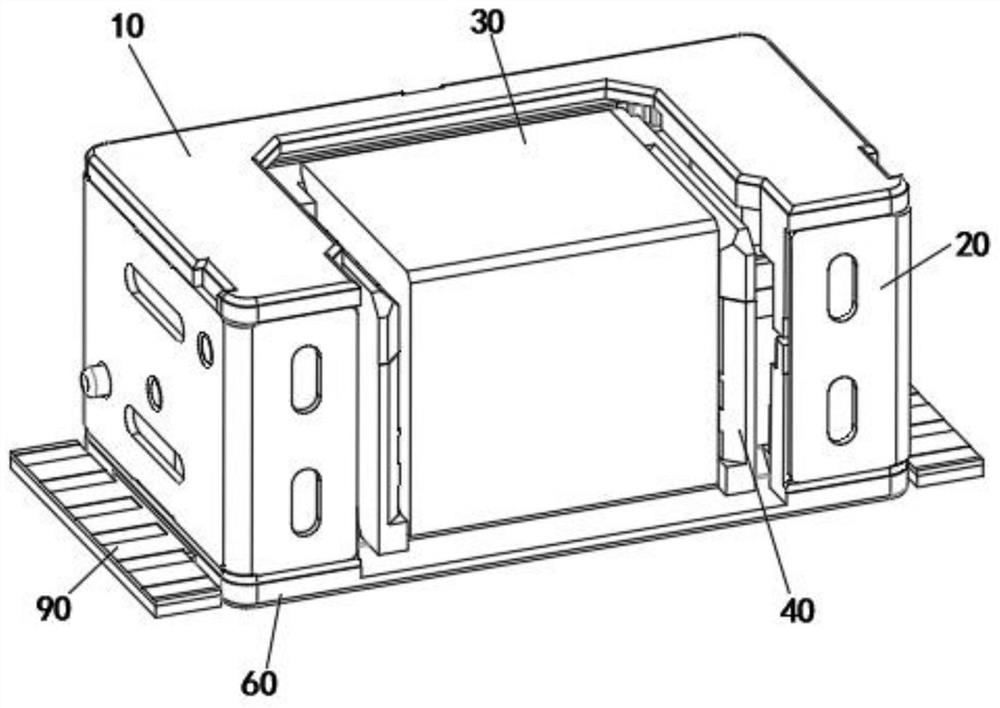

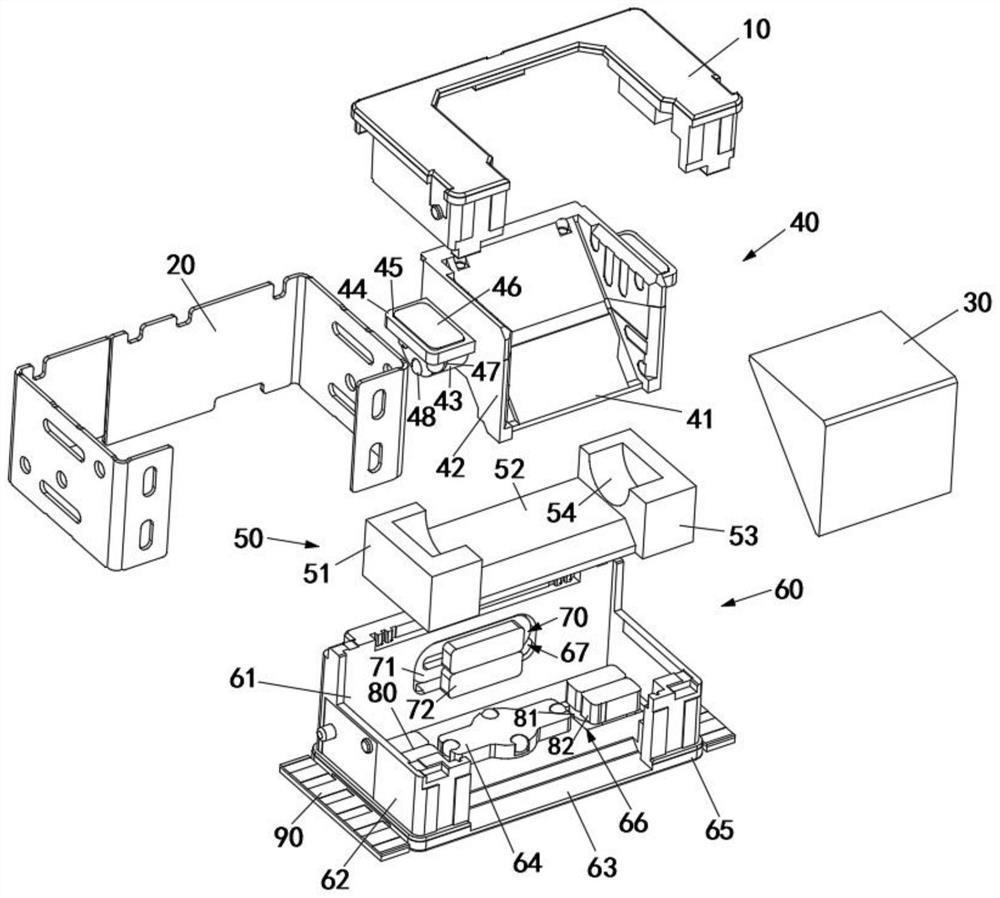

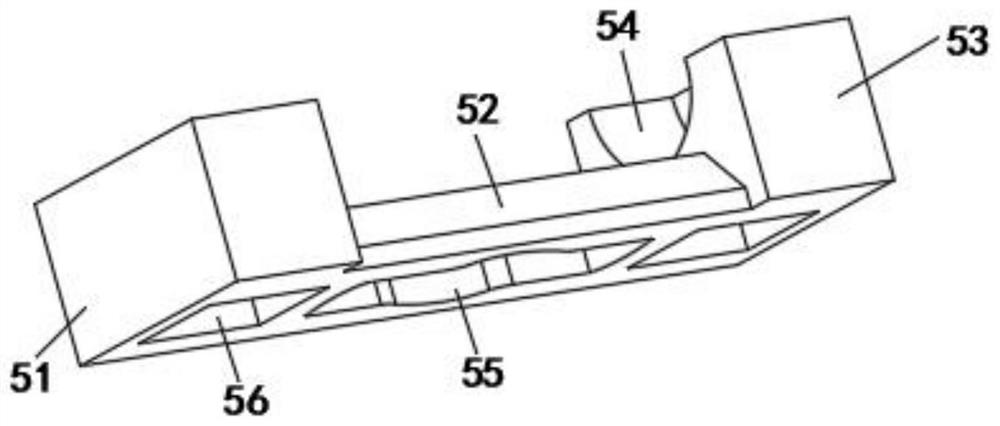

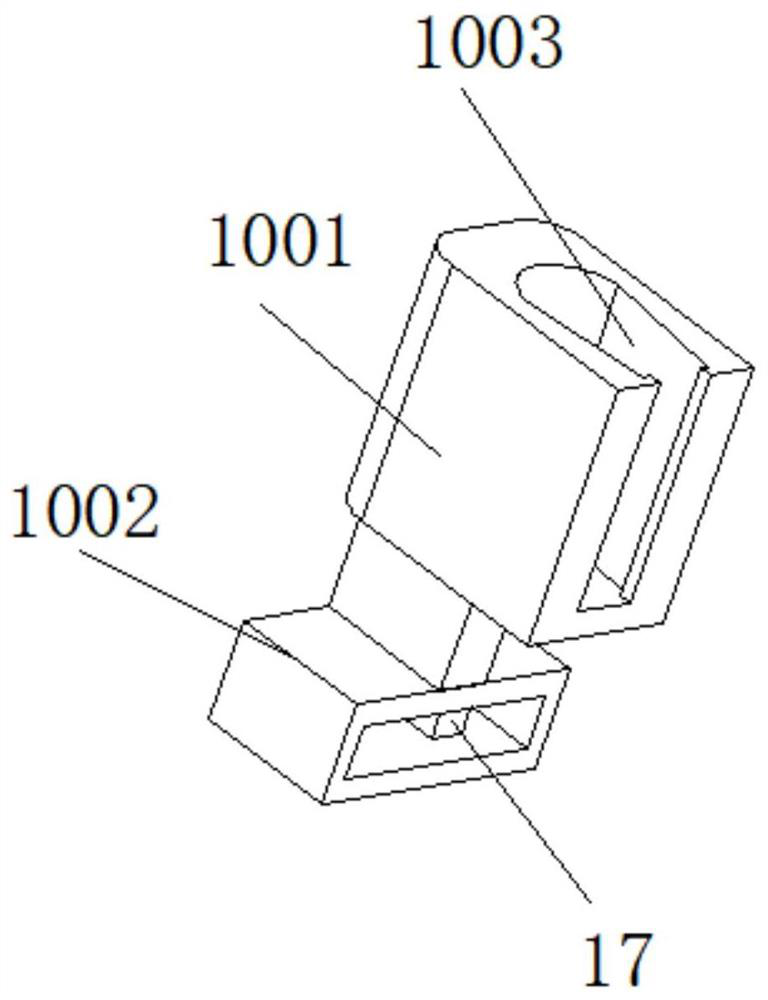

Hinge beam assembly and novel synthesis press

PendingCN108525610AHigh precisionImprove reliabilityUltra-high pressure processesReciprocating motionBearing capacity

The invention relates to the technical field of ultra-hard materials, in particular to a hinge beam assembly and a novel synthesis press. The hinge beam assembly comprises a body, a thrust column, a small-stroke ultrahigh-pressure oil cylinder, a threaded part and a driving device. The thrust column is slidably arranged on the body along a first preset direction, the small-stroke ultrahigh-pressure oil cylinder is arranged at the front end of the thrust column, transmission and bearing connection between the body and the thrust column is formed by the threaded part, and the driving device andthe threaded part are in transmission connection. The thrust column is driven to reciprocate along a first preset direction, the small-stroke ultrahigh-pressure oil cylinder generates ultrahigh-pressure thrust, and the thrust column transmits bearing force to the body. The novel synthesis press is formed on the basis of the hinge beam assembly.

Owner:河南天钻晶体材料有限公司

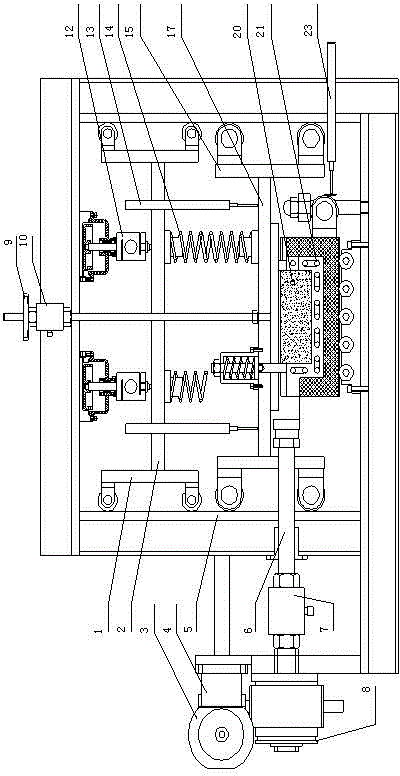

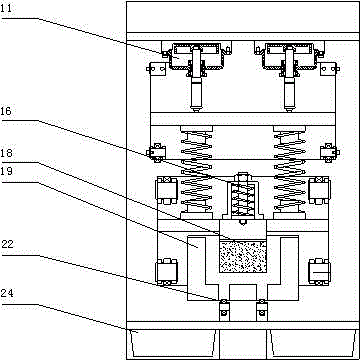

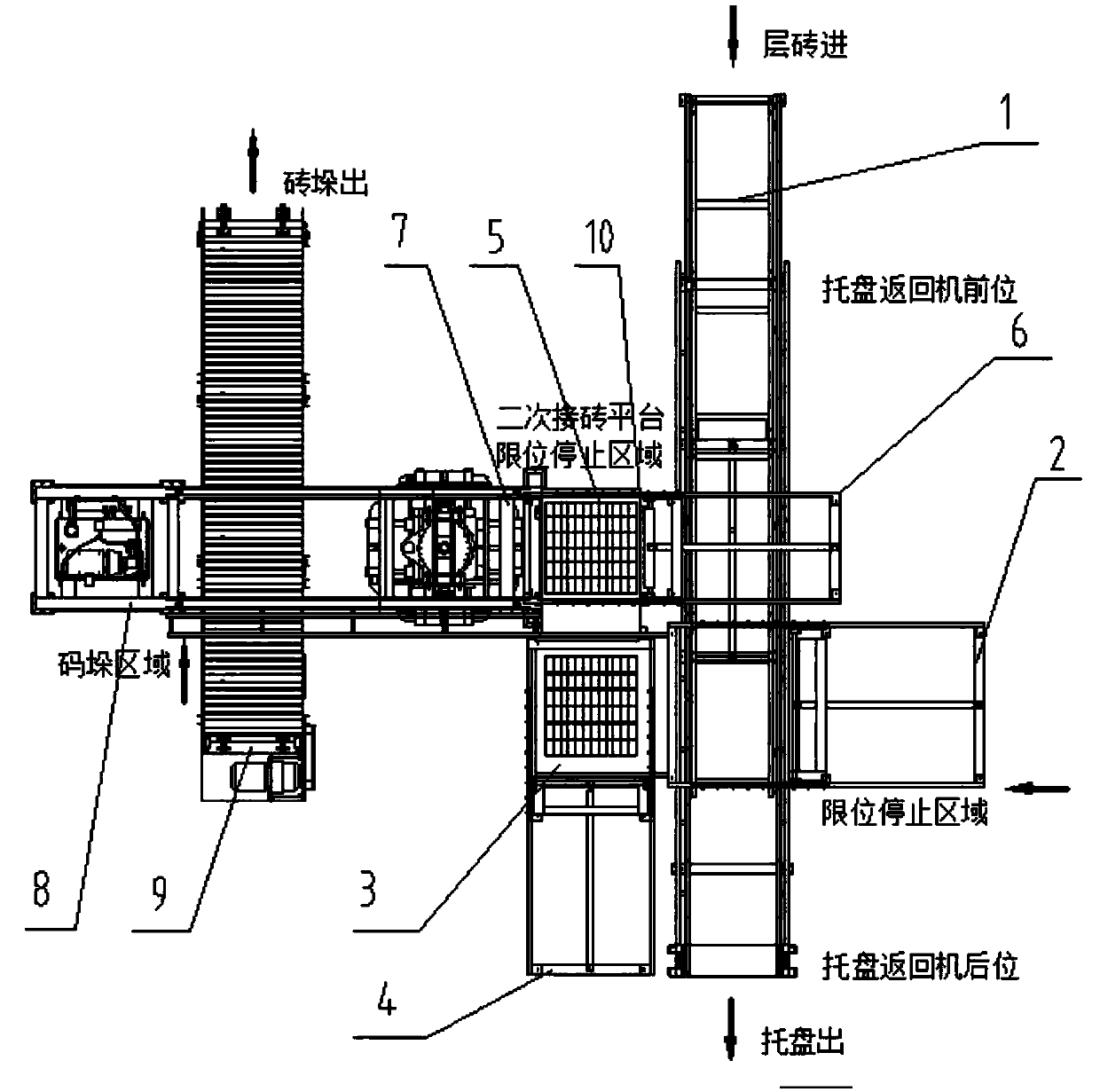

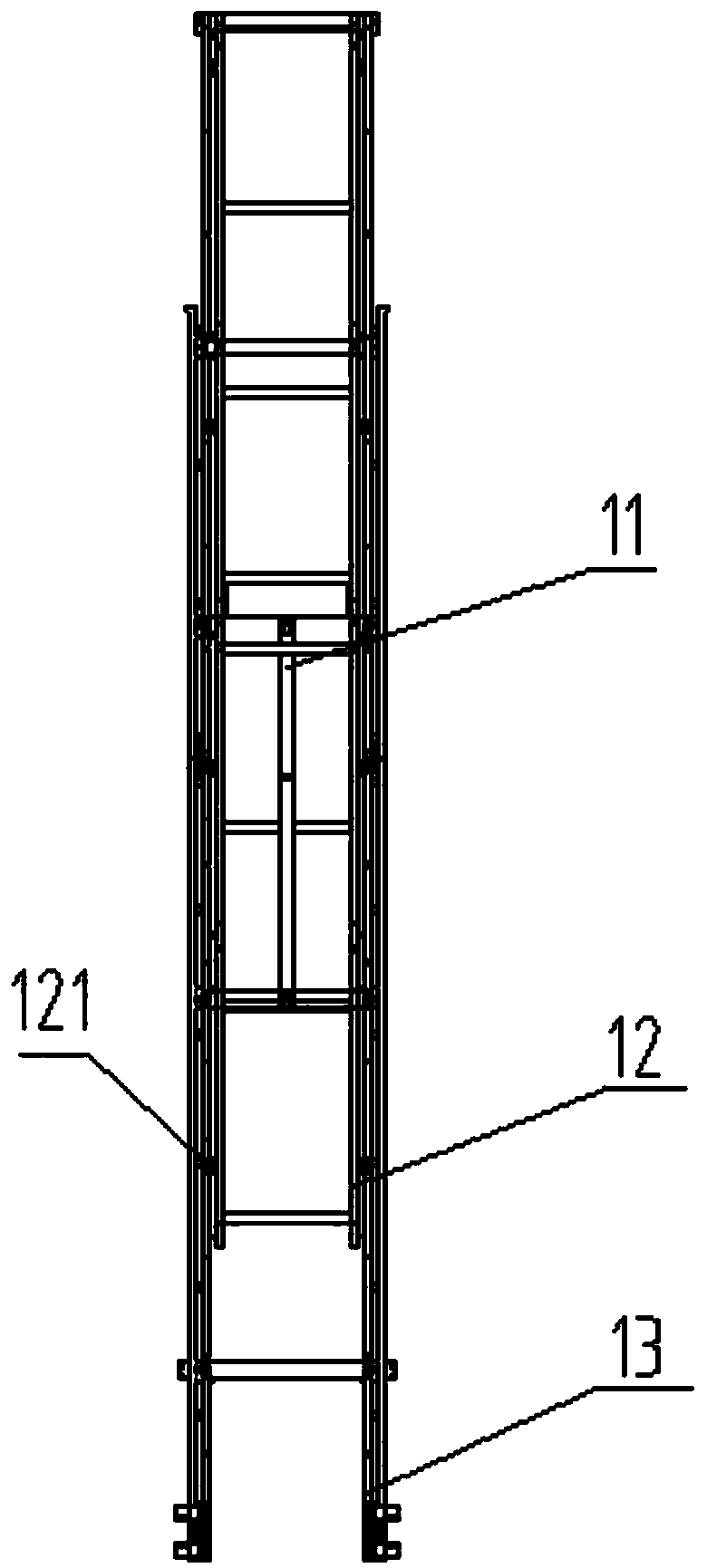

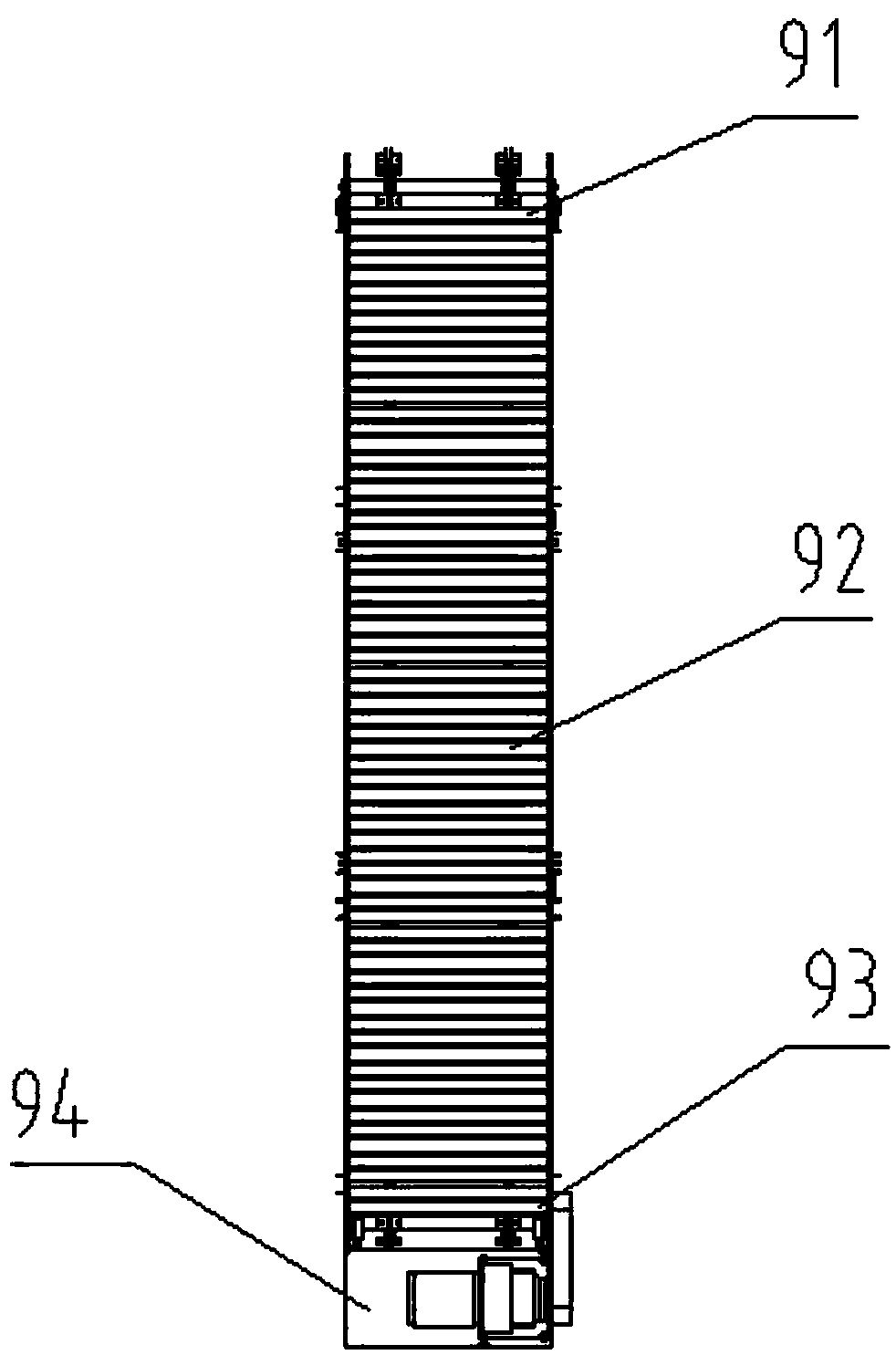

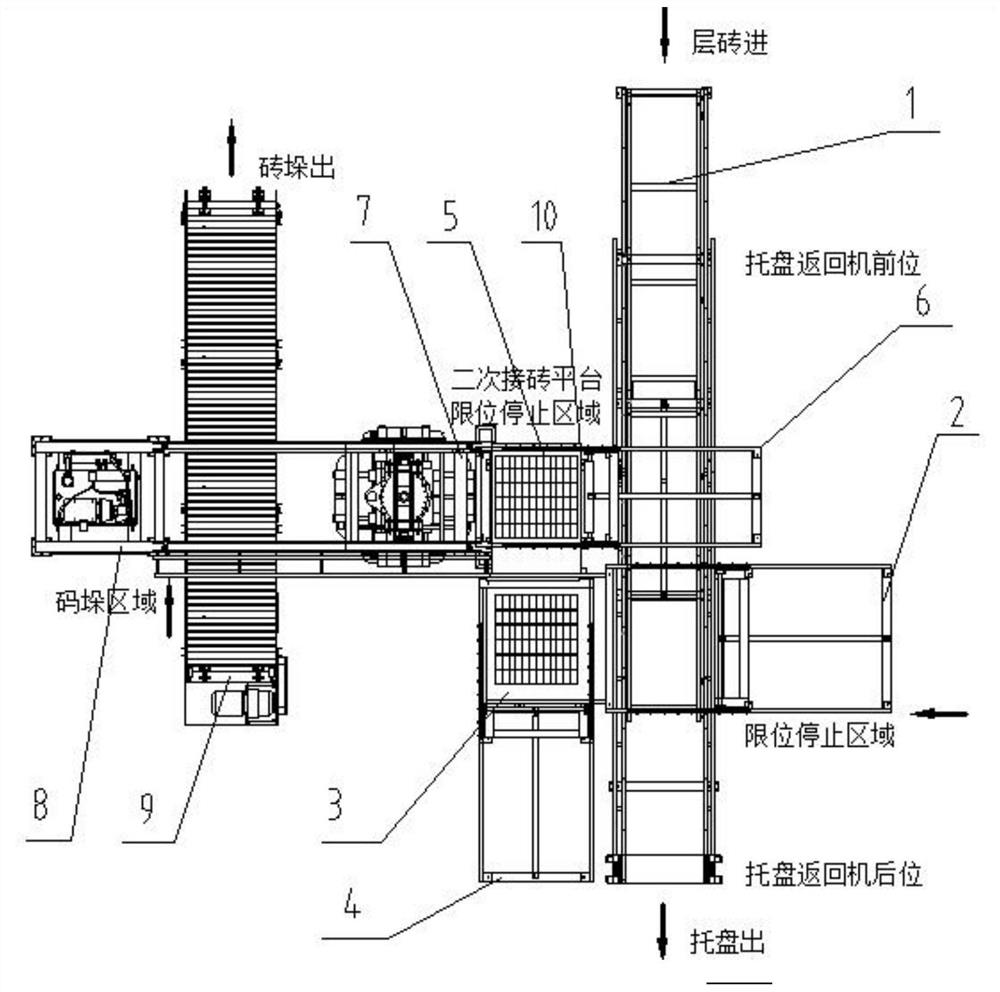

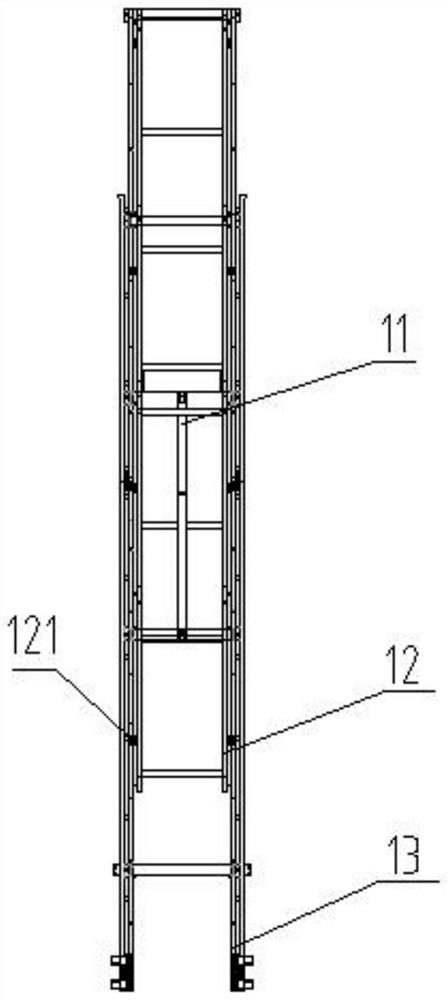

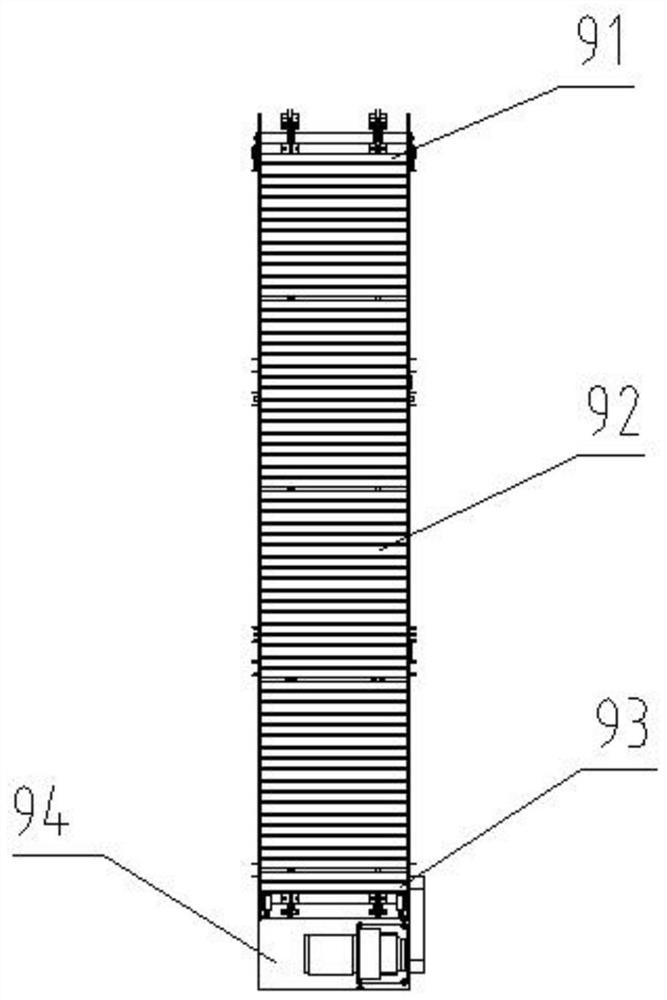

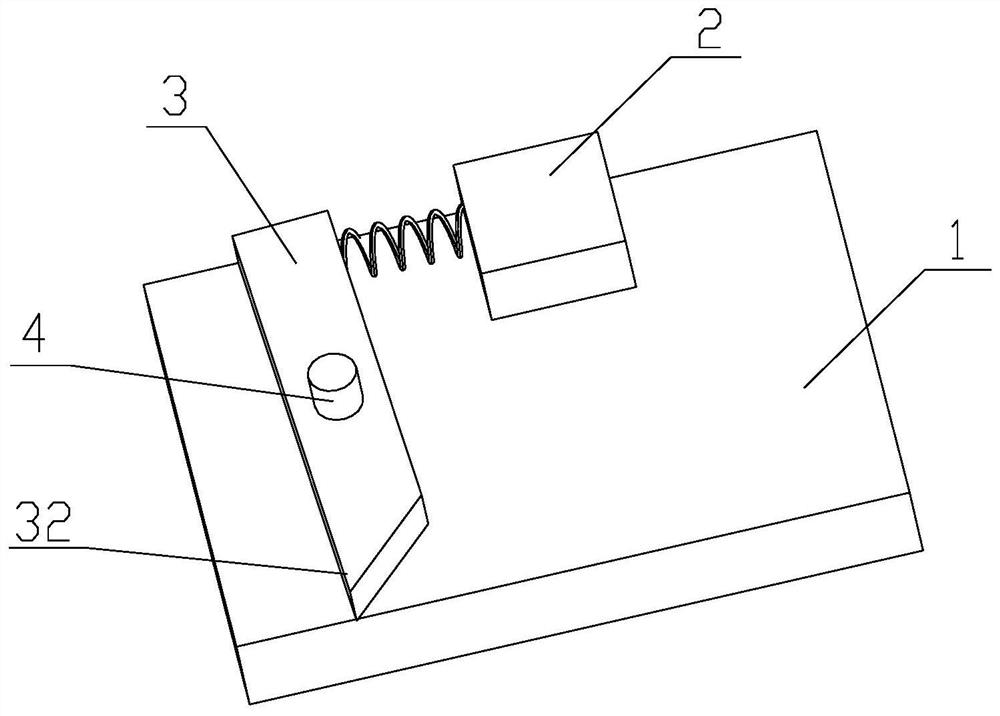

Pallet-free off-line stacking device

ActiveCN109665329AReliable transportationEfficient transportStacking articlesDe-stacking articlesBrickStack machine

The invention discloses a pallet-free off-line stacking device. The pallet-free off-line stacking device comprises a pallet returning machine, a primary brick push mechanism, a primary brick receivingplatform, a secondary brick push mechanism, a secondary brick receiving platform, a third brick push mechanism, a third brick receiving platform, a fully-automatic green brick stacking machine and apiled brick conveyor. By means of the primary brick push mechanism, bricks on each single layer can be pushed from the pallet returning machine to the primary brick receiving platform. By means of thesecondary brick push mechanism, the bricks on each single layer can be pushed from the primary brick receiving platform to the secondary brick receiving platform. By means of the third brick push mechanism, the bricks on each single layer can be pushed from the secondary brick receiving platform to the third brick receiving platform. By means of the fully-automatic green brick stacking machine, the bricks on each single layer can be clamped and delivered from the third brick receiving platform to the piled brick conveyor. The third brick push mechanism comprises two movable push block platesand multiple third fixing push plates, wherein the movable push block plates are used for pushing the bricks, and the third fixing push plates are used for achieving hole reservation operation of thebricks on each single layer. The pallet-free off-line stacking device is good in operation stability, reliable in stacking process, high in locating precision and capable of automatically stacking thebricks into piled bricks with lifting holes.

Owner:浙江诺丰环保科技有限公司

Intelligent rubber tensile testing device and testing method thereof

ActiveCN112504861APrecise displacement controlReduce impact inertiaMaterial strength using tensile/compressive forcesClassical mechanicsStructural engineering

The invention belongs to the technical field of rubber industry, particularly relates to an intelligent rubber tensile testing device and a testing method thereof, and aims to solve problems that thereplacement process of a sample is complicated and an internal sample clamp needs to be disassembled and assembled for multiple times, two ends of the rubber sample need to be tightly clamped and fixed in the testing process, and clamping parts are always broken firstly in the tensile process, and thus the testing result is inaccurate. According to the scheme, the device comprises a base, a supporting shell is fixedly installed at the top of the base, a partition plate is fixedly installed in the middle of the inner wall of the supporting shell, and a testing rotating shaft is installed at thebottom end of the interior of the supporting shell through a bearing. When a rubber strip sample is subjected to tensile detection, the impact inertia of parts at the two ends can be effectively reduced when the rubber strip is broken, the displacement of the fixing seats at the two ends is controlled more accurately, cracks and tensile states on the surface of the sample can be observed more visually in the tensile test process, and the accuracy and safety of a detection result are improved.

Owner:SHEN ZHEN SQUARE BOTTLE CO LTD

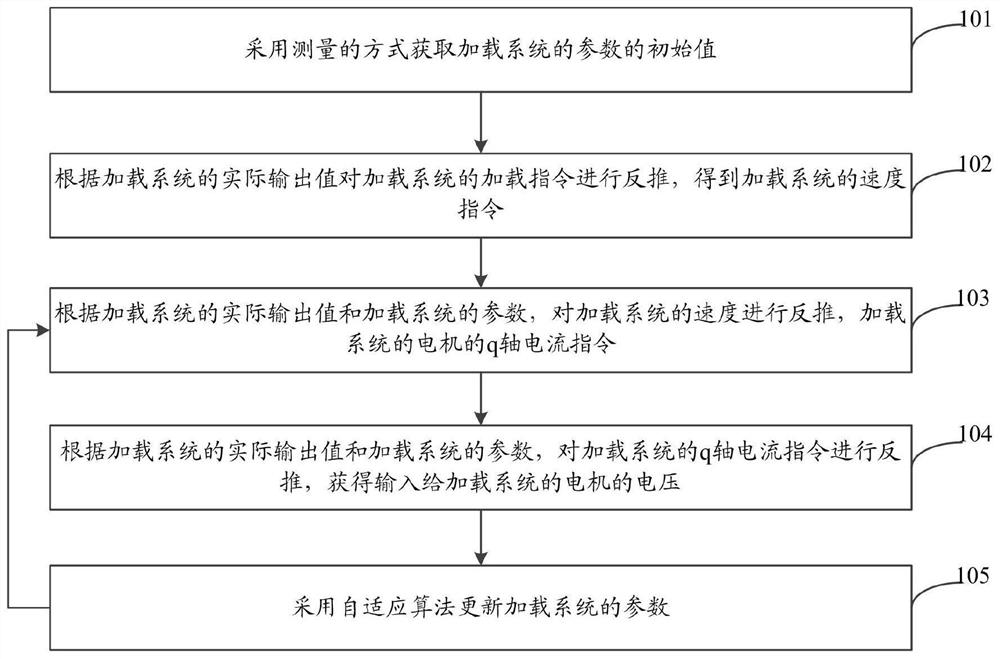

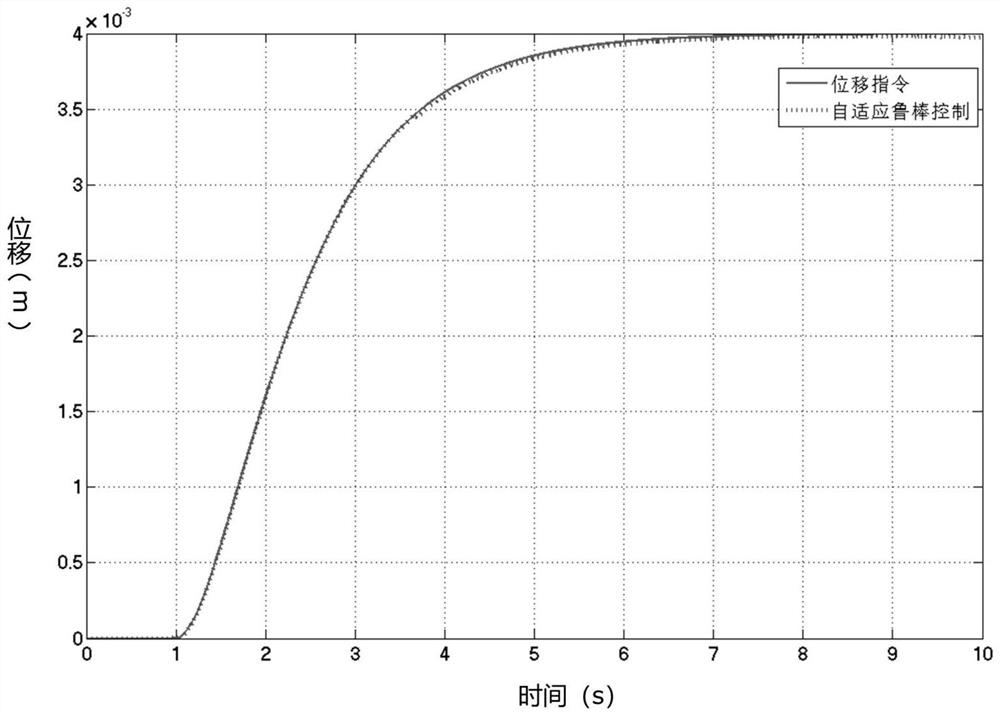

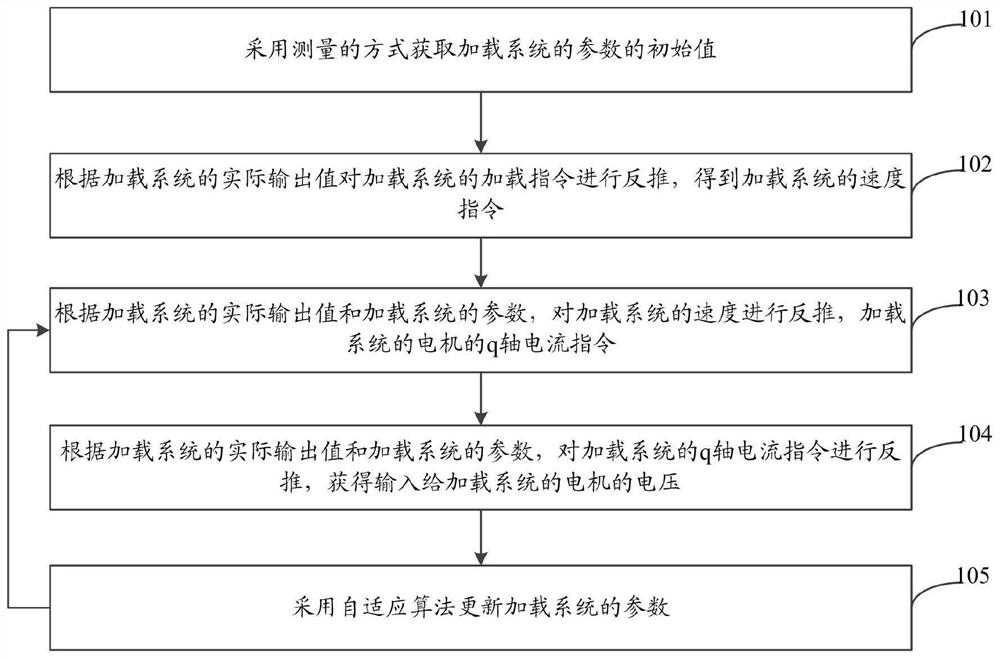

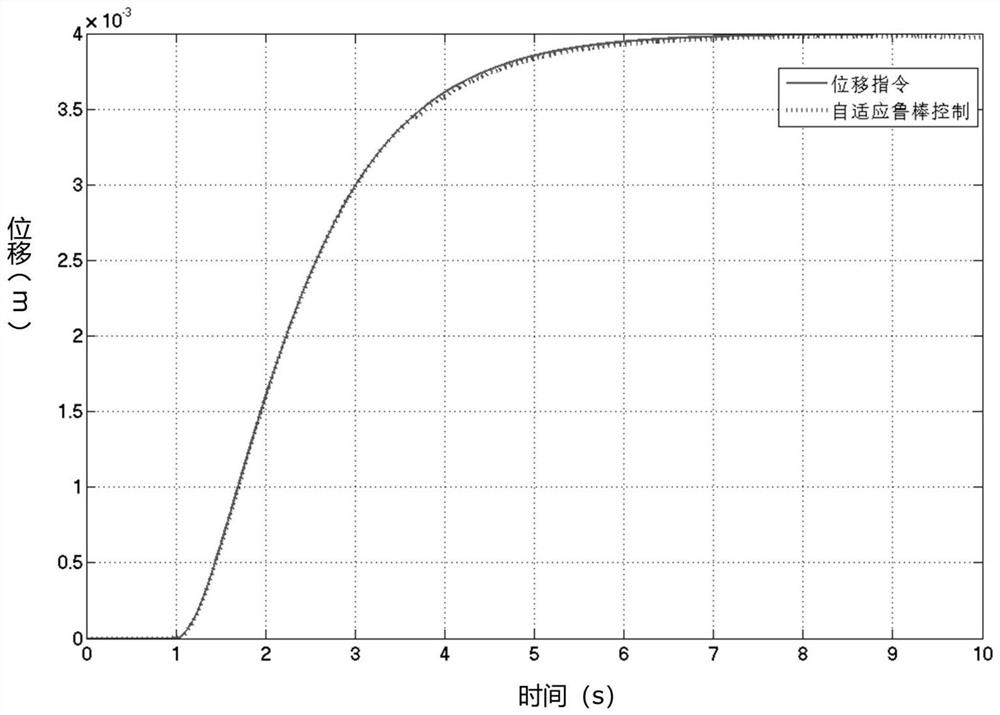

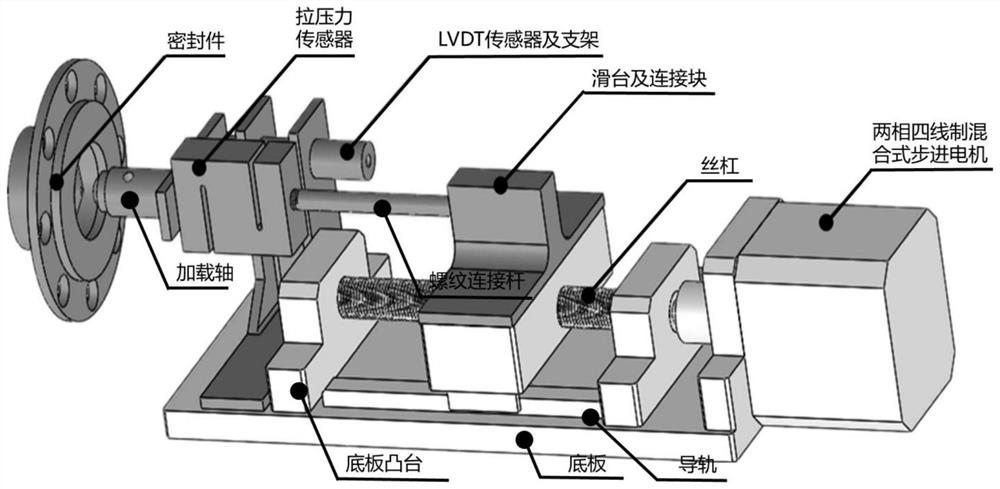

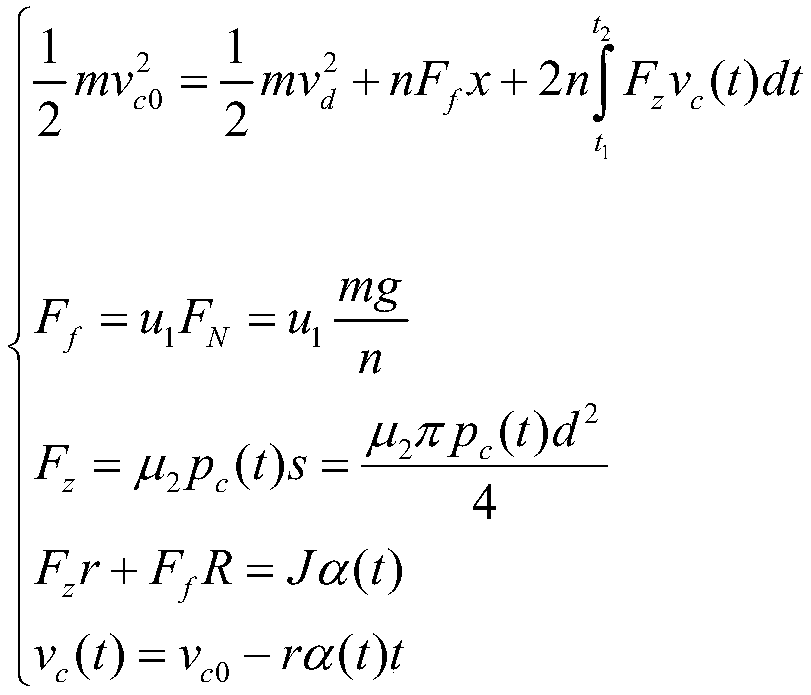

Self-adaptive robust control method of electric loading system and electric loading system

The invention discloses a self-adaptive robust control method for an electric loading system, and the control method comprises the following steps: carrying out the backstepping of a loading instruction of the loading system according to an actual output value of the loading system, and obtaining a speed instruction of the loading system; according to the actual output value of the loading systemand the parameters of the loading system, reversely deducing the speed instruction of the loading system, and obtaining a q-axis current instruction of a motor of the loading system; according to theactual output value of the loading system and the parameters of the loading system, reversely deducing the q-axis current instruction of the loading system, and obtaining the voltage input to a motorof the loading system; and updating parameters of the loading system by adopting an adaptive algorithm in the voltage calculation process. The electric loading system is controlled by adopting a self-adaptive robust control method, the influence of a high-temperature and low-temperature alternating environment on the motor performance and the influence of external disturbance on the control precision of the loading system can be effectively coped with, and accurate displacement control of the loading system is realized.

Owner:BEIHANG UNIV

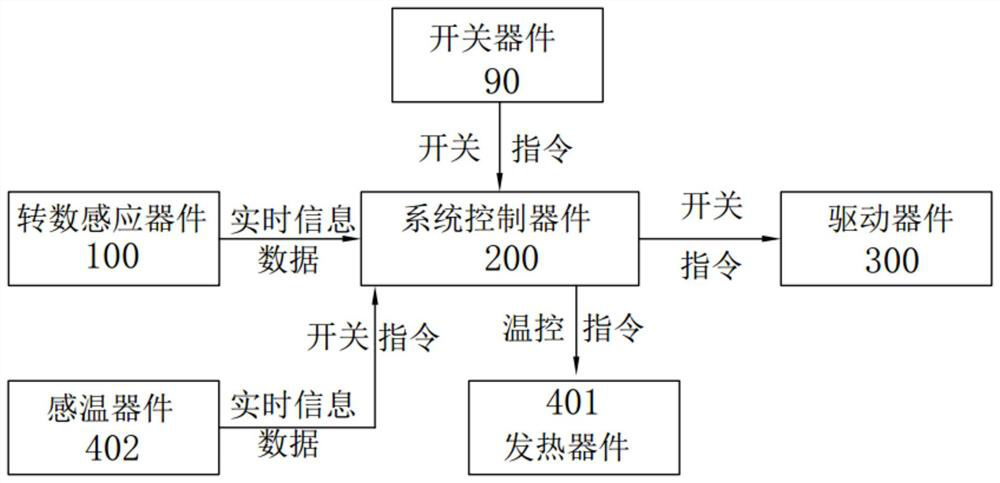

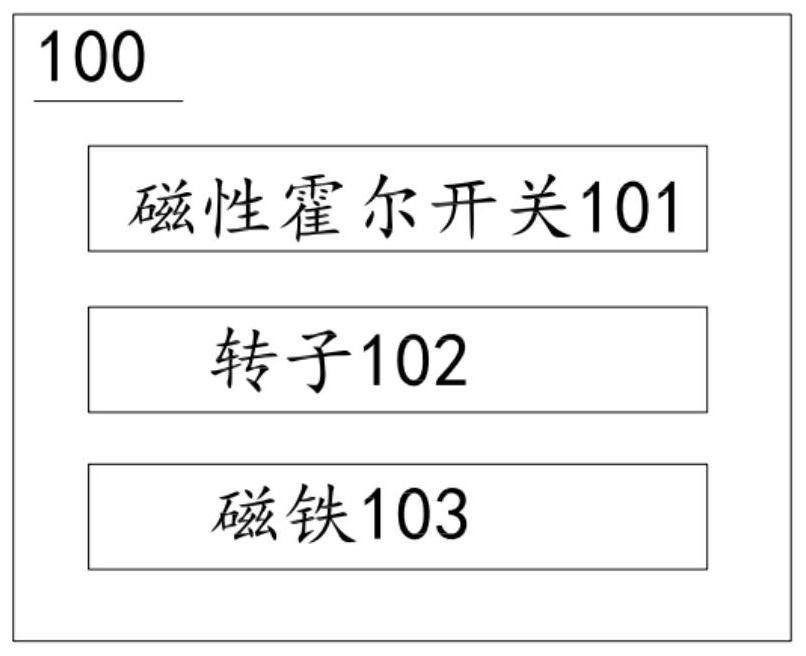

Heat-not-burn smoking set system and control method

The invention discloses a heat-not-burn smoking set system and a control method. The system comprises a system control device, and a switching device, a heating device, a driving device, a revolution sensing device and a temperature sensing device which are connected with the system control device, the switching device is used for sending a control instruction; the heating device is used for heating; the driving device is used for realizing forward or reverse rotation of a motor in the driving device for a preset number of turns; the revolution sensing device is used for collecting the revolution of the motor in real time; the temperature sensing device is used for collecting the temperature of the heating device in real time; and the system control device is used for receiving a control instruction of the switching device, receiving data acquired by the revolution sensing device and the temperature sensing device, and sending the control instruction to the heating device and / or the driving device. The driving device can prevent fuel from displacing in the cigarette to block airflow, and after smoking, residues generated during heating are greatly reduced to be left on the heating device; and the revolution sensing device collects the number of turns of rotation of the motor in real time, and accurate displacement control is achieved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

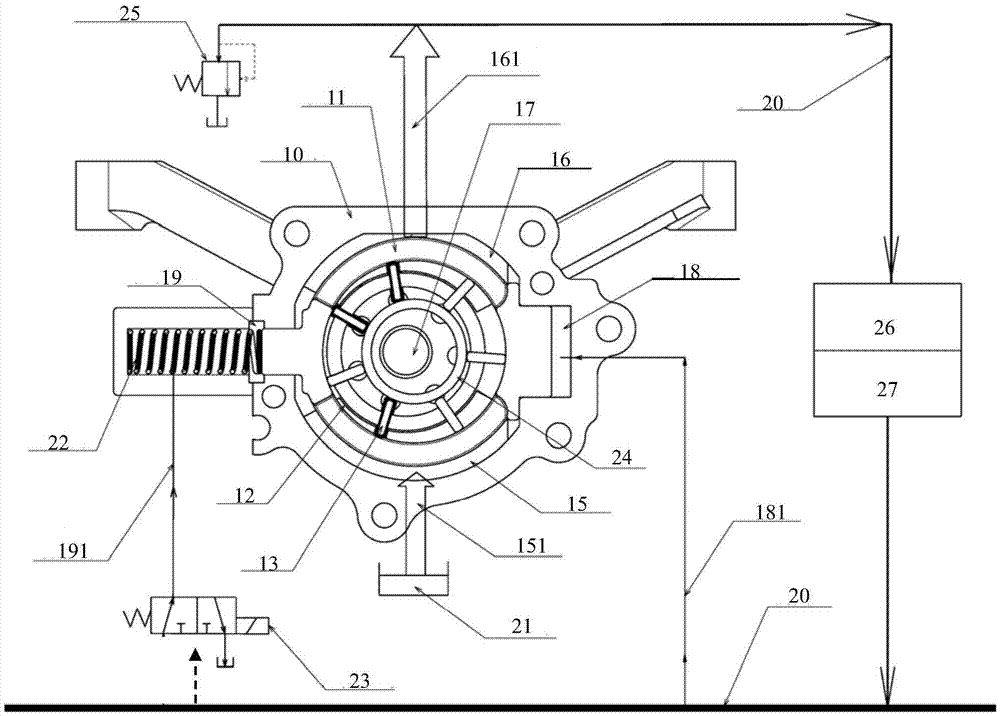

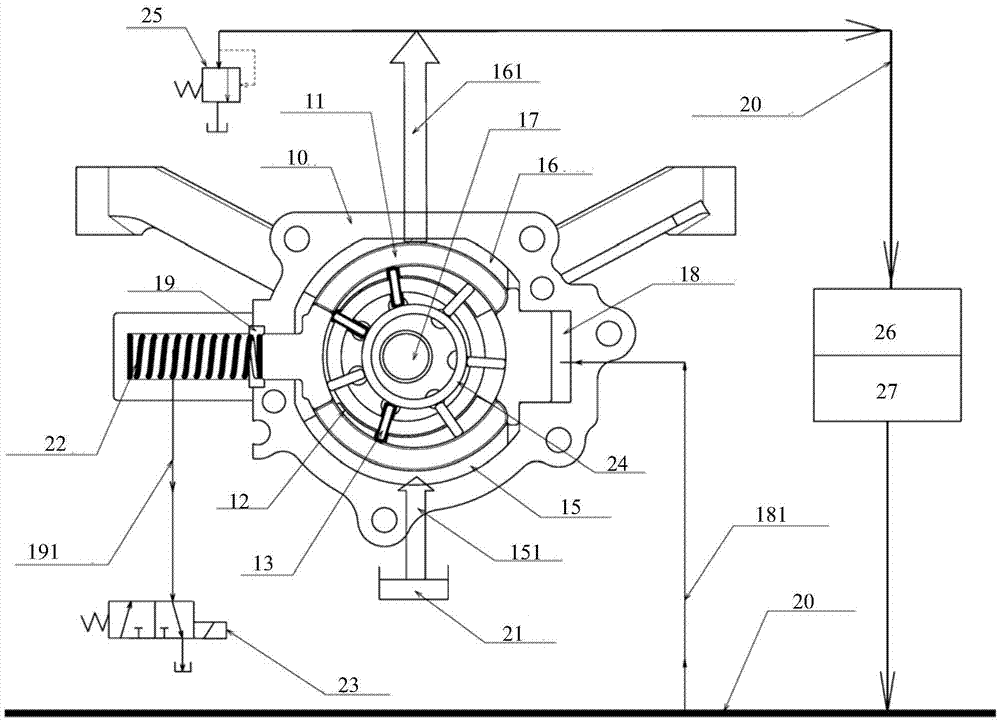

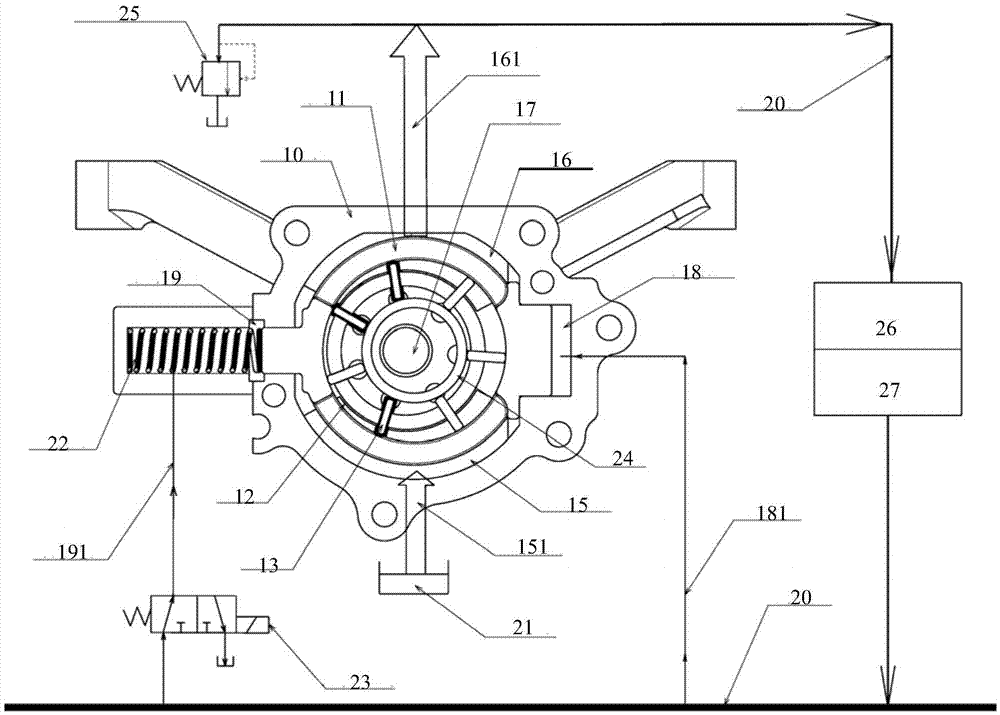

Blade variable pump

InactiveCN105443963ARealize level adjustmentReduce the impactLubricating pumpsLubrication check valvesPressure controlOil pressure

The invention provides a blade variable pump which comprises a pump body, a pump cover, a stator, a rotor and blades arranged on the rotor. A first control cavity body and a second control cavity body which are opposite to each other are formed in the inner wall of a cavity body. The two ends of the stator are provided with a first force bearing boss connected with the first control cavity body in a matched manner and a second force bearing boss connected with the second control cavity body in a matched manner. The area of a force bearing face of the second force bearing boss is smaller than that of the force bearing face of the first force bearing boss. The first control cavity body is communicated with a main oil way. The second control cavity body is connected with an oil pressure control element. At least one elastic element for providing elastic force for the stator through the first force bearing boss or the second force bearing boss is arranged. The stator can slide under the pressure control effect of the first control cavity body or the second control cavity in the linear direction of the first force bearing boss and the second force bearing boss, and the output displacement is fed back and adjusted, so that the output displacement is stable.

Owner:DONGFENG MOTOR PUMP CO LTD

Flexible flat cable conductor spacing control rod and arrangement control device

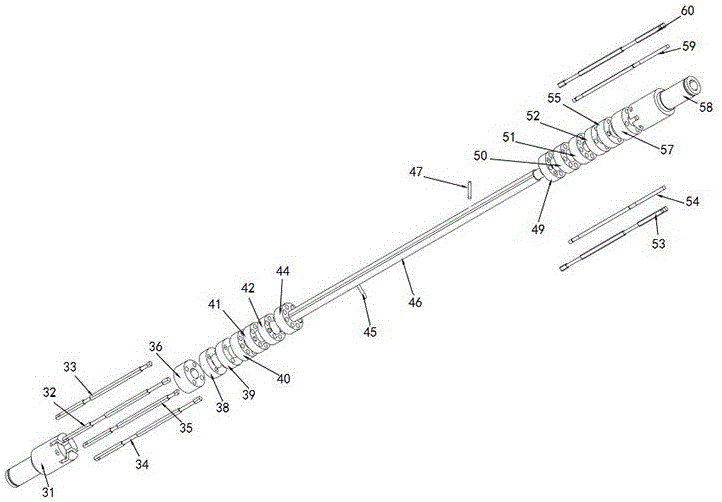

ActiveCN106847416APrecise displacement controlImprove adaptabilityManufacturing wire harnessesElectrical conductorMotor drive

The invention discloses a flexible flat cable conductor spacing control rod. The flexible flat cable conductor spacing control rod comprises a core shaft, at least one positioning wheel fixed to the core shaft, a rod group, a left control block and a right control block; the left control block and the right control block are arranged on the core shaft in a sliding mode, a left PIN wheel group sliding on the core shaft is arranged at the left side of the positioning wheels, a right PIN wheel group sliding on the core shaft is arranged at the right side of the positioning wheels, the left PIN wheel group and the right PIN wheel group form a PIN wheel group pair, and fixed wheels fixed to the core shaft are arranged at the two sides of the PIN wheel group pair; the rod group comprises a left combination rod, a left separation rod, a right combination rod and a right separation rod, the left control block is connected with the left combination rod and the left separation rod, and the right control block is connected with the right combination rod and the right separation rod so as to control combination and separation of the left PIN wheel group and the right PIN wheel group. The invention further discloses a flexible flat cable conductor spacing arrangement control device. A lead screw kinematic pair composed of a servo motor drives the left control block and the right control block. By means of the device, production of flexible flat cables with variable conductor spacing is achieved, and conductor spacing variation can be precisely and rapidly controlled.

Owner:CHANGSHU HONGBO COMM TECH CO LTD

Stamp-pad ink smearing device of stamping machine

PendingCN111559184ASimple structureOperational intelligenceStampingEngineeringElectrical and Electronics engineering

The invention discloses a stamp-pad ink smearing device of a stamping machine. The device comprises a shell, a stamp-pad ink disc and a horizontal moving mechanism, wherein a stamp inlet and outlet hole is formed in the bottom of the shell, the horizontal moving mechanism is arranged in the shell, the stamp-pad ink disc is arranged on the horizontal moving mechanism in a sliding mode, and when thestamp-pad ink disc moves to the position above the stamp inlet and outlet hole, the stamp inlet and outlet hole is shielded by the stamp-pad ink disc. According to the stamp-pad ink smearing device of the stamping machine, the stamp-pad ink disc moves above the stamp inlet and outlet hole through the horizontal moving mechanism, and the stamp-pad ink disc can add stamp-pad ink to a stamp and plays a role of a protective cover; when the stamp-pad ink disc is moved away, the stamp inlet and outlet hole is opened, and the stamp can freely enter and exit so as to perform the stamping action; whenthe stamp-pad ink disc moves back, the stamp inlet and outlet hole is shielded, the stamp is protected, and the stamp-pad ink adding action can be carried out on the stamp; and the device is simple in structure and intelligent in operation.

Owner:佛山市数融通信息科技有限公司

Piezoelectric micromirror structure and preparation method

PendingCN111413794AReduce moistureEasy to processOptical elementsWafer bondingChemical vapor deposition

A piezoelectric micromirror structure comprises a substrate wafer, a reflector metal surface, a cantilever beam structure, a metal connecting wire, a piezoelectric film, a cover plate wafer, a bondinginterface and a getter box, wherein the substrate wafer is used as a supporting and structural layer of the micromirror, the metal connecting wire is a film-shaped connecting wire, and the piezoelectric film is arranged on the cantilever beam structure. According to the preparation method for the piezoelectric micromirror structure, the substrate wafer is used as a supporting and structural layerof the micromirror, and a cavity is formed after wafer bonding; a metal reflecting mirror surface of the micromirror is manufactured by utilizing a physical vapor deposition plan, a photoetching technology, an etching or stripping technology and a polishing technology; the piezoelectric film is prepared on the cantilever beam by using a physical vapor deposition or chemical vapor deposition technology, the photoetching technology and the etching technology. The structure has the advantages that the processing is simple, the cantilever beam structure is adopted, the piezoelectric material is deposited on the cantilever beam structure, the metal surface is used as a reflector, one or more groups of arranged mirror surfaces can be packaged, the function of an optical switch and a higher deflection angle are realized, and the displacement control is accurate.

Owner:HANKING ELECTRONICS LIAONING

A pallet-free off-line palletizing device

ActiveCN109665329BReliable transportationEfficient transportStacking articlesDe-stacking articlesBrickIndustrial engineering

Owner:浙江诺丰环保科技有限公司

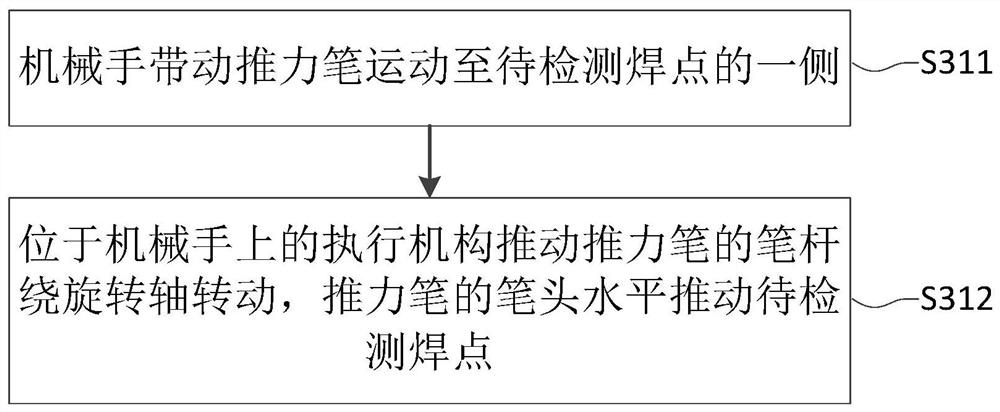

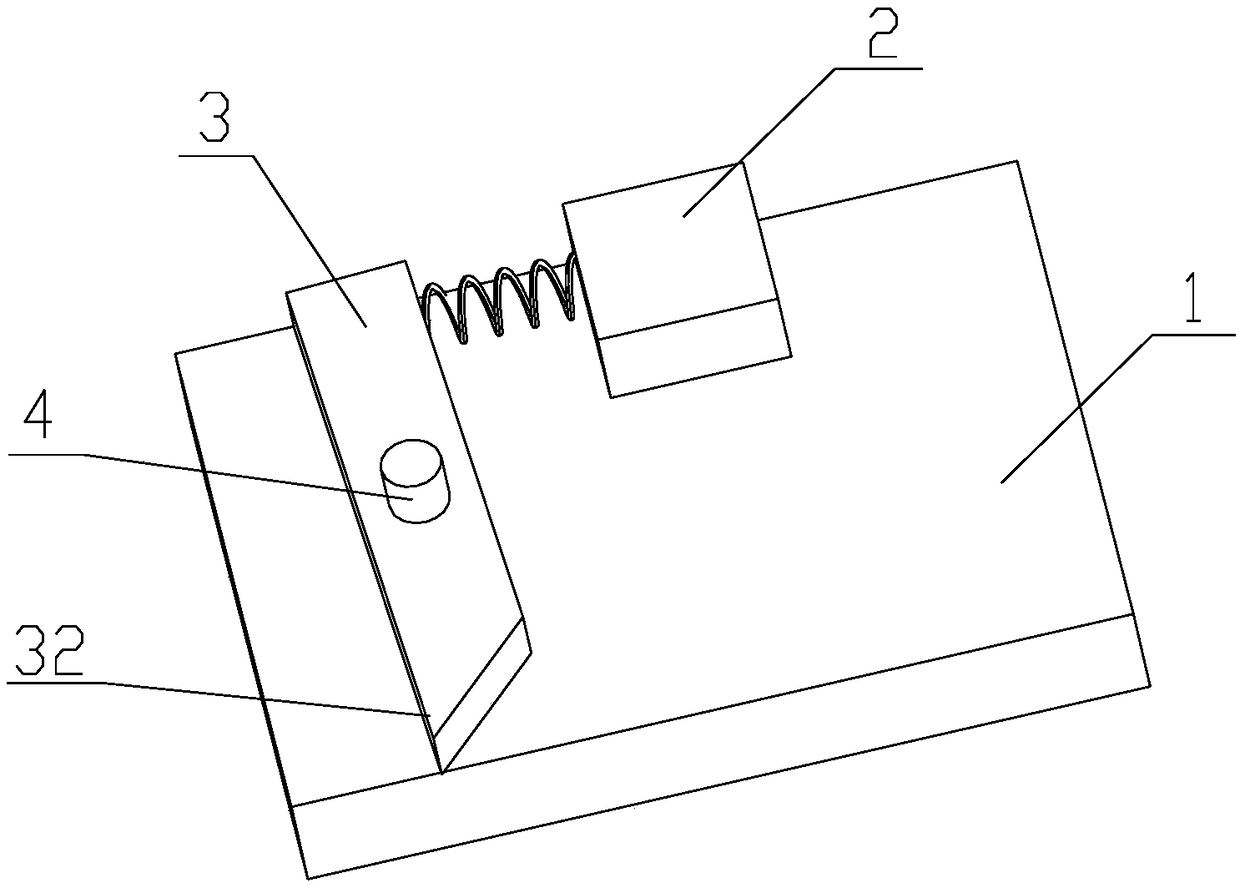

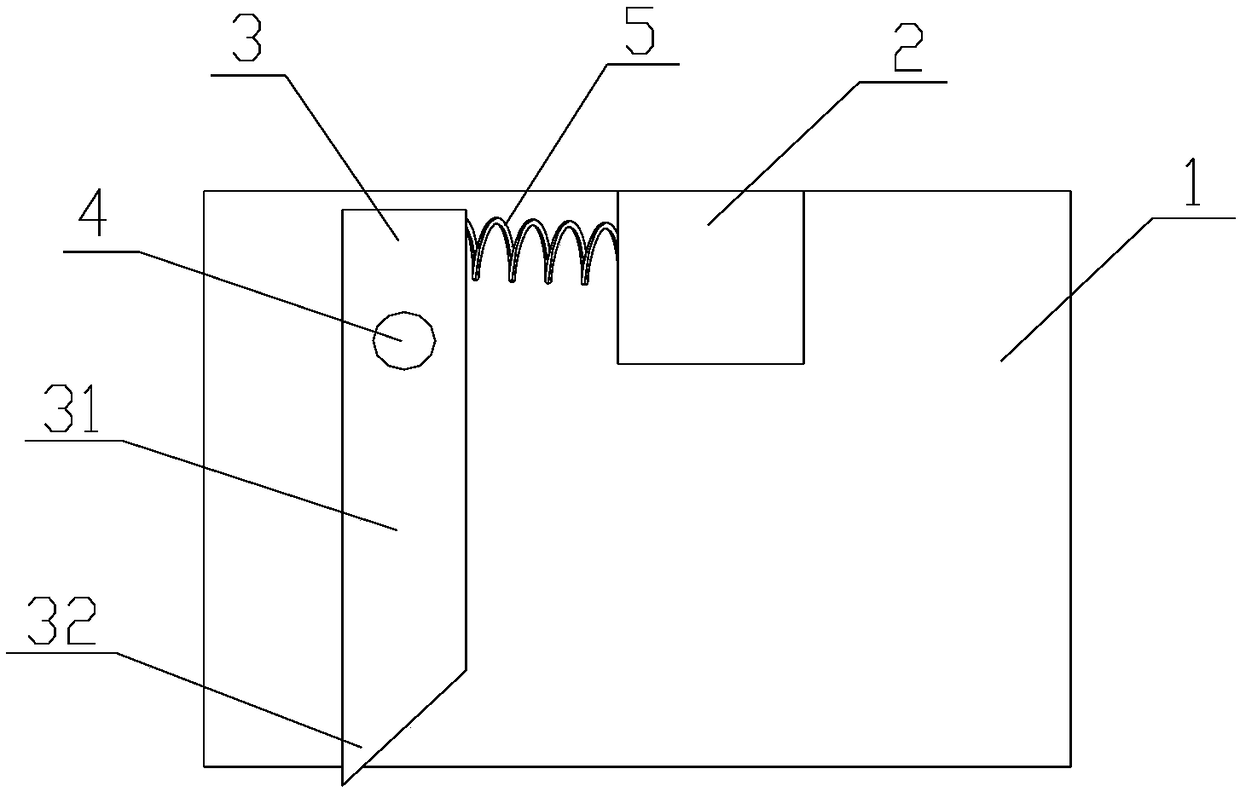

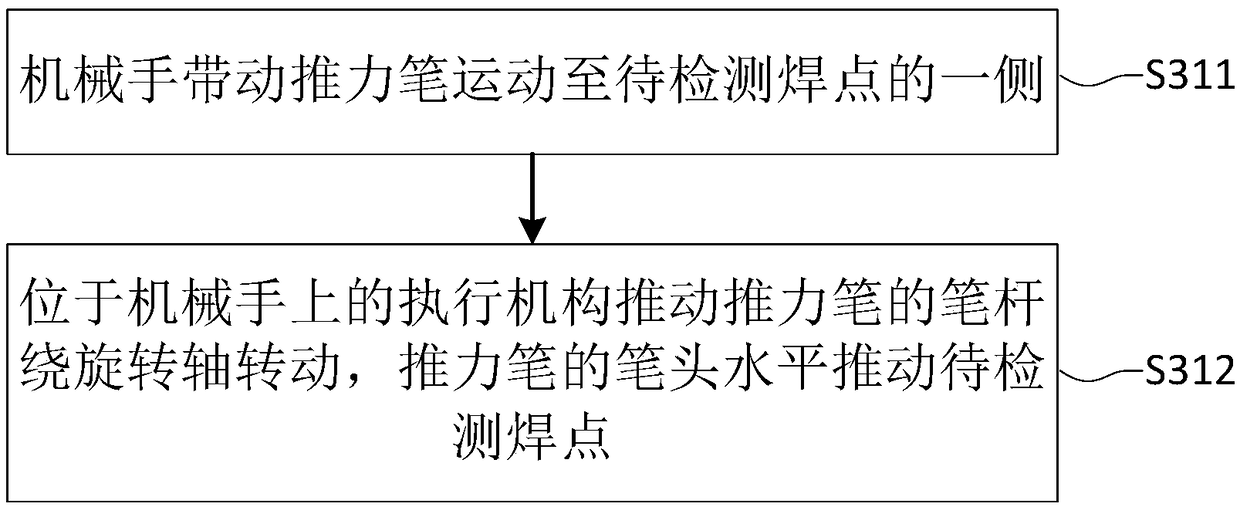

Solder joint thrust detection device and method

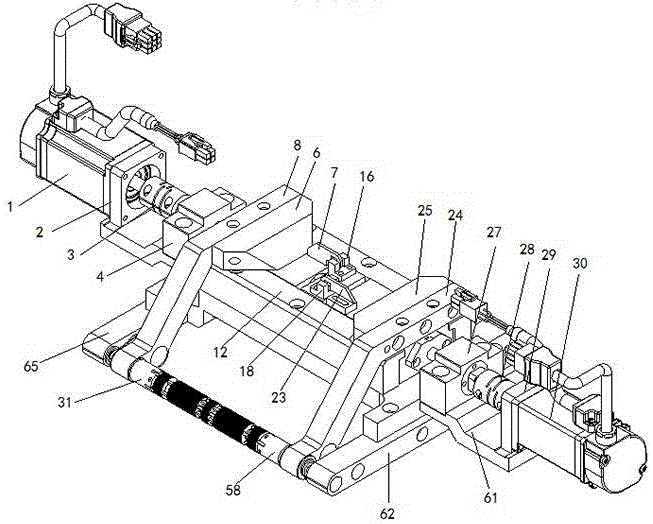

ActiveCN109030201BPrecise displacement controlReduce lost stepsMaterial strength using tensile/compressive forcesRotational axisManipulator

The invention provides a welding spot thrust detection device and method. The welding spot thrust detection device comprises a manipulator, an executing mechanism and a thrust pen, wherein the executing mechanism and the thrust pen are arranged on the manipulator; the thrust pen is fixed to the manipulator through a rotating shaft; the executing mechanism is arranged on the side, away from a to-be-detected welding spot, of the thrust pen; the manipulator is used for driving the thrust pen to move to the side, close to the executing mechanism, of the to-be-detected welding spot; and the executing mechanism is used for pushing a pen holder of the thrust pen to rotate around the rotating shaft and horizontally pushing the to-be-detected welding spot through a pen point of the thrust pen. Through the welding spot thrust detection device and method, the detection quality of the welding spot can be improved.

Owner:GOERTEK INC

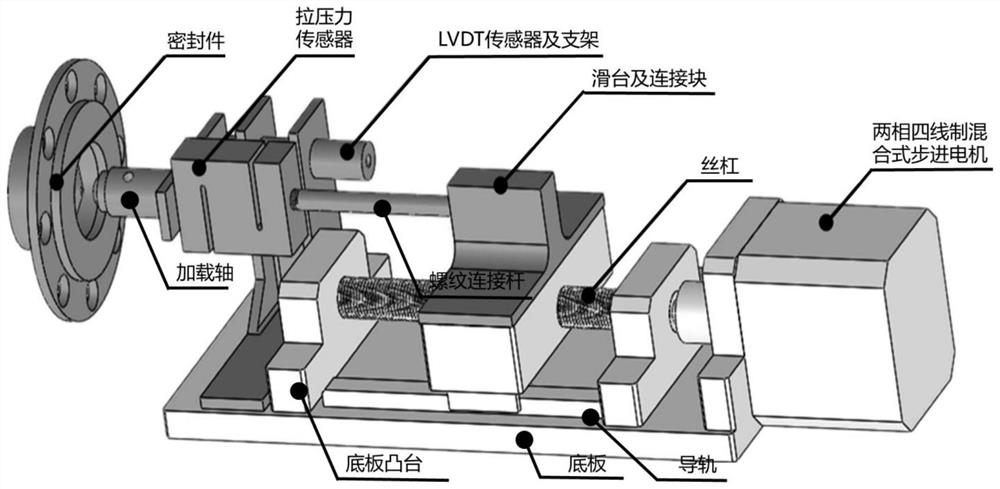

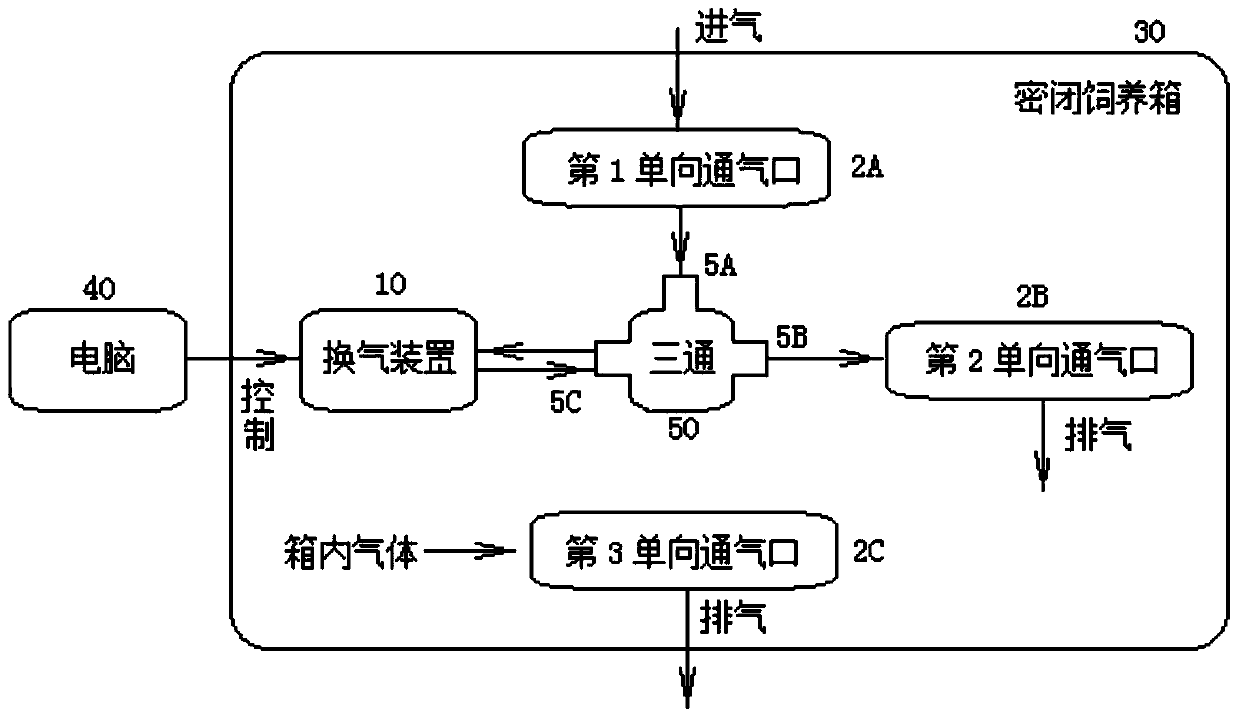

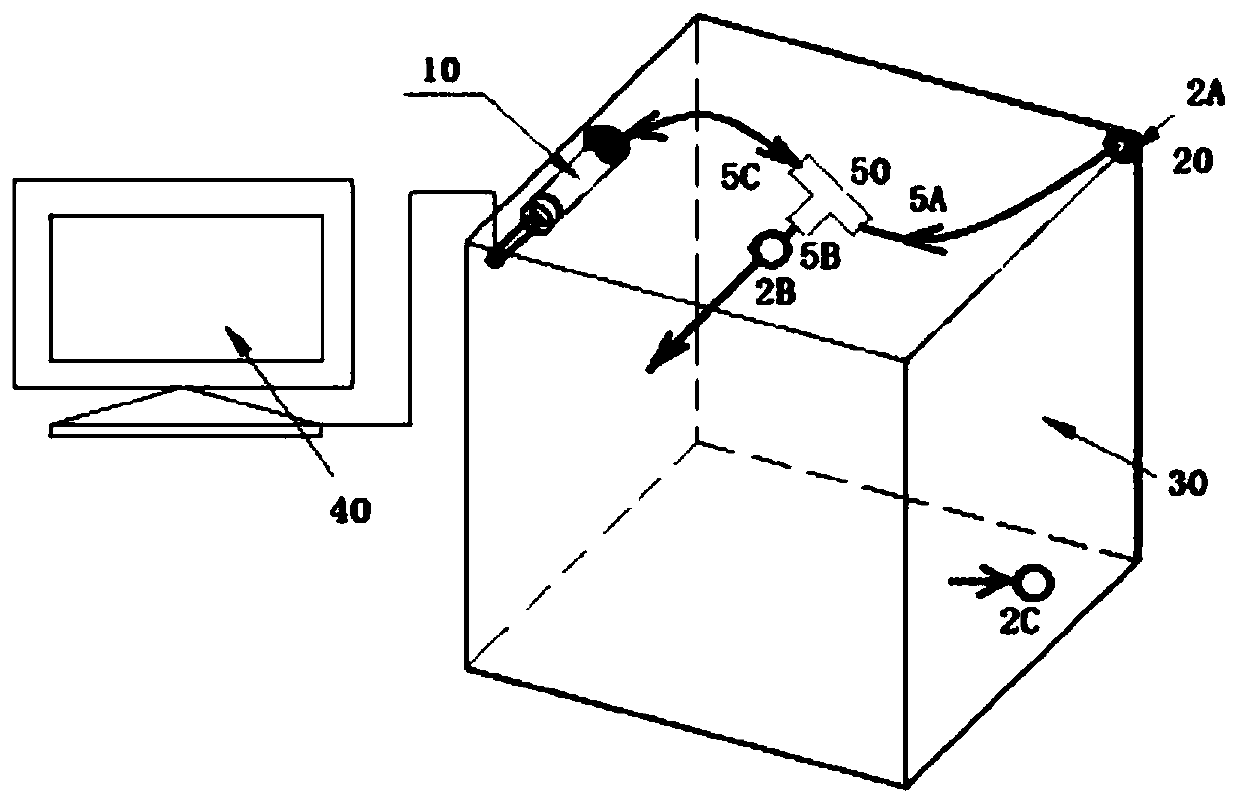

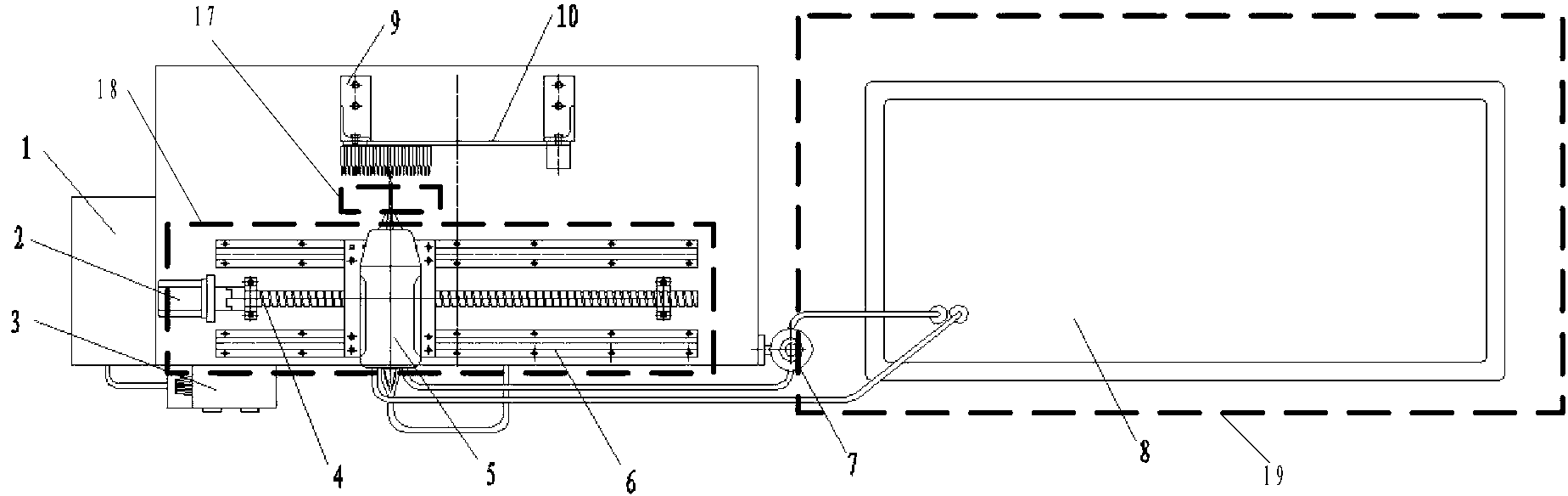

Quantitative air exchange experiment system for closed breeding box based on stepping motor

InactiveCN105594600BPrecise Control of DisplacementPrecise control of input and output volumesAnimal housingBird housingsEngineeringAir exchange

The invention discloses a quantitative air exchange experiment system for a closed breeding box based on a stepping motor, and relates to a livestock and poultry closed breeding box. The experiment system is characterized in that an air exchange device is arranged at the top on the left inner side of the closed breeding box; a first one-way air vent for air inflow is formed in the top on the right inner side of the closed breeding box; a second one-way air vent for air outflow is formed in the inner middle of the closed breeding box; a third one-way air vent for air outflow is formed in the right inner side of the closed breeding box; the first tee opening, the second tee opening and the third tee opening of a tee are respectively connected with the outlet of the first one-way air vent, the inlet of the second one-way air vent and the outlet of a piston sleeve of the air exchange device; a computer is connected with the stepping motor of the air exchange device. Through the adoption of the stepping motor for control, the purpose of accurately controlling the air input-output volume is achieved; through the adoption of the one-way air vents, one-way flow of air is ensured, and the accurate quantitative air exchange is realized; the experiment system is suitable for accurate control of air control amount in the closed breeding environment.

Owner:HUAZHONG AGRI UNIV

A high temperature gas-cooled reactor reactor pressure vessel inspection device

ActiveCN105810259BSimple form of exercisePrecise displacement controlNuclear energy generationNuclear monitoringReactor pressure vesselEngineering

The technology belongs to the field of pressure vessel inspection devices, and in particular relates to a high-temperature gas-cooled reactor pressure vessel inspection device. The inspection device 1 is located between the outer cylinder wall 2 of the pressure vessel and the cabin cylinder wall 3. The inspection device 1 includes a circular guide rail 4, a track running trolley 5, a lifting rod 6, a two-axis scanner 7, a positioning pin pointing mechanism 8, and a circular guide rail. 4 is a whole ring spliced by a plurality of arc guide rails; the track running trolley 5 is located on the circular guide rail 4 and can move along the track; a lifting rod 6 is installed on the track running trolley 5, and the lower end of the lifting rod 6 carries a positioning pin to point to the mechanism 8. It can be controlled and fixed with the positioning pin at the bottom of the pressure vessel. The lower end of the lifting rod 6 of the present invention carries a positioning pin pointing mechanism 8, which can be controlled and fixed with the positioning pin at the bottom of the pressure vessel.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Automatic high-frequency needle burning machine

InactiveCN103290197AUniform annealingReduce labor intensityIncreasing energy efficiencyFurnace typesEngineeringAutomation

The invention relates to an automatic high-frequency needle burning machine. The machine comprises a high-frequency probe, a heating unit, a travel unit, a cooling unit and an electrical cabinet, wherein the bottom of the high-frequency probe is fixed with a movable connection end of the travel unit, the needle head of the high-frequency probe is fixed with a heating end of the heating unit, a cooling connection end of the cooling unit is communicated with the interior of the high-frequency probe, and the electrical cabinet is used for supplying power for the high-frequency probe, the heating unit, the travel unit and the cooling unit. According to the machine, the current can be adjusted and the temperature can be controlled according to annealing requirements of different kinds of products, the running speed of a high-frequency heating head can be controlled by a stepping motor, so that the annealing of the needle head is uniform, and the product quality is improved; the heating speed of the heating unit is much higher than the heating speed of a traditional alcohol blast burner technology, and the automation advantage of the machine can reduce the labor intensity of an operator, reduce the production cost and improve the work efficiency; no pollution exists after alcohol burning, so that the cleanliness requirement and the environment protection requirement of the product are met.

Owner:SANMENXIA XINHONG PRECISION TEXTILE EQUIP

An anti-shake periscope module

The invention discloses an anti-shake periscope module, which comprises: a base, a rotating bracket set movably relative to the base, a prism bracket set movably relative to the rotating bracket, and embedded in the prism bracket A prism, a frame fitted with the base, a shell wrapped around the fixed base and the outer periphery of the frame; a first ball assembly, the first ball assembly includes a cylindrical base with a flat end and a plane fixed to the cylindrical base The first magnetic plate seat on the first magnetic plate seat is provided with a fitting groove, and the first magnetic plate is fitted in the fitting groove, and the first magnetic plate is provided on the end surface of the inclined base away from the prism. Magnet fitting groove. According to the present invention, the structure is simple, the performance of the motor is improved and the performance of the motor is stable, and the displacement control of the periscope motor is precise, the power consumption is lower, and the size is reduced to achieve a better anti-shake effect.

Owner:SHANGHAI BILLU ELECTRONICS CO LTD

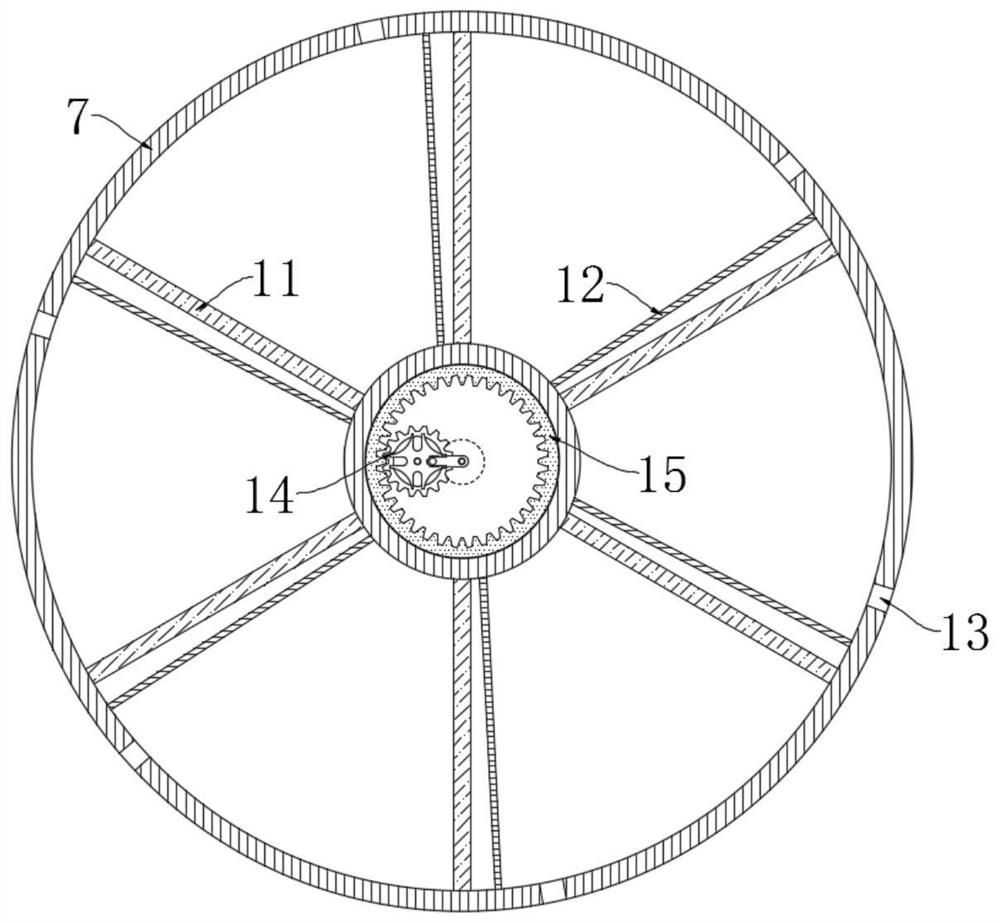

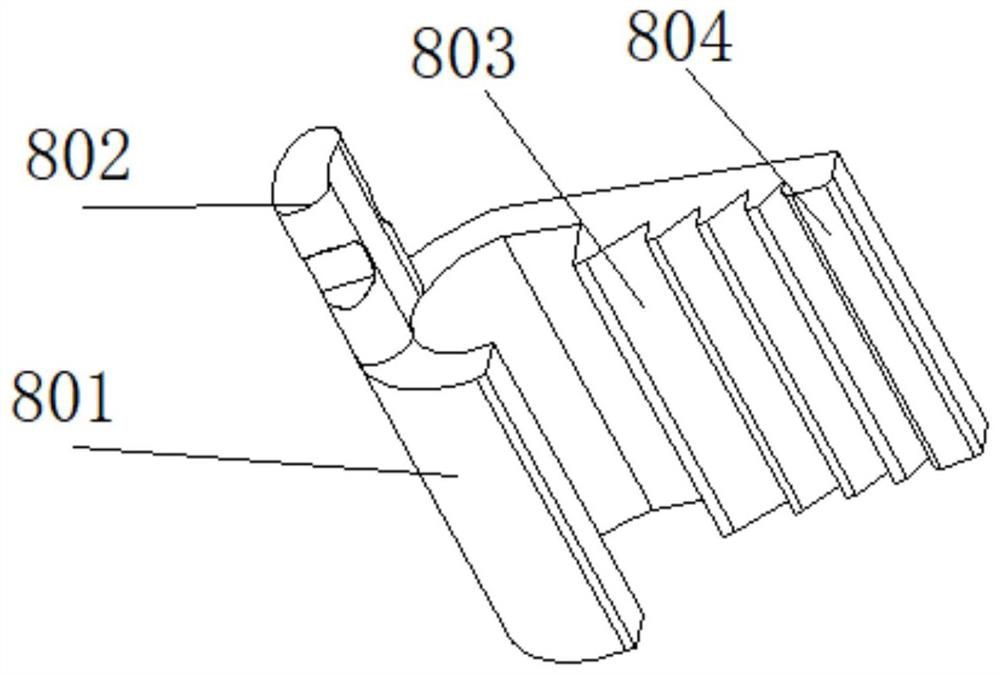

High-speed notching machine

ActiveCN103949526APrecise displacement controlFor precise cuttingMetal-working feeding devicesPositioning devicesDisplacement controlEngineering

The invention provides a high-speed notching machine and relates to the field of machining equipment. The high-speed notching machine comprises a machine body, a motor, an indexing box, a swinging block mechanism and a driving mechanism, wherein the motor, the indexing box, the swinging block mechanism and the driving mechanism are arranged on the machine body; the motor is connected with the swinging block mechanism; the indexing box comprises an indexing spindle and an indexing box body; the indexing spindle is horizontally and slidably arranged on the indexing box body; the indexing box body is horizontally and slidably arranged on a guide rail arm extending out of the machine body; the indexing box body is connected with the guide rail arm through at least one rolling guide rail pair; a screw rod is further arranged between the indexing box body and the guide rail arm; one end of the screw rod is connected with the indexing box body, and the other end of the screw rod penetrates through the guide rail arm and is connected with the driving mechanism. According to the high-speed notching machine provided by the invention, the indexing box is connected with the machine body by using a rolling sliding pair; the friction force of the rolling sliding pair is stable and easy to control, so that displacement of the indexing box on the machine body can be accurately controlled, and a sample can be more accurately cut and can be more conveniently controlled.

Owner:芜湖天鹏数控高速冲槽机制造有限公司

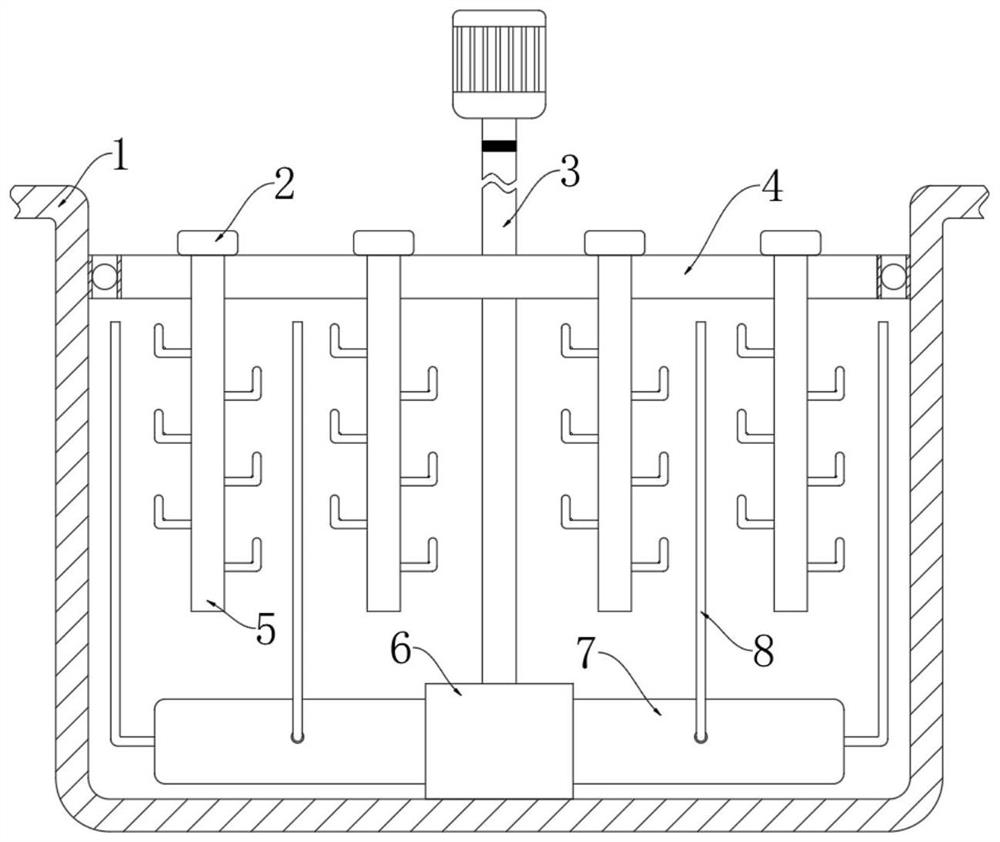

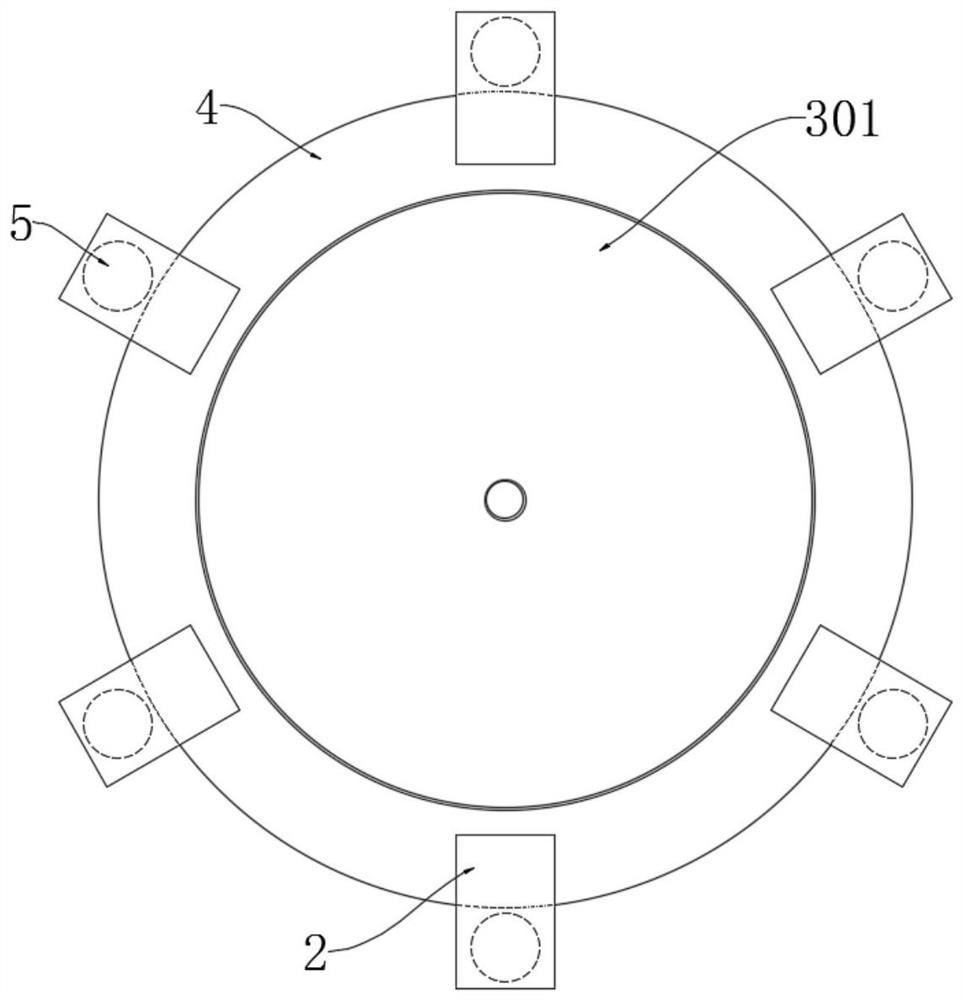

Electroplating equipment capable of reducing edge effect and working method of electroplating equipment

InactiveCN111850666AConsistent thicknessUniform distribution of ionsCellsInterference fitElectric machine

The invention discloses a working method of electroplating equipment capable of reducing an edge effect. The working method comprises the following steps of S1, clamping a workpiece; S2, supplementingelectrolyte; and S3, electroplating. The electroplating equipment comprises a plating tank and a driving motor; a positioning disc is rotationally installed in the plating tank through a bearing, a plurality of hangers are circumferentially connected to the positioning disc through a fixed seat, an output shaft of the driving motor is fixedly connected with a rotating shaft through a coupler, andthe rotating shaft is coaxial with the positioning disc and fixedly connected with the positioning disc through a connecting disc; and the bottom end of the rotating shaft is fixedly connected with atransmission mechanism, and the transmission mechanism is in interference fit with an annular sealing box. The edge effect during electroplating can be effectively reduced, the bubble adhesion on thesurface of a workpiece is reduced, the plating quality is improved, and in addition, position distribution of the hangers can be quickly changed according to workpiece specification, and the platingthickness is more uniform.

Owner:孙国栋

A rubber tensile intelligent testing device and testing method thereof

ActiveCN112504861BPrecise displacement controlReduce impact inertiaMaterial strength using tensile/compressive forcesClassical mechanicsDisplacement control

The invention belongs to the technical field of the rubber industry, in particular to a rubber tensile intelligent testing device and a testing method thereof. The replacement process of the sample is cumbersome, and the internal sample fixture needs to be disassembled many times. Secondly, during the testing process, the rubber The two ends of the sample need to be tightly clamped and fixed. During the stretching process, the clamped part is often broken first, resulting in inaccurate test results. The following scheme is proposed, including the base, and the top of the base is fixedly installed with a support shell. In addition, a partition is fixedly installed in the middle of the inner wall of the support housing, and a test rotating shaft is installed at the inner bottom of the support housing through a bearing. The present invention can effectively reduce the impact inertia of the parts at both ends when the rubber strip is broken when performing tensile testing on the rubber strip sample. Secondly, the displacement control of the fixing seats at both ends is more accurate, and it can be more intuitive during the tensile test process. It can accurately observe the surface crack and tensile state of the sample, and improve the accuracy and safety of the test results.

Owner:SHEN ZHEN SQUARE BOTTLE CO LTD

Preparation method and preparation mold of amorphous alloy-copper laminated composite material

ActiveCN102848073BGood removal effectGuaranteed accuracyNon-electric welding apparatusRoom temperatureAtomic diffusion

Owner:NORTHWESTERN POLYTECHNICAL UNIV

An adaptive robust control method for an electric loading system and the electric loading system

The invention discloses an adaptive robust control method for an electric loading system. The control method includes the following steps: reversely push the loading instruction of the loading system according to the actual output value of the loading system to obtain the speed instruction of the loading system; The actual output value of the loading system and the parameters of the loading system are reversed to the speed command of the loading system to obtain the q-axis current command of the motor of the loading system; according to the actual output value of the loading system and the parameters of the loading system, the The q-axis current command is reversed to obtain the voltage input to the motor of the loading system; and an adaptive algorithm is used to update the parameters of the loading system during the voltage calculation process. The electric loading system in the present invention is controlled by an adaptive and robust control method, which can effectively cope with the impact of high and low temperature alternating environments on the performance of the motor, as well as the impact of external disturbances on the control accuracy of the loading system, and realize Precise displacement control of the loading system.

Owner:BEIHANG UNIV

A conical/cylindrical linear raceway ultra-precision equipment

ActiveCN104690619BPrecise displacement controlSimple structureGrinding machinesSuperfinishing machinesSuperfinishingEngineering

The invention discloses conical / cylindrical linear rollaway nest superfinishing equipment. The conical / cylindrical linear rollaway nest superfinishing equipment comprises an operating table and a material feeding and discharging conveying mechanism arranged on the operating table, wherein a big reciprocating and small vibrating mechanism, a rollaway nest superfinishing swinging head and a flange superfinishing swinging head are further arranged on the operating table; a feeding opening is formed in the middle of the material feeding and discharging conveying mechanism; a main shaft is arranged on the back side of the feeding opening; an inner hole centering component is arranged at the upper end of the main shaft; the big reciprocating and small vibrating mechanism comprises a big reciprocating mechanism and a small vibrating mechanism; the big reciprocating mechanism and the small vibrating mechanism are connected through a first connecting plate; a first skipping component is arranged on the back side of the rollaway nest superfinishing swinging head; a second skipping component is arranged on the back side of the flange superfinishing swinging head; both the rollaway nest superfinishing swinging head and the flange superfinishing swinging head are driven by the big reciprocating and small vibrating mechanism for superfinishing. The conical / cylindrical linear rollaway nest superfinishing equipment performs rollaway nest superfinishing and flange superfinishing at the same time, is simplex in rollaway nest superfinishing vibration and stable and reliable in working conveying, and can meet superfinishing requirements of a high-precision workpiece.

Owner:WUXI LANMA MACHINERY MFR

Brake control system and method for an unmanned vehicle

ActiveCN106740764BSimple structureImprove transmission efficiencyBraking action transmissionAutomatic initiationsWheel speed sensorControl system

The invention provides an unmanned vehicle braking control system and method. The unmanned vehicle braking control system comprises an electric cylinder, a braking pipeline system, a data collection card, a controller, a decision making layer, a wheel speed sensor for detecting vehicle speed and an oil pressure meter for detecting braking pressure of the braking pipeline system, the data collection card is used for collecting data of the wheel speed sensor and the oil pressure meter, the decision making layer sends an expected vehicle speed signal to the controller, and the controller is used for collecting data transmitted by the decision making layer and data of the oil pressure meter. Braking effect controllable in braking force is accurately realized by collecting current vehicle speed and current braking pressure, comparing them with expected vehicle speed and expected braking pressure and controlling extension and contraction of the electric cylinder.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Welding spot thrust detection device and method

ActiveCN109030201APrecise displacement controlReduce lost stepsMaterial strength using tensile/compressive forcesManipulatorAerospace engineering

The invention provides a welding spot thrust detection device and method. The welding spot thrust detection device comprises a manipulator, an executing mechanism and a thrust pen, wherein the executing mechanism and the thrust pen are arranged on the manipulator; the thrust pen is fixed to the manipulator through a rotating shaft; the executing mechanism is arranged on the side, away from a to-be-detected welding spot, of the thrust pen; the manipulator is used for driving the thrust pen to move to the side, close to the executing mechanism, of the to-be-detected welding spot; and the executing mechanism is used for pushing a pen holder of the thrust pen to rotate around the rotating shaft and horizontally pushing the to-be-detected welding spot through a pen point of the thrust pen. Through the welding spot thrust detection device and method, the detection quality of the welding spot can be improved.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com