Stamp-pad ink smearing device of stamping machine

A stamping machine and printing ink technology, applied in printing, stamping, etc., can solve the problems affecting the quality of intelligent stamping, easy to forget to cover the protective cover, complex internal structure, etc., to achieve simple structure, easy removal, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

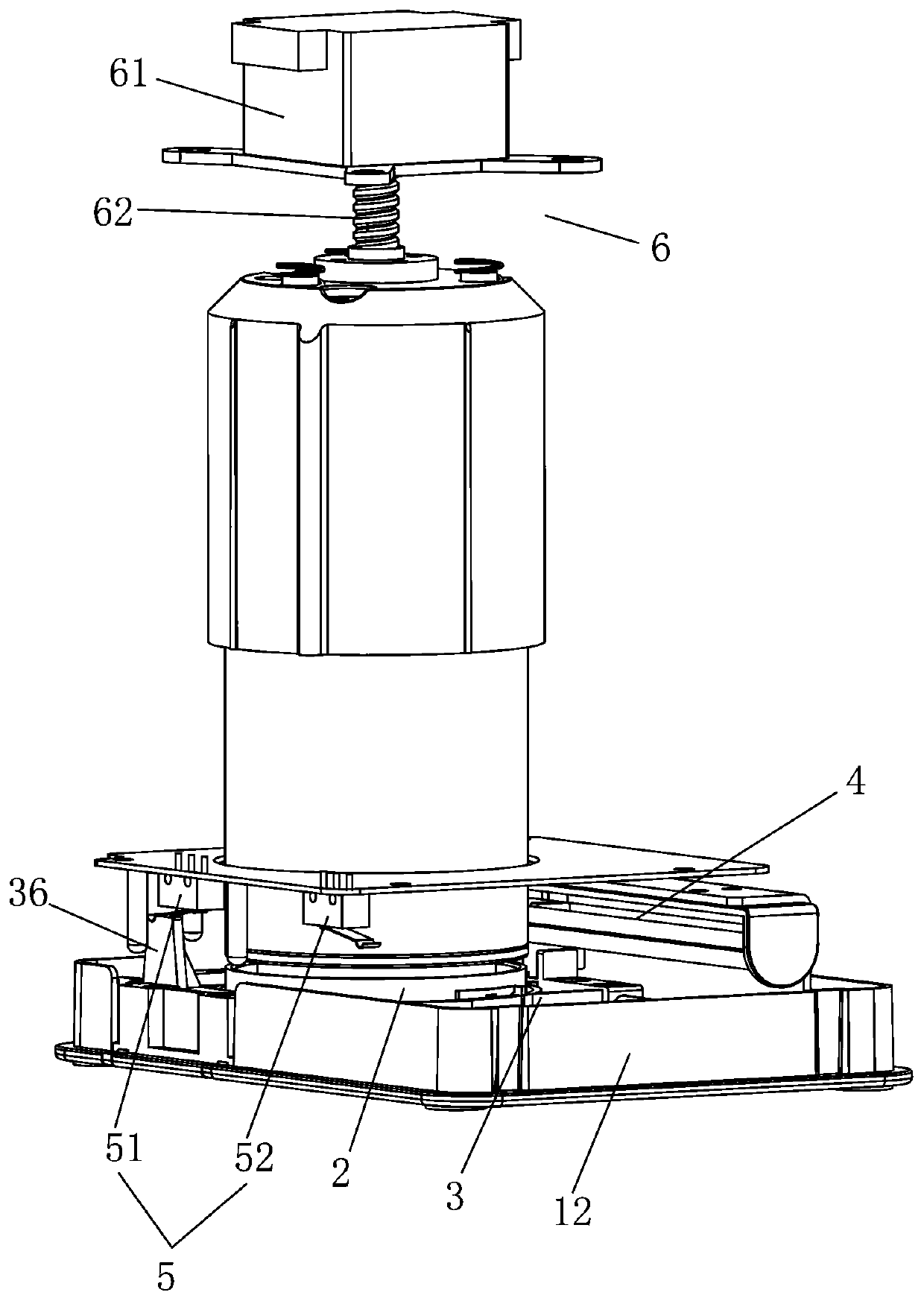

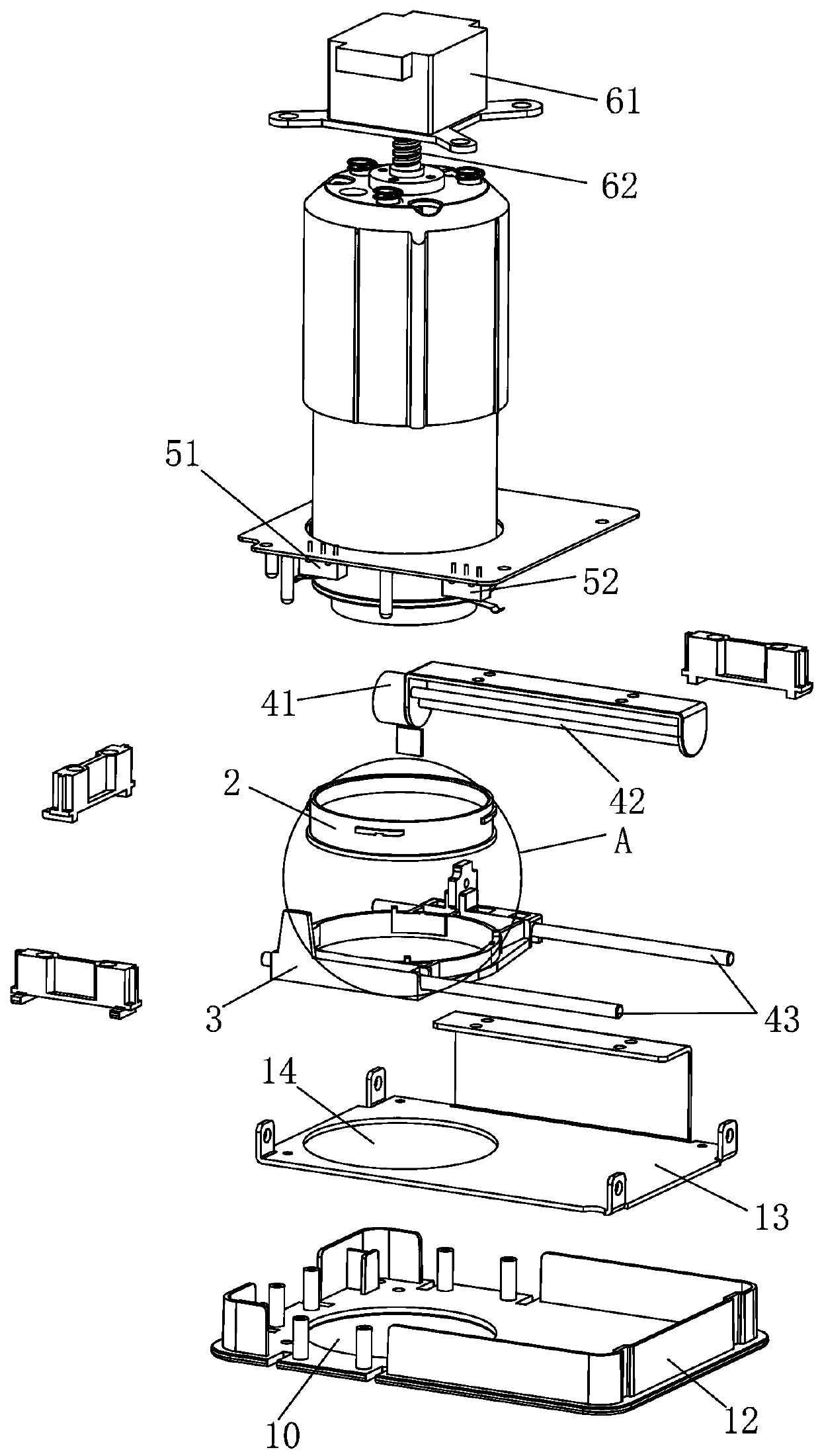

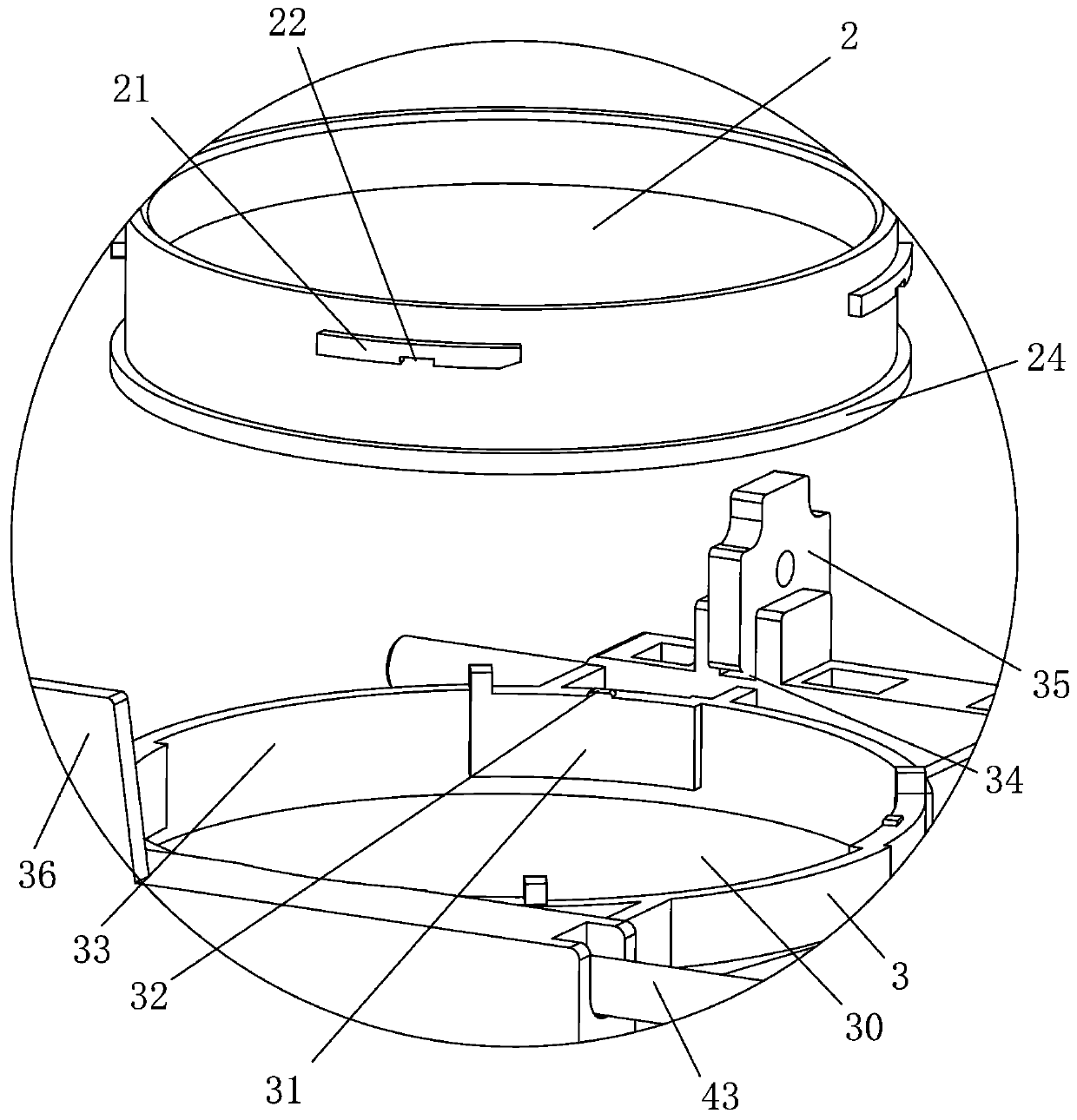

[0027] see Figure 1 to Figure 5 As shown, the ink smearing device of the stamping machine includes a housing 1, an ink tray 2, a deck 3, a horizontal movement mechanism 4, an induction mechanism 5 and a lifting mechanism 6, and the housing 1 includes a box body 11 and a bottom cover 12. The cover 12 is fixed on the bottom surface of the box body 11, the bottom cover 12 is hollowed out with a stamp access hole 10, the top surface of the bottom cover 12 is provided with a bracket 13, the horizontal movement mechanism 4 is fixed on the bracket 13, and the bracket 13 is provided with a seal corresponding to the seal access hole 10. Give way to hole 14. Lifting mechanism 6 packs lifting motor 61 and screw rod 62, and lifting motor 61 is fixed on box body 11 tops, and lifting motor 61 screw rods 62 rotate, and screw rod 62 drives seal to move up and down, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com