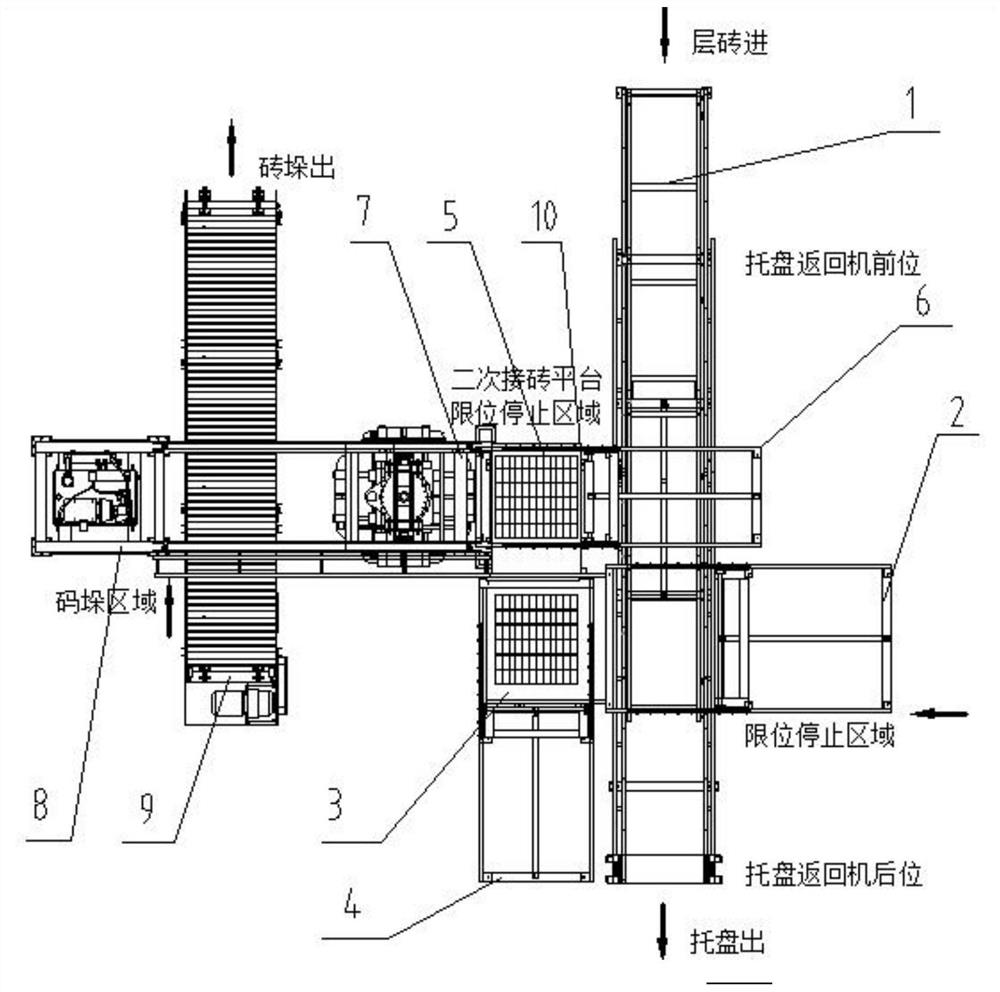

A pallet-free off-line palletizing device

A palletizing device and pallet technology, applied in the field of pallet-free offline palletizing device, can solve the problems of wasting human resources, unnecessary block rotation process, unstable brick stacking, etc., and achieve the effect of eliminating horizontal and vertical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

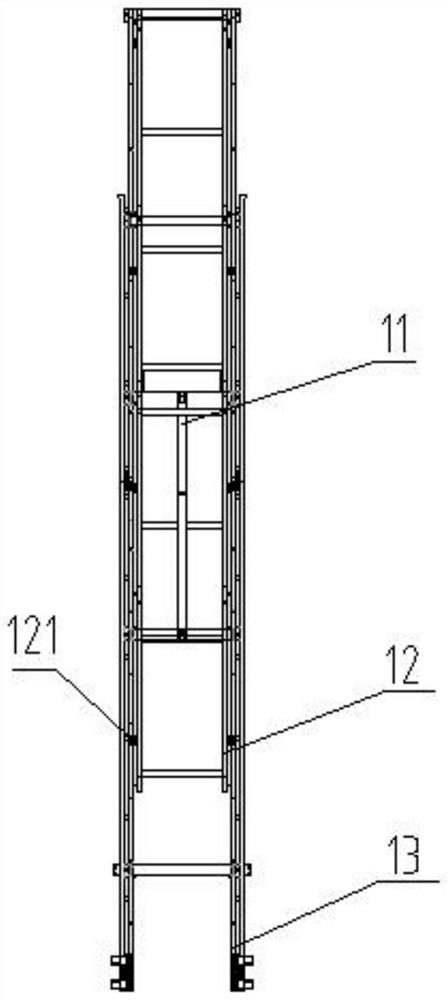

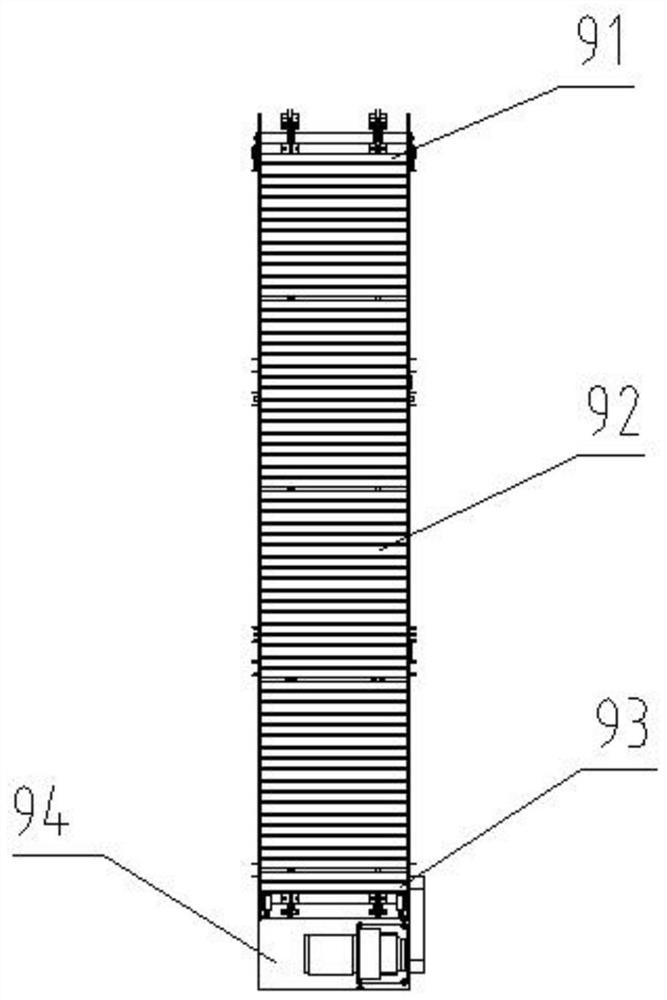

Method used

Image

Examples

example 1

[0077] In order to stack a floor brick with a size of 200*100*60, each layer of bricks is designed to have 6 rows and 12 columns (to ensure that the overall outline of the single layer of bricks is a square), and the size of the bricks after removing the gap is 1200*1200. In order to make the direction of the hole-retaining layer, the bottom layer and the top floor brick consistent, a total of 16 layers are established, and through holes are reserved on the fourth and fifth layers.

[0078] The steps when code the first pile of bricks are as follows:

[0079] The first layer of bricks: the bricks will be sent to the gap removal module, the gap removal module will eliminate the gap between the bricks, send them to the hole retention module, send the bricks of the hole retention module to the palletizing module, and stack the bricks in the palletizing module pile.

[0080] The second layer of bricks: the bricks will be sent to the gap removal module, the gap removal module will...

example 2

[0100] In order to stack a standard brick with a size of 238*51*113, each layer of bricks is designed to have 5 rows and 12 columns, and the size of the bricks after removing the gap is 1190*1122. In order to make the direction of the hole-retaining layer, the bottom layer and the top layer of bricks consistent, nine layers are established, and through holes are left on the second layer.

[0101] The steps when code the first pile of bricks are as follows:

[0102] The first layer of bricks: the bricks will be sent to the gap removal module, the gap removal module will eliminate the gap between the bricks, send them to the hole retention module, send the bricks of the hole retention module to the palletizing module, and stack the bricks in the palletizing module pile.

[0103] The second layer of bricks: Send the future bricks to the gap removal module, which eliminates the gaps between the bricks, and sends them to the hole retention module, leaving the second and fourth row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com