Patents

Literature

70results about How to "Prevent overspray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

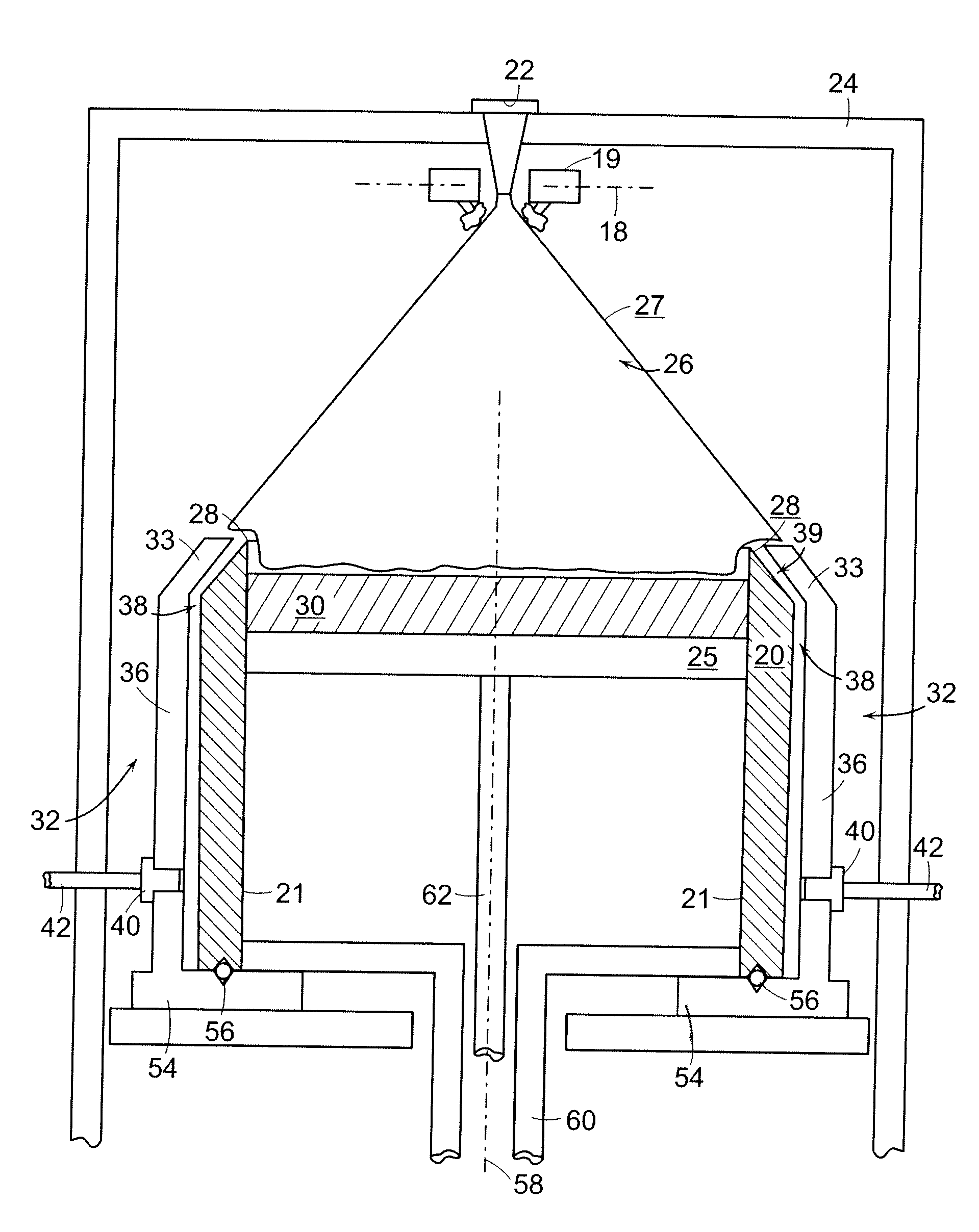

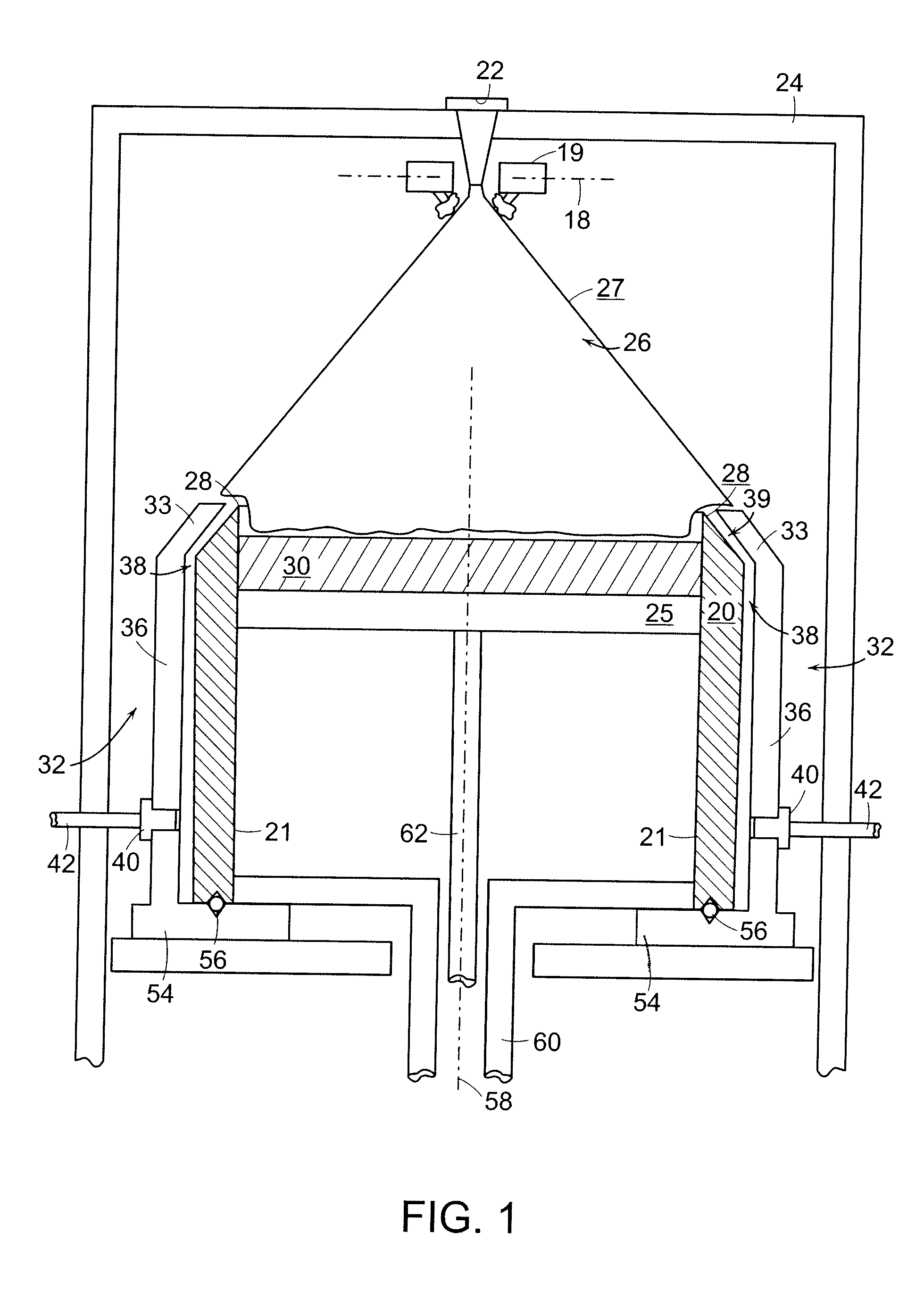

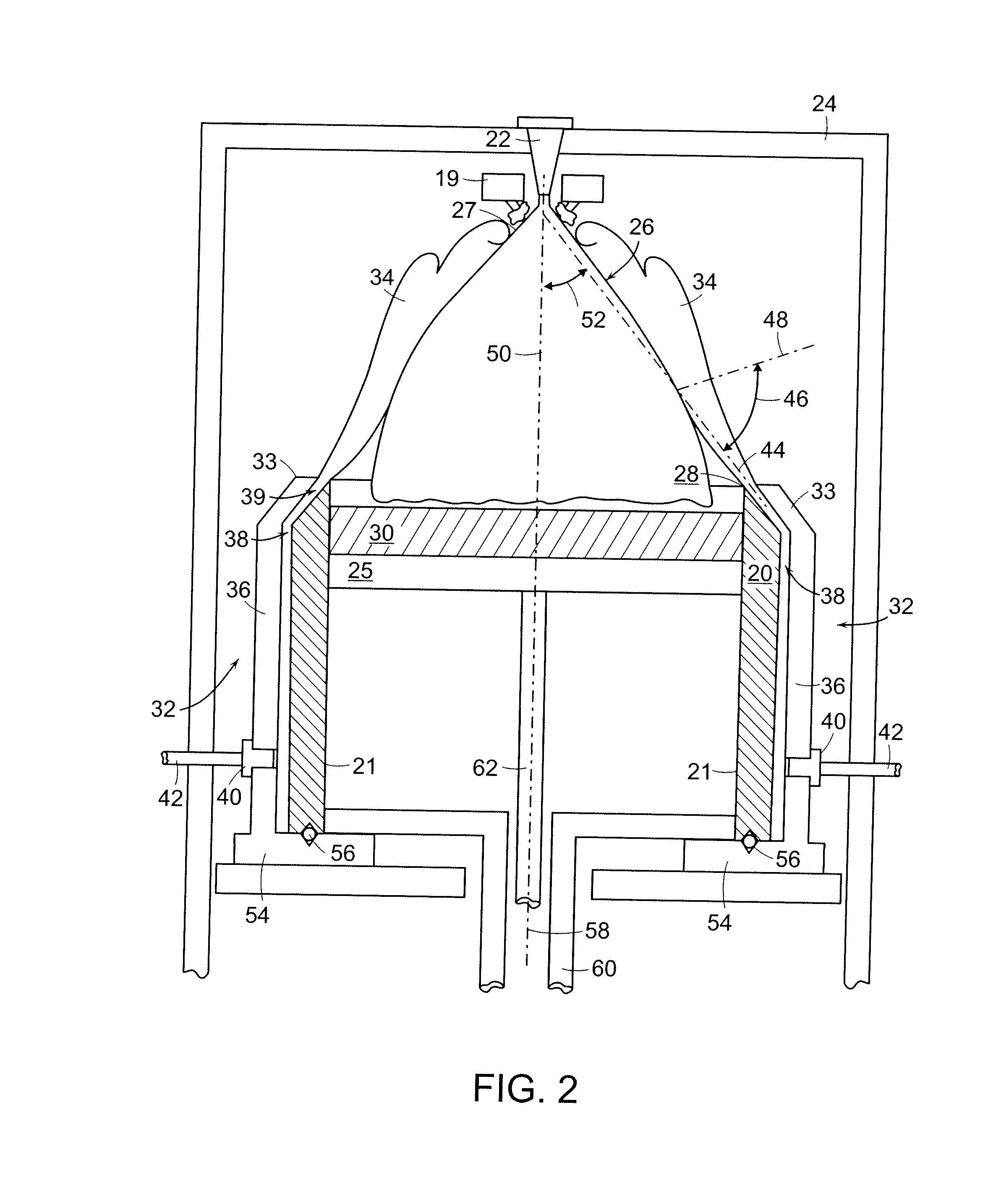

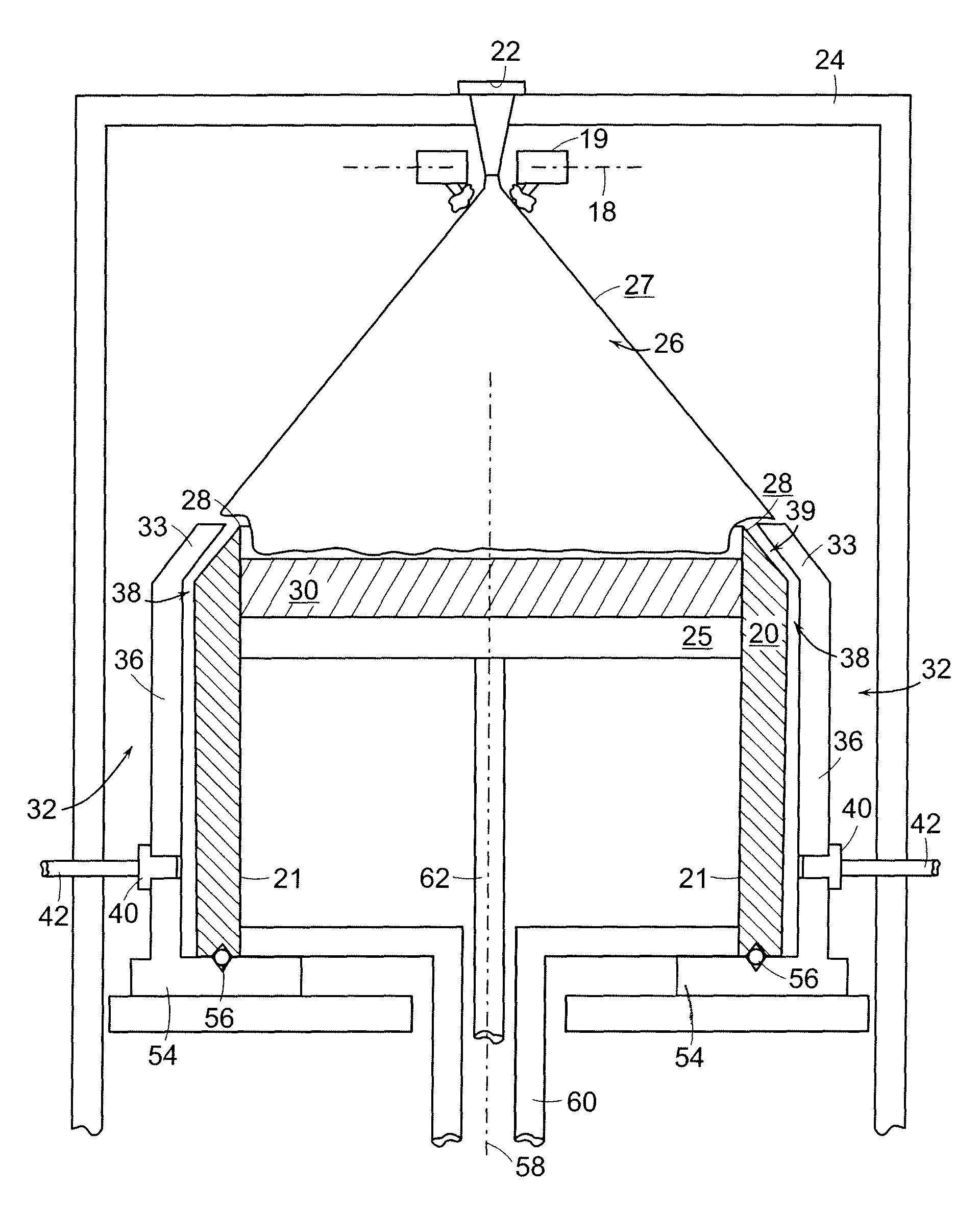

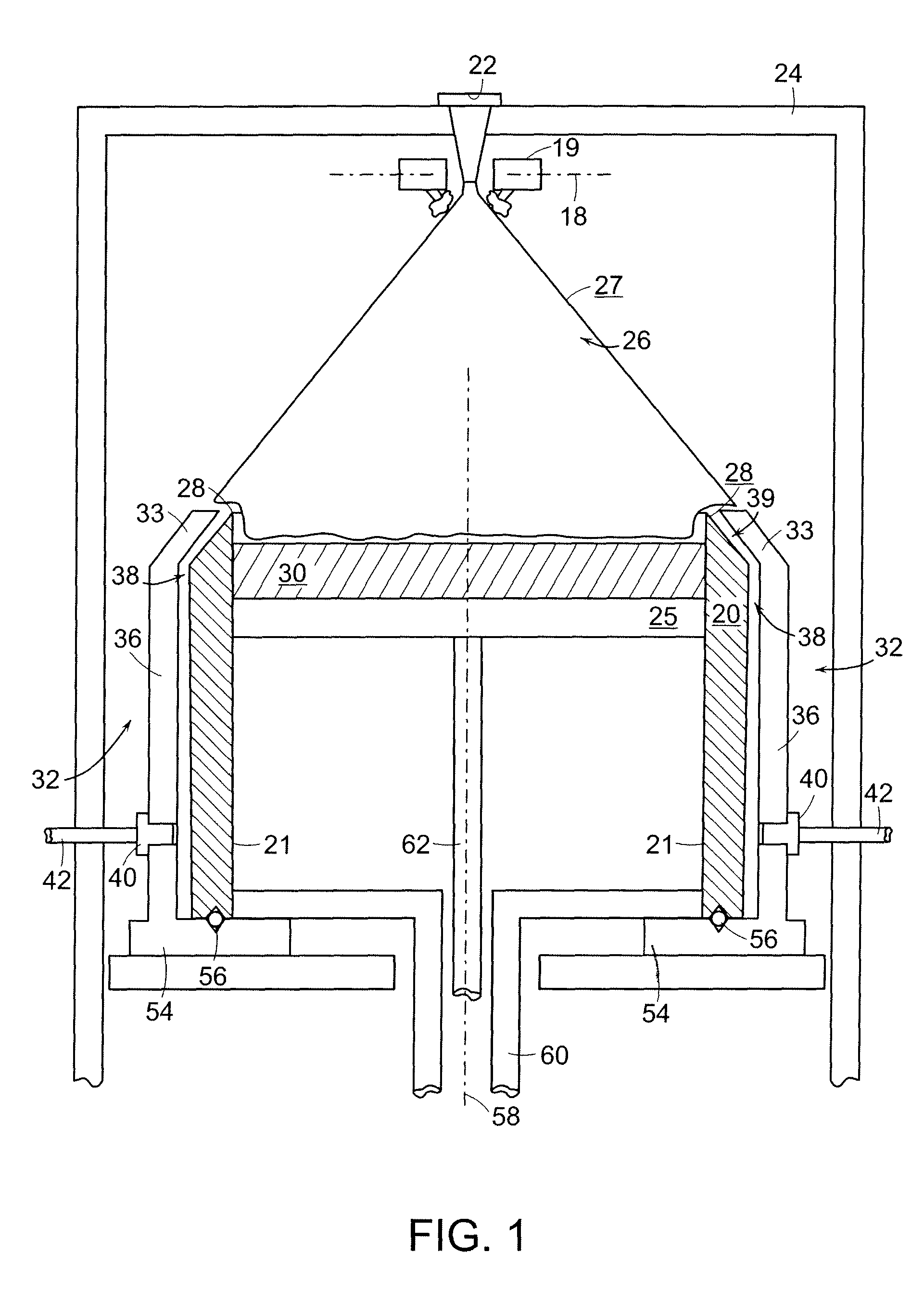

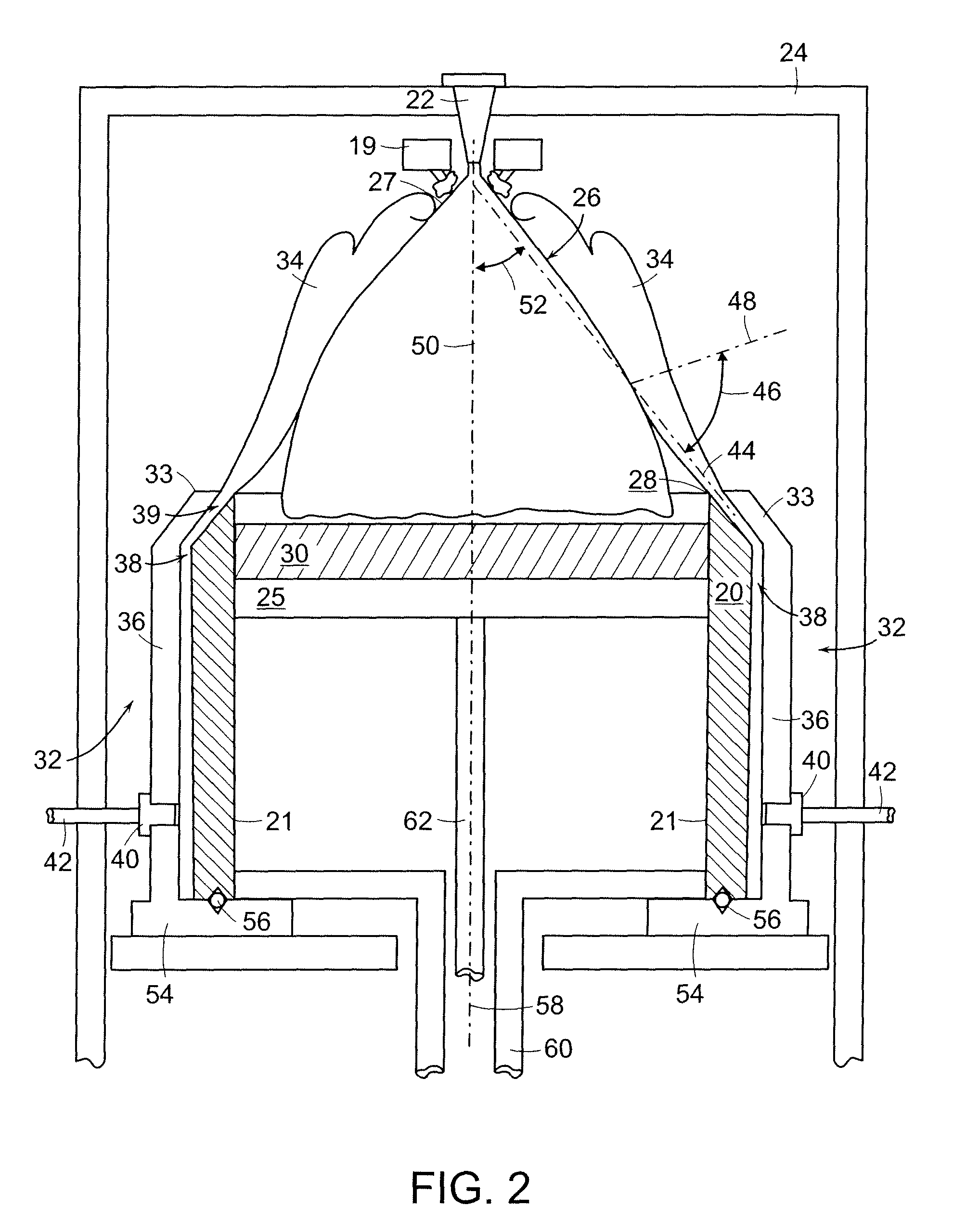

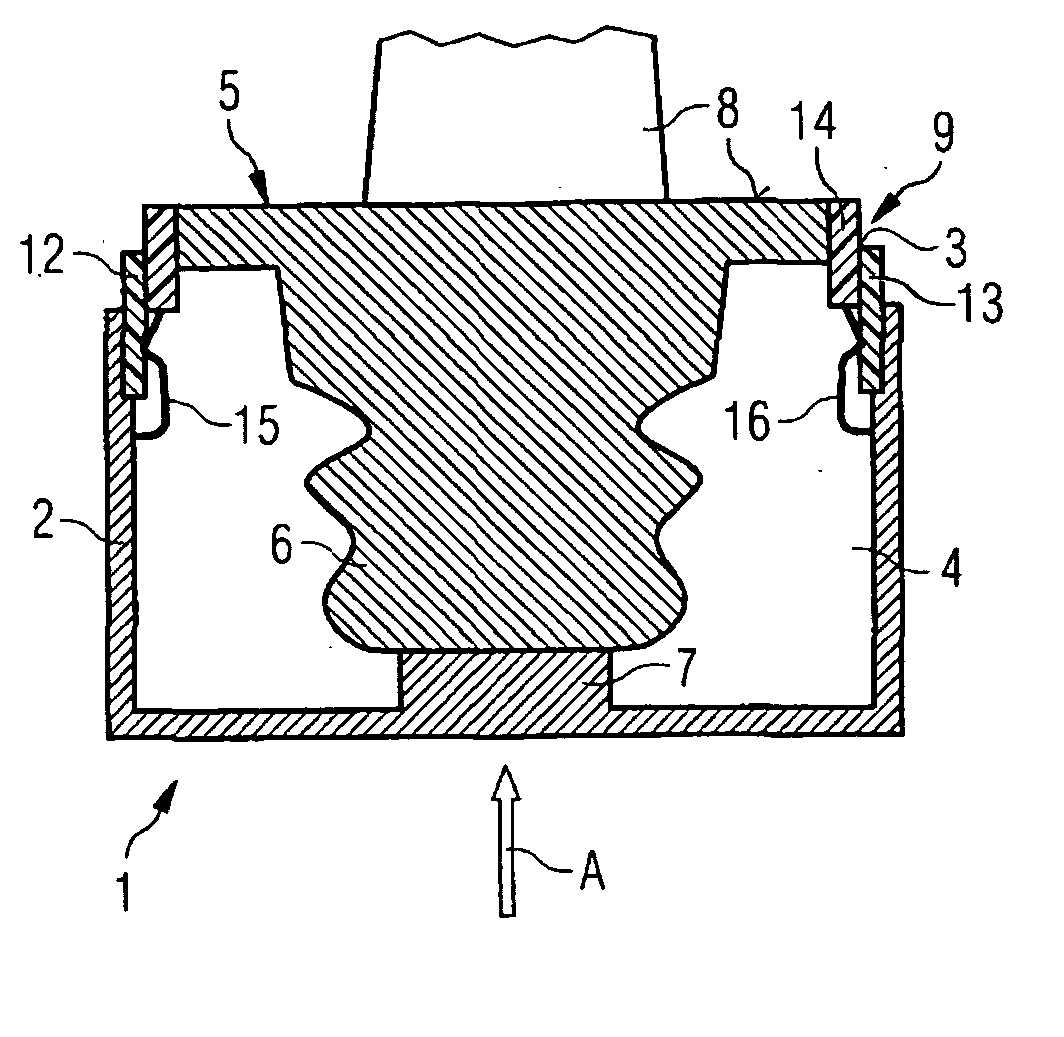

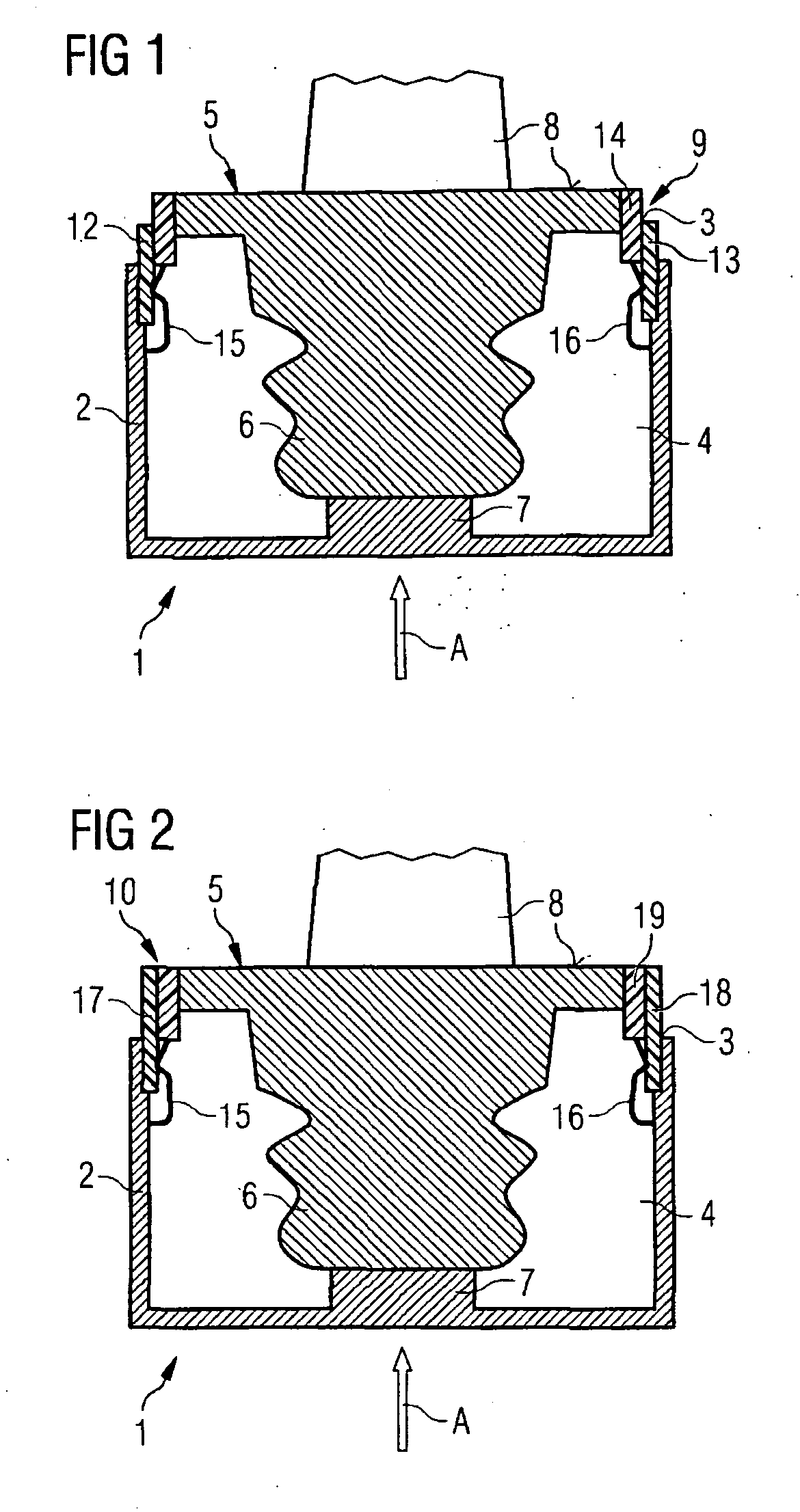

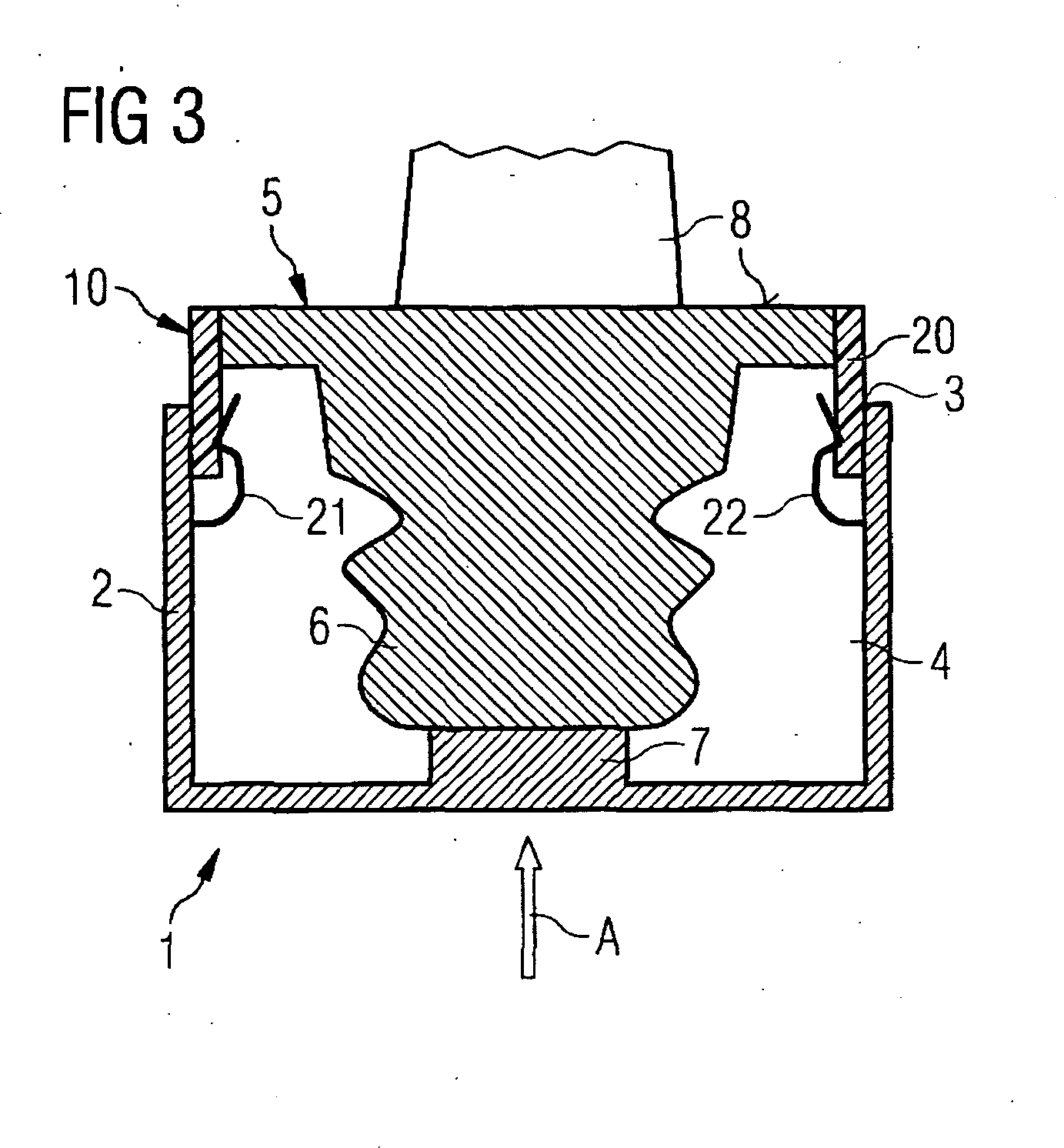

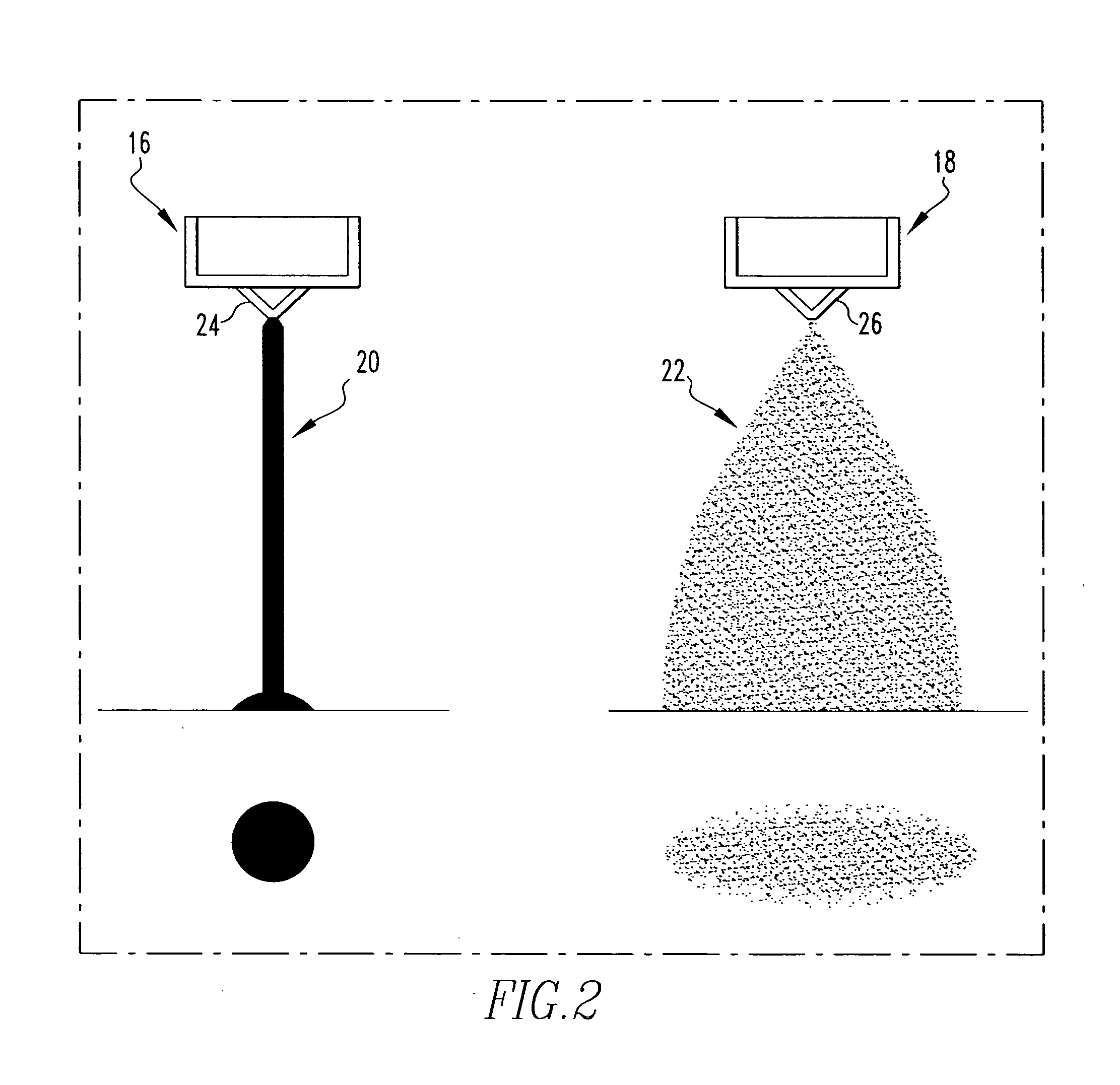

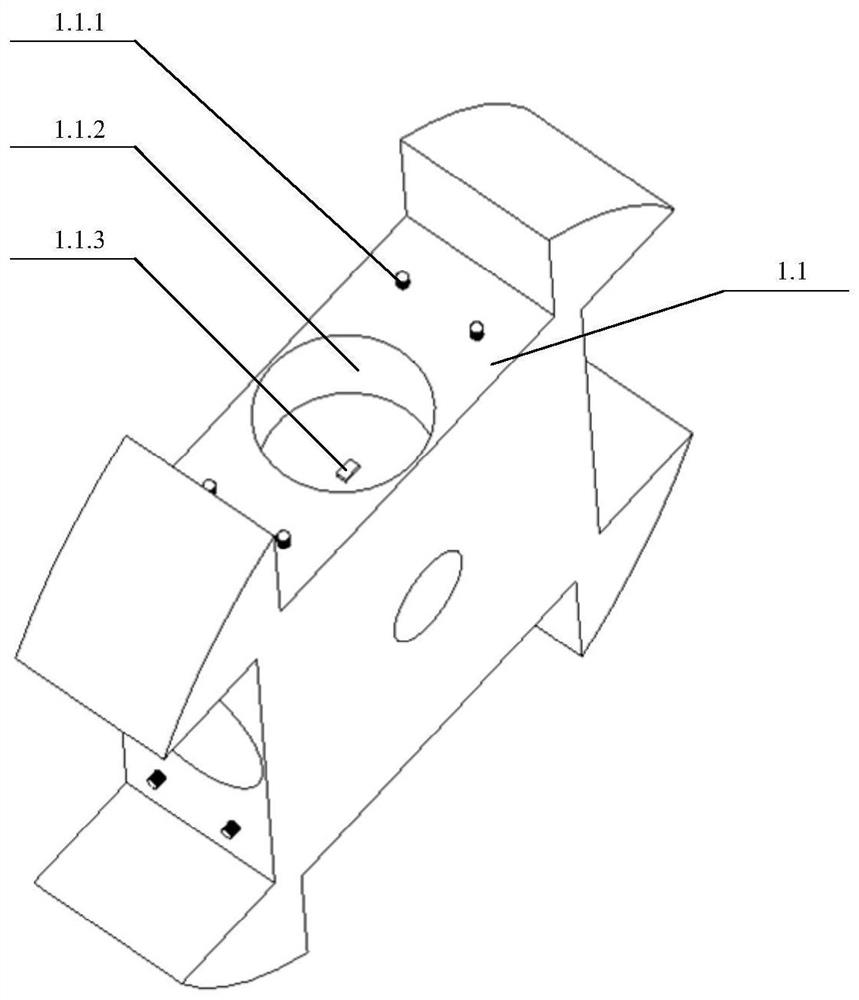

Casting Apparatus and Method

ActiveUS20090139682A1Reduce the amount requiredPrevent, oversprayMolten spray coatingMetallic materialsGas syringe

A nucleated casting apparatus including an atomizing nozzle configured to produce a droplet spray of a metallic material, a mold configured to receive the droplet spray and form a preform therein, and a gas injector which can limit, and possibly prevent, overspray from accumulating on the mold. The gas injector can be configured to produce a gas flow which can impinge on the droplet spray to redirect at least a portion of the droplet spray away from a side wall of the mold. In various embodiments, the droplet spray may be directed by the atomizing nozzle in a generally downward direction and the gas flow may be directed in a generally upward direction such that the gas flow circumscribes the perimeter of the mold.

Owner:ATI PROPERTIES

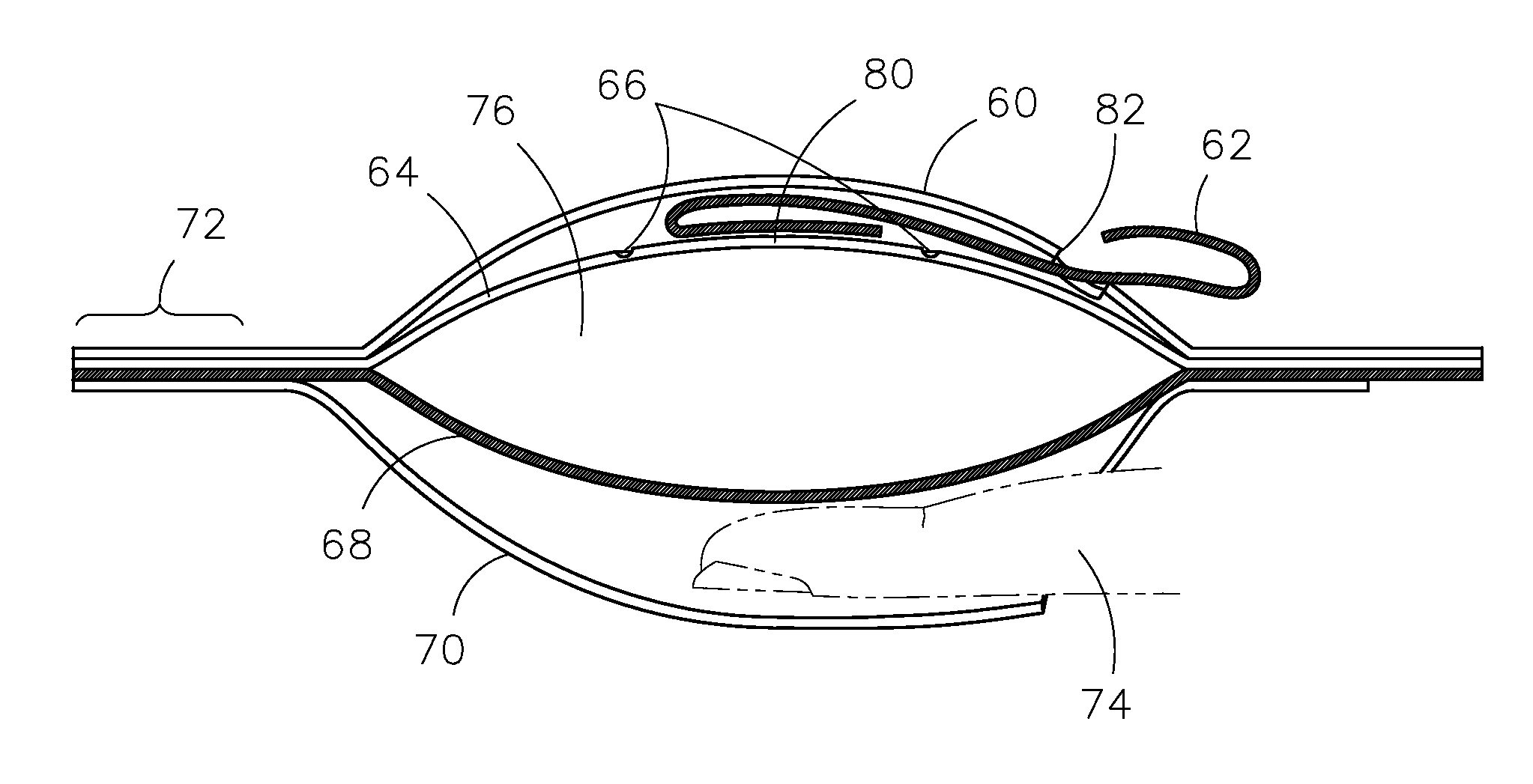

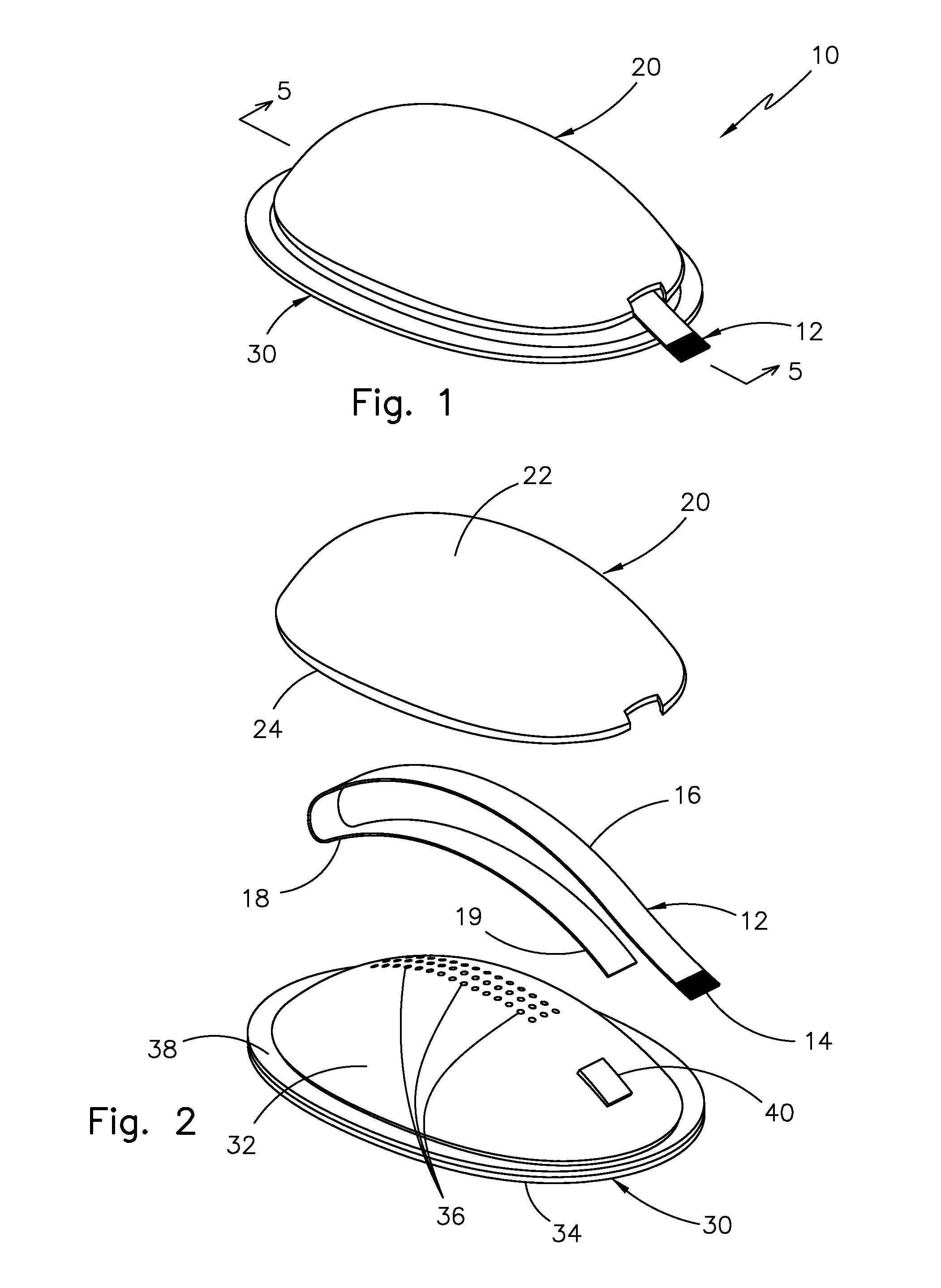

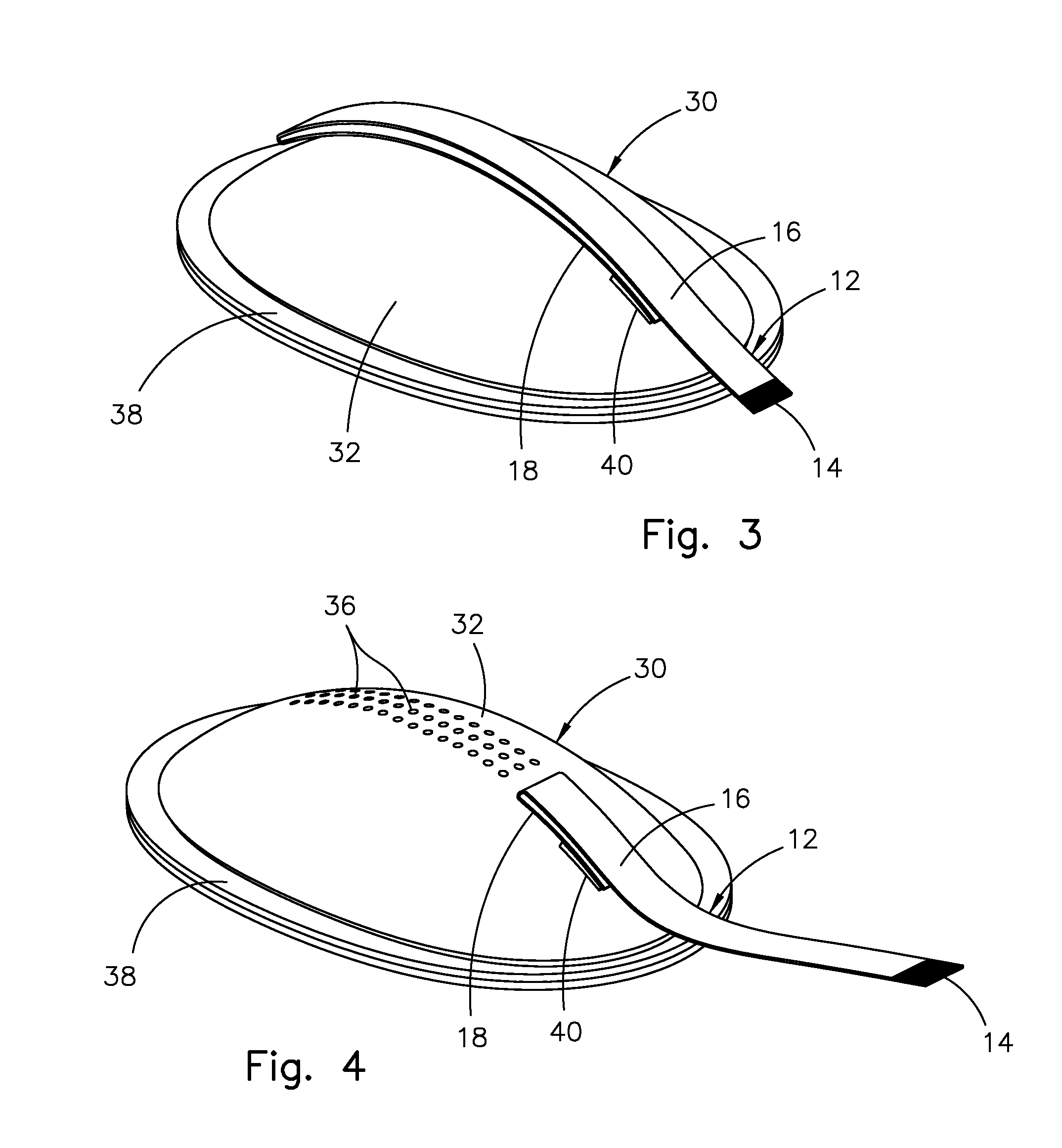

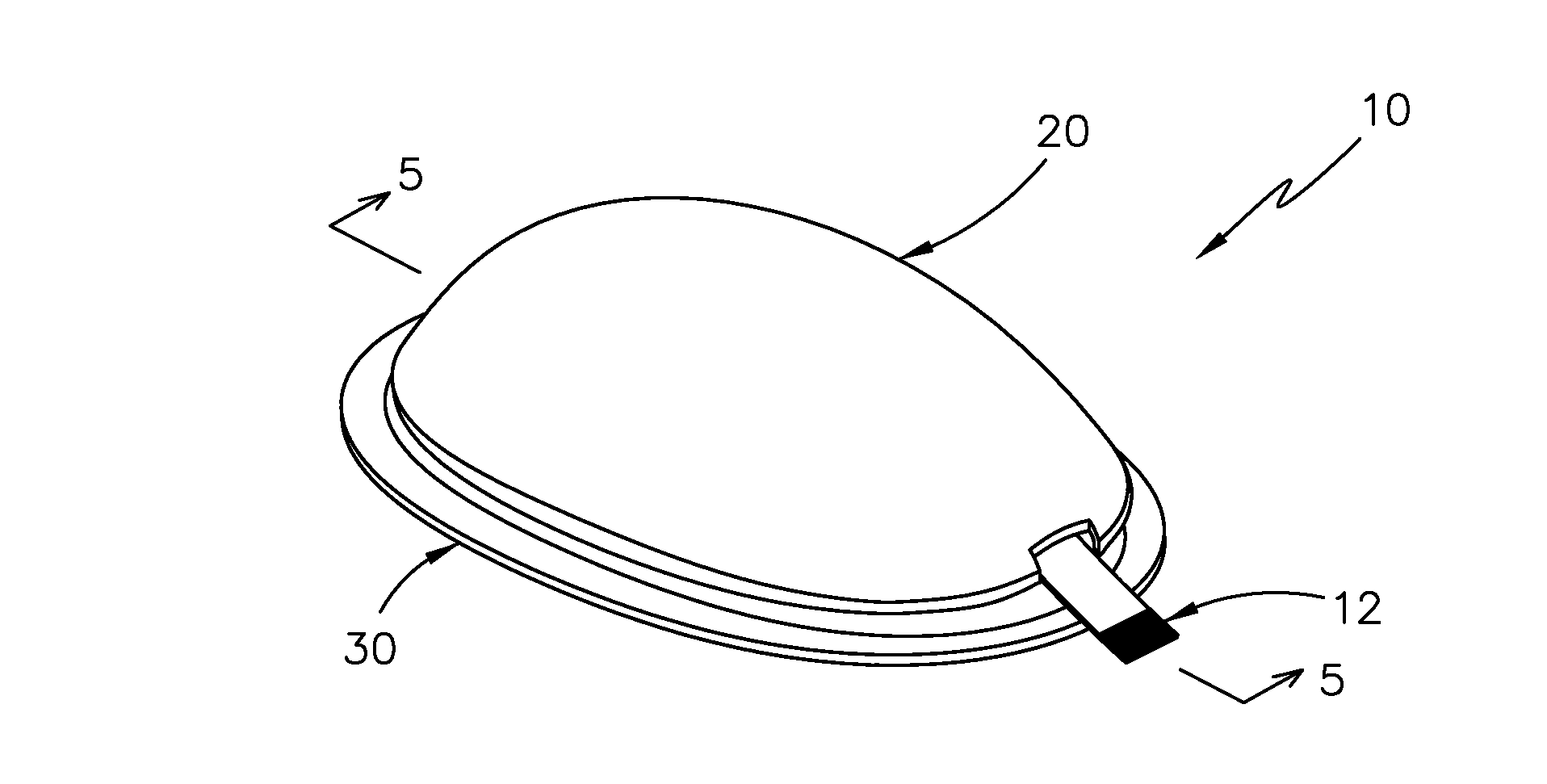

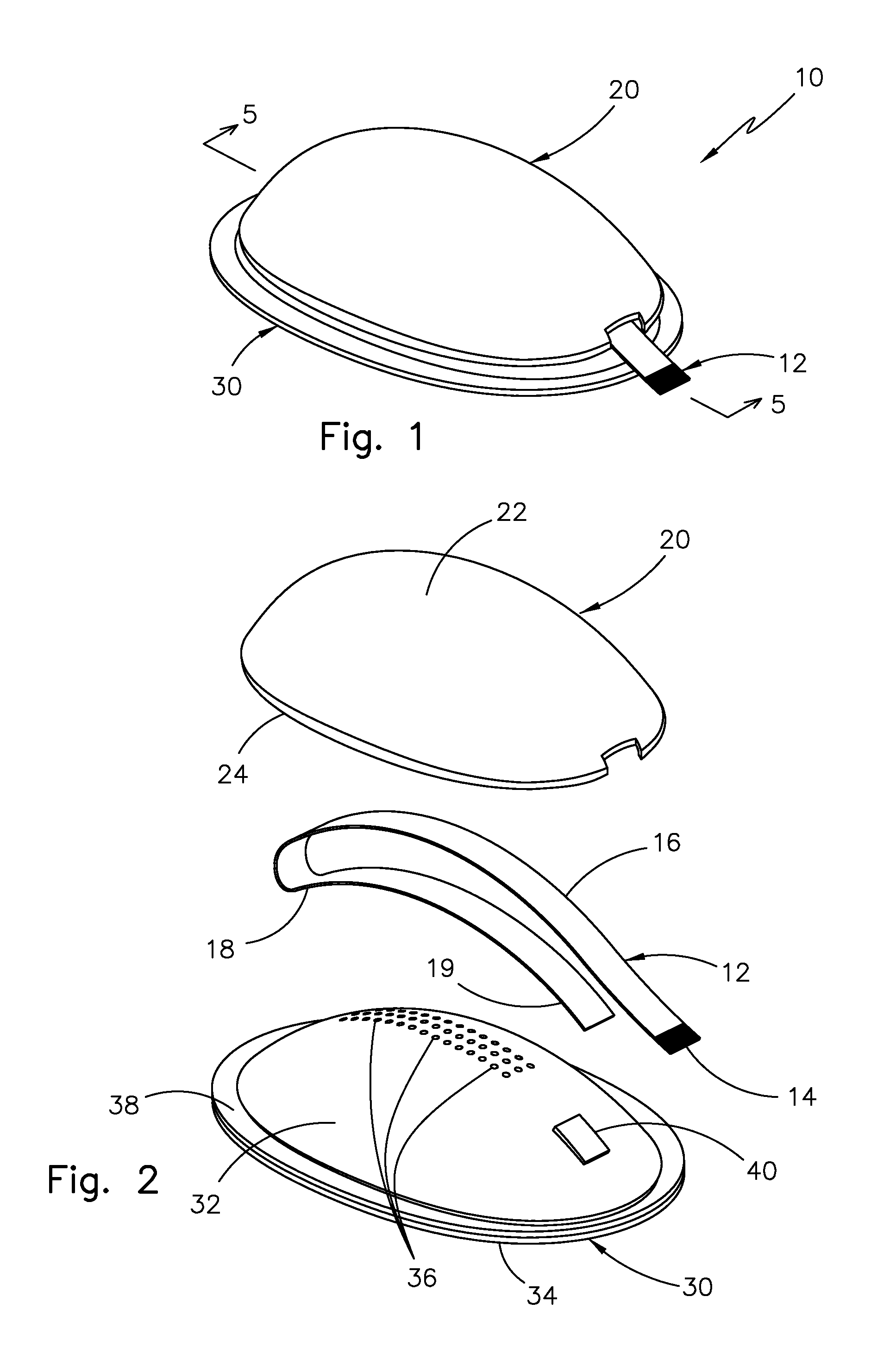

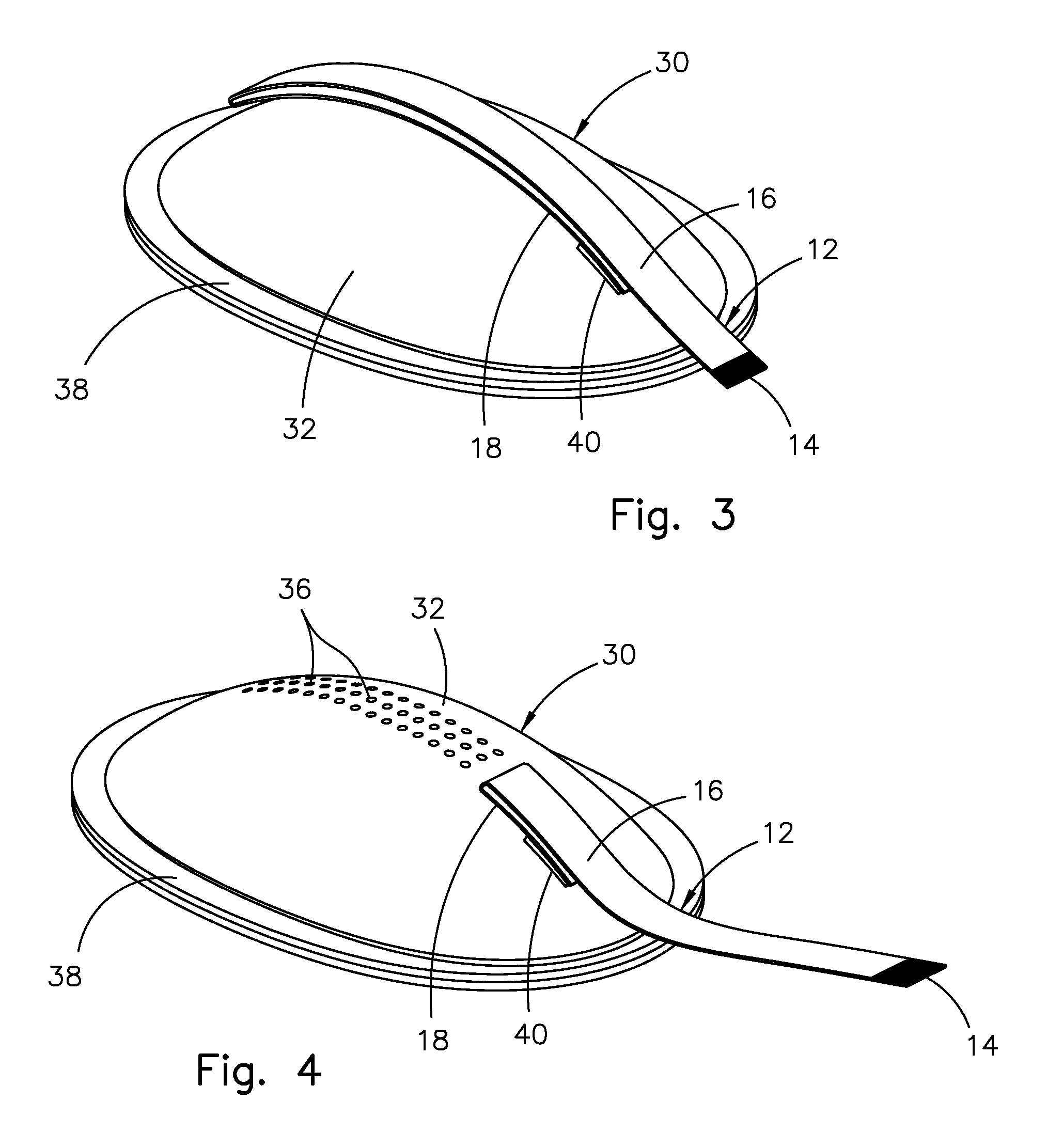

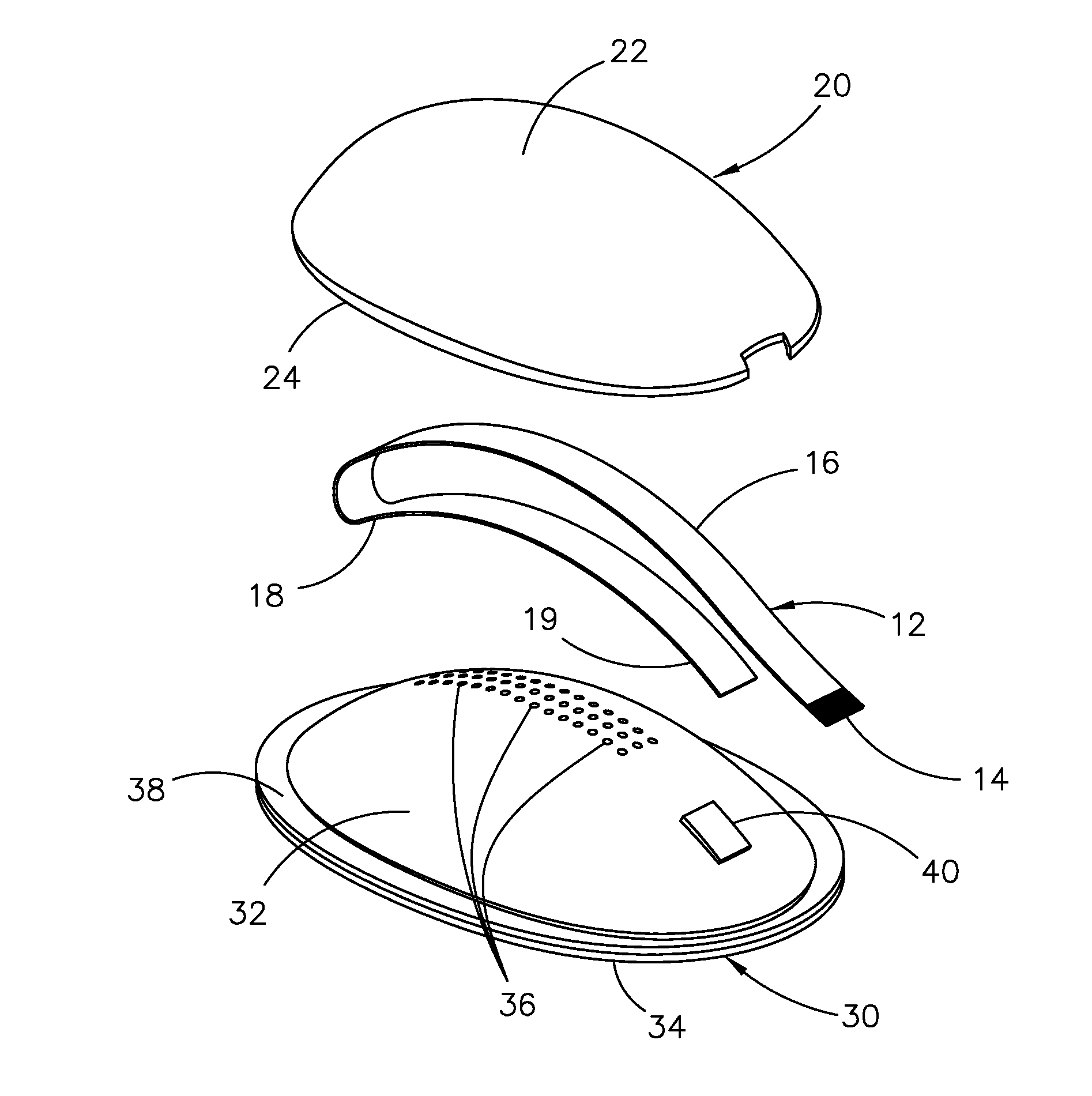

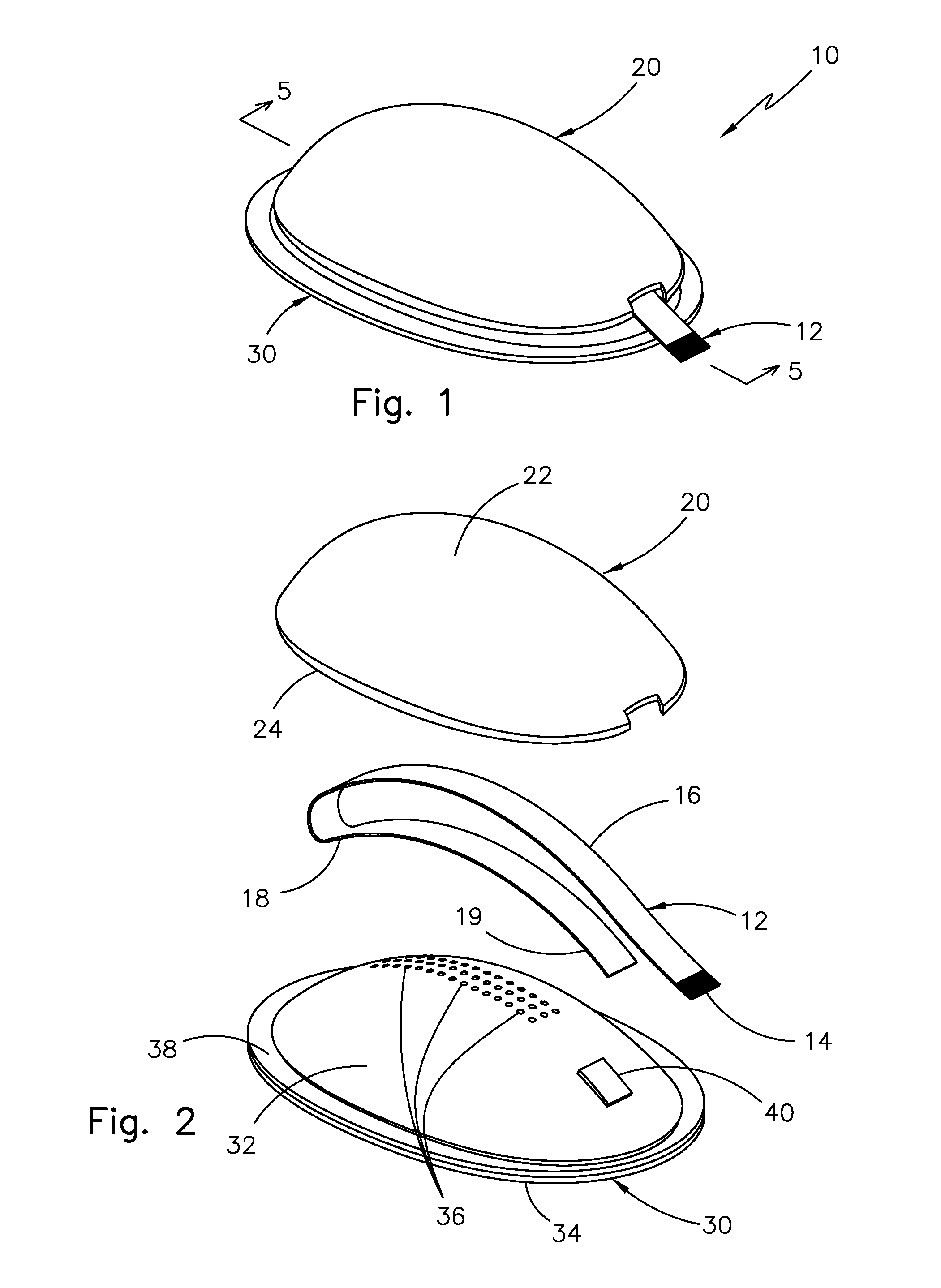

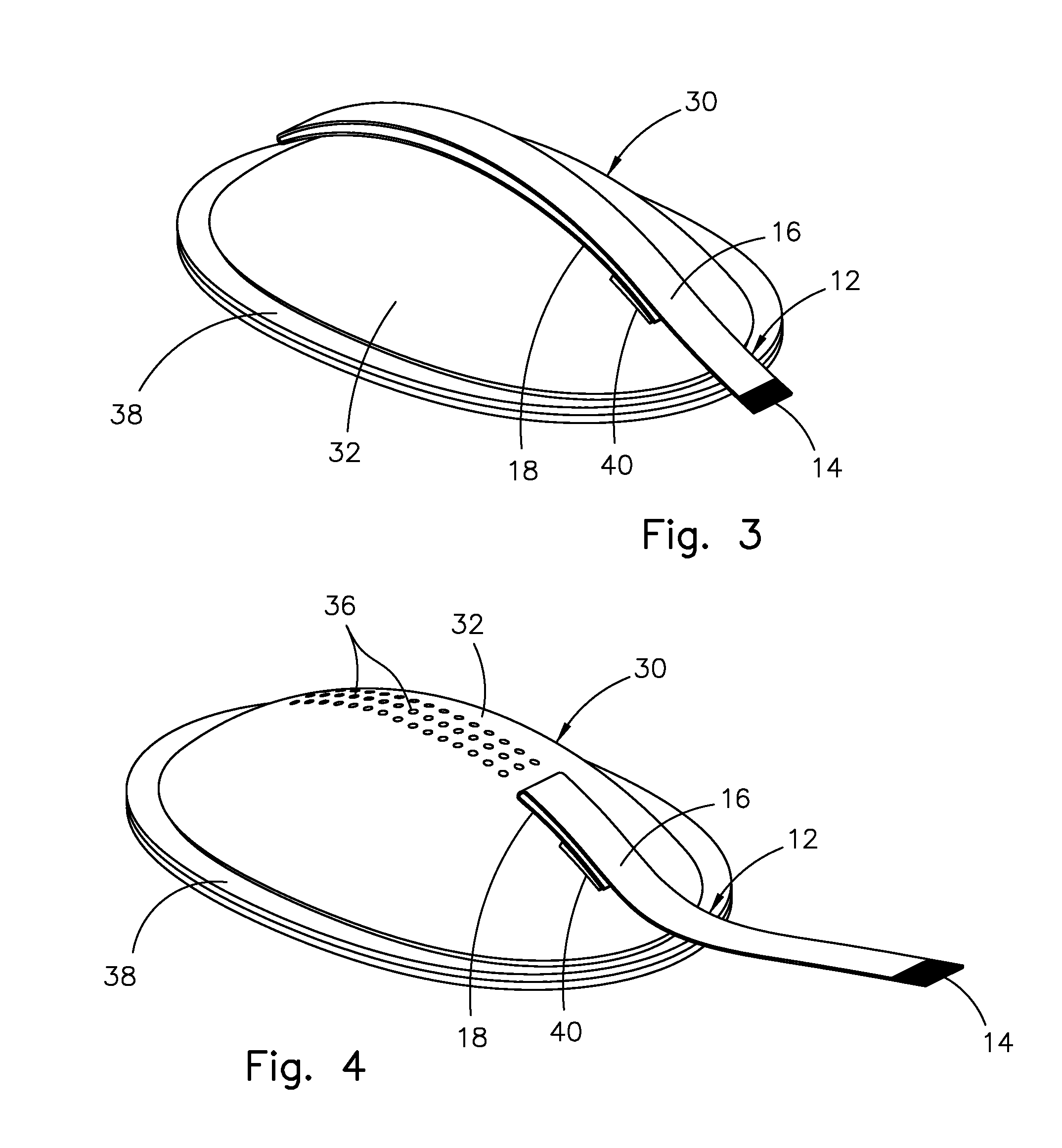

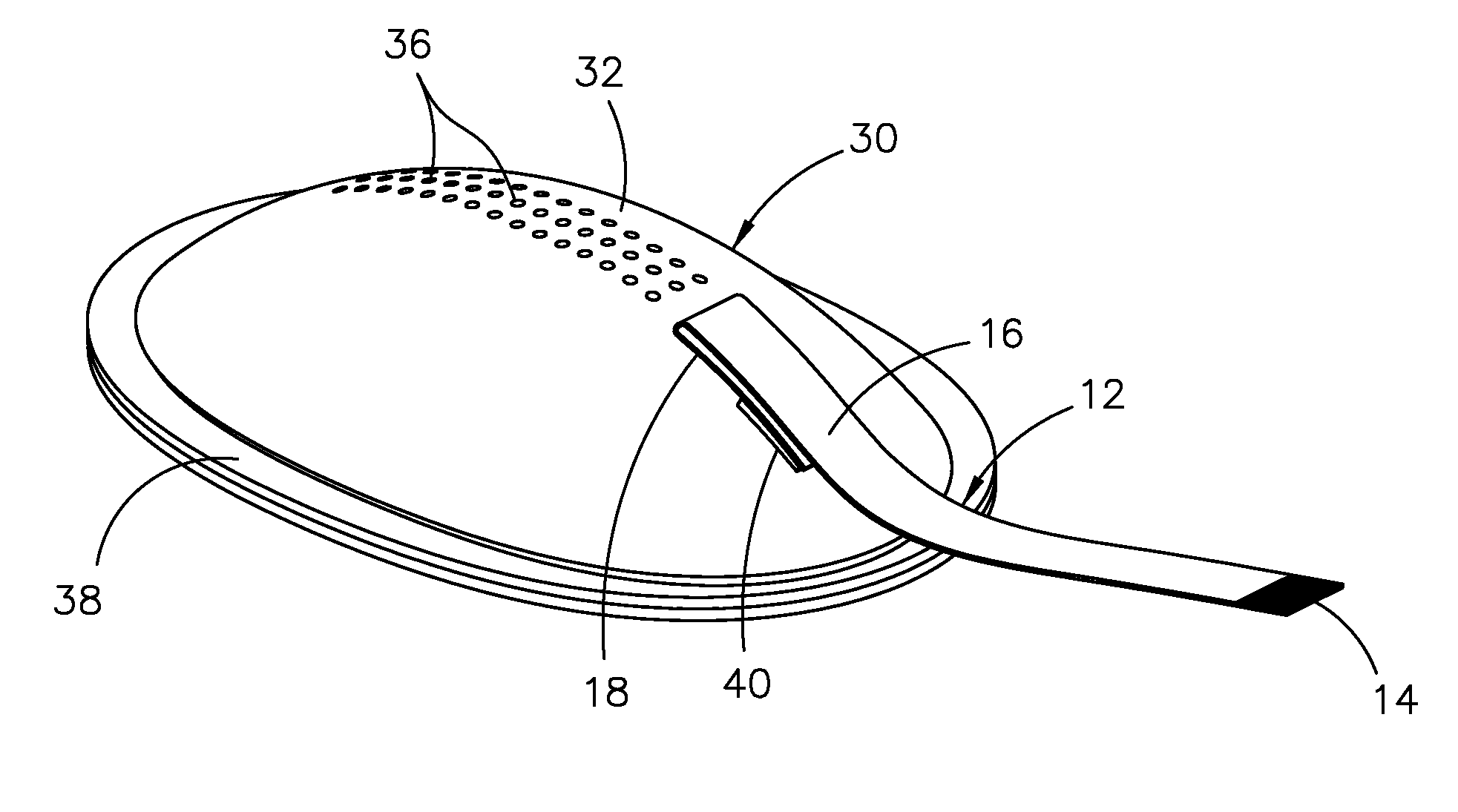

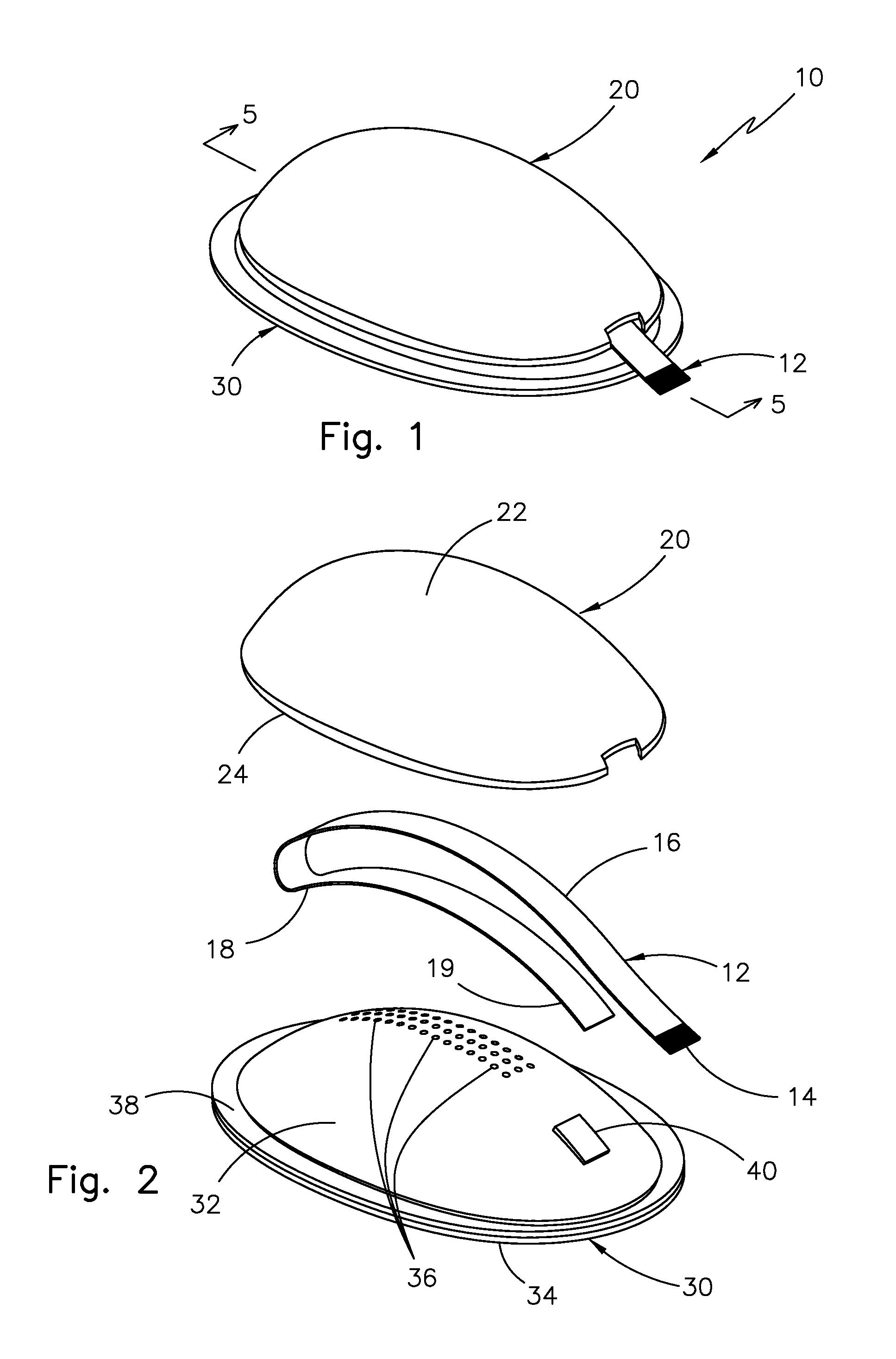

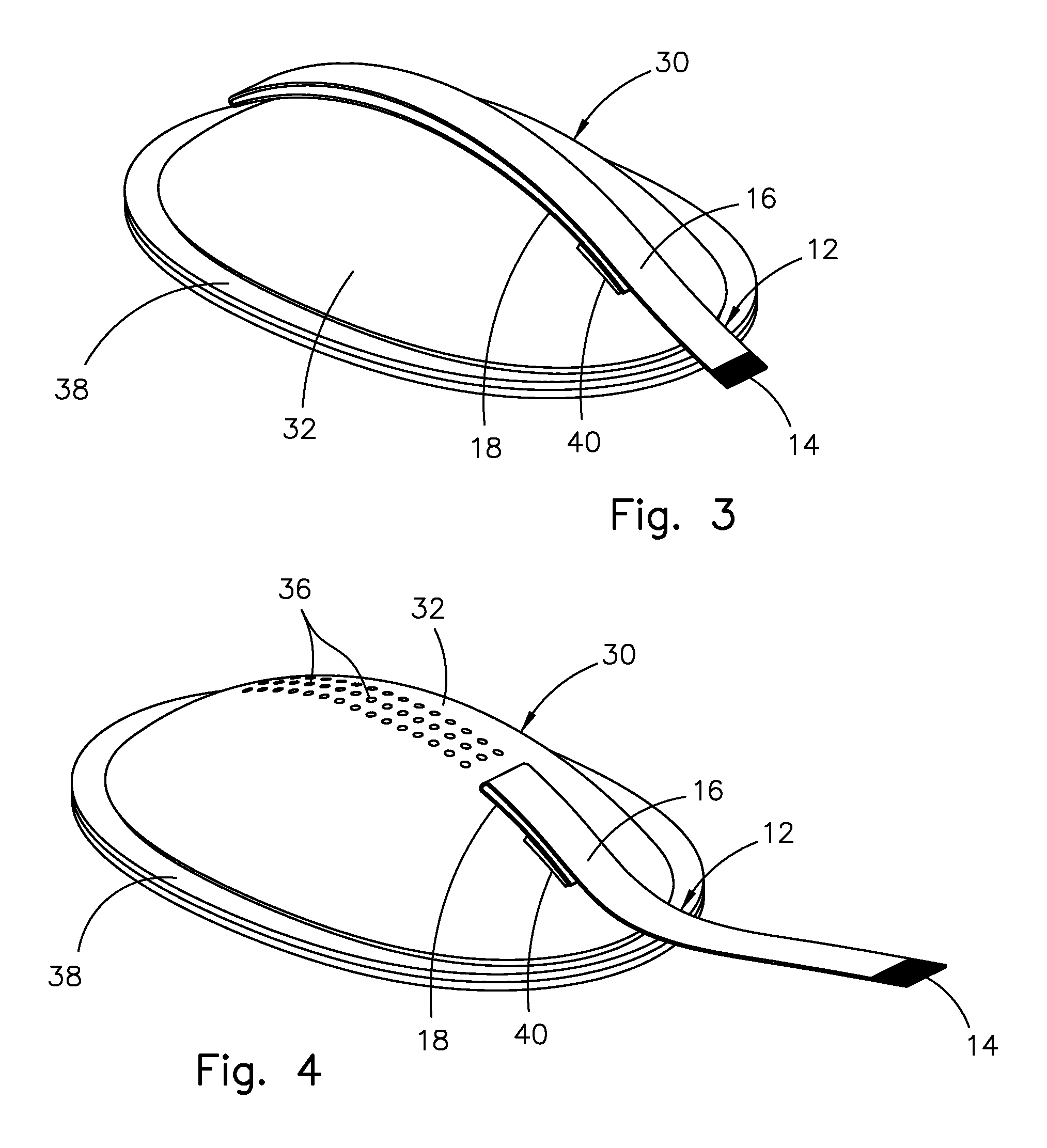

Disposable fluid applicator

ActiveUS8157464B2Efficiently and safely dispensesPrevent oversprayPackaging toiletriesInk reservoir pensMaterial PerforationBiomedical engineering

A disposable fluid applicator having a reservoir with a first membrane and a second membrane. Said reservoir containing a fluid to be dispensed. Said first membrane of the reservoir having perforations and being covered by a permeable and / or absorbent spreader. A removable tab assembly is disposed between said spreader and said first membrane of the reservoir that seals said reservoir. When the tab is pulled from between said spreader and said first membrane of the reservoir the reservoir becomes unsealed allowing the fluid contained inside the reservoir to flow out through an opening in the first membrane into and through the spreader where the fluid can be applied to a desired surface.

Owner:PRAX RALF

Disposable fluid applicator

InactiveUS8534947B2Efficiently and safely dispensesPrevent oversprayPackaging toiletriesInk reservoir pensMaterial PerforationBiomedical engineering

A disposable fluid applicator having a reservoir with a first membrane and a second membrane. Said reservoir containing a fluid to be dispensed. Said first membrane of the reservoir having perforations and being covered by a permeable and / or absorbent spreader. A removable tab assembly is disposed between said spreader and said first membrane of the reservoir that seals said perforations. When the tab is pulled from between said spreader and said first membrane of the reservoir the perforations are unsealed allowing the fluid contained inside the reservoir to flow out through the perforations into and through the spreader where the fluid can be applied to a desired surface.

Owner:PRAX CORP

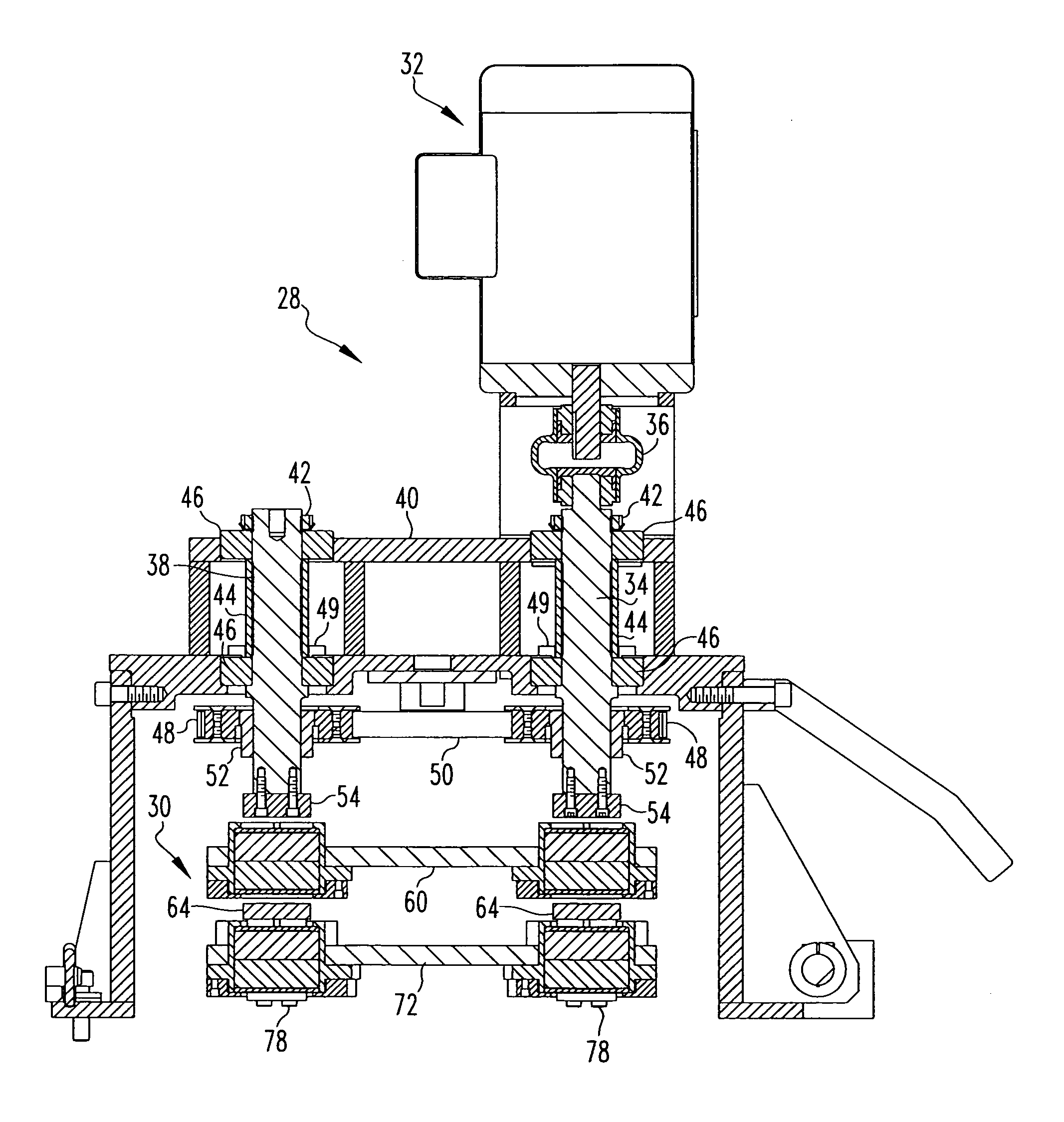

Casting apparatus and method

ActiveUS7798199B2Reduce the amount requiredPrevent, oversprayMolten spray coatingGas syringeMetallic materials

A nucleated casting apparatus including an atomizing nozzle configured to produce a droplet spray of a metallic material, a mold configured to receive the droplet spray and form a preform therein, and a gas injector which can limit, and possibly prevent, overspray from accumulating on the mold. The gas injector can be configured to produce a gas flow which can impinge on the droplet spray to redirect at least a portion of the droplet spray away from a side wall of the mold. In various embodiments, the droplet spray may be directed by the atomizing nozzle in a generally downward direction and the gas flow may be directed in a generally upward direction such that the gas flow circumscribes the perimeter of the mold.

Owner:ATI PROPERTIES

Disposable Fluid Applicator

ActiveUS20100239353A1Efficiently and safely dispensesPrevent oversprayPackaging toiletriesInk reservoir pensBiomedical engineeringMaterial Perforation

A disposable fluid applicator having a reservoir with a first membrane and a second membrane. Said reservoir containing a fluid to be dispensed. Said first membrane of the reservoir having perforations and being covered by a permeable and / or absorbent spreader. A removable tab assembly is disposed between said spreader and said first membrane of the reservoir that seals said reservoir. When the tab is pulled from between said spreader and said first membrane of the reservoir the reservoir becomes unsealed allowing the fluid contained inside the reservoir to flow out through an opening in the first membrane into and through the spreader where the fluid can be applied to a desired surface.

Owner:PRAX RALF

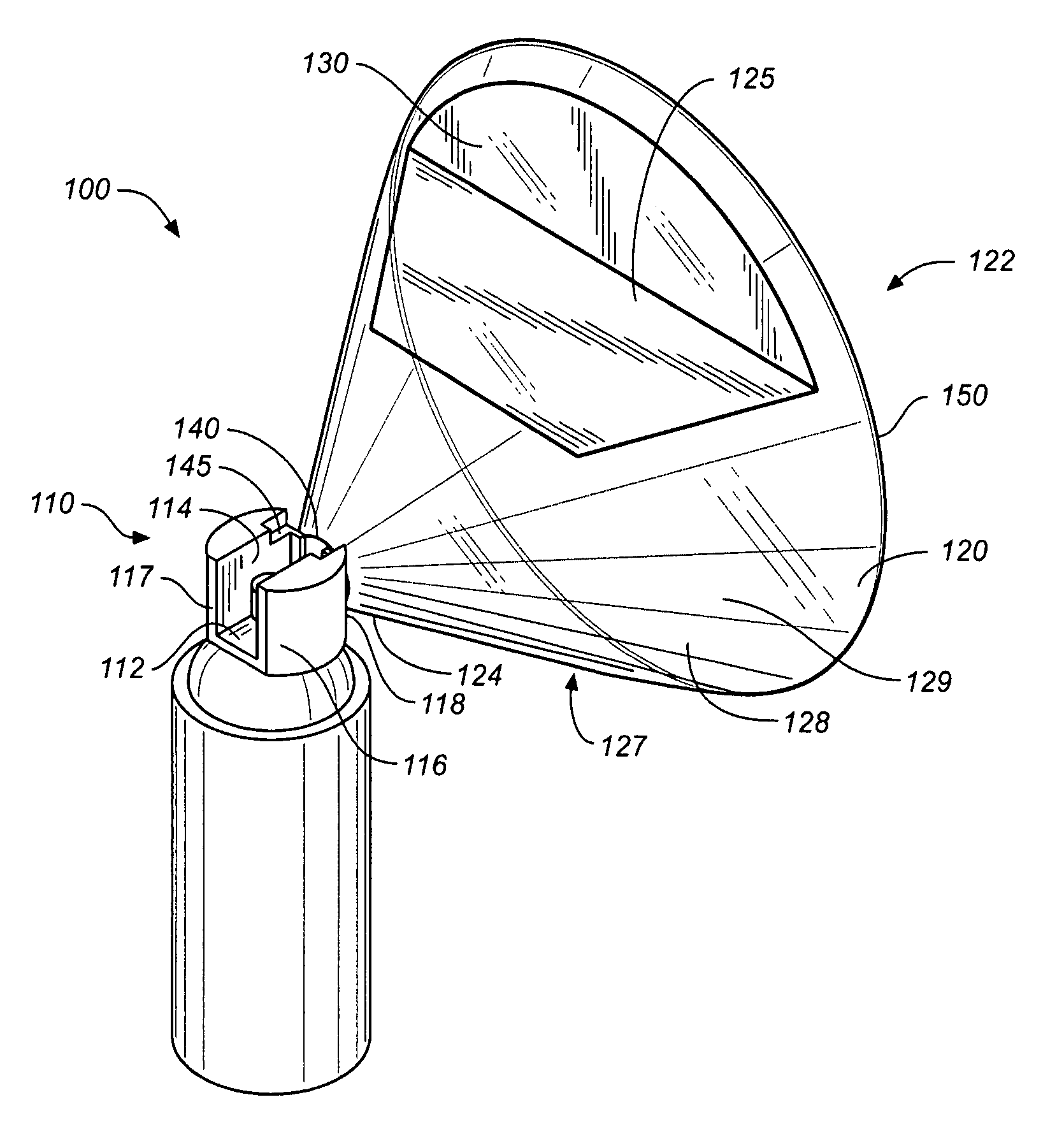

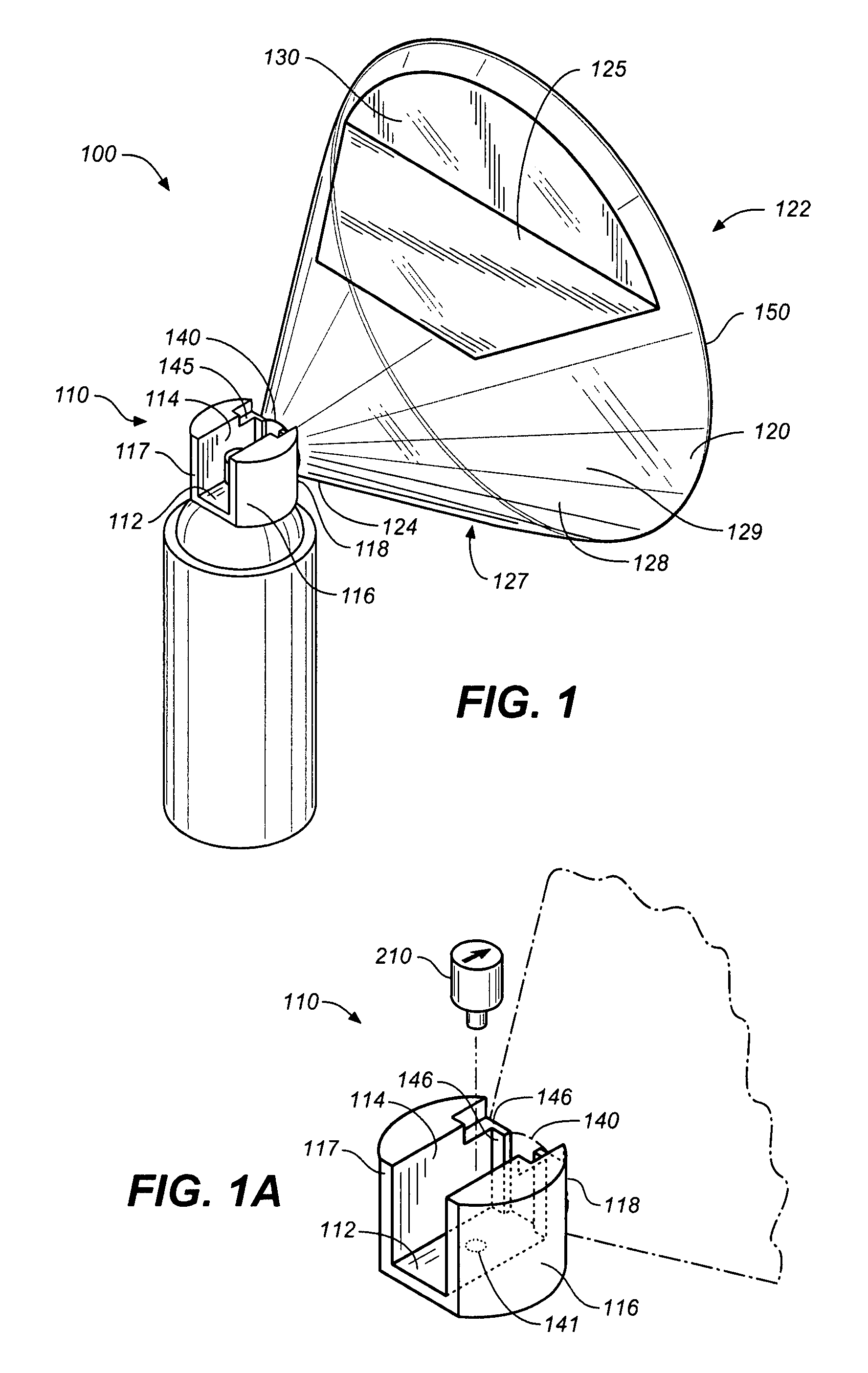

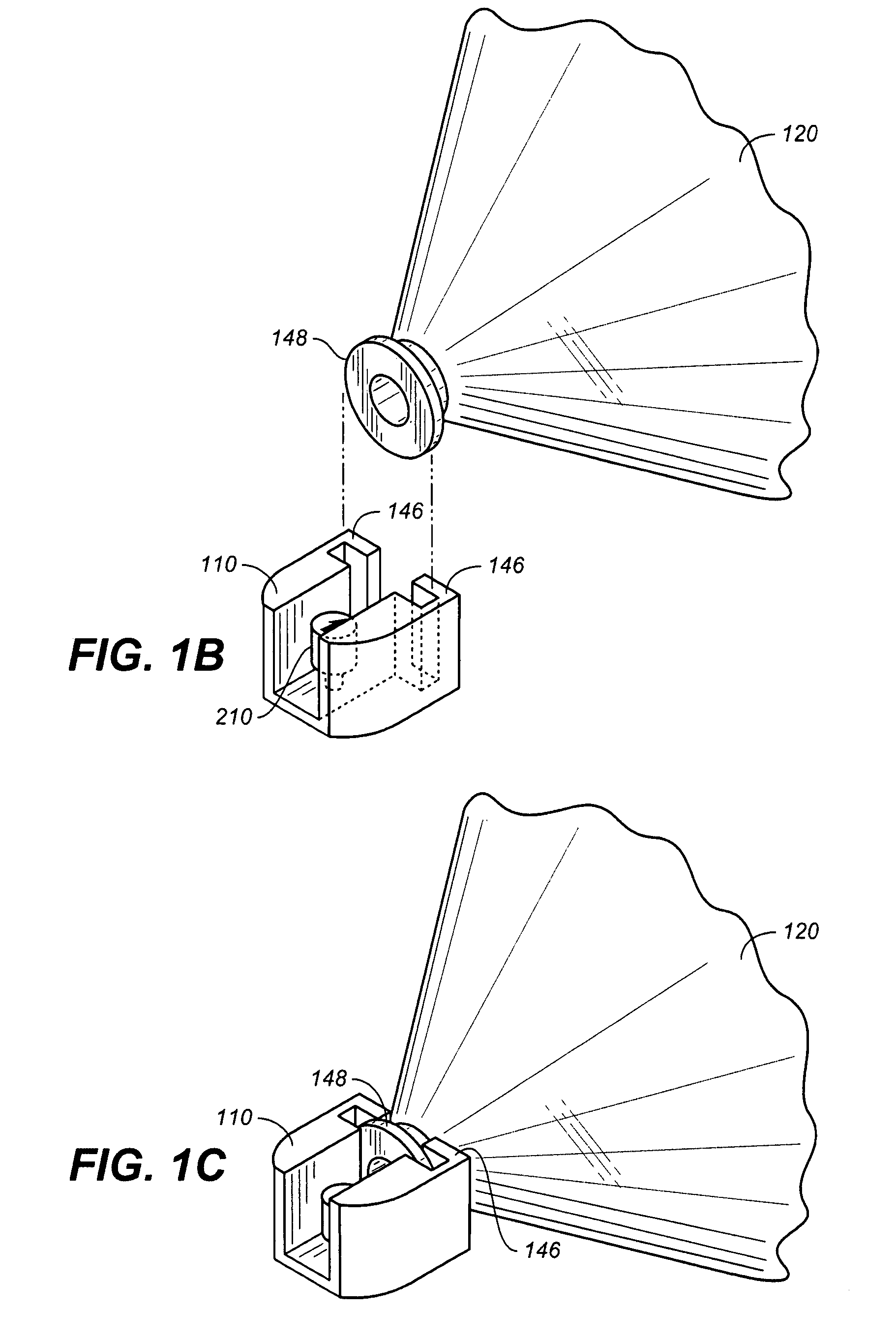

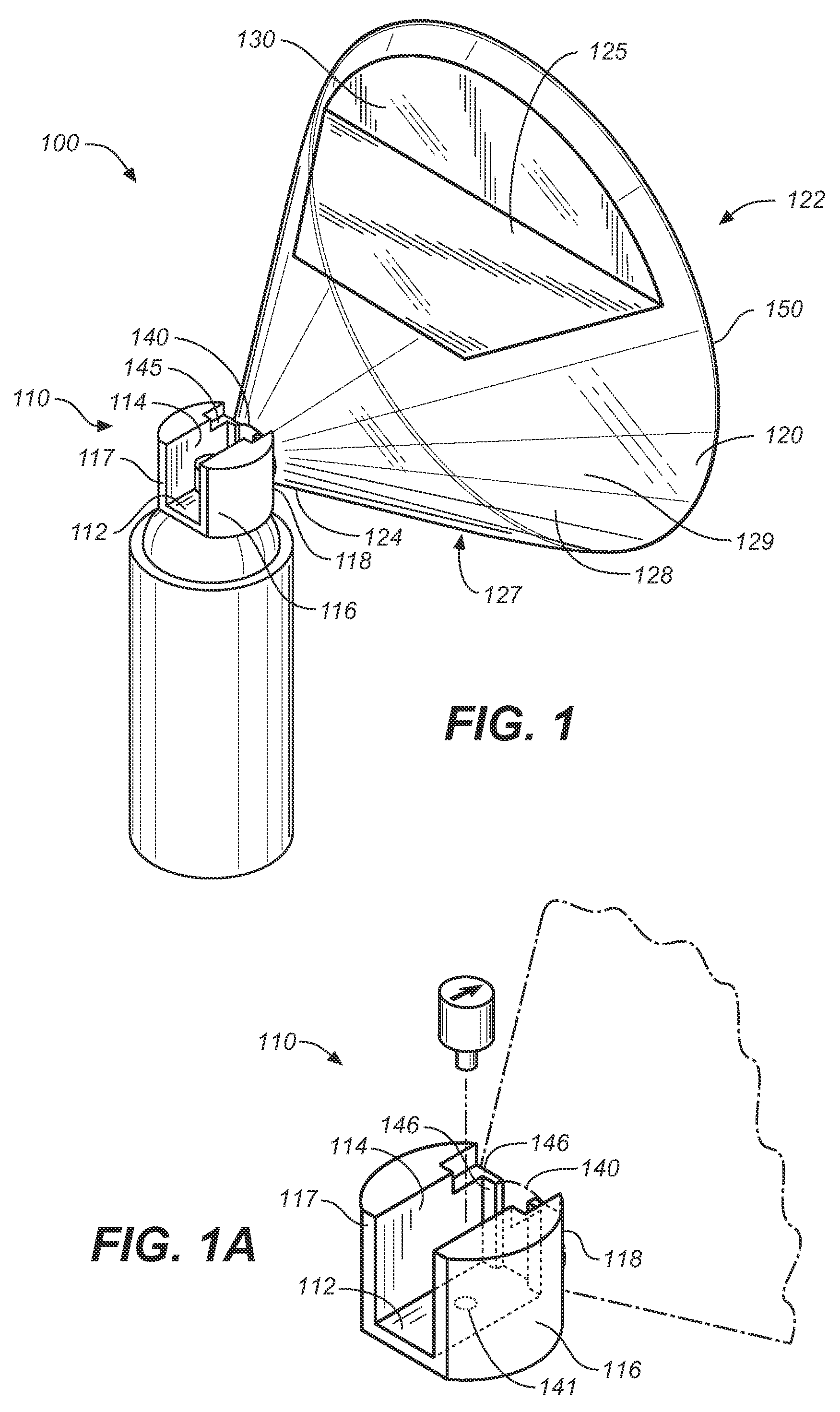

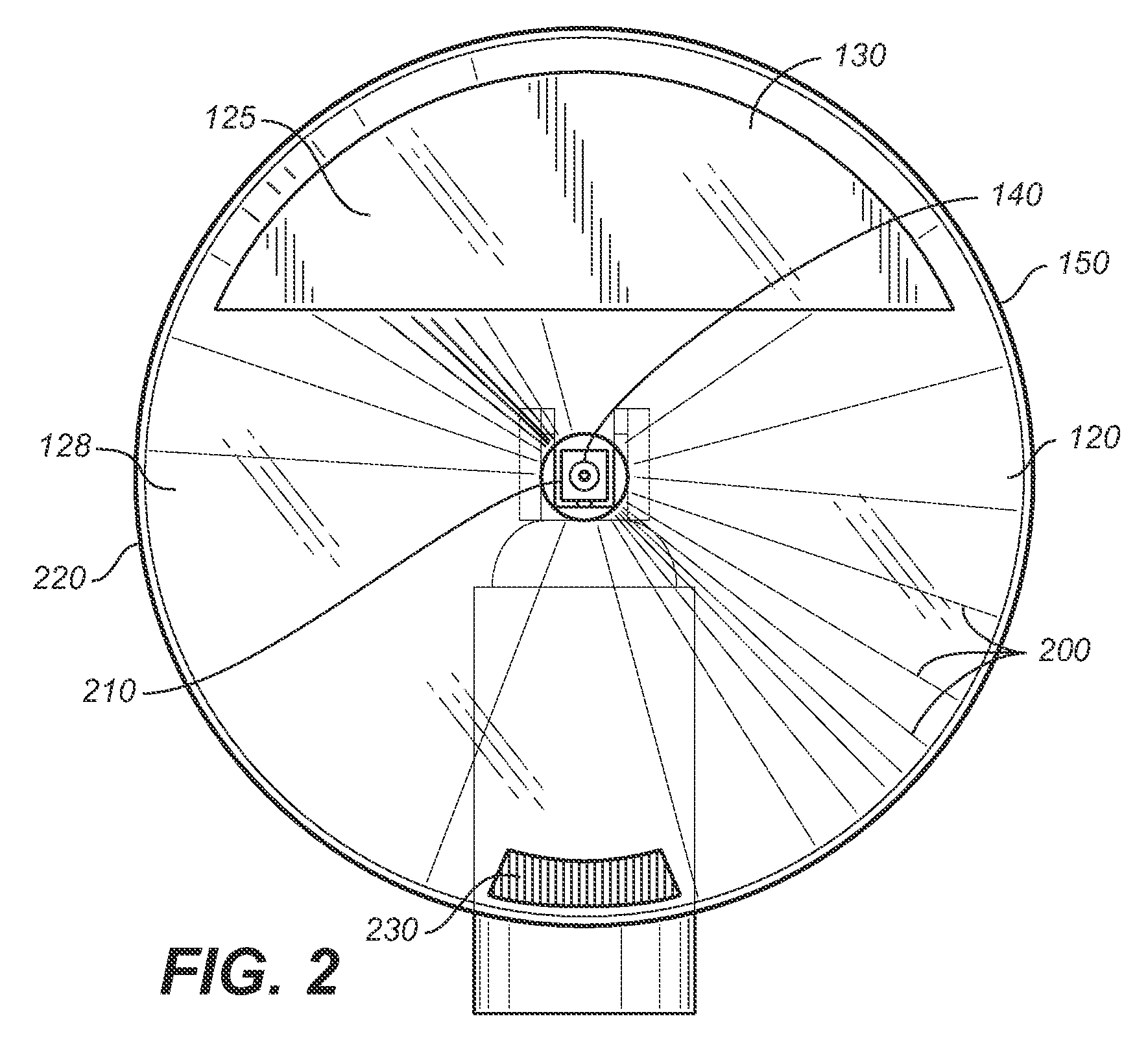

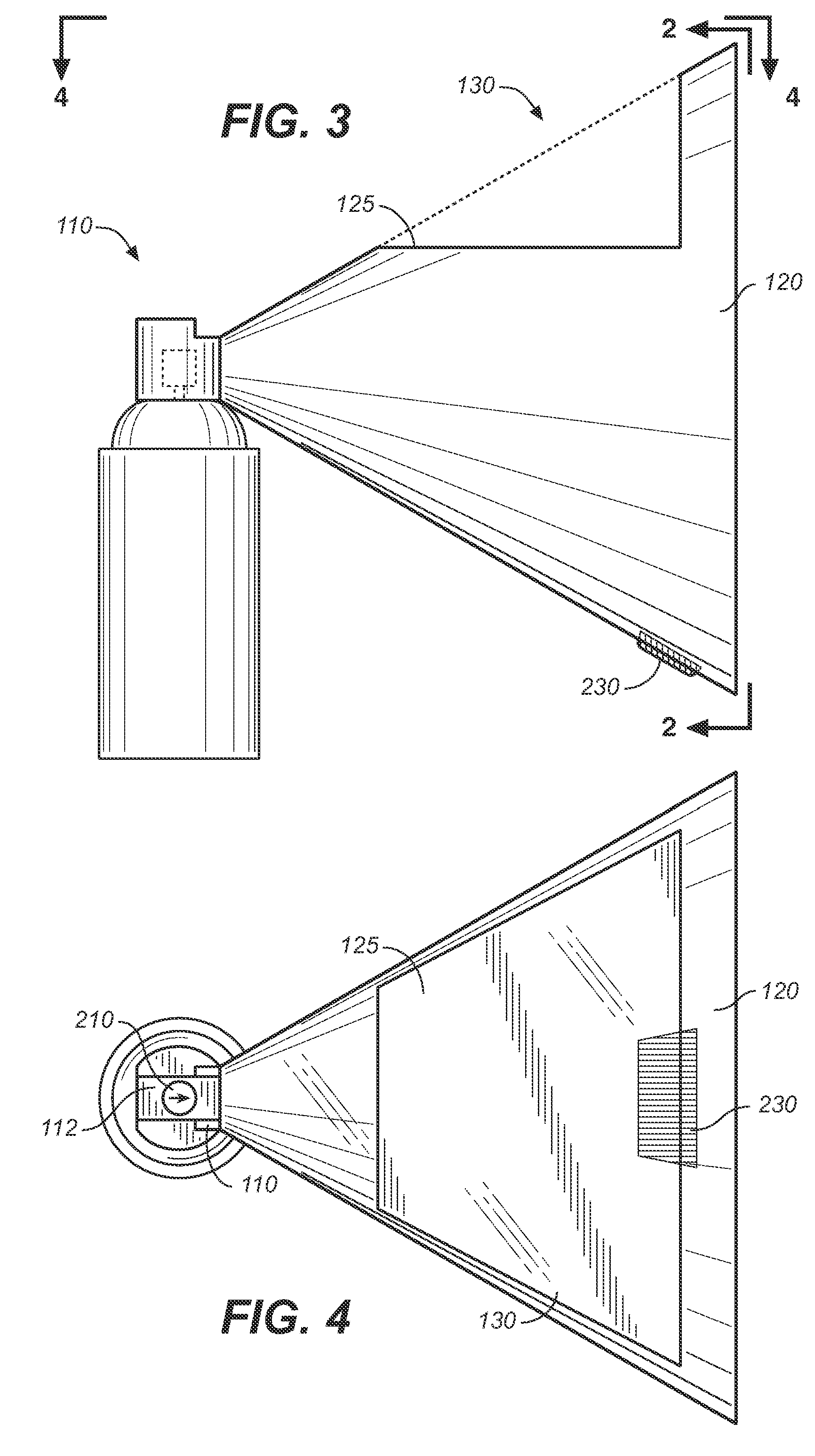

Aerosol spray masking device

A masking device to prevent over-spray when using an aerosol can to apply aerosols to a work surface. The device includes a horizontal channel structure, the back end of which is essentially open and serves as an insertion point for an aerosol nozzle feed tube from an aerosol can, while the front end serves as an attachment seat for a masking unit. The back end of the horizontal channel is open, providing the user access to the aerosol nozzle in order to actuate the aerosol nozzle with a finger, whereby an aerosol is propelled forward into a masking unit. The masking unit has a small orifice creating a planar opening at the back, and a large orifice creating a generally planar opening at the front The masking unit is essentially hollow, providing the ability to contain an aerosol, the large orifice serving as a mask against a target surface. The masking unit has an observation cut out covered with a transparent film, a vent to exhaust excess pressure and aerosol, and raised beads radiating from the small orifice to the large orifice, which serve as excess aerosol accumulators.

Owner:MONTERROSA CHRISTOPHER H

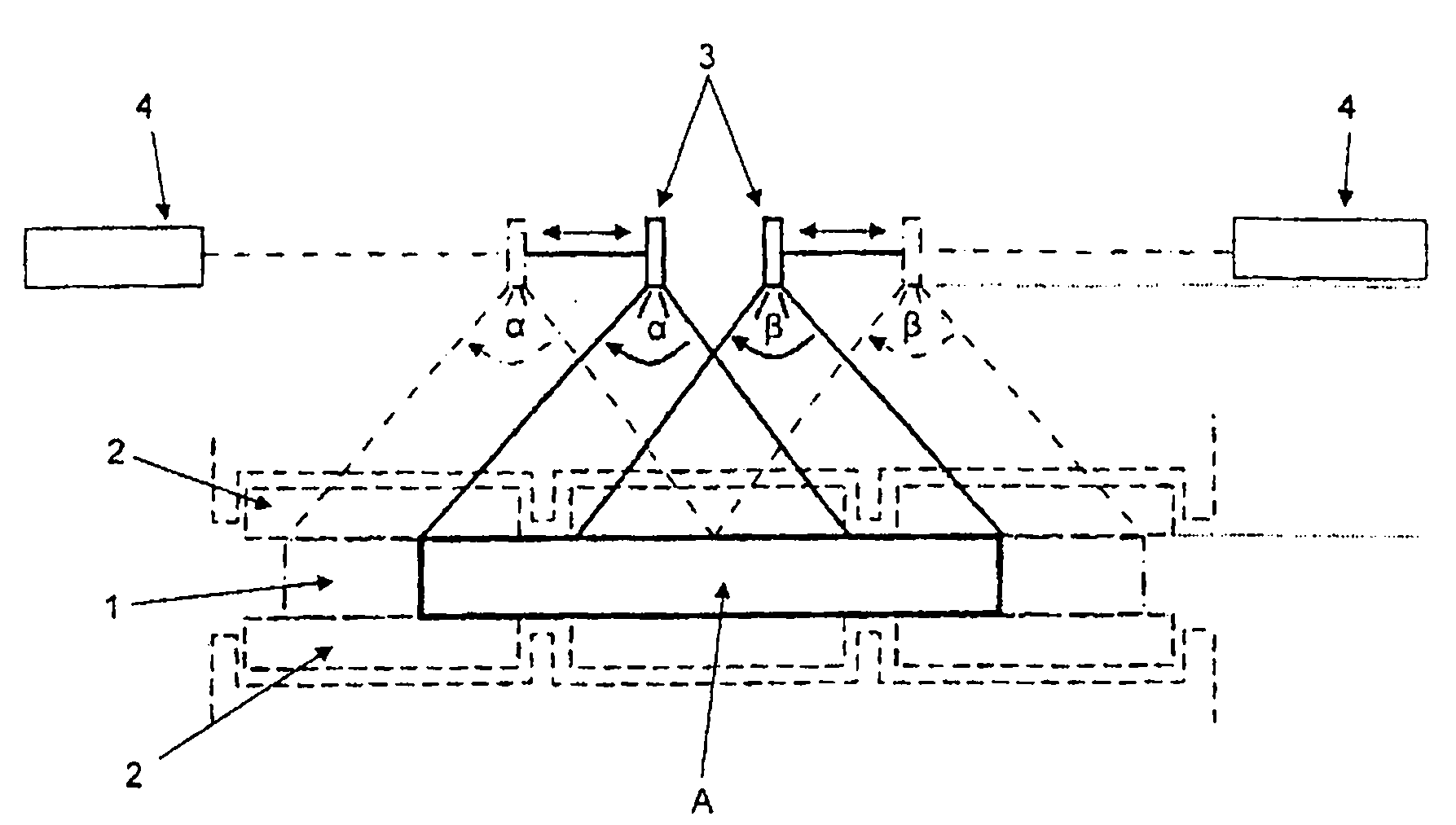

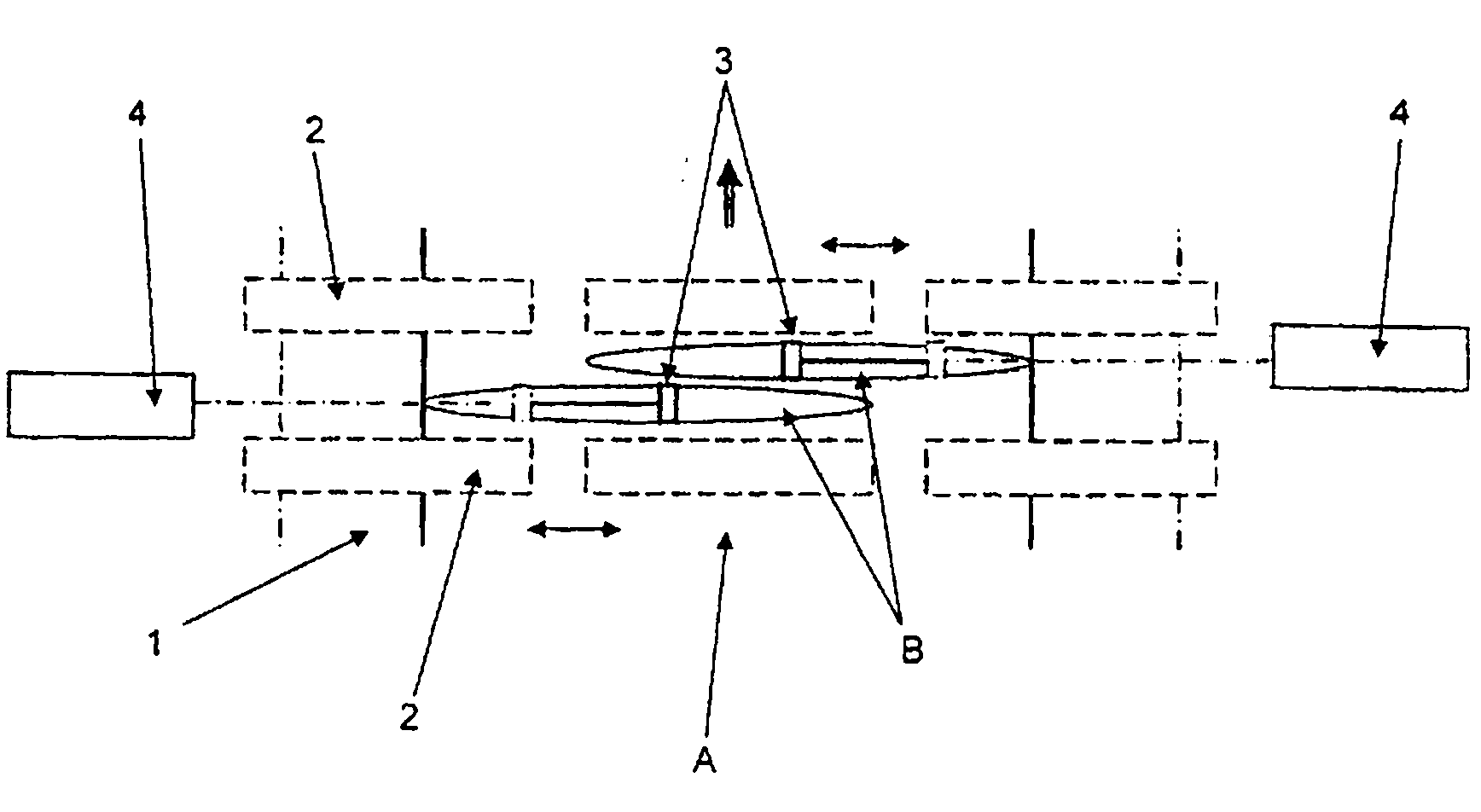

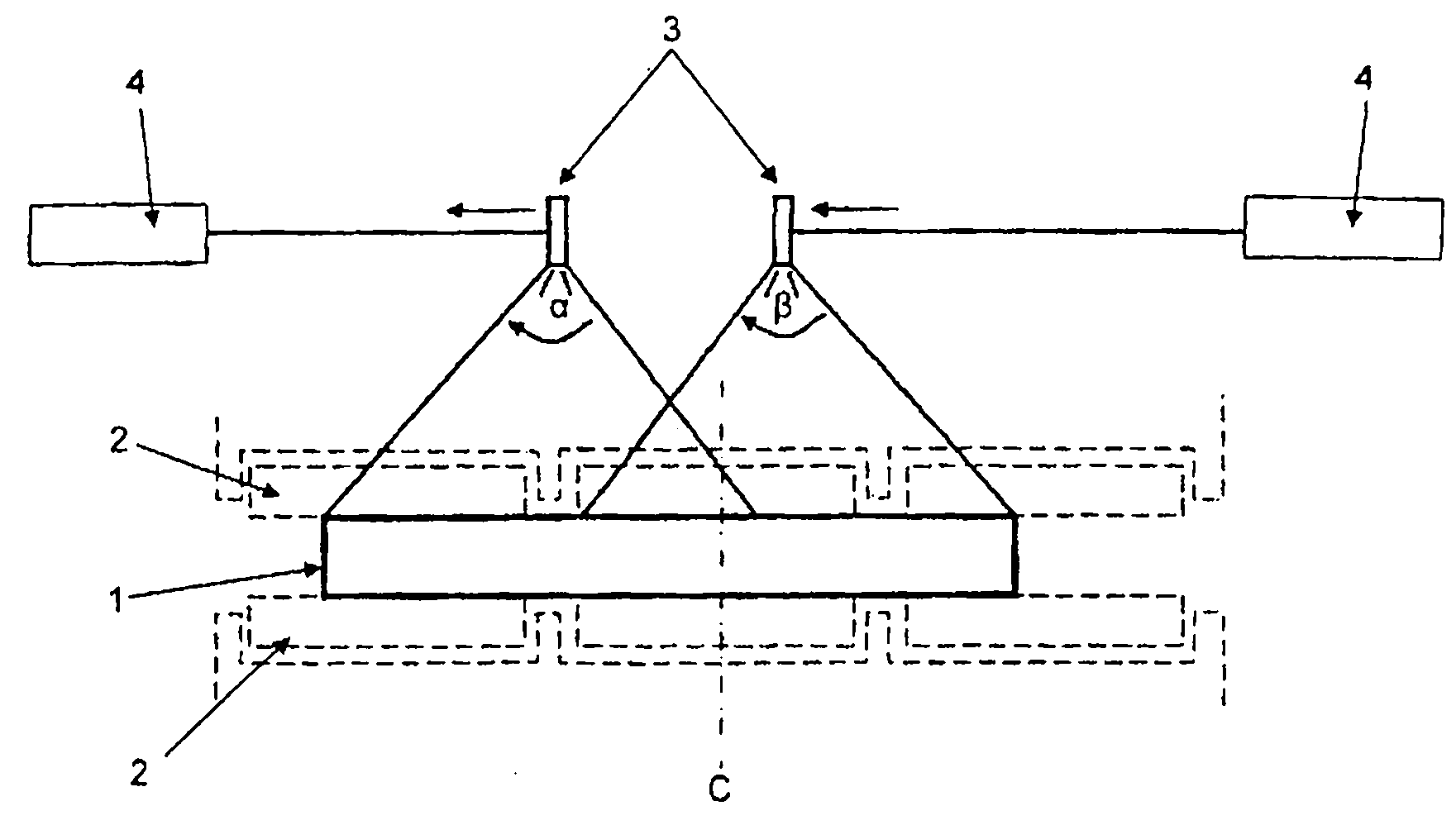

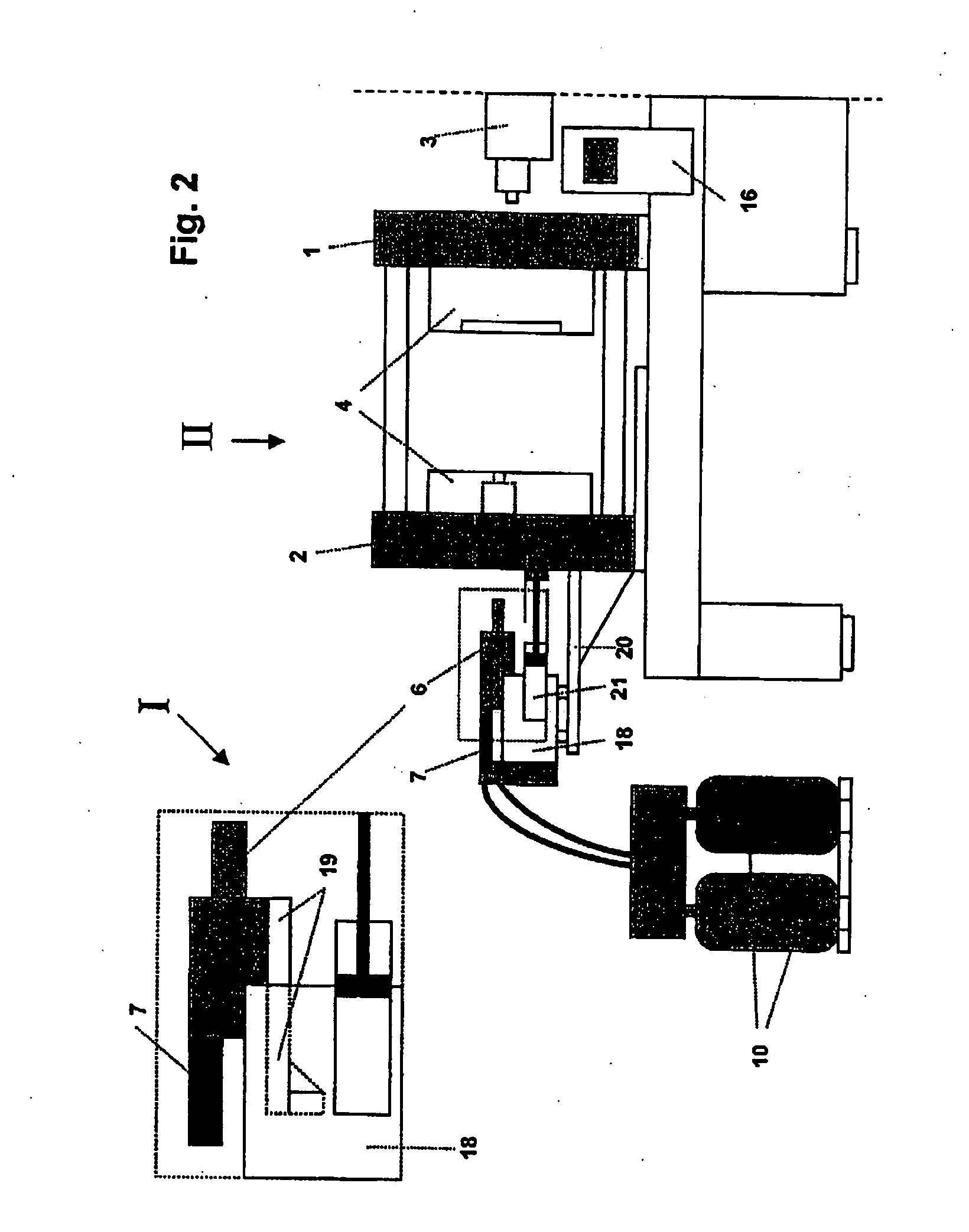

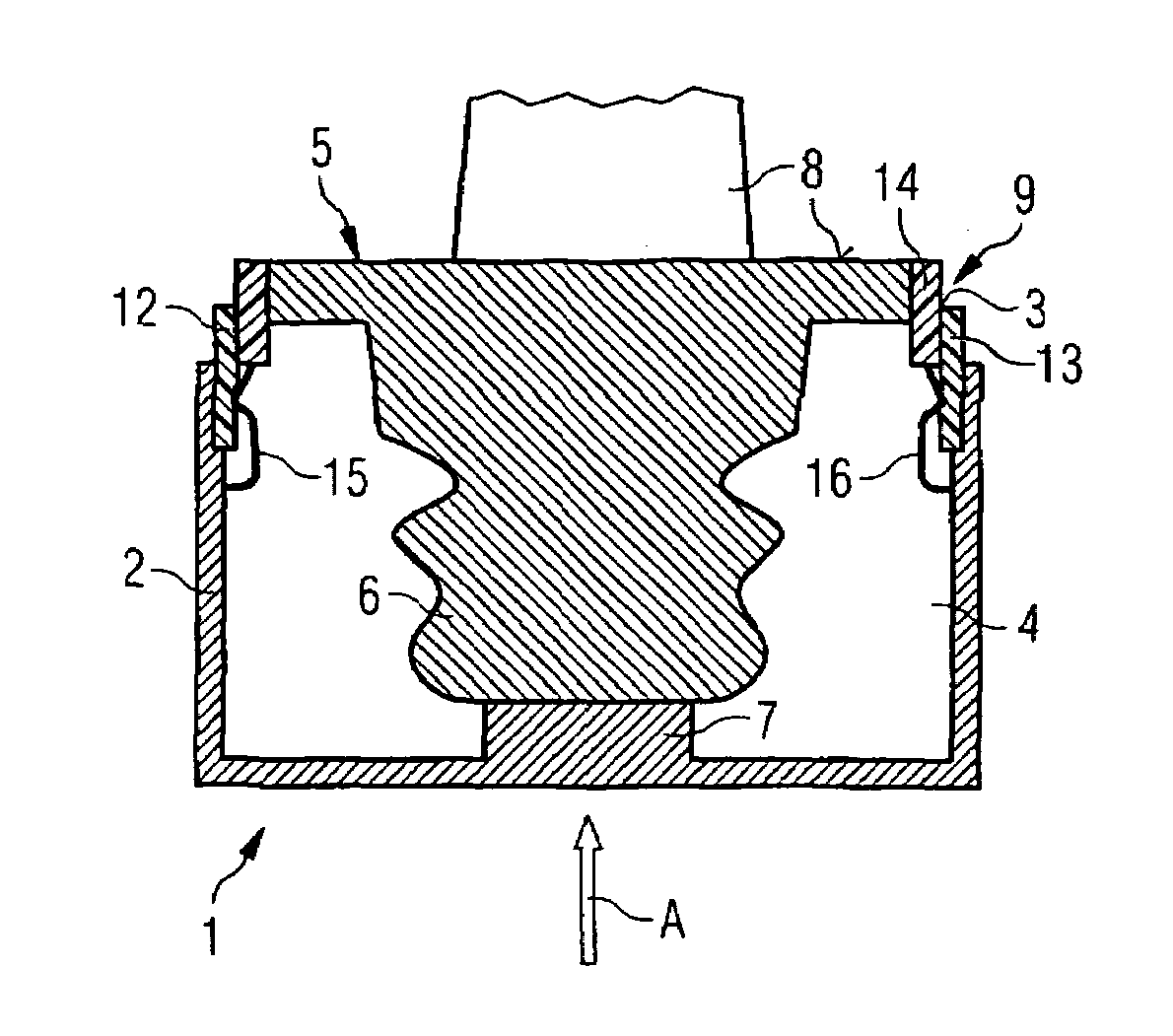

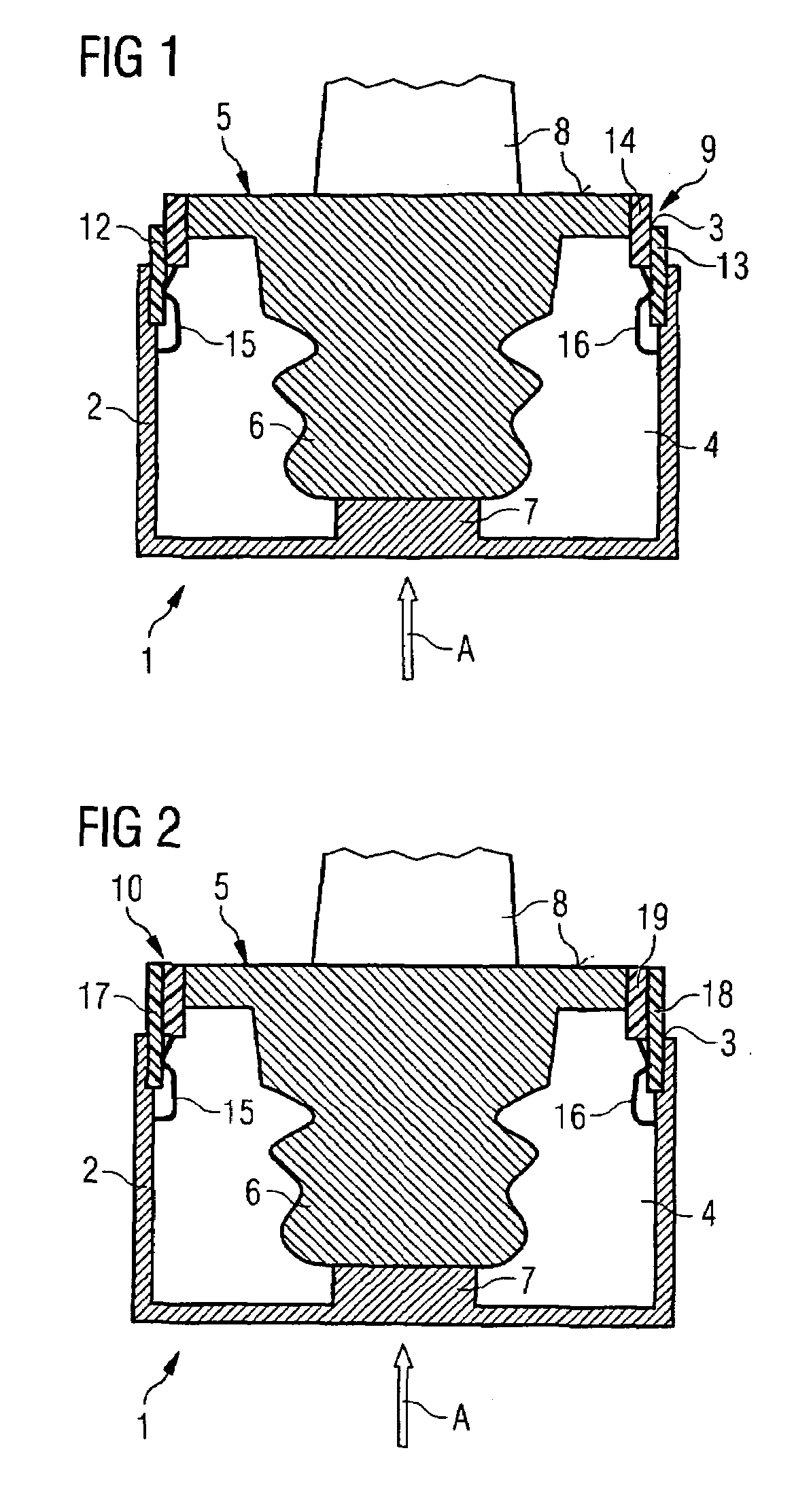

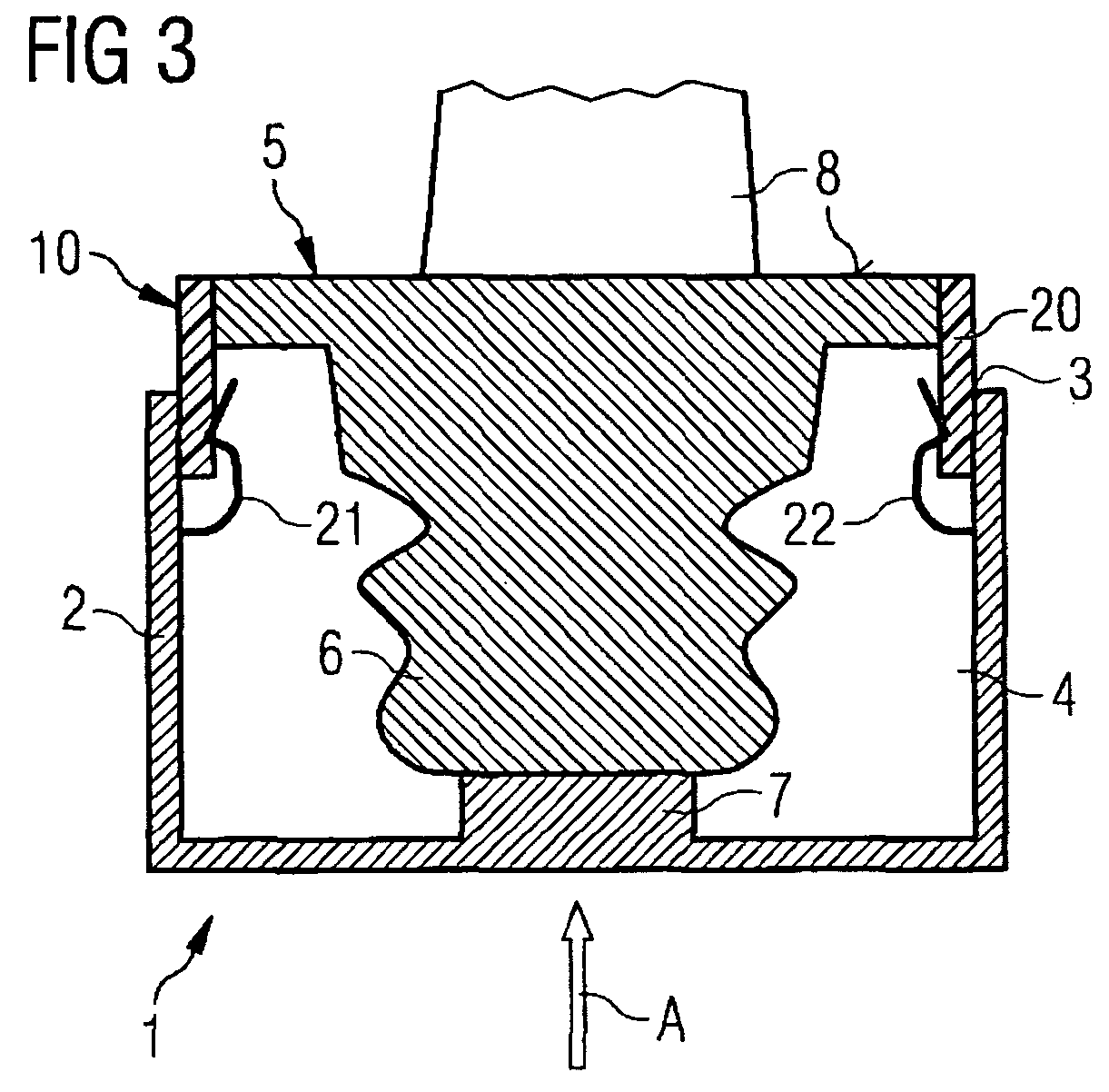

Device and method for secondary cooling in a continuous casting system

The invention relates to a device and to a method for secondary cooling in a continuous casting system and to a continuous casting system designed accordingly. According to the invention, nozzles (3) are arranged between two rolls or rollers (2) adjacent to each other in the casting direction, in a roller guide or in a strand guide, said nozzles applying coolant onto the surface of the strand 1, 1', 1''. According to the invention, the vertical distance of the nozzles (3) to the strand 1, 1', 1'' remains constant, wherein the nozzles (3) can be moved independently of each other parallel to the longitudinal axis of the rollers (2) by a displacement and positioning device (4). Thus a low space requirement and high flexibility during cooling of a strand 1, 1', 1'' is achieved. According to the invention, overspraying of the strand edge can thus be prevented, intensive cooling of the strand center is made possible, an asymmetrical strand course can be taken into consideration in the cooling, and strands in a multistrand operation can be optimally cooled.

Owner:SMS GRP GMBH

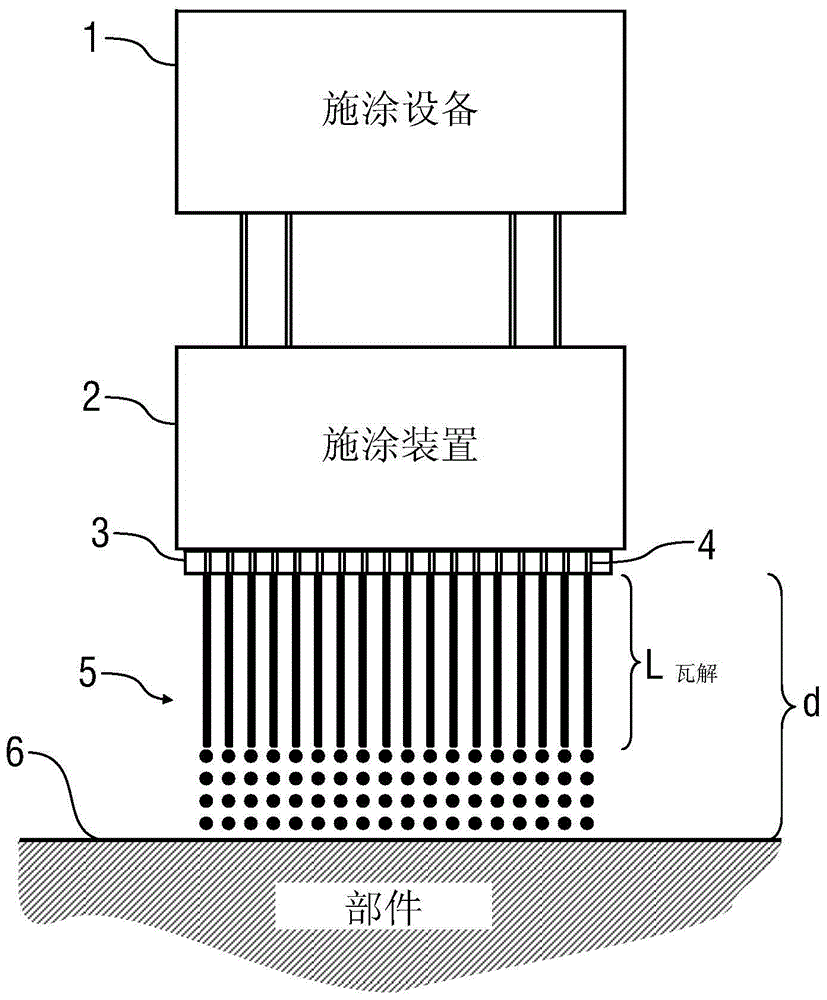

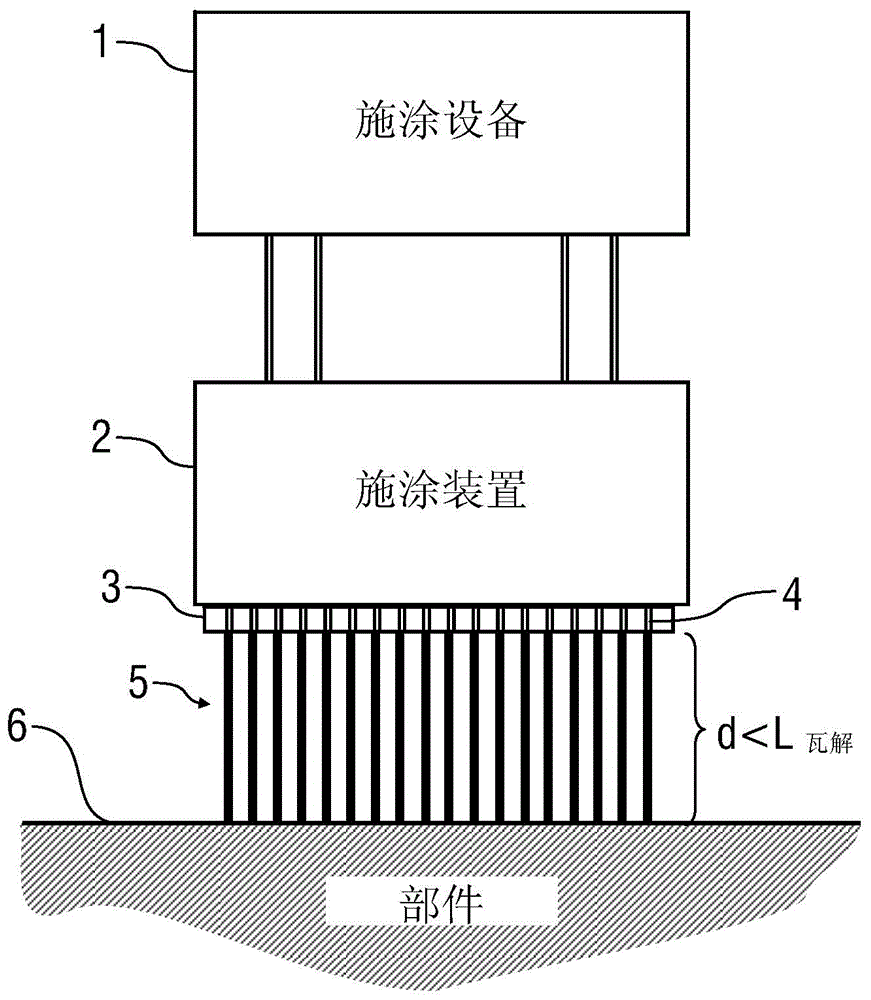

Application method and application facility

ActiveCN104994966AHigh application efficiencyIncrease the number ofSpray nozzlesSpecial surfacesSeparating agentAdhesive

The invention relates to an application method for applying a coating agent, in particular a varnish or paint, a sealant, a separating agent or an adhesive, to a component (6), in particular to a motor vehicle body component. The application method comprises the following steps: dispensing a coating agent jet (5) from an application device (2) and positioning the application device (2) relative to the component (6) at a defined application distance (d) between the application device (2) and the component (6) such that the coating agent jet (5) strikes the component (6) and coats the component (6). According to the invention, the application distance (d) is less than the collapse length (LZERFALL) of the coating agent jet (5) so that the coating agent jet (5) strikes the component (6) with its continuous portion. The invention further relates to a corresponding application facility.

Owner:DUERR SYST GMBH

Method of preparing turbine blades for spray coating and mounting for fixing such a turbine blade

InactiveUS20070110910A1Prevent oversprayImprove cooling effectMolten spray coatingSpraying apparatusTurbine bladeEngineering

The invention relates to a method of preparing turbine blades for spray coating their blade region that is subjected to the medium flowing through during operation in a spray coating apparatus, in which the turbine blade is inserted with its blade root into a cavity of a mounting in such a way that it protrudes with the blade region that adjoins the blade root from an opening of the cavity to form a gap between the rim of the opening and the turbine blade, and in which the gap is bridged by a shielding fixed on the mounting, which is characterized in that a shielding layer of a plastic which is resistant during the spray coating is used for the shielding, the shielding layer being arranged in such a way that it reaches up to the boundary between the blade root and the blade region.

Owner:SIEMENS AG

Disposable Fluid Applicator

InactiveUS20100074671A1Efficiently and safely dispensesPrevent oversprayPackaging toiletriesInk reservoir pensMaterial PerforationBiomedical engineering

A disposable fluid applicator having a reservoir with a first membrane and a second membrane. Said reservoir containing a fluid to be dispensed. Said first membrane of the reservoir having perforations and being covered by a permeable and / or absorbent spreader. A removable tab assembly is disposed between said spreader and said first membrane of the reservoir that seals said perforations. When the tab is pulled from between said spreader and said first membrane of the reservoir the perforations are unsealed allowing the fluid contained inside the reservoir to flow out through the perforations into and through the spreader where the fluid can be applied to a desired surface.

Owner:PRAX CORP

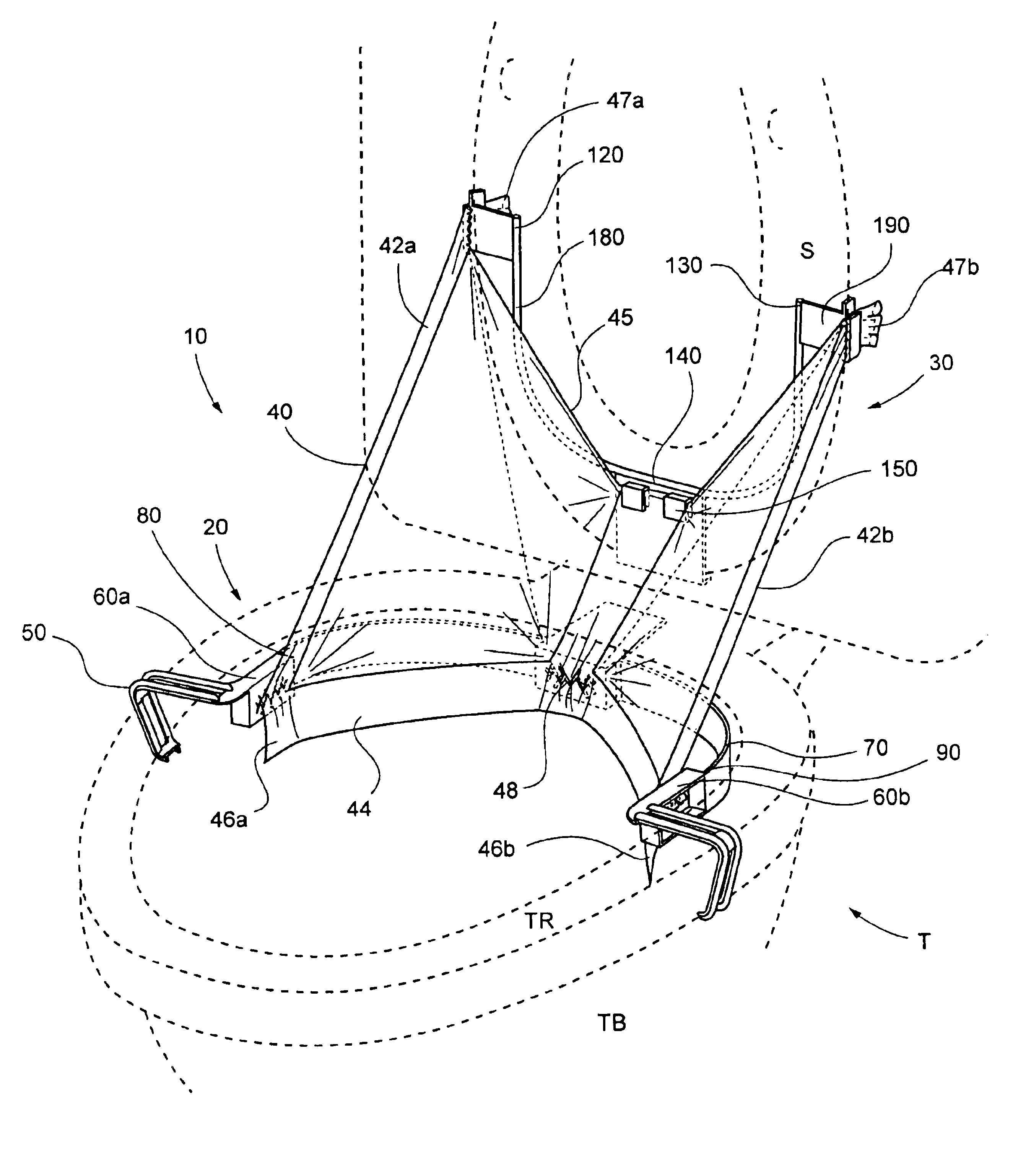

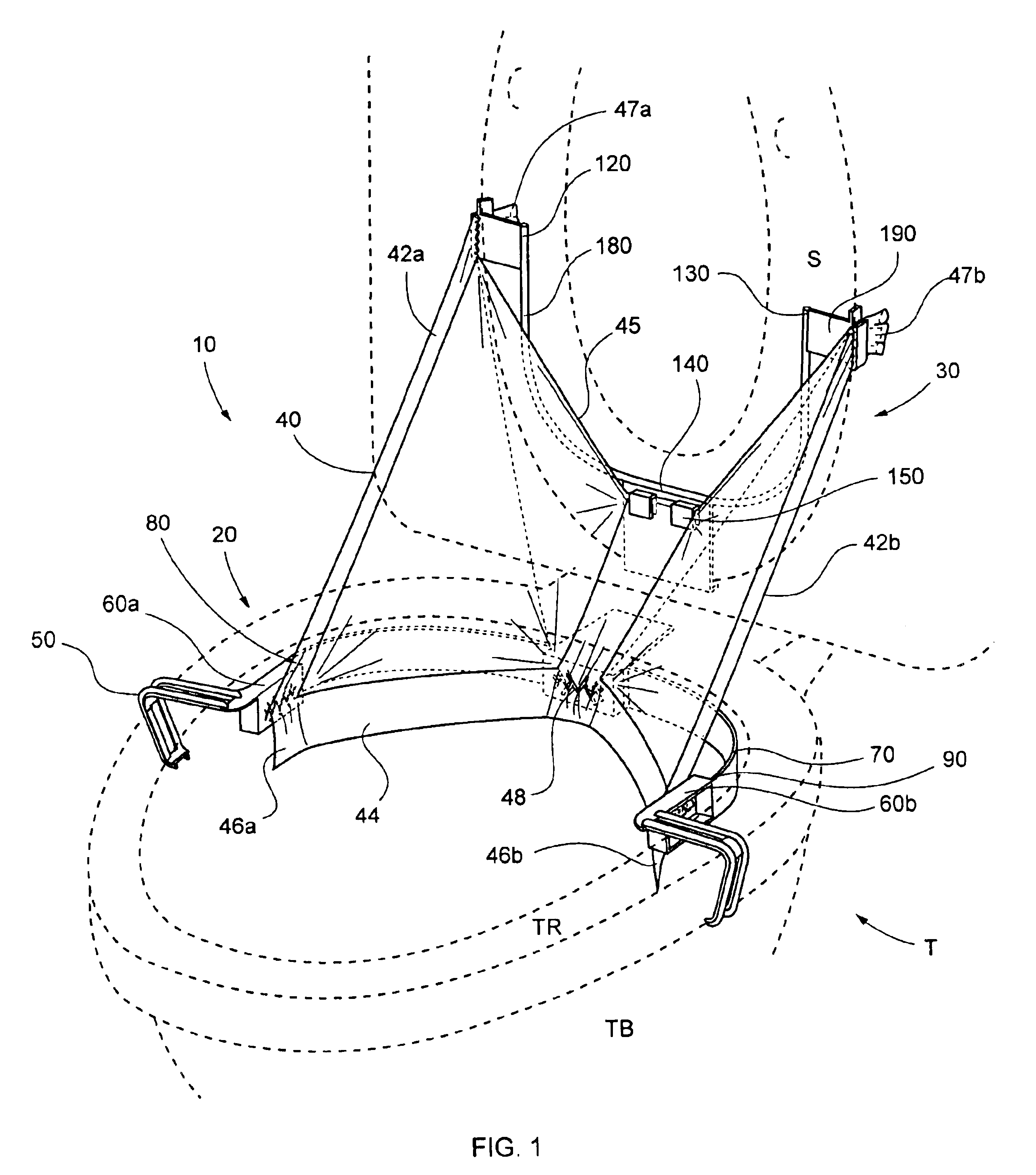

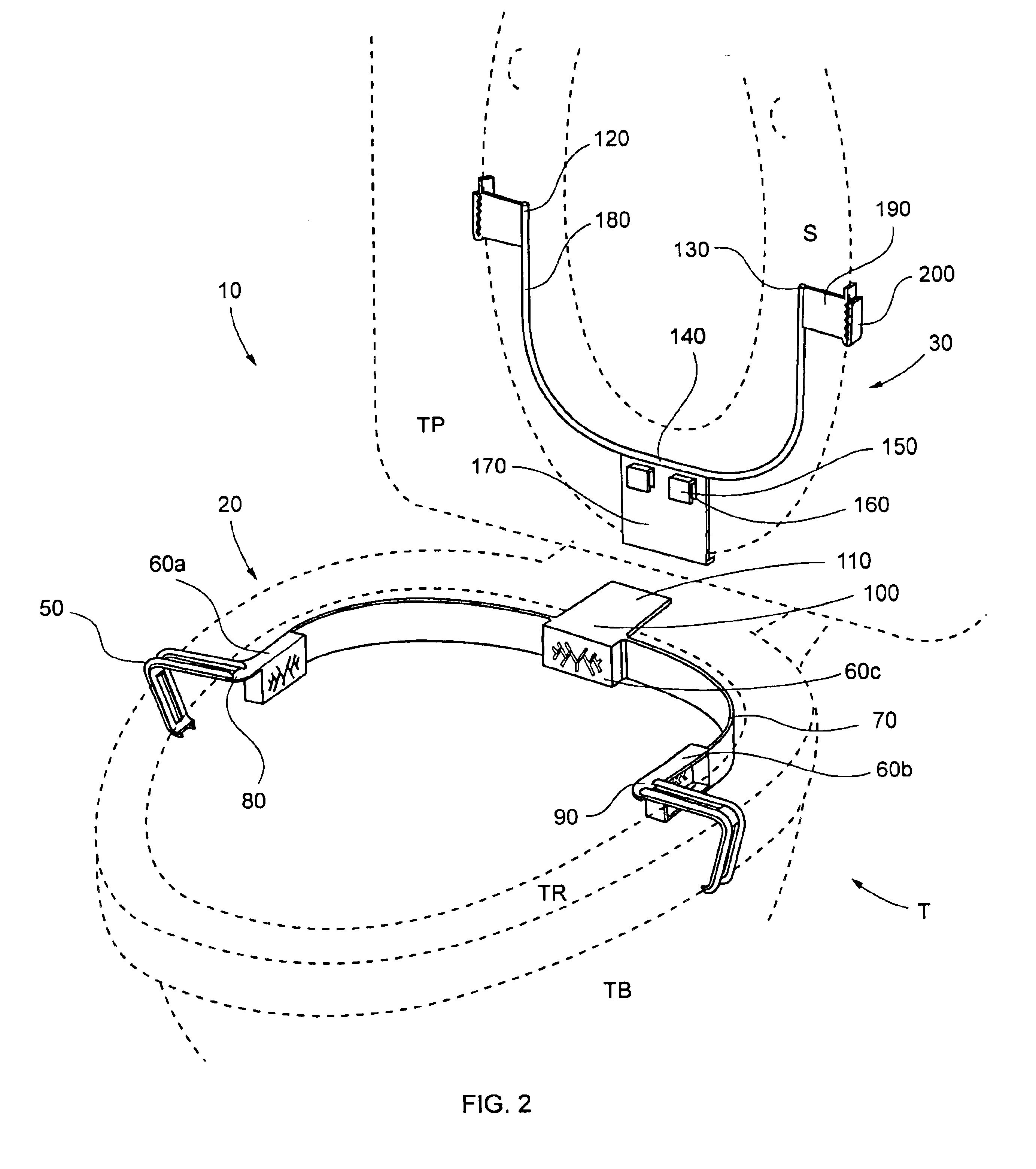

Overspray shield for toilet

InactiveUS6874171B2Quick installationPrevent oversprayFluid dynamicsLavatory sanitoryEngineeringFlush toilet

A disposable urinal device and method suitable for installation on a toilet preventing overspray of urine and for containing said urine within the confines of the toilet. Said device comprises a frame having top and bottom portions attaching respectively to the toilet seat and the toilet bowl and an attachable sheet of material. The sheet attaches to said frame and may be readily removed therefrom for disposal.

Owner:ERVES DEANNA

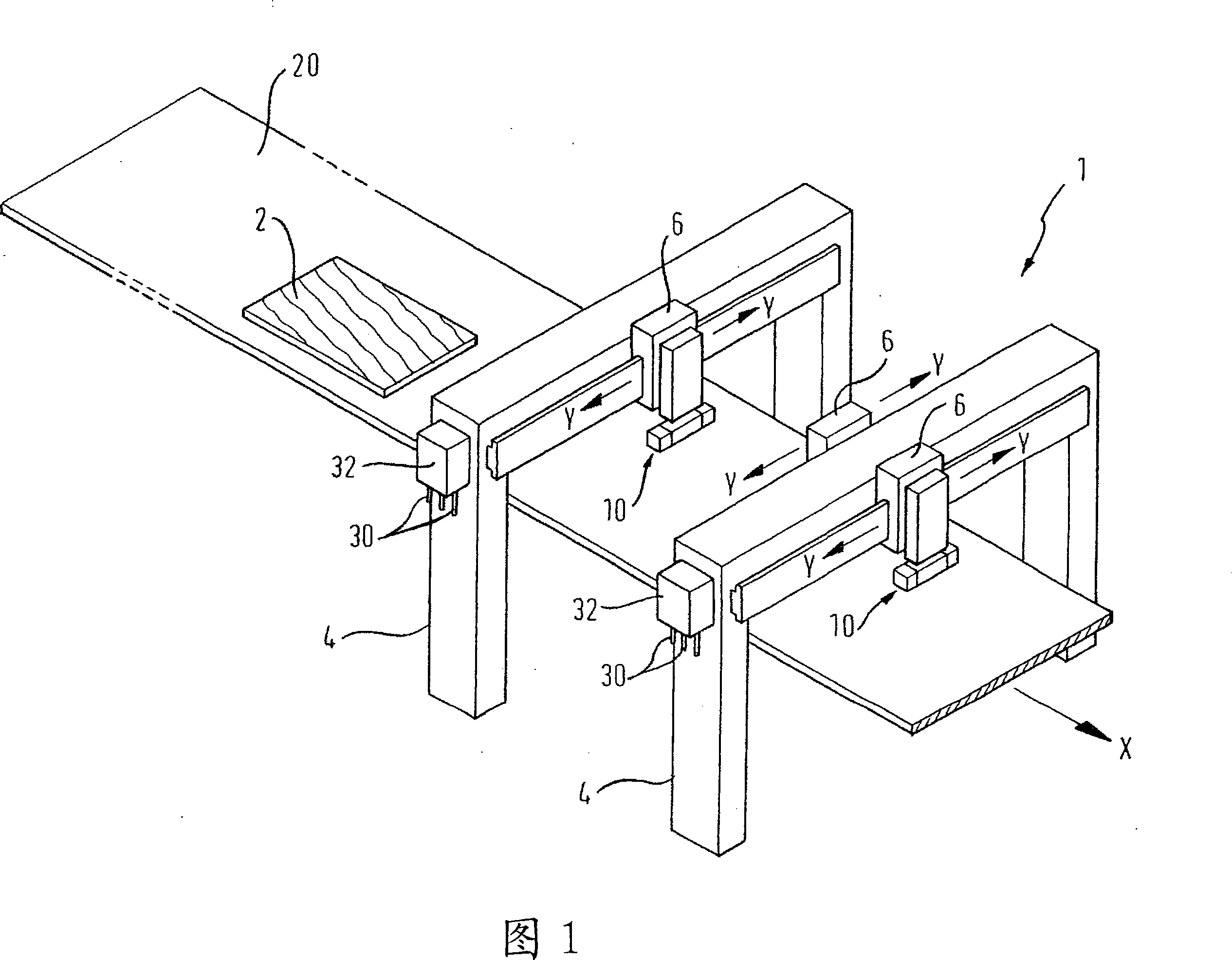

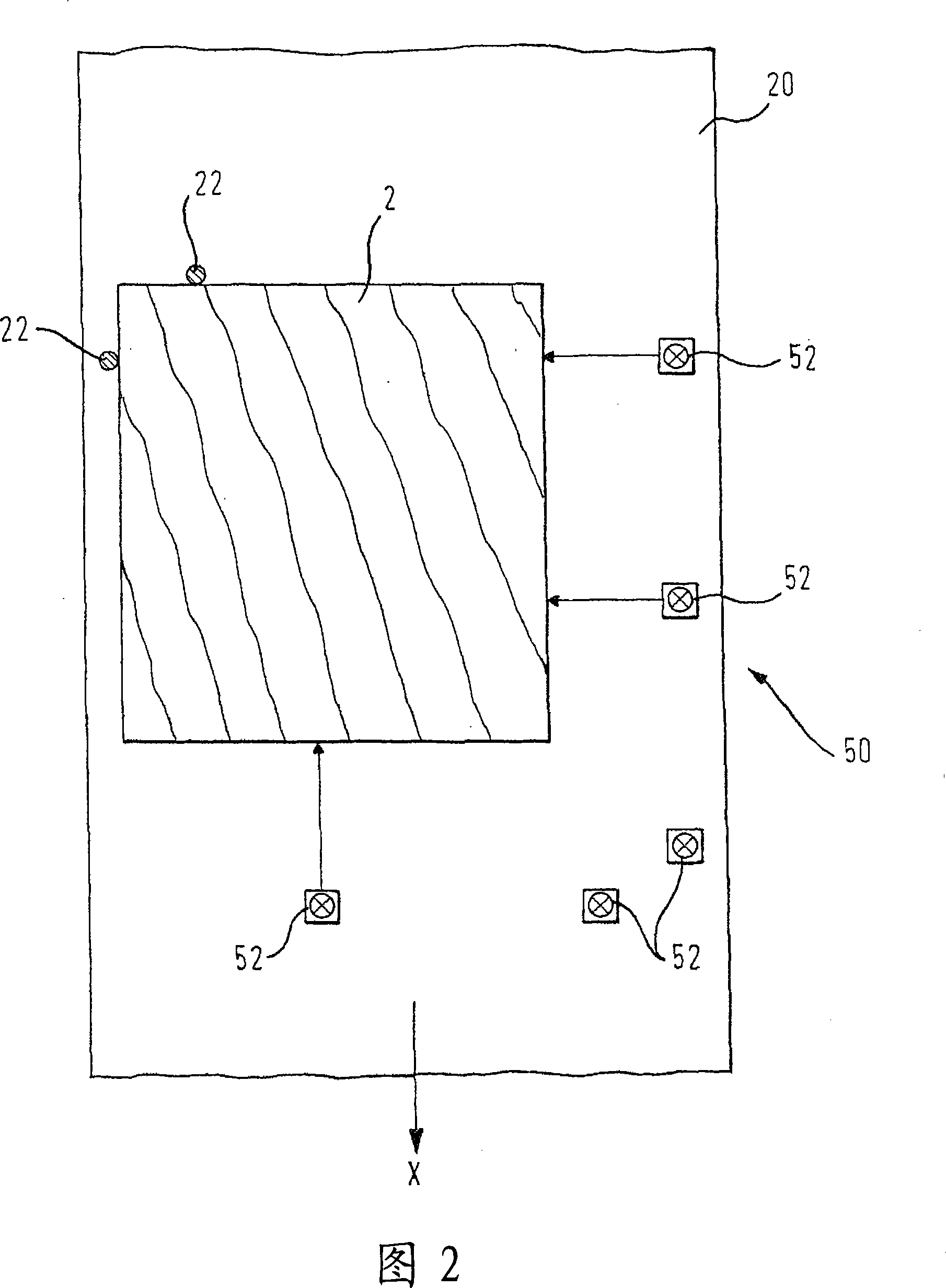

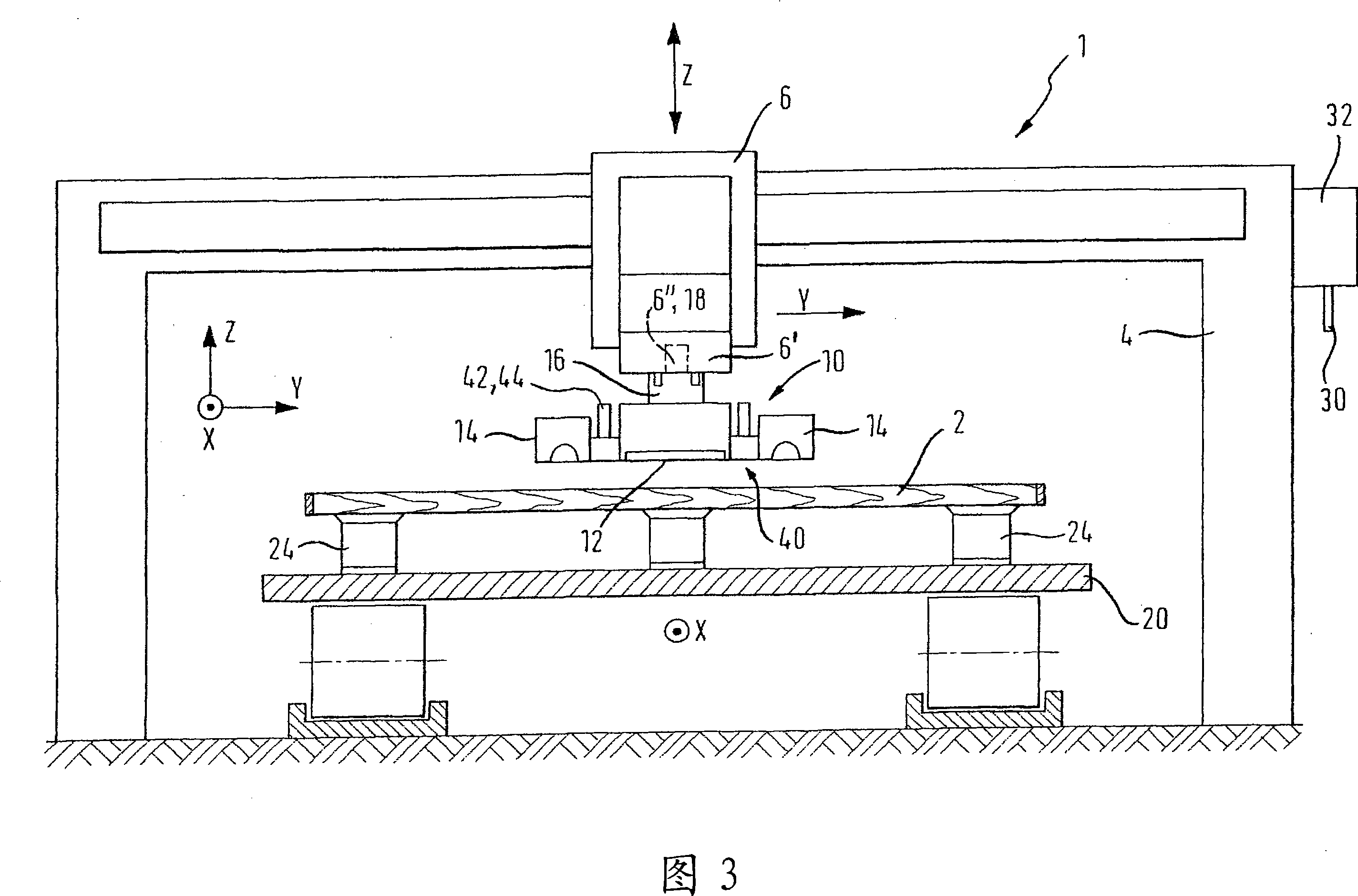

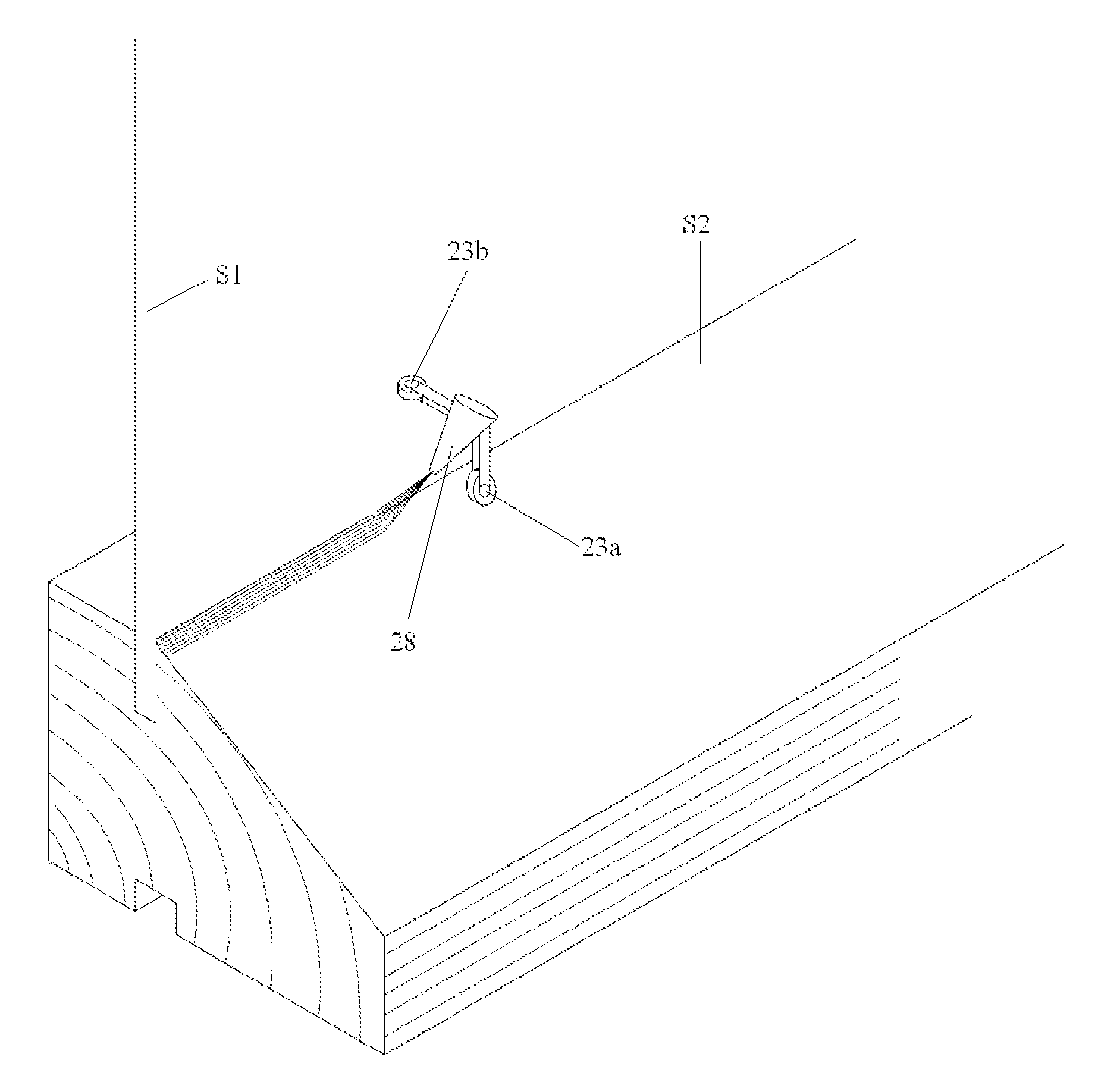

Device for patterning workpieces

ActiveCN101177074APrevent oversprayQuality improvementSpecial ornamental structuresTypewritersImage detectionPrinting ink

The invention relates to a device (1) for producing a pattern on a workpiece (2), preferably at least partially made of wood, wooden material, etc., the device having an inkjet printing device (10), the printing device There are a plurality of nozzles (12) capable of ejecting ink droplets; a workpiece carrying device (20), the workpiece carrying device is used to carry the workpiece (2) to be patterned; a conveying device, the conveying device is used to cause the workpiece to be made Relative movement between said workpiece (2) of a pattern and said printing device (10). The device according to the invention is characterized in that it also has at least one image detection sensor (46).

Owner:HOMAG GMBH

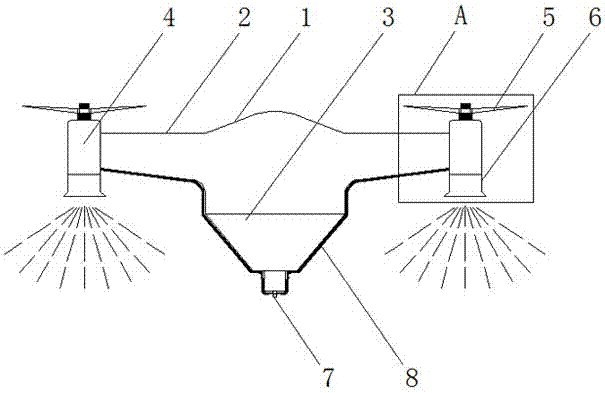

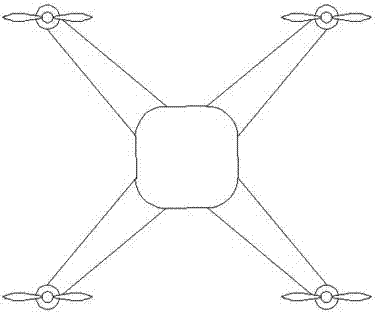

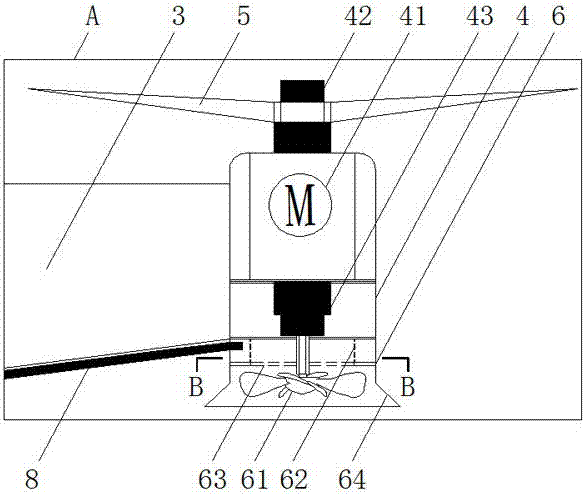

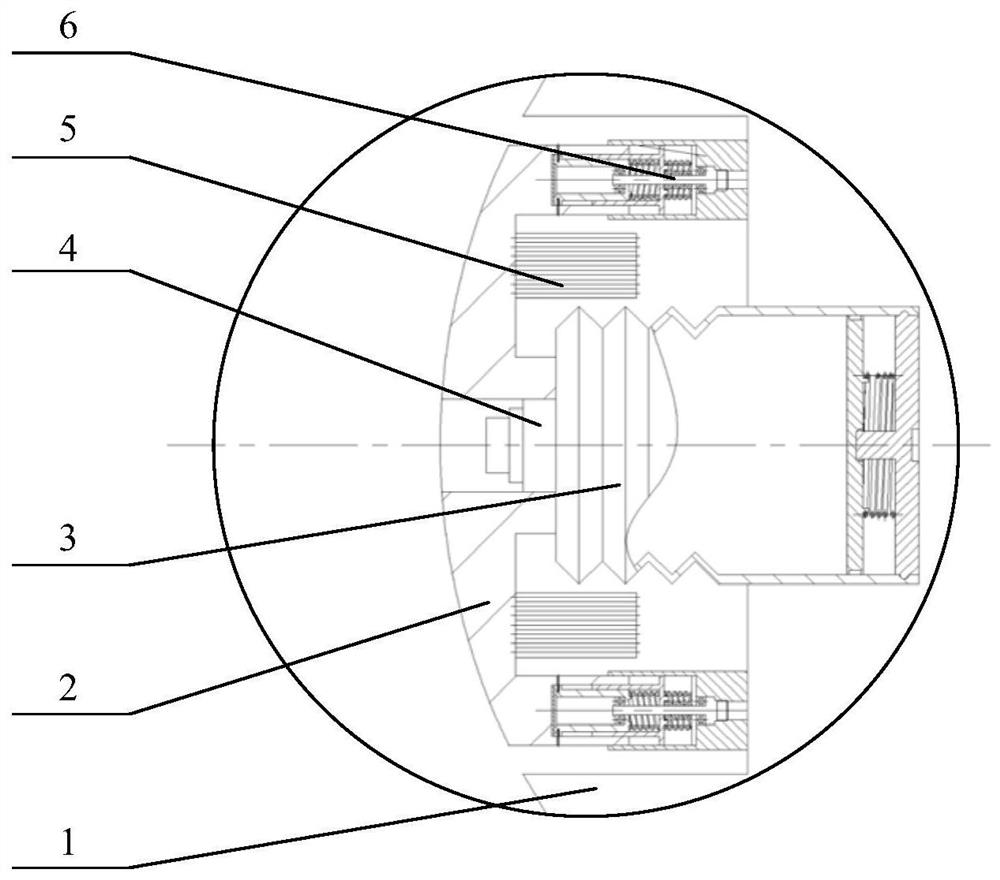

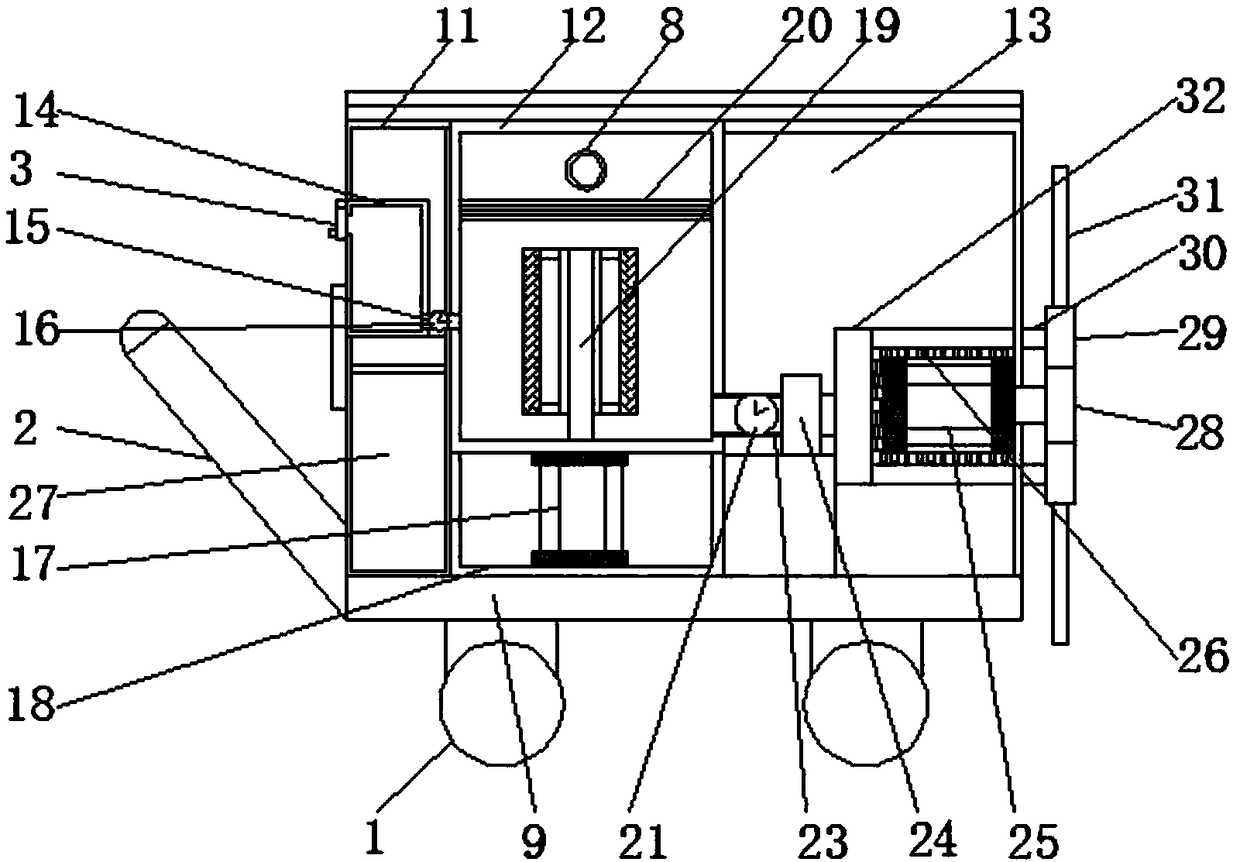

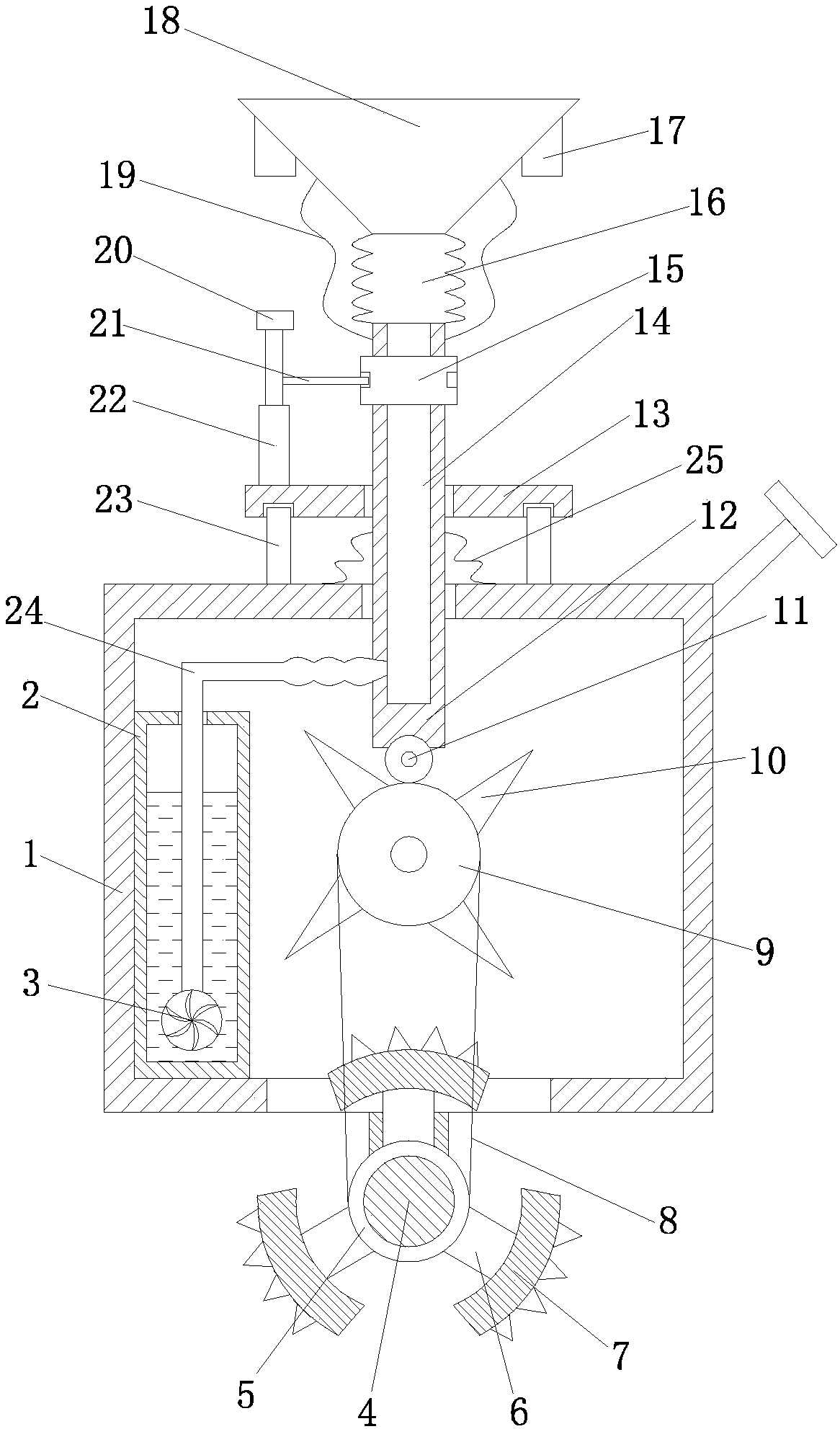

Centrifugal farm-chemical spraying multi-rotor unmanned aerial vehicle

PendingCN107487445AGood stabilityStrong maneuverabilityAircraft componentsInsect catchers and killersElectric machineryAutomotive engineering

The invention discloses a centrifugal farm-chemical spraying multi-rotor unmanned aerial vehicle (UAV). The centrifugal farm-chemical spraying multi-rotor UAV comprises a vehicle body, vehicle arms and a motor seat; a spraying head system is connected to the motor seat and comprises a shell body and impellers for atomizing farm-chemicals; a double-head motor is mounted in the motor seat and is in driving connection with rotor wings and the impellers; a storage bin provided with a pressure pump is mounted below the vehicle body, and a conveying pipe is arranged between the storage bin and the shell body; and a switch module is mounted on the pressure pump and is connected with a controlling module of the UAV. The characteristics of being small in carrying weight and high in flight maneuverability of the multi-rotor UAV are utilized, the centrifugal farm-chemical spraying multi-rotor UAV is suitable for farm-chemical spraying in a small and medium-sized farmland, and emphasizing spraying can be achieved; the motor is arranged as the double-head motor, on the basis of no adding a driving device, the high-speed rotating impellers are utilized to atomize and spray medicinal liquid, manual labor is replaced, cost is reduced, field ditches used for walking is not required to be reserved in the farmland, and the utilization rate of the farmland is improved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

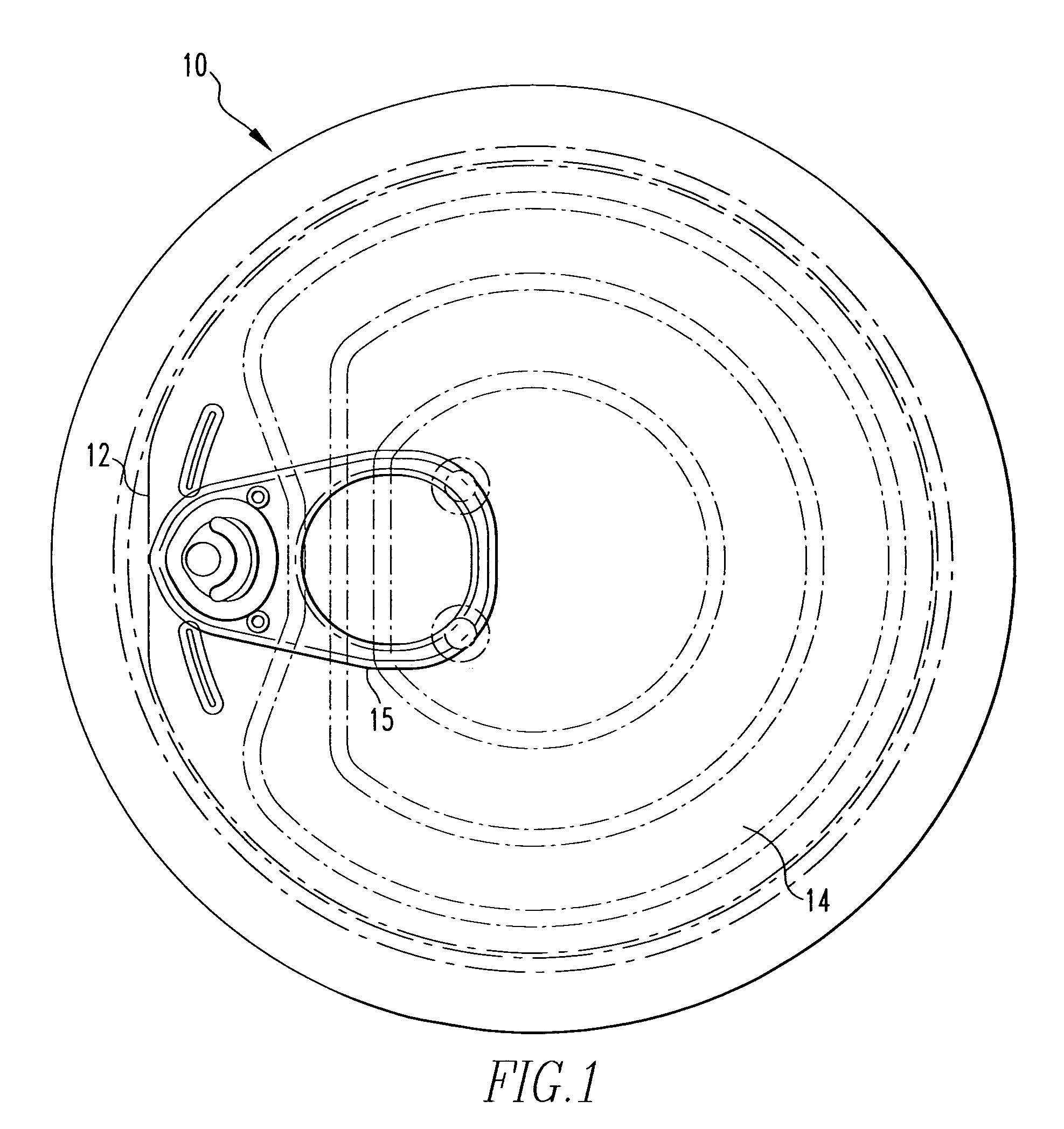

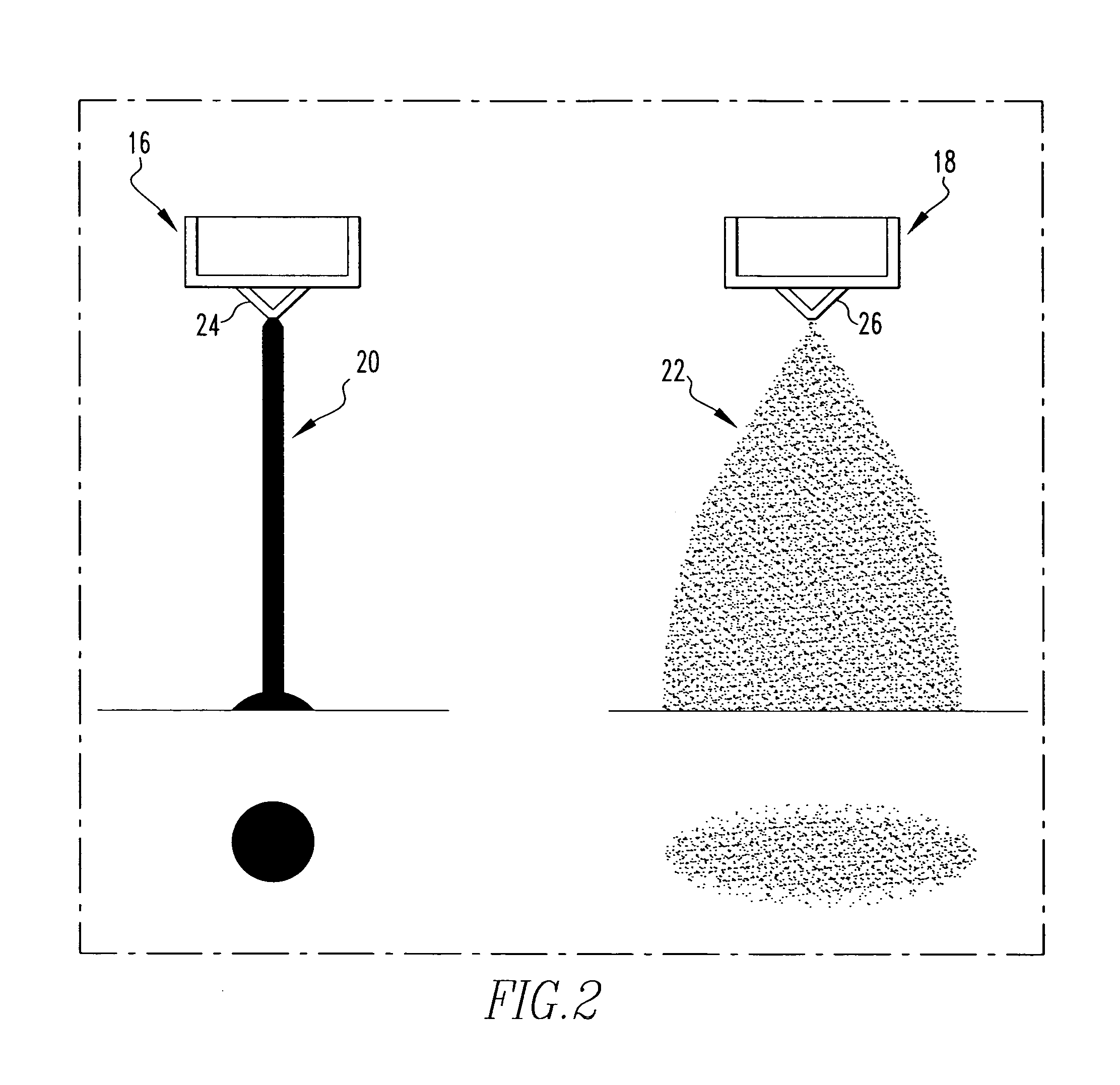

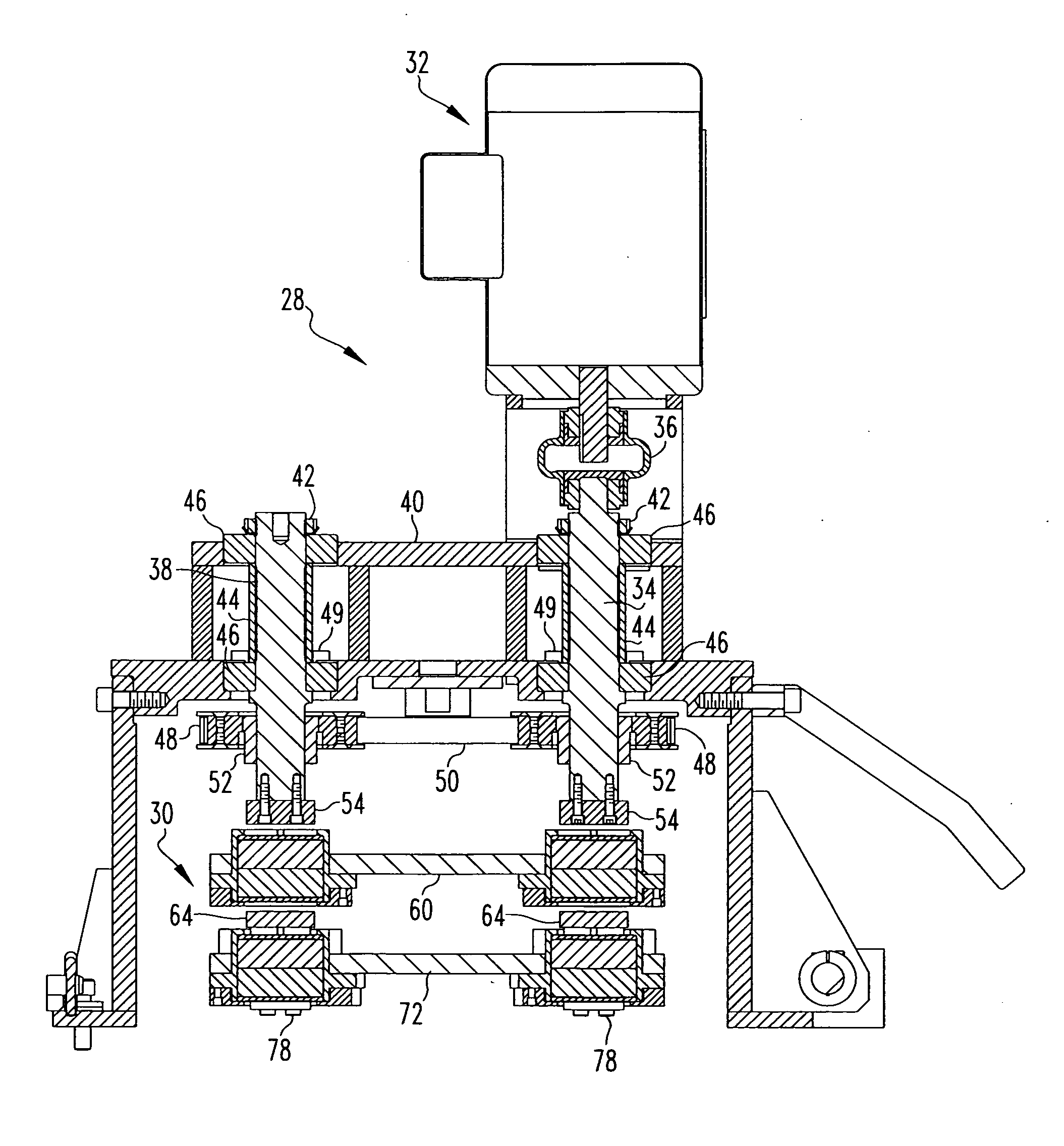

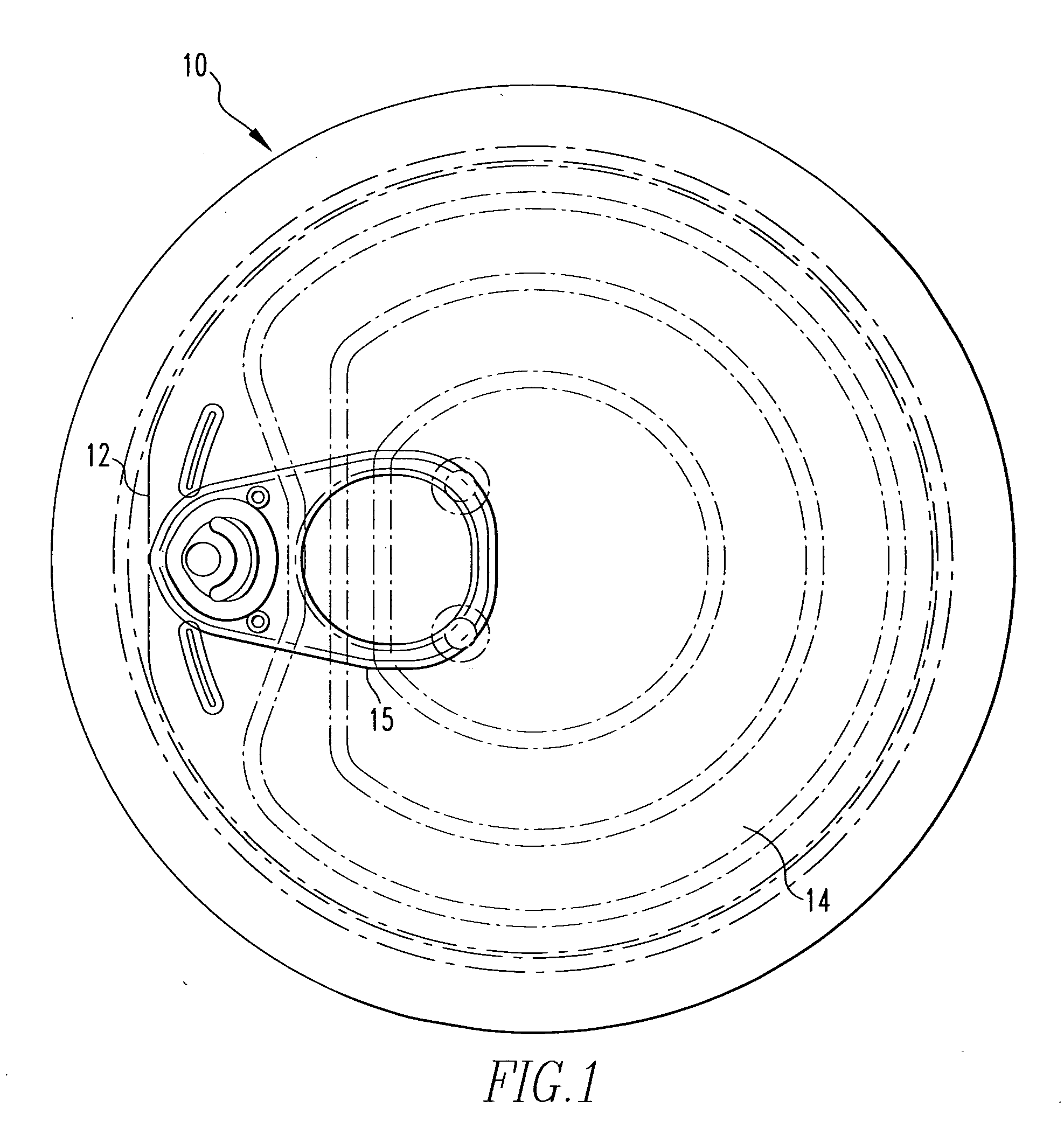

Spray apparatus and method for the repair of can ends

ActiveUS7622002B2Low and high film weightIncrease volumeLiquid surface applicatorsMovable spraying apparatusBiomedical engineeringPackaging industry

This invention generally relates to a spray apparatus and a method useful in the repair of coating adhered to can ends used in the food and beverage packaging industries. The spray apparatus has one or more elongated shafts rotatably coupled to a frame. One or more bearing members are rotatably coupled to the shafts. One or more plates are rotatably coupled to the bearing members. One or more spray guns are coupled to the plates. The spray guns of the spray apparatus are structured to apply fluid to the can end with a solid stream emitted from the spray guns in a circular pattern. A method for the repair of coating adhered on a can end is provided as well.

Owner:STOLLE MACHINERY CO LLC

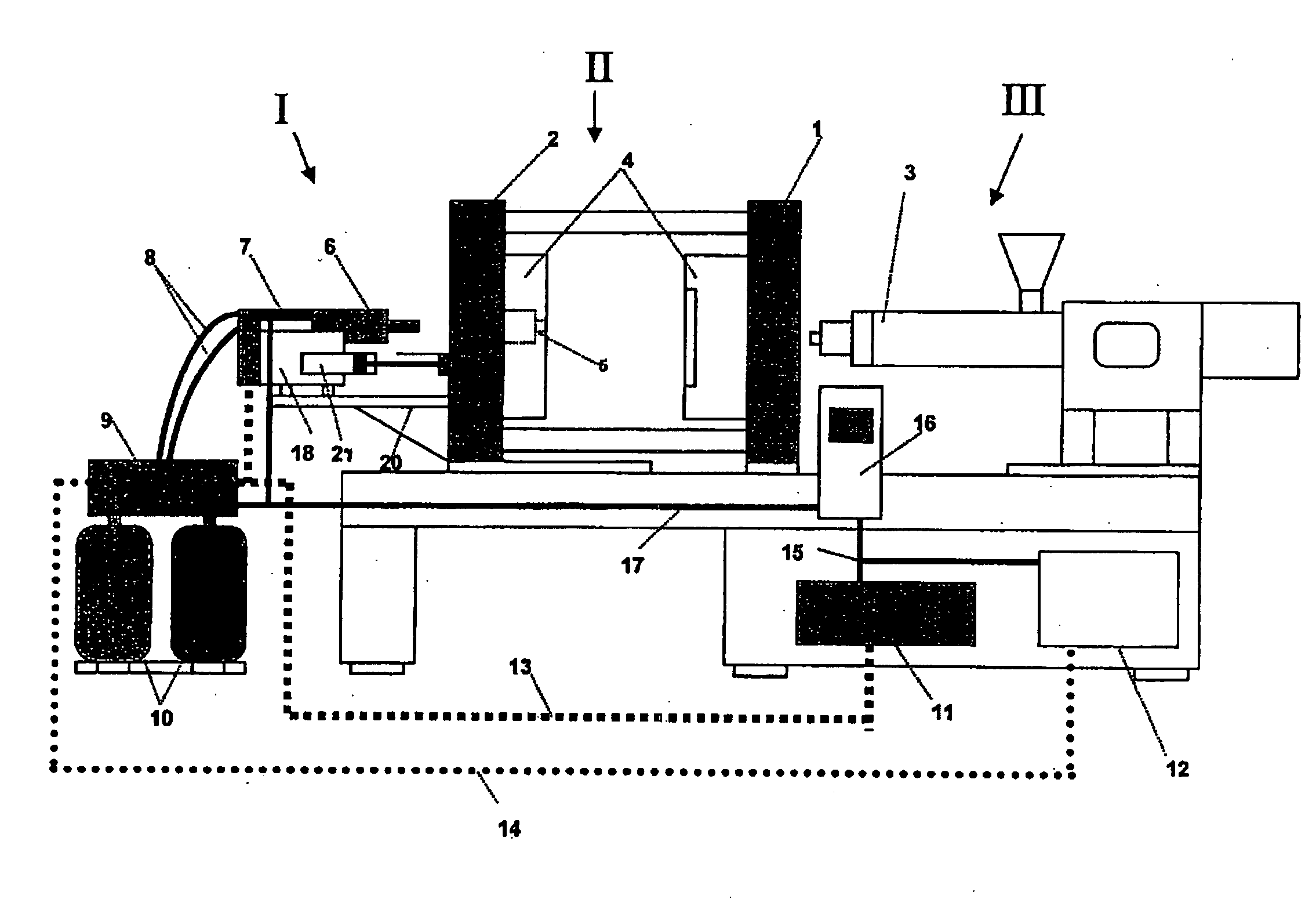

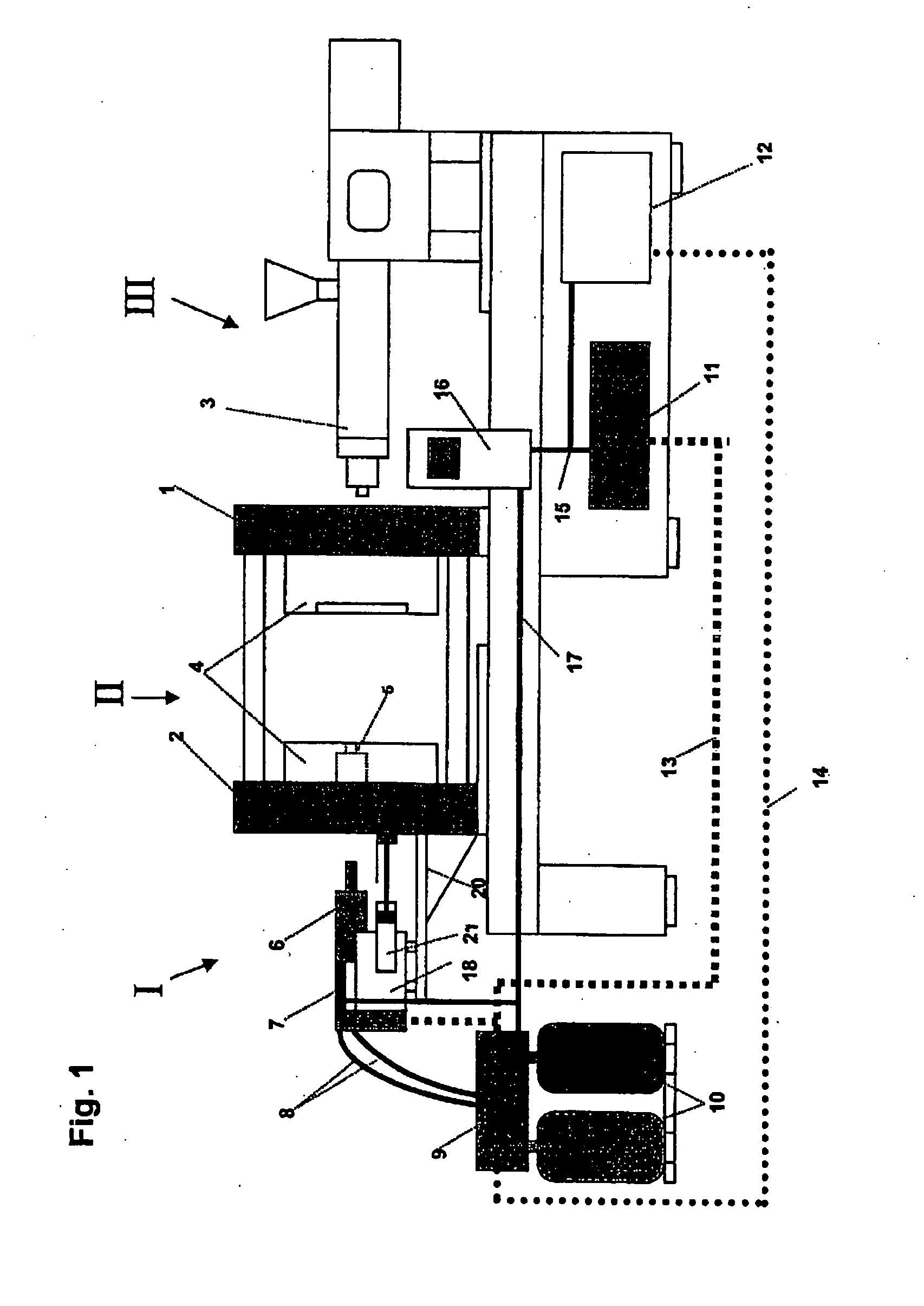

Integrated system for producing composites

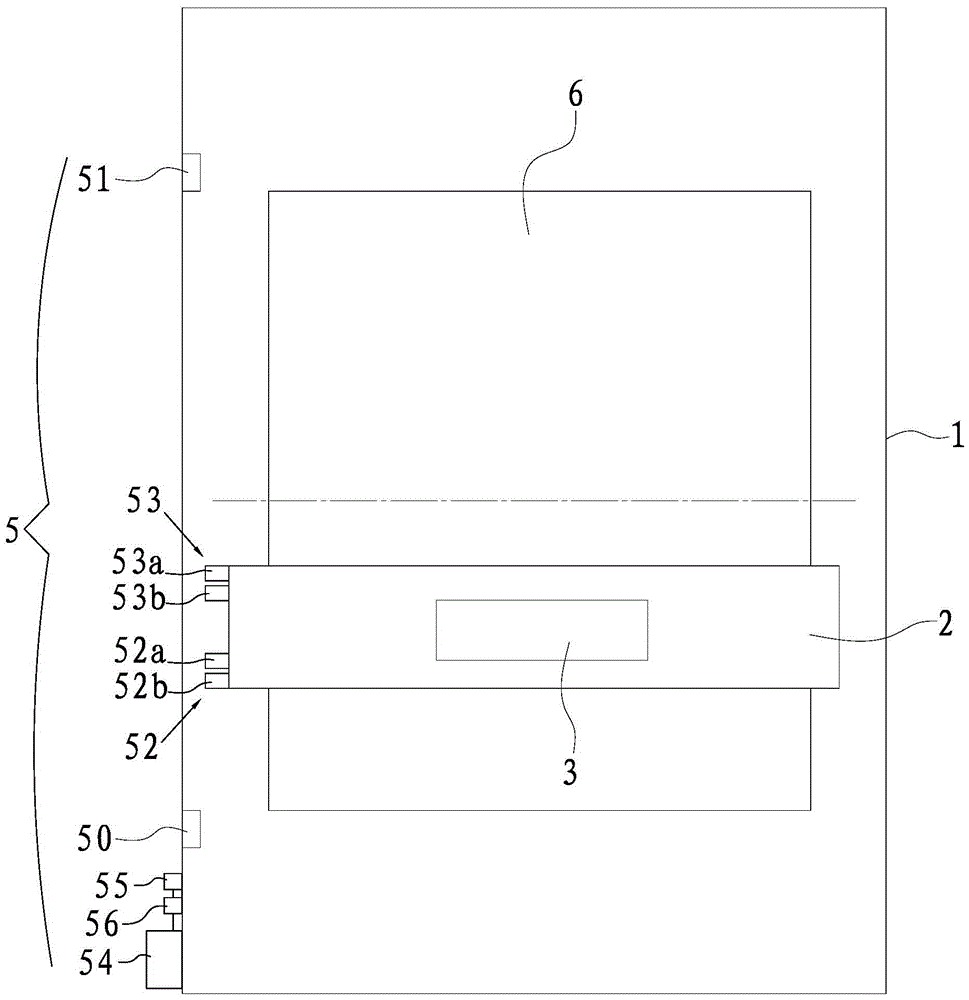

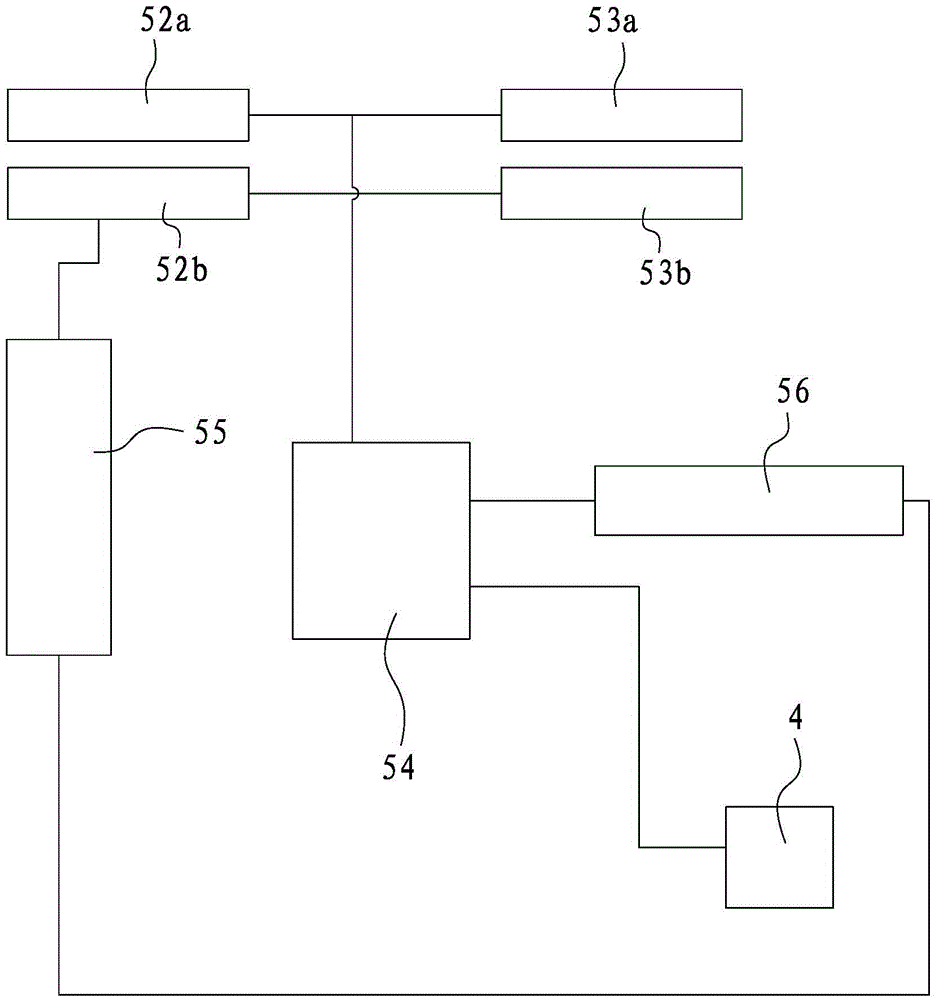

InactiveUS20080317893A1Simple and quick changeImprove precisionAuxillary shaping apparatusEngineeringControl unit

An integrated system for production of composites includes at least one polyurethane unit with a mixing head for mixing a polyol component and an isocyanate component, at least one plasticizing and injection unit, which is suitable for the melting and subsequent injection of a thermoplastic material, and one clamping unit to receive at least one mold. The plasticizing and injection unit and the polyurethane unit can each introduce material to be processed into a mold cavity within the clamping unit. In order to implement a unitary strategy of control and regulation and a unitary approach to operation of this type of integrated system apparatus, a single central control unit and at least one common supply device are provided, with the central control unit being connected at least with the at least one supply device. The at least one common supply device acts at least on both the polyurethane unit and the plasticizing and injection unit.

Owner:KRAUSSMAFFEI TECH GMBH

Spray apparatus and method for the repair of can ends

ActiveUS20070218196A1Low and high film weightIncrease volumeLiquid surface applicatorsMovable spraying apparatusBiomedical engineeringIngested food

This invention generally relates to a spray apparatus and a method useful in the repair of coating adhered to can ends used in the food and beverage packaging industries. The spray apparatus has one or more elongated shafts rotatably coupled to a frame. One or more bearing members are rotatably coupled to the shafts. One or more plates are rotatably coupled to the bearing members. One or more spray guns are coupled to the plates. The spray guns of the spray apparatus are structured to apply fluid to the can end with a solid stream emitted from the spray guns in a circular pattern. A method for the repair of coating adhered on a can end is provided as well.

Owner:STOLLE MACHINERY

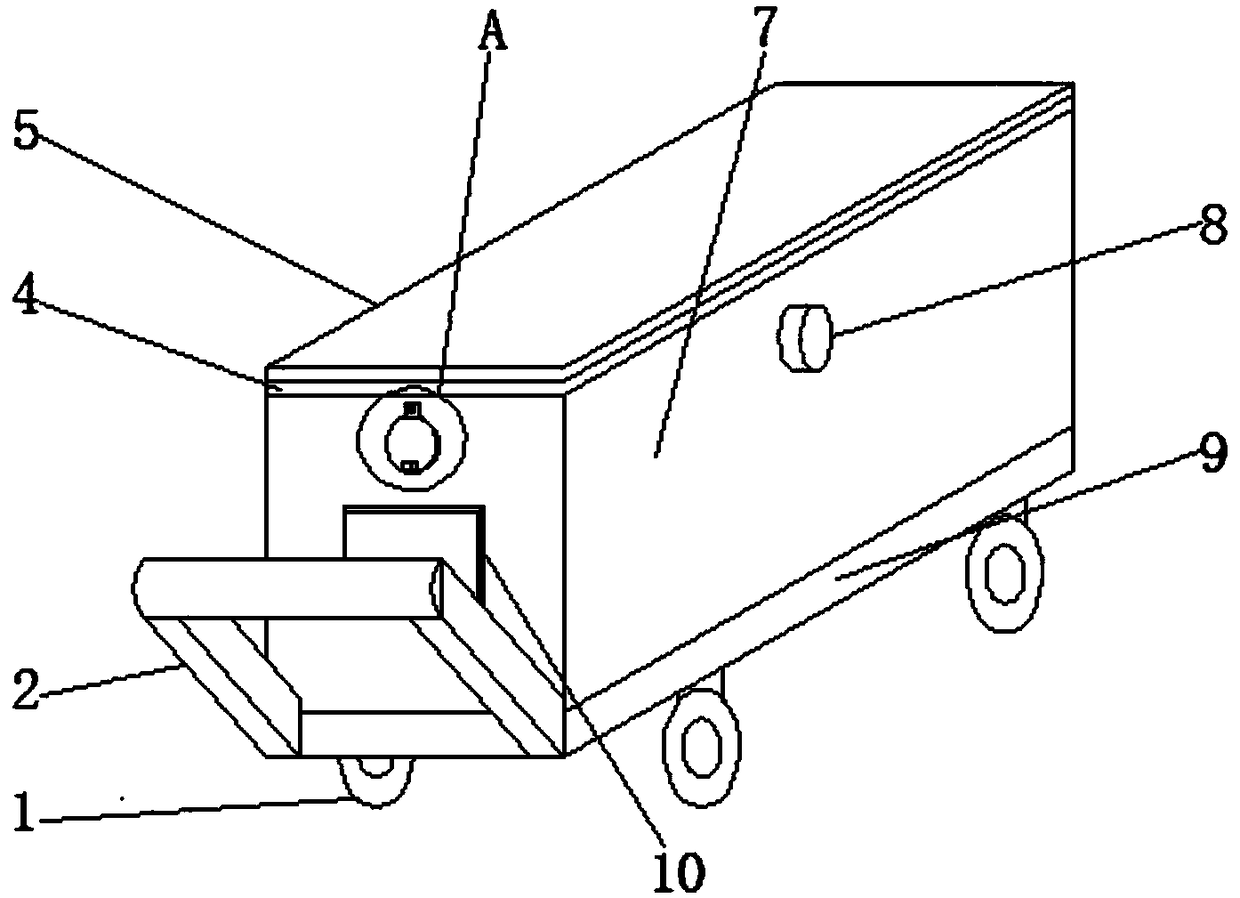

Automatic paint sprayer and control unit thereof

The invention relates to an automatic paint sprayer and a control unit thereof. The control unit comprises a sensing part, a sensor, a PLC (Programmable Logic Controller), a counter and a relay, wherein the PLC is used for receiving a sensing signal of the sensor and controlling a first driving mechanism to drive a truss to move backwards according to the sensing signal; an on-off control electromagnetic valve for controlling on and off of a spray gun; the counter is respectively connected with the sensor and the relay and is used for sending a power-off signal to the relay when the counted number reaches a set value; the relay is arranged on a power supply circuit of the PLC and / or the first driving mechanism and is connected with the on-off control electromagnetic valve; the relay is cut off after receiving the power-off signal so that the on-off control electromagnetic valve, the PLC and the like stop working because power is off, and thus the paint sprayer is shut down. By adopting the control unit disclosed by the invention, the amount of paint-sprayed layers can be precisely controlled, over spraying is prevented, the labor intensity of workers is greatly alleviated, occurrence of insufficient spraying or over spraying is effectively prevented, the spraying quality is guaranteed, and waste of paint materials is reduced.

Owner:苏州市赖氏喷漆机科技有限公司

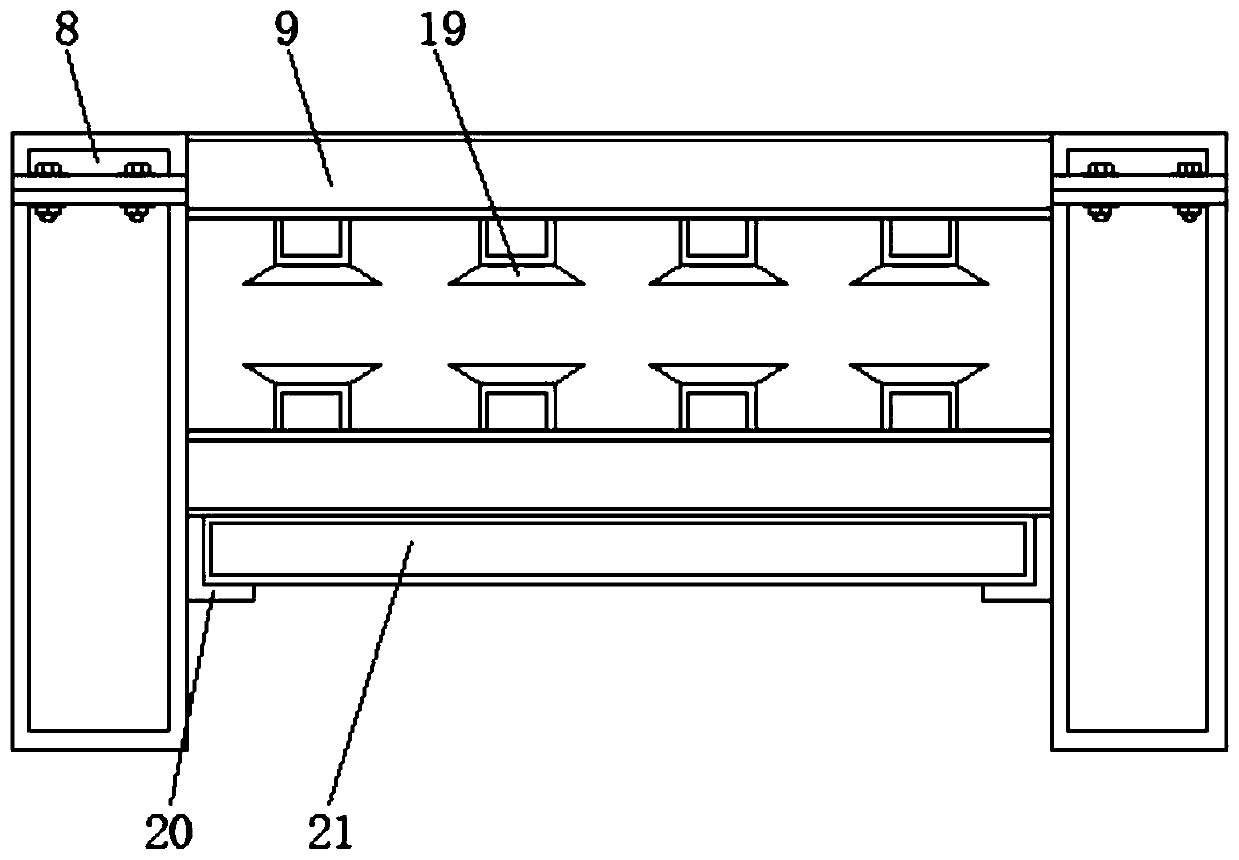

Fabric fast-carding device for textile production

ActiveCN110318244AEasy to installEasy to disassemble and replaceMechanical cleaningPressure cleaningCorrosionMoisture

The invention discloses a fabric fast-carding device for textile production. The device includes a fixing support, a heating plate and a dust sucking head; the upper ends of the fixing support are provided with a support frame, an unreeling shaft is fixed to the interior of the support frame, the two ends of the unreeling shaft are provided with thread blocks, rotating blocks are fixed to the outer surfaces of the thread blocks, the unreeling shaft is provided with a roll shaft, and the outer surfaces of the two ends of the roll shaft are provided with balls. Compared with an existing common fabric fast-carding device for textile production, the fabric fast-carding device for textile production can remove dust, cotton fibers and other impurities adhering to fabrics, the carding effect of the carding device is improved, water is prevented from overflowing during the use of the device so as to avoid parts from moisture and corrosion, centralized treatment of waste liquid is convenient, waste of water resources is avoided, meanwhile, the fabrics with different thicknesses can be flattened, and the applicability of the device is improved.

Owner:YUHUAN ZITI COSMETICS CO LTD

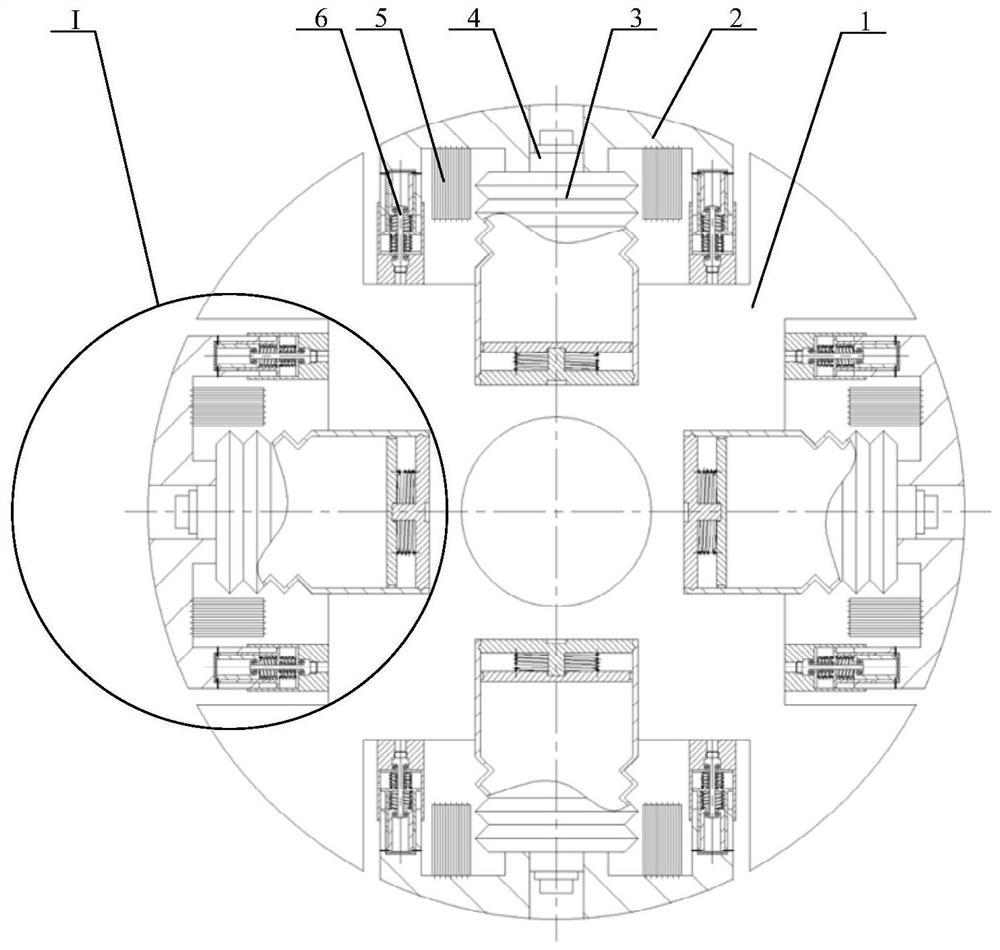

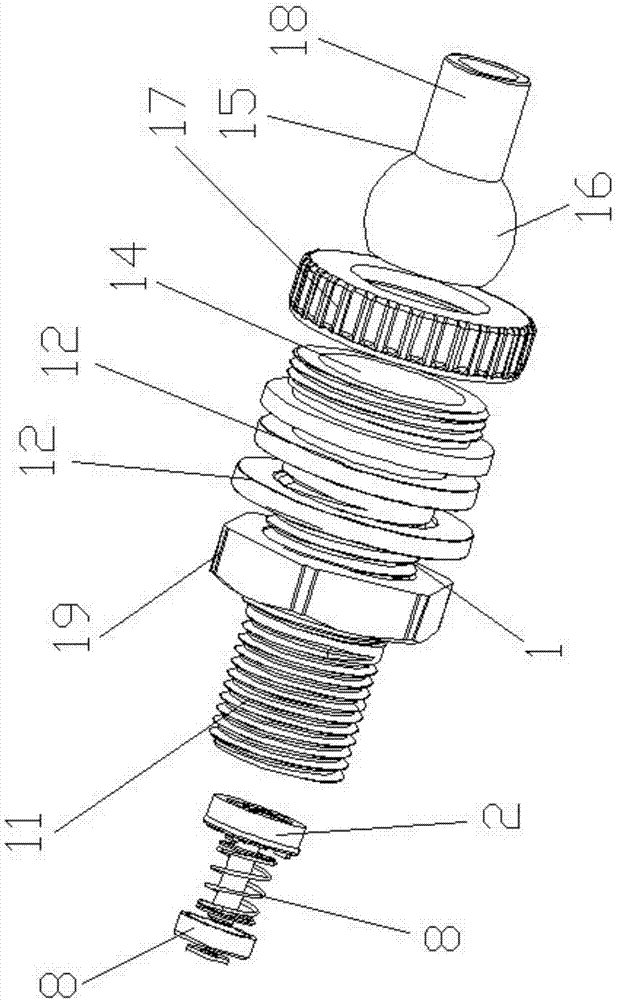

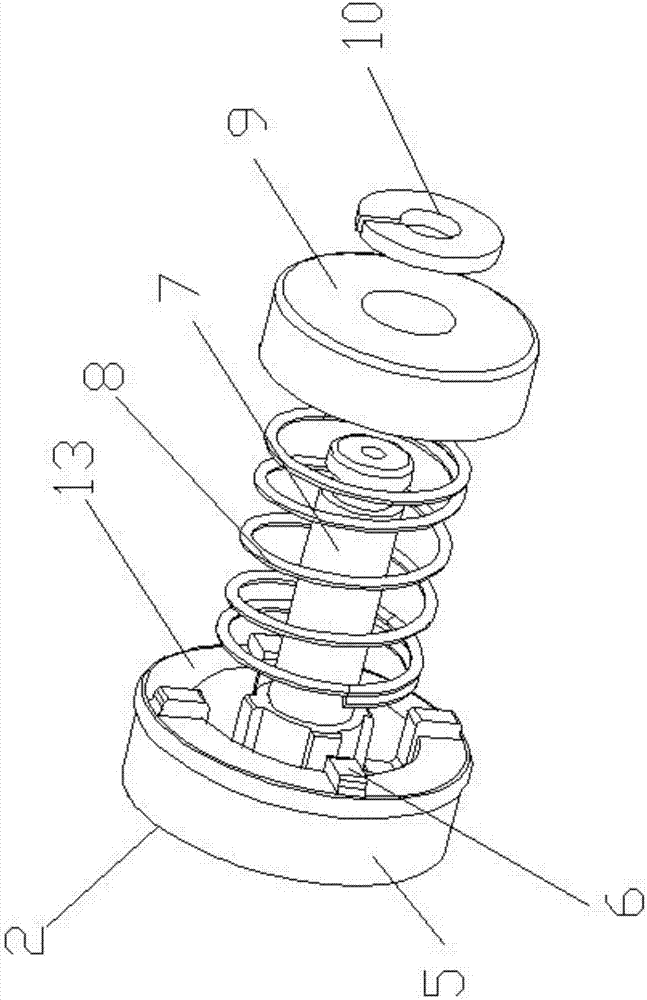

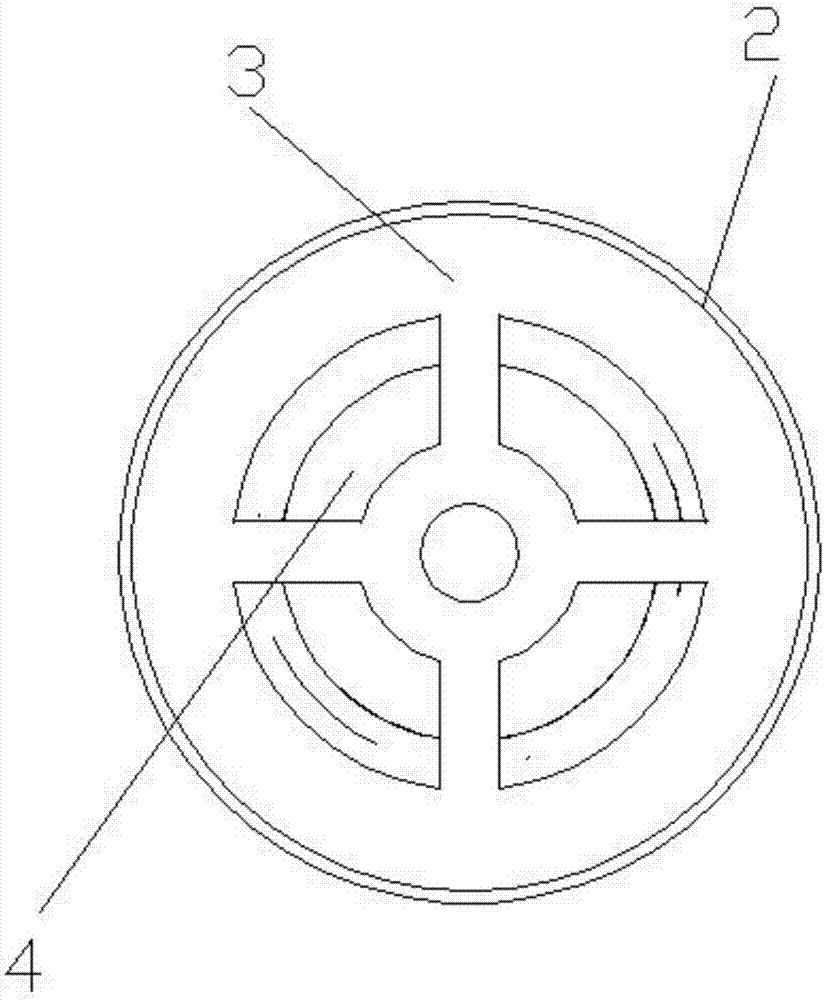

Heavy-load grinding wheel for self-adaptive cooling based on normal grinding force of grinding area

ActiveCN112720254AAvoid damageExtended service lifeGrinding machine componentsBonded abrasive wheelsCooling effectEngineering

The invention discloses a heavy-load grinding wheel for self-adaptive cooling based on normal grinding force of a grinding area. The heavy-load grinding wheel comprises a grinding wheel substrate, a grinding block, a cooling spray bottle, a spray bottle nozzle, a plate-shaped heat pipe radiator and a self-resetting mechanism. During work, the grinding block entering the grinding area compresses the self-resetting mechanism under the normal grinding force and extrudes the cooling spray bottle at the same time, and then a cooling liquid is sprayed out of the spray bottle nozzle. Pressure springs in the self-resetting mechanism are adjusted to set a critical value of the normal grinding force critical value, when the normal grinding force is reduced to below the critical value or the grinding block is separated from a grinding working area, automatic resetting of the grinding block is achieved through the self-resetting device, and the cooling spray bottle stops spraying of the cooling liquid. Self-adaptive internal cooling of the heavy-load grinding wheel is achieved. The heavy-load grinding wheel is compact in structure, the spraying flow of the cooling liquid can be adjusted in real time according to the working condition, the cooling effect is greatly improved, the wear rate of the grinding wheel in heavy-load grinding is effectively reduced, and the service life of the heavy-load grinding wheel is prolonged.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

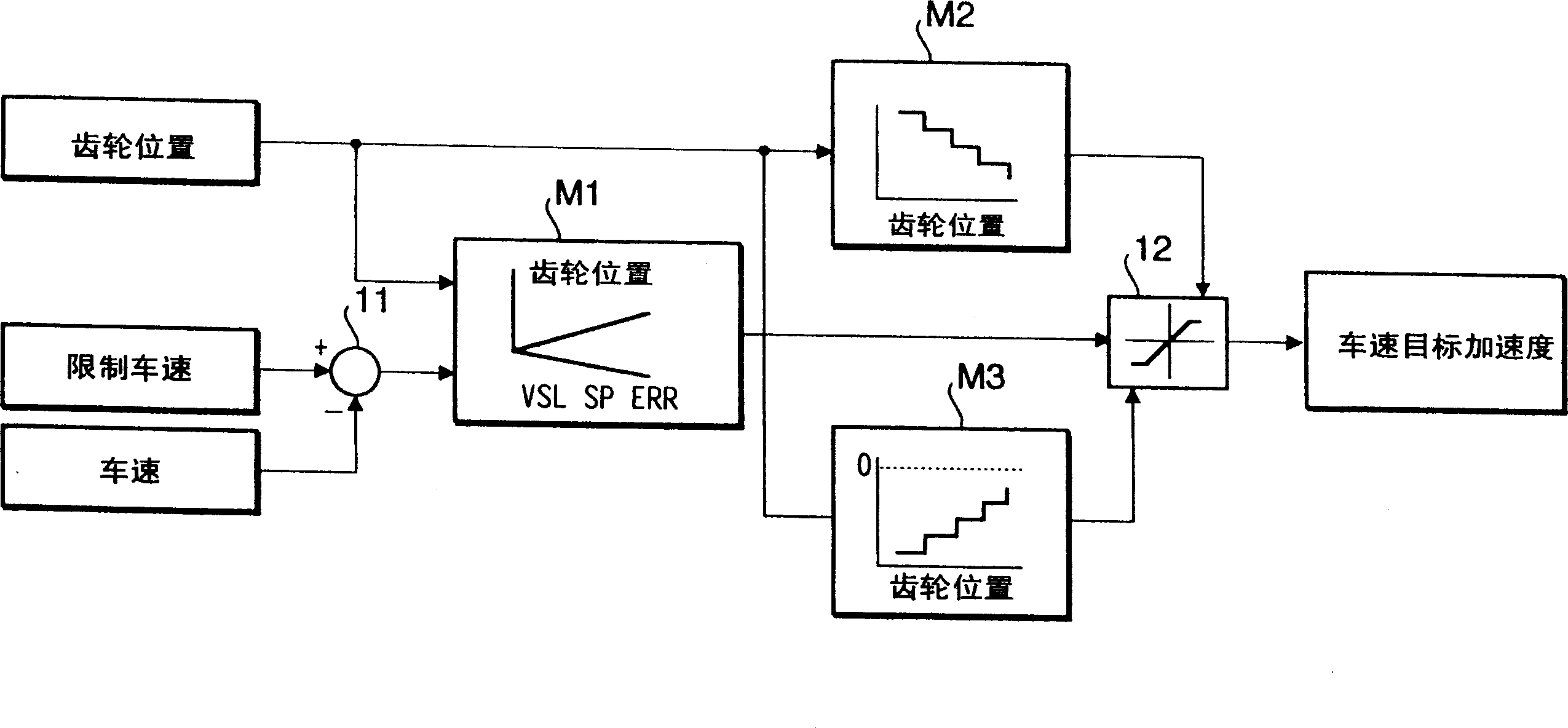

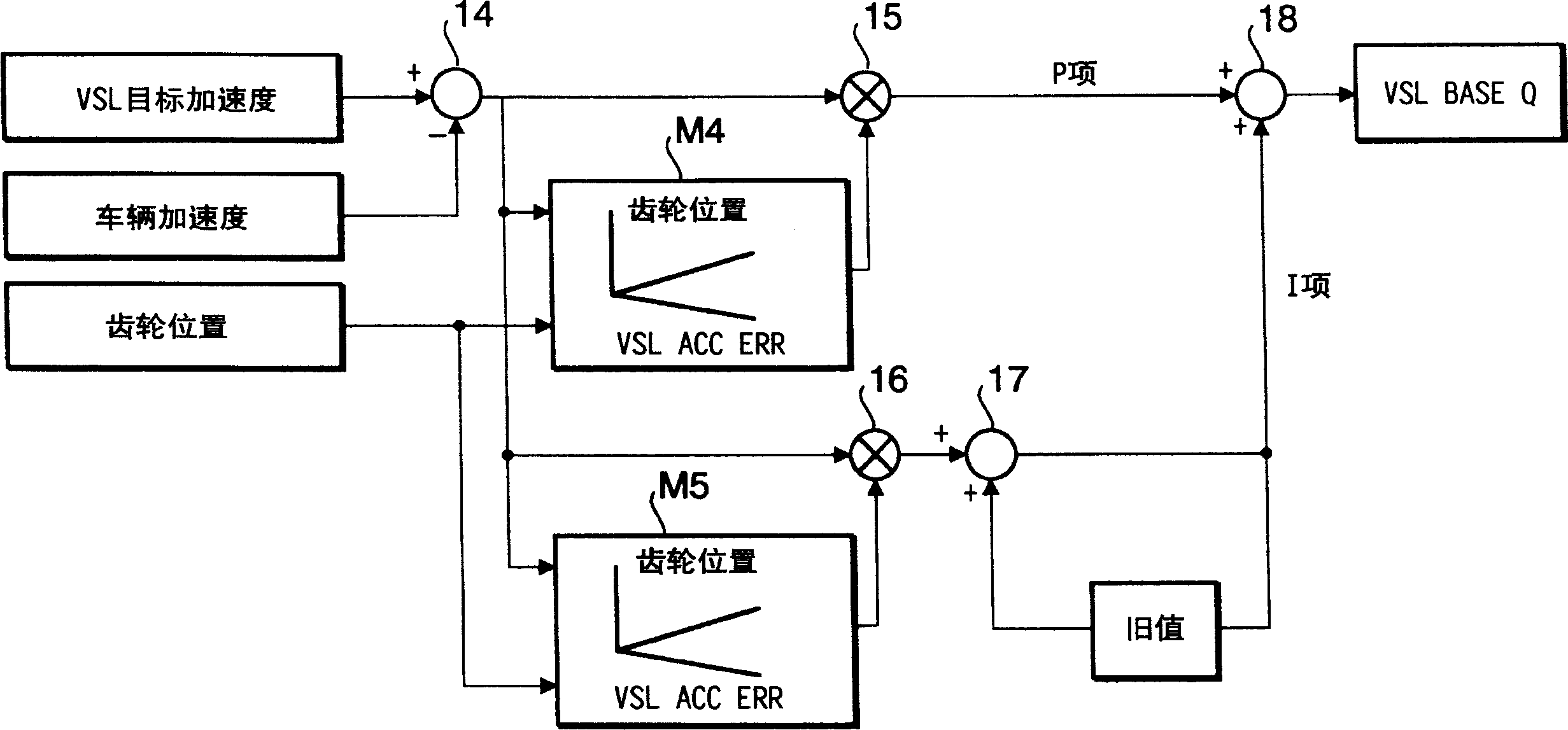

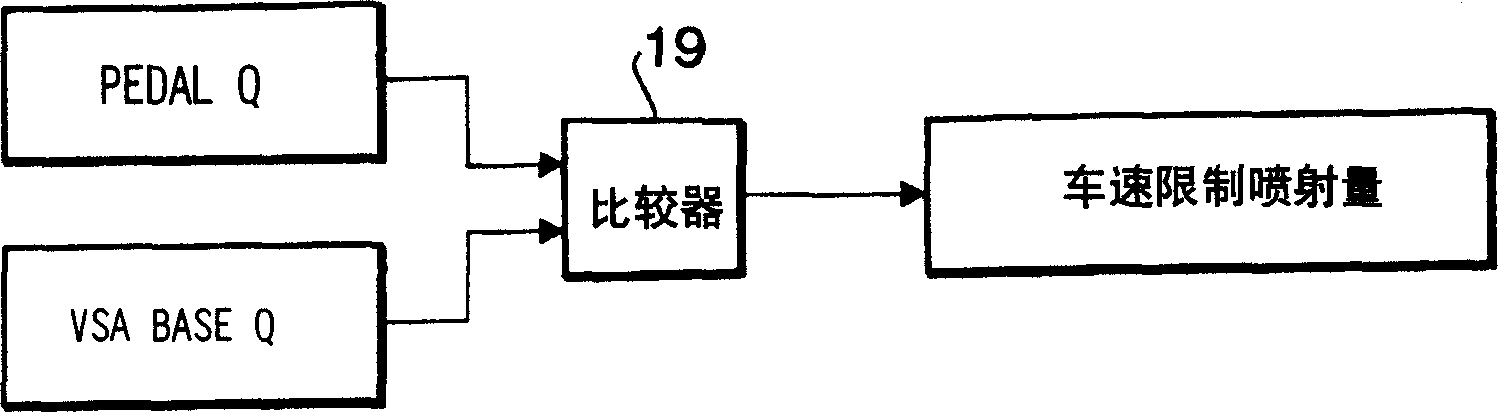

FUel jet volume controller

A fuel injection quantity control device includes: vehicle speed detection unit; gear position detection unit; engine revolution speed detection unit; accelerator opening degree detection unit; target acceleration value computation unit for finding a basic target acceleration value corresponding to the difference between the set limit vehicle speed and an actual vehicle speed and an upper limit value and lower limit value of the basic target acceleration value for each gear position in a map, limiting the basic target acceleration value with the upper limit value and lower limit value, and determining a target acceleration value; basic fuel injection quantity for vehicle speed limit computation unit for determining a basic fuel injection quantity for vehicle speed limit by feedback computation from the difference between the determined target acceleration value and the actual acceleration value; an accelerator required injection quantity computation unit for computing an accelerator required injection quantity from the engine revolution speed and accelerator opening degree; and vehicle speed limit injection quantity computation unit for selecting the smaller of the basic fuel injection quantity for vehicle speed limit and accelerator required injection quantity and setting it as a fuel injection quantity for vehicle speed limit.

Owner:ISUZU MOTORS LTD

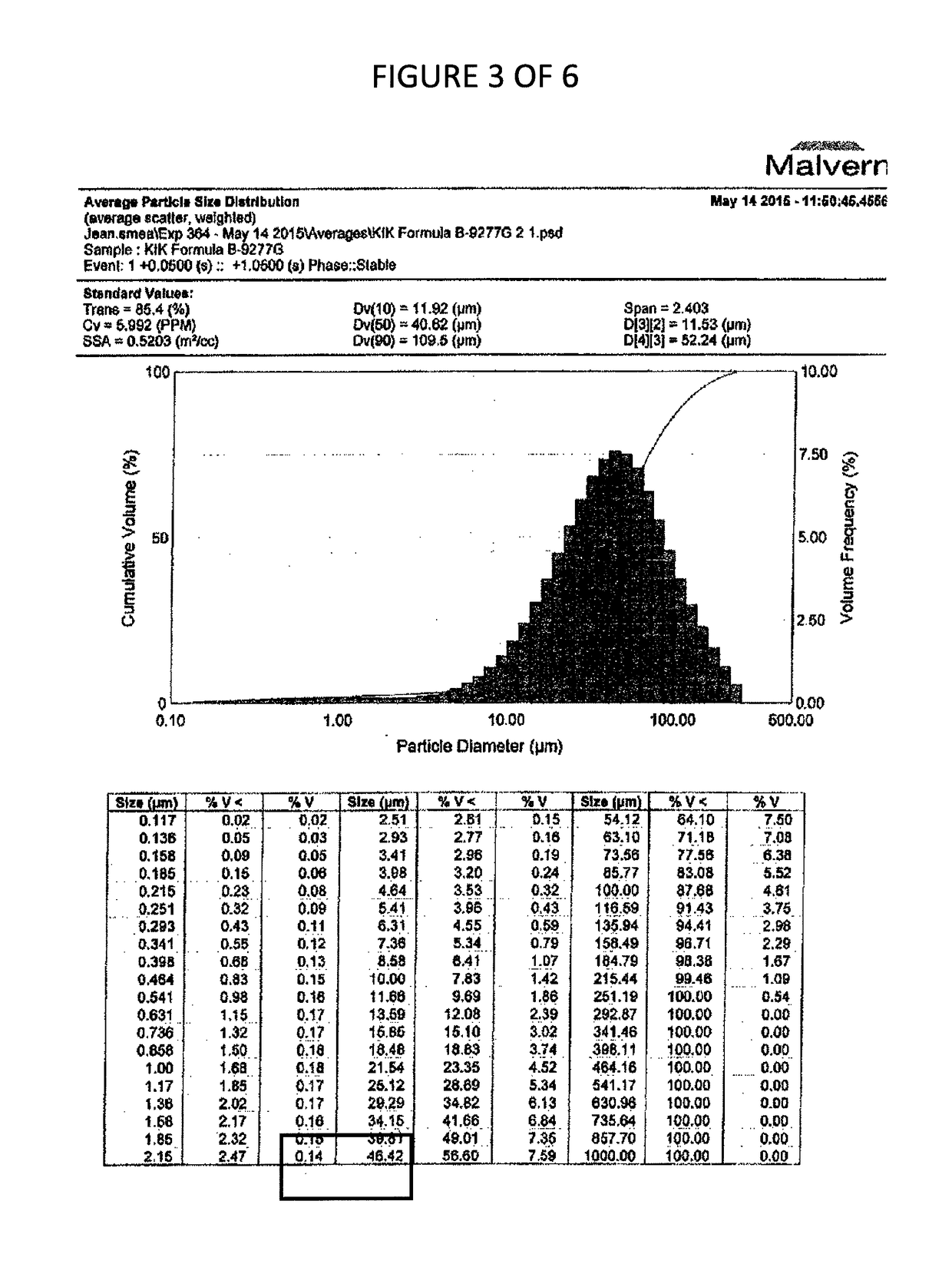

Preparation method of positive plate or negative plate for solid-state battery, positive plate or negative plate for solid-state battery and solid-state battery

PendingCN111799514AAccurate distributionPrevent oversprayFinal product manufactureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteComposite electrolyte

The invention discloses a preparation method of a positive plate or a negative plate for a solid-state battery, a plate and the solid-state battery, and the preparation method comprises the followingsteps: putting inorganic solid-state electrolyte powder with lithium ion conductivity and an organic polymer electrolyte material into an organic solvent, and uniformly mixing the inorganic solid-state electrolyte powder and the organic polymer electrolyte material; carrying out pre-dispersion on the obtained composite electrolyte coating slurry; uniformly spraying the pre-dispersed composite electrolyte coating slurry onto a positive plate or a negative plate by adopting an ultrasonic atomization spraying machine; and drying the pole piece sprayed with the composite electrolyte coating slurryto obtain the positive plate or negative plate coated with a composite electrolyte layer. By the adoption of the method, excessive spraying can be avoided, accurate liquid drop distribution is achieved, an accurate micron-thickness coating is formed, and the coating is thin, uniform and controllable; waste and air pollution caused by reverse spraying can be reduced, and the cost is saved; the energy consumption is low, the atomization efficiency is high, the limitation on atomized liquid is small, the slurry utilization rate is up to 90% or above, and the production efficiency can be greatlyimproved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Fish feeding device for freshwater fish pond

InactiveCN104221979AAvoid throwing too much fish foodCause hungerPisciculture and aquariaFeeding MethodsSparid Fish

The invention discloses a fish feeding device for a freshwater fish pond. The fish feeding device comprises a plurality of fish feeding troughs, transmission devices, fixing devices and connecting devices, wherein the transmission devices are arranged at the two sides of the fresh water pond in pairs, the fish feeding troughs are arranged on the transmission devices and can do relative movement to the transmission devices, each connecting device is arranged between the two adjacent fish feeding troughs, and the fixing devices are used for fixing the fish feeding troughs. Through the transmission devices, a plurality of fish feeding troughs are uniformly distributed above the fish pond, fish food can be uniformly spread and thrown, the problem of nonuniform spreading and throwing of the fish food during the adoption of an artificial fish feeding method in the prior art is solved, and great significance is realized on the culture of the freshwater fish pond.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Aerosol Spray Masking Device

InactiveUS20060272575A1Prevent oversprayLiquid surface applicatorsSpraying apparatusTarget surfaceAerosol spray

The present invention is a masking device to prevent over-spray when using an aerosol can to apply aerosols to a work surface. The device has comprised of a horizontal channel structure, the back end of which is essentially open having an aperture that serves as an insertion point for an aerosol nozzle feed tube from an aerosol can, while the front end serves as an attachment seat for a masking unit. The back end of the horizontal channel is open, providing the user access to the aerosol nozzle in order to actuate the aerosol nozzle with a finger, whereby an aerosol is propelled forward into a masking unit. The masking unit has a small orifice creating a planar opening at the back, and a large orifice creating a planar opening at the front The masking unit is essentially hollow, providing the ability to contain an aerosol, the large orifice serving as a mask against a target surface. The masking unit has an observation cut out covered with a transparent film, a vent to exhaust excess pressure and aerosol, and raised beads radiating from the small orifice to the large orifice which serve as excess aerosol accumulators.

Owner:MONTERROSA CHRISTOPHER H

Landscaping device and method

PendingCN109105358AAvoid drug leakageImprove insecticidal effectRotary stirring mixersTransportation and packagingWater pipeEngineering

The invention discloses a landscaping device, comprising a pull rod, an outer box and a base, the top of the base is provided with the outer box, the top of the outer box is provided with a battery board mounting seat, the battery board mounting seat is provided with a solar cell panel assembly, a display is arranged at the central portion of the side wall of the outer box, and the pull rod is fixed on the base below the display. The output end of a second motor drives a driving gear on an output shaft to rotate, and because a half axle gear at one end of each of two water pipes is engaged with the driving gear, the water pipes rotate to a horizontal position to enlarge the spray area of a chemical liquid, and a worker can complete chemical liquid spraying of a large range only by pullingthe device to move, also the spraying is even and normal effect of the chemical liquid is guaranteed. At the same time, a second electromagnetic throttle valve is utilized to control the flow rate ofthe chemical liquid to avoid excessive spraying of the chemical liquid, and when the chemical liquid is not required to be sprayed, by controlling the second motor to reverse, the two water pipes areplaced in a vertical direction, and thus the occupied volume is reduced and storage is easy.

Owner:缙云县智禾环保科技有限公司

Aerosolized dye and system for delivering aerosolized dye

InactiveUS20180344589A1Easy to cleanPrevent oversprayCosmetic preparationsHair cosmeticsHair dyesSolvent

An aerosolized semi-permanent hair dye is provided for, which is non-toxic to humans and shelf stable, utilizing coal tar dyes, solvents, propellants, neutralizers, colorant treatments and humectants. The invention has the benefit of being easily applied to hair or other keratinous substances and dyes hair for a period longer than currently available spray-in temporary colorants, but shorter than oxidized or otherwise developed permanent hair dyes.

Owner:LITOWITZ JENNIFER DONYA

Novel closestool brushing head

PendingCN107119778APrevent oversprayPrevent prolapseWater closetsLavatory sanitoryCurrent limitingEngineering

A novel closestool brushing head comprises a water outlet pipe, wherein a pressure stabilizing and flow limiting device is arranged in the water outlet pipe and comprises a flow limiting cover, the flow limiting cover comprises a cover plate, a water outlet hole is formed in the cover plate, the periphery of the cover plate is vertically connected with a cover ring, and a plurality of stopping blocks are arranged at the tail end of the cover ring. The center of the cover plate is connected with a sliding column, the sliding column is in sleeved connection with a spring, a water blocking plate is movably connected to the sliding column in a penetrating mode, the tail end of the sliding column is fixedly connected with a limiting device, one end of the spring abuts against the cover plate, and the other end of the spring abuts against the water blocking plate. The water blocking plate is matched with the cover plate in size, and the edge of the water blocking plate corresponds to the position of the stopping blocks. The size of the flow limiting cover is matched with the diameter of the water outlet pipe. The flow limiting cover faces the water outlet end of the water outlet pipe, and the water blocking plate faces the water inlet end of the water outlet pipe. The novel closestool brushing head can adjust flushing water pressure and flow and has a flushing water stabilizing effect.

Owner:浙江和正智能卫浴有限公司

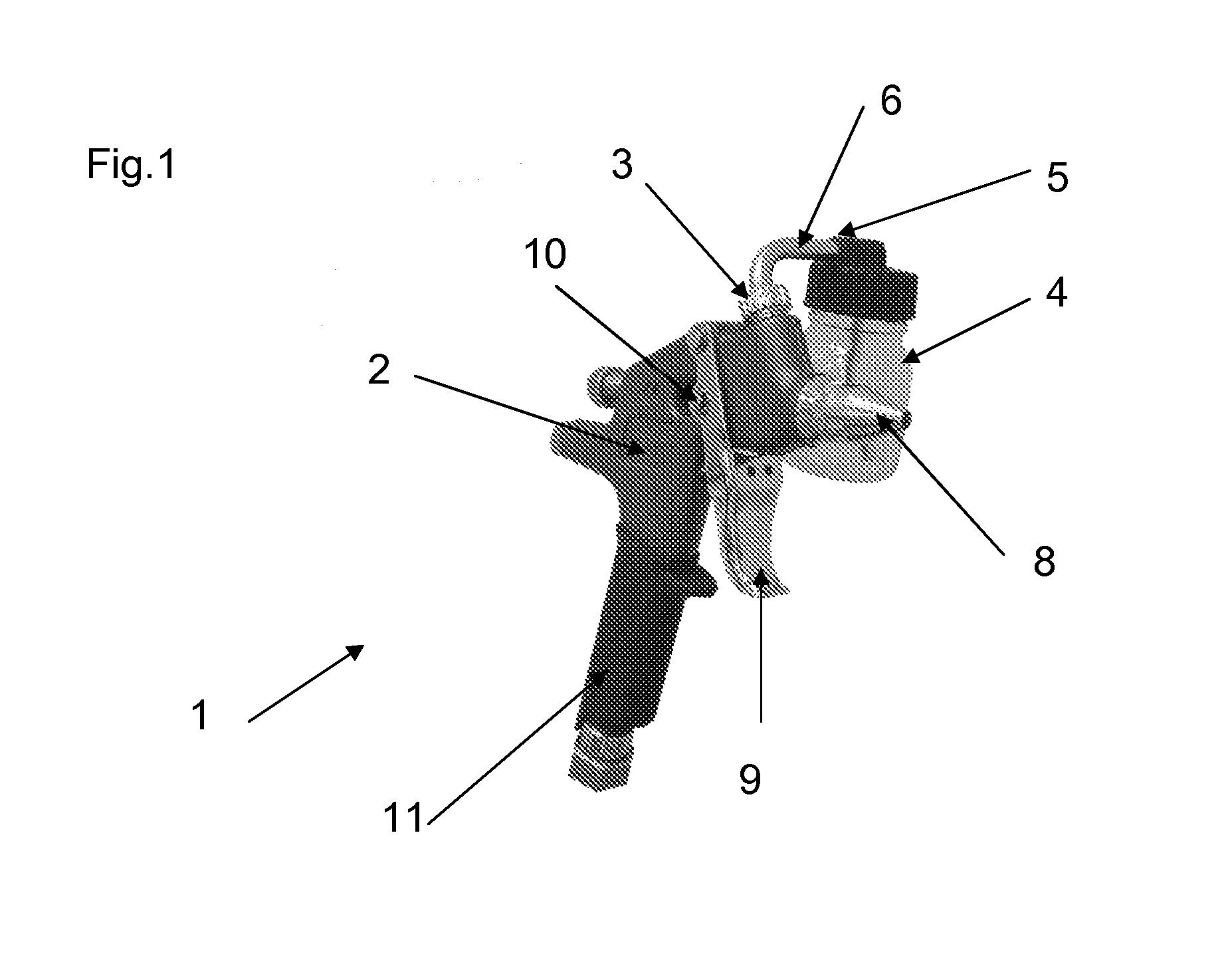

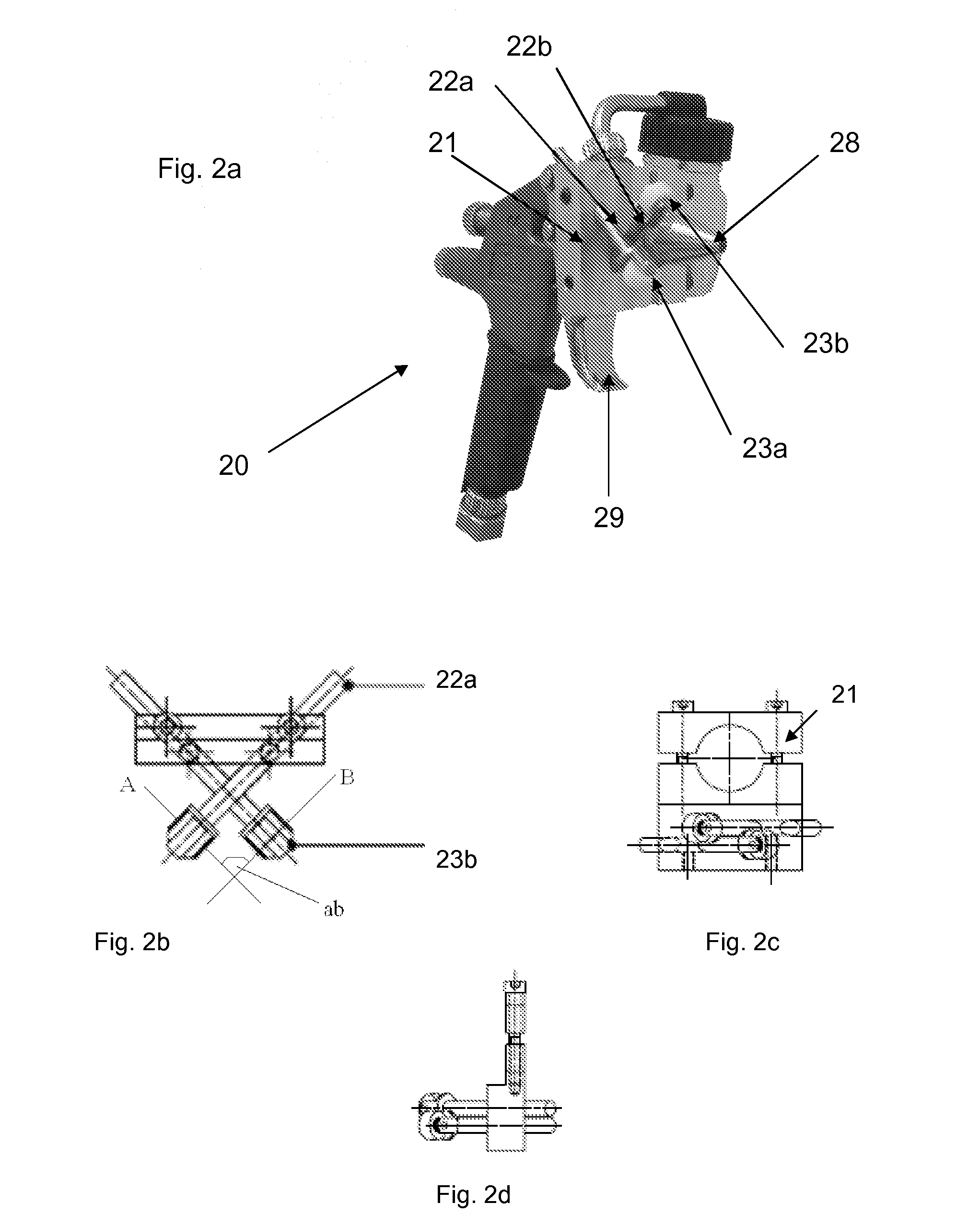

Painting device

ActiveUS20110017138A1Easy to controlPrevent oversprayLiquid surface applicatorsCarpet cleanersSash windowWindow sill

Owner:AKZO NOBEL COATINGS INT BV

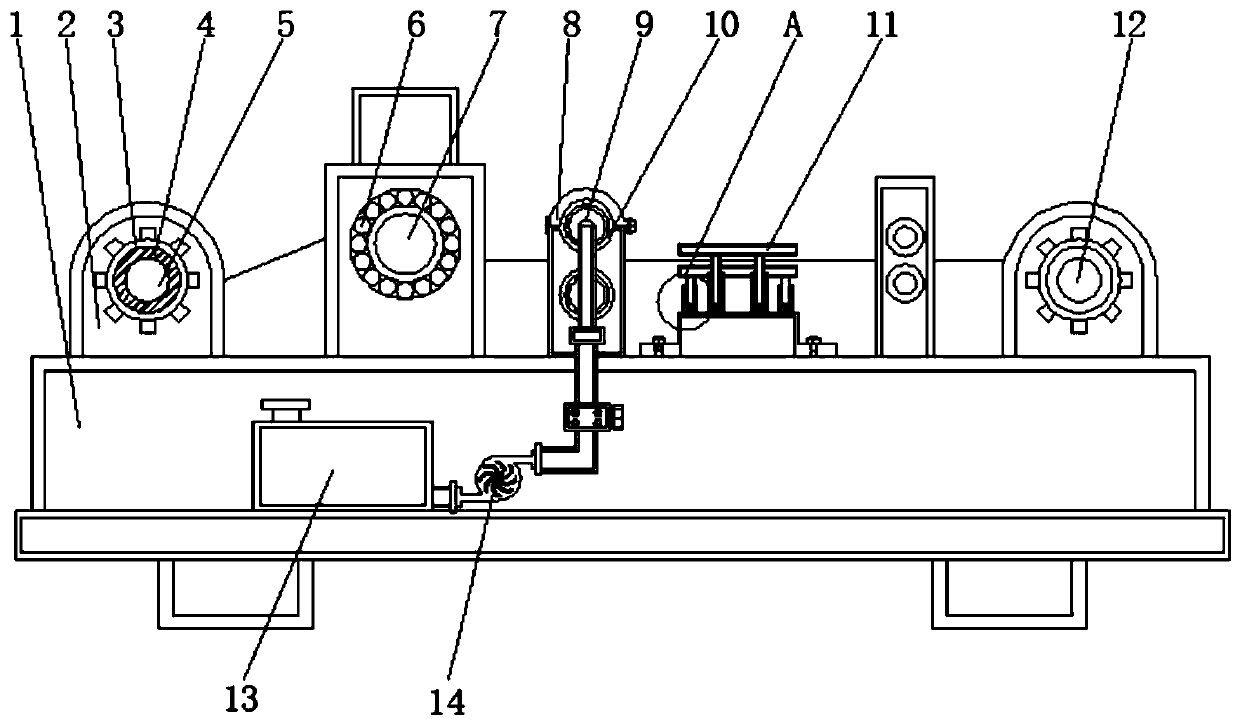

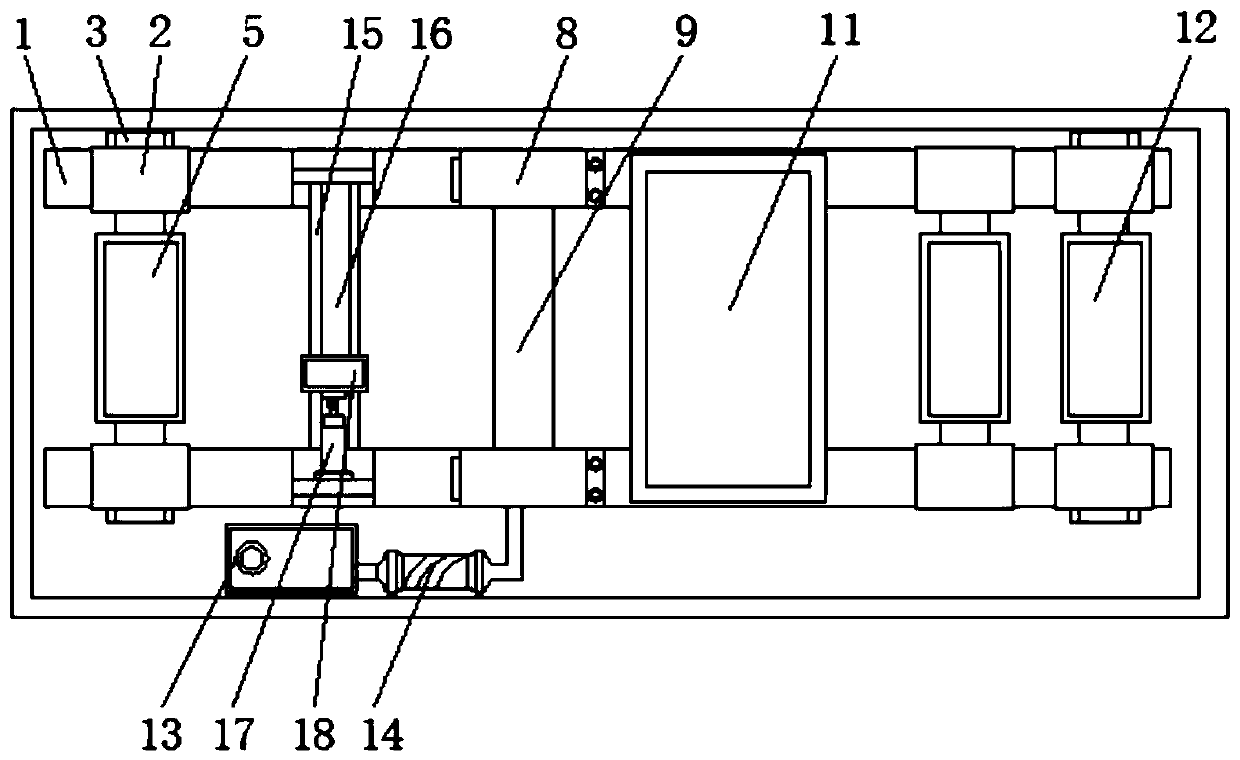

Agricultural water spraying machine capable of achieving comprehensive spraying

ActiveCN108353766ASimple structureImprove gripWatering devicesCultivating equipmentsSpray nozzleAgricultural engineering

The invention discloses an agricultural water spraying machine capable of achieving comprehensive spraying. The machine includes a mounting box, a water tank is fixedly connected to the inner bottom wall of the mounting box, and a water pump is arranged in the water tank. The agricultural water spraying machine capable of achieving comprehensive spraying is simple in structure, through connectionwith an external power source, the water pump is started, the mounting box is pushed manually to move, a mounting plate rotates on a field, and through arrangement of teeth, the spraying range of a spray nozzle is enlarged; moreover, a first electromagnet and a second electromagnet are powered on, and due to the characteristics of a twist rod, the second electromagnet rotates; since the first electromagnet repulses the second electromagnet, the distance between the first electromagnet and the second electromagnet is changed, the spray nozzle can vibrate under the action of first springs, waterin the water tank is uniformly sprayed out through the spray nozzle, excessive spraying is avoided, and the growth of crops is ensured.

Owner:安徽舒州生态农业科技股份有限公司

Method of preparing turbine blades for spray coating and mounting for fixing such a turbine blade

InactiveUS7717058B2Prevent oversprayImprove cooling effectMolten spray coatingSpraying apparatusTurbine bladeSpray coating

The invention relates to a method of preparing turbine blades for spray coating their blade region that is subjected to the medium flowing through during operation in a spray coating apparatus, in which the turbine blade is inserted with its blade root into a cavity of a mounting in such a way that it protrudes with the blade region that adjoins the blade root from an opening of the cavity to form a gap between the rim of the opening and the turbine blade, and in which the gap is bridged by a shielding fixed on the mounting, which is characterized in that a shielding layer of a plastic which is resistant during the spray coating is used for the shielding, the shielding layer being arranged in such a way that it reaches up to the boundary between the blade root and the blade region.

Owner:SIEMENS AG

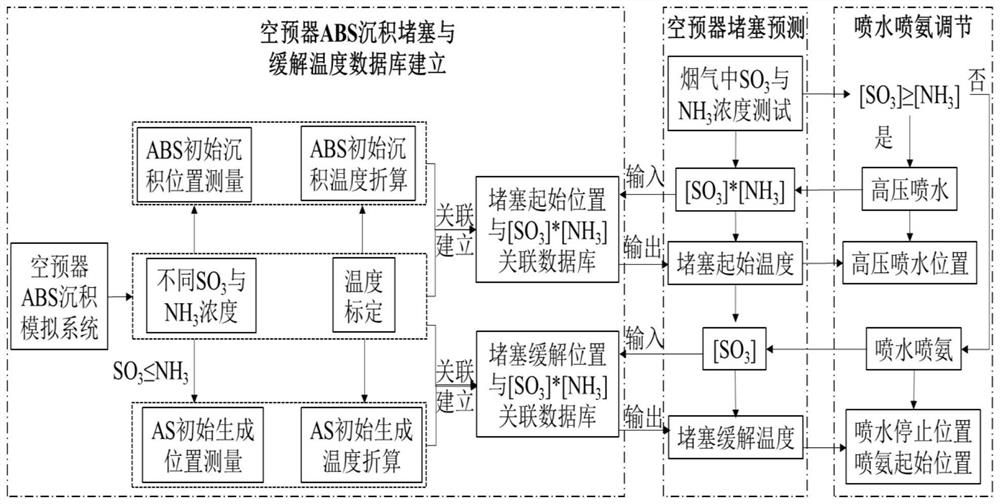

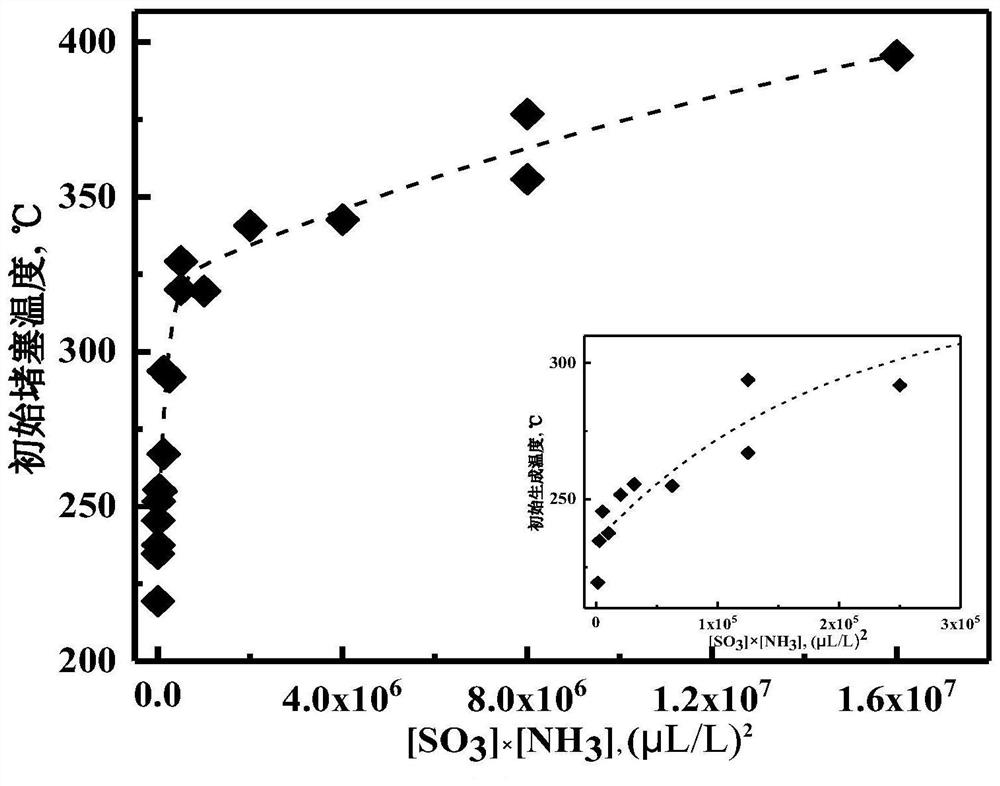

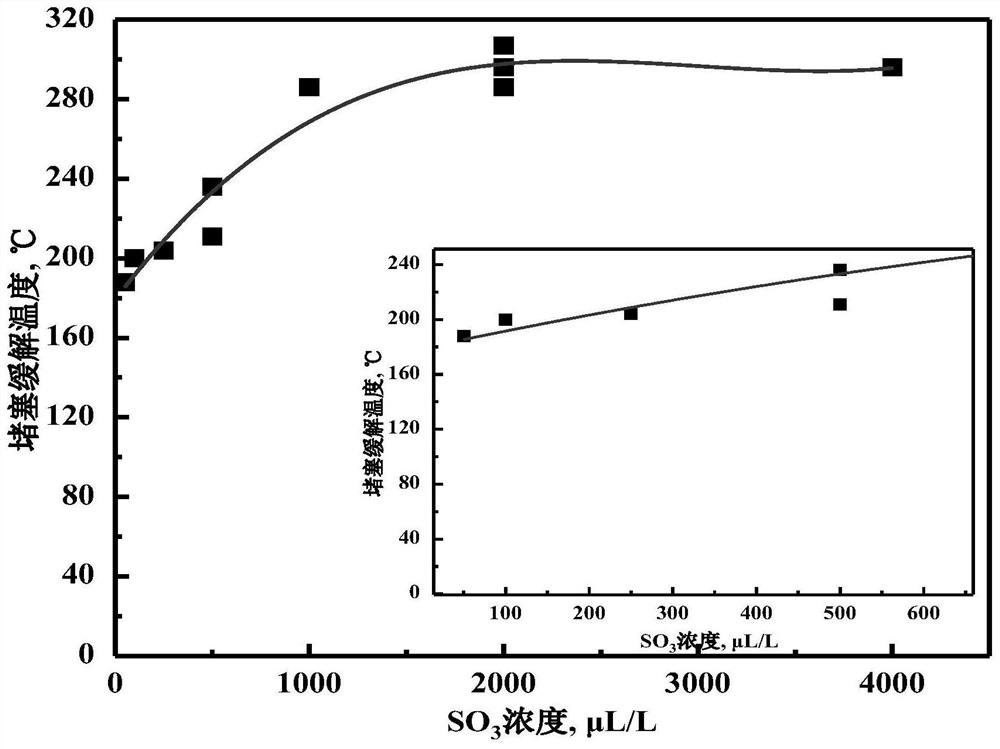

Prediction of air preheater blockage and optimized anti-clogging method of water injection and ammonia injection

ActiveCN113217941BWide applicabilityAccurate predictionCombustion processIndirect carbon-dioxide mitigationAir preheaterDeposition temperature

The invention discloses a method for predicting the blockage of an air preheater and optimizing the blockage prevention by spraying water and ammonia, comprising: (1) establishing the initial deposition temperature of ABS and SO2 3 Concentration and NH 3 Concentration product [SO 3 ]*[NH 3 ] associated database and NH 3 AS initial deposition temperature and SO in excess condition 3 Concentration [SO 3 ] associated database; (2) perform SO on the inlet of the air preheater in the actual power plant flue 3 with NH 3 concentration test; (3) the characteristic parameters of the flue gas to be tested [SO 3 ]*[NH 3 ], [SO 3 ] Compared with the established ABS and AS deposition temperature database, according to the corresponding mapping relationship, the initial deposition characteristic temperature of ABS and AS of the flue gas to be measured is obtained; (4) According to the predicted ABS deposition temperature, intelligently adjust the high-pressure water nozzle to At the corresponding position, spray water on the air preheater to prevent the air preheater from being blocked due to ABS deposition. The method is accurate, efficient, and low-cost, and can effectively solve the SO in coal-fired flue gas. 3 Air preheater ABS blockage caused by reaction with fugitive ammonia.

Owner:HUANENG TONGCHUAN ZHAOJIN COAL POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com