Application method and application facility

A coating and primer technology, applied in the direction of coating, device for coating liquid on the surface, spray device, etc., to achieve the effect of high application efficiency and increased quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

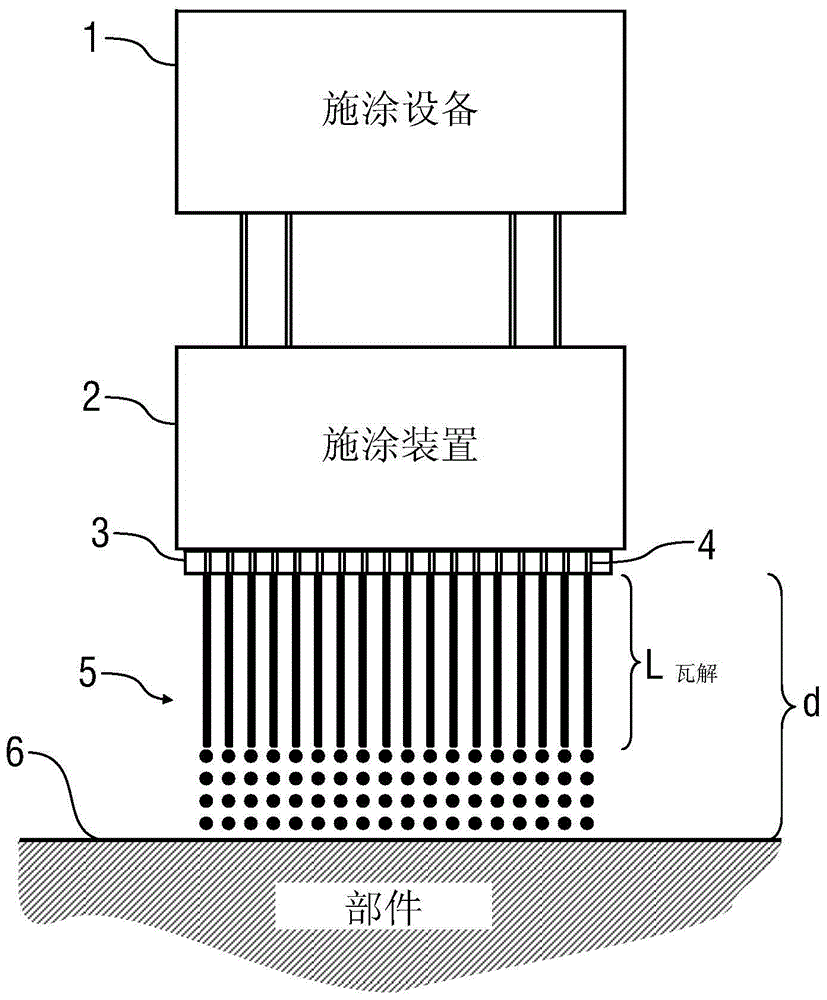

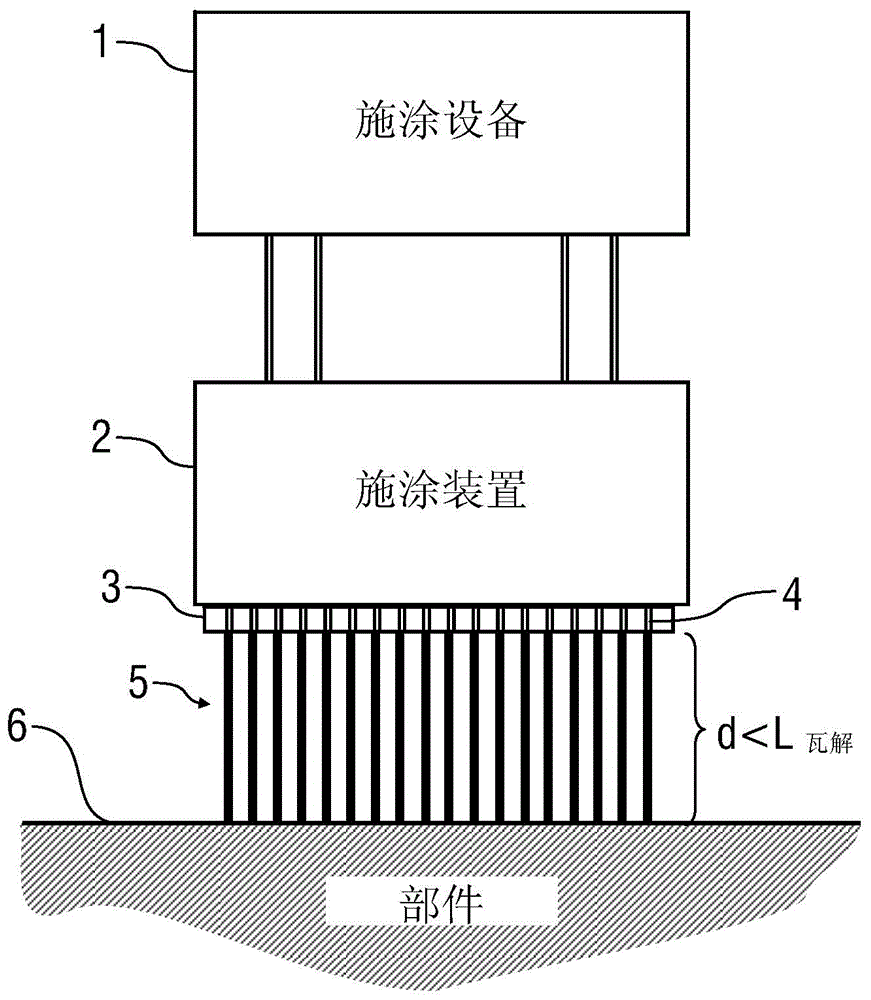

[0049] Figure 1 shows a conventional application system known for example from DE 10 2010 019 612 A1. Here, the application device 1 supplies the application device 2 with the required medium, for example the coating medium to be applied, which may be paint, for example.

[0050] The application device 2 has a perforated plate 3 in which a plurality of application nozzles 4 are formed. Each application nozzle 4 of the perforated plate 3 emits a coating medium jet 5, wherein, just after being emitted from the application nozzle 4, the coating medium jet 5 is initially along the jet direction at a disintegration distance L collapse The internal cohesion and then collapse into droplets, the reason why droplet collapse is enforced specifically in this traditional application system is vibration access.

[0051] The application device 2 is positioned at an application distance d relative to the component 6 to be coated, wherein the positioning is achieved in such a way that the applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com