Automatic paint sprayer and control unit thereof

An automatic paint spraying machine and control unit technology, applied in the direction of spraying devices, etc., can solve the problems of missing or multi-layered paint layers, increase labor intensity of workers, waste of paint and time, etc., to ensure quality, reduce labor intensity, Avoid spraying less or spraying more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific examples.

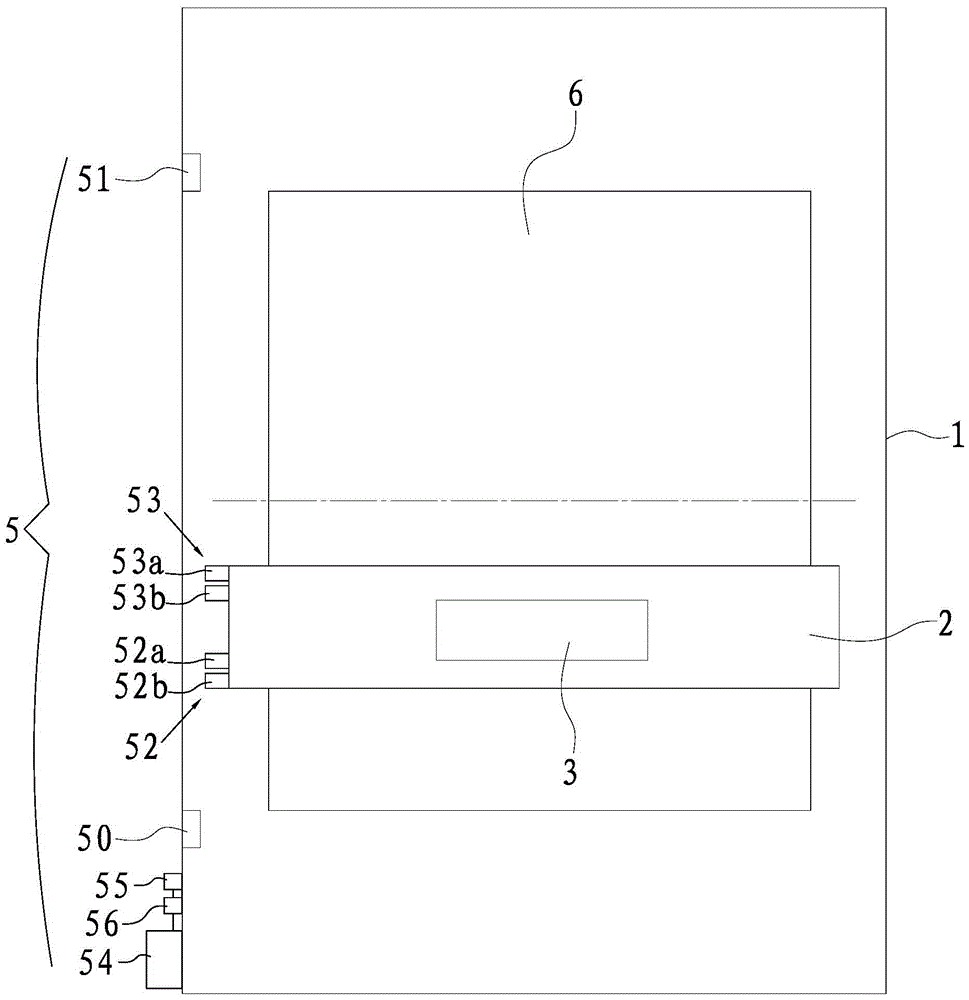

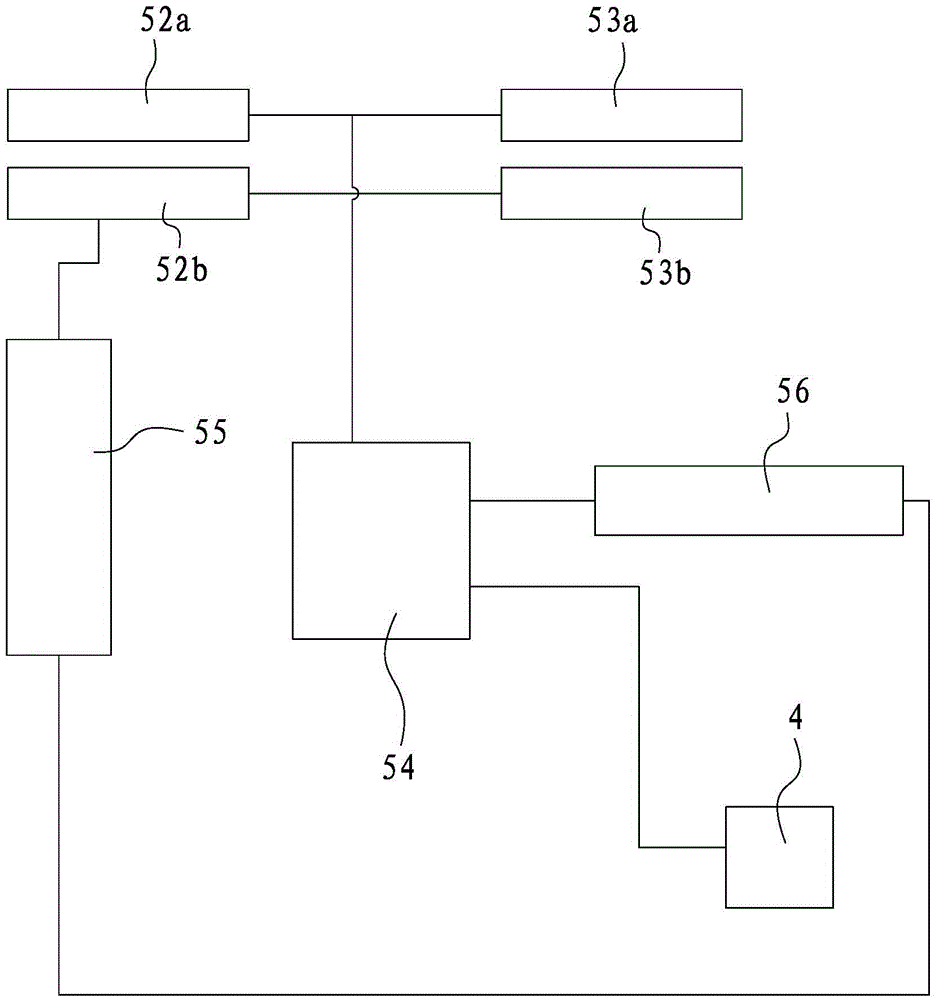

[0029] Such as figure 1 and 2 As shown, the automatic painting machine provided in this embodiment includes a machine cabin 1, a truss 2 that can move along the length direction of the machine cabin 1 and extends along the width direction of the machine cabin 1, and can move along the length direction of the truss 2 The paint spraying device 3 arranged on the truss 2, the first drive mechanism 4 for driving the truss 2 and the paint spraying device 3 to move, and the control unit 5 for controlling the operation of the automatic paint spraying machine. The painting device 3 includes a spray gun for painting. The first driving mechanism 4 includes a driver and a motor controlled by the driver.

[0030] The control unit 5 includes: sensing elements 50, 51; sensors 52, 53; PLC controller 54; counter 55;

[0031] Specifically, there are two sensing elements 50, 51, and the two sensing elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com