Patents

Literature

63results about How to "Strong cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

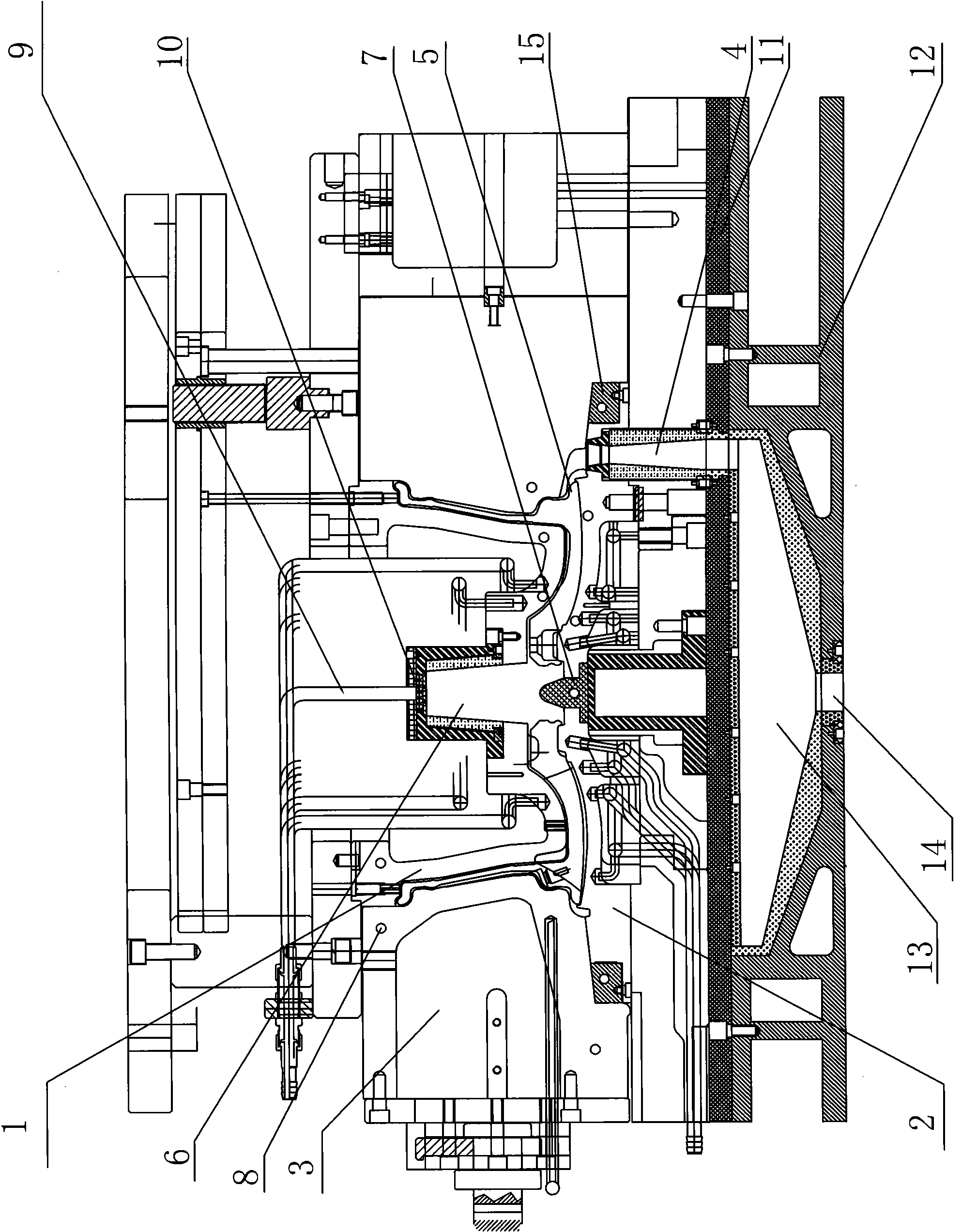

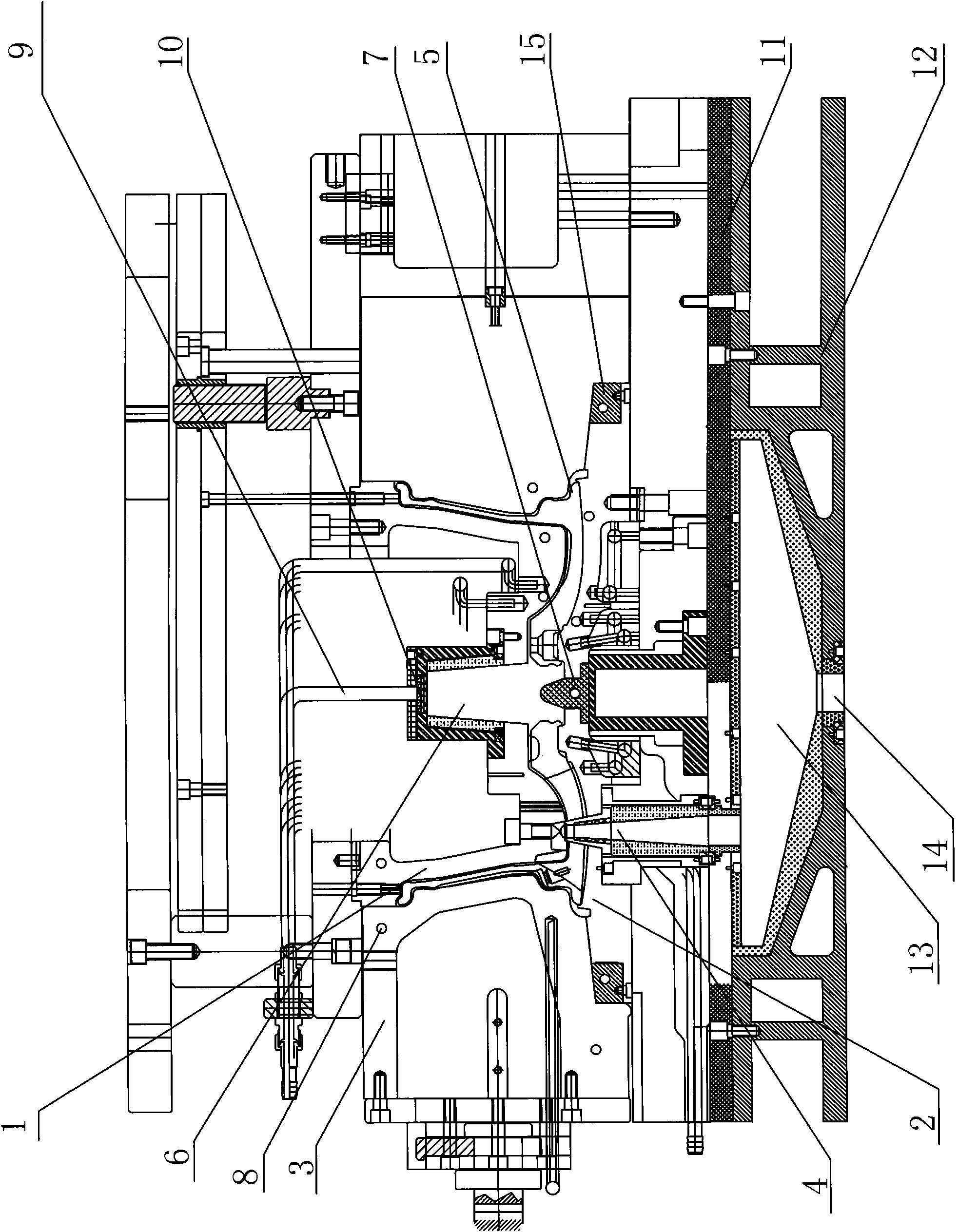

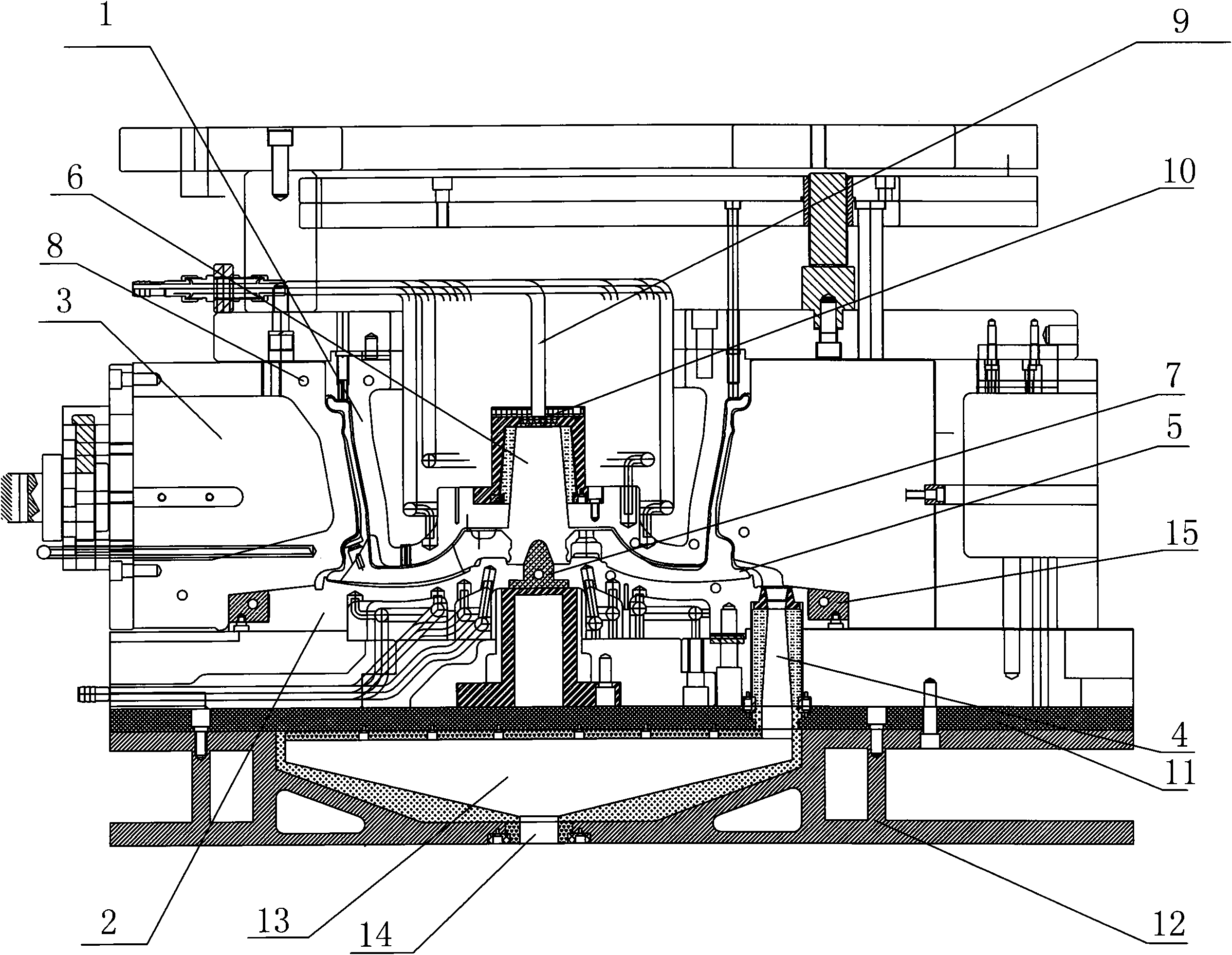

Low-pressure casting die of aluminium alloy wheel and casting method thereof

The invention discloses a low-pressure casting die of an aluminium alloy wheel and a casting method thereof. The low-pressure casting die comprises a top die (1), a bottom die (2) and a side die (3), wherein a plurality of gates (4) are arranged on the bottom die (2); the center of the top die is provided with a central riser (6) which is used for feeding; the center of the bottom die is provided with a shunt cone (7) which is used for forming the center of a wheel disc, and the gates are arranged at the outer side of the lower wheel lip of the bottom die or at the window of the bottom die. The casting method comprises the following steps of mold filling, exhausting, pressurization, cooling, feeding, aluminium liquid reflux and the like. By using the invention, the quality of casting parts is increased, the mechanical property index of produced vehicle wheel spokes and wheel centers is good, and pinholes do not easily appear on products. The invention can be suitable for occasions with high requirements for product quality, is beneficial to achieving the light weight of the products, improves production efficiency, and reduces die erosion.

Owner:何丙军 +1

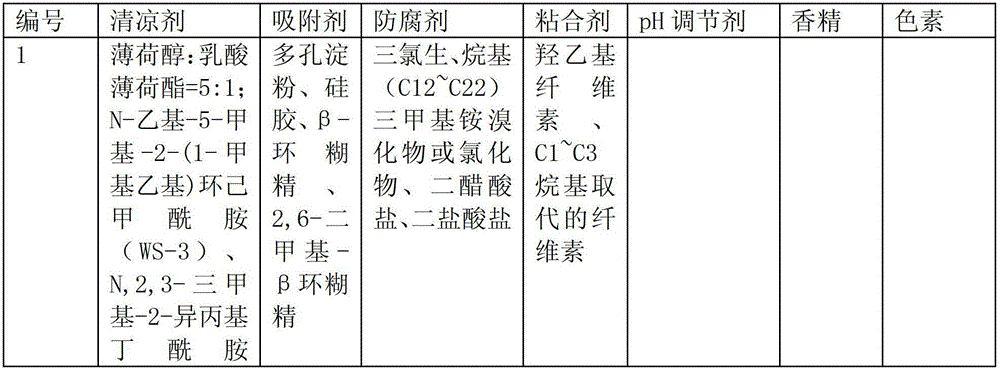

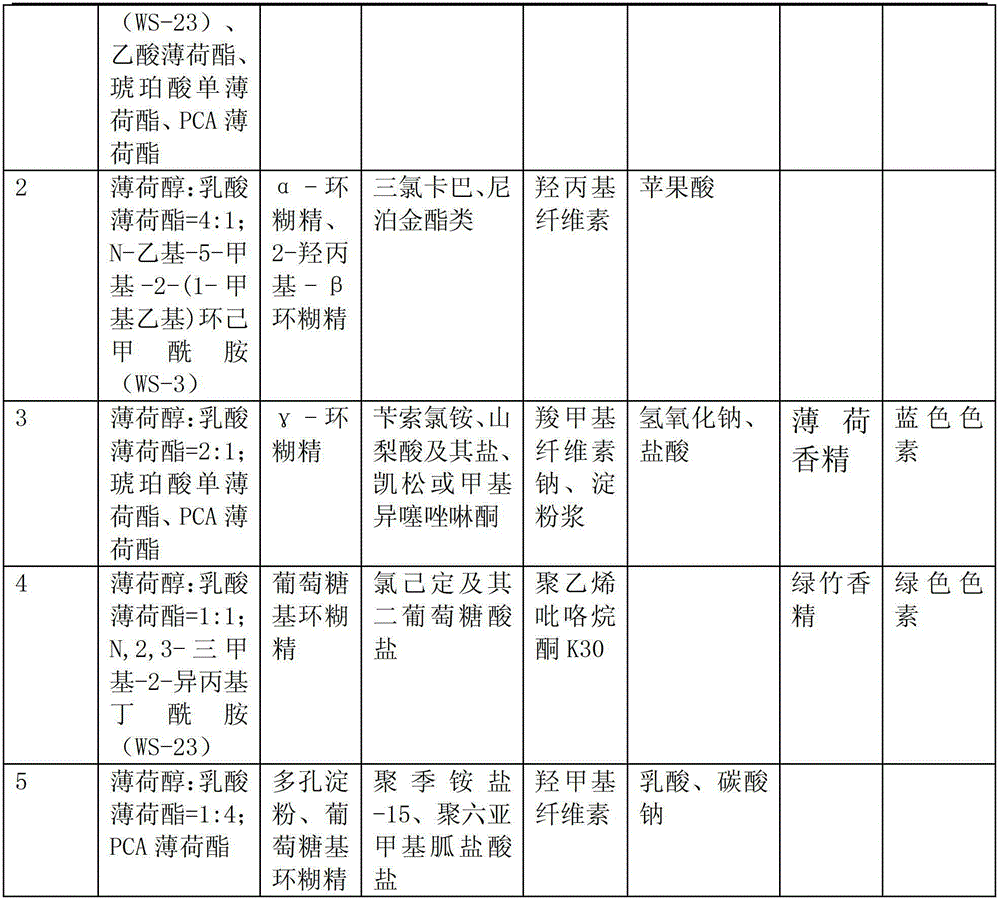

Coolness delivery composition for absorptive product and preparation method thereof

ActiveCN102908656ANo need to change external local surface temperatureOvercoming power lossAbsorbent padsBandagesMenthyl acetateChemistry

The invention provides a coolness delivery composition for an absorptive product. A freshener is added into sanitary towels, panty-shape diapers or protection pads in the form of microcapsules or powder, and menthyl acetate with mild and durable cooling performance is taken as a raw material, so that the problems of easiness in volatilizing of a liquid freshener, low utilization ratio of effective substances, short product shelf life and easiness in stimulating skin of the freshener are solved. Due to the adoption of the technical scheme, a formula is simple, and a preparation process is simple and convenient. The utilization ratio of a microcapsule or powder freshener effective substance is high, the product shelf life is long, and the cooling feel is mild and durable.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

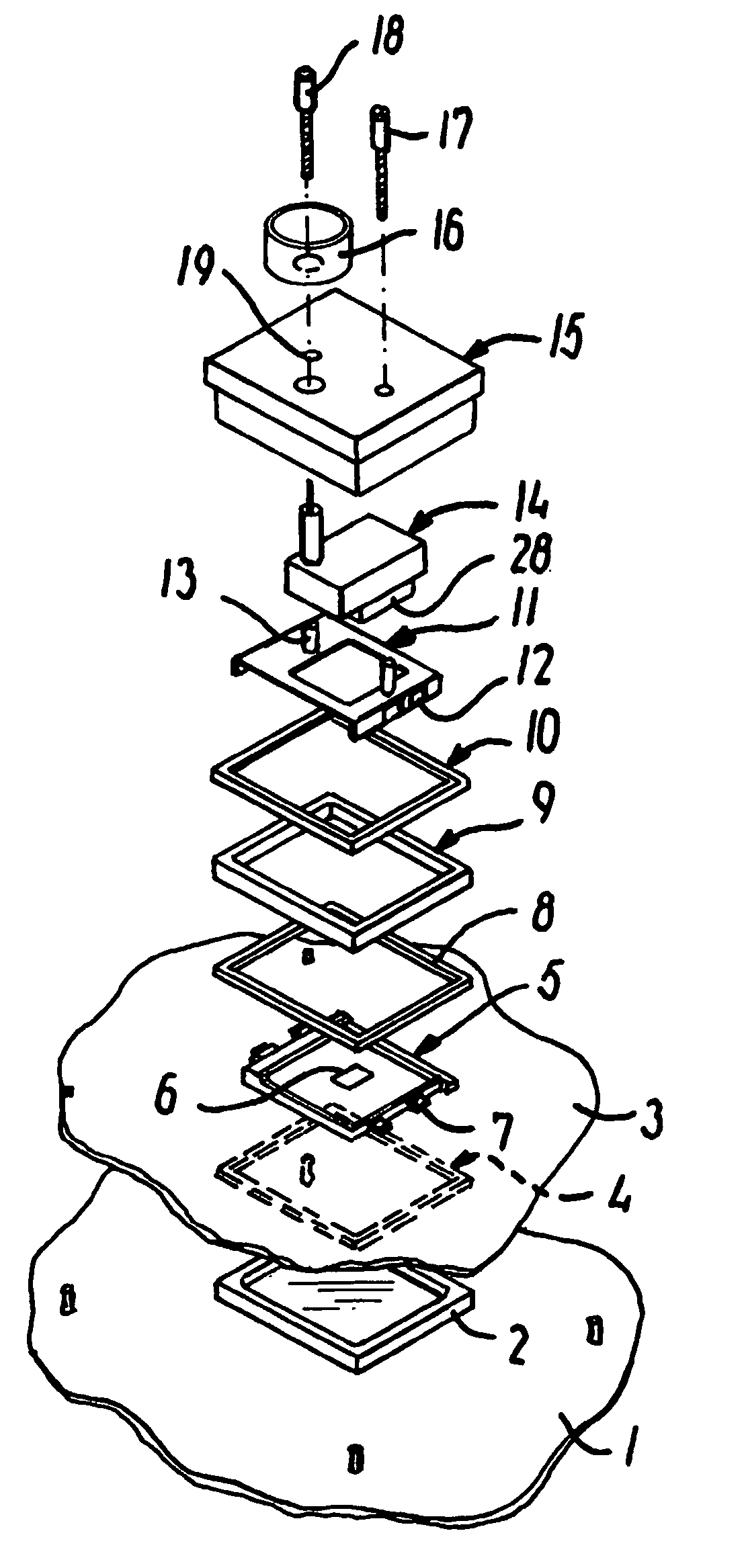

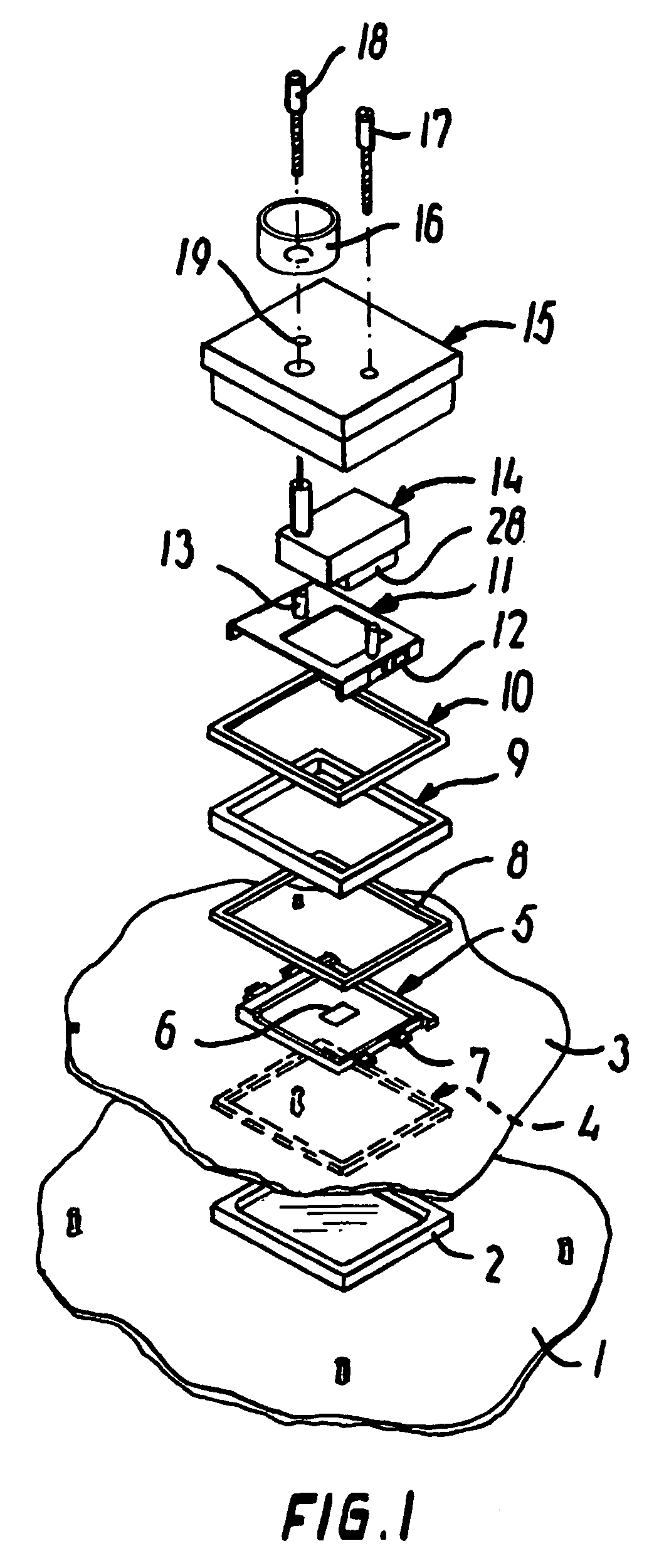

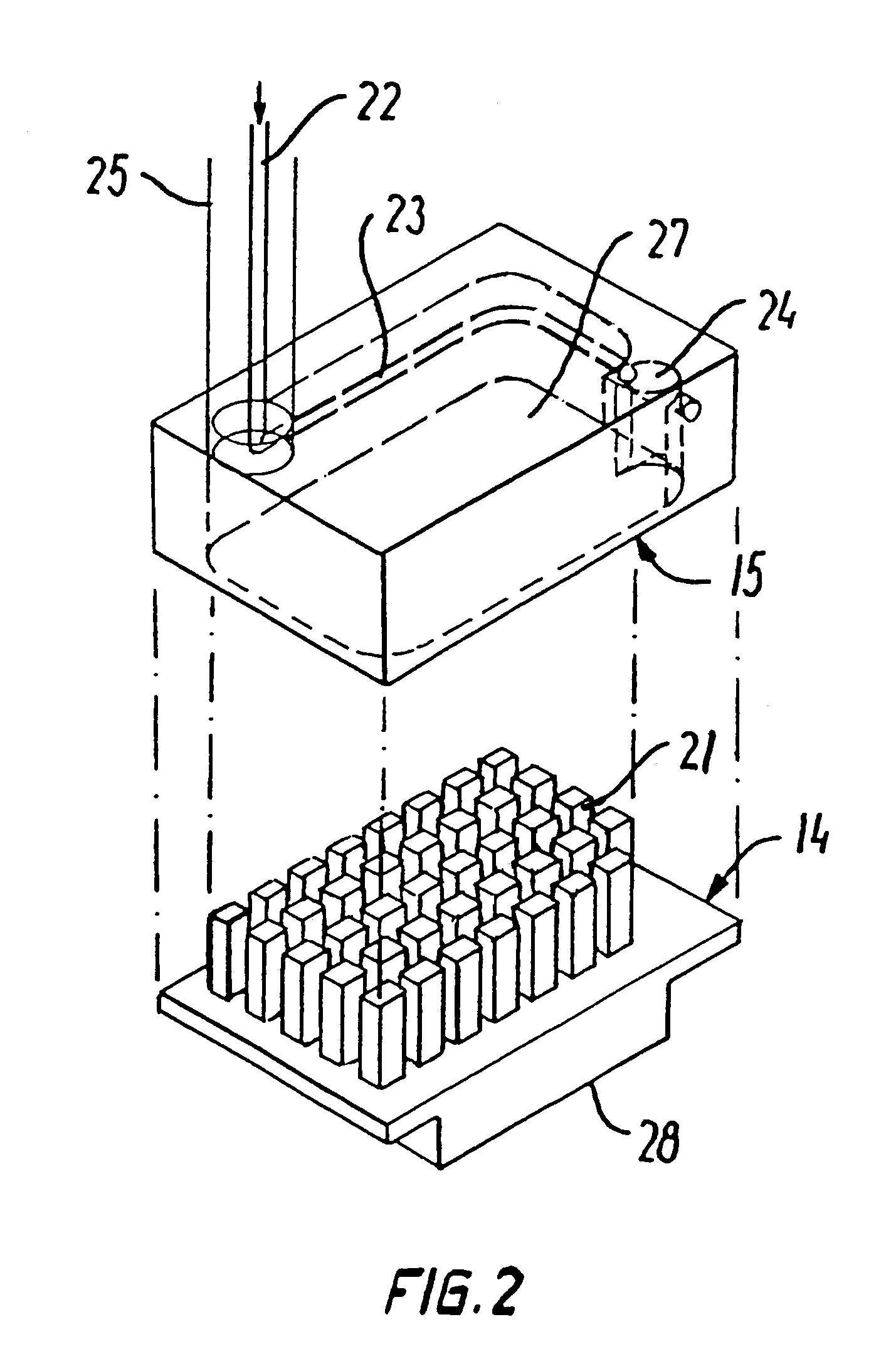

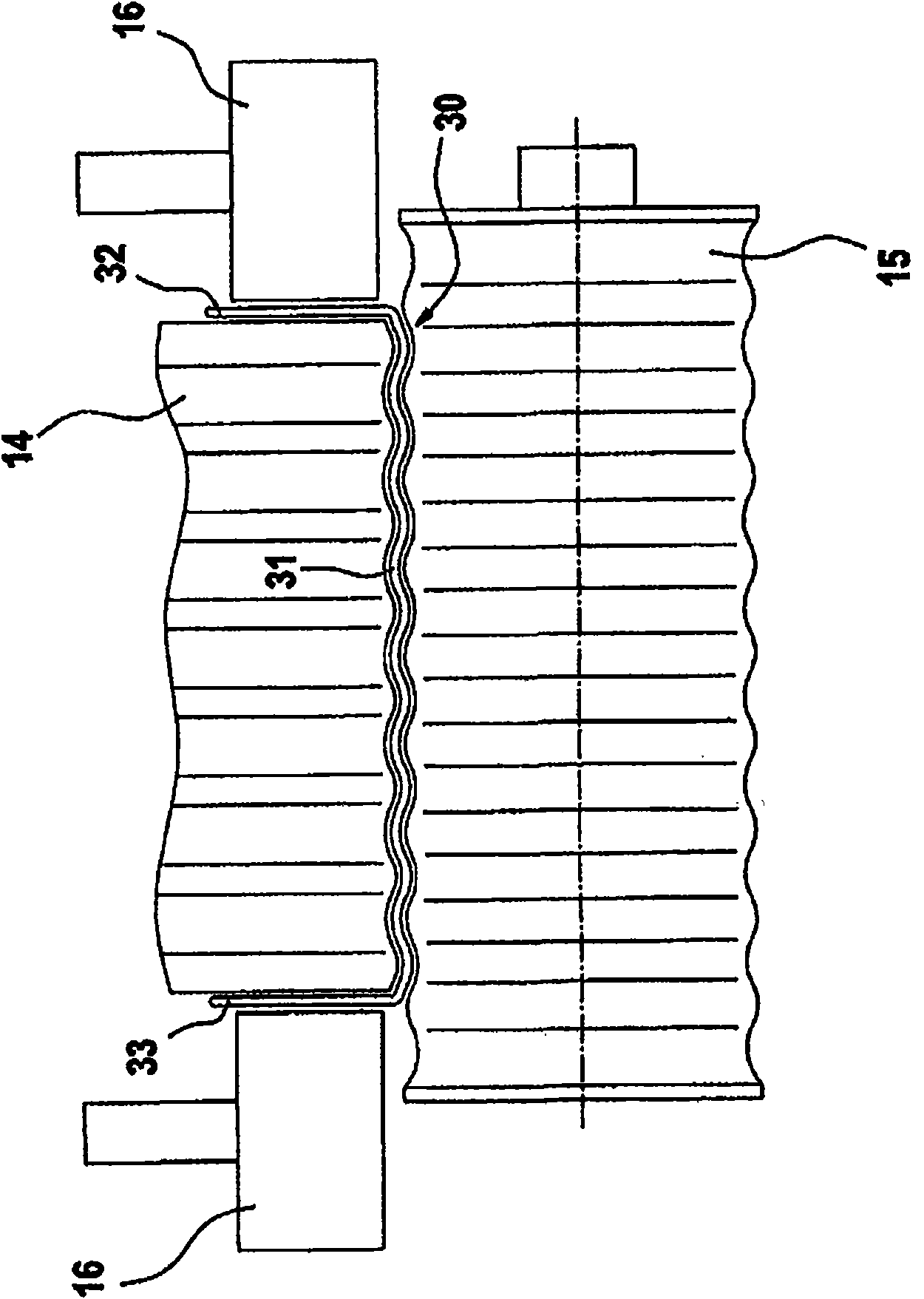

Cooling arrangement for an integrated circuit

InactiveUS7042723B2Strong coolingLarge caliberSemiconductor/solid-state device detailsSolid-state devicesEngineeringPrinted circuit board

A cooling arrangement for one or more integrated circuits which are mounted in a socket on a printed circuit board and which each are cooled by a cooling element based on a compressor. The surface of each integrated circuit has arranged thereon a cooling element which is formed by an evaporator in the form of a housing (15) which has a lid with protruding cooling rods. Coolant is supplied to the housing (15) via a supply pipe (22, 23) that ends in an inlet stub (24) in the housing, which is constructed such that the coolant changes its direction, such as 90°, when entering the interior of the housing. The coolant is returned form the housing via an outlet stub (25) which is concentric with the inlet stub (22). The supply pipe has a smaller diameter than the inlet stub (24) and the outlet stub (25), which means that cooling of the coolant and thereby of the cooling rods takes place in the housing, said cooling being transferred to the individual ICs. With a view to avoiding formation of condensate in connection with the cooling process, the housing is fixed against the printed circuit board according to the invention, a sealing material, such as butyl, being arranged between the housing (15) and the printed circuit board (3). For additional sealing, a rear flange may be fixed on the rear side of the printed circuit board in the area where wires are run to the IC, said rear flange being sealed with butyl against the printed circuit board.

Owner:EXTREME COOLING TECH

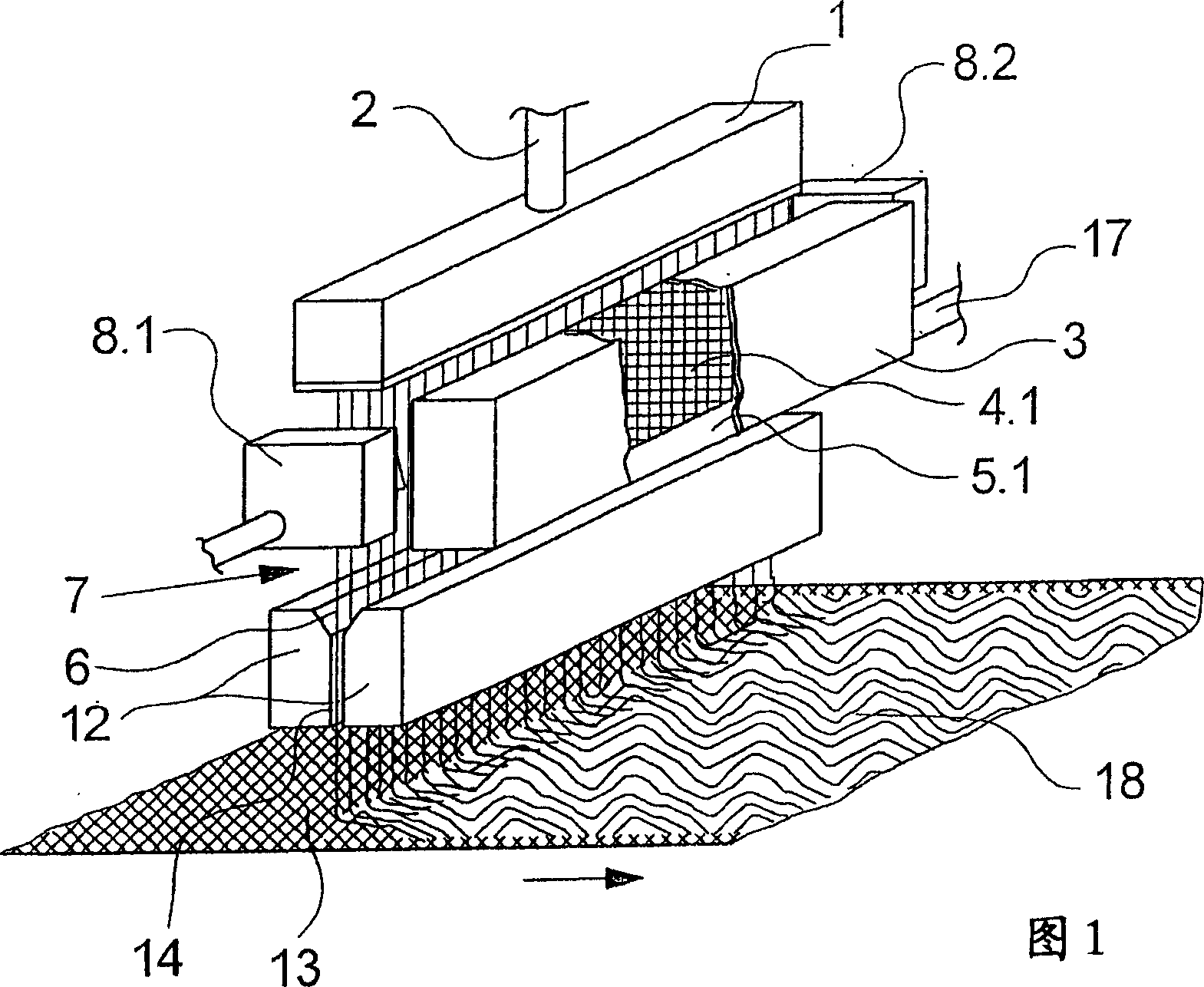

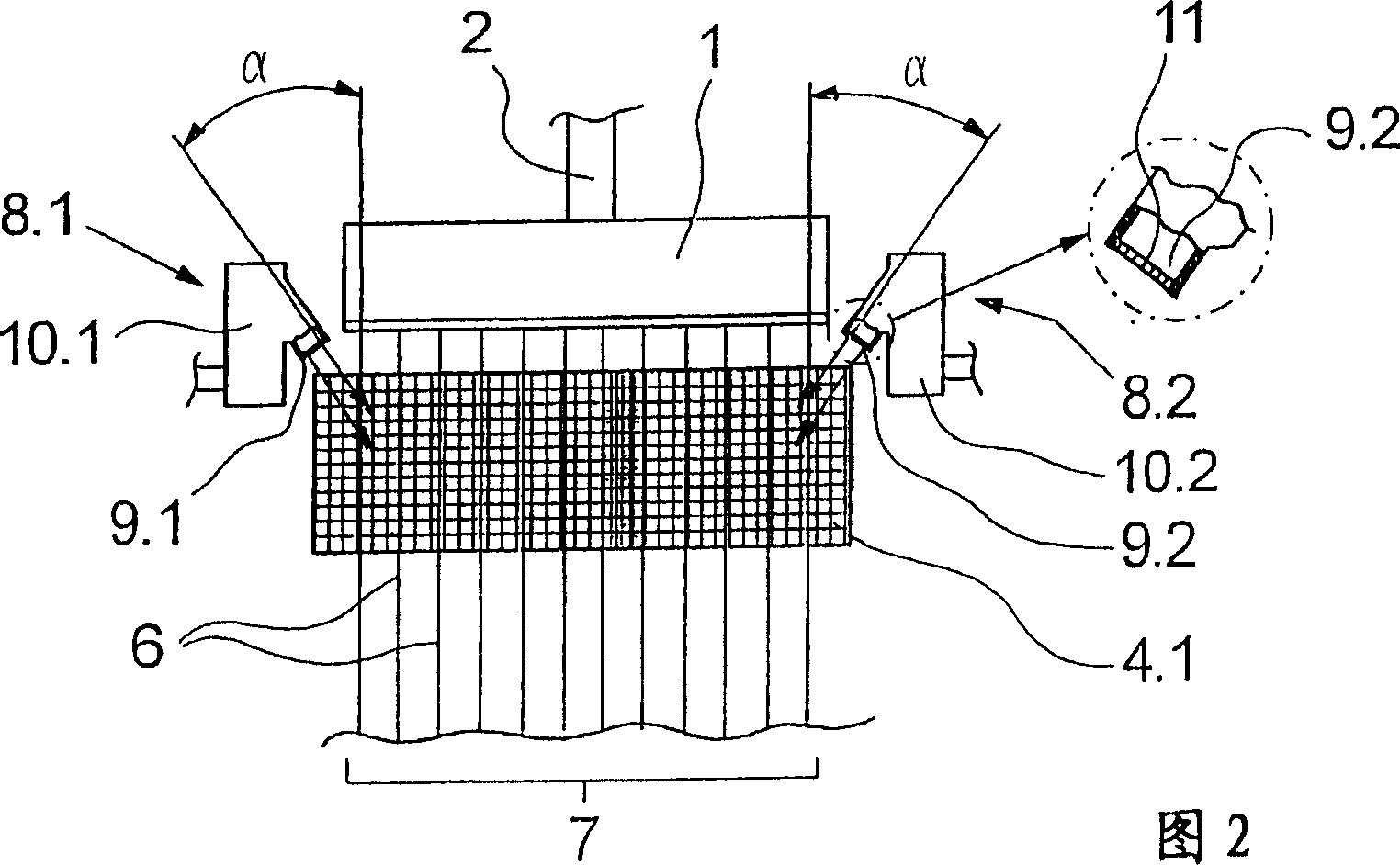

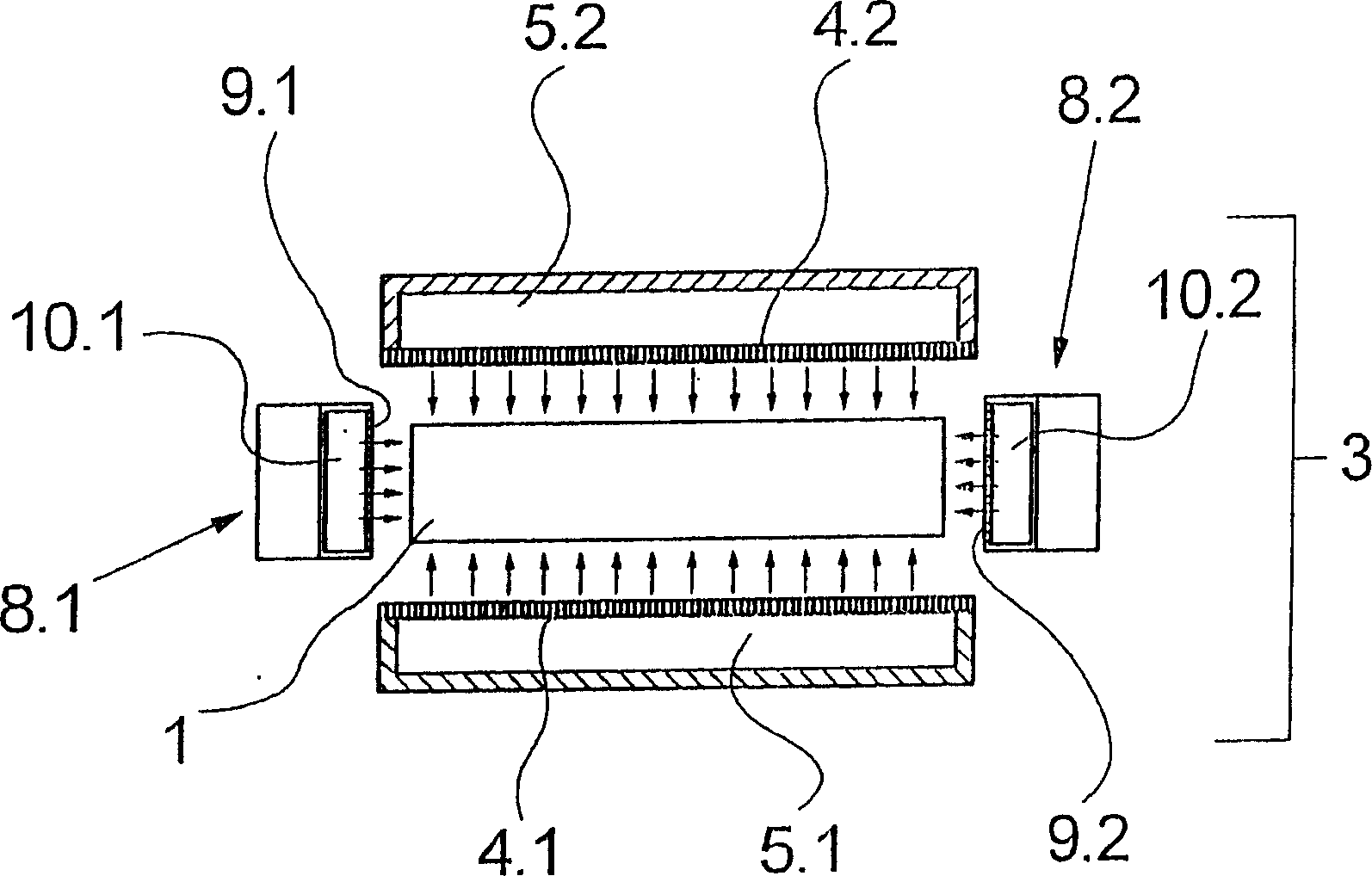

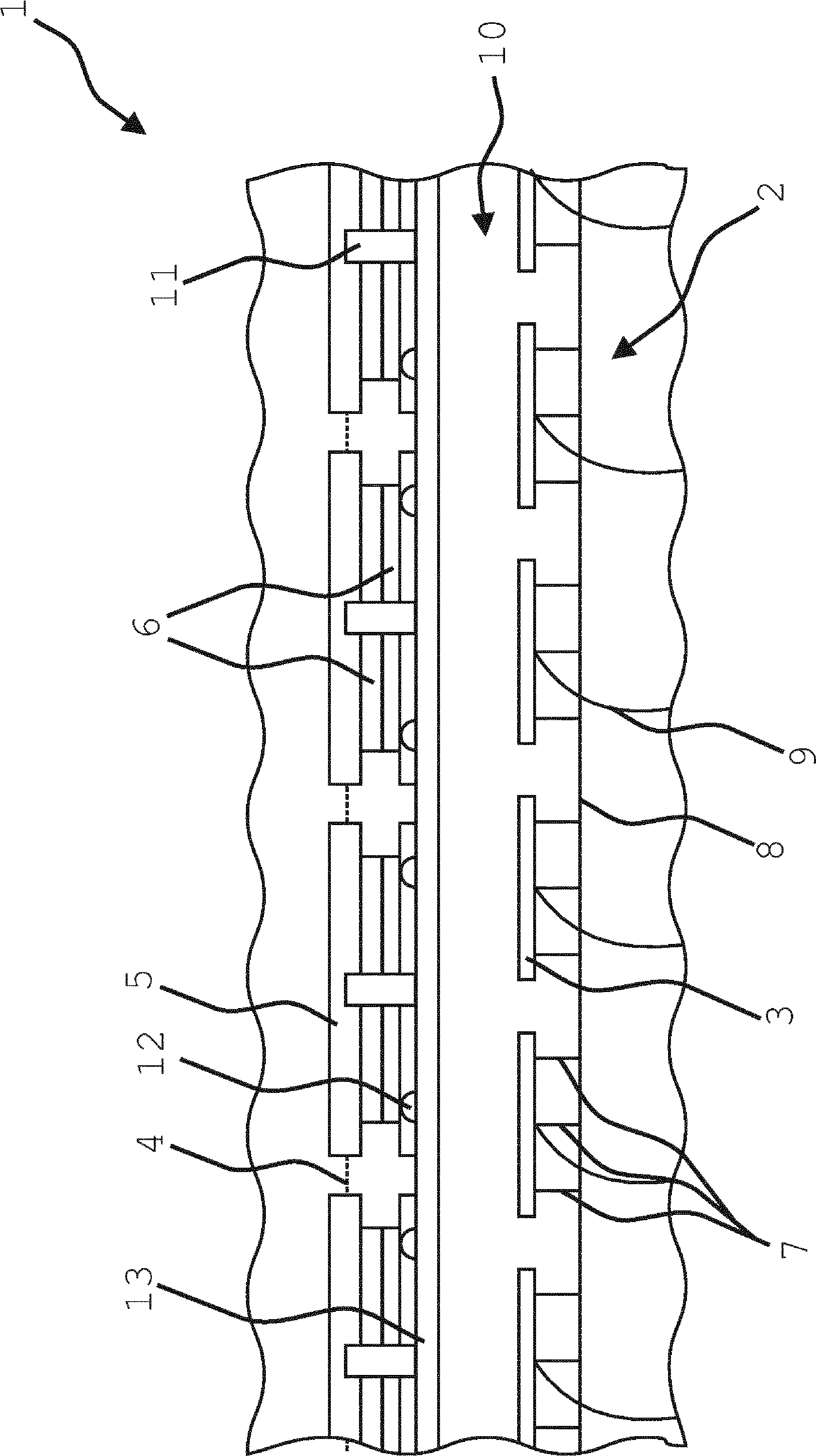

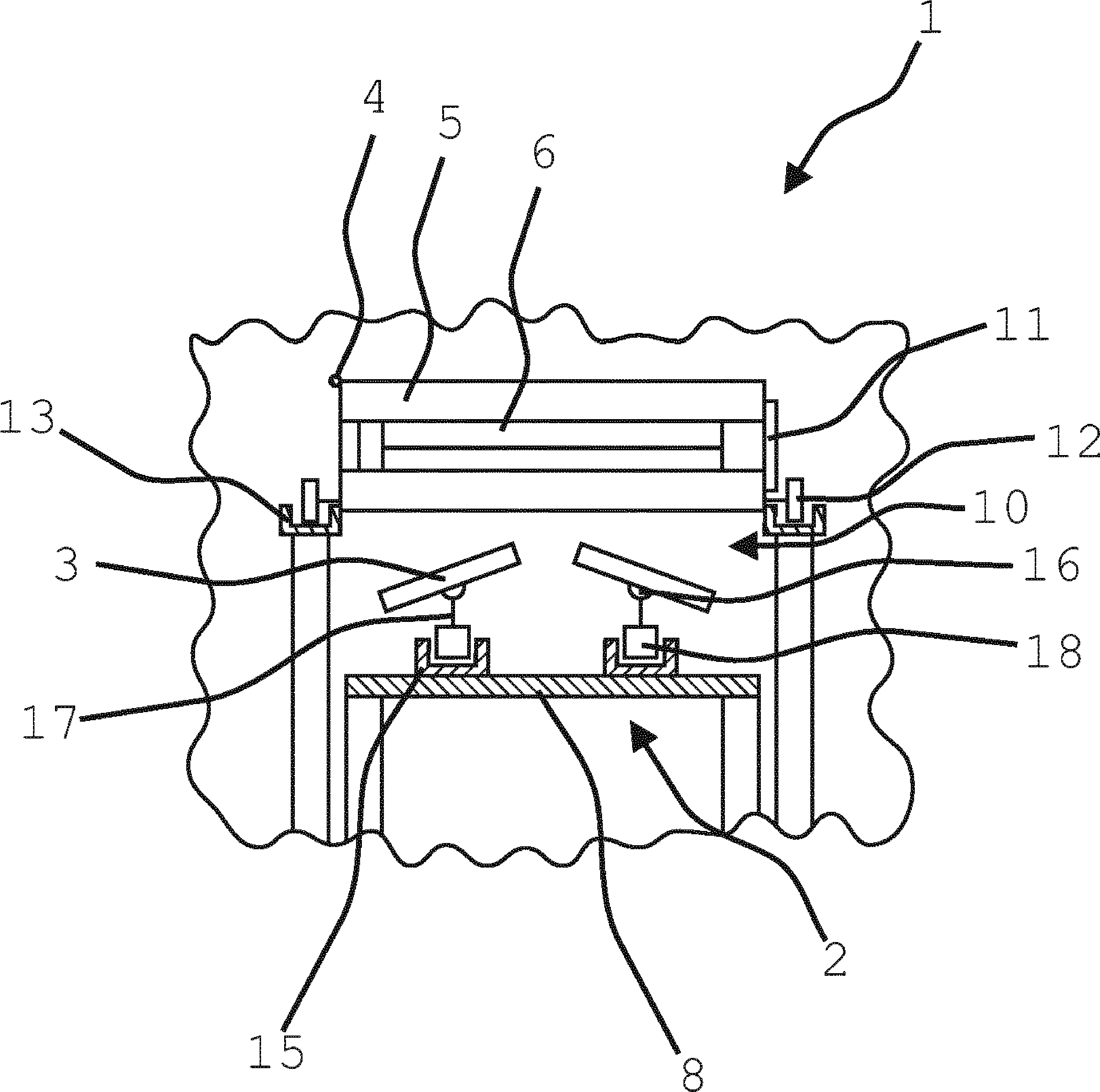

Device and method for secondary cooling in a continuous casting system

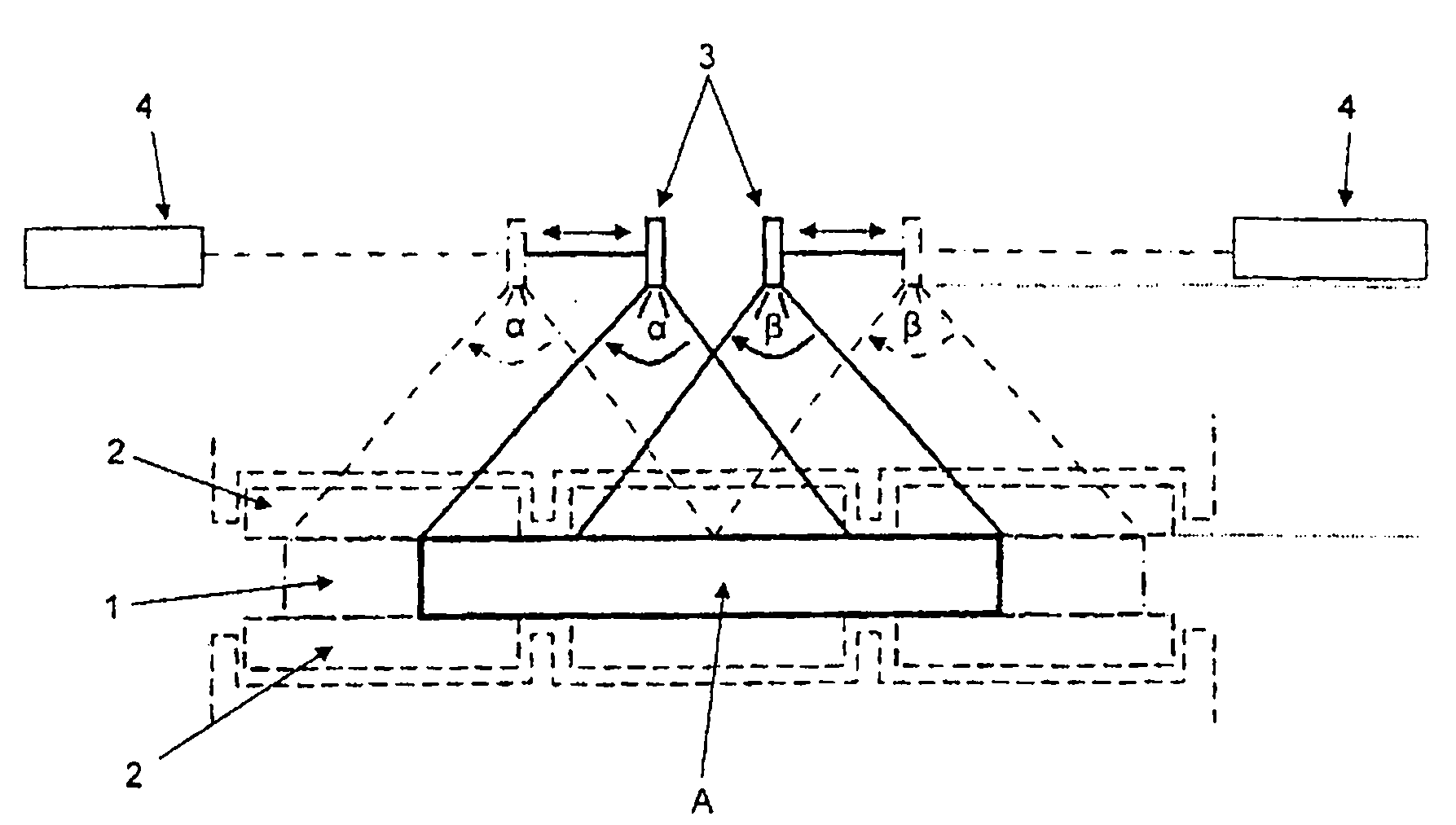

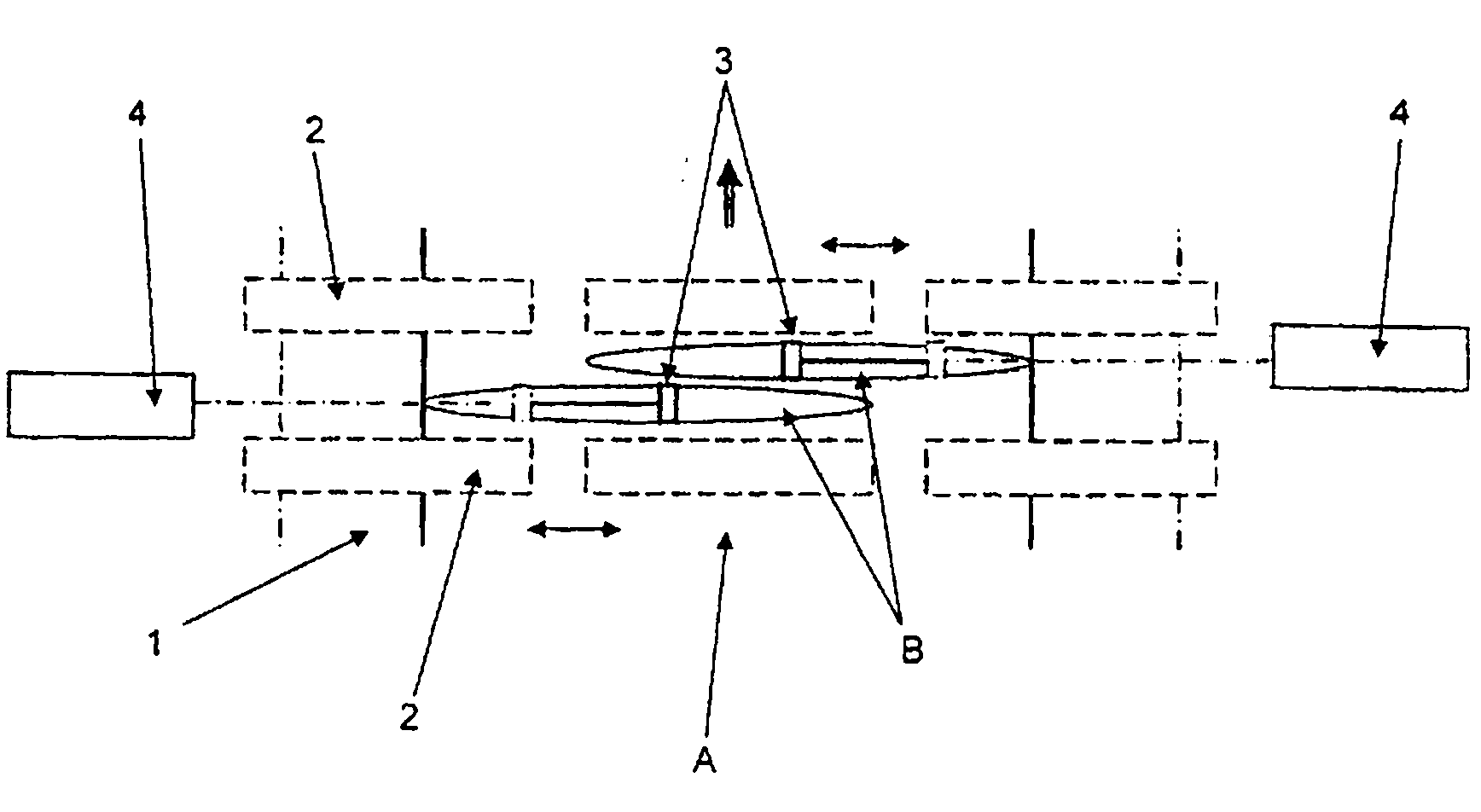

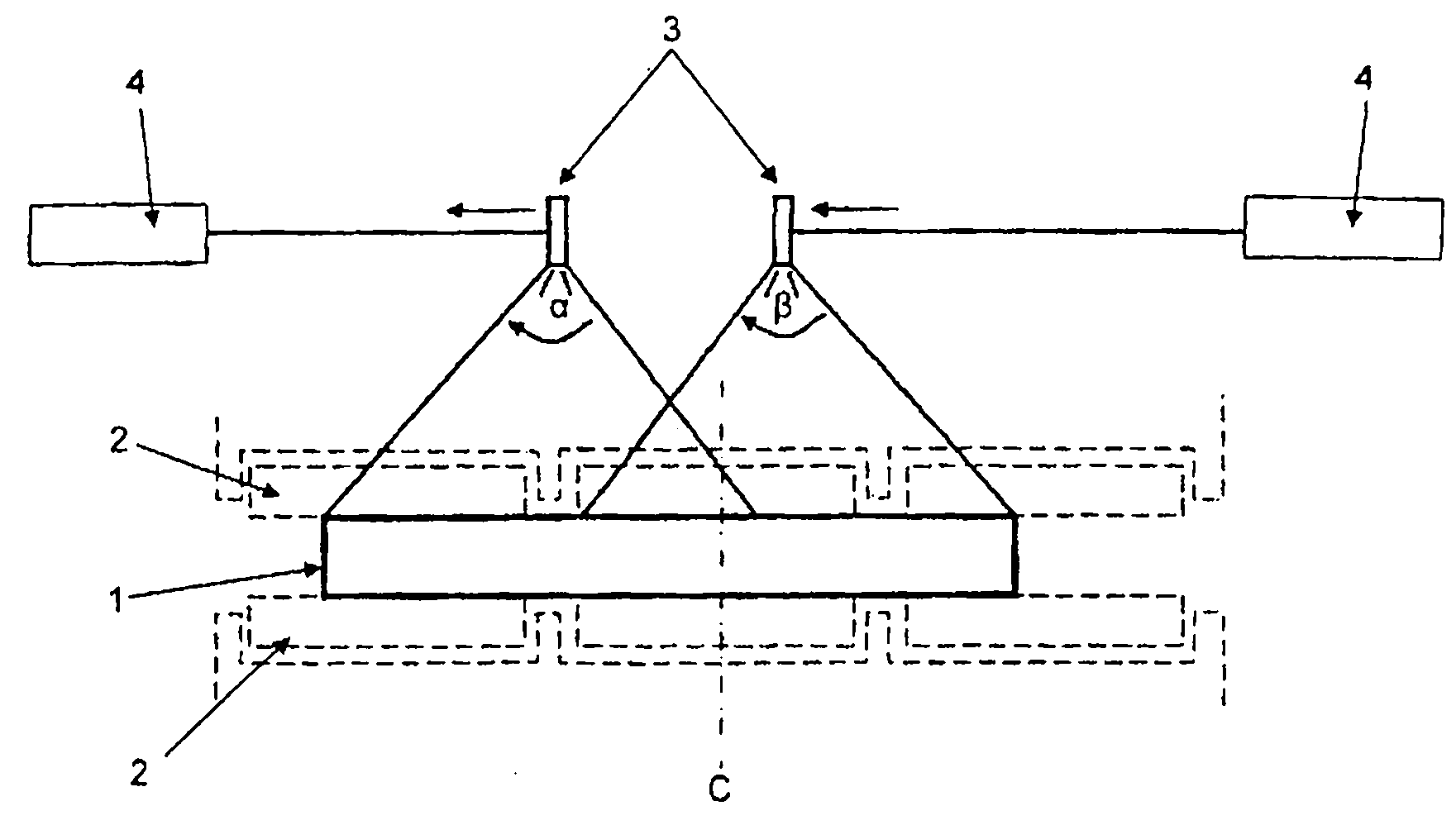

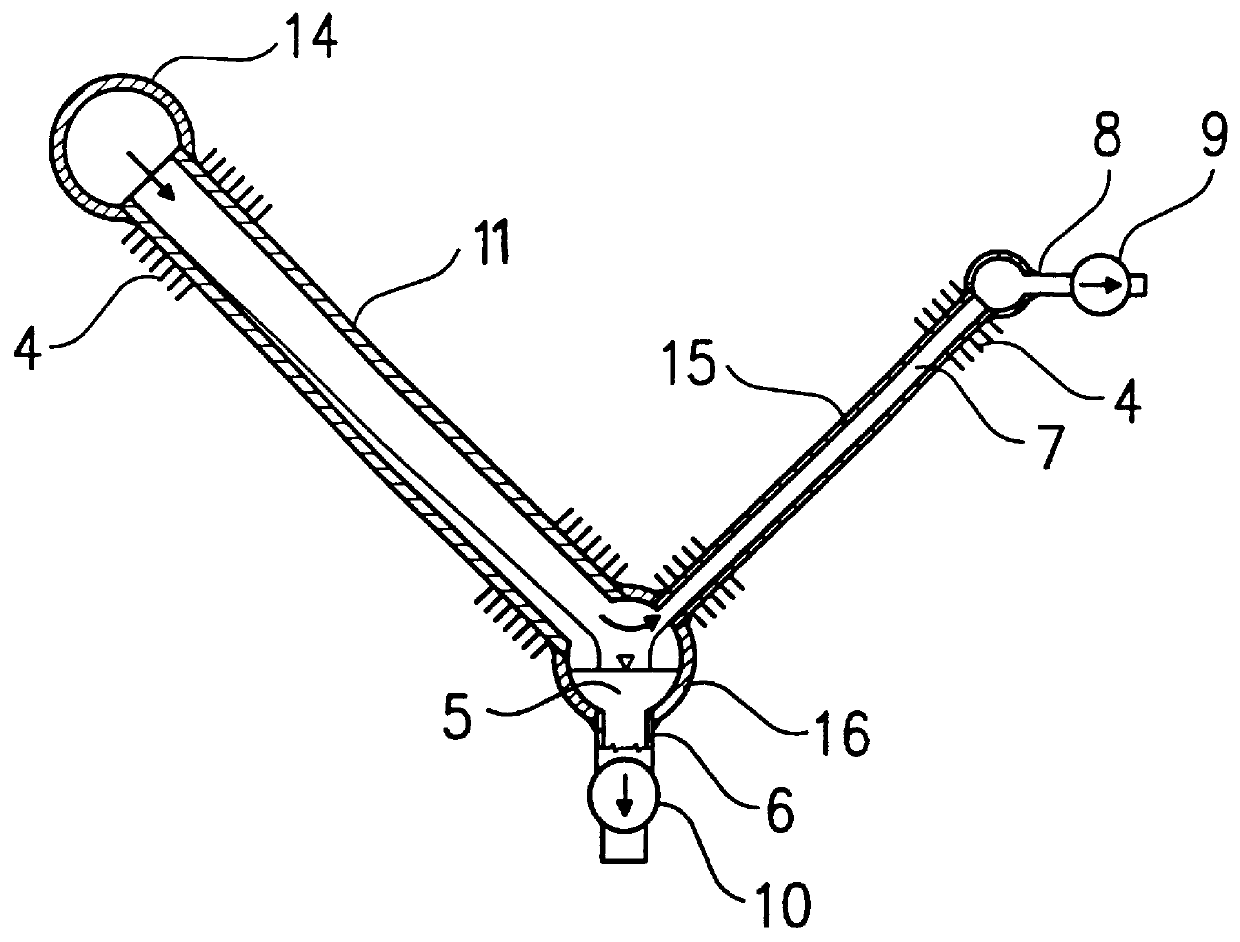

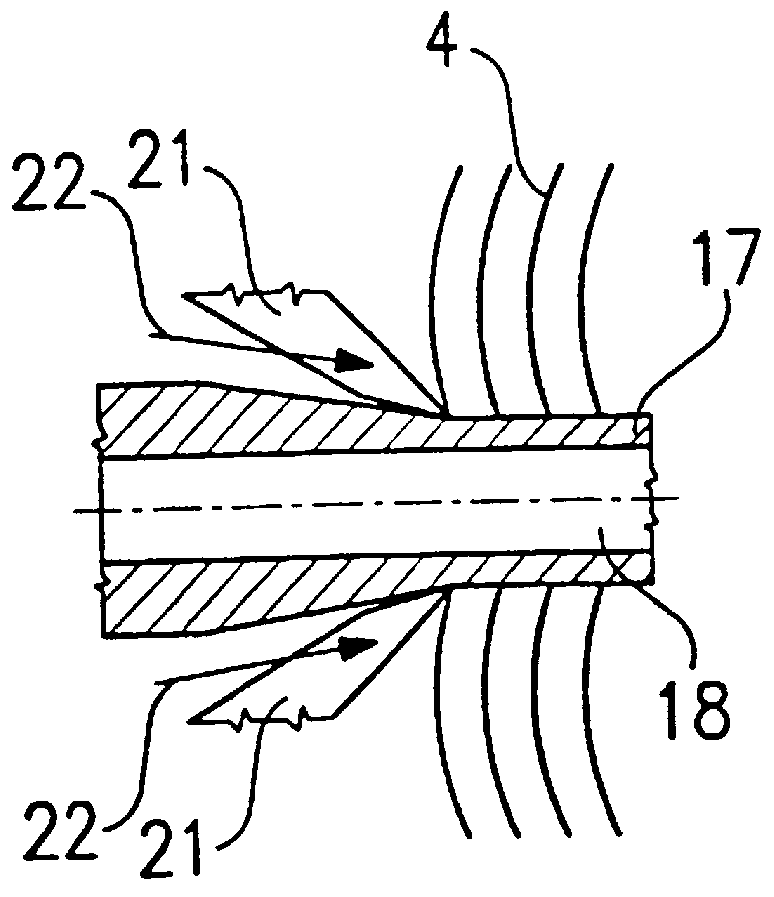

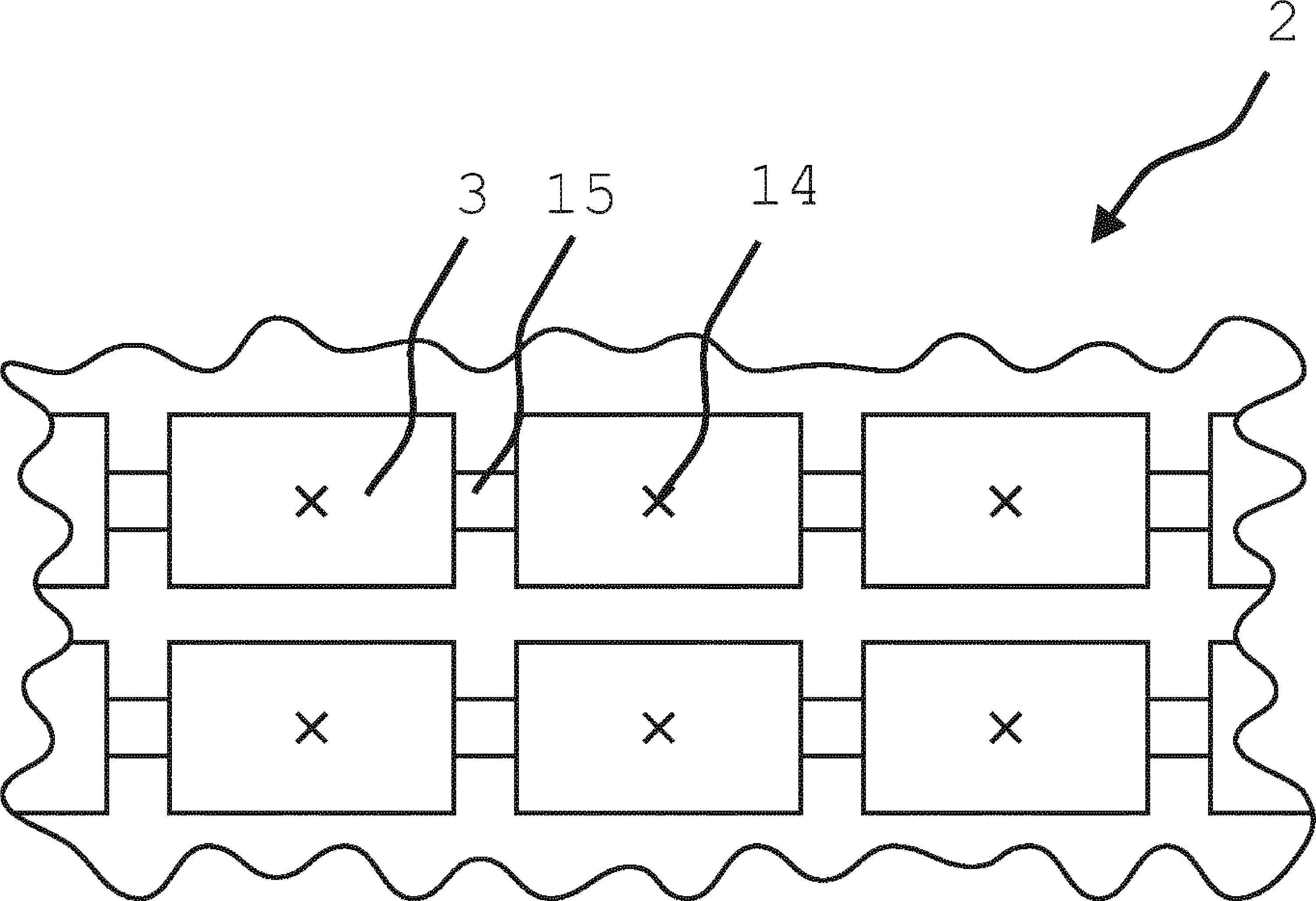

The invention relates to a device and to a method for secondary cooling in a continuous casting system and to a continuous casting system designed accordingly. According to the invention, nozzles (3) are arranged between two rolls or rollers (2) adjacent to each other in the casting direction, in a roller guide or in a strand guide, said nozzles applying coolant onto the surface of the strand 1, 1', 1''. According to the invention, the vertical distance of the nozzles (3) to the strand 1, 1', 1'' remains constant, wherein the nozzles (3) can be moved independently of each other parallel to the longitudinal axis of the rollers (2) by a displacement and positioning device (4). Thus a low space requirement and high flexibility during cooling of a strand 1, 1', 1'' is achieved. According to the invention, overspraying of the strand edge can thus be prevented, intensive cooling of the strand center is made possible, an asymmetrical strand course can be taken into consideration in the cooling, and strands in a multistrand operation can be optimally cooled.

Owner:SMS GRP GMBH

Air-cooled condenser

InactiveUS6142223AStrong coolingAvoid developmentSteam/vapor condensersLaminated elementsEngineeringParallel channel

Owner:ENERGIAGAZDALKODASI RESZVENYTARSASAG

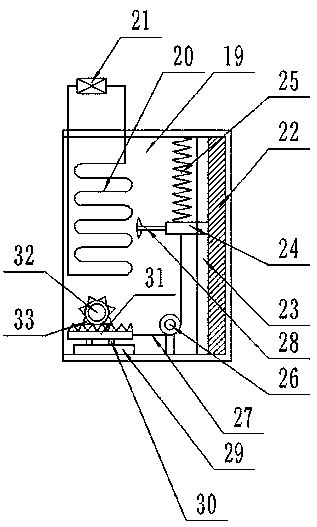

Heat dissipation apparatus used for electric vehicle motor

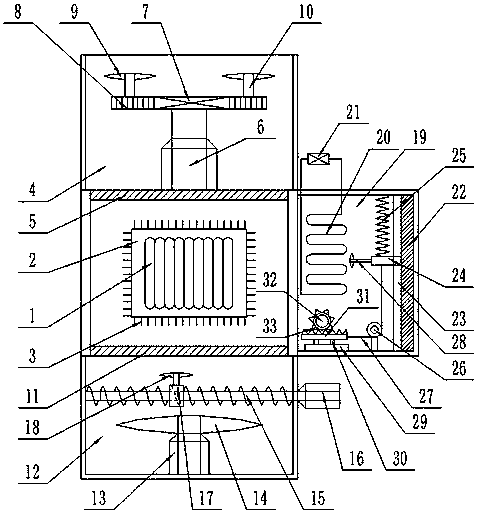

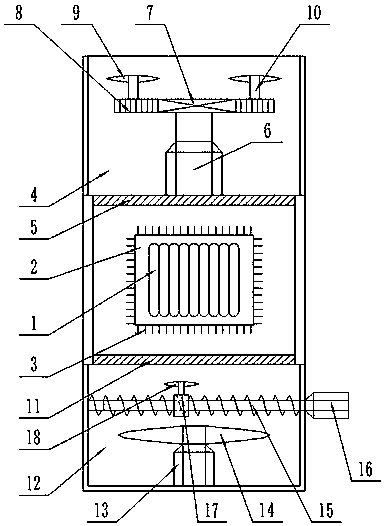

ActiveCN107733159AStrong coolingEffective coolingElectric machinesCooling/ventillation arrangementCold airGear drive

The invention discloses a heat dissipation apparatus used for an electric vehicle motor. The heat dissipation apparatus is reasonable and simple in structure, low in production cost and convenient tomount; by adoption of powerful wind power heat dissipation, effective heat dissipation can be performed on a permanent magnet motor, thereby greatly improving performance of the permanent magnet motor; the heat of the electric vehicle motor is dissipated through a heat dissipation cover shell and heat dissipation sheets; an air-blowing fan and a first circulation fan blow hot air; the first circulation fan moves left and right under driving of a screw rod, so that hot air can be blown quickly; a rack wheel drives exhaust fans on two pinions to realize quick air exhausting; for further improving the heat dissipation effect, a condenser can lower the temperature in a third heat dissipation chamber through a snake-shaped pipe; a rotary motor drives a gear and the gear drives a rack to realizereciprocating movement of a second circulation fan; the second circulation fan blows cold air to the heat dissipation cover shell to realize cooling; and by virtue of the technical scheme, strong heat dissipation to the permanent magnet motor is realized.

Owner:YANTAI ZHIXING INTPROP CONSULTATION SERVICES CO LTD

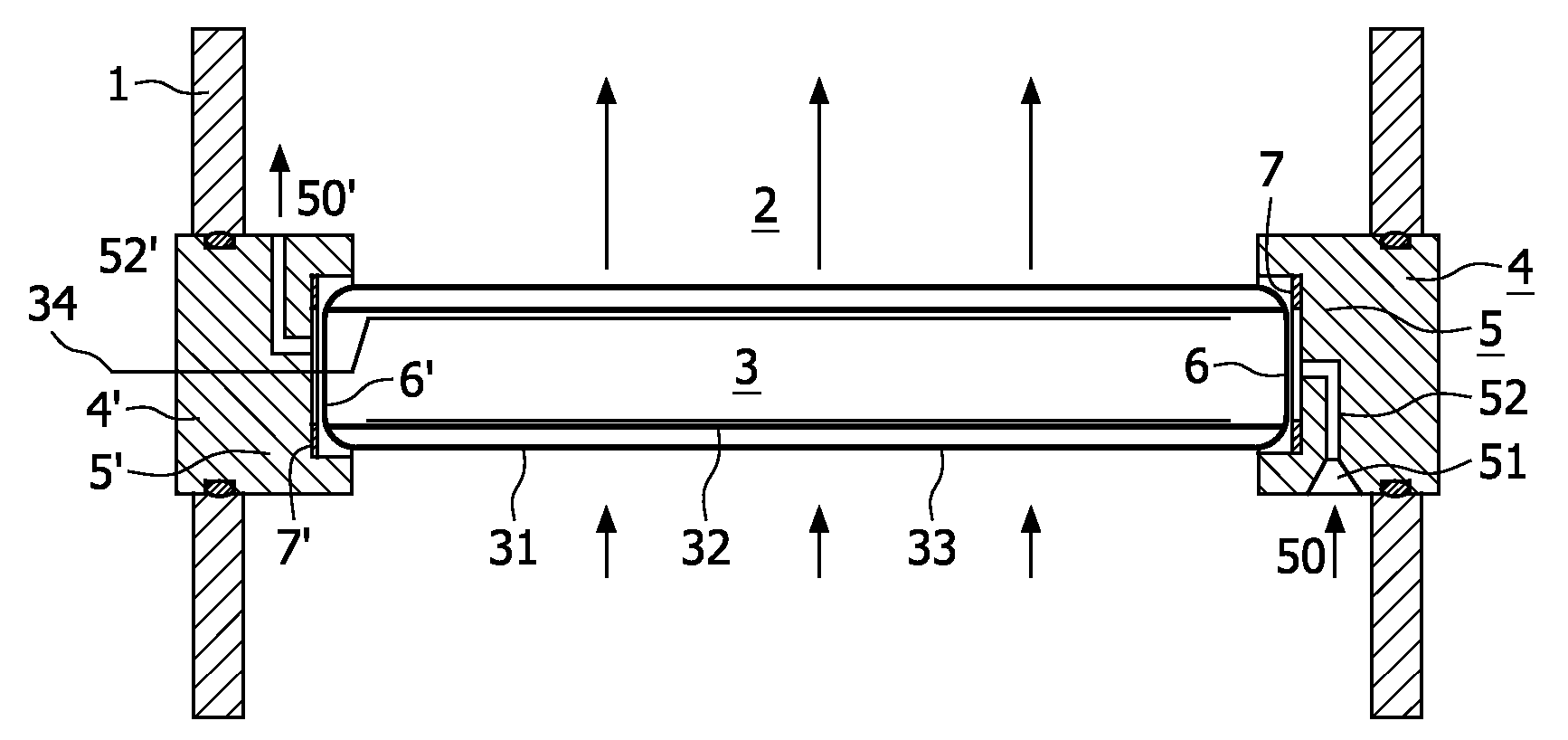

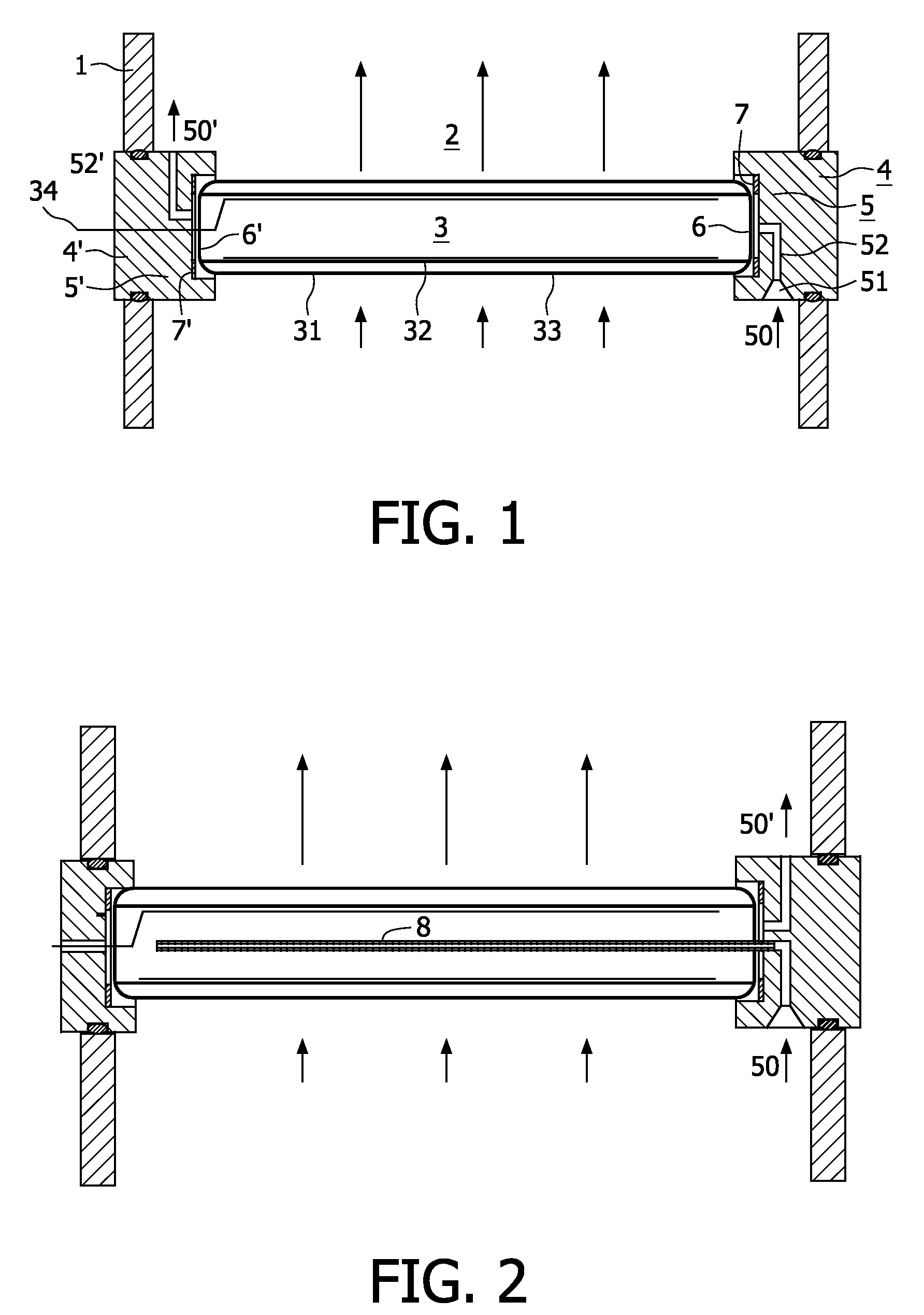

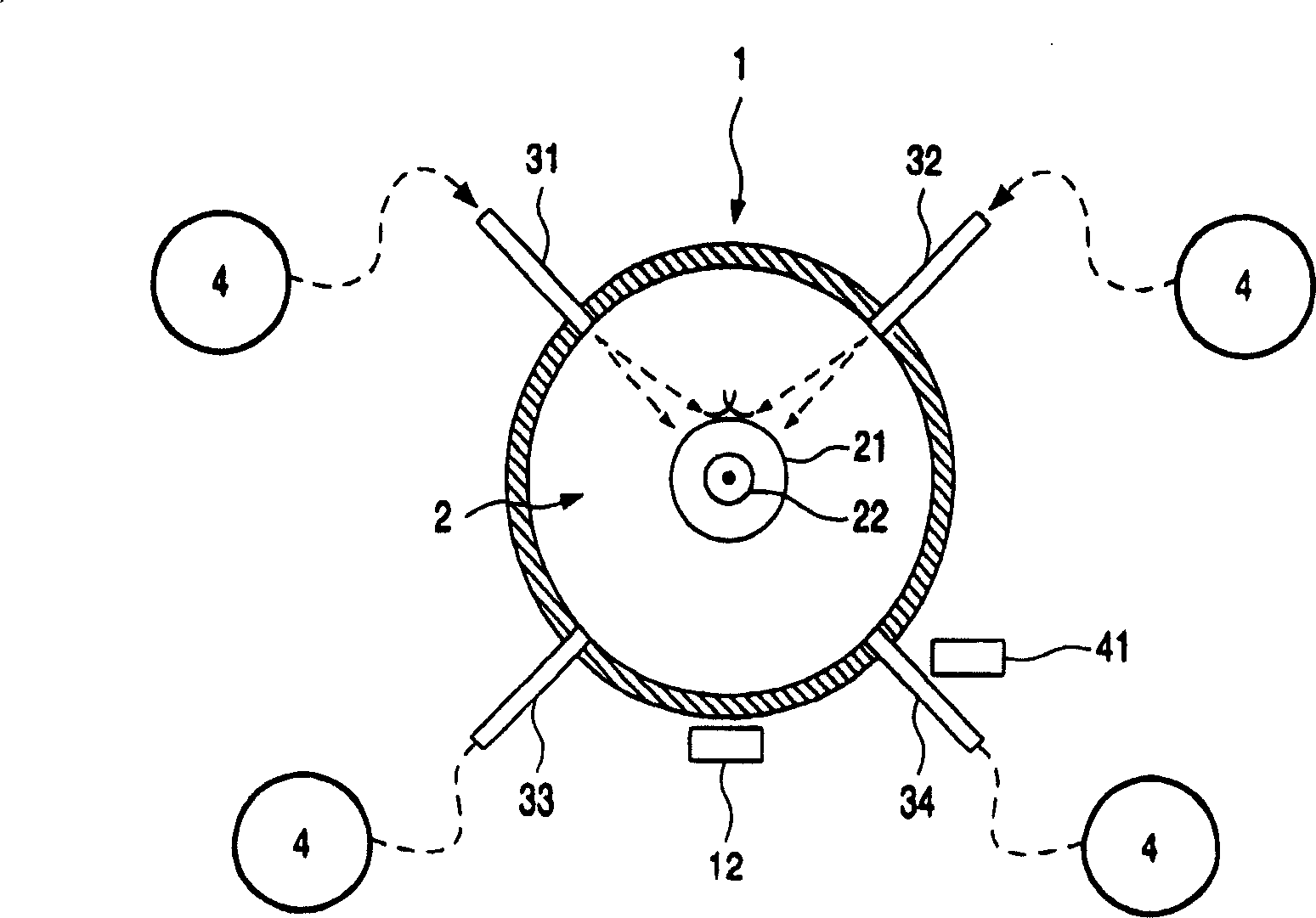

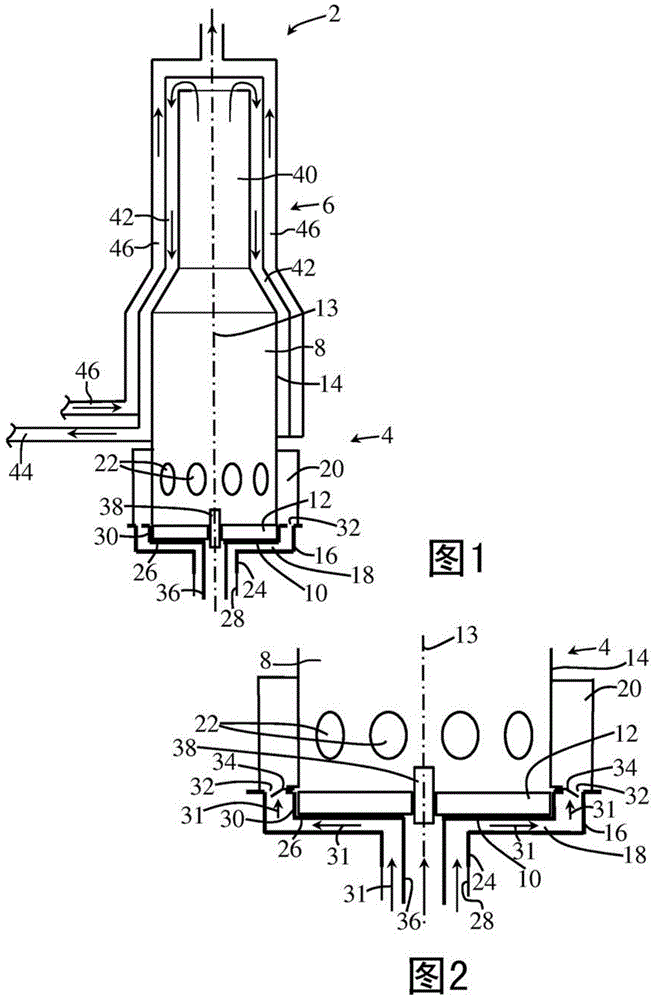

Fluid treatment system comprising radiation source module and cooling means

InactiveUS20090257926A1Easy maintenanceLow costWater/sewage treatment by irradiationSpecific water treatment objectivesIrradiationBiomedical engineering

In a fluid treatment system comprising a housing with a fluid inlet and a fluid outlet for a process fluid, an irradiation zone disposed between the fluid inlet and fluid outlet, and at least one radiation source module comprising at least one radiation source comprising a discharge vessel with an outer wall and an inner wall, the inner wall enclosing an internal volume with at least one opening and means for igniting and maintaining a discharge, the radiation source module also comprising a submersible frame with guiding means to guide the process fluid into and out of the internal volume of the radiation source. The dissipation of the heat generated by the discharge in the discharge gap via a fluid flow in the internal volume of the lamp and in contact with the internal electrodes is substantially more effective than dissipation via a cooling channel separated from the internal electrode. It is therefore substantially easier to maintain the discharge at an approximately optimal temperature.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

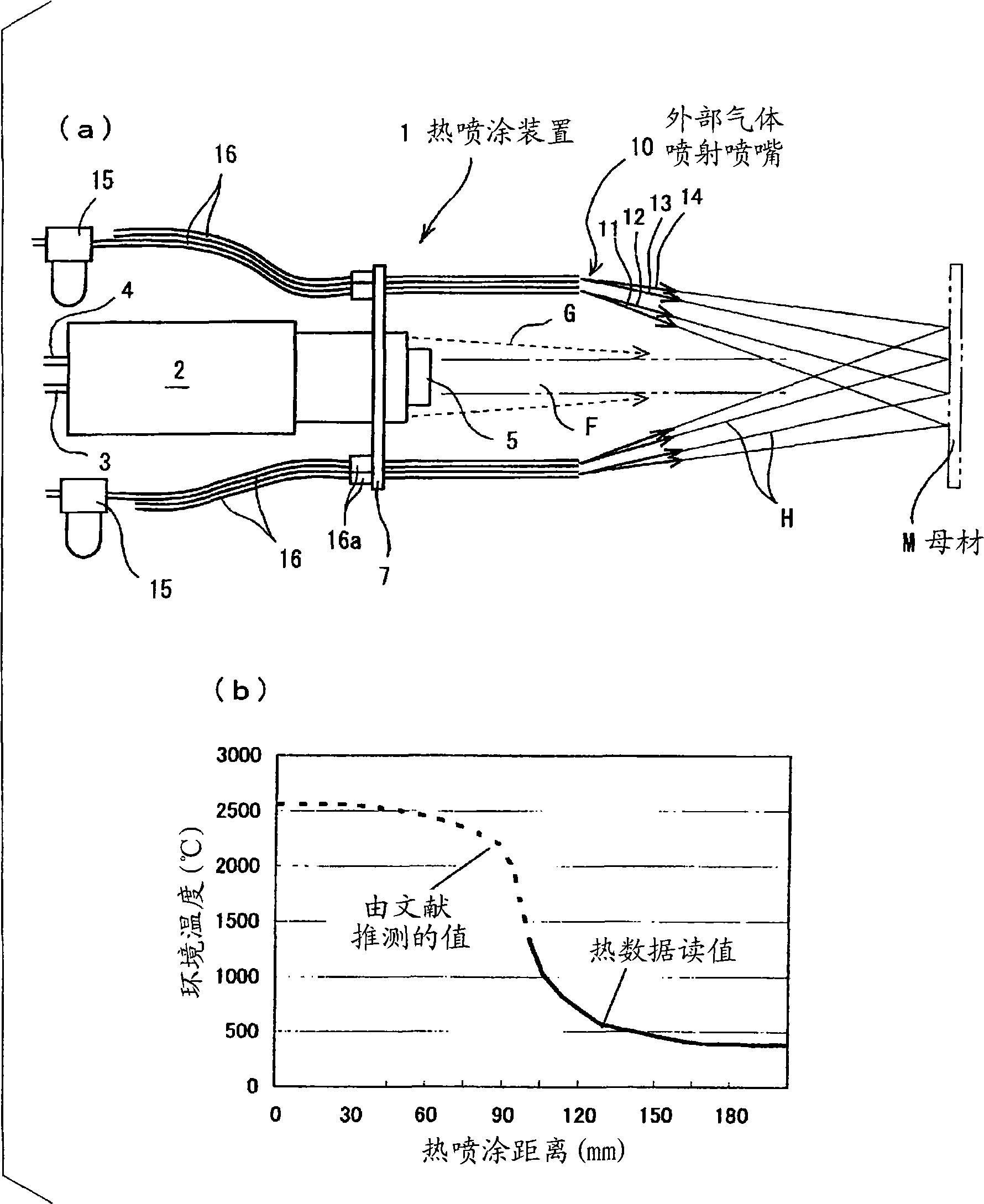

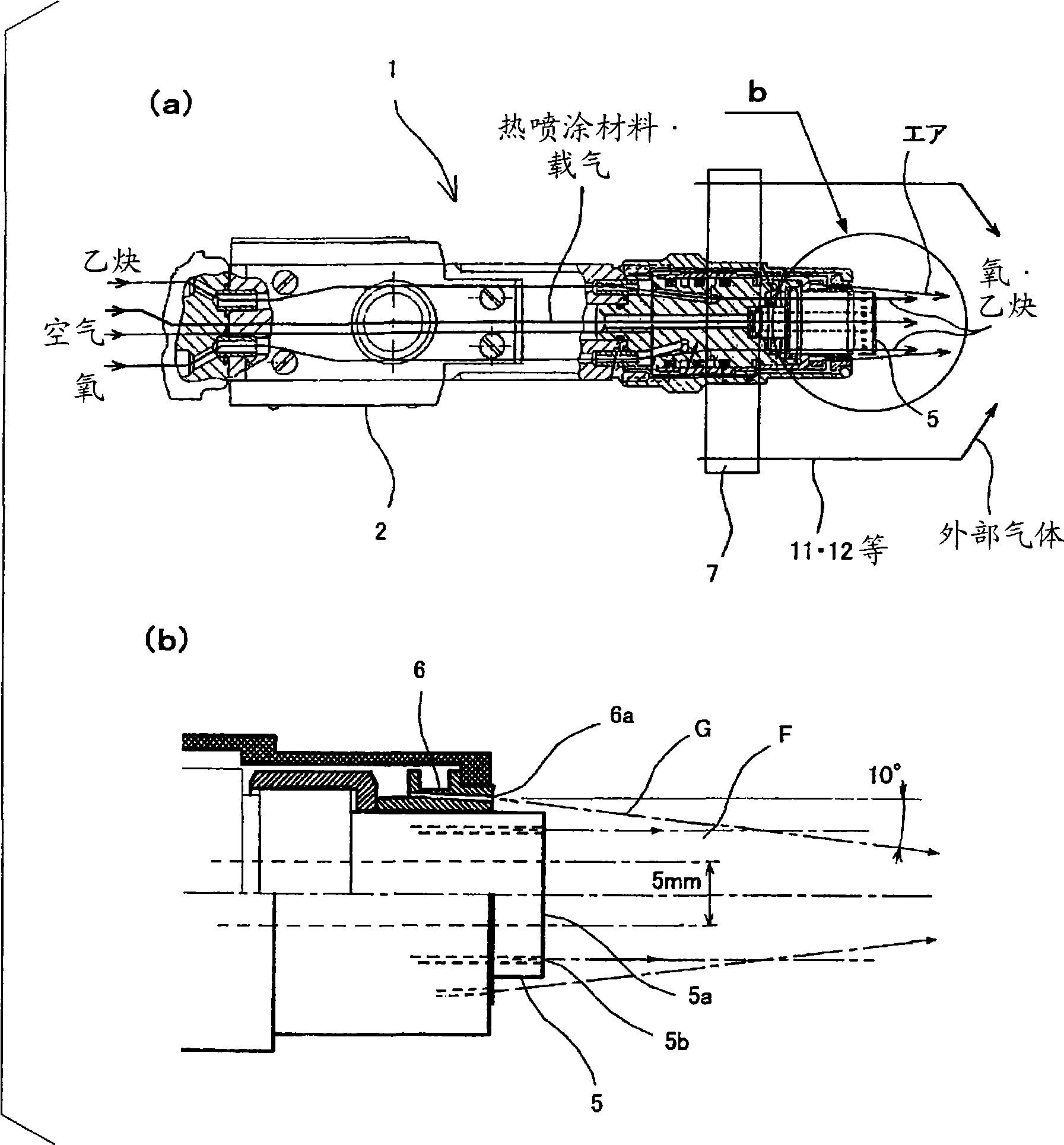

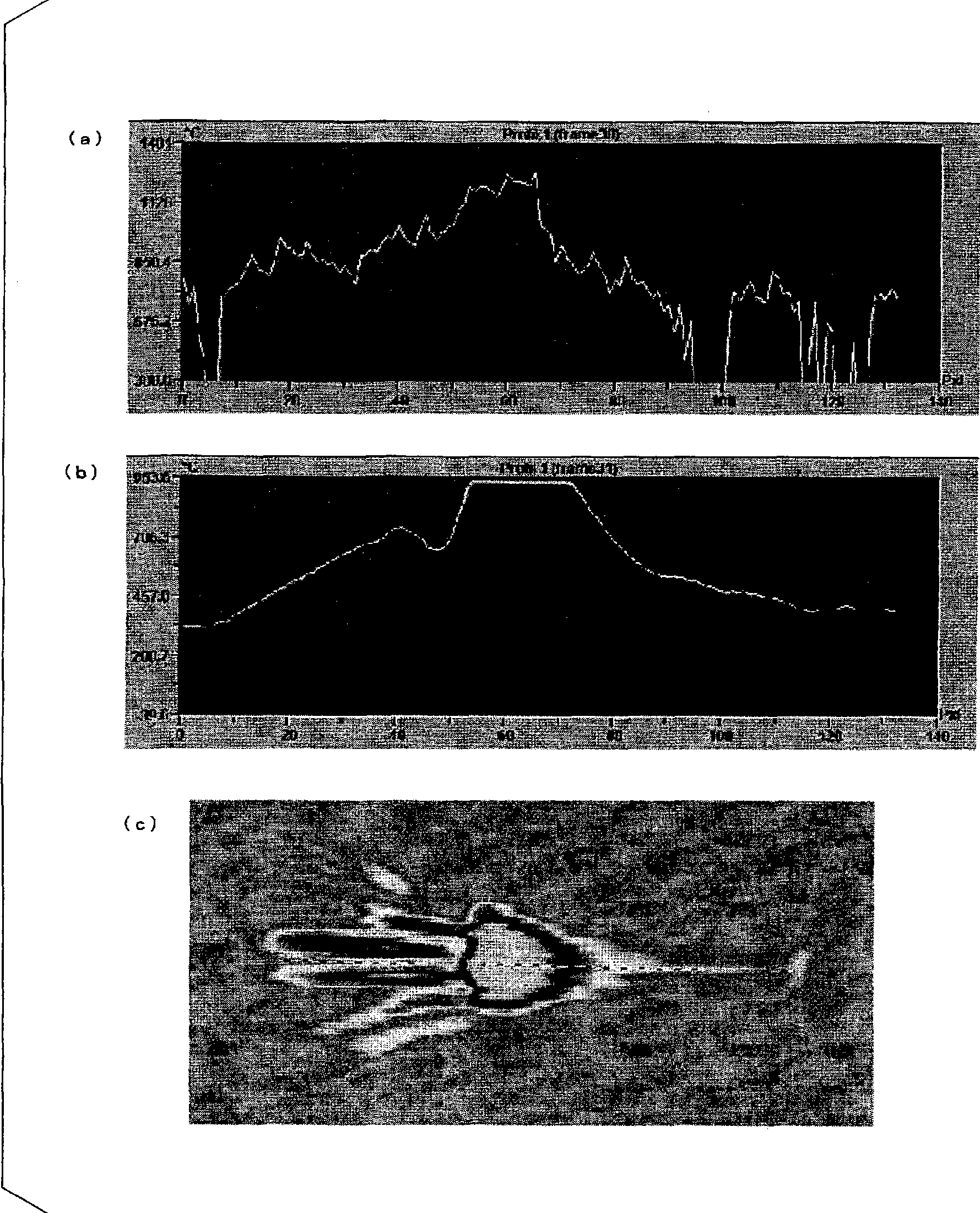

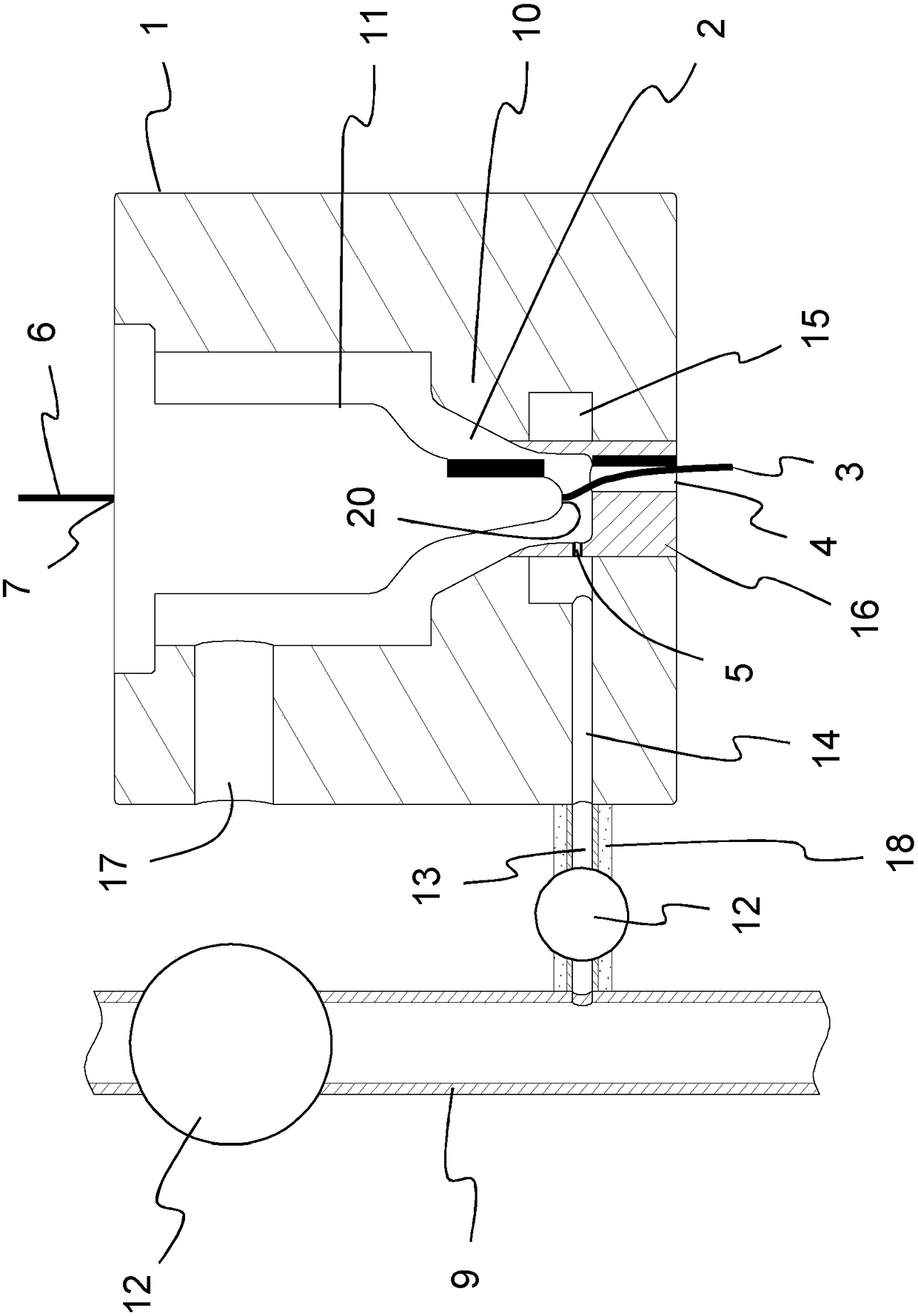

Method and apparatus for forming amorphous coating film

ActiveCN101501236AStrong coolingReduce the temperatureMolten spray coatingLiquid spraying apparatusThermal spray coatingCoating

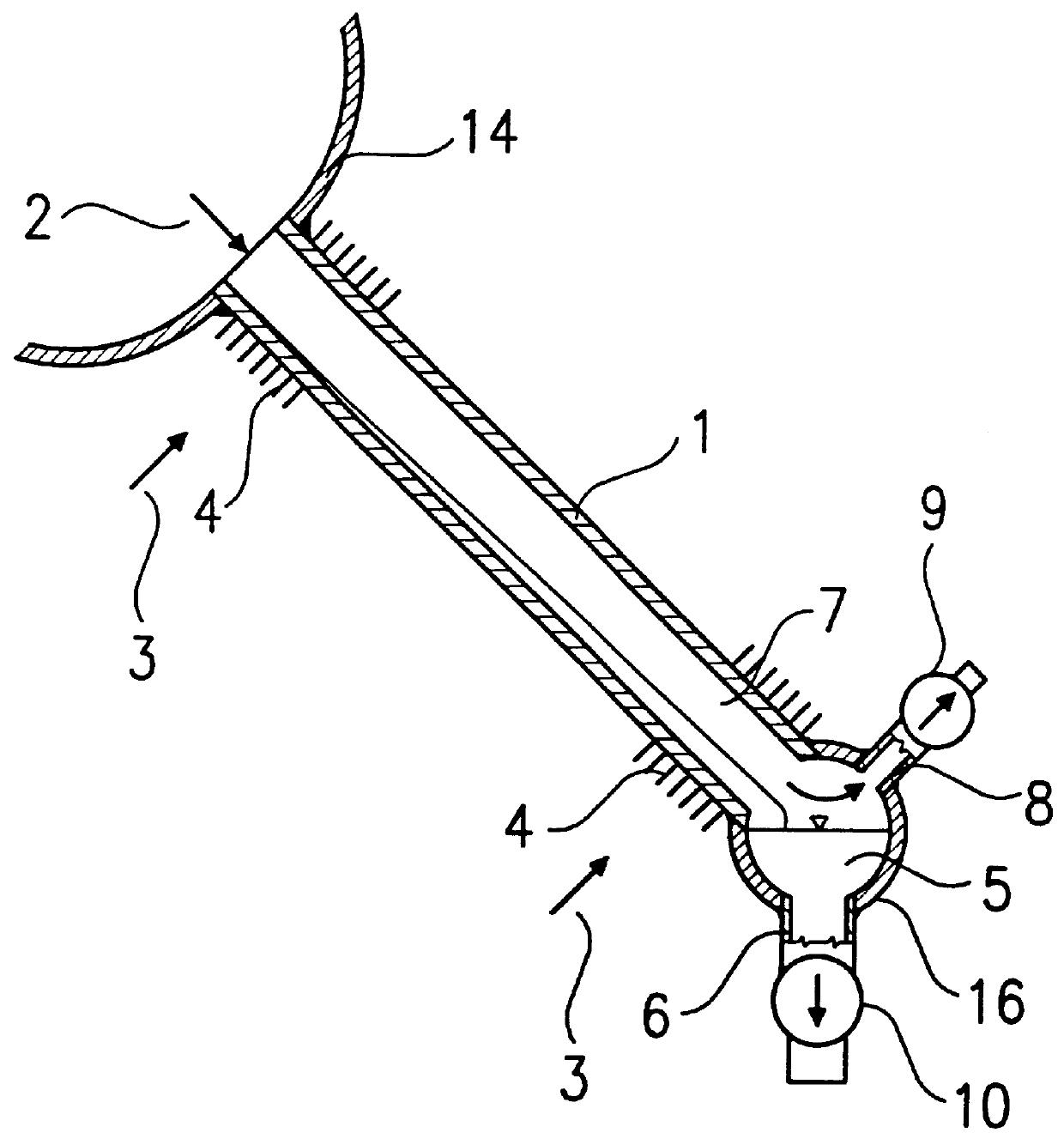

A method and apparatus for forming an ordinary amorphous coating film not limited to metallic glasses, etc. by thermal spraying.A flame (F) containing material particles is ejected from a nozzle (5) toward a base material (M). The material particles are melted by the flame (F), and these material particles and the flame (F) begin to be cooled before they reach the base material (M).For the cooling, a gas (H) is blown from outer peripheral areas apart from the flame (F) so that the gas (H) approaches the center line for the flame (F). It is preferable that the material particles in the flame (F) have a particle diameter of 10-100 [mu]m.

Owner:臼井株式会社 +1

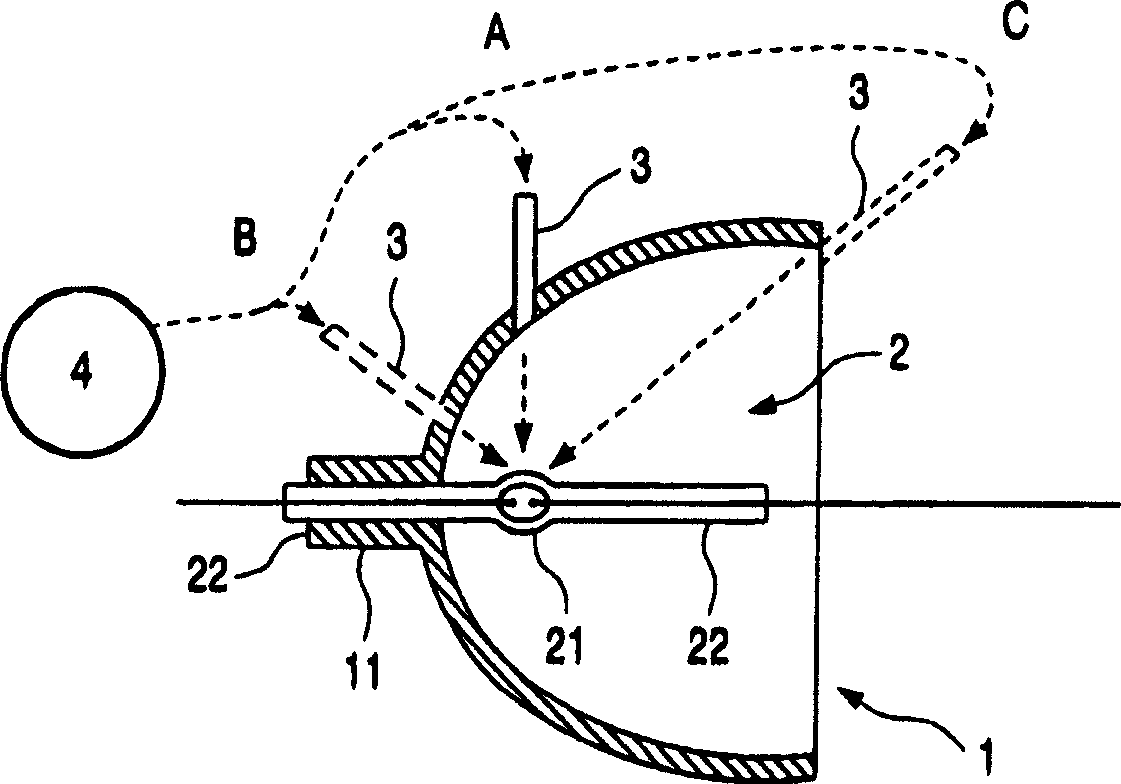

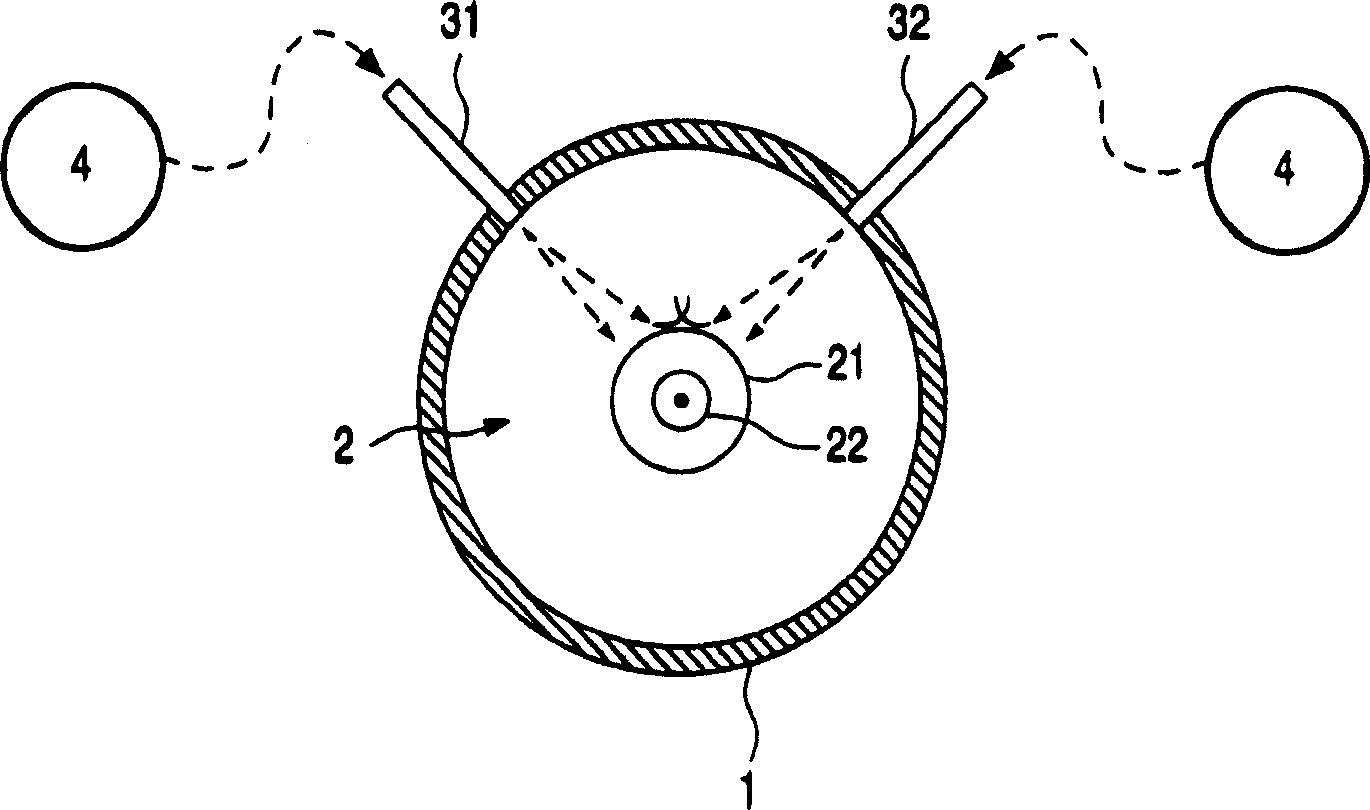

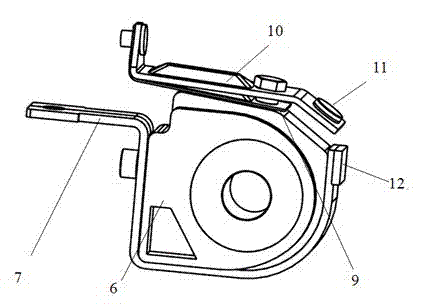

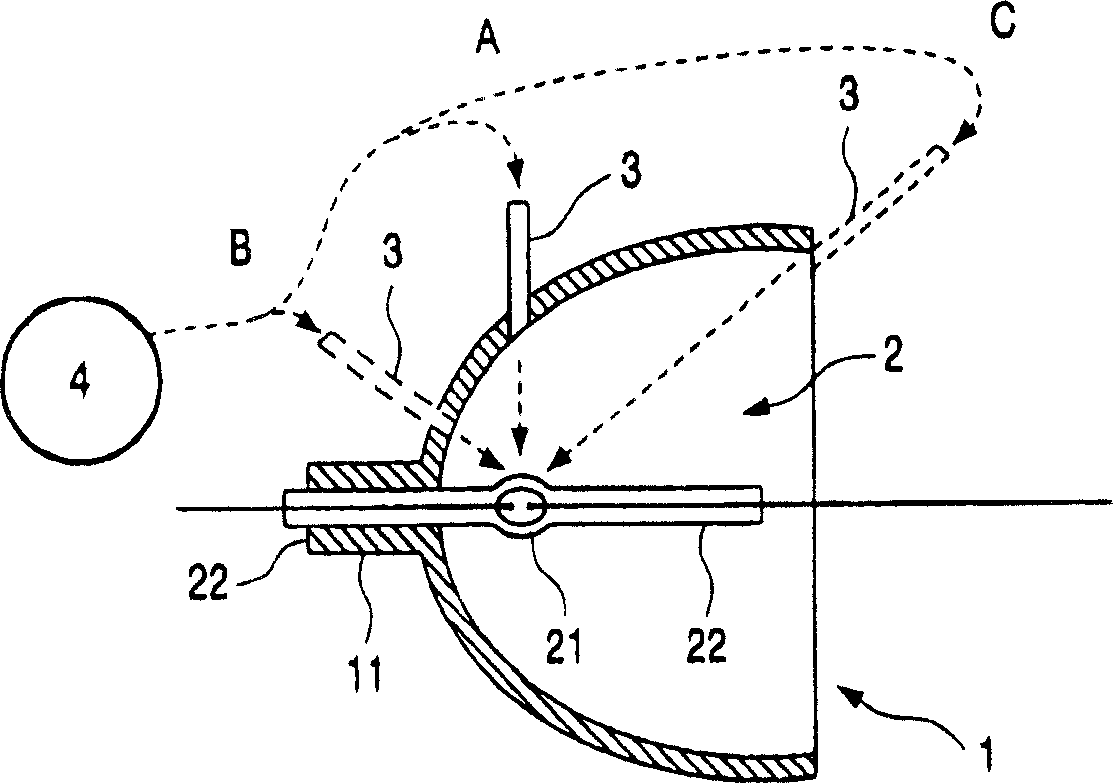

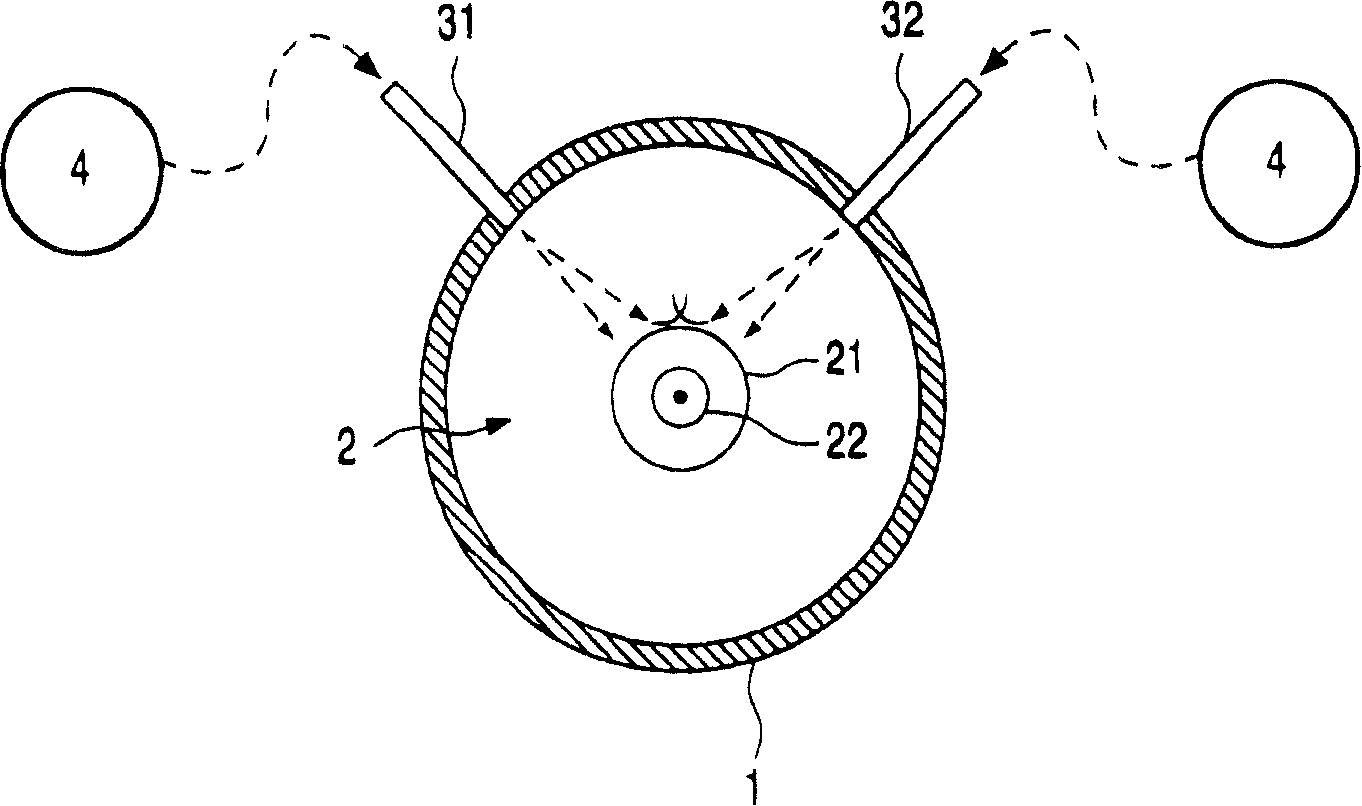

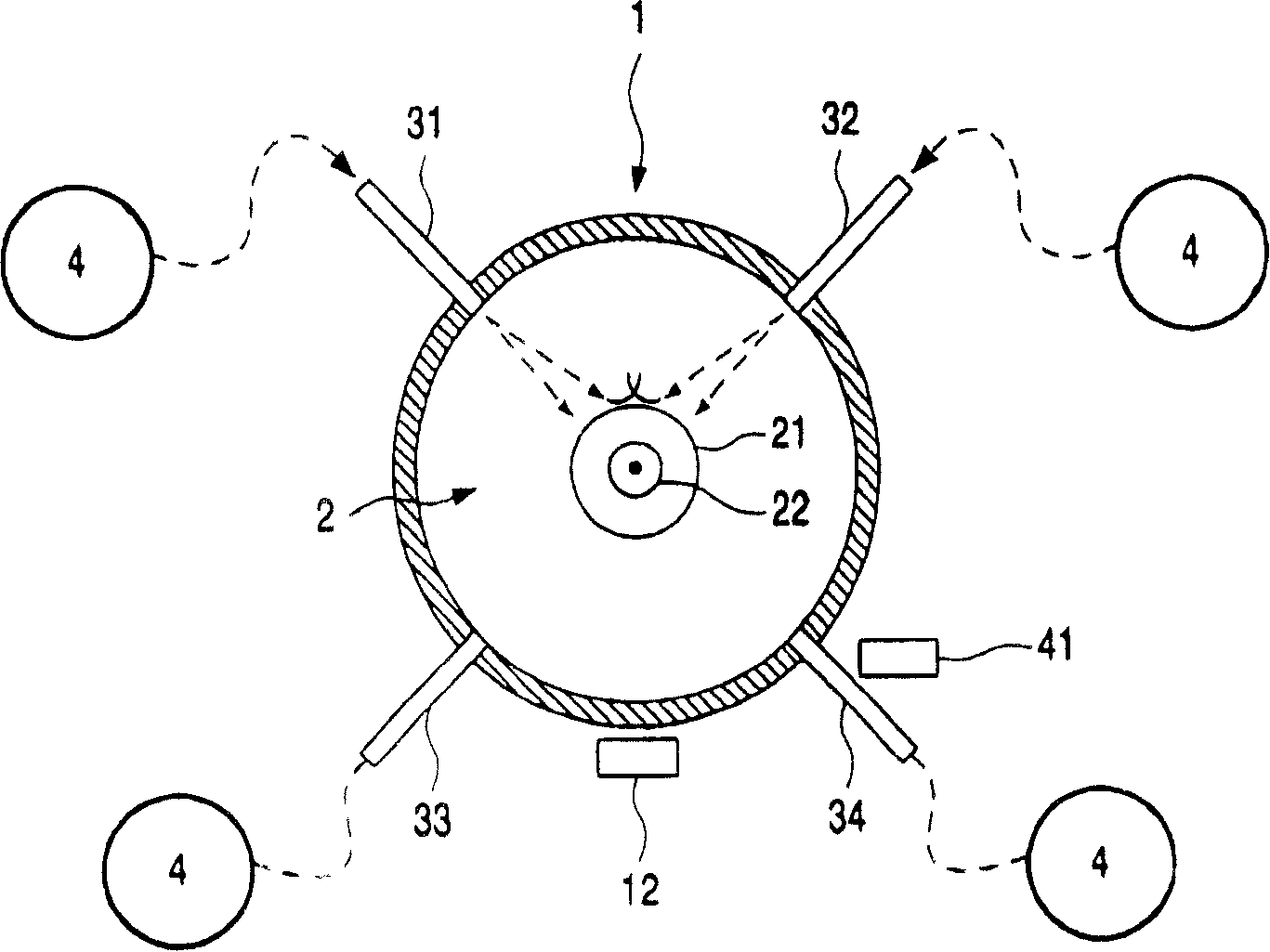

Discharge lamp having cooling means

InactiveCN1669115AImprove efficiencyNot adversely affected by shieldingLighting heating/cooling arrangementsHigh-pressure discharge lampsEngineeringHigh intensity

A discharge lamp, and particularly a high-pressure gas-discharge lamp (an HID (high-intensity discharge) lamp or UHP (ultra-high performance) lamp), having a reflector and a cooling means is described. The cooling means comprises at least one nozzle ( 3 ) by which a flow of gas can be directed onto the discharge lamp, the at least one nozzle ( 3 ) being so arranged that it does not extend, at least to any substantial degree, into a beam path produced by the lamp ( 2 ) and the reflector ( 1 ). In this way, the cooling means does not produce any obstacles on the beam path for the light. With preferred embodiments, it is possible to produce a turbulent flow that surrounds particularly the discharge vessel ( 21 ) of the lamp and that considerably increases the effectiveness of the cooling means. Further embodiments also allow the discharge lamp to be operated in a plurality of different positions without individual regions of the lamp being too little or too severely cooled.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

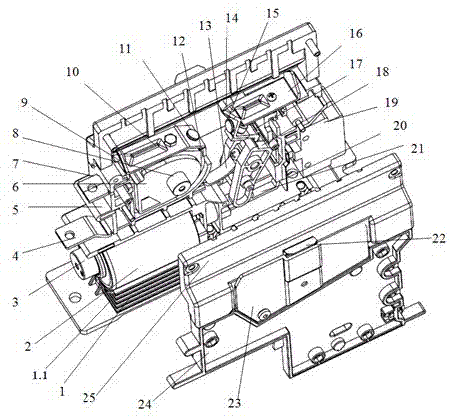

High-voltage direct-current contactor

ActiveCN102436976ACompact spaceImprove cooling effectElectric switchesElectromagnetic relay detailsCapacitanceHigh-voltage direct current

The invention relates to a high-voltage direct-current contactor which is suitable for medium load systems in electrical power, metallurgy, mines, petroleum, traffic transportation and the like, and is especially suitable for a capacitor charging loop on an electric locomotive converter. The high-voltage direct-current contactor comprises an engine part, an electromagnetic drive part, a transmission part, a magnetic blow-out part, an auxiliary contact and an arc extinguish chamber, wherein the engine part is provided with a base, a main frame and a main frame cover plate; the transmission part is provide with a push rod, a reset spring, a rotary rack, a moving main contact and a moving arc contact; the electromagnetic drive part is provided with a cylindrical yoke, a movable iron core and a coil, and a lining is arranged between the cylindrical yoke and the movable iron core; and the magnetic blow-out part is provided with an iron core, a magnetic conducting iron plate, a magnetic blow-out coil, a static arc contact, an upper connecting copper bar and a static main contact. The high-voltage direct-current contactor has the advantages of long electric service life, high breaking speed, strong shock resistance capacity, compact structure, small volume, good tightness and the like, and is convenient in assembly and maintenance.

Owner:武汉长海电气科技开发有限公司

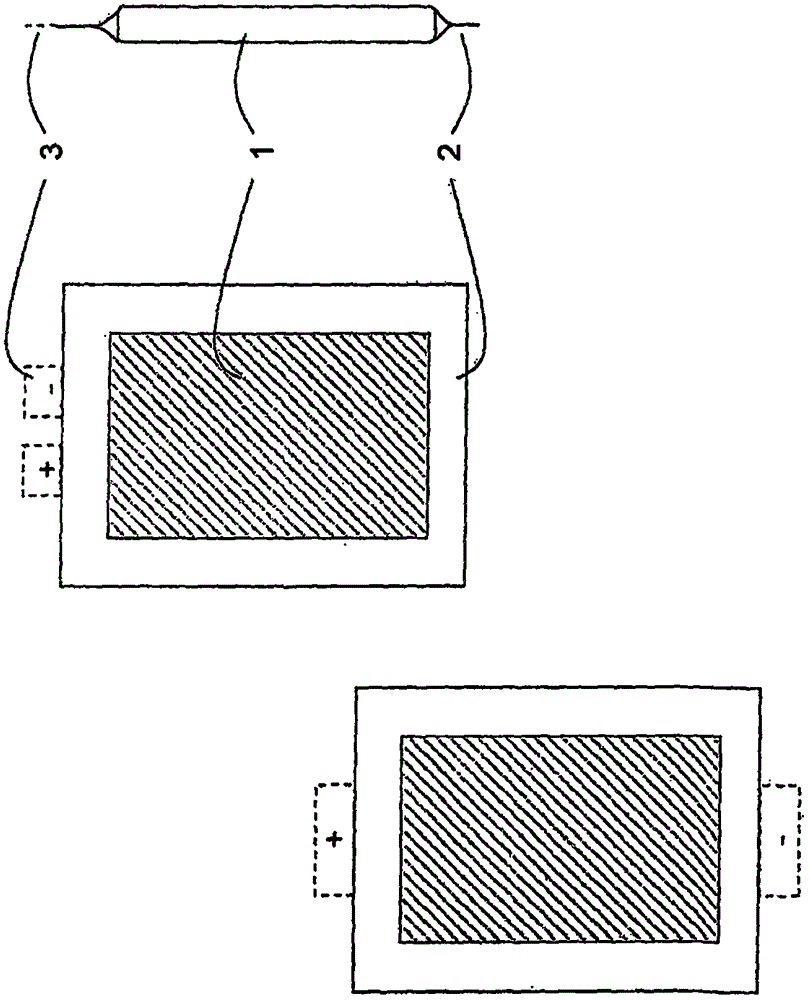

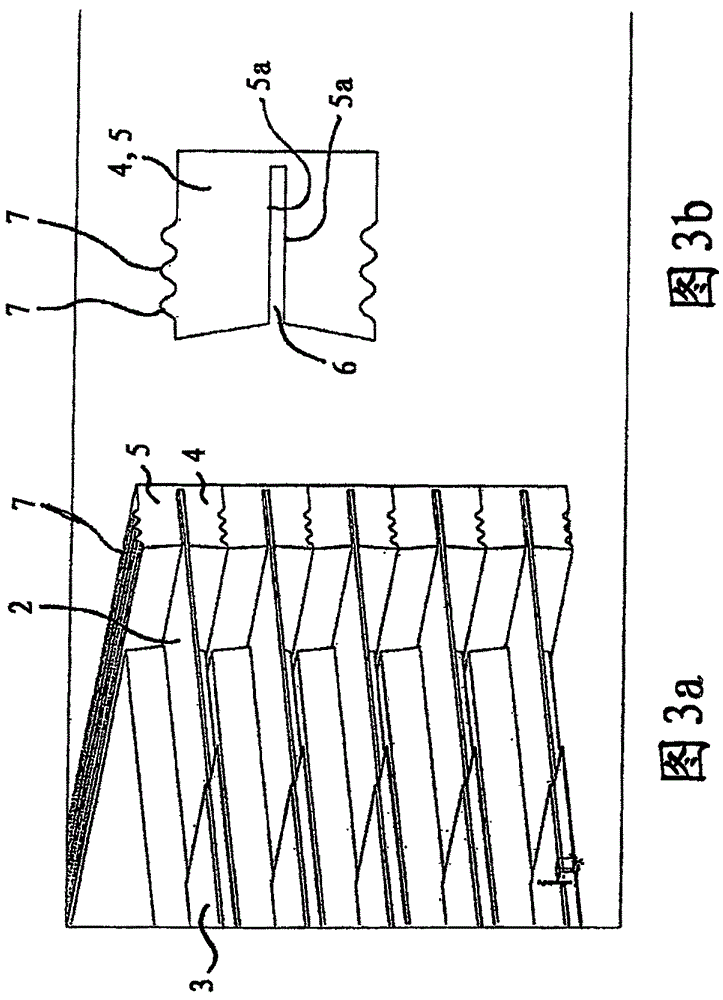

Receiving element for pouch cells

InactiveCN106384795AEasy to processNo penetrationFinal product manufactureBattery isolationEngineeringMechanical engineering

The invention relates to a receiving element (4) for mounting pouch cells, has a base body. The receiving element comprises a base body (5). With respect to an object of receiving the pouch cells securely and cost-effectively in a frame or housing, the receiving element is characterized in that the base body (5) is formed as a profile having a contact surface (5a) for contact against a sealing seam (2) of a pouch cell.

Owner:CARL FREUDENBERG KG

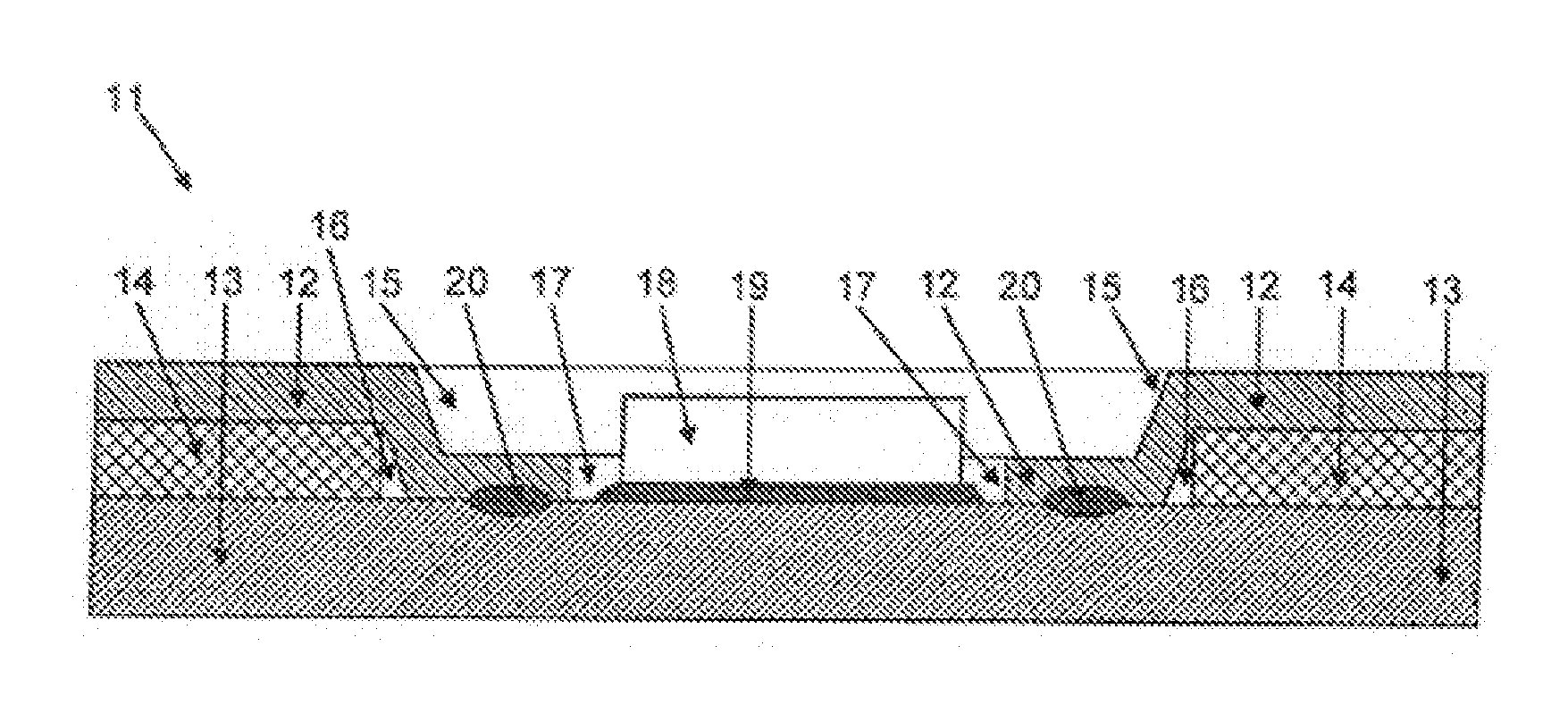

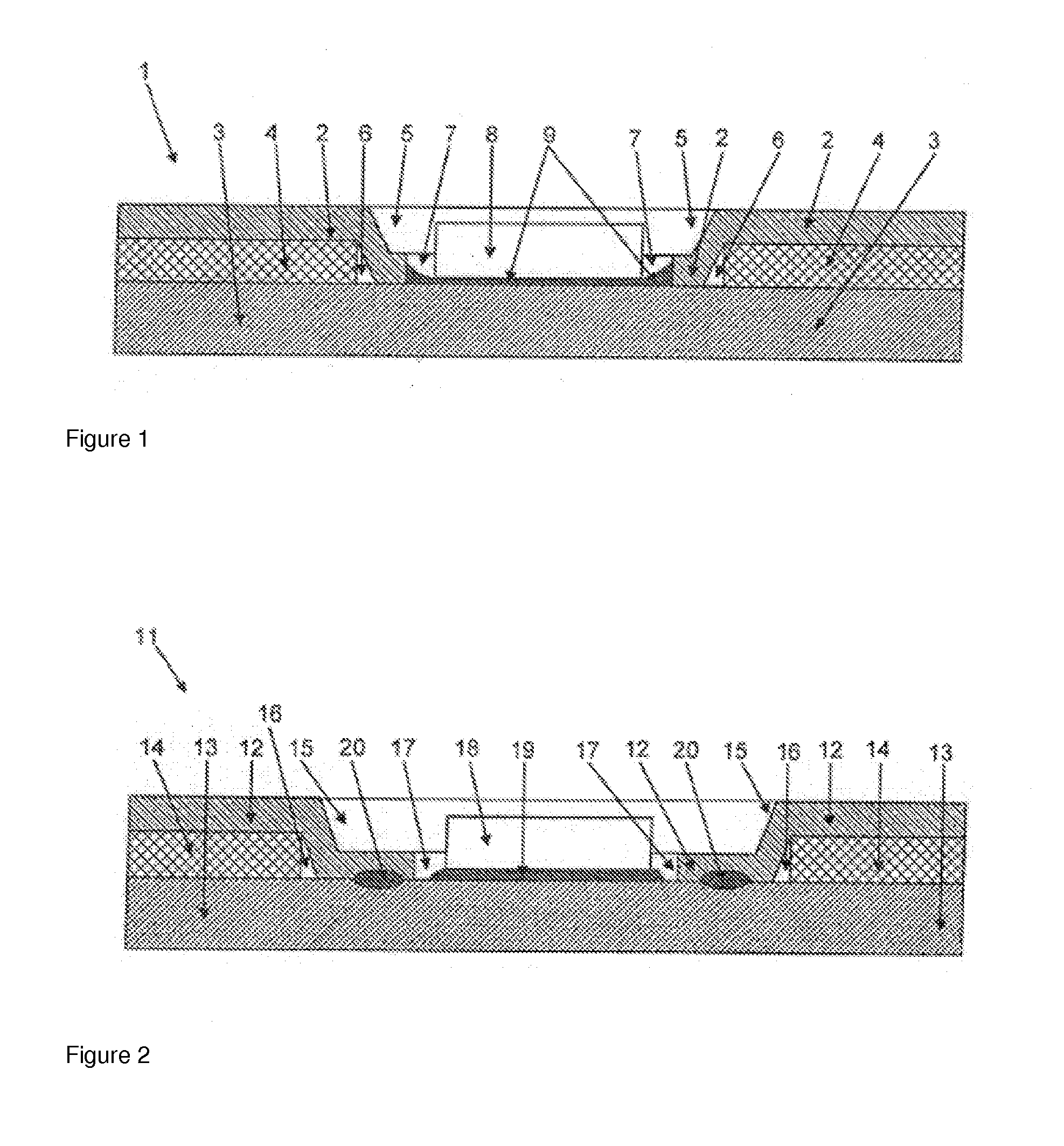

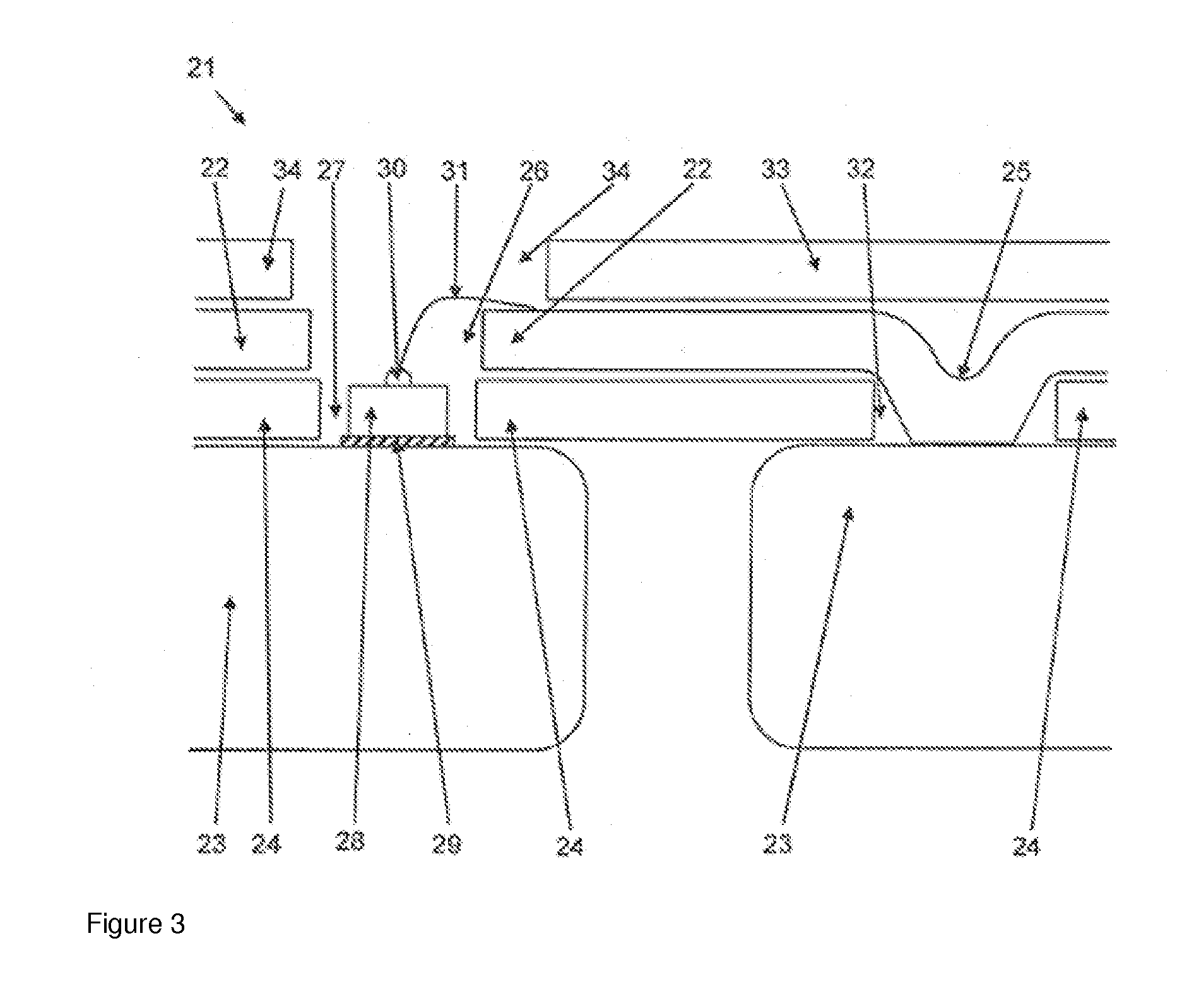

Laminate with integrated electronic component

InactiveUS20130215584A1Low design heightImprove heat dissipationSemiconductor/solid-state device detailsSolid-state devicesMetalContact region

The invention relates to methods for producing a laminate for contacting an electronic component, in which an insulating layer is arranged between first and second metal layers. The method includes contacting the metal layers to each other in a contact region, generating a recess in the insulating layer, laminating the metal layers to the insulating layer, generating a notch for accommodating the electronic component in the contact region in the first metal layer, inserting the electronic component in a depression in the laminate formed through a notch and recess. The electronic component is connected in a conductive manner to the second metal layer, such that an entire circumference of the electronic component is accommodated in the recess and / or notch, and at least part of the height of the electronic component is accommodated in the notch and / or recess. The invention also relates to such a laminate for contacting an electronic component.

Owner:HERAEUS MATERIALS TECH

Discharge lamp having cooling means

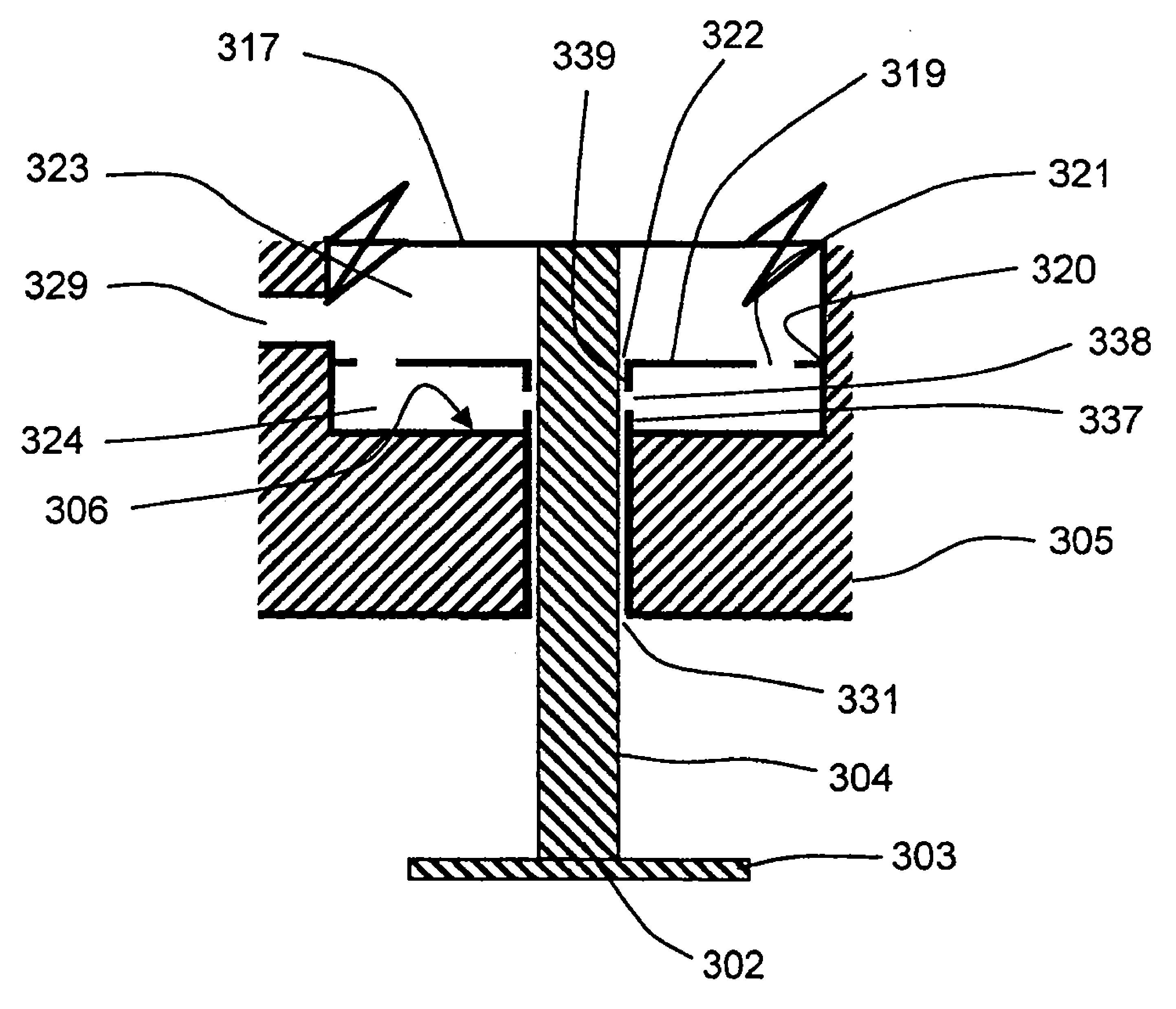

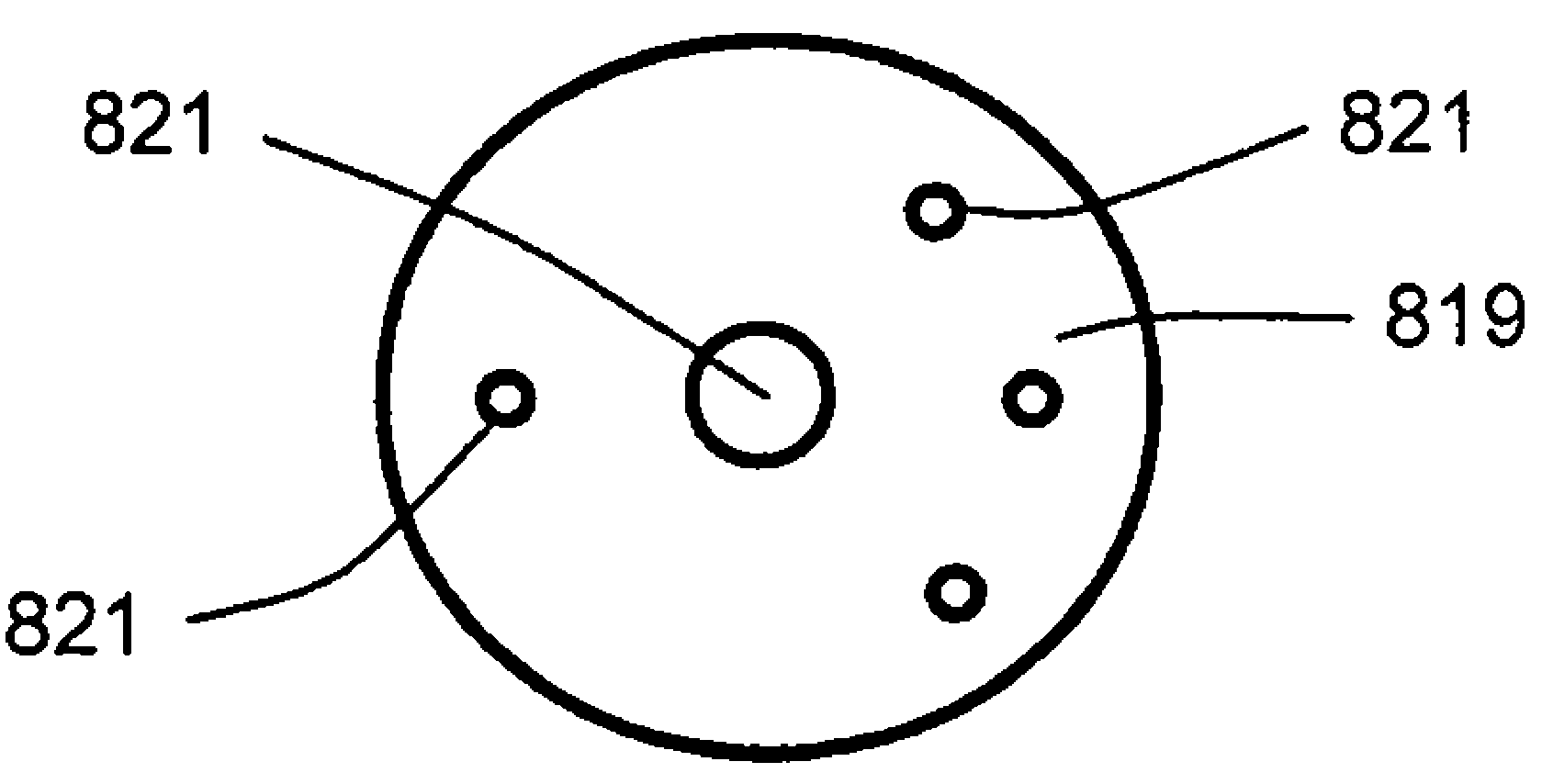

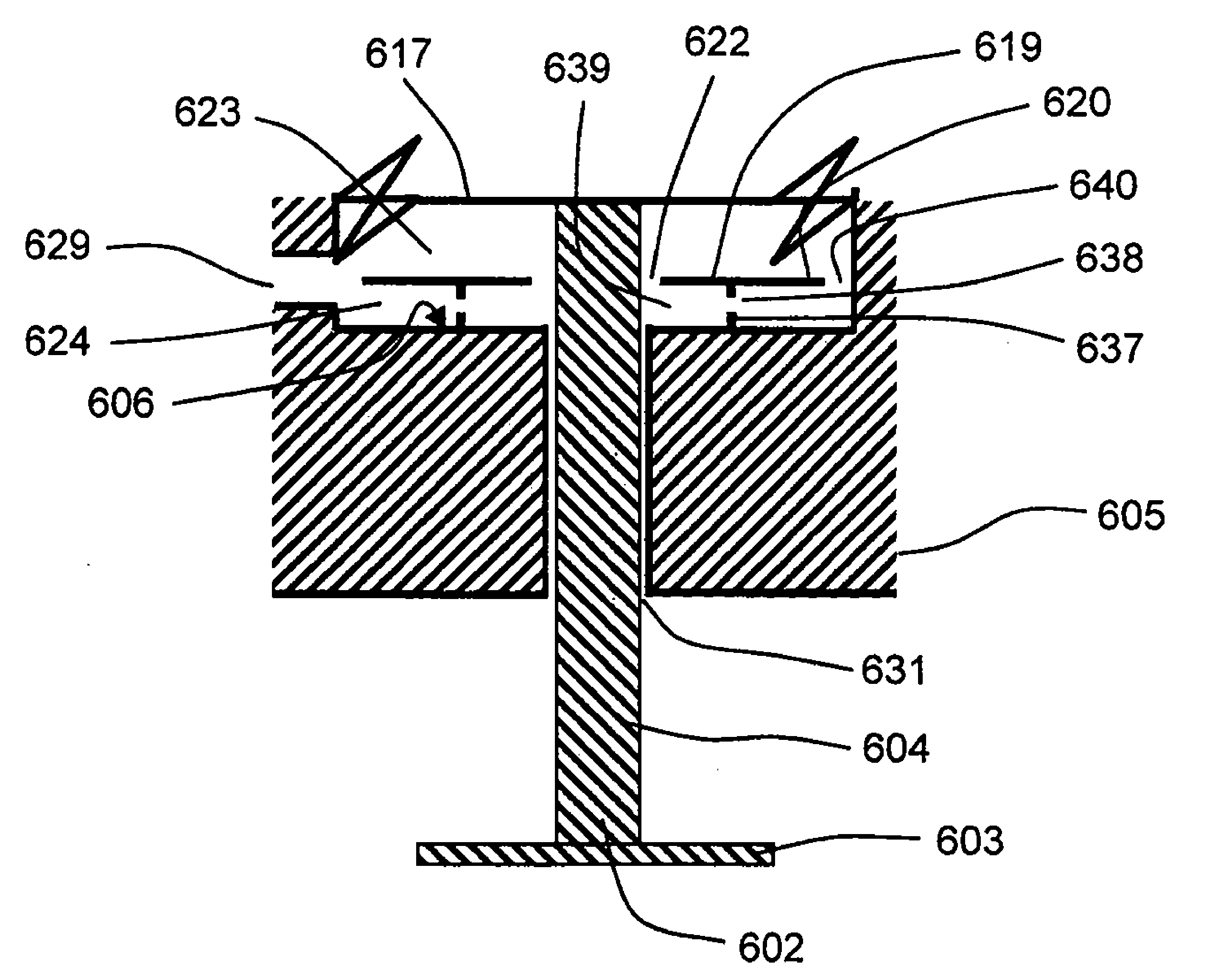

InactiveCN100385607CNot adversely affected by shieldingStrong coolingLighting heating/cooling arrangementsHigh-pressure discharge lampsGas-discharge lampLight beam

A discharge lamp, and particularly a high-pressure gas-discharge lamp (an HID (high-intensity discharge) lamp or UHP (ultra-high performance) lamp), having a reflector and a cooling means is described. The cooling means comprises at least one nozzle ( 3 ) by which a flow of gas can be directed onto the discharge lamp, the at least one nozzle ( 3 ) being so arranged that it does not extend, at least to any substantial degree, into a beam path produced by the lamp ( 2 ) and the reflector ( 1 ). In this way, the cooling means does not produce any obstacles on the beam path for the light. With preferred embodiments, it is possible to produce a turbulent flow that surrounds particularly the discharge vessel ( 21 ) of the lamp and that considerably increases the effectiveness of the cooling means. Further embodiments also allow the discharge lamp to be operated in a plurality of different positions without individual regions of the lamp being too little or too severely cooled.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

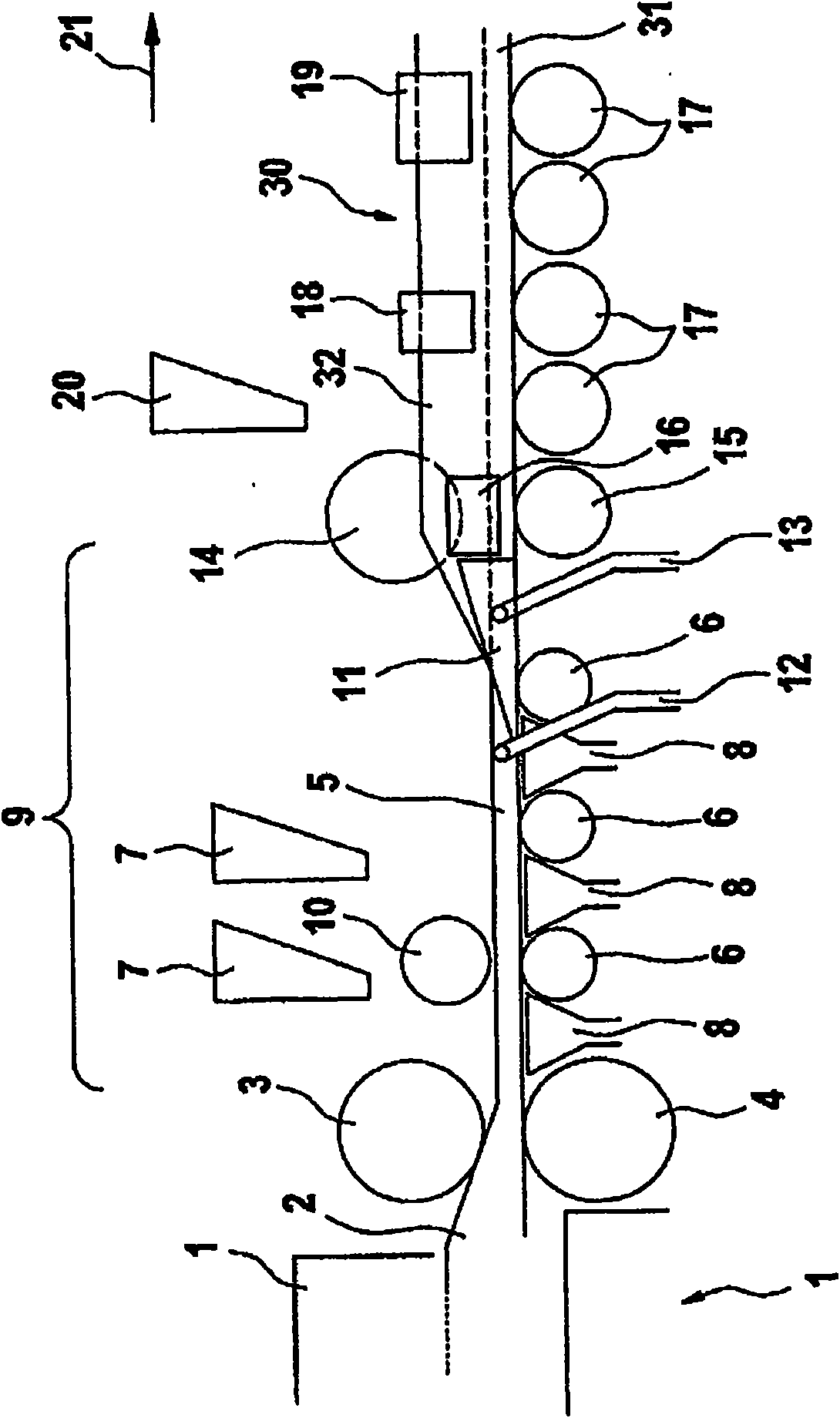

Device and method for melting spinning and cooling multiple monofilament

InactiveCN1844505AAvoid air vortexHomogenization of supply air characteristicsFilament/thread formingMelt spinningSingle filament

Owner:SAURER GMBH & CO KG

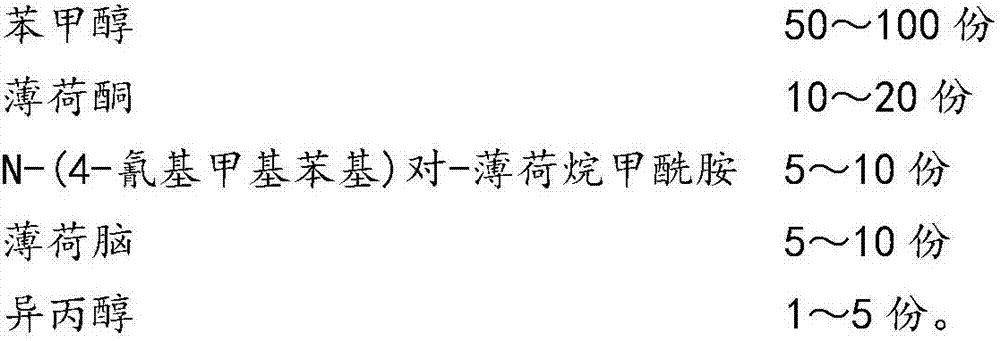

Nonwoven fabric for protective clothing and preparation method of non-woven fabric

PendingCN111749009ABiodegradableBacteriostaticBiochemical fibre treatmentFibre typesCellulosePolymer science

The invention relates to the technical field of non-woven fabrics, and provides a non-woven fabric for protective clothing and a preparation method of the non-woven fabric. The non-woven fabric comprises a non-woven fabric substrate, and the non-woven fabric substrate can be applied to the protective clothing after being treated by microcapsule finishing liquid, wherein the microcapsule finishingliquid is prepared from the following raw material in parts by weight: 35 to 60 parts of microcapsule emulsion, 6 to 12 parts of cross-linking agent, 2 to 4 parts of carboxymethyl cellulose and 1.5 to2.5 parts of fatty alcohol-polyoxyethylene ether; the microcapsule emulsion is prepared by taking chitosan and sodium alginate as wall materials and xylitol, N-ethyl-L-menthyl formamide and ammoniumnitrate as core materials by using a complex coacervation method, and the non-woven fabric substrate treated by the microcapsule finishing liquid solves the problems that in the prior art, the medicalprotective clothing non-woven fabric is single in function, a cool feeling cannot be generated, and stuffiness and discomfort are easily caused when a large amount of sweat is sweated.

Owner:FUJIAN HENGAN HLDG CO LTD +2

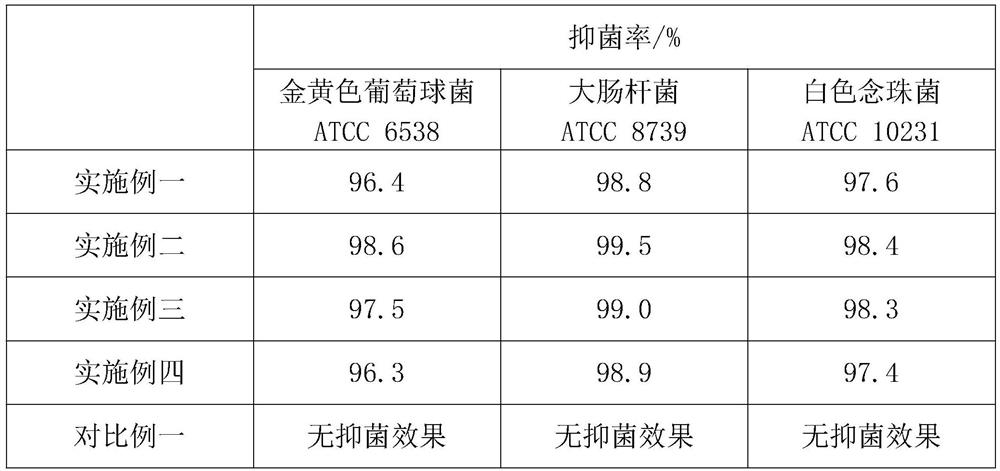

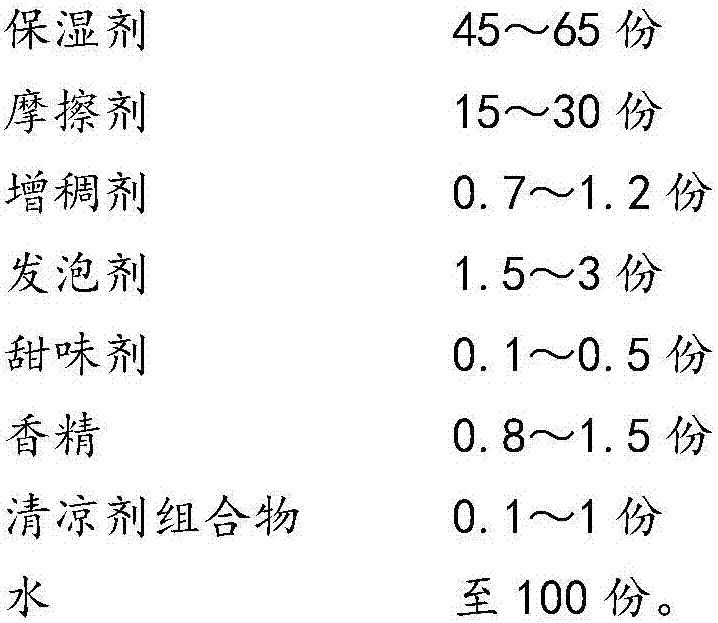

Freshener composition and application thereof

ActiveCN107028779AStrong coolingDoes not affect the cooling effectCosmetic preparationsToilet preparationsFormamidesBitter taste

The invention discloses a freshener composition and application thereof. The freshener composition is prepared from, by weight, 40-60 parts of L-menthol, 5-20 parts of N,2,3-trimethyl-2-isopropyl butamide, 5-20 parts of N-ethyl-L-menthyl formamide and 20-40 parts of cool oil. By the adoption of the freshener composition, people can feel a strong cool feeling at the beginning of tooth brushing while no obvious bitter taste is generated, and freshness and coolness can be maintained for a long time in the oral cavity after tooth brushing.

Owner:广州舒客实业有限公司

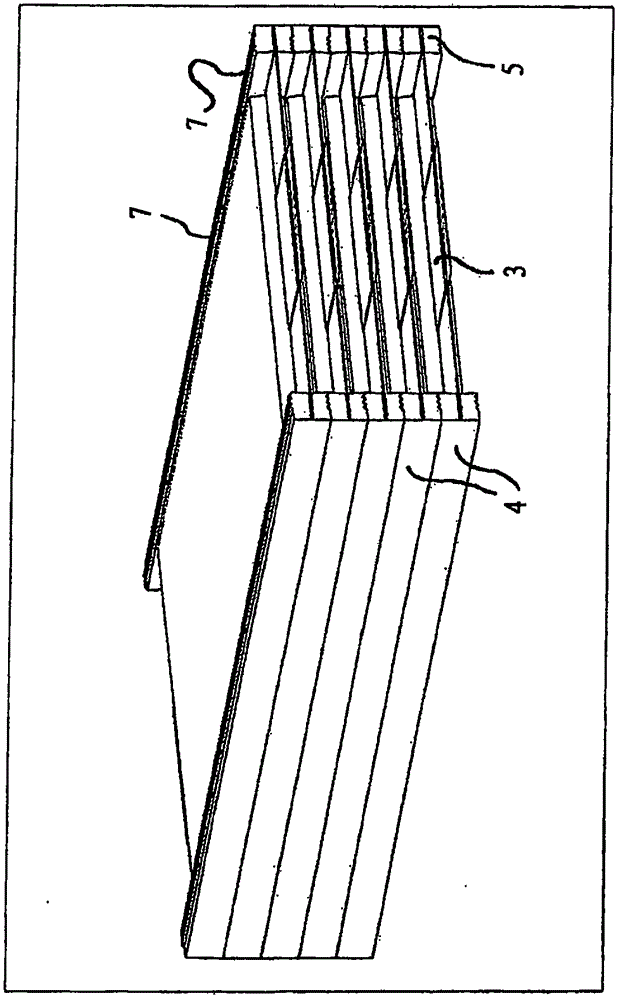

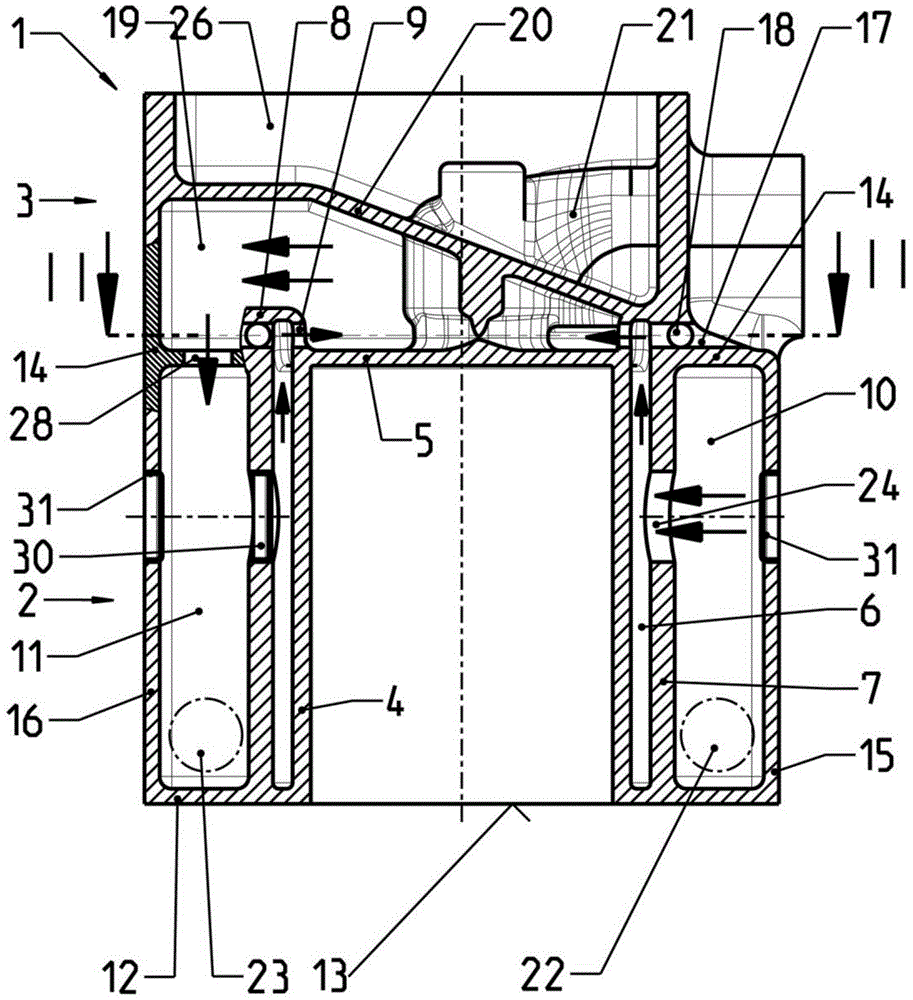

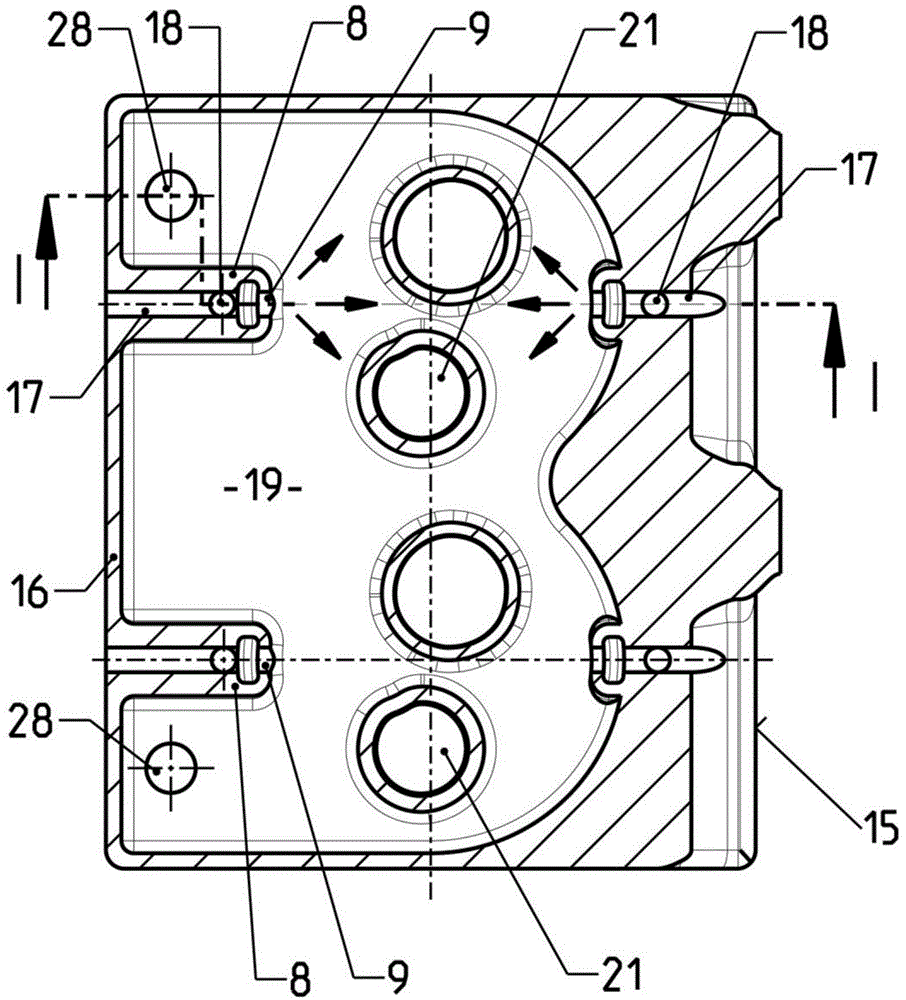

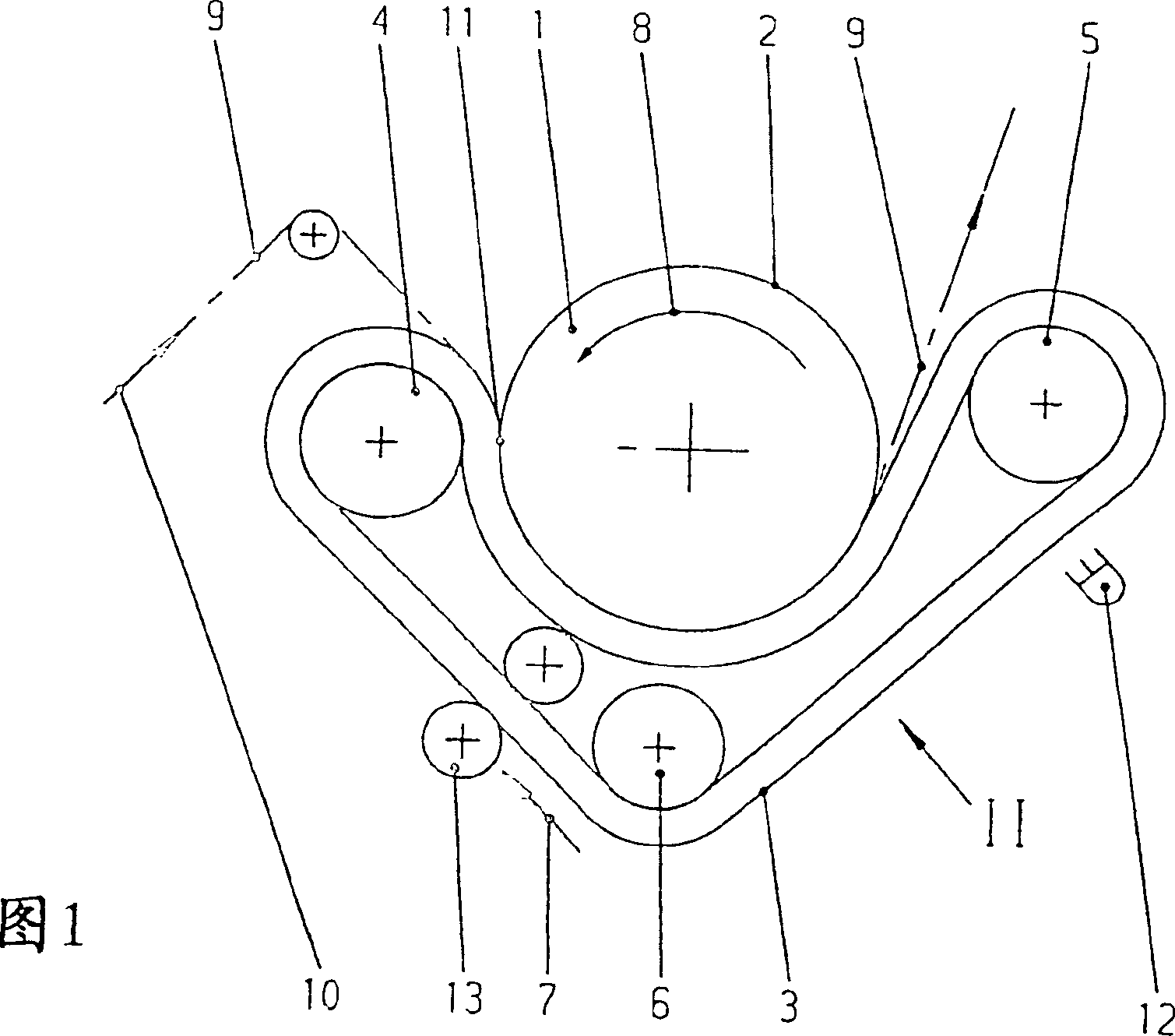

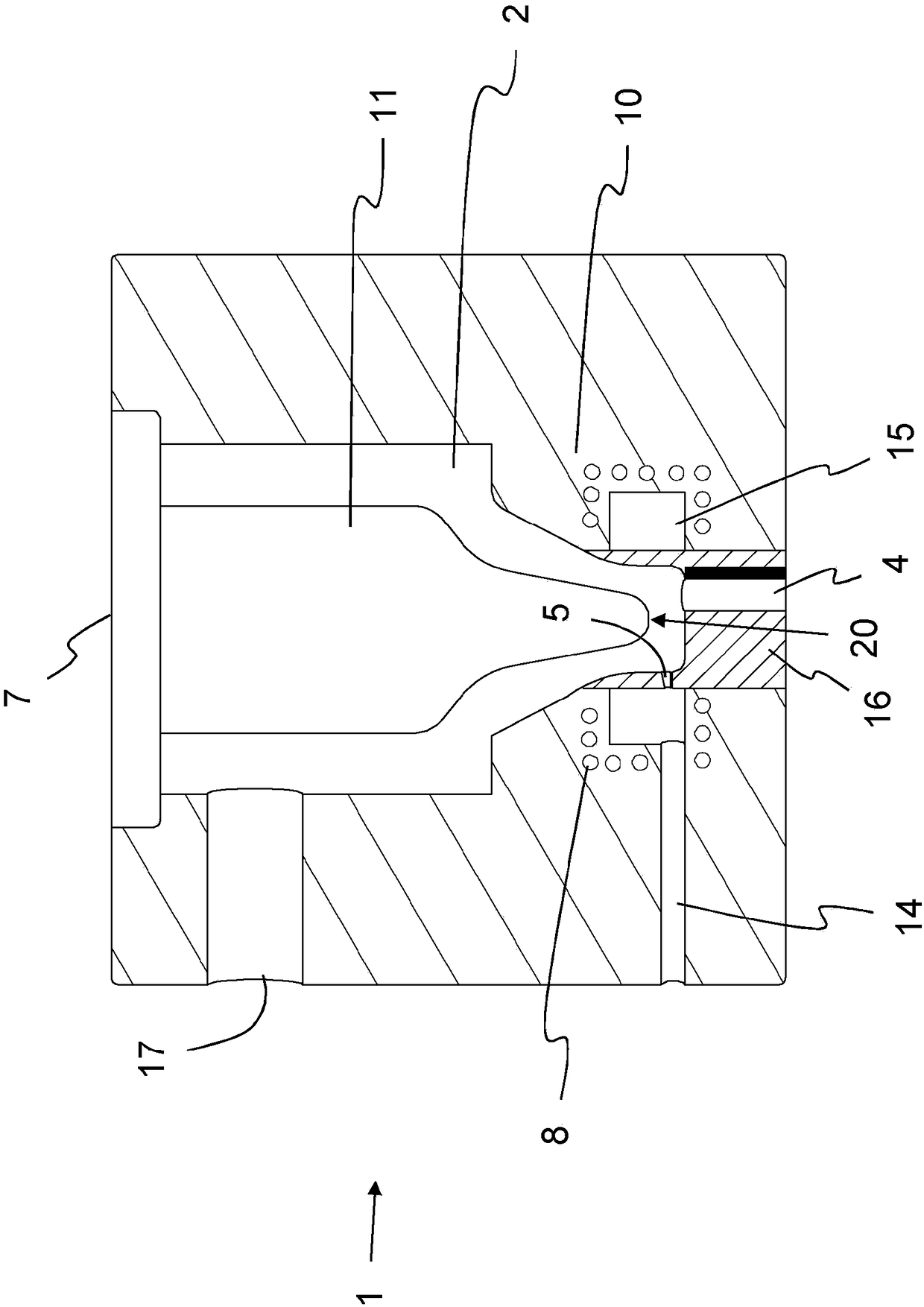

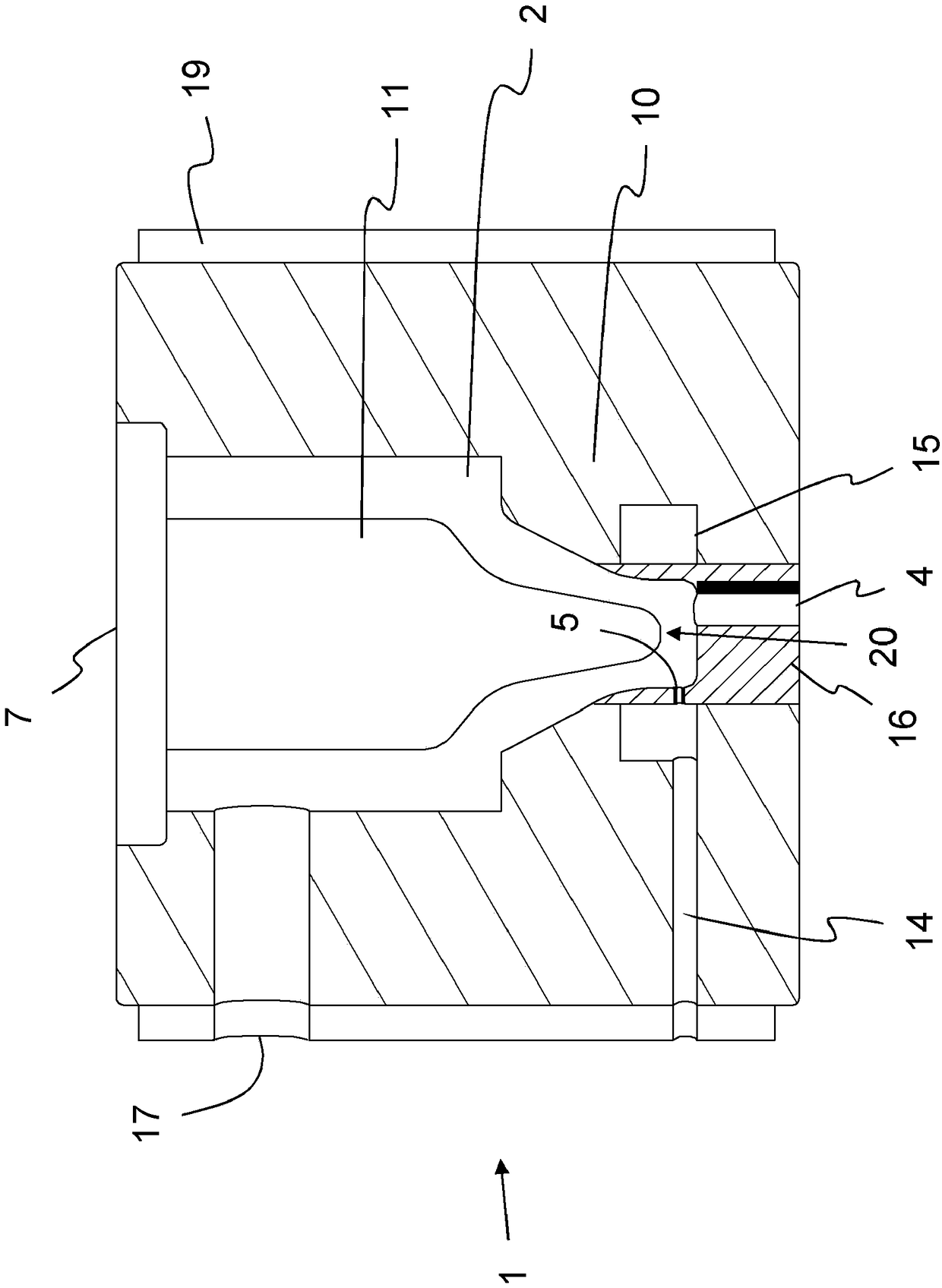

An integral cylinder body of liquid-cooled type internal combustion engine and a mould for manufacturing thereof

InactiveCN104696092ASpeed up the flowLarge flow cross sectionCylinder headsFoundry mouldsEngineeringInternal combustion engine

The invention relates to a liquid-cooled type air cylinder body (1) comprising a plurality of air cylinders encloses by a common cooling casing pipe (7). A first cooling water cavity (6) is arranged in the air cylinder body (1) in a position between the cooling casing pipe (7) and a plurality of circulating air cylinders. A second cooling water cavity (19) communicated with the first cooling water cavity (6) is arranged above the air cylinders (4, 5). To realize complete and uniform cooling of the air cylinders (4), a flow allocation pipe (10) and a flow concentration pipe (11) are installed on a longitudinal surface of the cooling casing pipe (7). The cooling casing pipe (7) separating the flow allocation pipe (10) and the first cooling water cavity (6) is provided with first through holes (24) associated with the air cylinders (4, 5). The flow concentration pipe (11) is communicated with the second cooling water cavity (19) above the flow concentration pipe (11) through a line of second through holes (28).

Owner:STEYR MOTORS GMBH

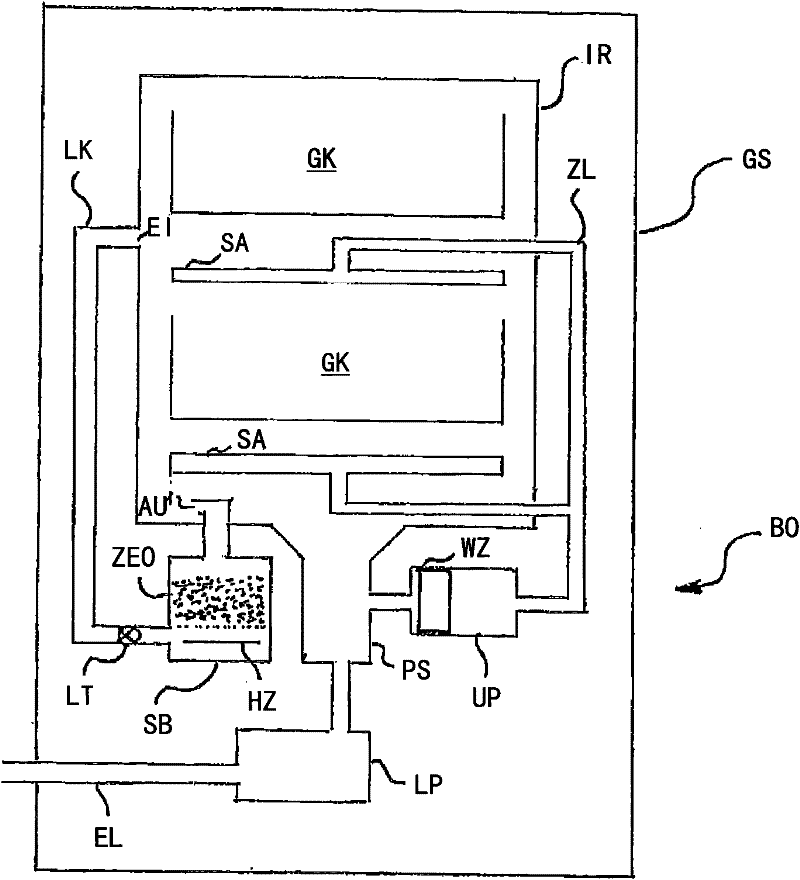

Method for operating dishwasher

InactiveCN102131442AReduce demandSpace will not increaseTableware washing/rinsing machine detailsWashing processesEngineeringMechanical engineering

The invention relates to a method for operating a dishwasher (GS), in particular, a domestic dishwasher, wherein at least articles to be washed, supported in an inner chamber (IR), is at least temporarily treated with heated fluid, wherein in order to heat the fluid air is first passed through a drying material (ZEO) suitable for exothermic drying and then the air together with the heated fluid driven out of the drying material (ZEO) is led through an outlet opening (AU), through which the air with fluid driven out of the drying material (ZEO) enters into the inner chamber (IR). According to the invention, the outlet opening (AU) is cooled.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Heating system

ActiveCN103974623AAvoid temperature fluctuationsUniform and stable releaseBaking ovenHollow article bakingBaked goodsProcess engineering

The invention relates to a heating system (2) for heating carriers for baked goods, in particular baking trays (6), in a housing of an automatic baking machine installation (1). The heating system (2) has a plurality of gas-operated burners which are arranged at a distance from one another. The gas-operated burners are porous burners (3). The heating system (2) has a pivoting device (7) which allows a pivoting movement in any desired direction. The heating system (2) additionally has a running rail apparatus (15) on which the porous burners (3) are mounted such that they can move along a predefinable running direction. The heating system (2) also has at least one controllable drive apparatus with which the porous burners (3) and / or the supporting frame (8) can be moved. The heating system (2) can also have a sensor device for detecting process parameters of the heating system (2) and a control device which is connected to the sensor device such that data can be transmitted.

Owner:HEBENSTREIT

Relief valve

ActiveCN103502602AAvoid heat buildupStrong coolingInternal combustion piston enginesFluid-pressure actuatorsTurbochargerEngineering

Owner:ROLLS ROYCE SOLUTIONS GMBH

Momordica grosvenori mint tea and preparation method thereof

InactiveCN104186868AThroat dryness improvedImprovement of constipation and other conditionsTea substituesChinese-oliveMentha spicata

The invention discloses a momordica grosvenori mint tea and a preparation method thereof. The momordica grosvenori mint tea is characterized by being prepared from the raw materials in parts by weight: 1-3 parts of momordica grosvenori, 1-3 parts of Chinese olive, 1-3 parts of scaphium scaphigerum and 1-3 parts of mint. The momordica grosvenori mint tea finished product is obtained by drying, smashing, mixing, bagging and sterilization. Two-gram and three-gram tea bags are prepared according to a personal taste and a health requirement of a user; a cool feeling can be supplied to a drinker in summer, and the situations such as dry throat, dry cough, uncomfortable expectoration, ozostomia and constipation which are caused by sphagitis and hyperactivity of fire due to yin deficiency are also improved.

Owner:HONGYA WAWUSHAN PHARMA

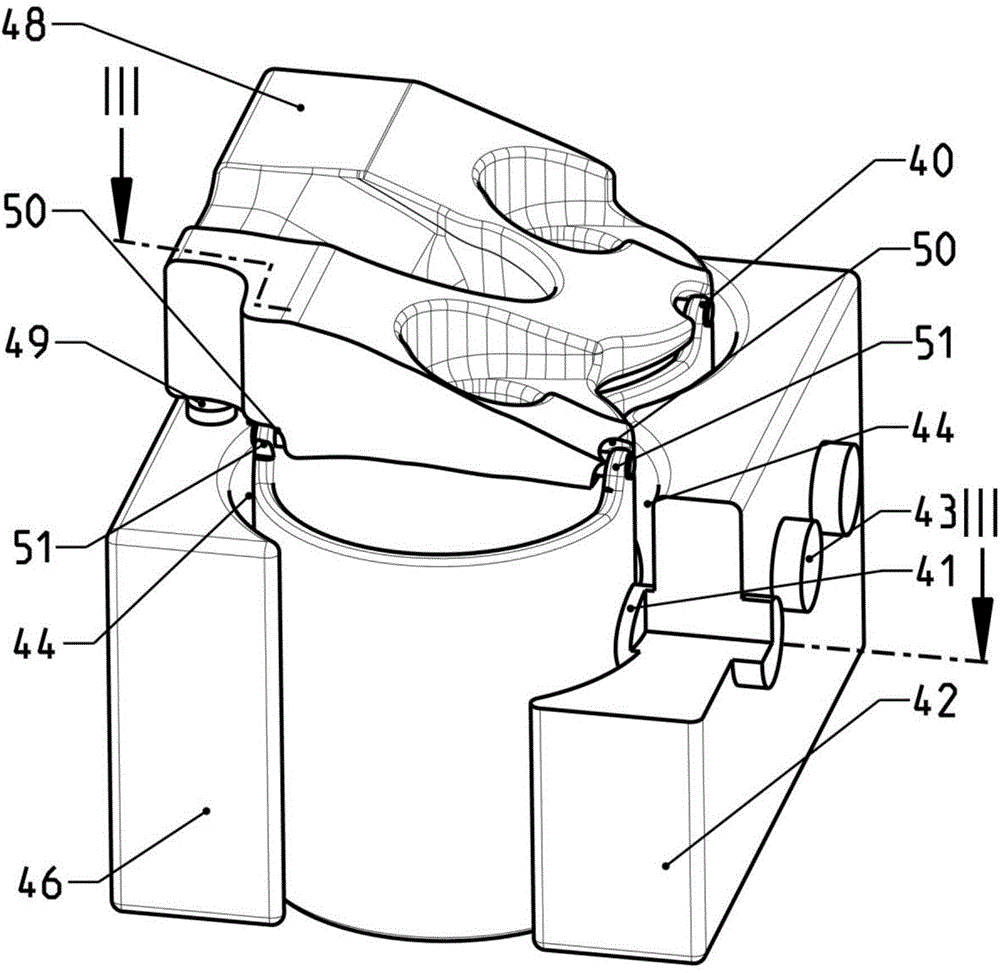

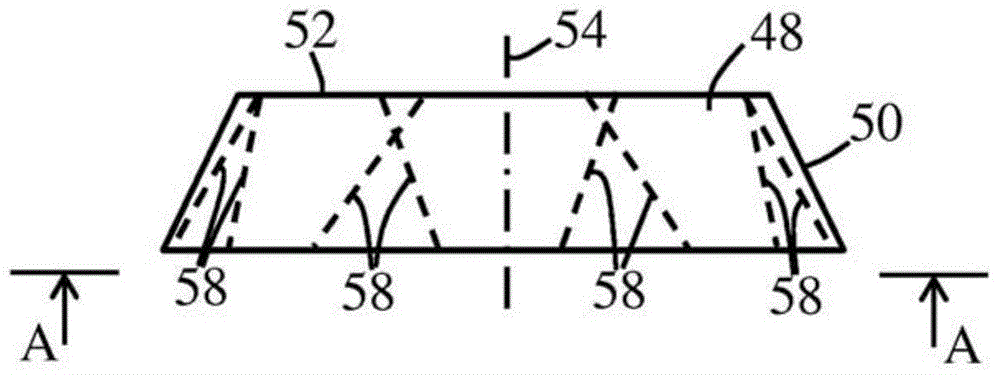

Evaporator burner for a mobile heating device

ActiveCN104040255ASimple structureStrong coolingCapillary burnersVehicle heating/cooling devicesCombustion chamberEvaporator

The invention relates to an evaporator burner (4) for a mobile heating device (2), comprising a combustion chamber (8), an evaporator receptacle (10), and an evaporator element (12) for evaporating liquid fuel. Said evaporator element (12) is received in the evaporator receptacle (10) on the side facing the combustion chamber (8). On the side of the evaporator receptacle (10) facing away from the combustion chamber (8), the evaporator burner (4) has at least one combustion air guide element (16), which is arranged in such a way that a combustion air flow path extending at least along a section of the bottom wall (26) of the evaporator receptacle (10) is formed between the combustion air guide element (16) and a bottom wall (26) of the evaporator receptacle (10).

Owner:WEBASTO AG

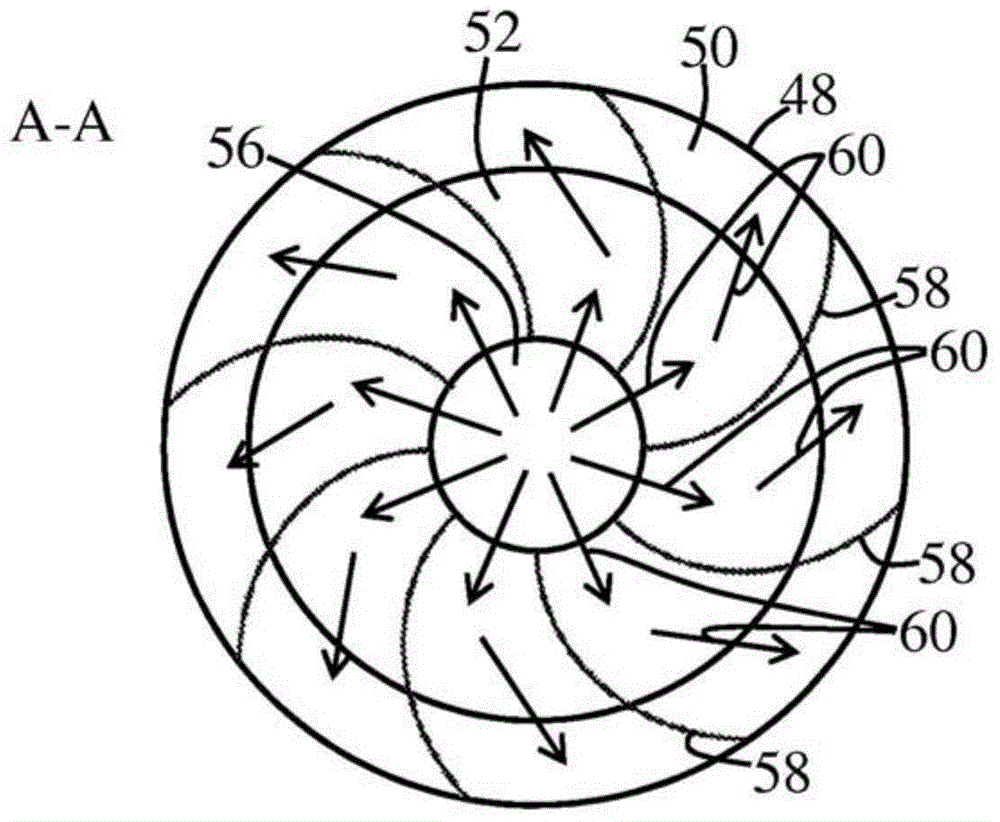

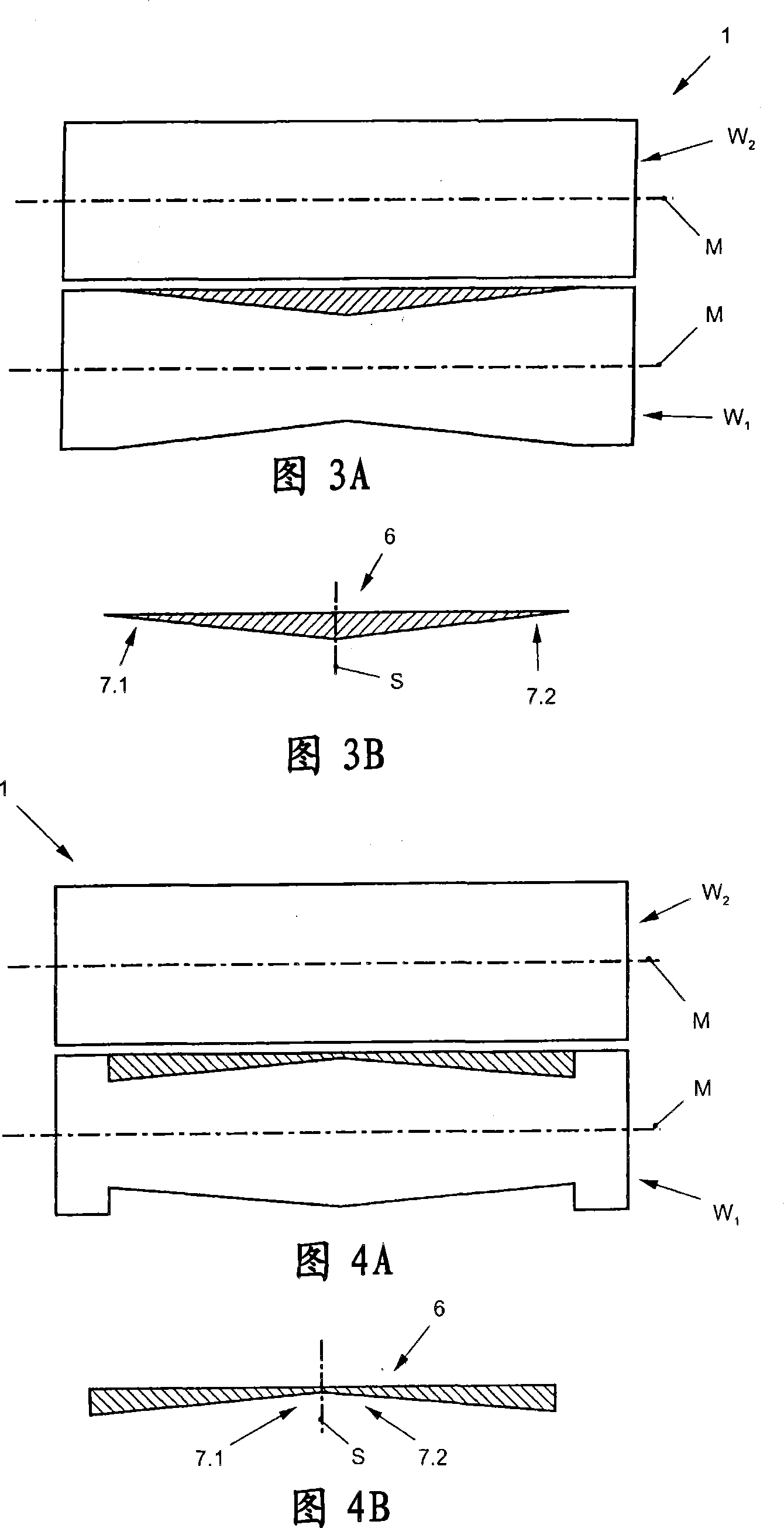

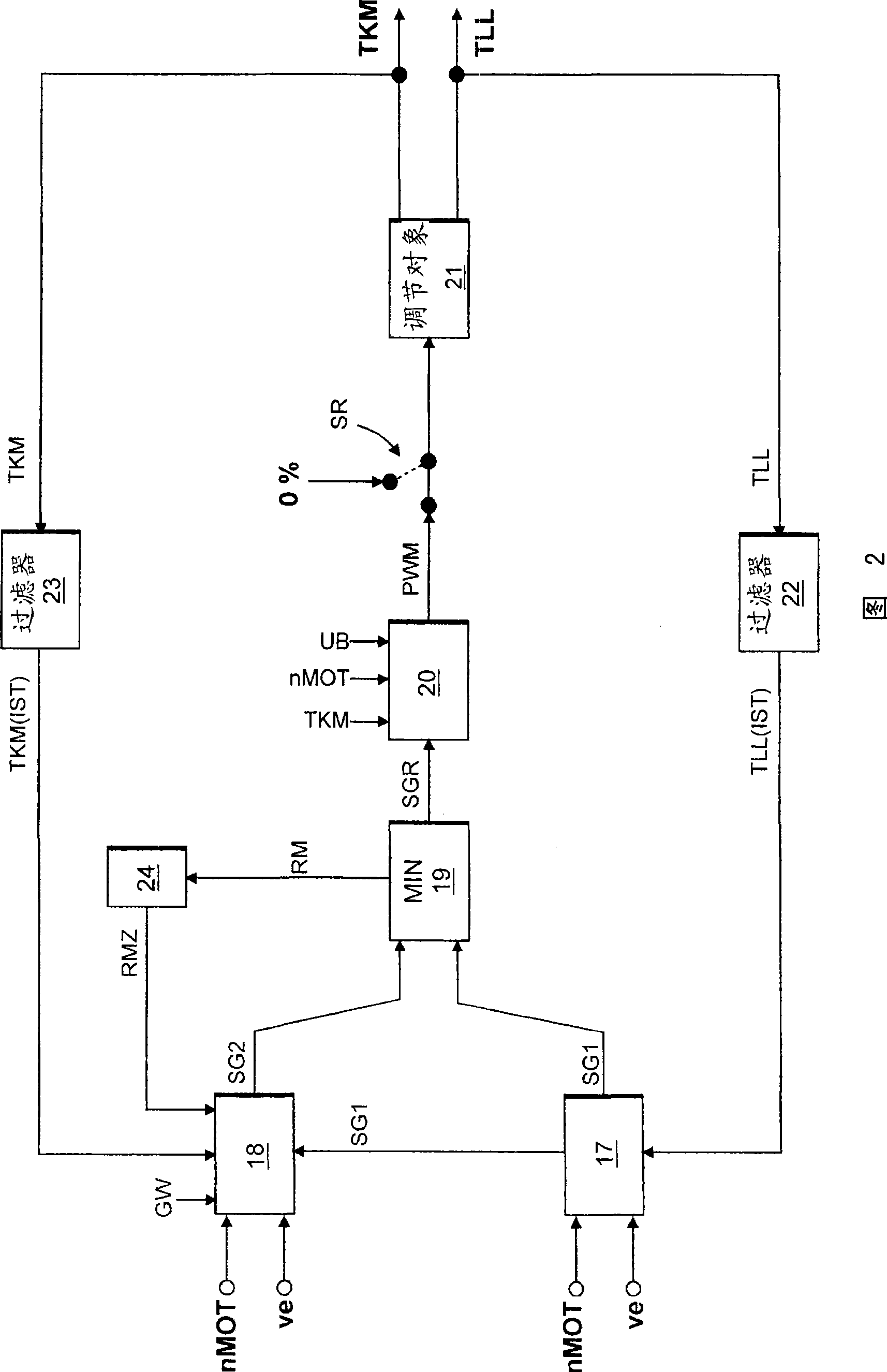

Method and device for the production of plates of thermoplastically extruded synthetic materials

The invention relates to a method and a device for manufacturing sheets which are made of plastic by means of thermoplastic extrusion and are in particular applicable for TFT-display screens. By using the method, sheets can be extruded into tapered shape. The device is provided with an extrusion nozzle and a calendering part connected to the extrusion nozzle. At least one roll of the calendering part is designed in a shape so that tapered sheets can be formed by means of extrusion. The invention aims to manufacture various sheets with high surface quality and degree of homogeneity simply at low cost by using the device, thus the method and the device provided by the invention are more applicable.

Owner:布莱尔机械制造有限公司

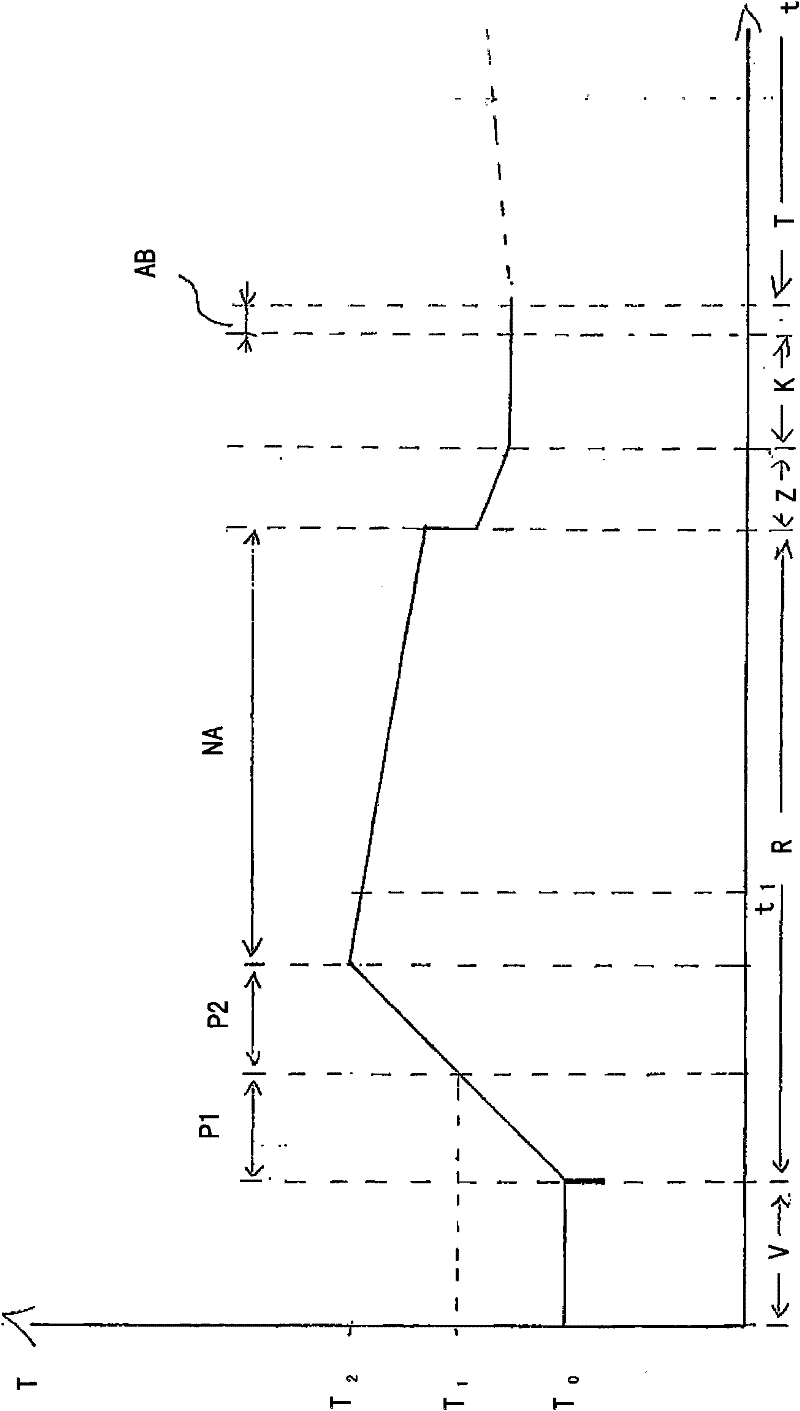

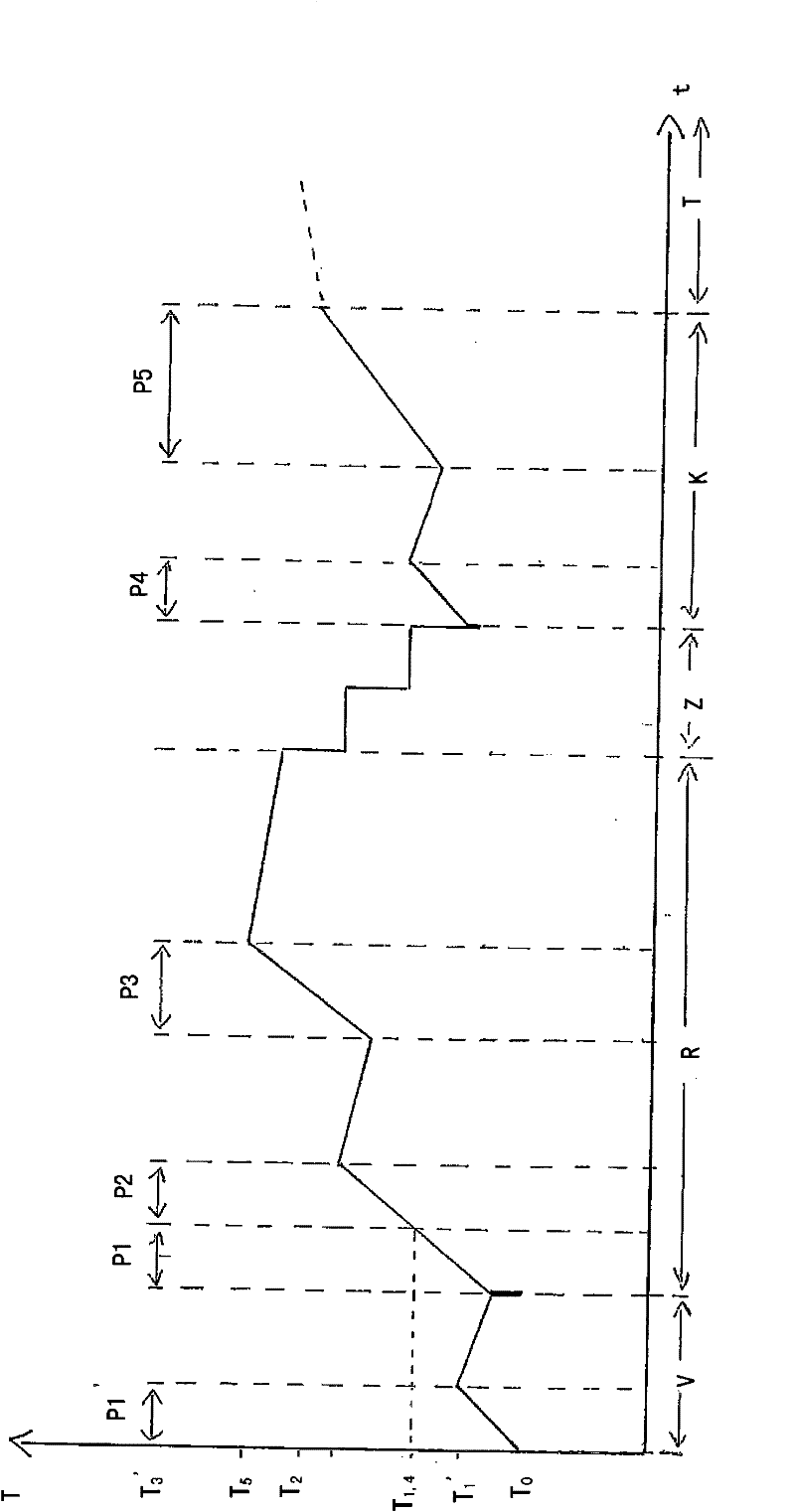

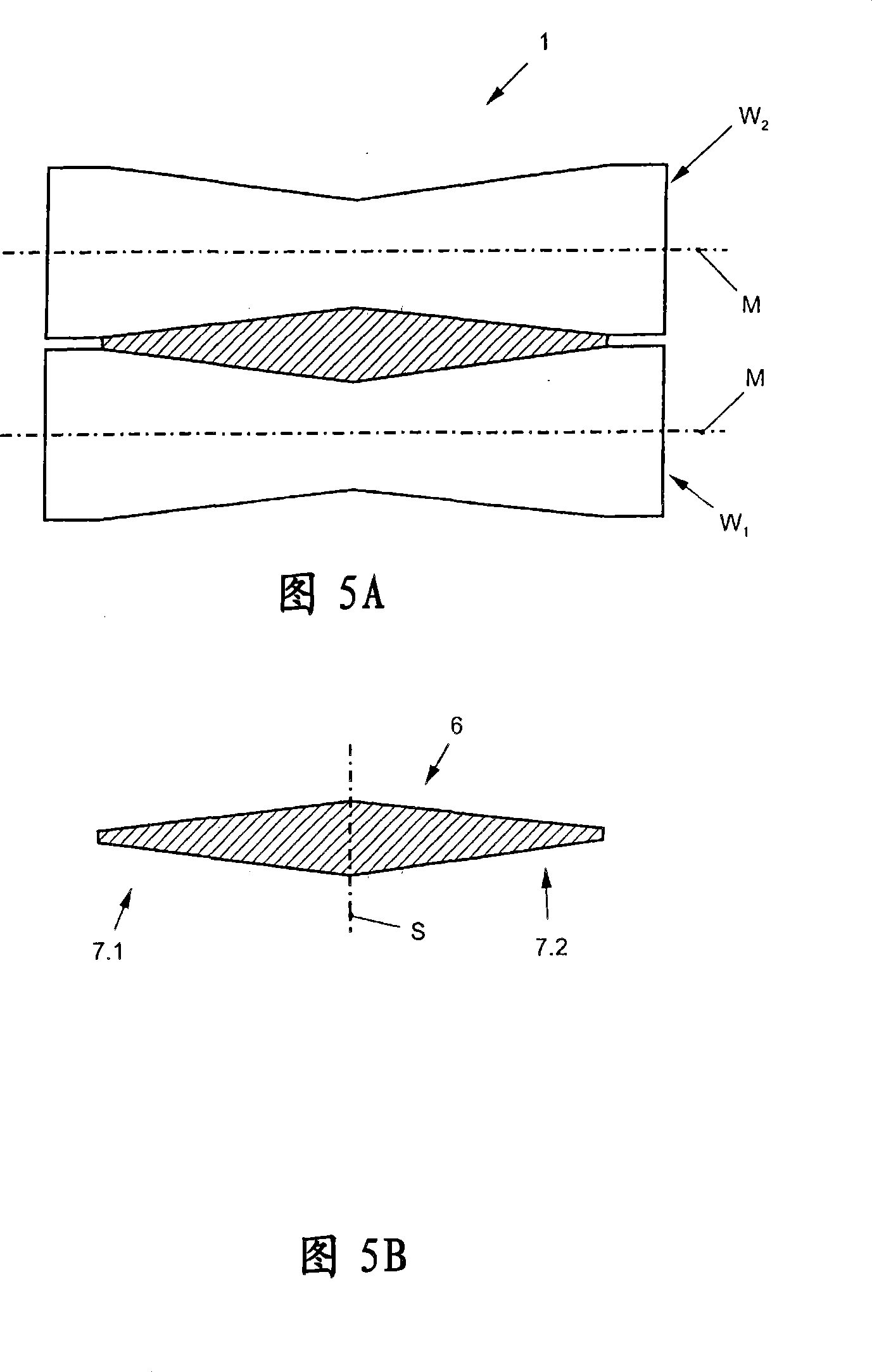

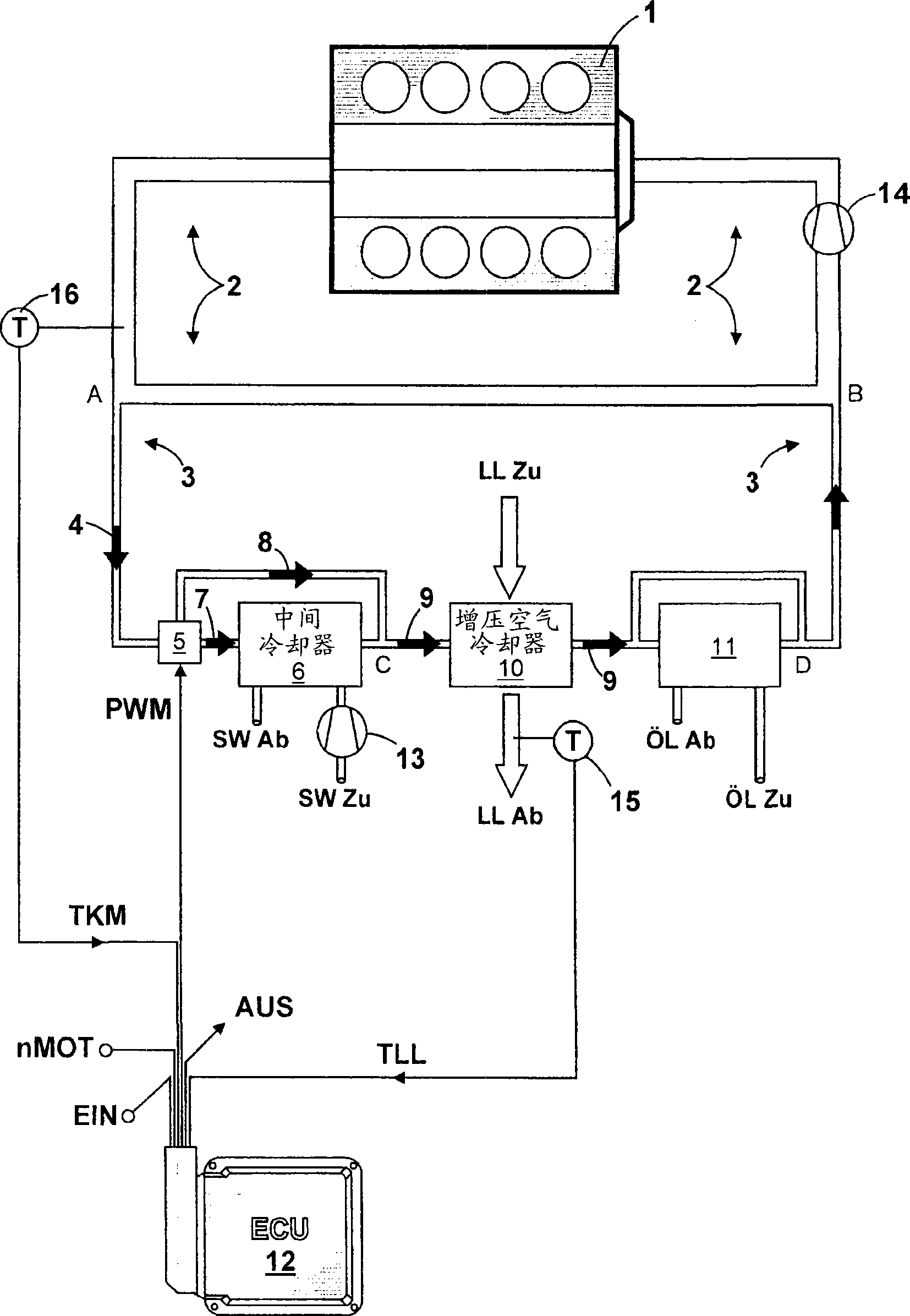

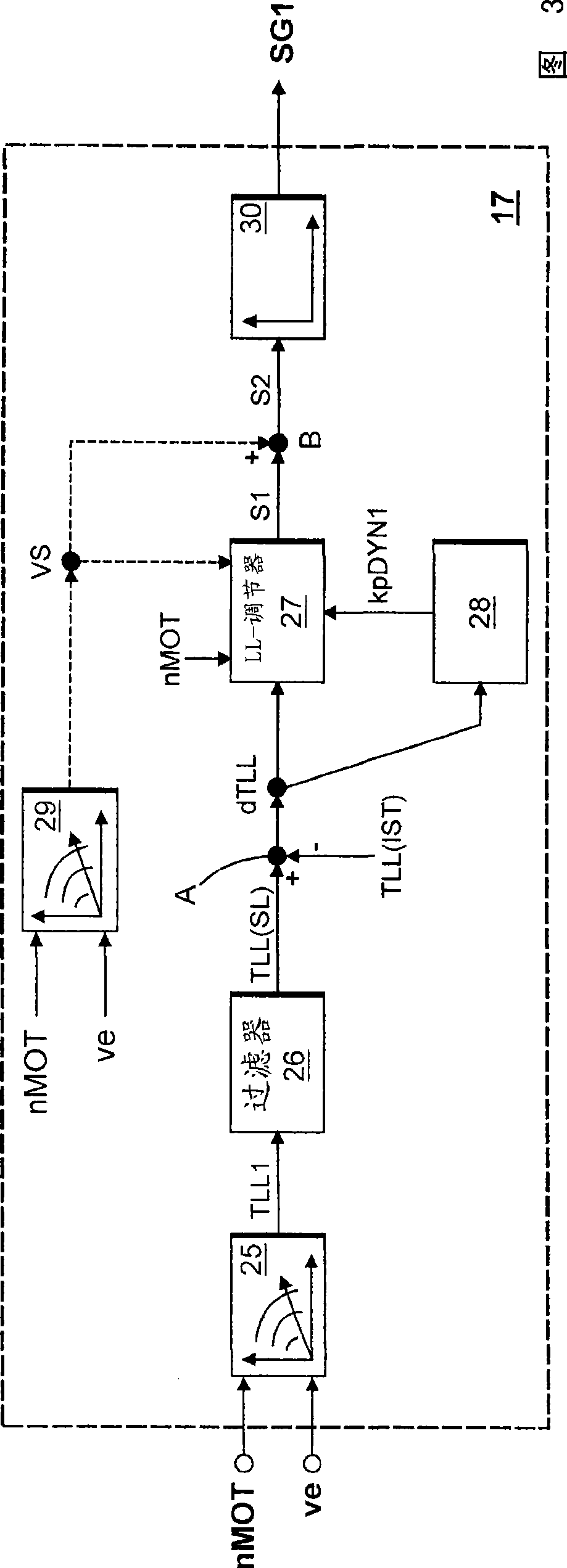

Method for controlling an internal combustion engine

InactiveCN101440743AStrong coolingRegulated stronglyElectrical controlCoolant flow controlCoolant flowCoolant temperature

The invention concerns a method for automatically controlling an internal combustion engine, wherein, in a first controller mode (RM1), a charge air temperature controller 27 is set as dominant for a map-controlled thermostatic valve 5, and, in a second controller mode (RM2), a coolant temperature limit controller 33 is set as dominant for the map-controlled thermostatic valve 5. Upstream of a recooler, a coolant flow 4 is divided into a recooler coolant flow 7 and a bypass coolant flow 8 as a function of the position of the map-controlled thermostatic valve 5. Downstream of the recooler, the temperature 9 of the charge air cooler coolant flow is determined from the combined fractions of the recooler coolant flow 7 and the bypass coolant flow 8 to control the charge air temperature (TLL) or to control the coolant temperature (TKM).

Owner:MTU MOTOREN & TURBINEN UNION FRIEDRICHSHAFEN GMBH

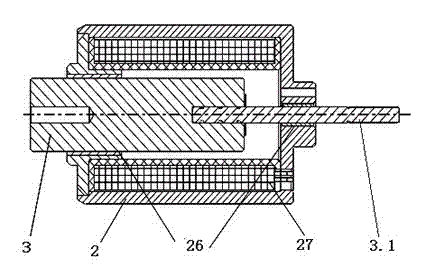

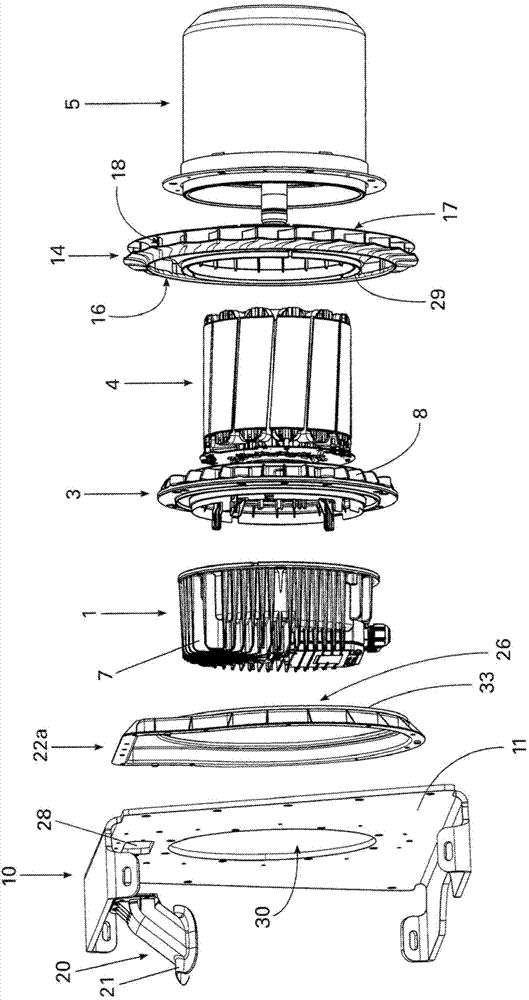

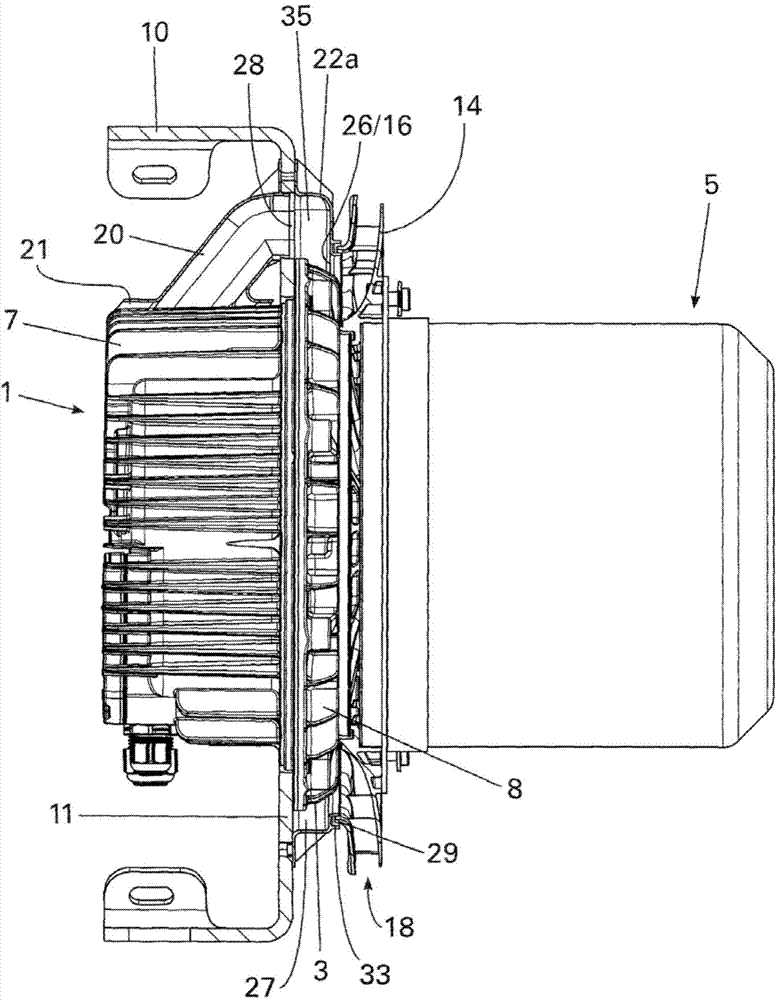

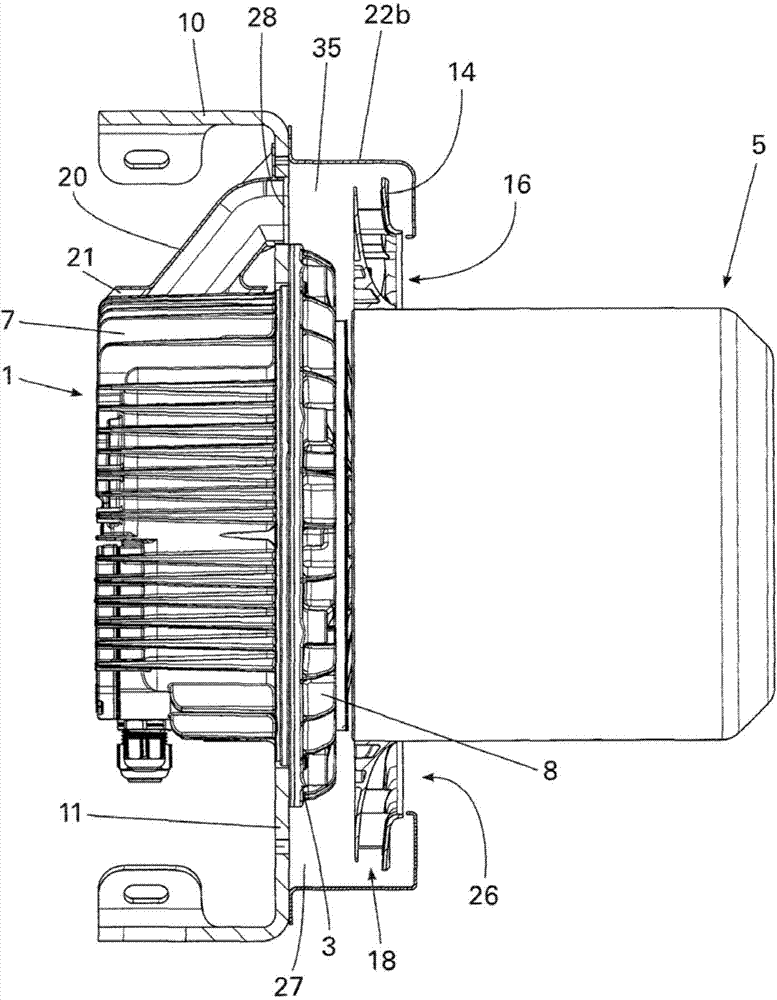

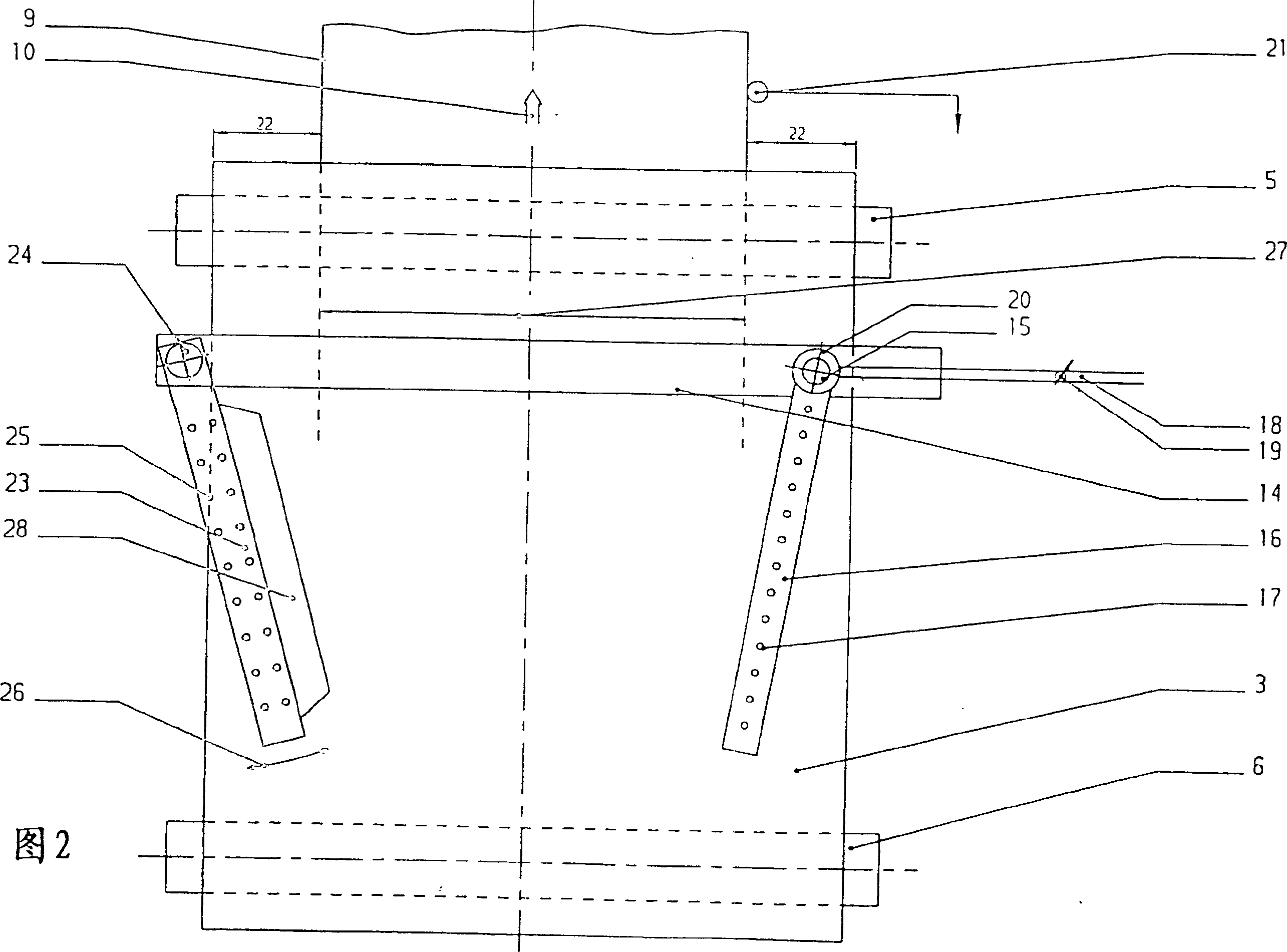

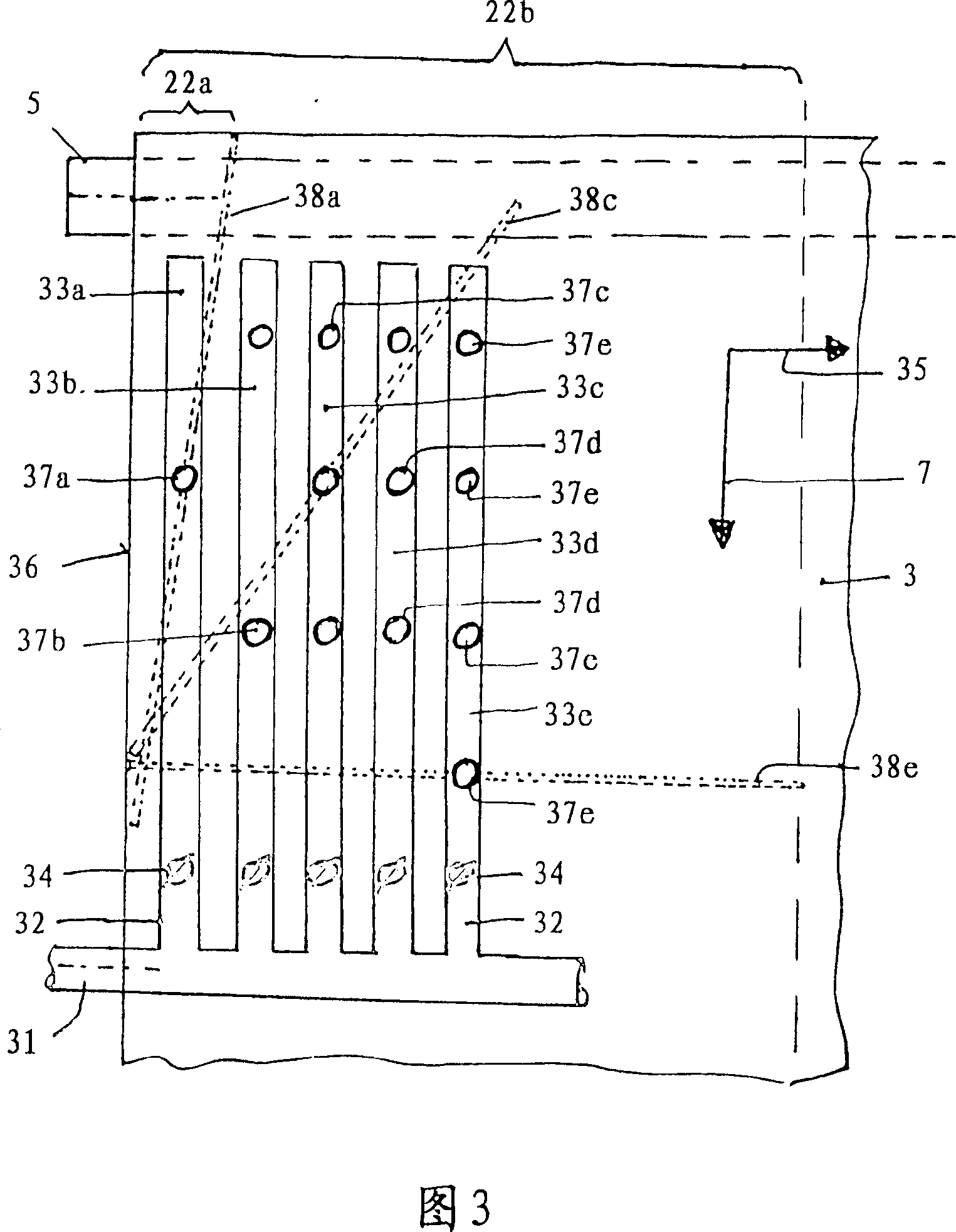

Active cooling of a motor

ActiveCN104521117AReduce the temperatureImprove sealingAssociation with control/drive circuitsCooling/ventillation arrangementActive coolingEngineering

The invention relates to a motor, comprising an electronics housing (1), a stator having a stator bushing (3), and a rotor (5). The motor can be fastened to a fastening wall (11) by means of the stator bushing (3). The motor according to the invention has an air conducting element and an air conveying element (14). The air conveying element is connected to the rotor (5) in a rotationally fixed manner. The air conducting element (22a) surrounds the stator bushing (3) and forms a flow space (35) between the air conducting element (22a) and an outer circumference of the stator bushing (3). The flow space (35) is open on the side of the electronics housing (1) in the direction of the fastening wall (11) through at least one flow gap (27). The air conducting element (14) opens with an intake opening (16) via a sealing gap in a rotor-side throughflow opening (26) of the air conducting element.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

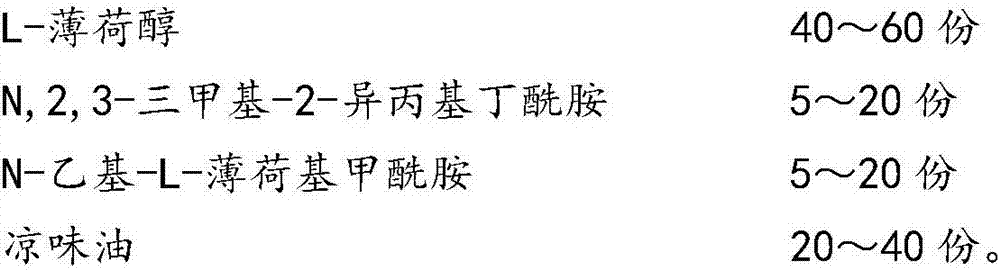

Loquat essence and preparation method thereof

The invention discloses a loquat essence. The loquat essence comprises, by weight, 60-85 parts of propylene glycol, 5-10 parts of benzaldehyde, 5-15 parts of dementholized peppermint oil, 2-8 parts ofmenthol, 2 to 10 parts of p-methoxyacetophenone, 1 to 5 parts of vanillin, 0.5 to 3 parts of isoamyl acetate, 0.3 to 1 part of ethyl isovalerate, 0.1 to 1 part of benzyl acetate, 0.1 to 1 part of peach aldehyde, 0.1 to 2 parts of sweet orange oil, 0.1 to 1 part of ethyl acetyl propionate. The invention also discloses a preparation method for the loquat essence. The loquat essence of the inventionis improved in natural feeling and endowed with strong cool and refreshing effect, can be perfectly combined with the fragrance of a throat lozenge, and increases a throat clearing and moistening function for the throat lozenge; moreover, the loquat essence has novel and unique fragrance and is effectively improved in quality, heat resistance and stability.

Owner:ARTSCI BIOLOGY TECH ZHEJIANG

Method for compressive shrinking and rubber blanket shrinking system

This plant is used to treat textile webs (9) which do not fully cover the width of the cloth belt (3) and of the cylinder (1). This leaves inactive regions of the belt at its edges, which may be subjected to greater heating. Such regions are separately and more strongly cooled than the active regions (27) of coverage, after lifting-off the main cylinder. An Independent claim is included for the corresponding pre-shrinkage plant for textiles.

Owner:A MONFORTS TEXTILMASCHINEN GMBH & CO KG

Method for operating air-jet spinning machine with cooling arrangement.

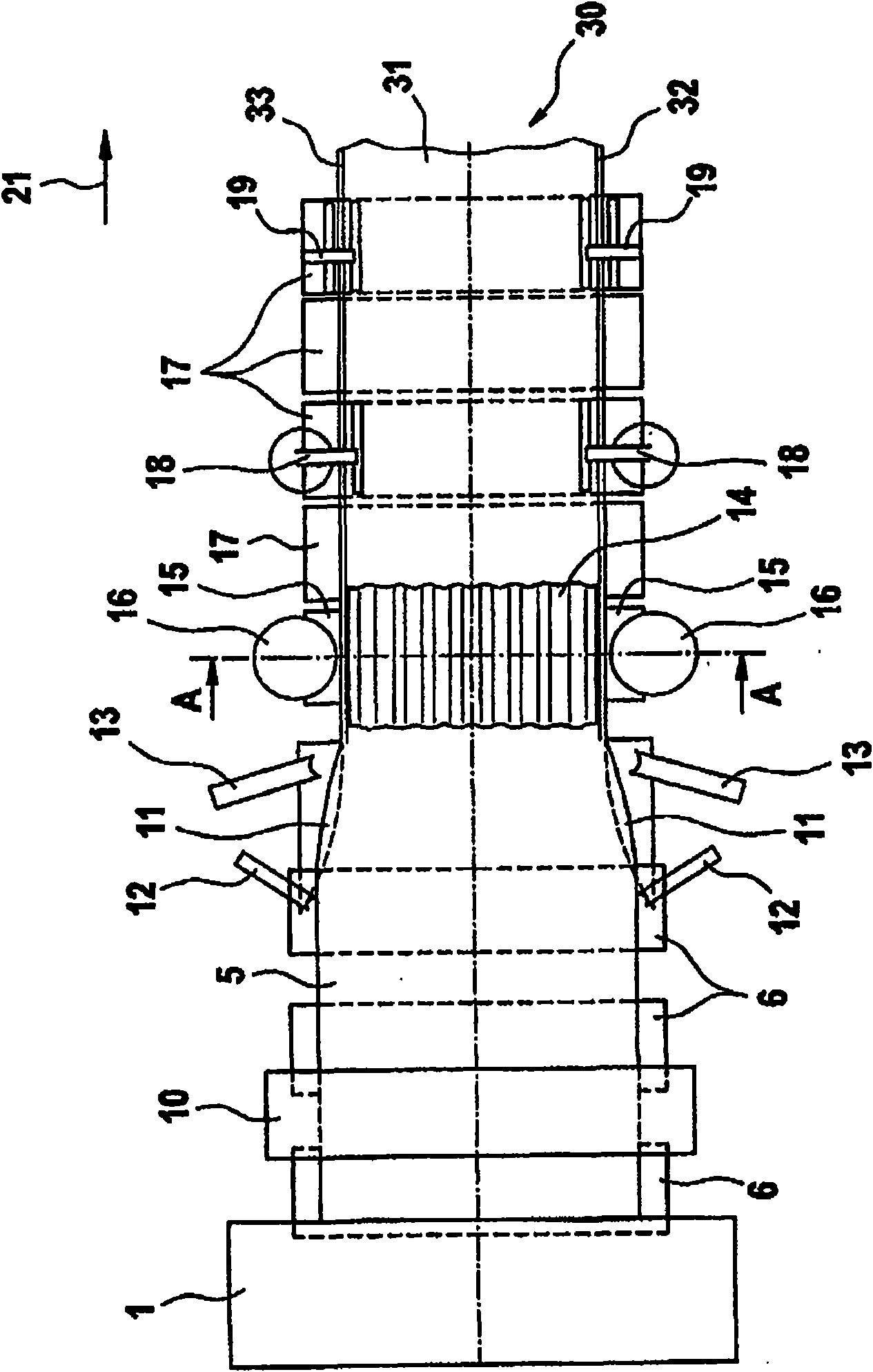

InactiveCN108570730AReduce the temperatureReduce depositionContinuous wound-up machinesOpen-end spinning machinesYarnFiber bundle

The invention relates to a method for operating an air-jet spinning machine with at least one spinning nozzle (1), wherein the spinning nozzle (1) comprises an internal eddy chamber (2); a fiber bundle (3) is fed into the spinning nozzle (1) through an inlet (4) of the spinning nozzle (1) during operation of the spinning nozzle; the spinning nozzle (1) has one or more air nozzles (5) communicatingwith the eddy chamber (2); spinning air flows into the eddy chamber (2) through the air nozzles during operation of the spinning nozzle (1) so as to generate an air eddy in the eddy chamber (2); thefiber bundle (3) acquires a certain twist through the air eddy in the eddy chamber (2) so that yarn (6) is formed from the fiber bundle (3); and the yarn finally leaves the spinning nozzle (1) from anoutlet (7). The spinning air before flowing into the eddy chamber (2) is cooled to a temperature below 10 DEG C, preferably below 5 DEG C, and the cooled spinning air then flows into the eddy chamber(2) and cools at least one segment, of the spinning nozzle (1), in contact with the fiber bundle (3) and / or the yarn (6) and / or the spinning air.

Owner:MASCHINENFABRIK RIETER AG

Process and device for the production of channel-section glass elements, channel-section glass element and its use

ActiveCN101588997AWill not deformStrong coolingGlass rolling apparatusBuilding componentsFlat glassEngineering

Process for the production of a channel-section glass element (30) with two flanges (32, 33) and a web formed between the flanges (32, 33), which comprises the following steps: a) making available a flat glass ribbon (5) by means of two cylindrial draw-in rollers (3, 4) disposed at the exit of a glass melting furnace (1) b) adjusting the temperature of the web (31) to a web temperature at which the web (31) is still plastically deformable, c) adjusting the temperature of the flanges (32,33) to a flange temperature which is lower then the web temperature, d) erecting the flanges (32,33) at the edges of the glass ribbon (5) e) profiling the web (31) with the aid of two web profiling rollers (14,15), in such a way that the web (31) has a corrugated cross-section, f) cooling the channel-section glass element (30). A device for the production of a channel-section glass element (30) is also disclosed, furthermore a channel-section glass element (30) producible by such process and device and its use.

Owner:BAUGLASINDUSTRIE GMBH

Emulsifiable paste for relieving muscle soreness and preparation method thereof

InactiveCN106581170AEase cycleReduce pain and discomfortHydroxy compound active ingredientsAntipyreticOil phaseChlorpheniramine Maleate

The invention relates to the technical field of medicine, and in particular, relates to an emulsifiable paste for relieving muscle soreness and a preparation method thereof. The preparation method comprises the following steps: 1) weighing the following oil phase component raw materials according to the weight parts, and putting into an oil phase container, to obtain an oil phase mixture: wintergreen oil, menthol, camphor, borneol and melaleuca alternifolia oil; and weighing the following aqueous phase component raw materials according to the weight parts, and putting into an aqueous phase container, to obtain an aqueous phase mixture: chlorpheniramine maleate, paeonol, PEG-7 glyceryl cocoate, carbomer and purified water; and 2) adding the oil phase mixture into the aqueous phase mixture, mixing, discharging out of the container, and aging to obtain the emulsifiable paste for relieving muscle soreness. The emulsifiable paste for relieving muscle soreness has the beneficial effects that the natural wintergreen oil, the melaleuca alternifolia oil, menthol, camphor, borneol and other spices in the emulsifiable paste are combined and have a superimposed cumulative effect on relieving muscle soreness, and can help other effective components rapidly be led into a corium layer of skin and quickly penetrate to a pain part to relieve pain effects.

Owner:黄开权

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com