Process and device for the production of channel-section glass elements, channel-section glass element and its use

A groove-shaped section, glass technology, applied in glass manufacturing equipment, glass molding, glass rolling, etc., can solve problems such as reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

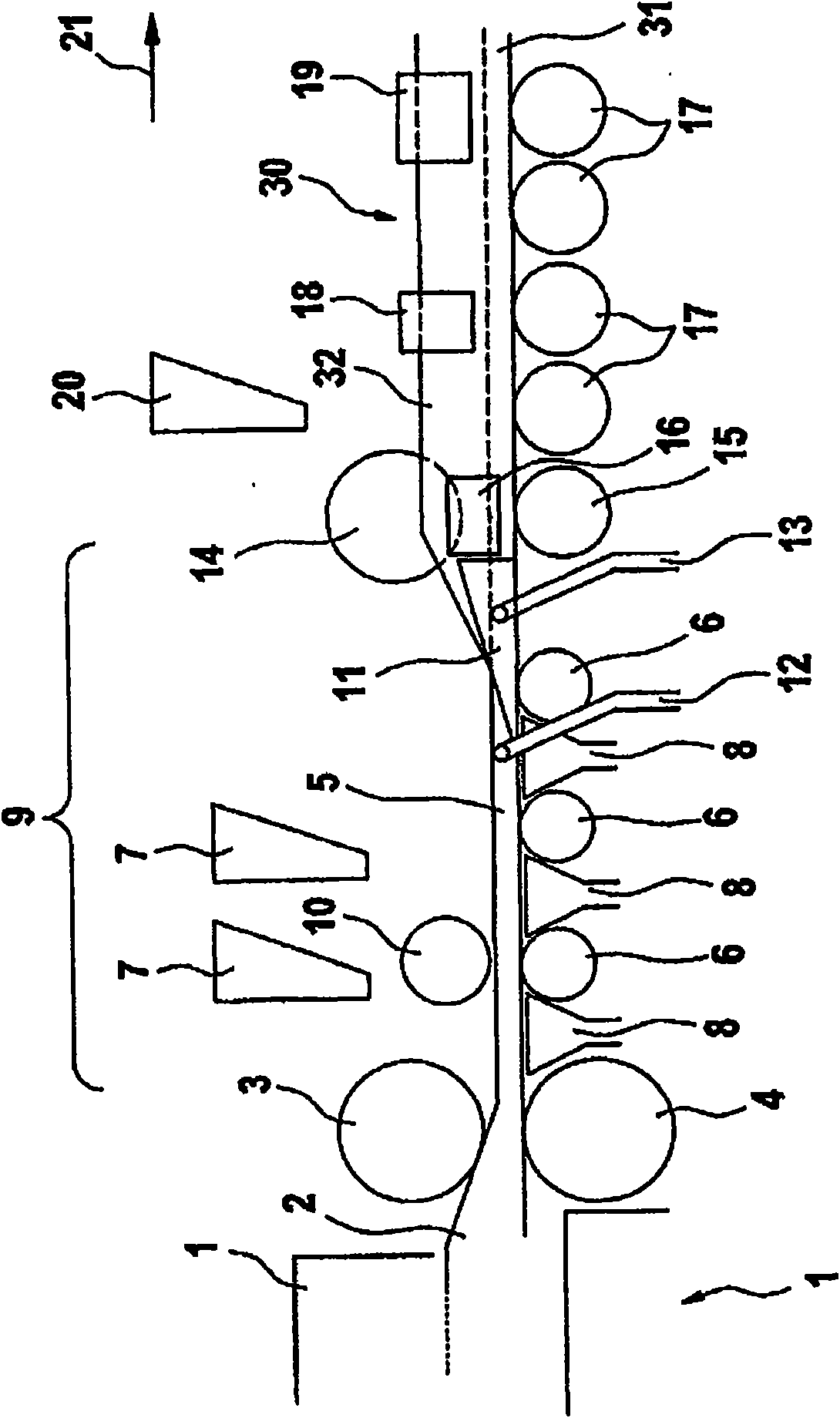

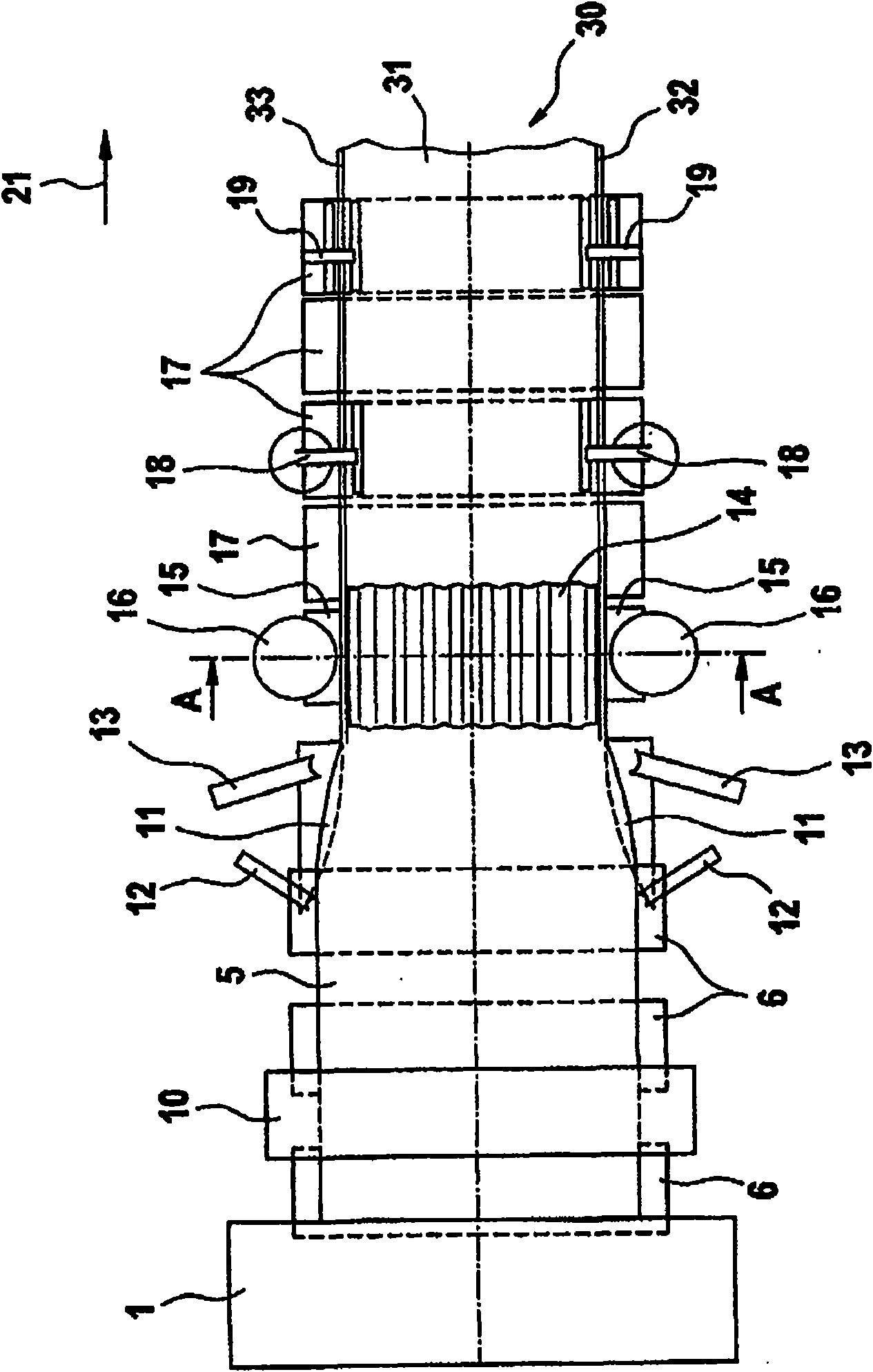

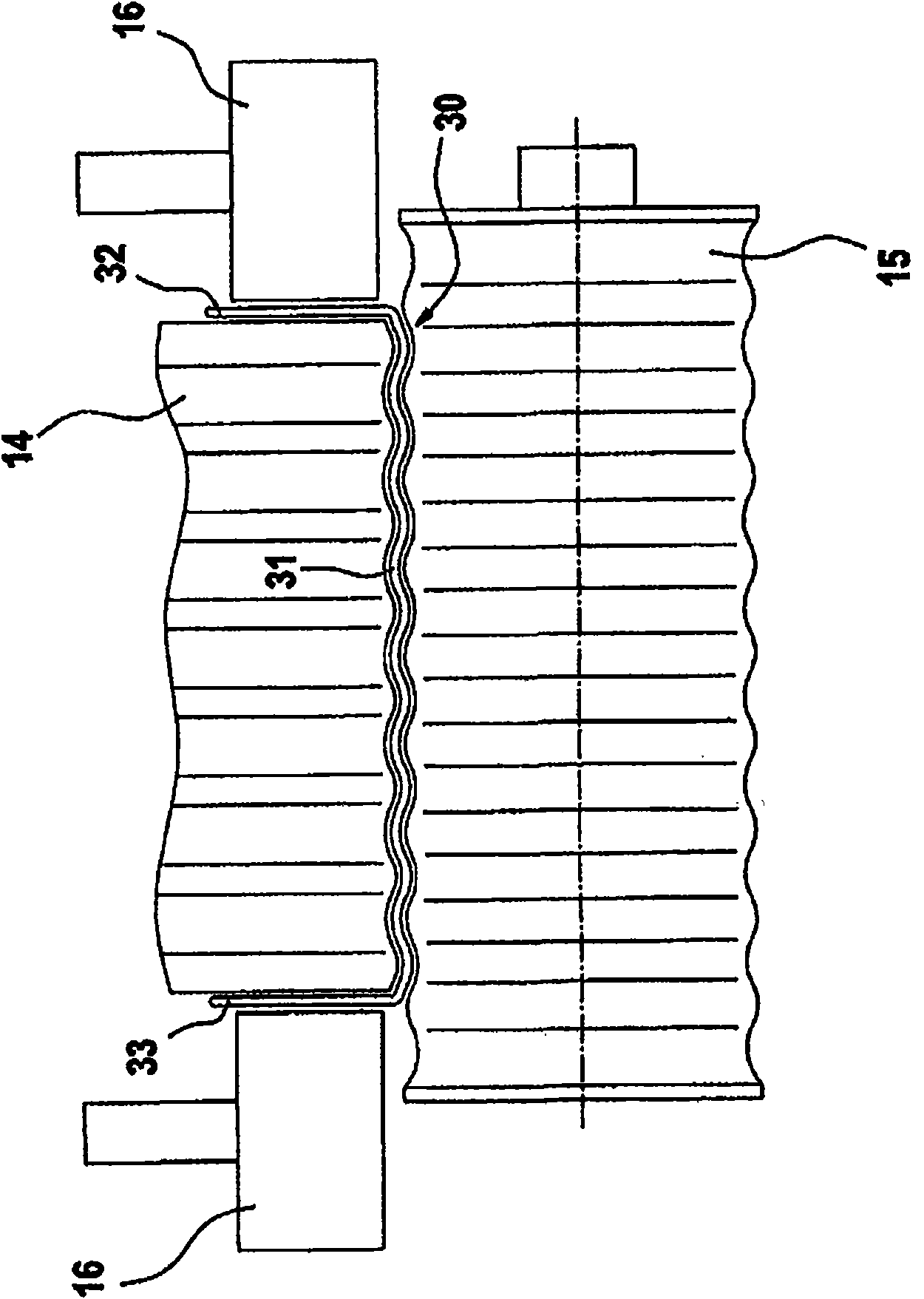

[0075] figure 1 A side view showing an embodiment of the inventive apparatus for the production of channel-section glass elements, while figure 2 A plan view of the device is shown.

[0076] The two cylindrical introduction rolls 3, 4, in which the two cylindrical introduction rolls 3, 4 are arranged to produce glass, have the same diameter and are arranged one above the other, leaving a nip of approximately constant width Standard design of melt 2 at the exit of glass melting furnace 1, which is in figure 1 , 2 shown only in general terms. A generally flat but still flexible glass ribbon 5 of predetermined thickness can be made (introduced from the melt) by means of the introduction rolls 3 , 4 . The lower introduction roll 4 has an irregular surface structure (pattern) transferred to the lower surface of the glass ribbon 5 .

[0077] The glass melt 2 of standard soda lime silicate glass has a temperature of the order of about 1100° C. in front of the introduction rolls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com