Low-pressure casting die of aluminium alloy wheel and casting method thereof

A low-pressure casting and aluminum alloy wheel hub technology, which is applied in the field of aluminum alloy casting, can solve the problems of poor mechanical performance index of wheel ribs and hubs, prone to pinholes in products, unfavorable product lightweighting, etc., to achieve lightweight products and molds Strong cooling and corrosion-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

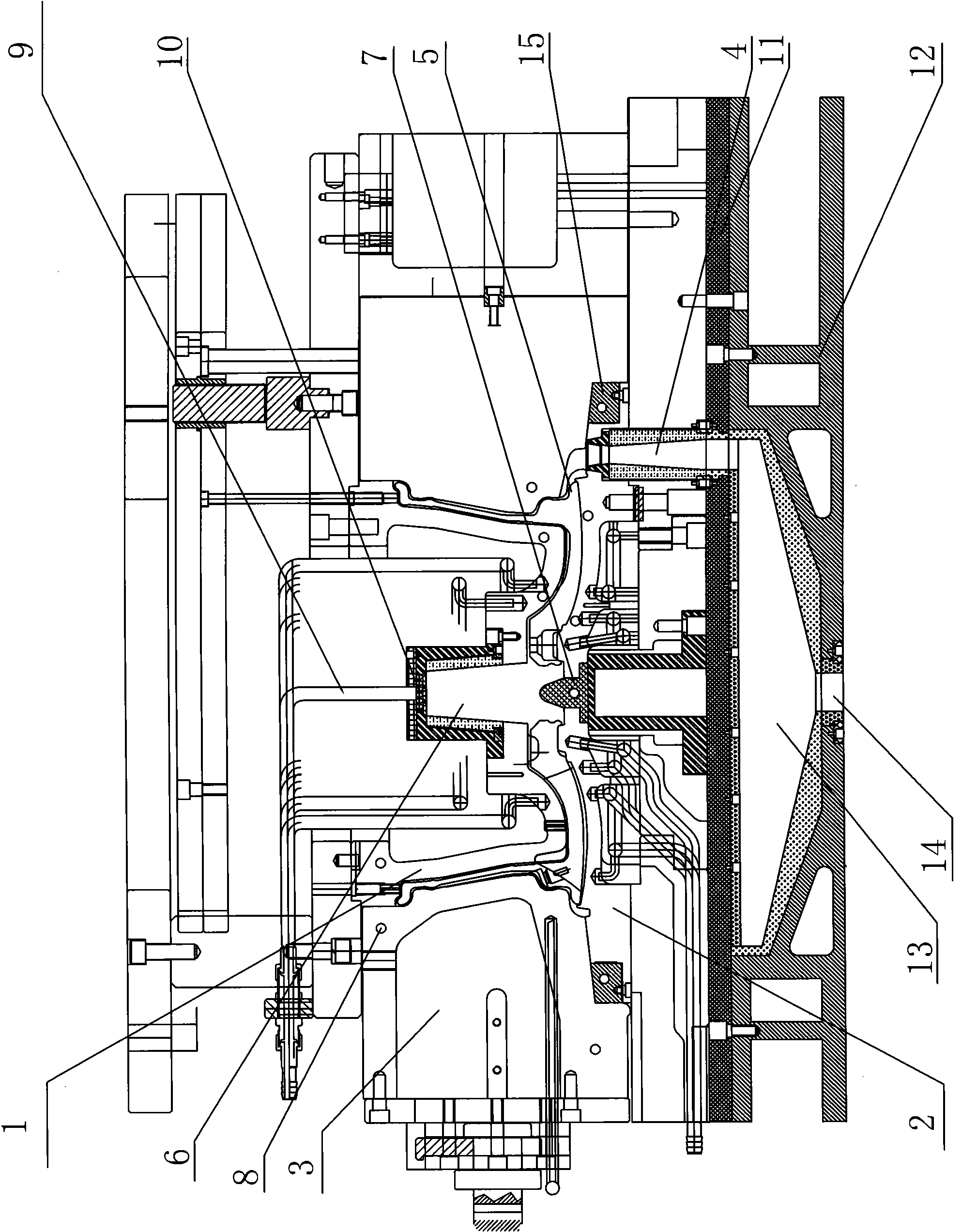

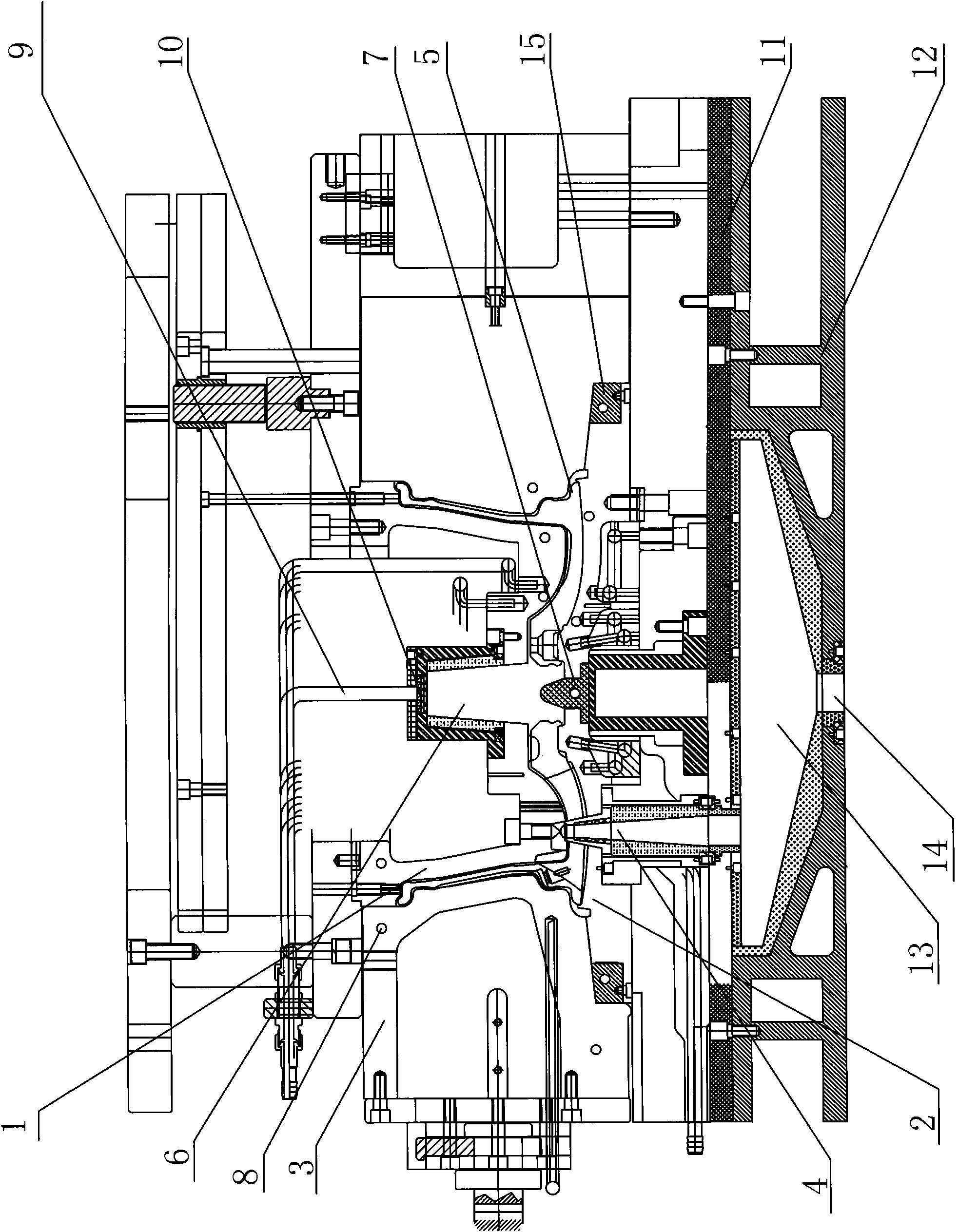

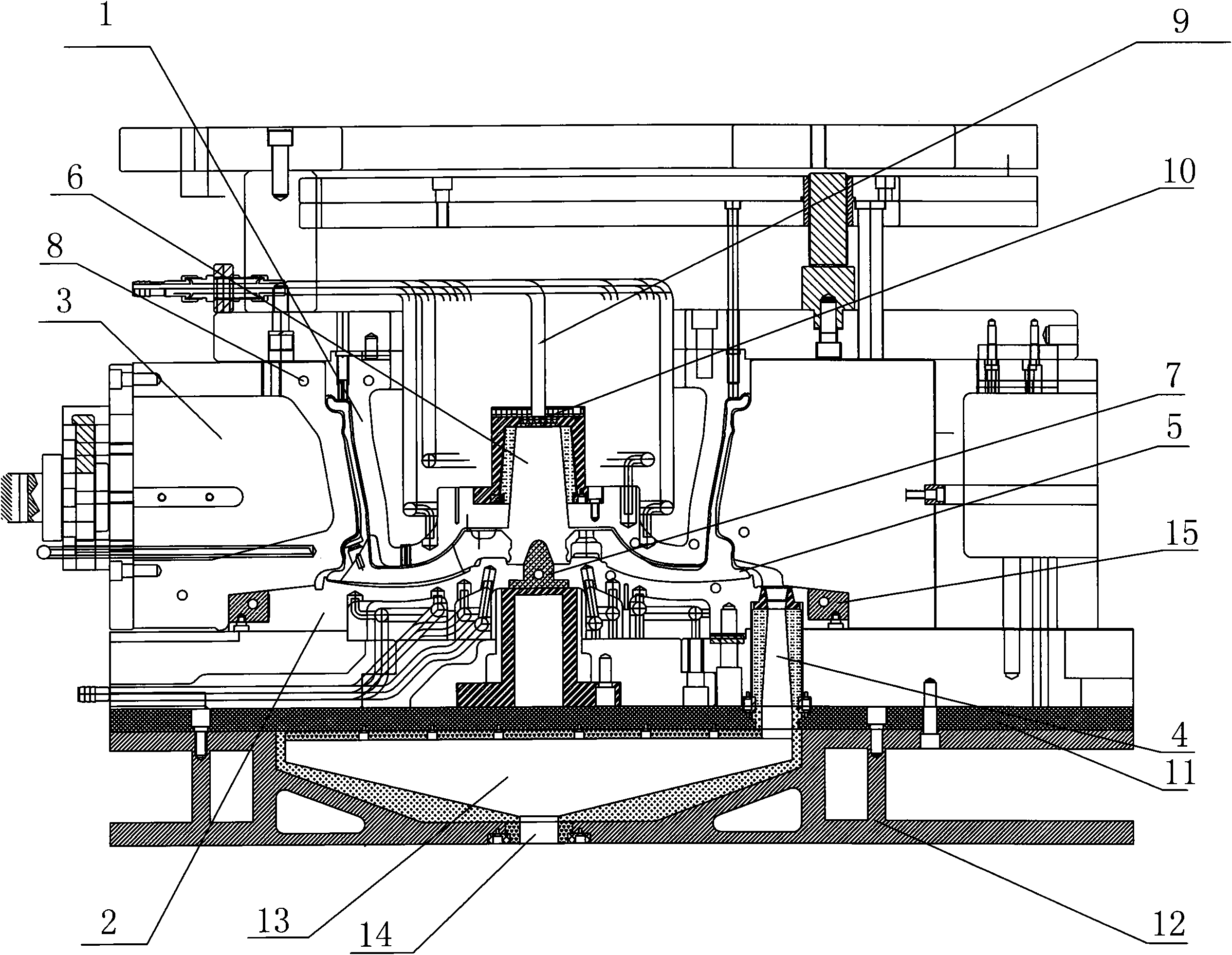

[0027] Such as figure 1 As shown, the low-pressure casting mold of the aluminum alloy wheel of the present invention comprises a top mold 1, a bottom mold 2 and a side mold 3, and the bottom mold 1 is provided with a plurality of gates 4 outside the lower wheel lip 5, and the top mold 1 The center of the mold is provided with a central riser 6 for feeding, and the center of the bottom mold is provided with a splitter cone 7 for forming the center of the wheel disc; the lower lip 5 refers to the lower lip of the wheel hub casting in the cavity The roulette refers to the roulette of the wheel; the gates are generally 2-4, and a gate is required for each rib for products with high mechanical performance indicators and flaw detection requirements of the roulette. Ribs and ribs are actually a concept, both refer to the spokes of the wheel.

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com