Receiving element for pouch cells

A technology for accommodating components and soft-pack batteries, which is applied to electrical components, household components, battery pack components, etc. It can solve the problems of battery embedding, high investment, and ineffective use of battery size, etc., and achieve the effect of weight optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

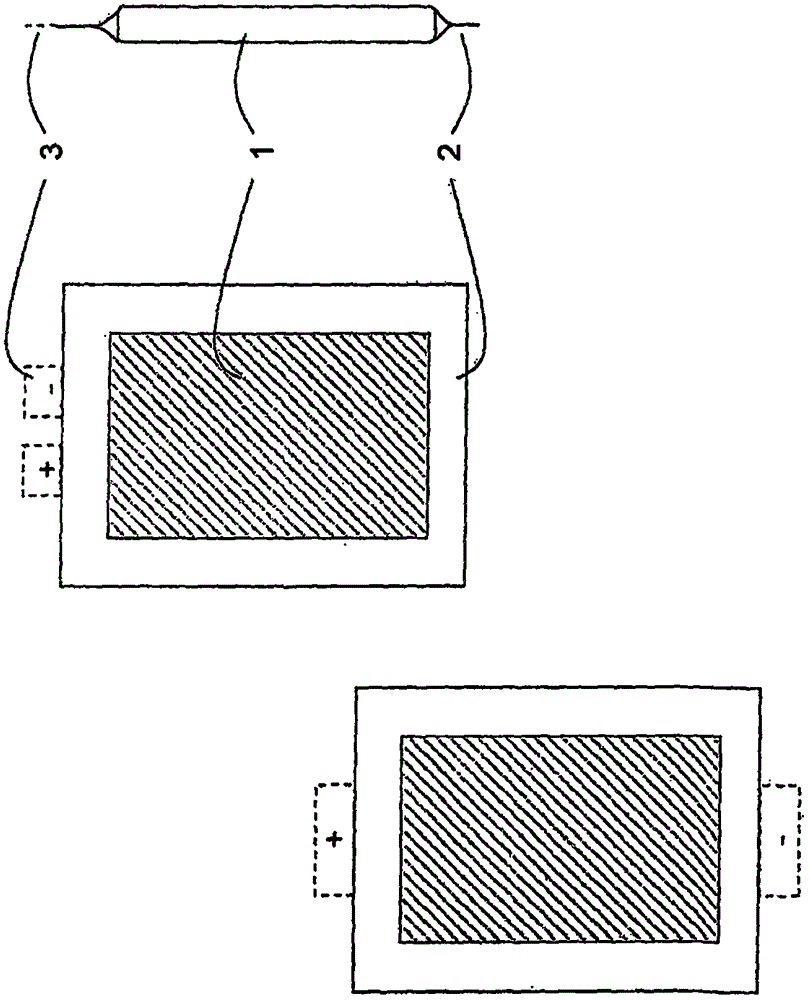

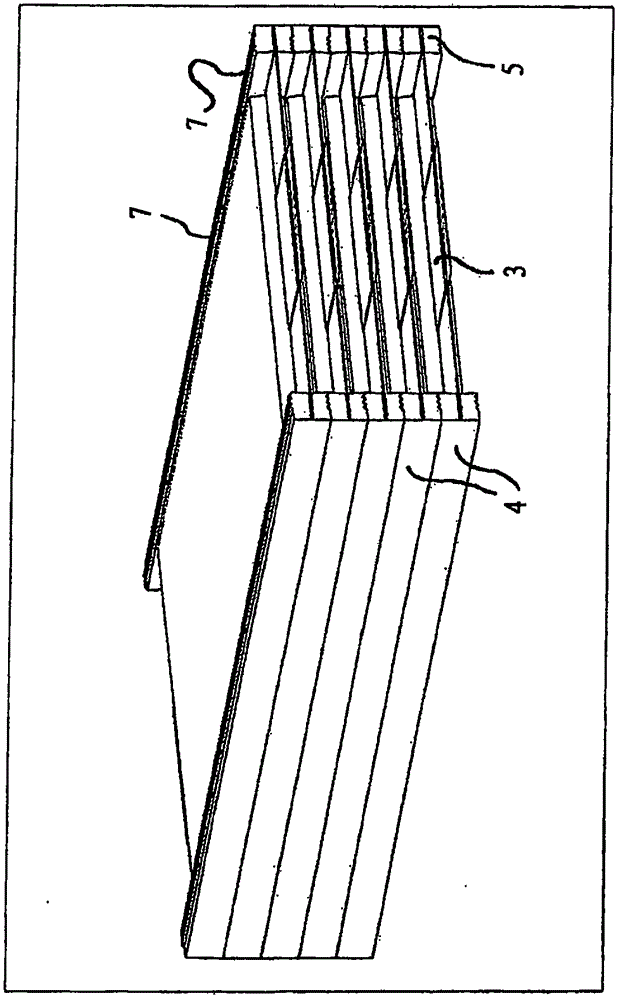

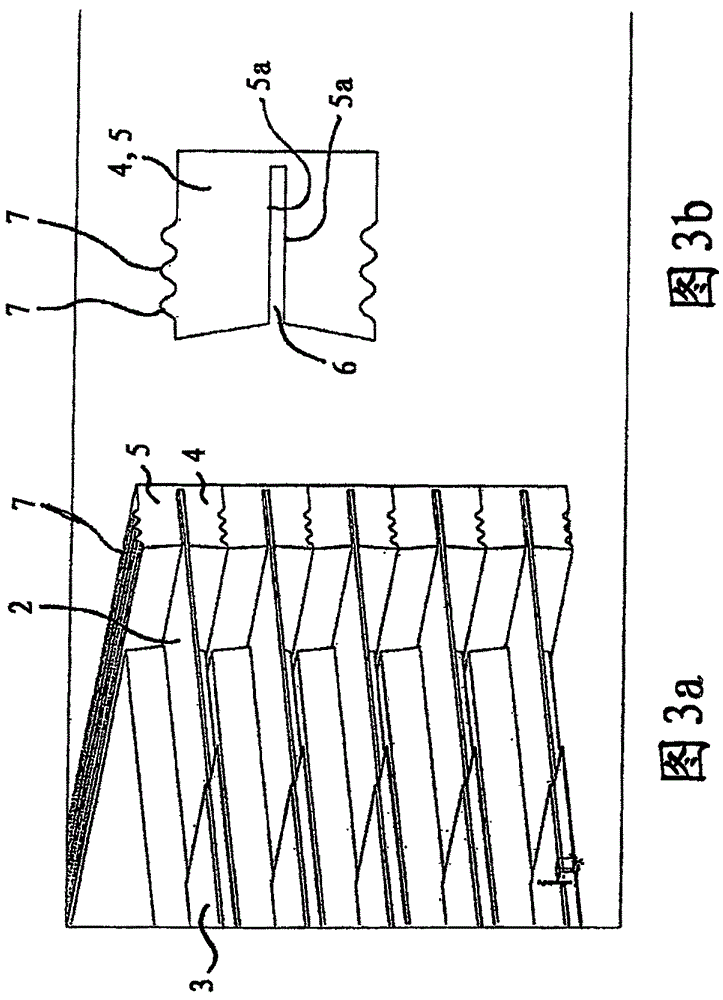

[0067] figure 1 A schematic diagram shows a soft-pack battery, that is, a galvanic battery with a flexible casing. The soft-pack battery includes an actual battery body 1 and a surrounding sealing seam 2. An electrode-separator layer structure is provided on the body of the battery. The upper and lower decorative films in the area of the sealing seam are welded to each other, and include a discharge terminal 3 extending from the battery between the cover films and additionally sealed with a film. Here, the discharge terminals 3 may protrude from the housing on the same side surface, or may also be located on different sides.

[0068] During the operation of the battery, that is, during charging and / or discharging, the thickness of the battery body 1 usually varies between the charged and discharged states by 5% to 10%. In addition, aging batteries are about 5% thicker than new batteries. Therefore, an aged and charged battery is about 10% to 15% thicker than a new and uncharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com