Device and method for melting spinning and cooling multiple monofilament

A cooling device, melt spinning technology, applied in textile and paper making, filament/thread forming, fiber processing, etc., to achieve the effect of uniform air supply characteristics and avoid air vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

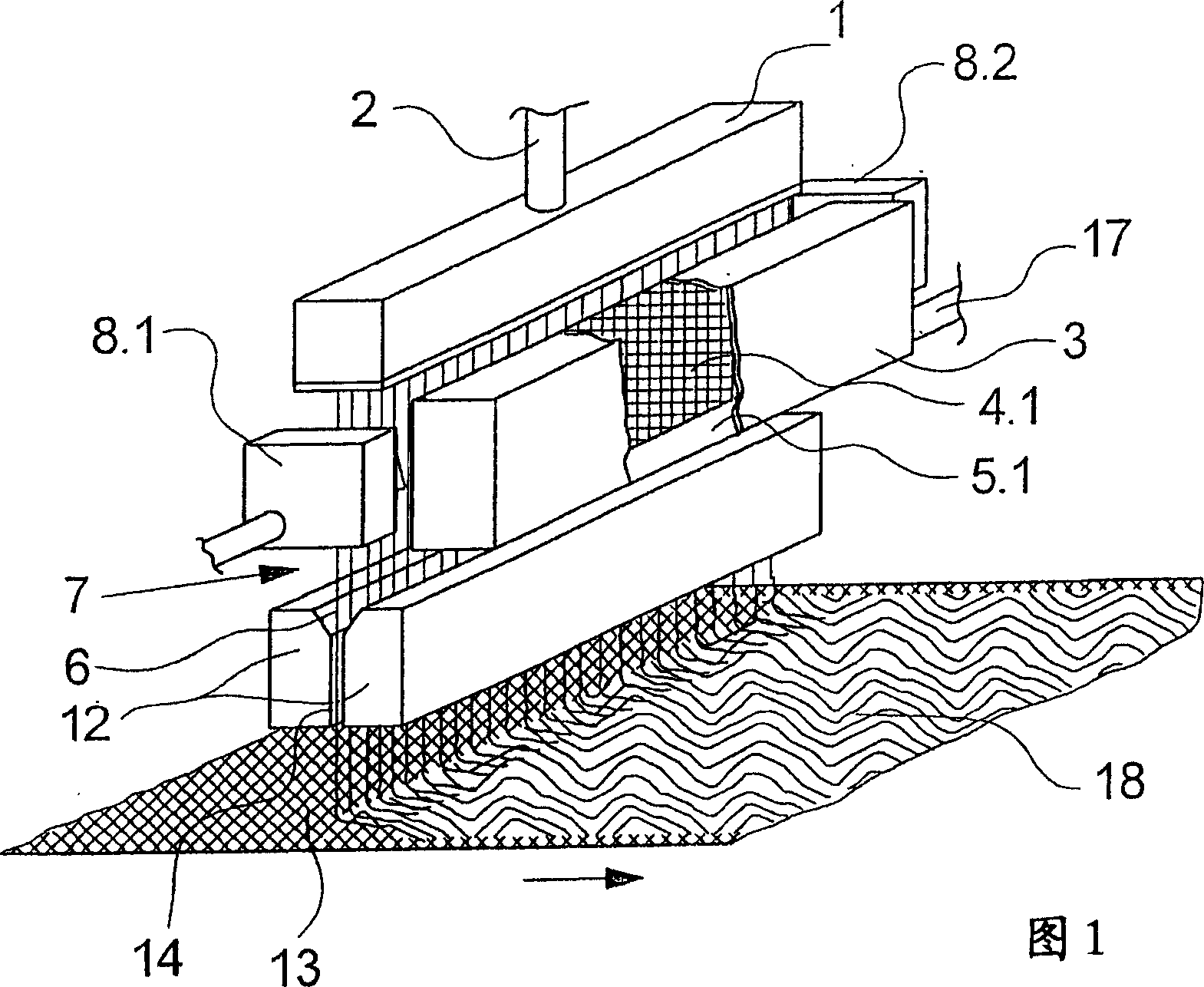

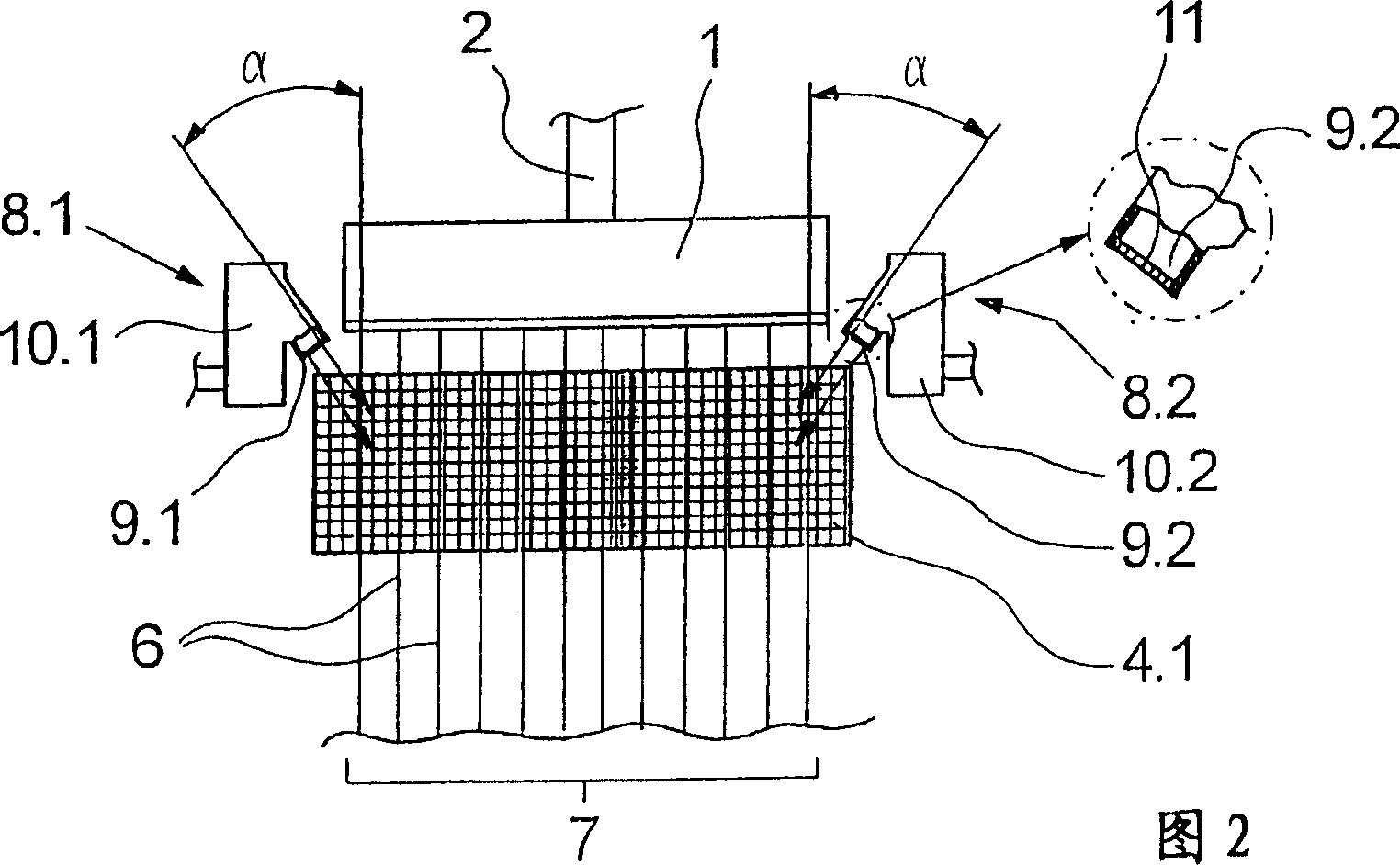

[0026] A first embodiment of the apparatus of the present invention for carrying out the method of the present invention for melt spinning and cooling a plurality of monofilaments is shown in FIGS. 1 and 2 . This embodiment is shown schematically in a view in FIG. 1 and in a transverse section in FIG. 2 . Therefore, if no specific reference is made to a particular figure, the following description applies to both figures.

[0027] The present exemplary embodiment has a spinning nozzle arrangement 1, which on its underside has a large number of spinning orifices, which are preferably arranged in a row. The spinning nozzle arrangement 1 is connected to a melt source (not shown here) via a melt feed line 2 .

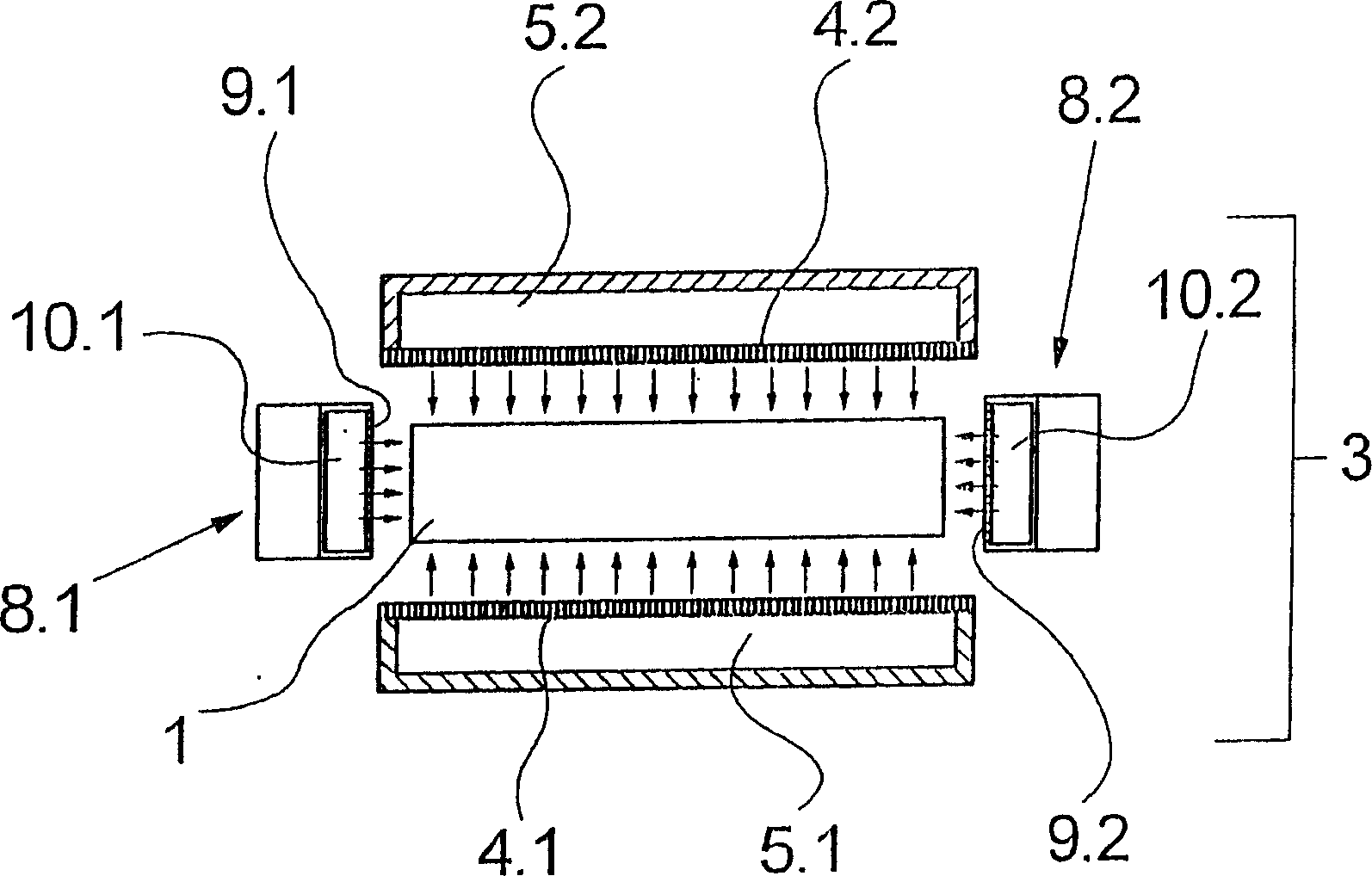

[0028] Below the spinning nozzle device 1 is arranged a cooling device 3, between the spinning nozzle device 1 and the cooling device 3 a short spinning zone is formed in which the filaments travel without actively cooling them. The cooling device 3 has a blowing wall 4.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com