Device and method for melting spinning and cooling multiple monofilament

一种冷却装置、熔融纺的技术,应用在纺织品和造纸、长丝/线成型、纤维处理等方向,达到送风特性均匀化、避免空气涡旋的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

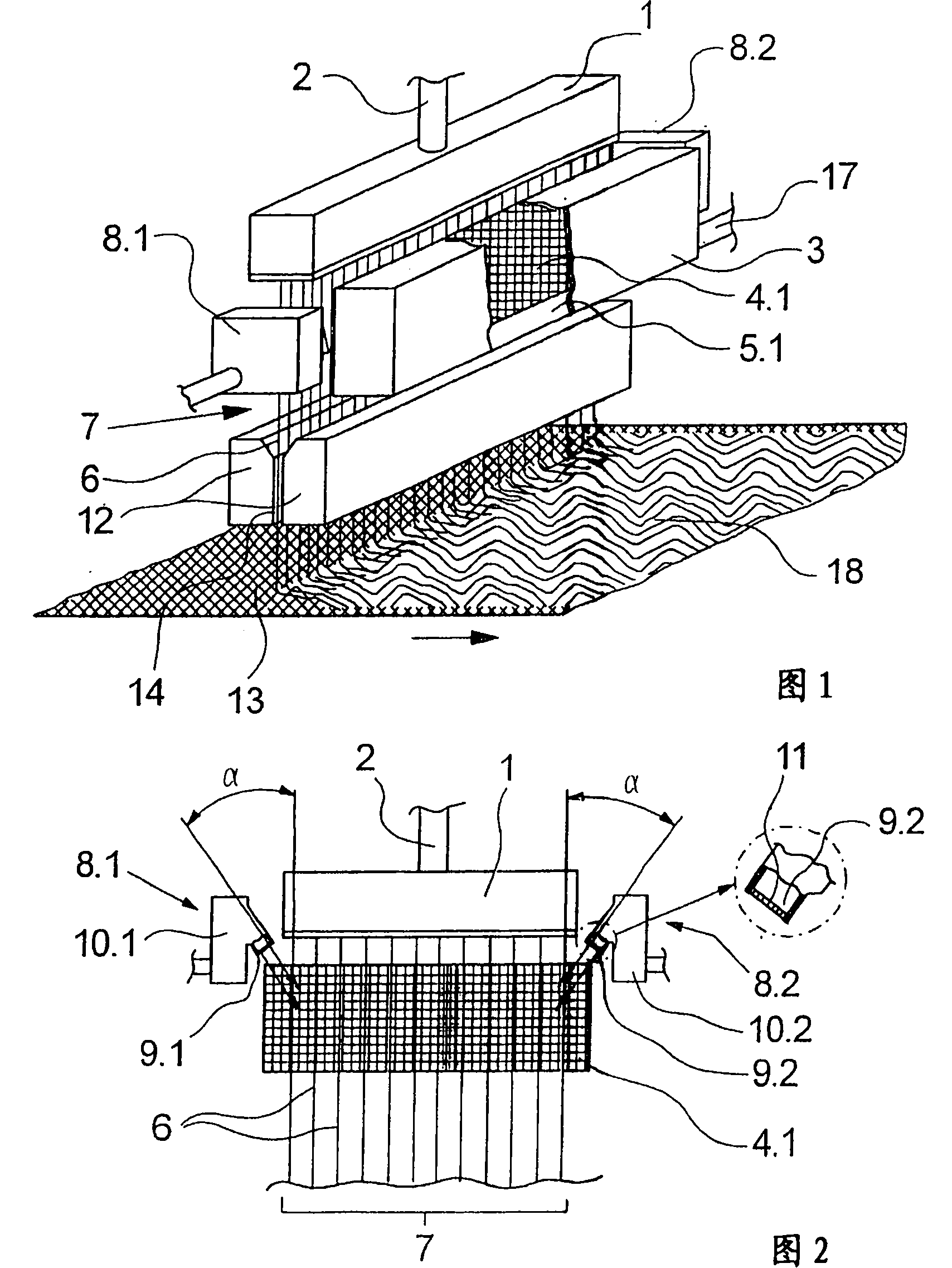

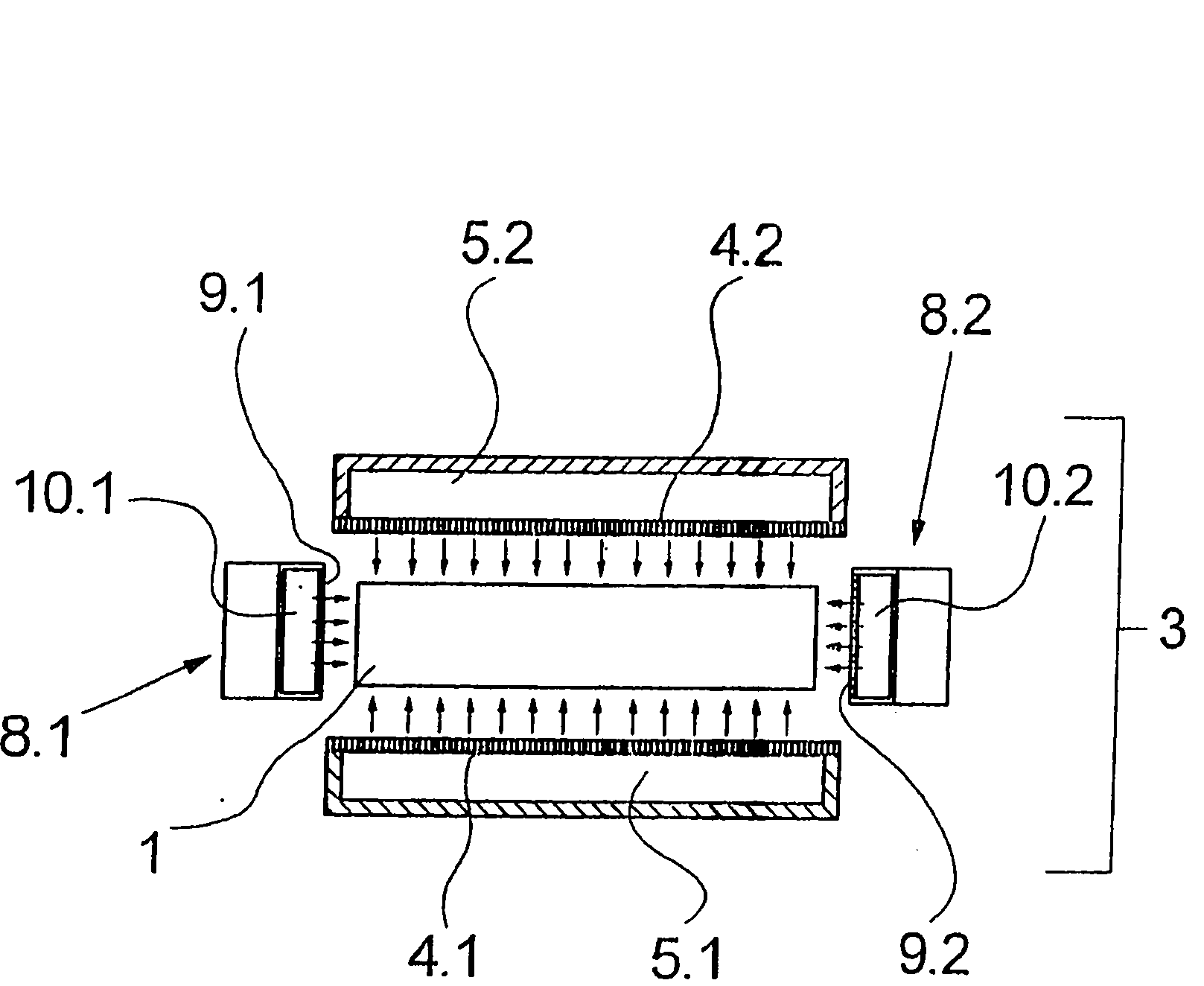

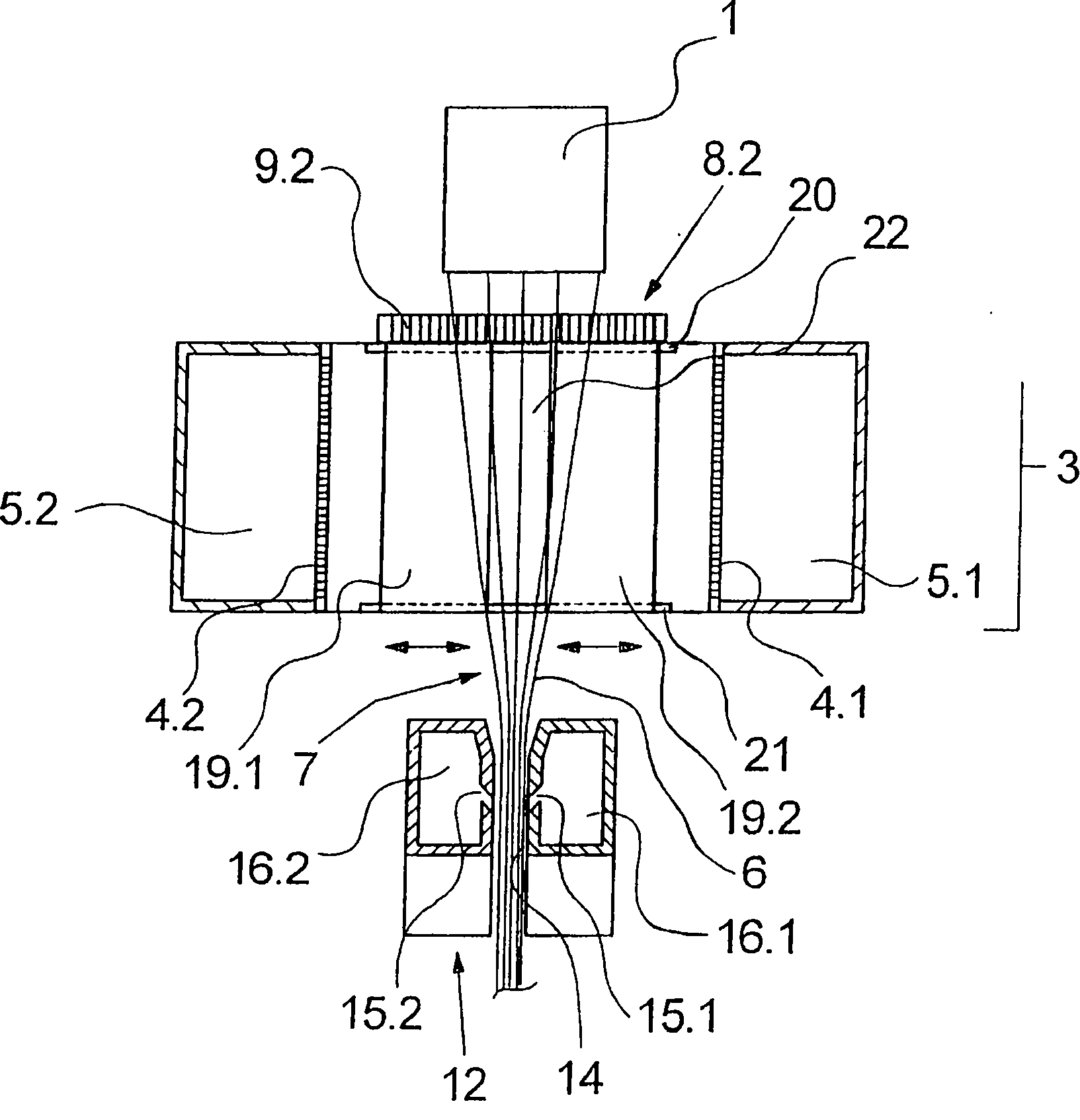

[0026] A first embodiment of the apparatus of the invention for carrying out the method of the invention for melt spinning and cooling a large number of filaments is shown in FIGS. 1 and 2 . This exemplary embodiment is shown schematically in one view in FIG. 1 and in a transverse section in FIG. 2 . The following description therefore applies to both figures if no one figure is specifically referred to.

[0027] The present exemplary embodiment has a spinning nozzle arrangement 1 which has a plurality of spinneret openings arranged preferably in a row on its underside. The spinning nozzle arrangement 1 is connected via a melt feed line 2 to a melt source (not shown here).

[0028] Below the spinning nozzle arrangement 1 a cooling device 3 is arranged, between which a short spinning zone is formed in which the filaments run without being actively cooled. The cooling device 3 has a blowing wall 4.1 extending parallel to the longitudinal sides of the spinning nozzle arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com