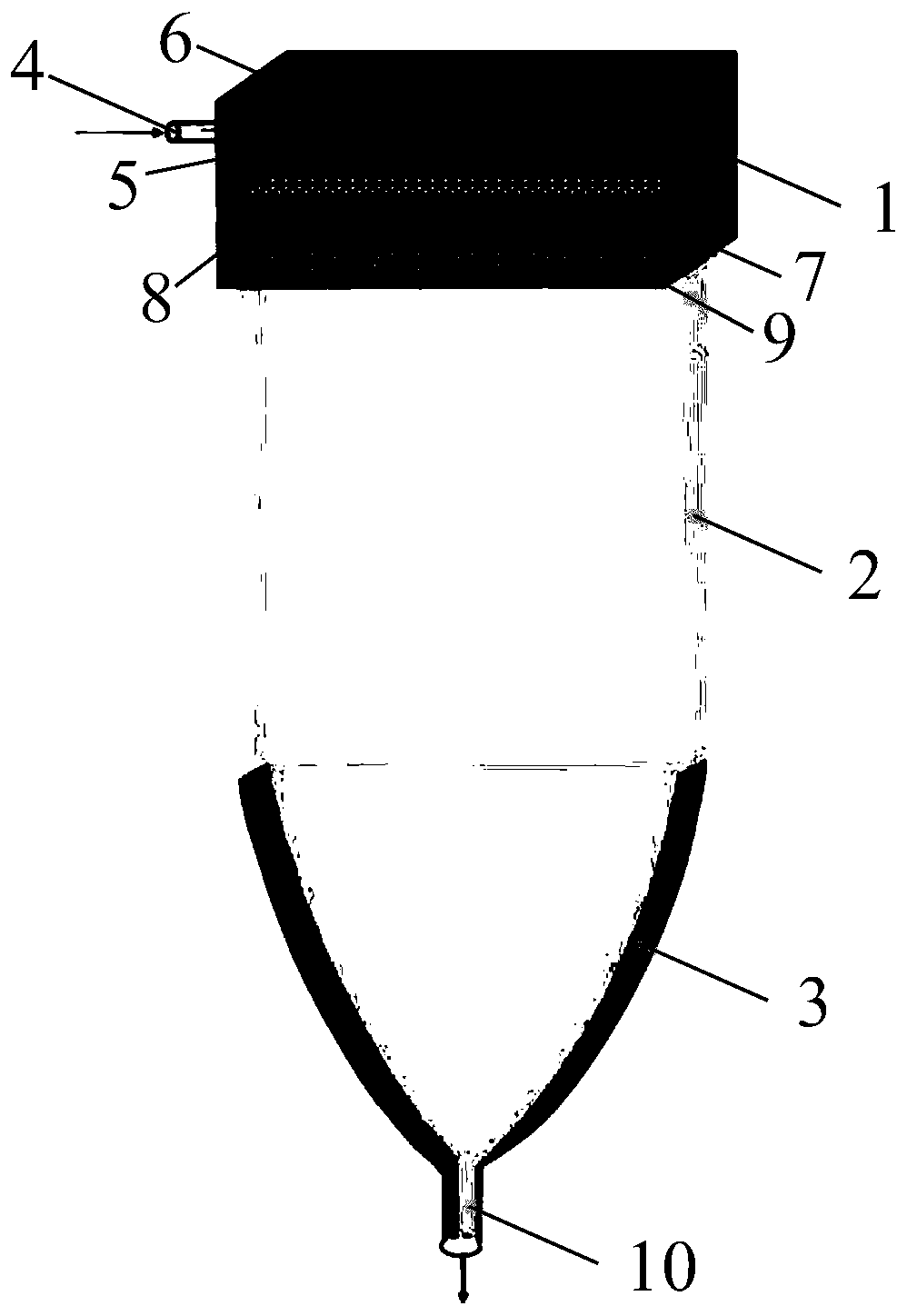

A uniform gas flow laser ablation pool and its application

A laser ablation and uniform technology, applied in the preparation of test samples, instruments, measuring devices, etc., can solve the problems affecting the transmission efficiency of ablation particles and the inability to form uniform airflow, and achieve the elimination of gravity deposition, elimination of dead volume, and elimination of particles The effect of the difference in transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

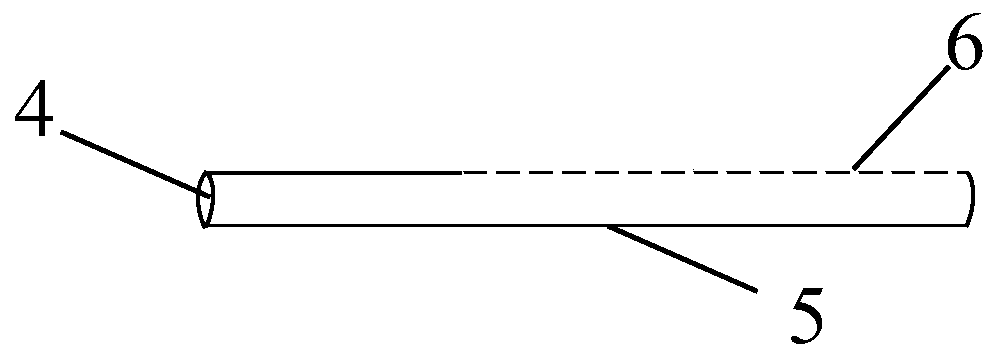

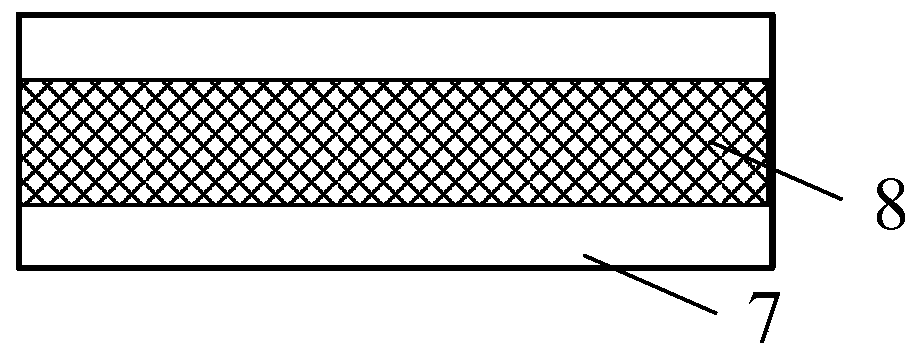

Method used

Image

Examples

Embodiment 1

[0046] Example 1: An experiment to evaluate the transmission efficiency of different ablation positions in a uniform gas flow laser ablation cell.

[0047] In this embodiment, a high-resolution multi-receiving inductively coupled plasma mass spectrometer (MC-ICP-MS) is used to approximate the transmission efficiency of laser ablation particles according to the peak and shape of the isotope signal peak and the pulse response time, and whether there is vortex.

[0048] In order to evaluate the transmission efficiency at different denudation locations, Balma pyrite (standard sample of pyrite with uniform Fe isotopic composition) was used as samples and poured on two epoxy resin plates with a diameter of 1.77 cm and one with a diameter of 2.54 cm. epoxy resin plate, and then polished to obtain three sample targets with a flat and smooth surface suitable for laser ablation analysis, the three sample targets were placed in such as Figure 5 The three sample positioning trays are sh...

Embodiment 2

[0052] Example 2: An experiment to evaluate the reduction of position effect in a uniform gas flow laser ablation cell.

[0053] This embodiment is based on the embodiment 1 to further evaluate the effect of reducing the position effect of the laser ablation pool with uniform gas flow. Since the elemental signal shape and impulse response time are in addition to being affected by position effects, e.g. 56 The Fe signal is also affected by the element concentration and the energy density of the laser beam. Although the composition of Fe isotopes in Balma pyrite grains is uniform, there may be differences in Fe concentration in Balma pyrite grains in different regions of the same sample target or different sample targets. The energy density of the same laser beam may also be different at different ablation positions. For example, in the GeoLasPro 193nm excimer laser ablation system, the energy density of the laser beam is set to 1.5J / cm 2 , its energy density may be 1.3J / cm 2...

Embodiment 3

[0061] Embodiment 3: The application experiment of uniform gas flow laser ablation cell in measuring Fe isotope composition of H1 pyrite (H1pyrite, laboratory internal standard).

[0062] In embodiment 3, using H1 pyrite as a sample, adopting the same method as in embodiment 1 to make a sample target with a diameter of 1.77 cm is placed on the B sample positioning plate, and using Balma pyrite as a standard material to make a diameter of 1.77 cm A sample target of cm was placed in the A sample positioning plate, and the Fe isotope composition in the H1-type pyrite sample was analyzed by laser ablation multi-receiver inductively coupled plasma mass spectrometry and solution method multi-receiver inductively coupled plasma mass spectrometry. The Fe isotope composition results of H1 pyrite samples obtained by these two methods are shown in Table 3 and Figure 8 As shown, the results of laser micro-area analysis and solution method are consistent within the analytical error range,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com