Patents

Literature

47results about How to "Eliminate dead volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

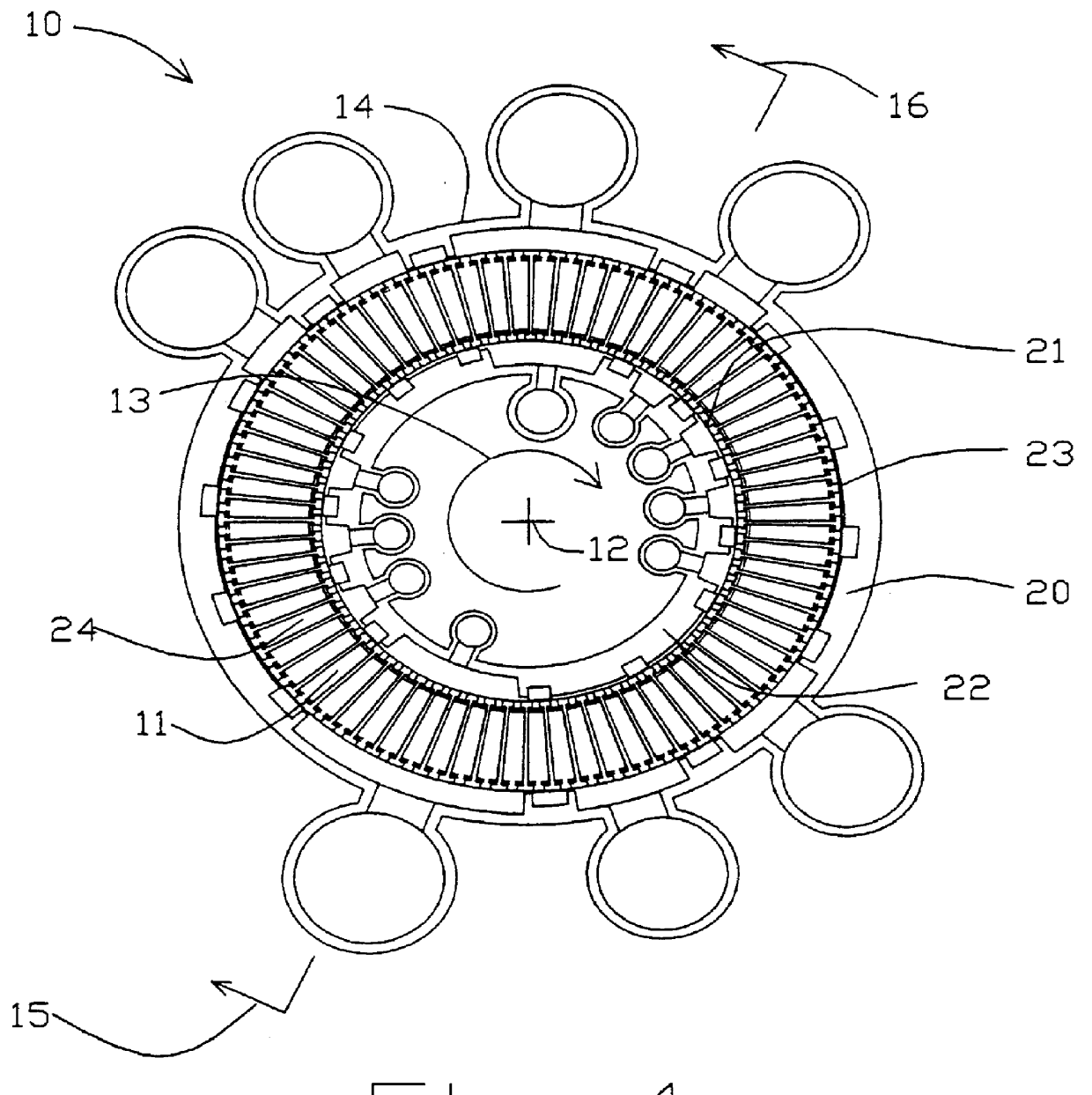

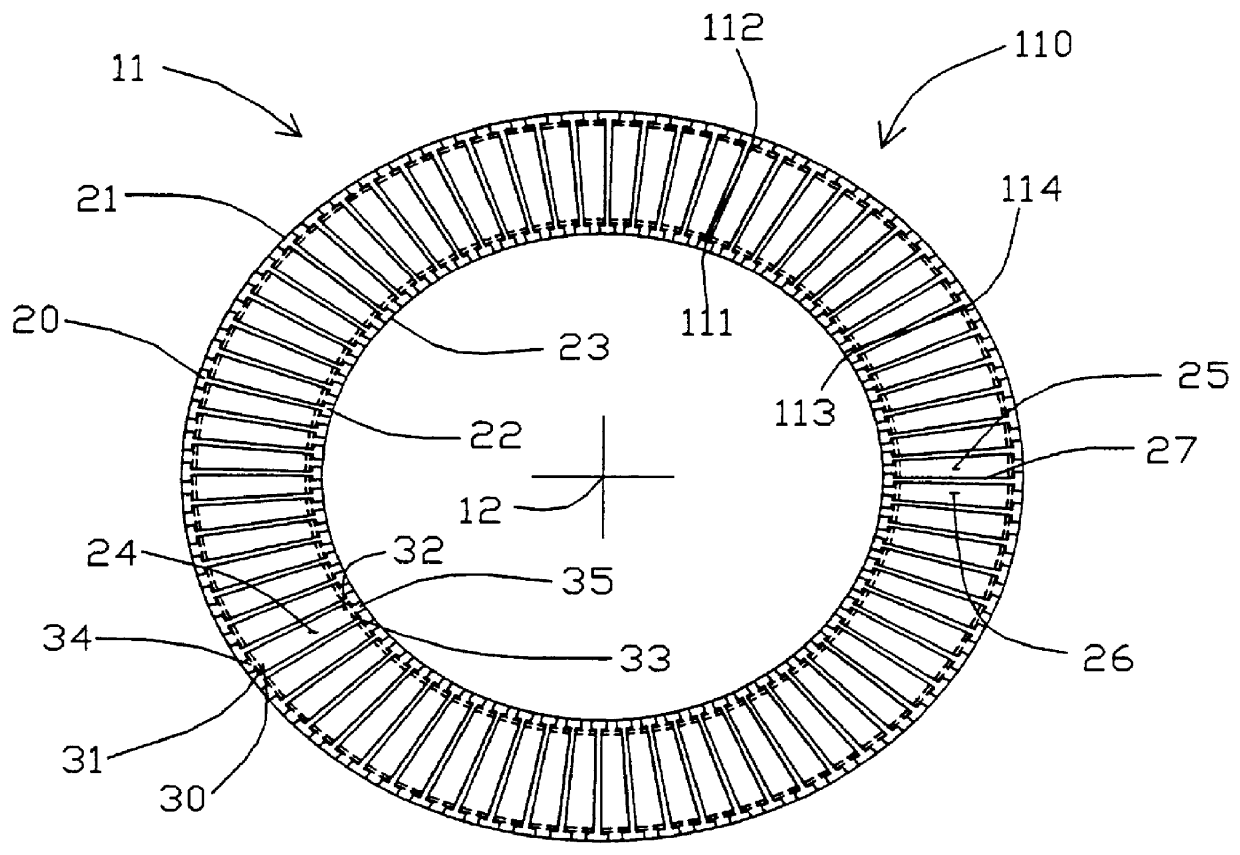

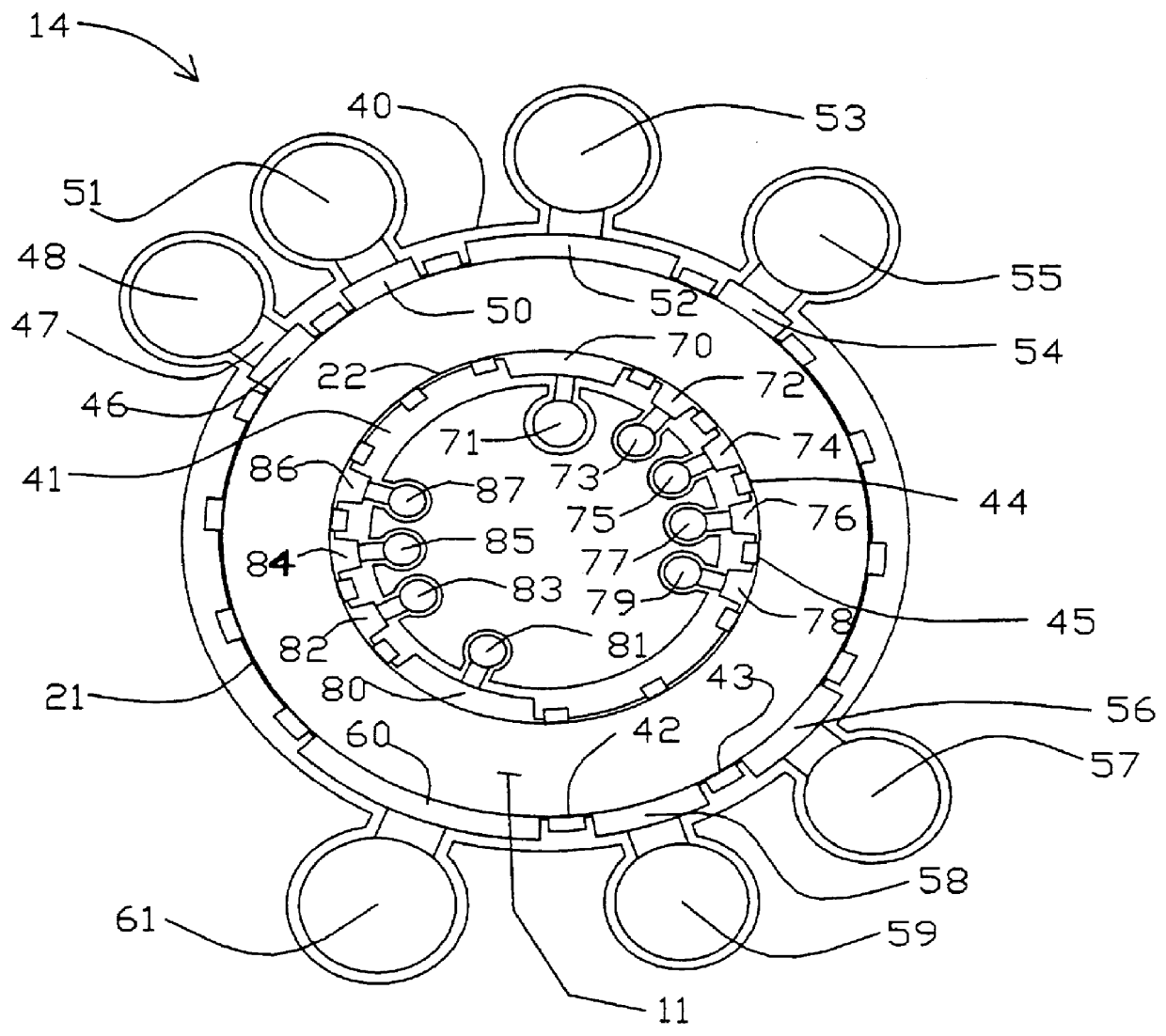

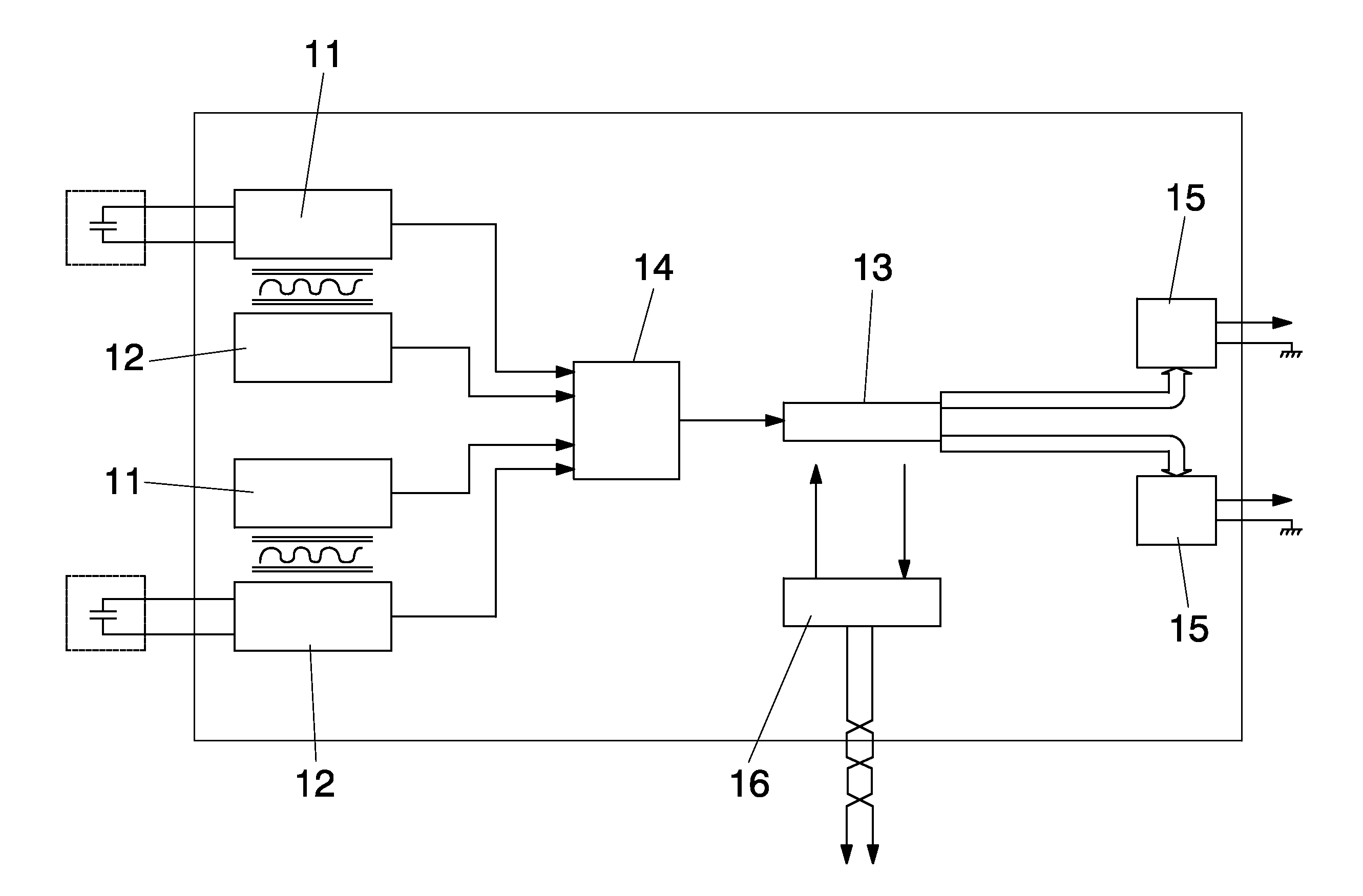

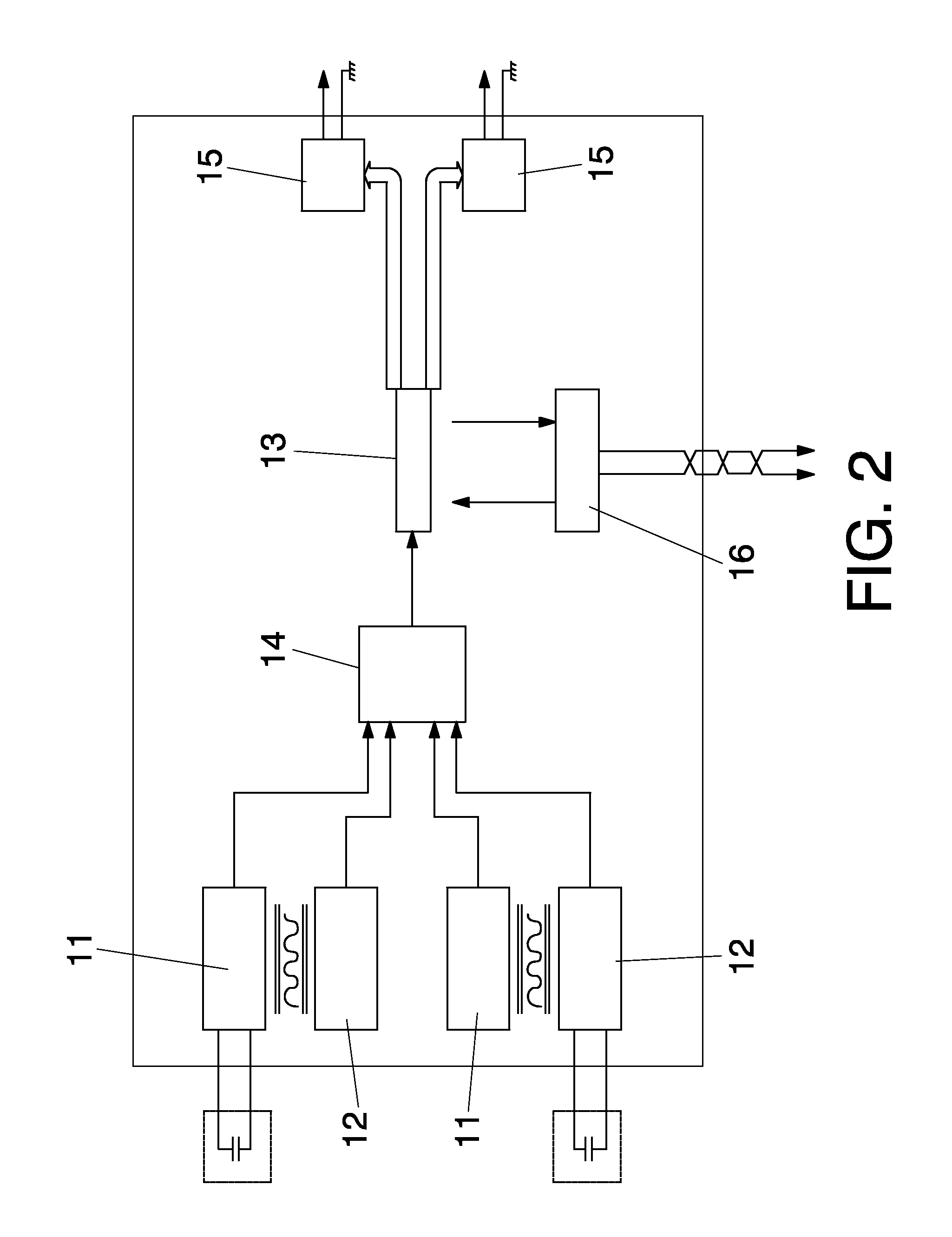

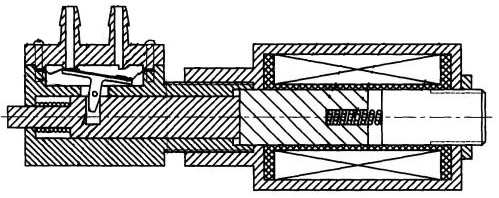

Modular pressure swing adsorption with energy recovery

InactiveUS6051050AHigh-frequency operationCompact equipmentIsotope separationRefluxProcess engineering

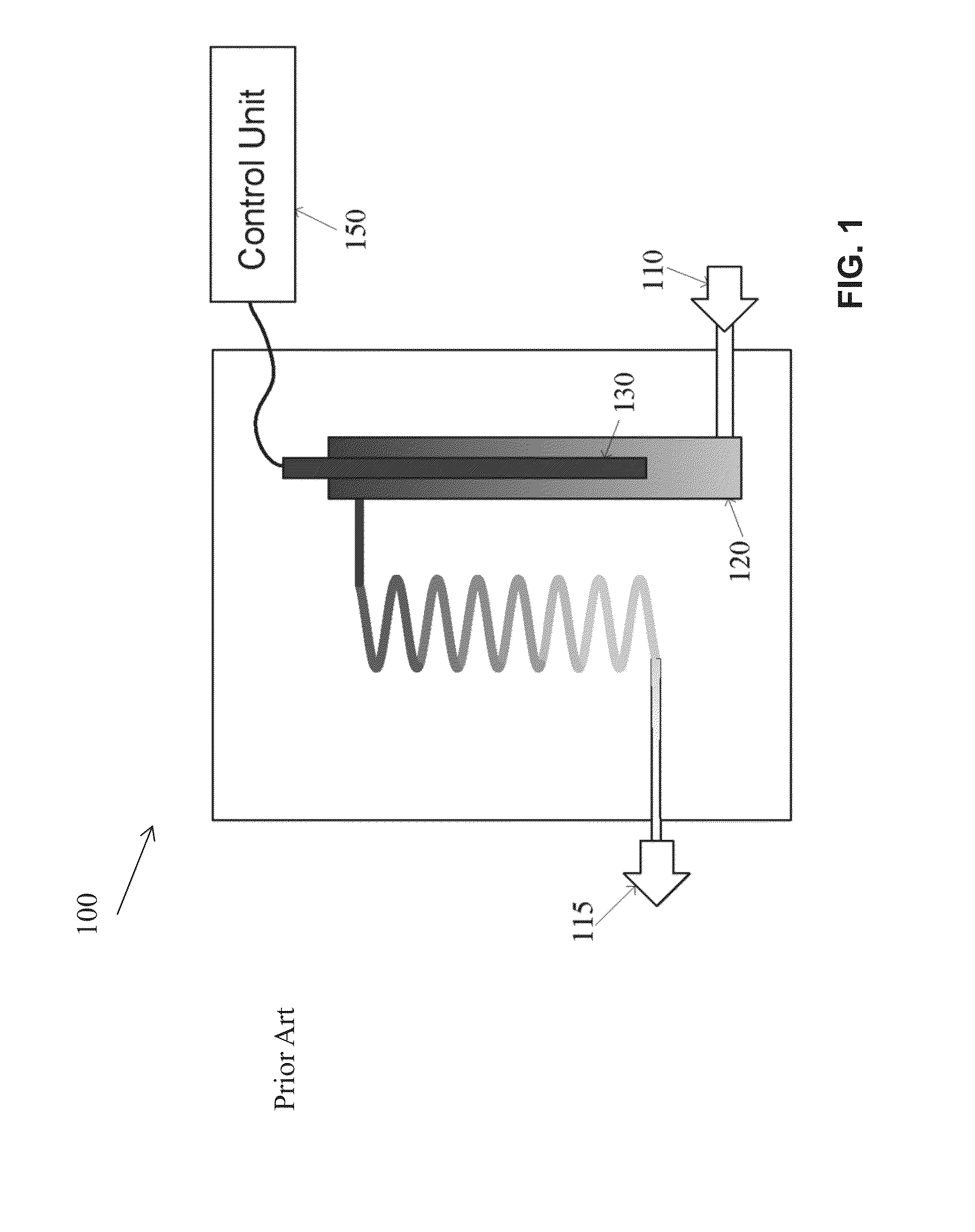

Pressure swing adsorption (PSA) separation of a feed gas mixture is performed within an apparatus having typically a single prime mover powering a feed compressor for one or multiple rotary PSA modules in parallel, each module including a rotor with a large number of angularly spaced adsorber elements, with valve surfaces between the rotor and a stator so that individual adsorber elements are opened to compartments for staged pressurization and blowdown, with thermally boosted energy recovery from staged expansion of countercurrent blowdown and light reflux gases, and a plurality of adsorber elements opened at any instant to each compartment so that each compressor and expander stage operates under substantially steady conditions of flow and pressure.

Owner:AIR PROD & CHEM INC

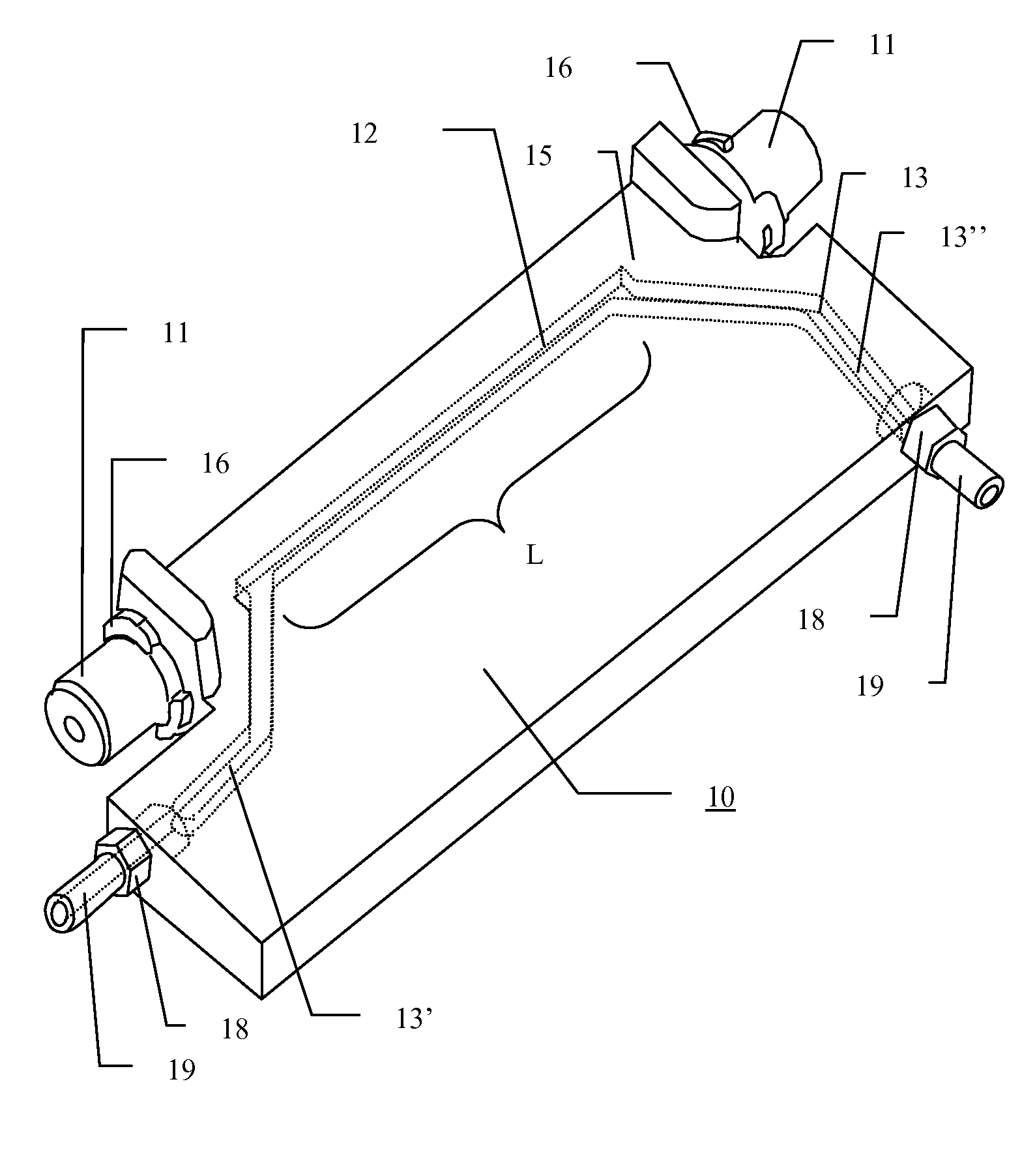

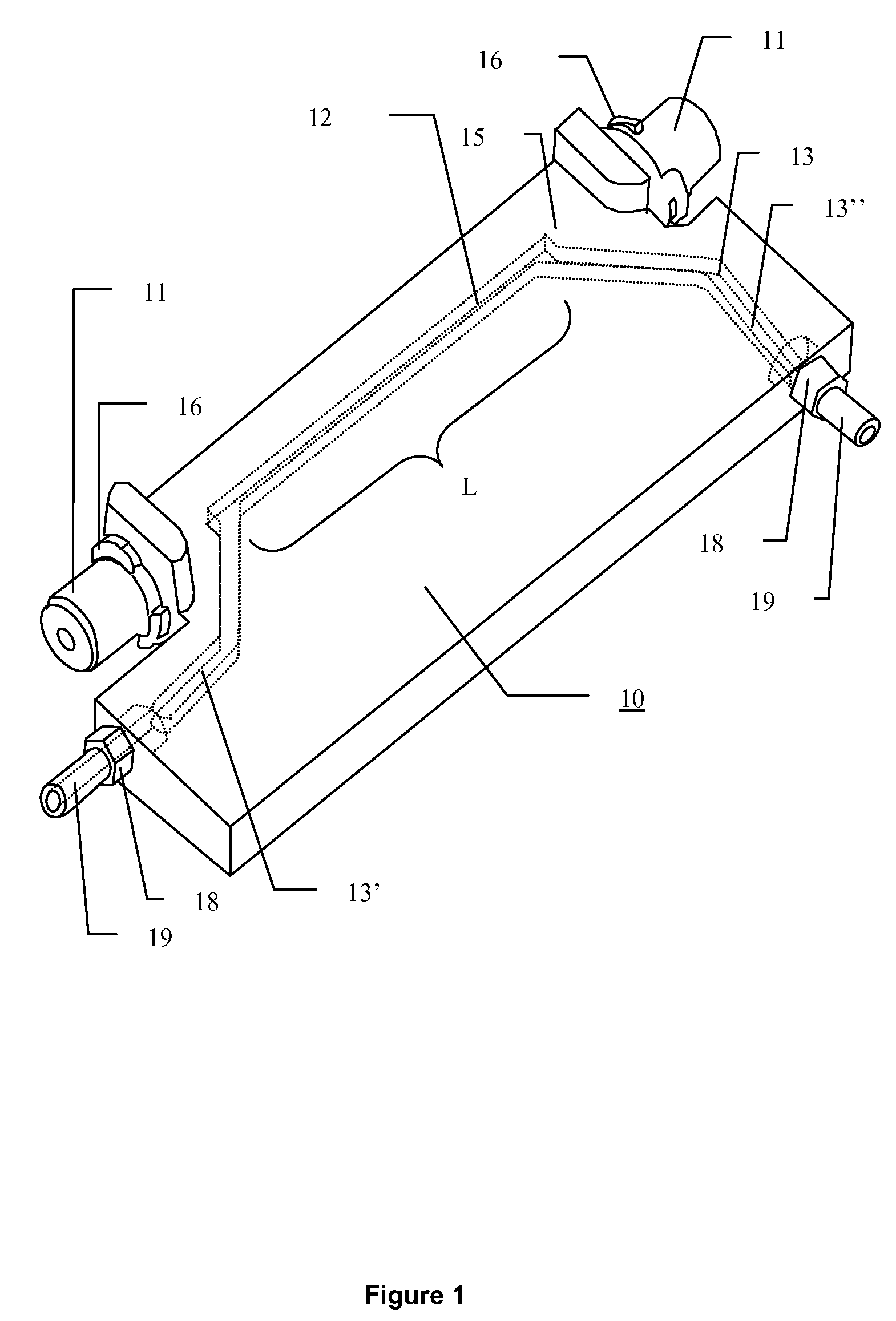

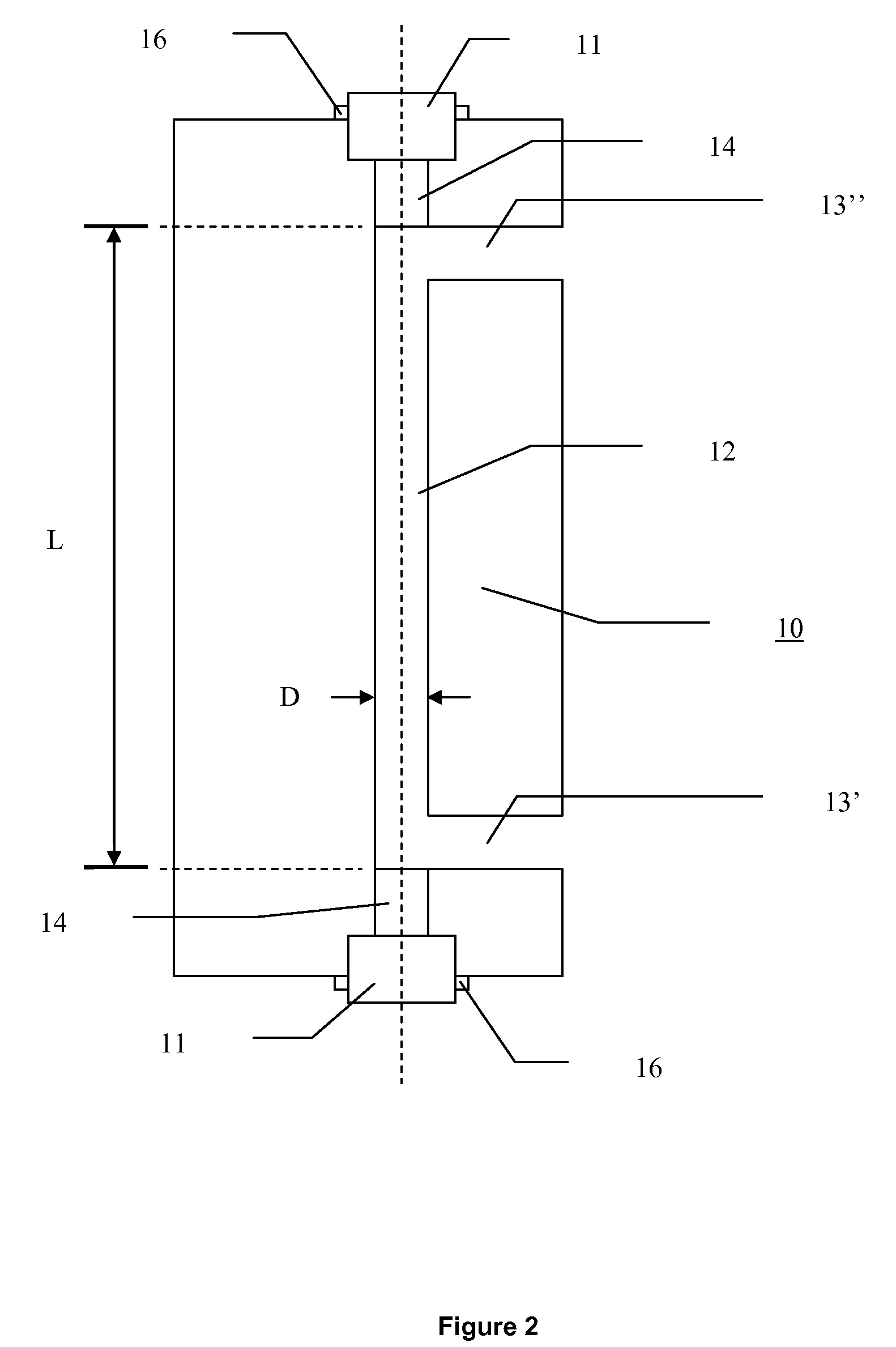

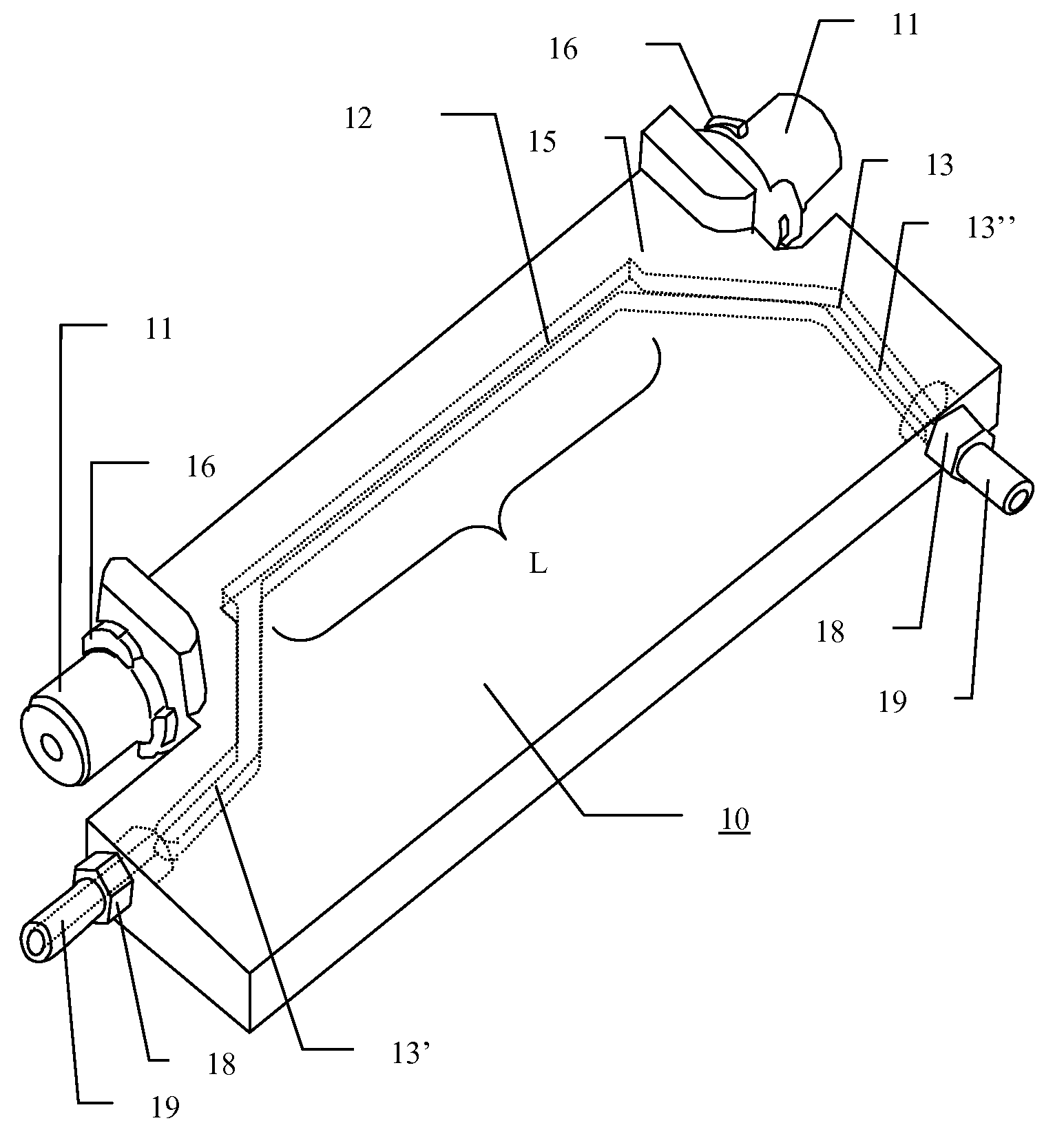

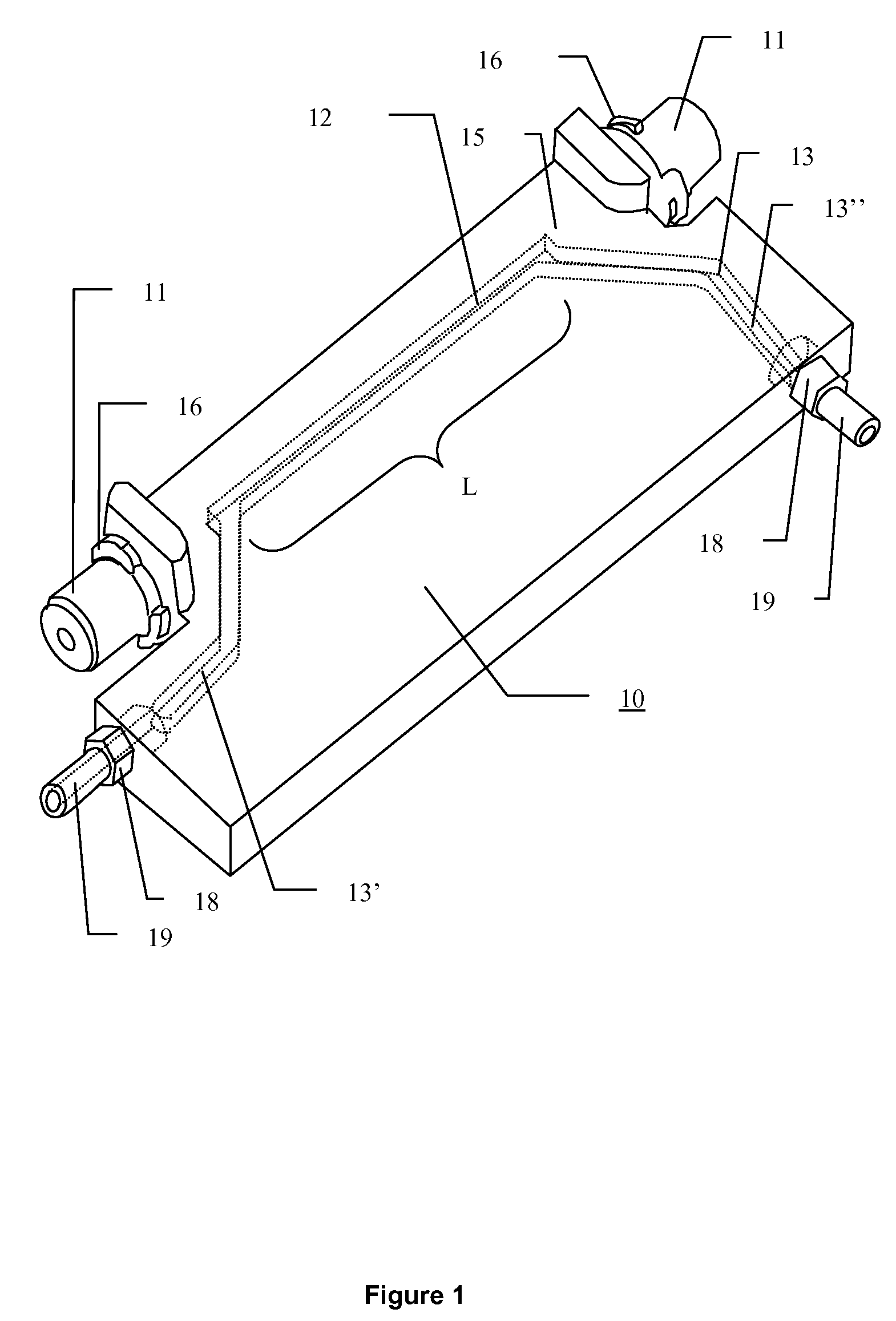

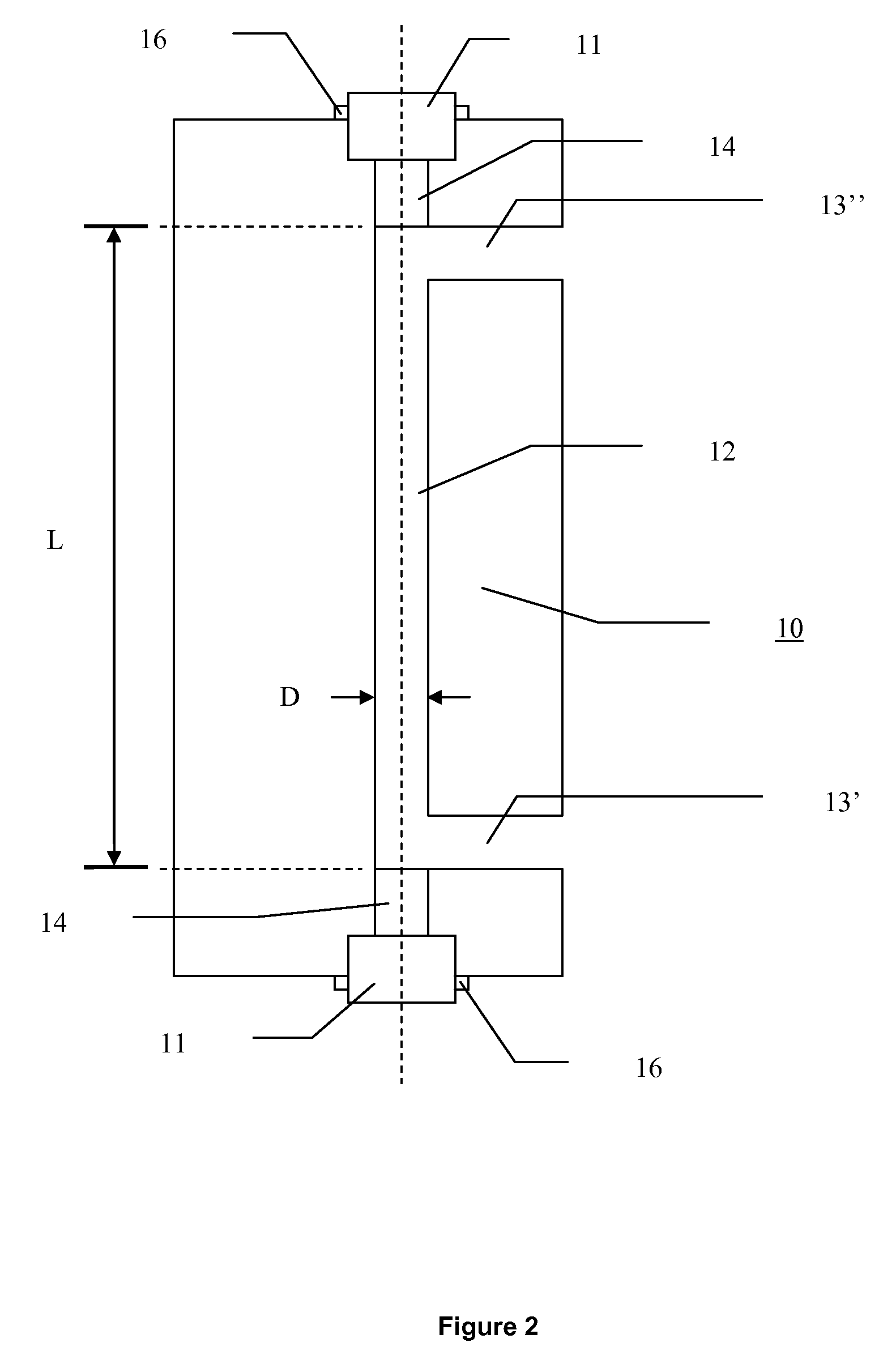

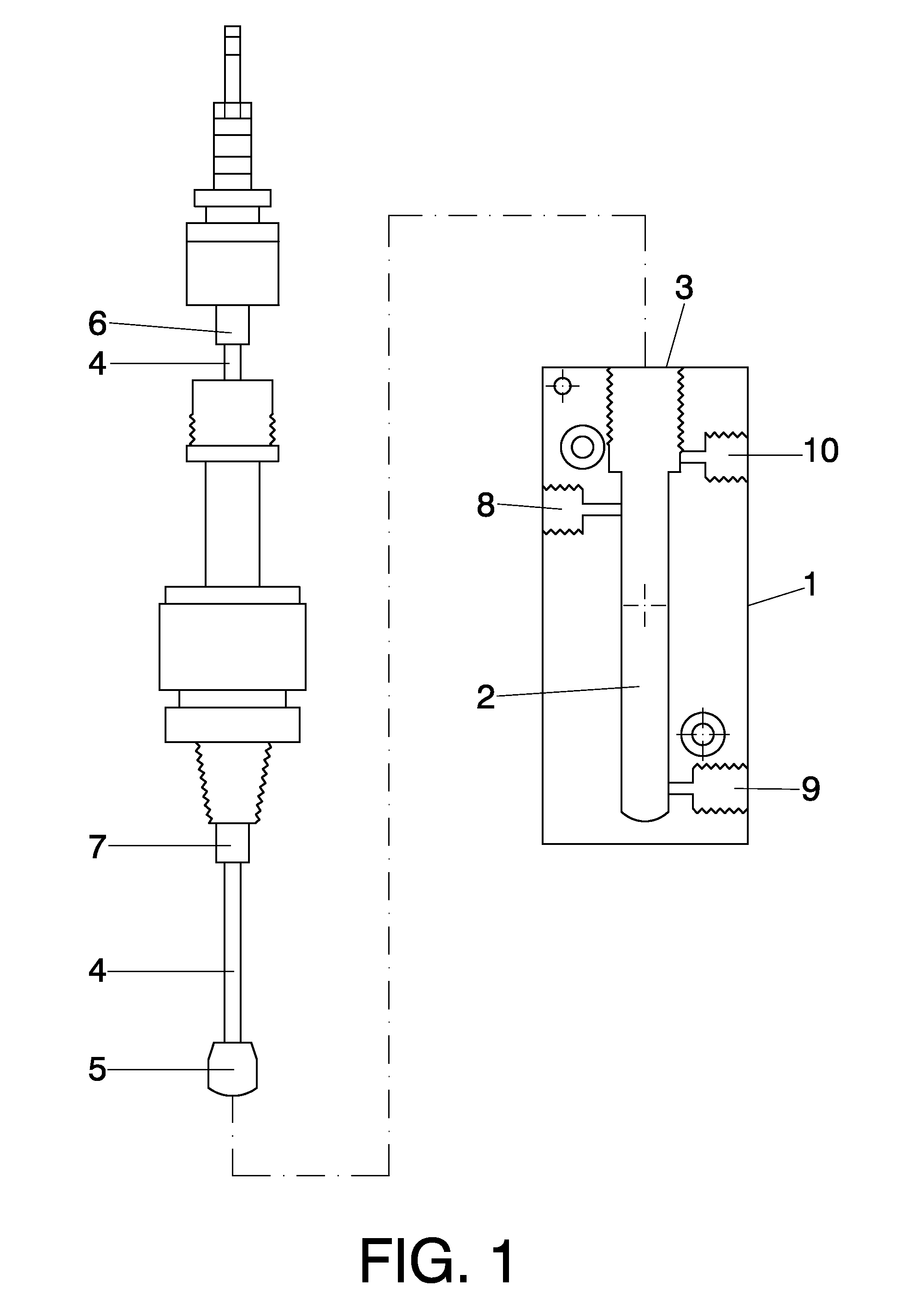

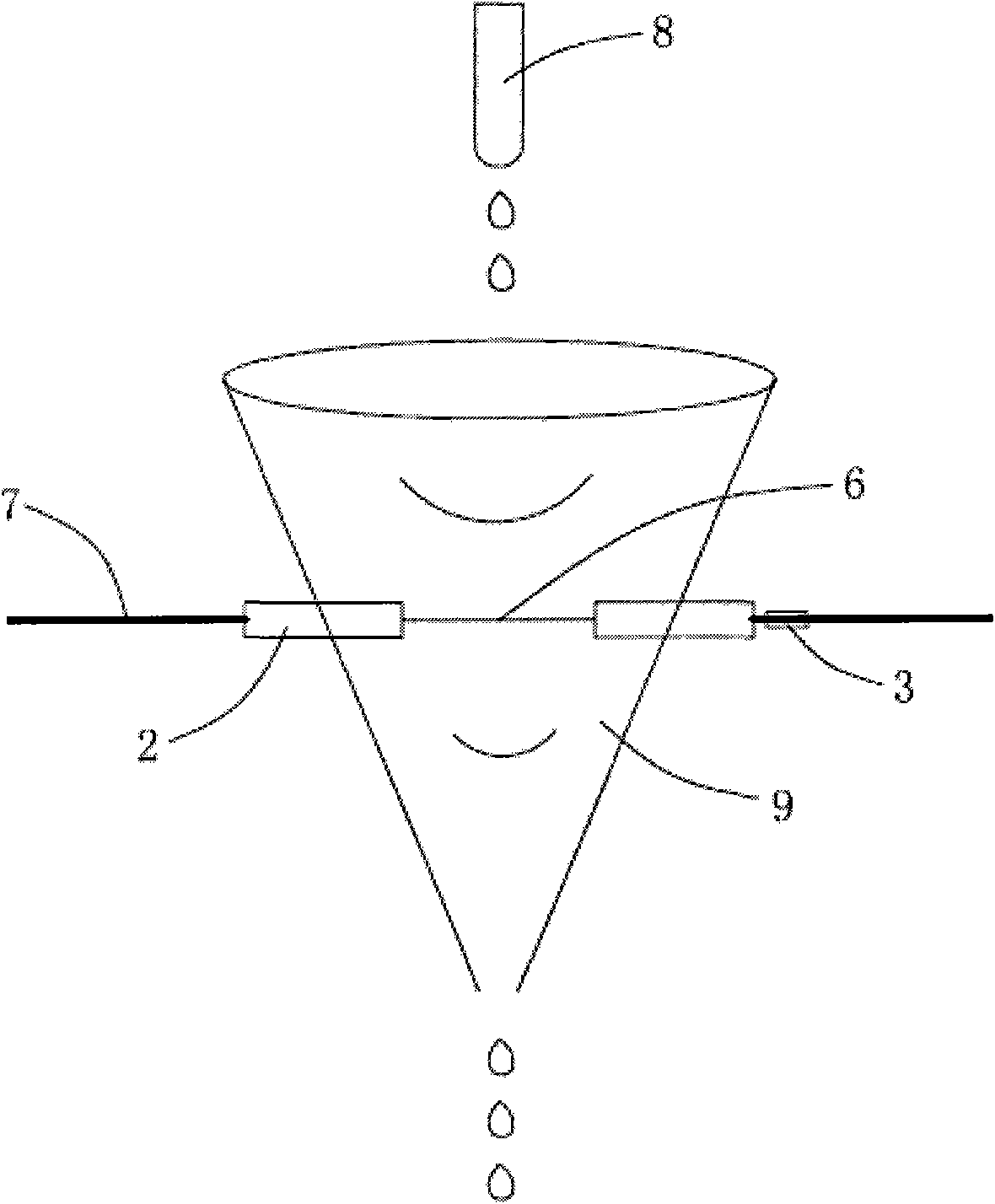

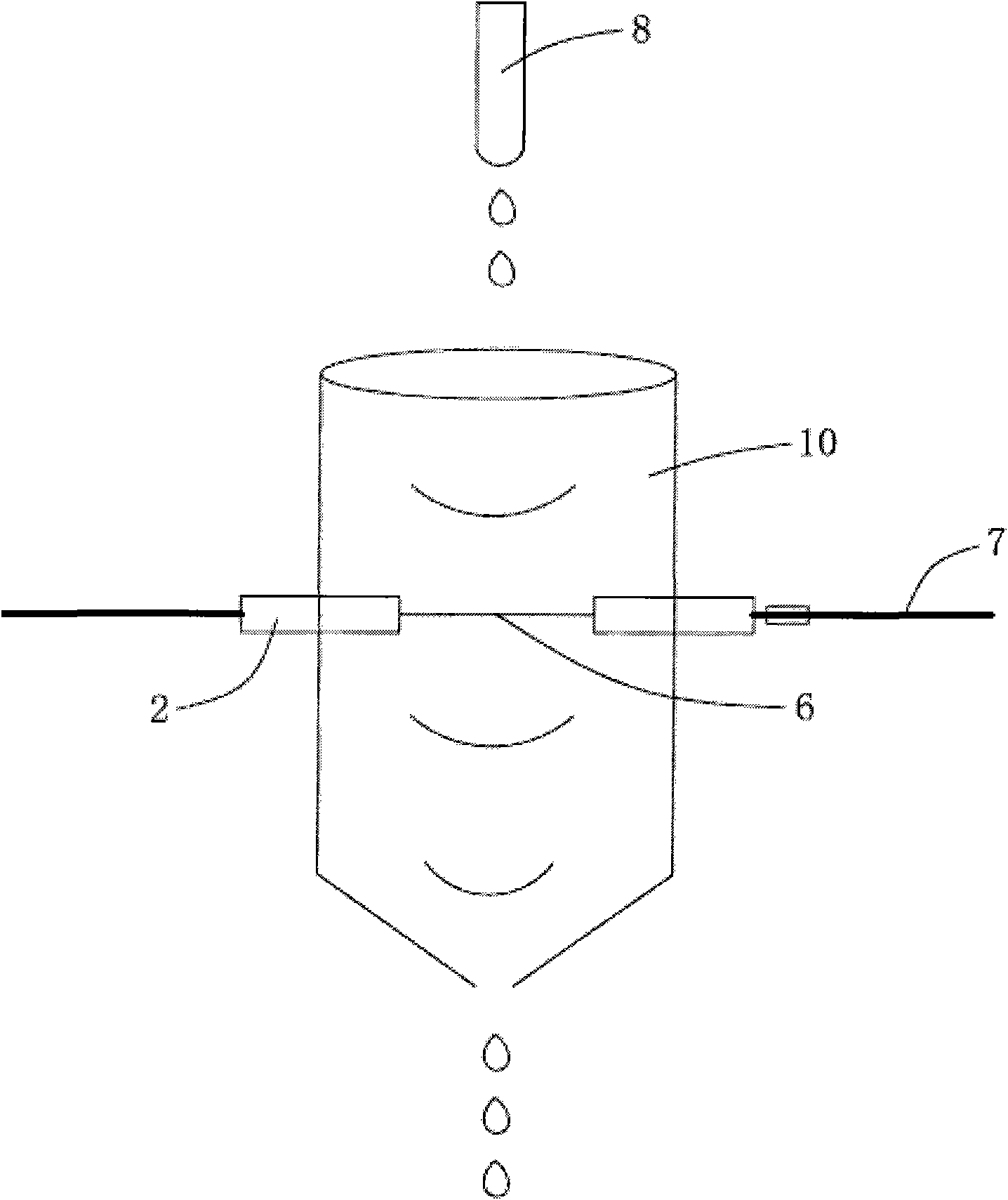

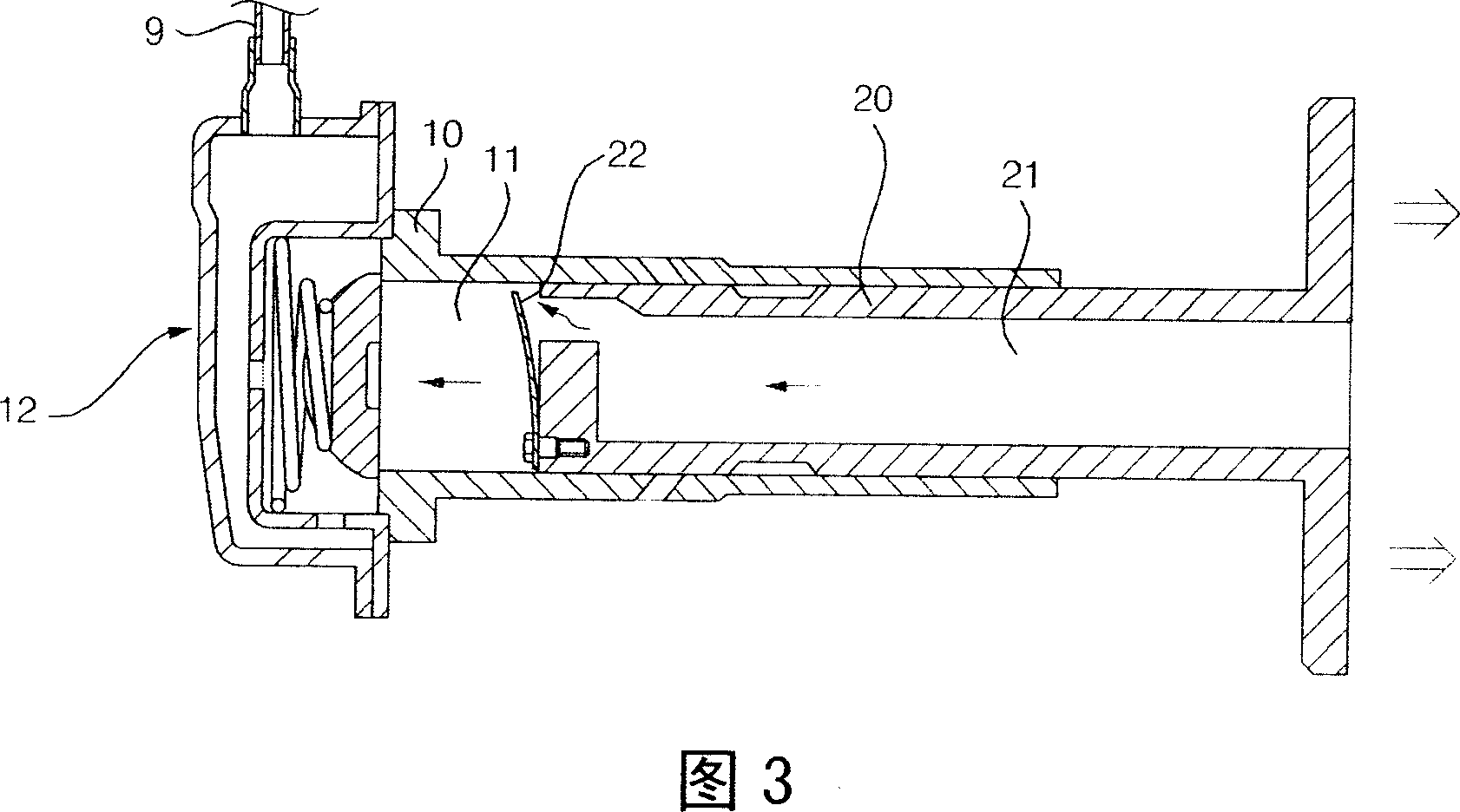

Flow cell for measuring flow rate of a fluid using ultrasonic waves

ActiveUS7673527B2Facilitate easy fastening and detachmentEasy to disassembleVolume/mass flow measurementDead animal preservationFlow cellTransducer

The invention relates to a flow cell for an ultrasonic flow meter comprising two transducers of ultrasonic waves wherein the two transducers are reversibly detachable from the flow cell. The flow cell with the transducers detached is sterilisable and is particularly suitable for use in disposable or single-use systems.

Owner:CYTIVA SWEDEN AB

Ultrasonic flow meter

ActiveUS20080196511A1Facilitate communicationEasy to disassembleVolume/mass flow measurementDead animal preservationFlow cellTransducer

The invention relates to a flow cell for an ultrasonic flow meter comprising two transducers of ultrasonic waves wherein the two transducers are reversibly detachable from the flow cell. The flow cell with the transducers detached is sterilisable and is particularly suitable for use in disposable or single-use systems.

Owner:CYTIVA SWEDEN AB

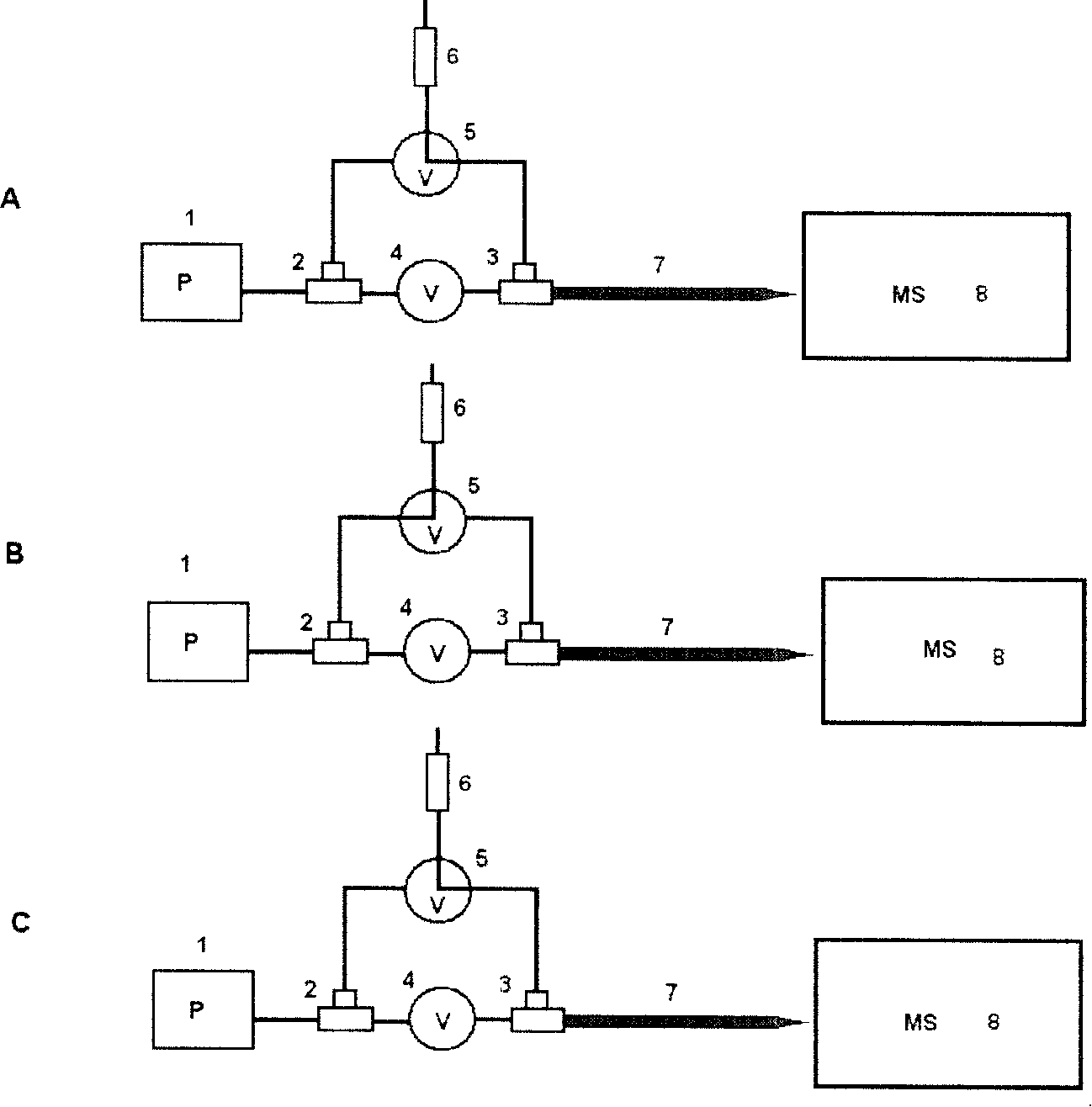

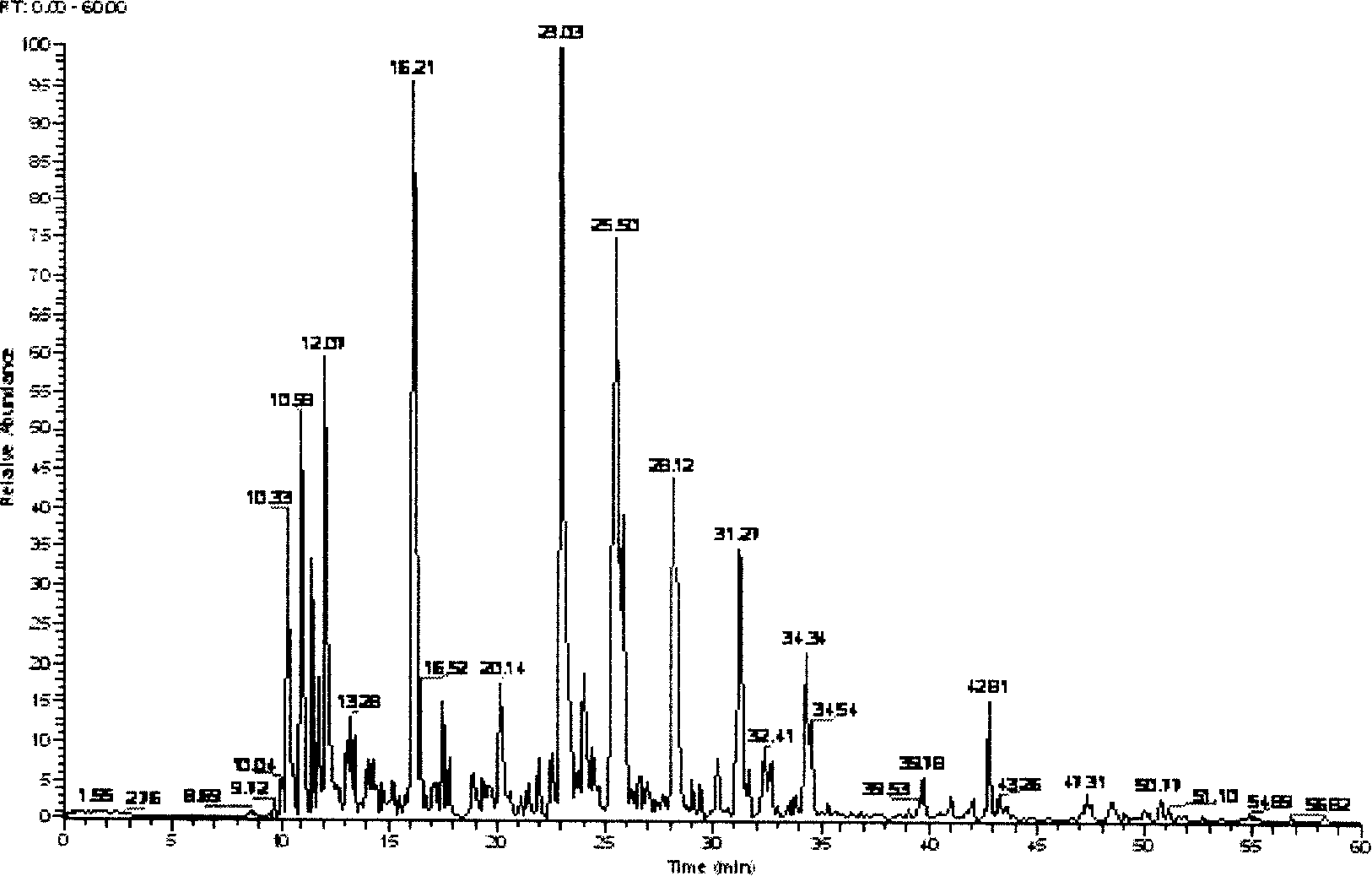

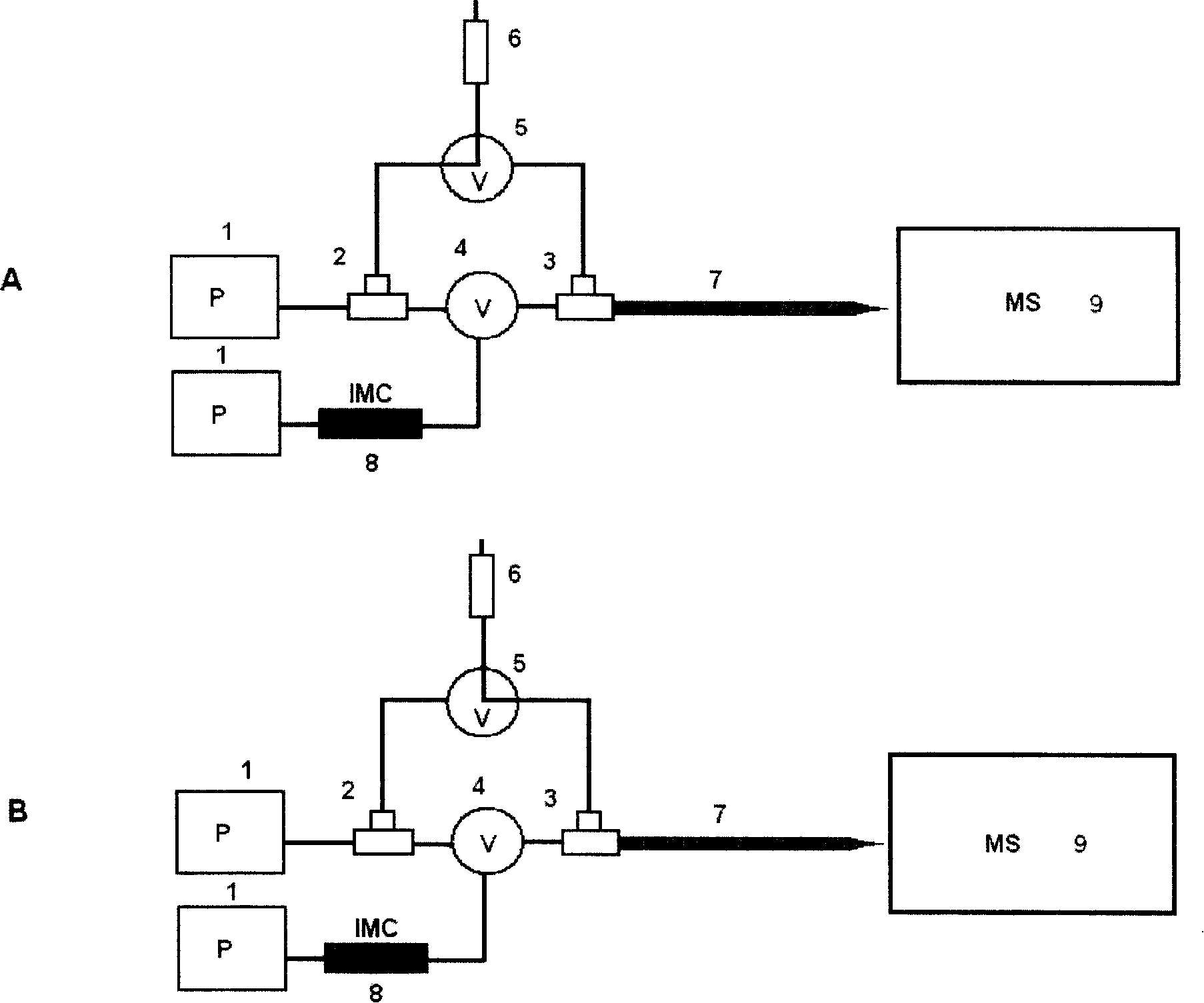

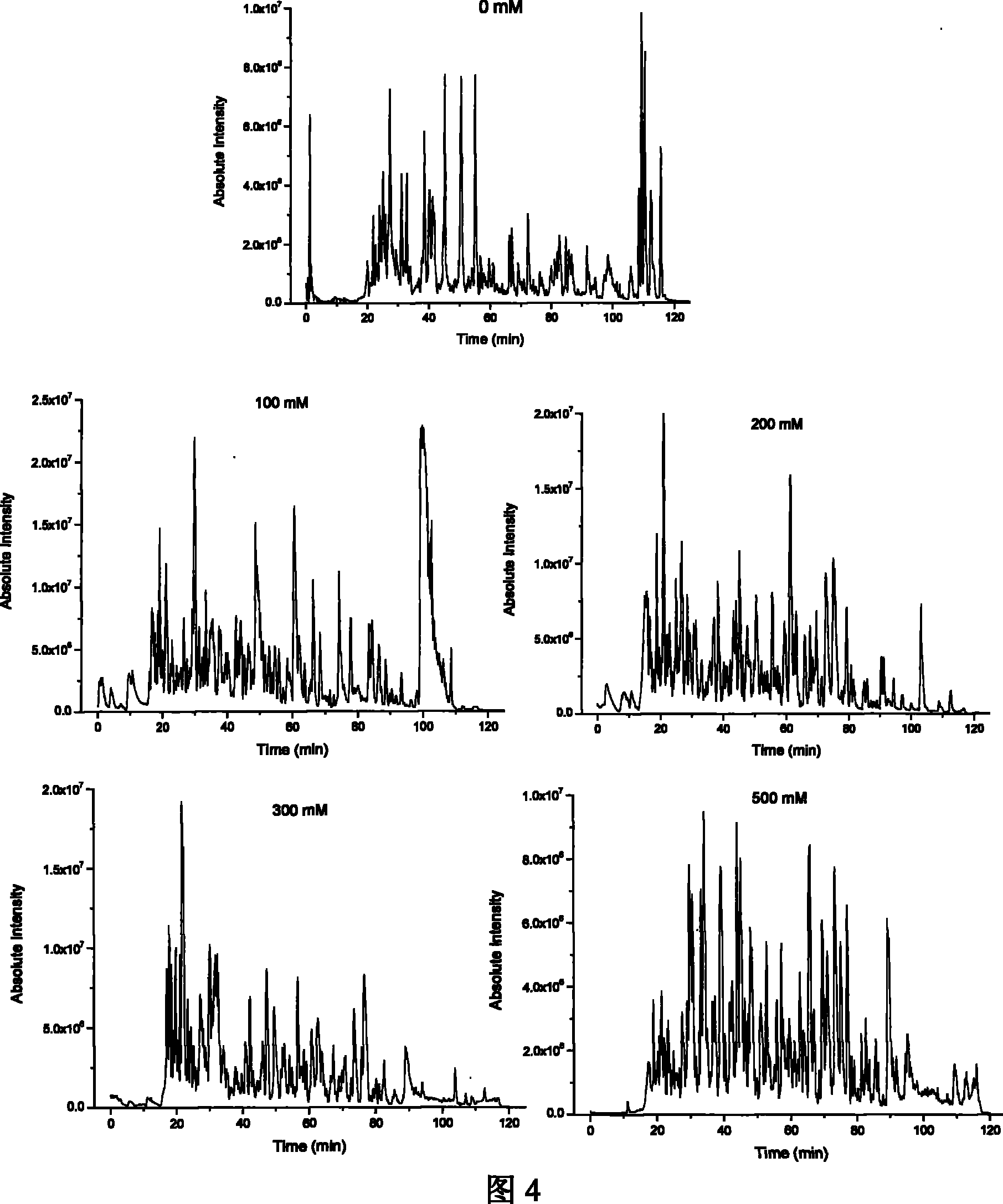

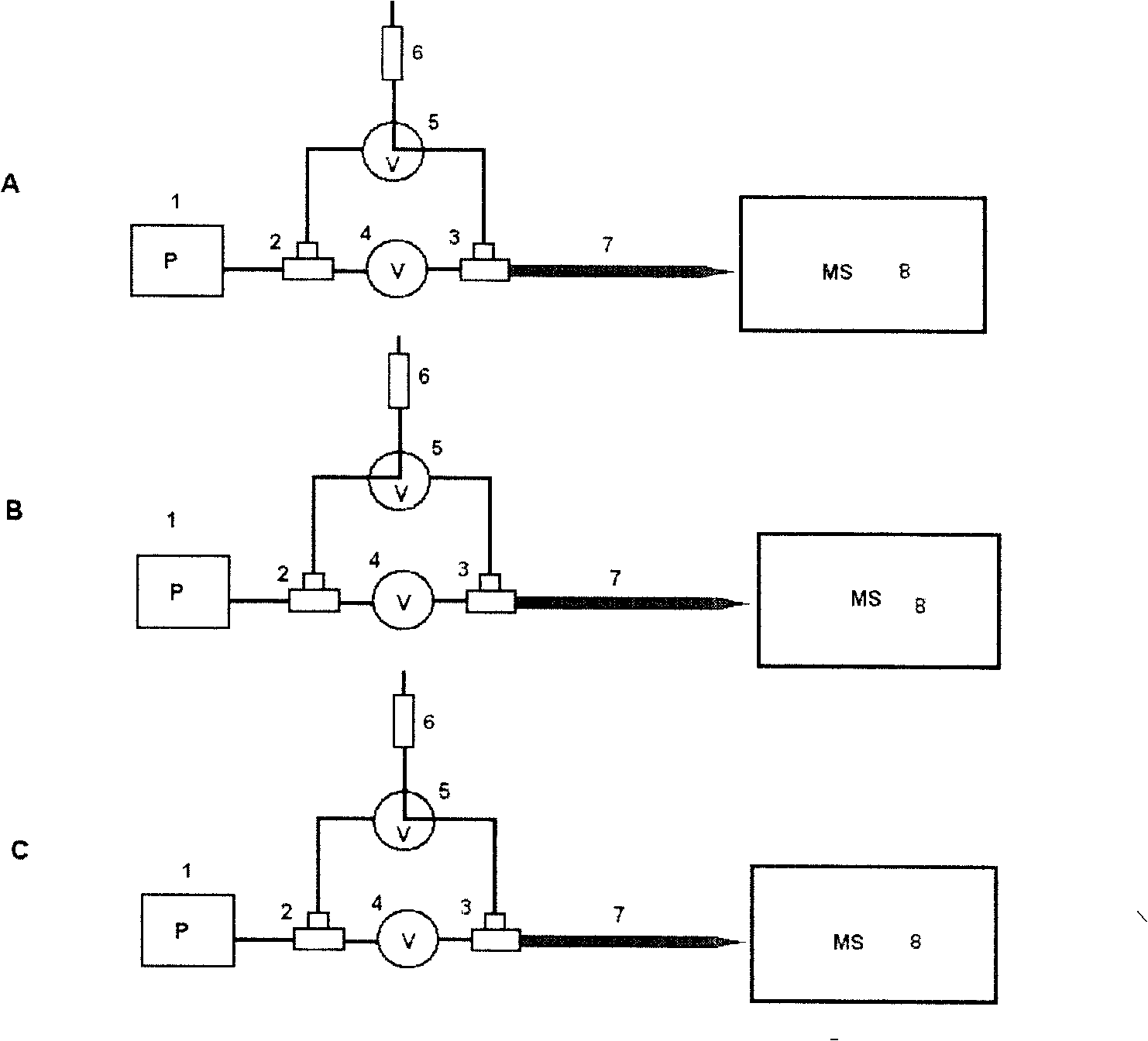

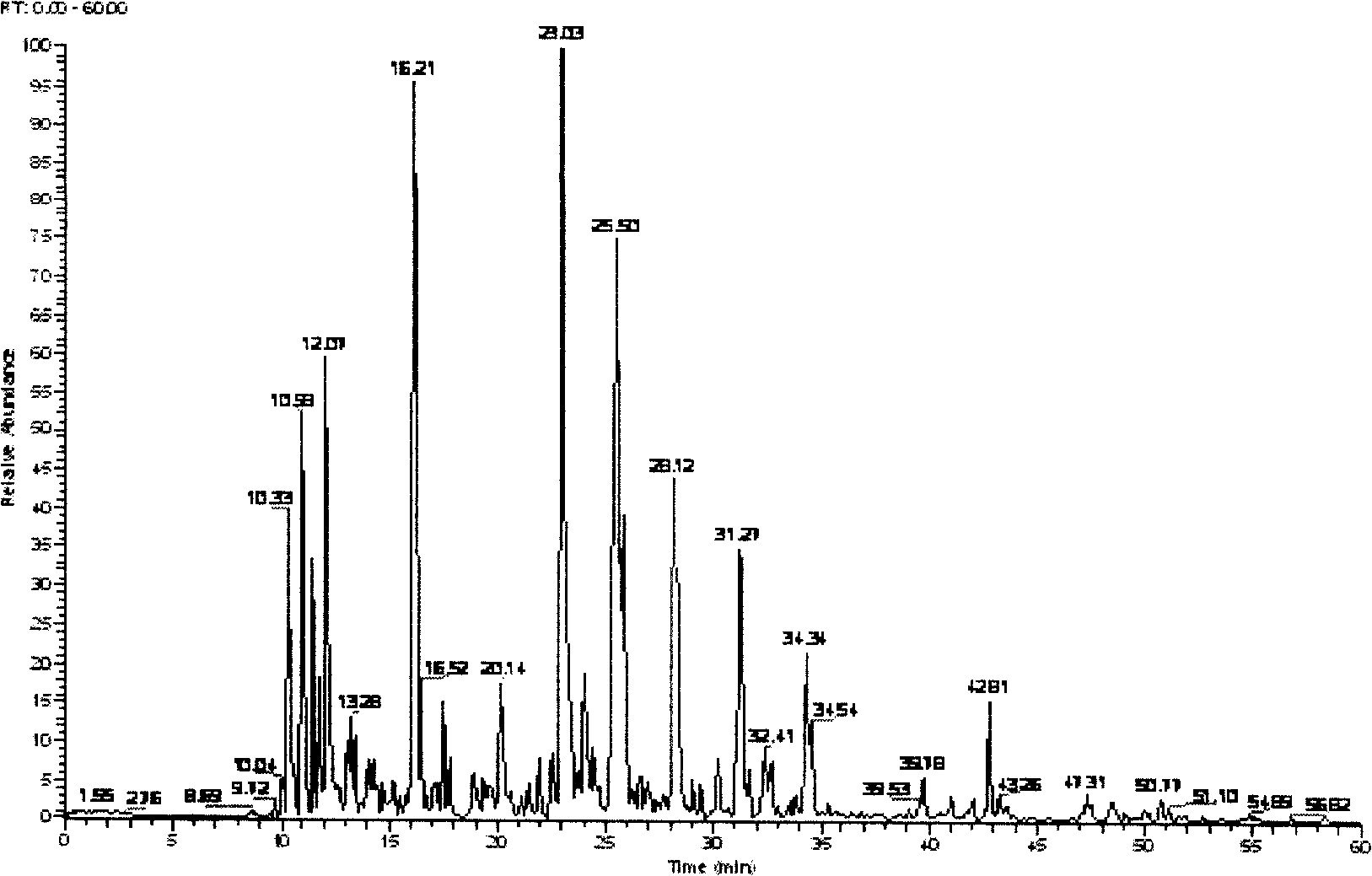

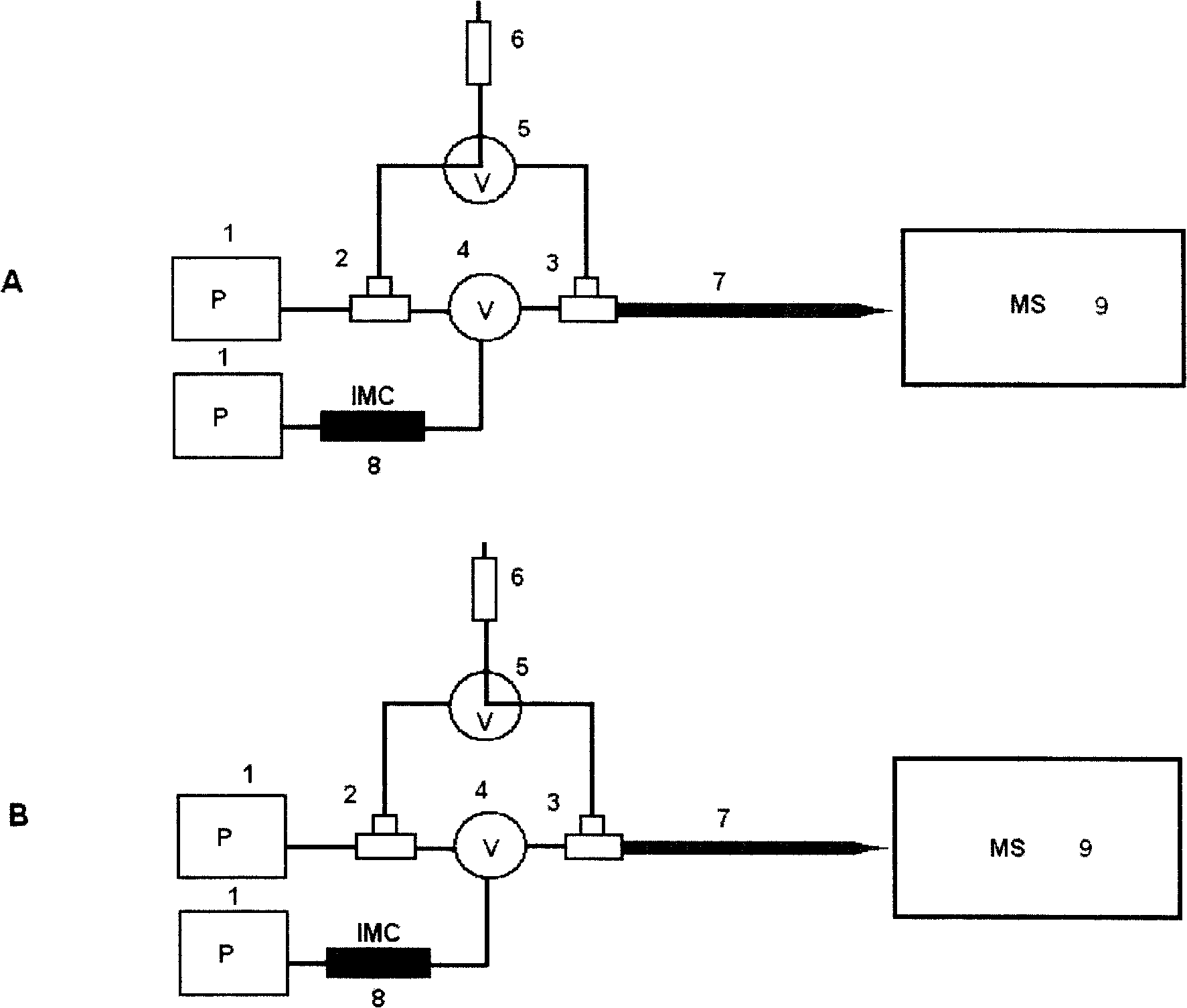

System for on-line desalinization, enrichment and mass spectrum of double split flow noy upgrade liquid chromatogram

InactiveCN101206197AEliminate dead volumeReduce the effects of ionizationComponent separationDead volumeSystem pressure

The invention relates to a double splitflow nano upgrade liquid phase chromatogram online desalting, enrichment and mass spectrum combination system which comprises a pump, a first splitter, a second splitter, a sample valve, a switching valve, a backpressure valve, a capillary tube separation column and a mass spectrometer, wherein, the pump, the first splitter, the sample valve, the second splitter, the capillary tube separation column and the mass spectrometer are connected in series in turn through pipelines; the split ports of the first splitter and the second splitter are respectively connected with the two inlets of the switching valve through the pipelines; moreover, the outlet of the switching valve is connected in series with the backpressure valve and then is communicated with a waste fluid pool through the pipeline. The system has the advantages that: during the sampling and separation of sample, the system has less pressure fluctuation; with small pre-column dead volume, the system overcomes the gradient delay effect caused by large-volume sampling adopted in the prior nano upgrade liquid phase separation system; with excellent separation repeatability, the system is particularly suitable for gradient separation; meanwhile, the system can be used in online desalting, enrichment and mass spectrum combination of sample with high salinity and low concentration; moreover, the system has a simple structure, convenient operation and easily realized automation.

Owner:徐州脉析医疗技术有限公司

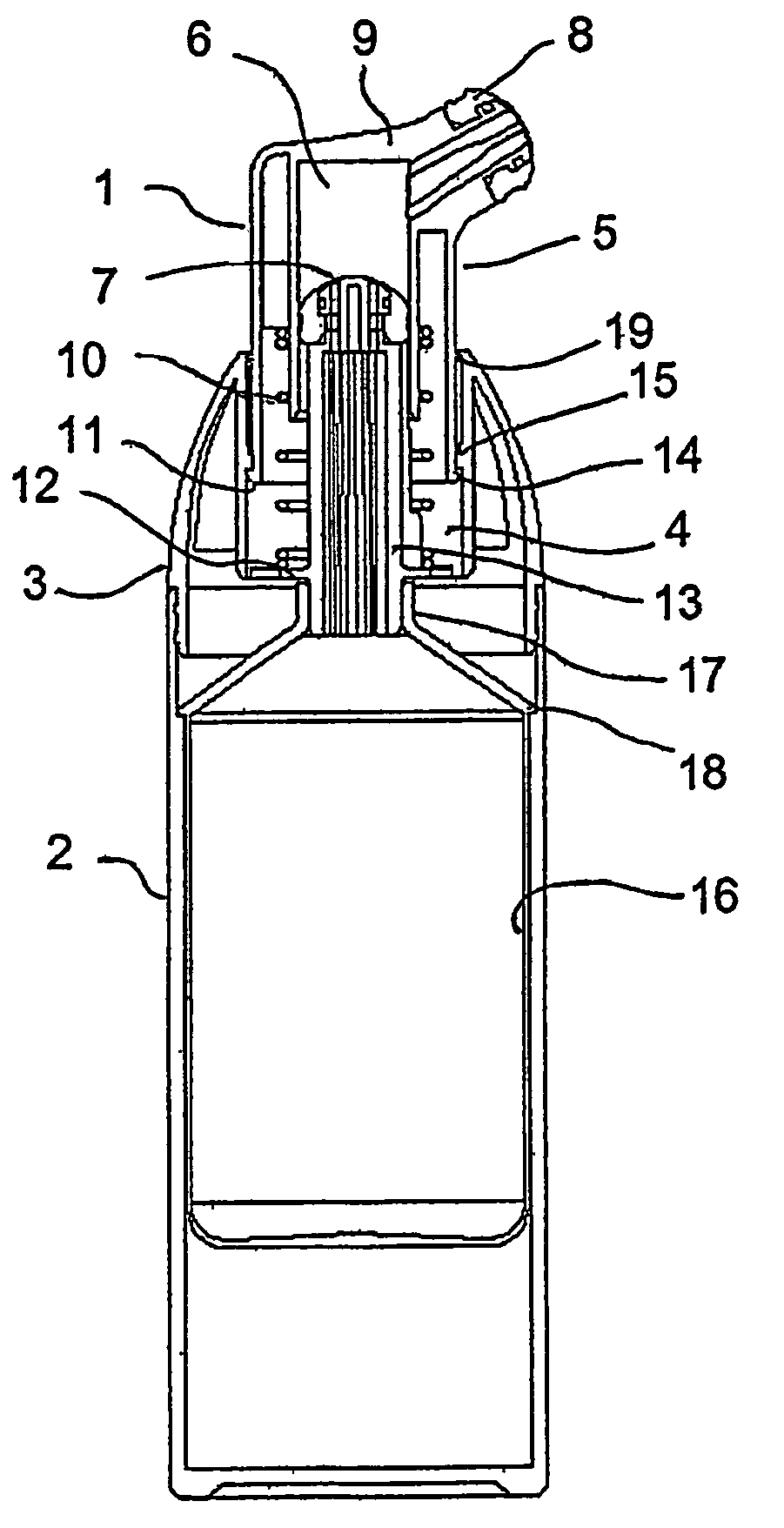

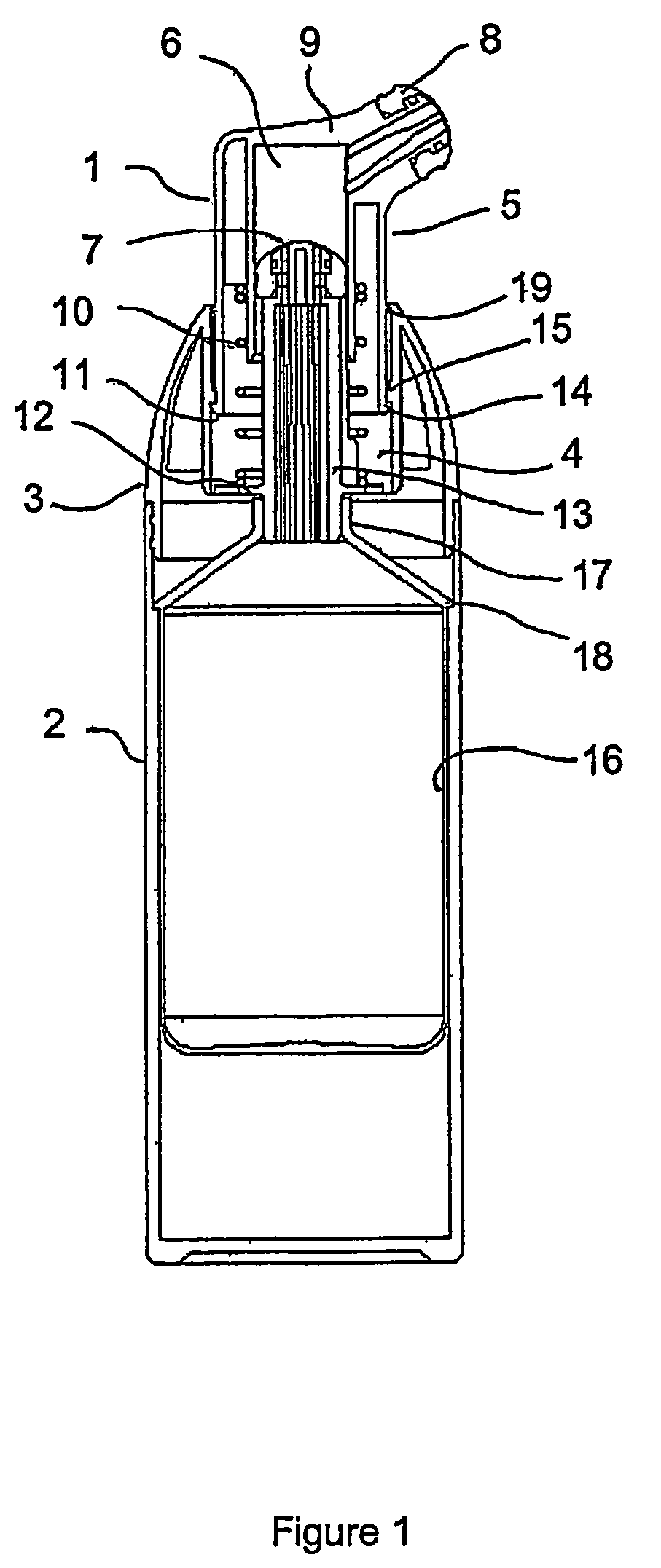

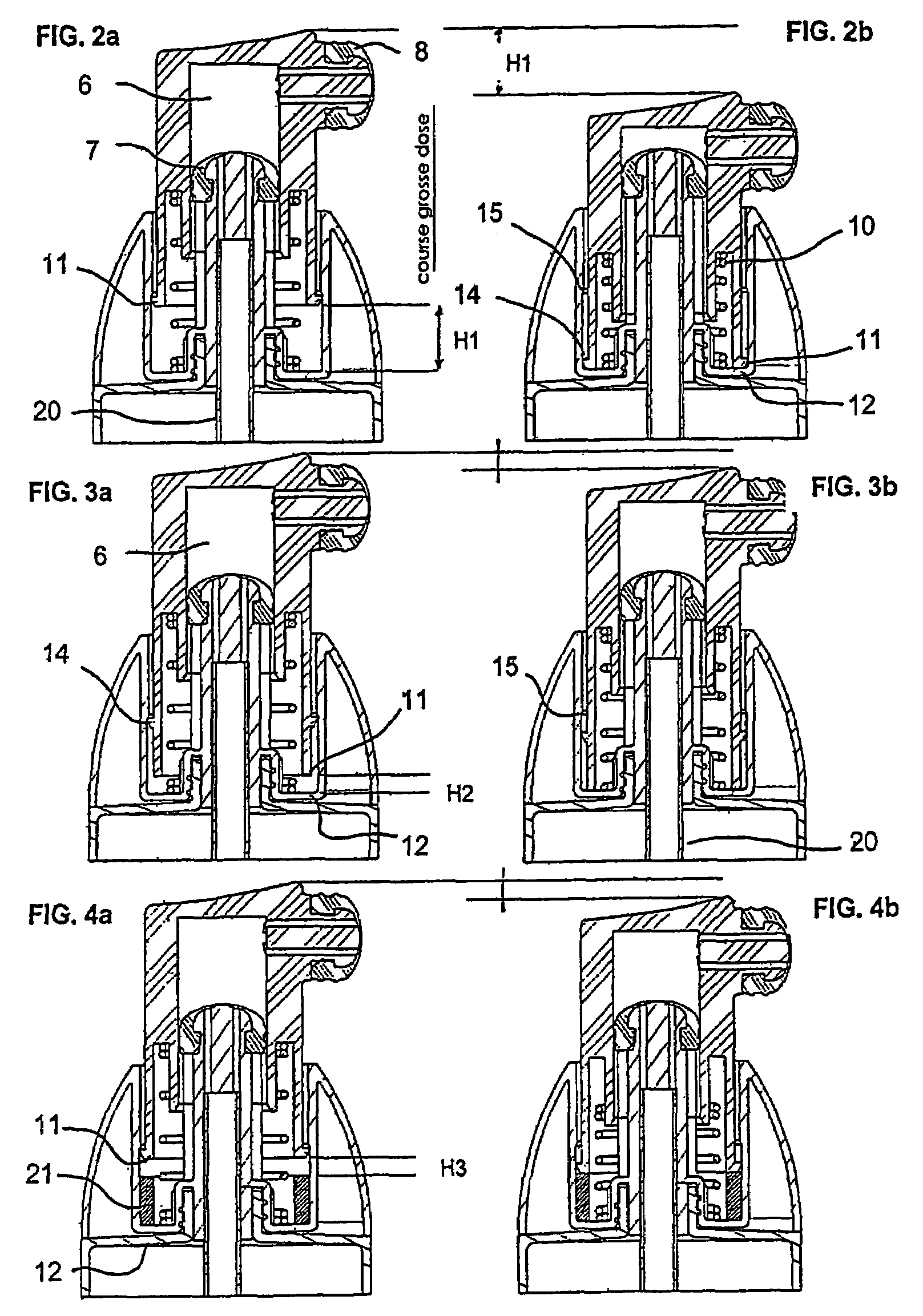

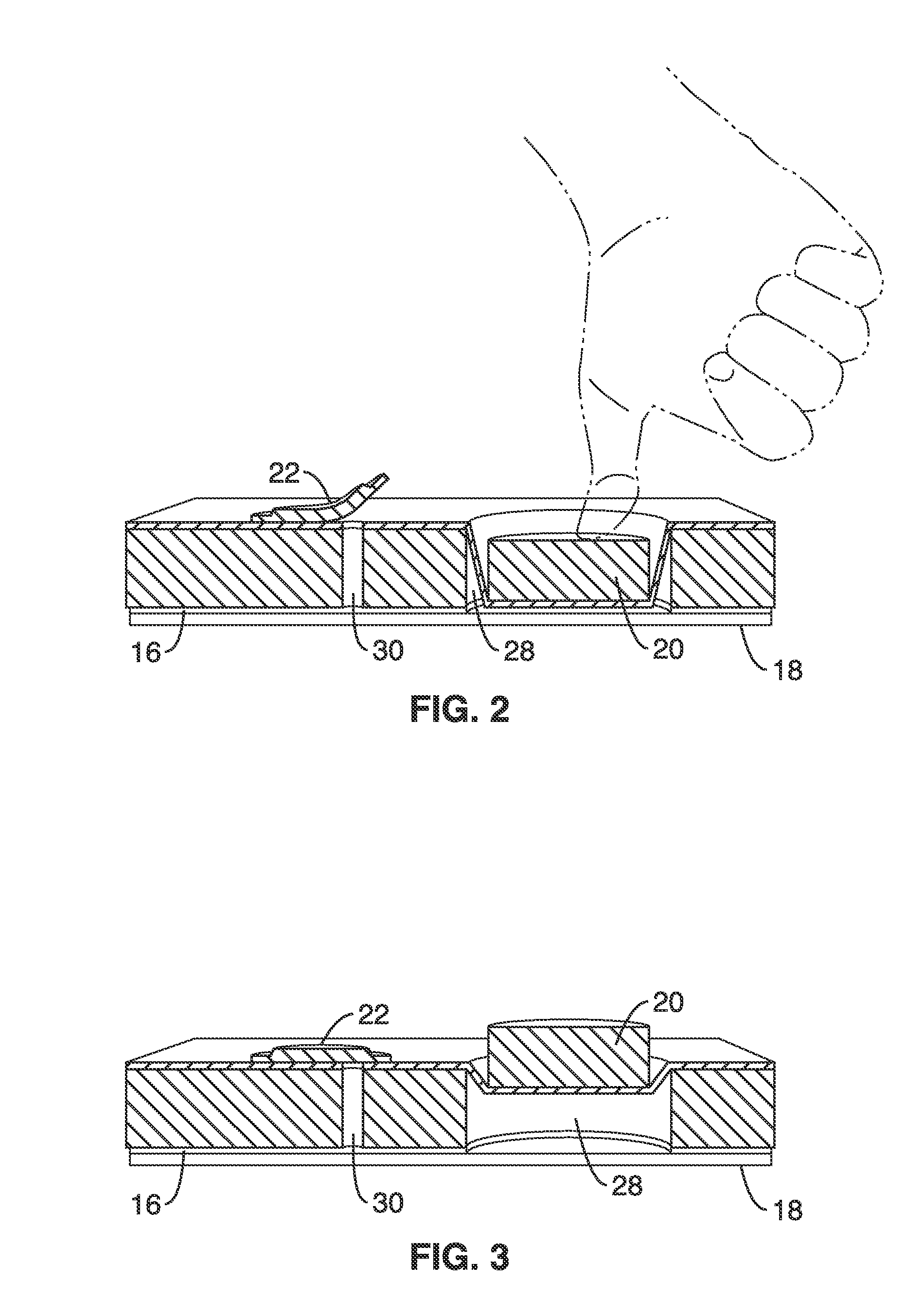

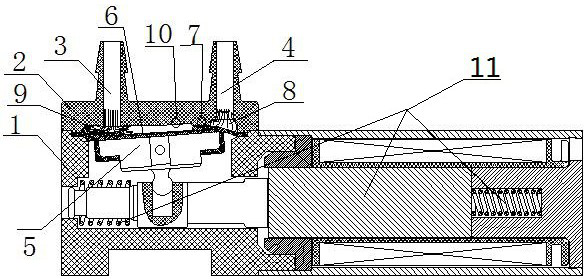

Manually-actuated metering pump

ActiveUS7481336B2Reduce the numberEliminate dead volumeLarge containersLiquid transferring devicesInlet valveEngineering

The invention relates to a manually-actuated metering pump of simple design, which is intended for a rigid container. The inventive metering pump is of the dual valve type, comprising a lower inlet valve and an upper ejection valve which are disposed at the input and output respectively of a metering chamber which is slidably mounted on the lower valve. Moreover, said lower valve is fixed to a hollow tube which communicates with the inside of the container. The invention can be used for dispensing fluid products.

Owner:LABLABO SRL

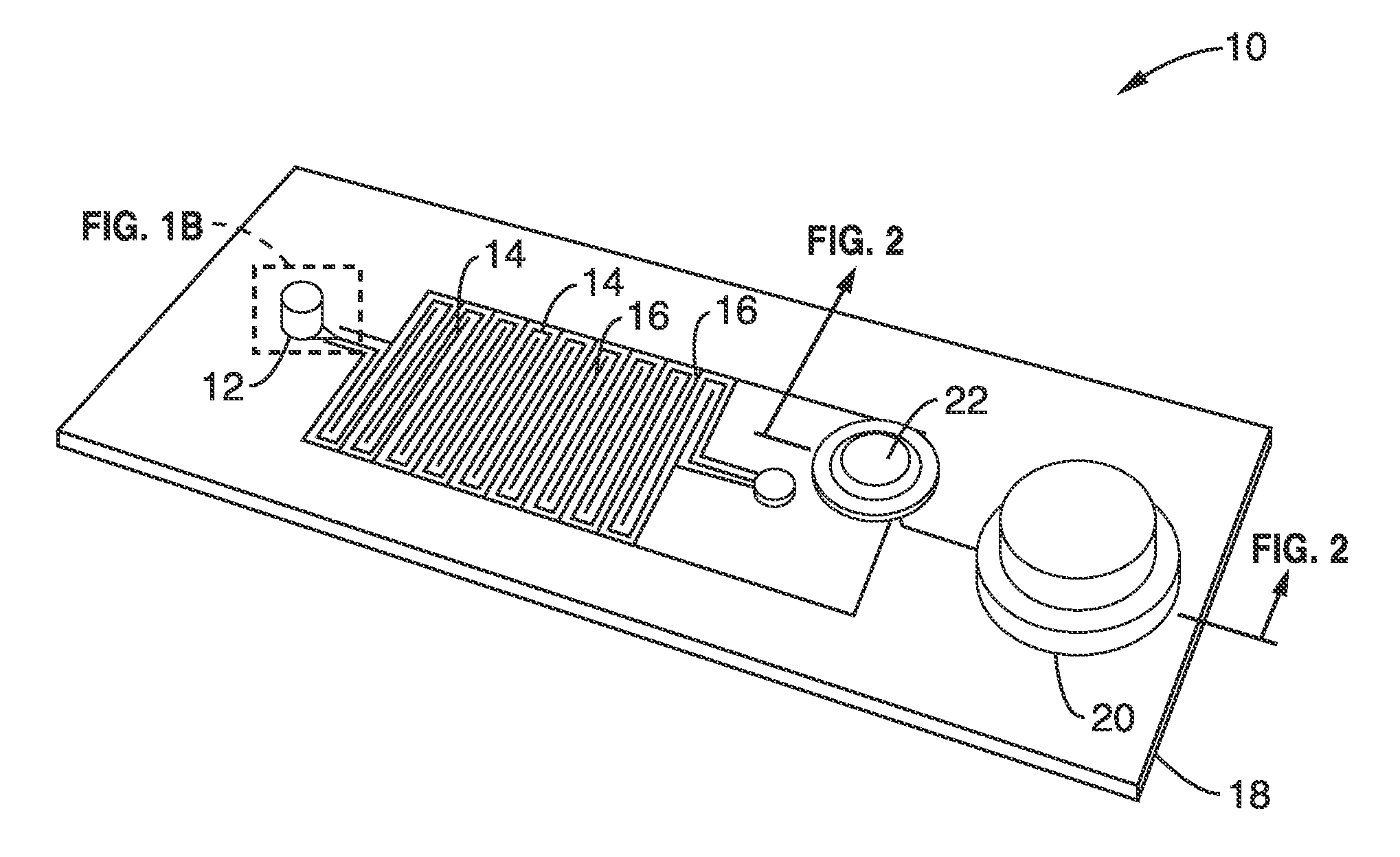

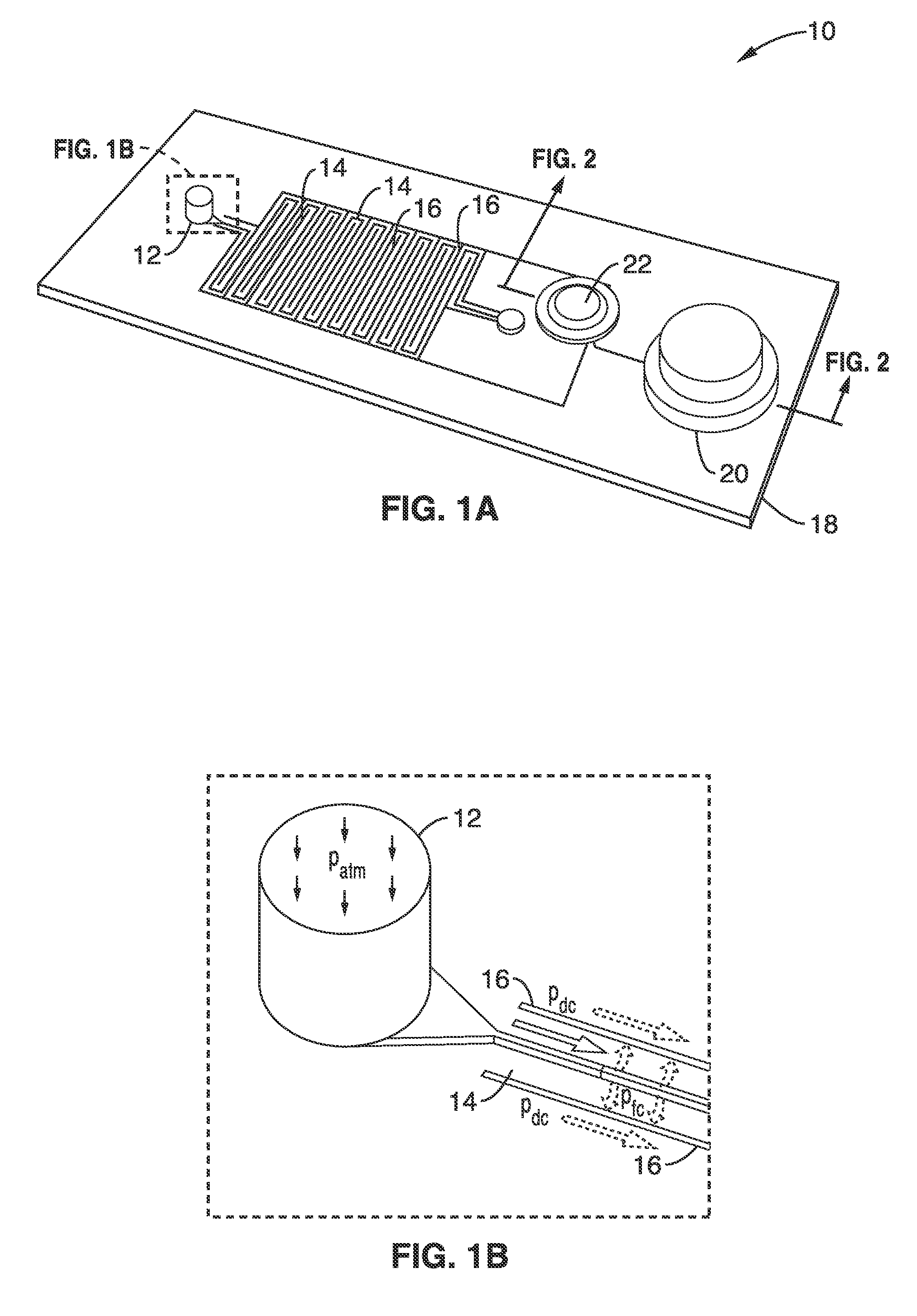

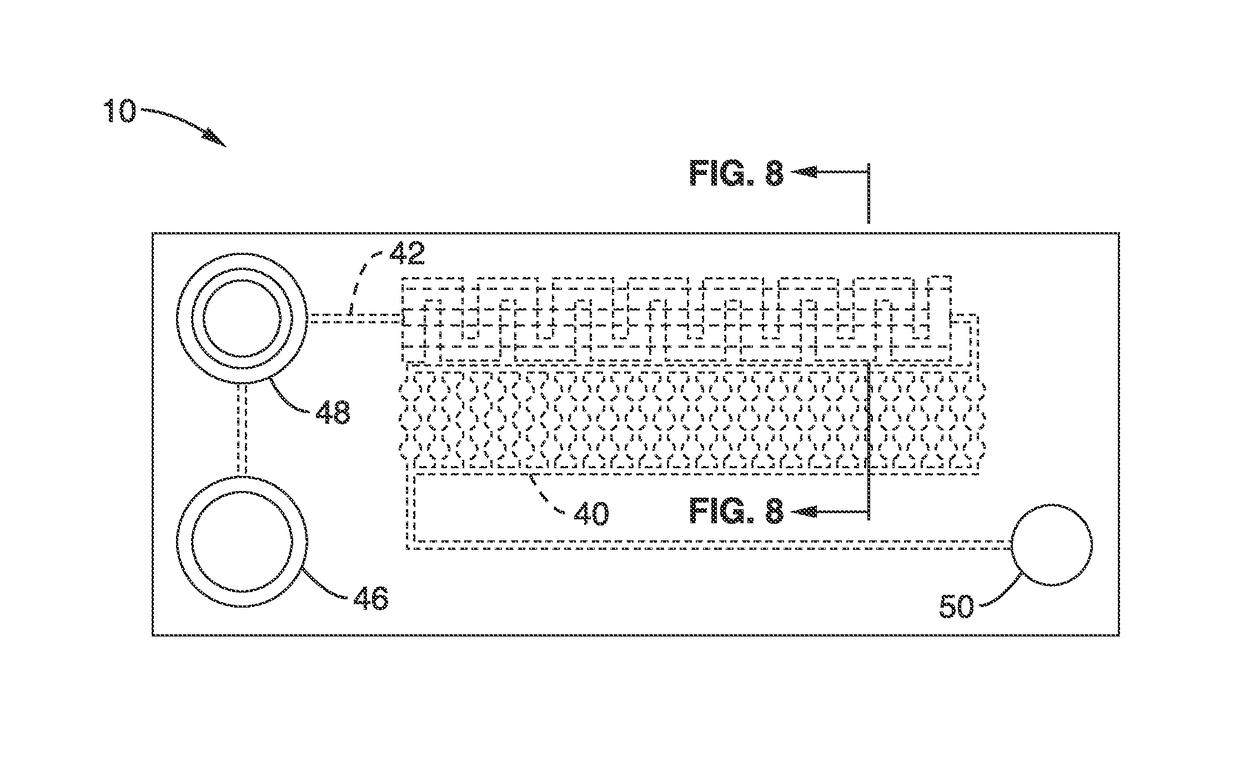

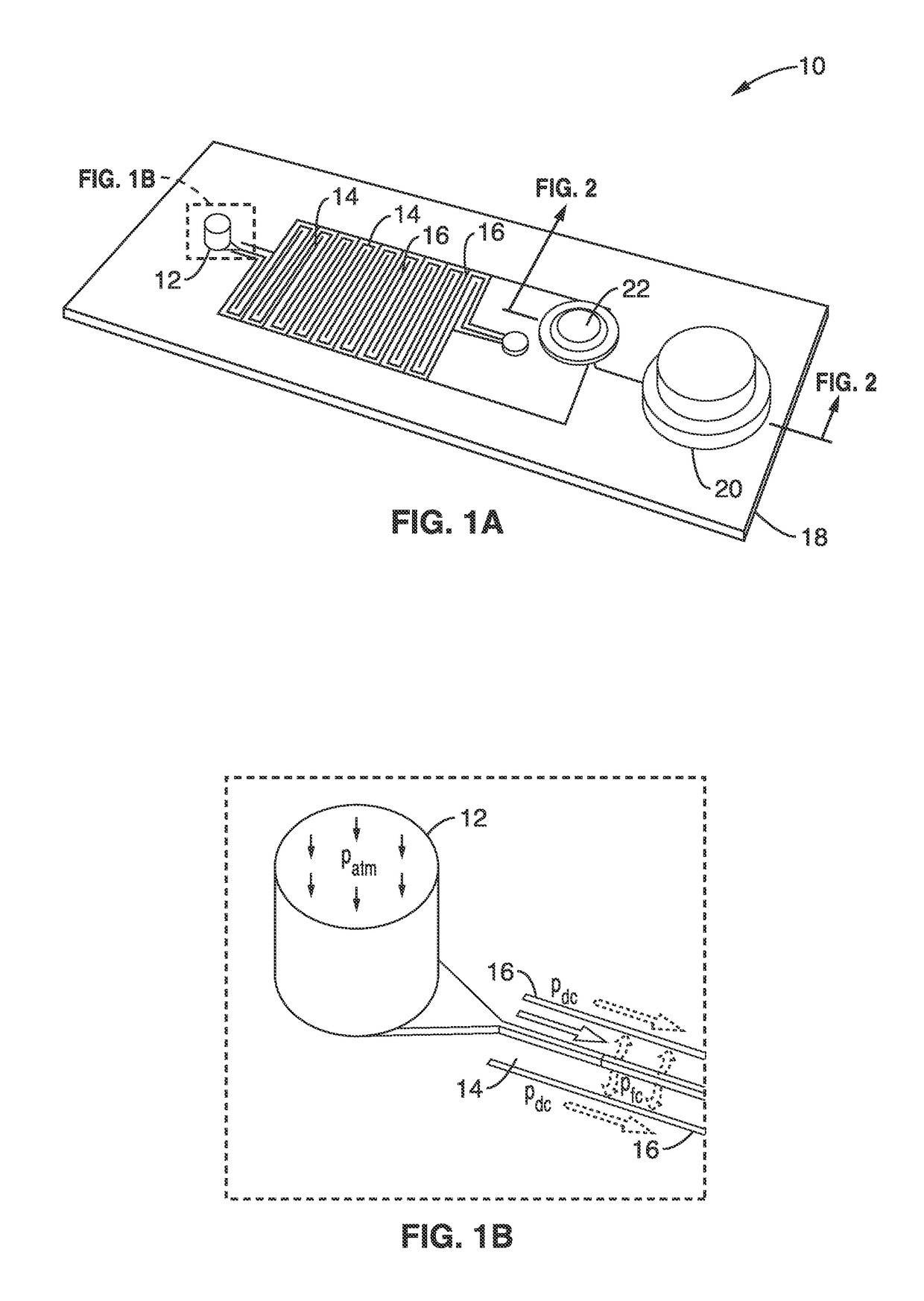

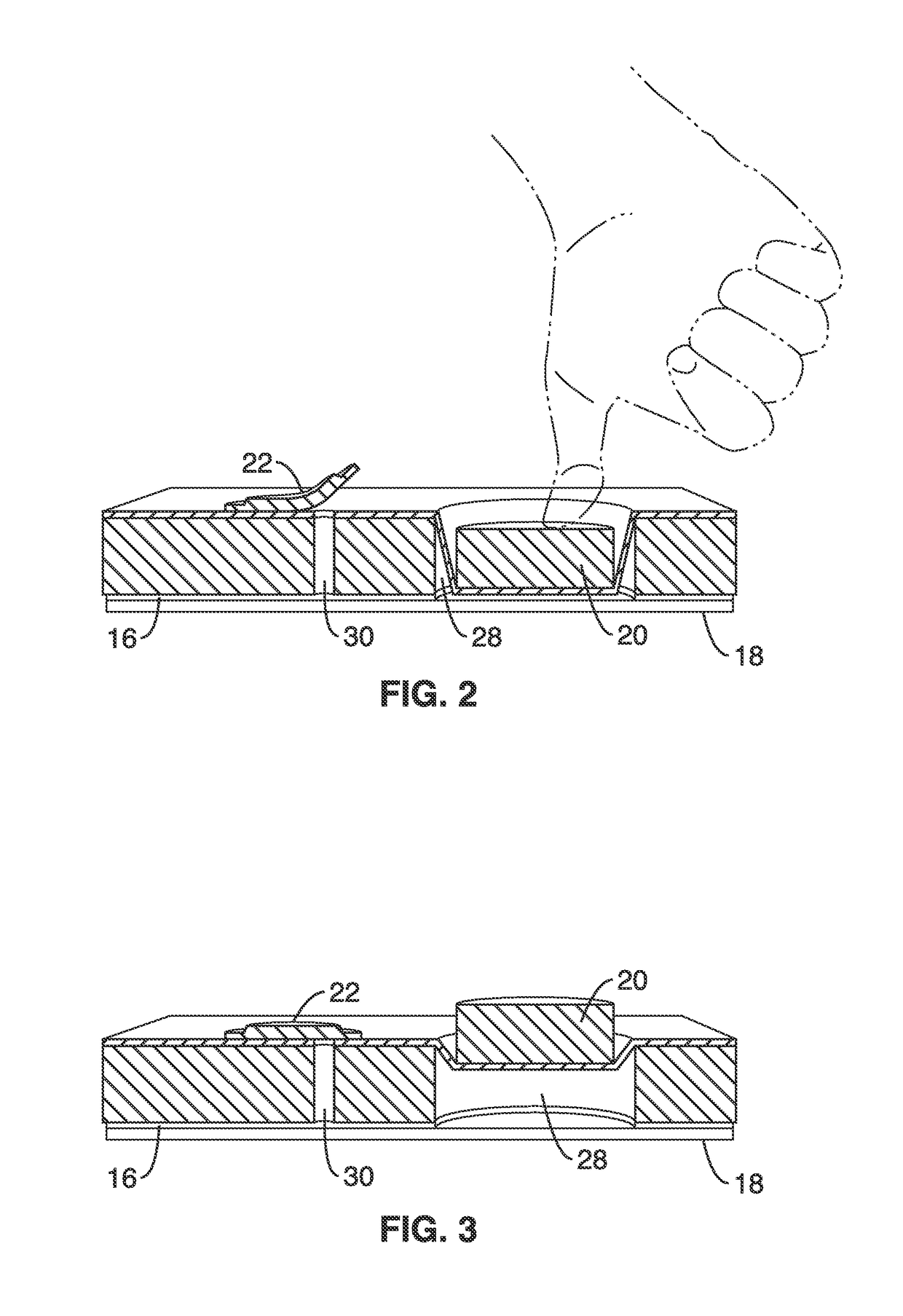

Proximal degas driven microfluidic actuation

ActiveUS20160144362A1High porosity and air solubilityReduce internal pressureSamplingLaboratory glasswaresEngineeringPre treatment

An apparatus with a self-contained, tunable, microfluidic pumping system that utilizes the high air permeability of the matrix material to actuate fluid flow in a network of fluidic microchannels and microstructures is provided. The pumping relies upon partial evacuation of degas / vacuum channels that are located next to the fluid channels to degas air from the fluid channels or structures producing a reduction of pressure in the fluidic channel leading to the flow of fluid from an inlet at atmospheric pressure through the device. The solution is isolated from the pumping apparatus since the liquid does not pass through the diffusion barriers. The apparatus and method can also provide bubble-free microfluidic pumping, without any auxiliary equipment or device pre-treatment, and can fill dead-end channels and chambers, providing a powerful liquid handling tool for a broad range of applications.

Owner:RGT UNIV OF CALIFORNIA

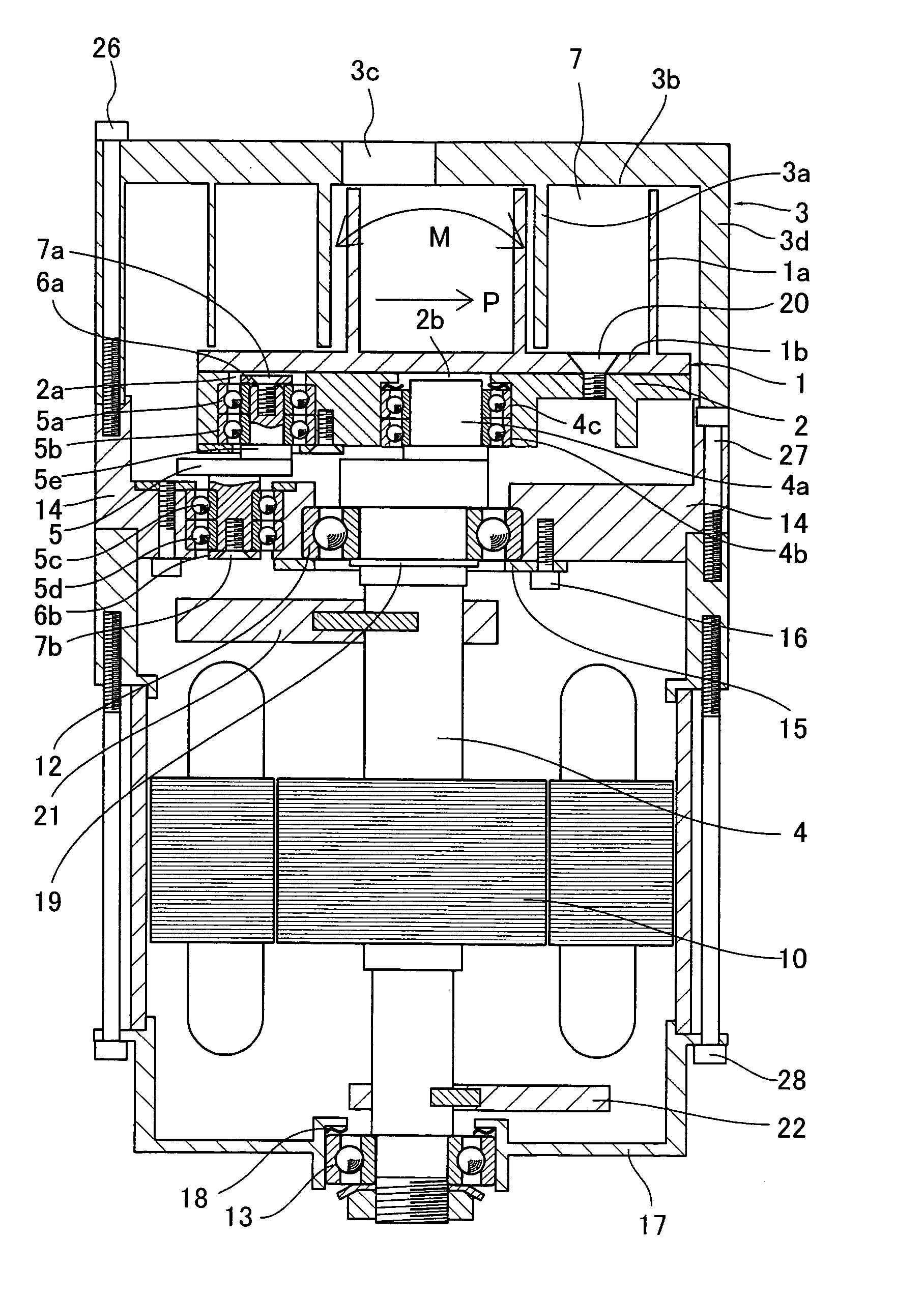

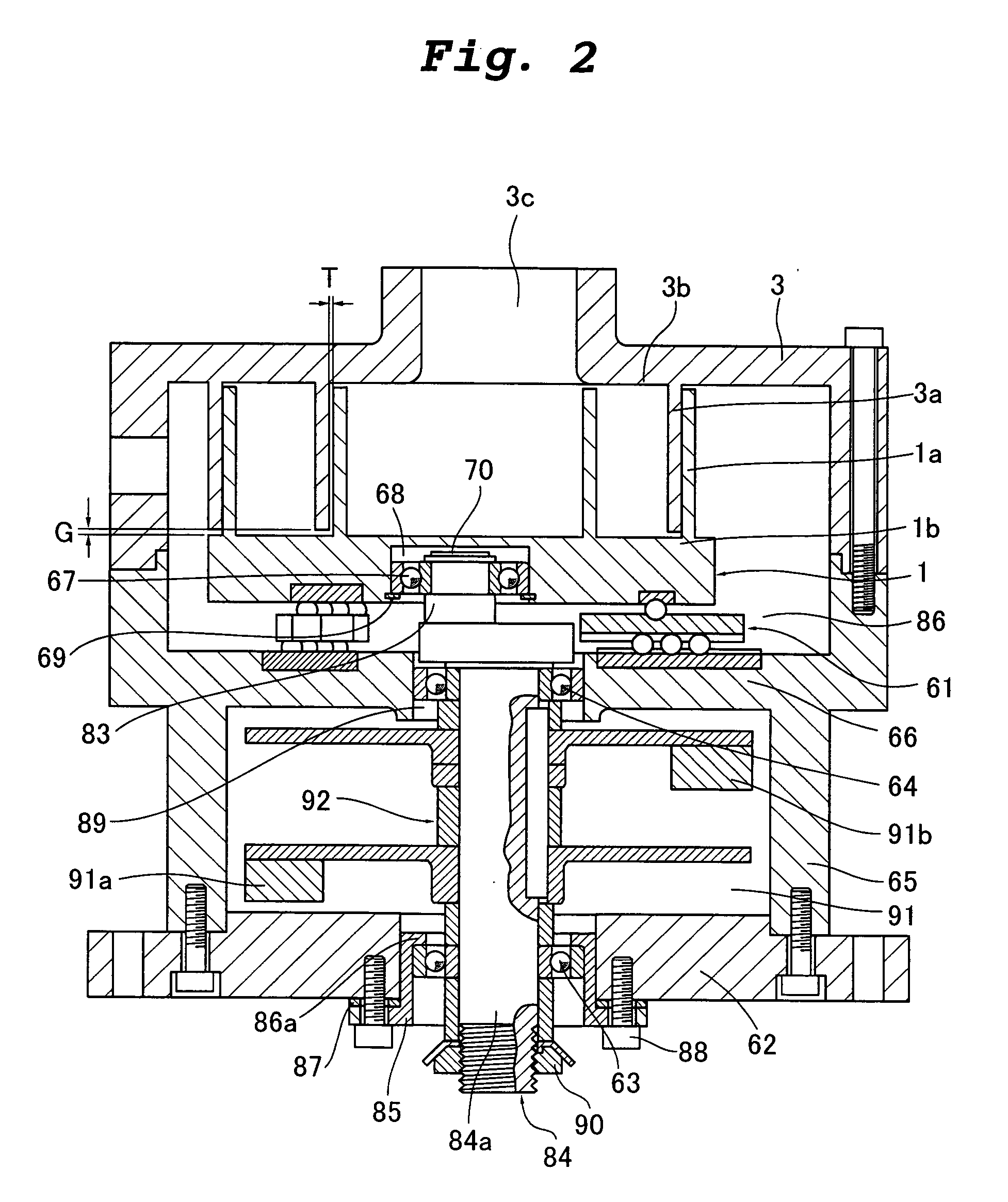

Power generating device

InactiveUS20050002816A1Avoid deformationReduce power consumptionRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringSynthetic resin

In a scroll compressor, a revolution scroll lap 1a stands on one of surfaces of a revolution lap support disk 1b of a revolution scroll member 1, and a revolution disk 2 is connected to the other surface. The revolution disk 2 is formed at its center with a revolution shaft support hole 2b into which an eccentric shaft 4a is to be inserted. An outer periphery of the revolution shaft support hole 2b is formed with a crankshaft support hole 2a into which an eccentric shaft 5e is to be inserted. The eccentric shaft 5e restrains the rotation of the revolution scroll member 1. The revolution scroll lap 1a and the revolution lap support disk 1b are integrally formed of synthetic resin. The revolution disk 2 is made of metal. The revolution shaft support hole 2b and the crankshaft support hole 2a are integrally formed together. With this configuration, the thermal deformation of revolution scroll member 1 is suppressed, and wear and mechanical loss caused by contact between laps are prevented.

Owner:MATSUSHITA SEIKO CO LTD

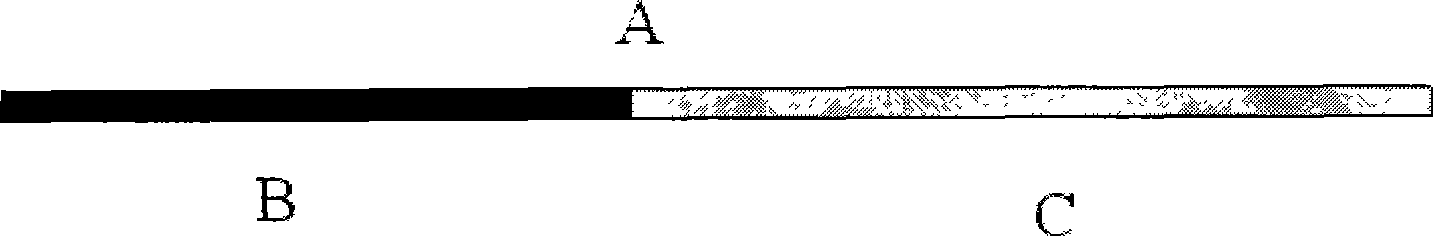

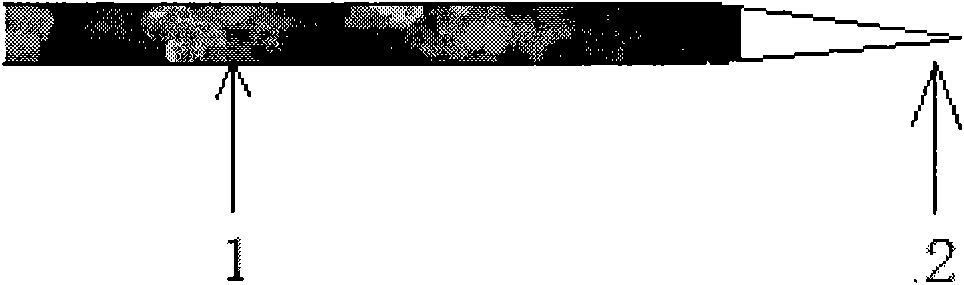

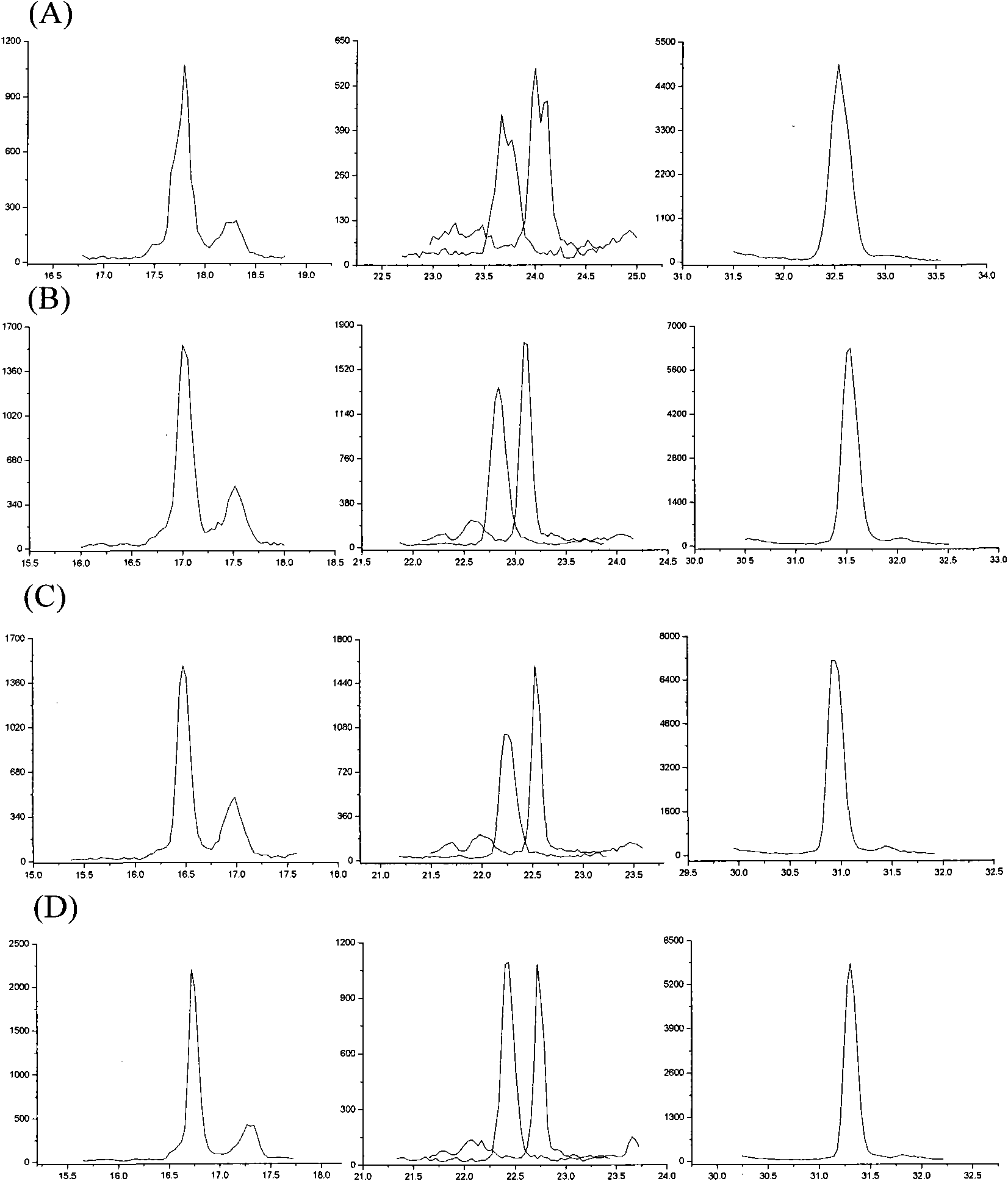

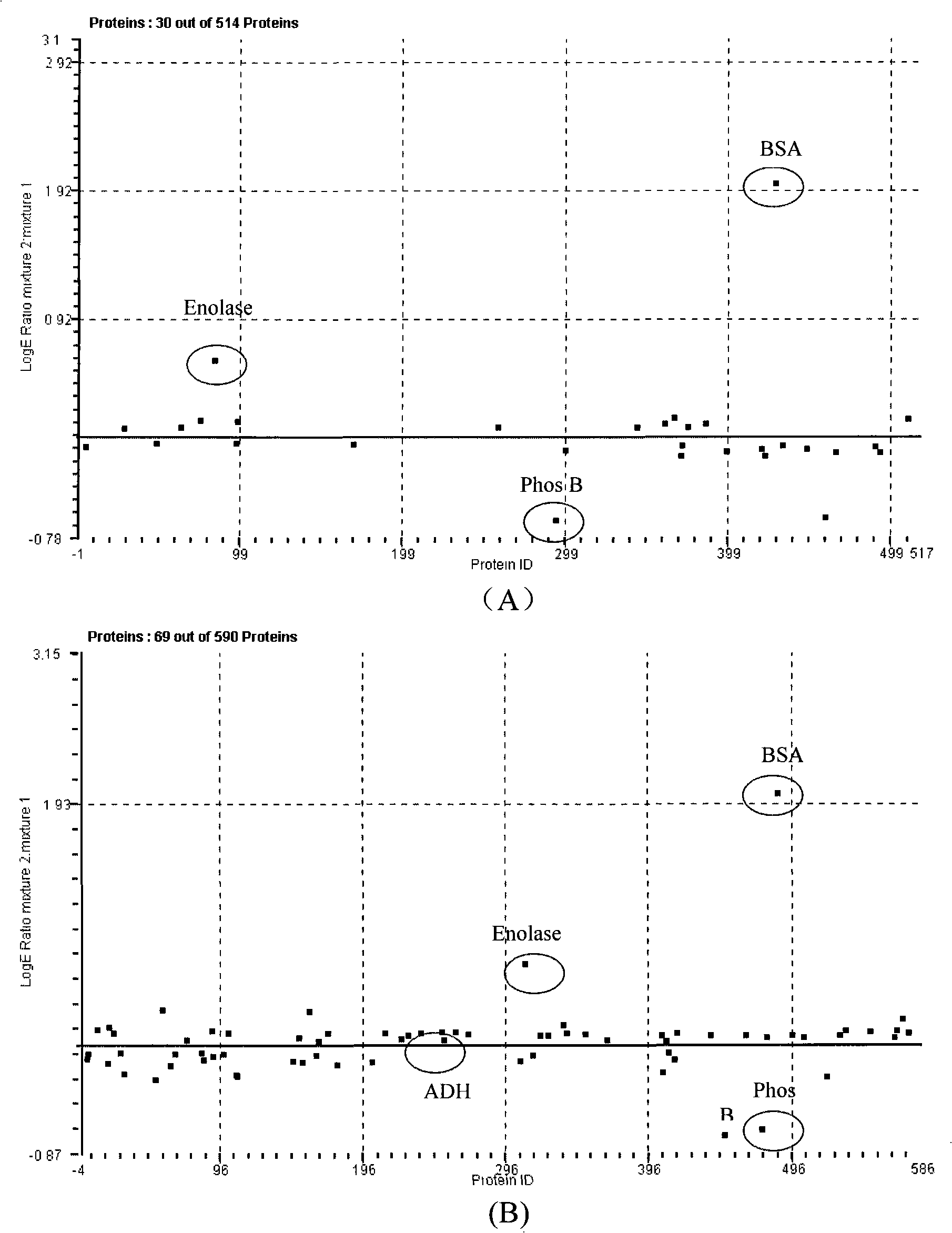

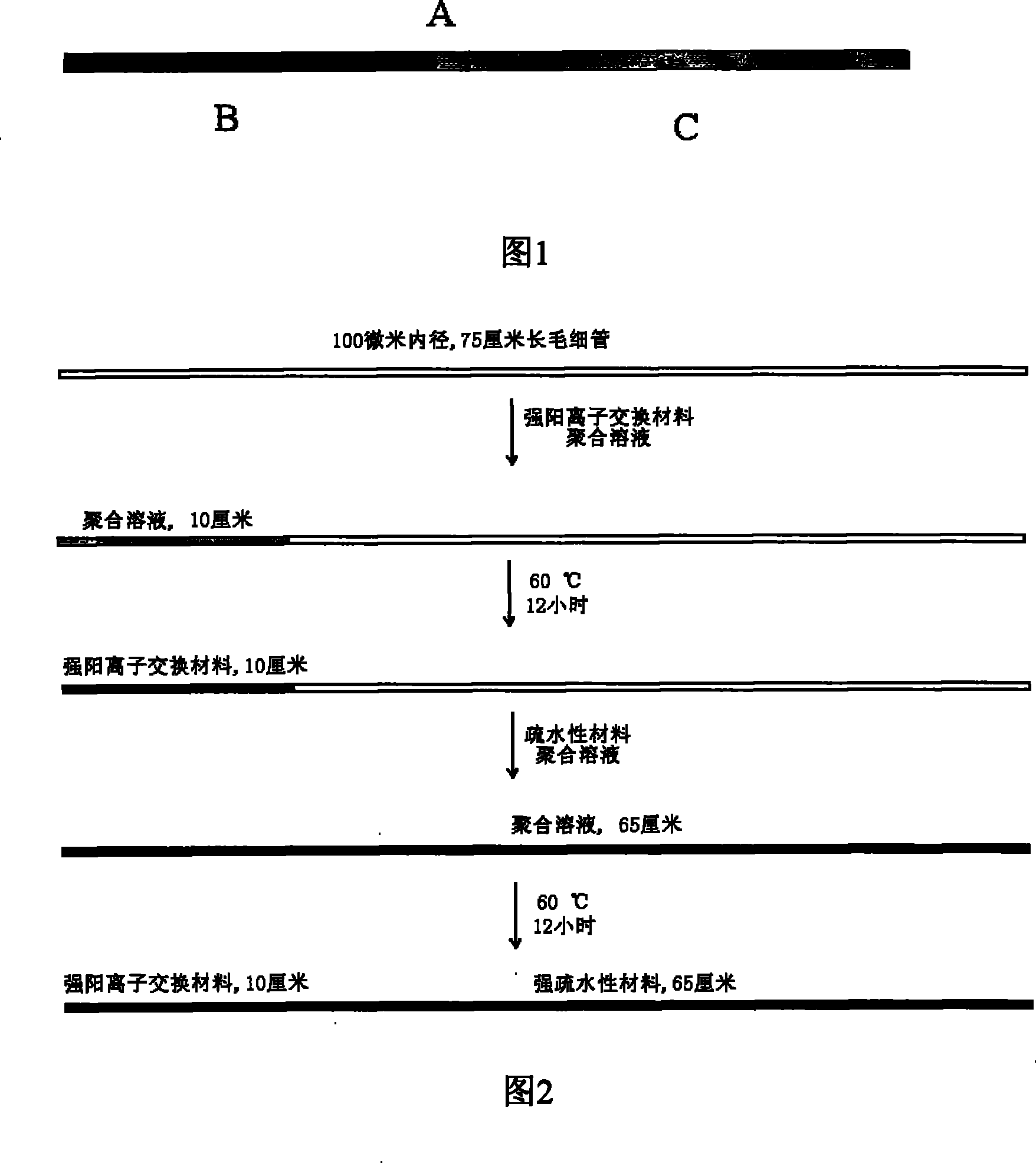

Two-phase integral column as well as preparation and application thereof

InactiveCN101413932AEliminate dead volumeRealize "zero dead volume" connectionComponent separationOther chemical processesChromatographic separationMicro column

The invention relates to a monolithic capillary column, in particular to a two-phase monolithic column which is characterized in that two fixed phases with different separation mechanisms exist in the same column pipe; the two phases exist in the form of a front section and a rear section. The two-phase monolithic column has the main advantages of basically eliminating dead volume which is generated when two monolithic columns with different separation mechanisms are connected in a micro-column liquid phase chromatographic separation system, carrying out automatic online multi-dimensional separation and having extremely strong capability of separating complex samples such as protein zymolyte; furthermore, the monolithic column has good permeability and low operation pressure, and is easy to be operated on a normal liquid chromatography and can obtain high-efficiency separation results.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

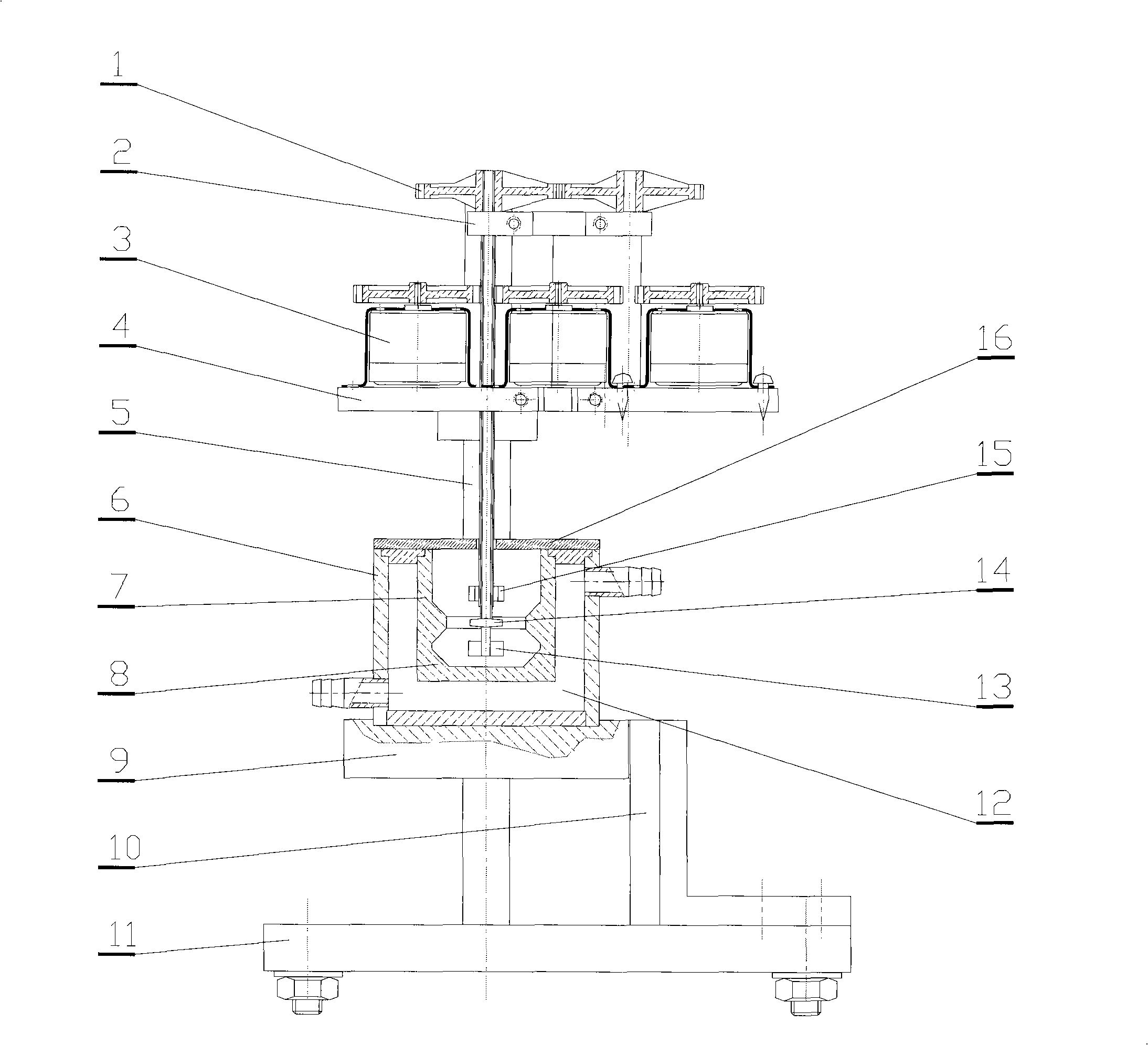

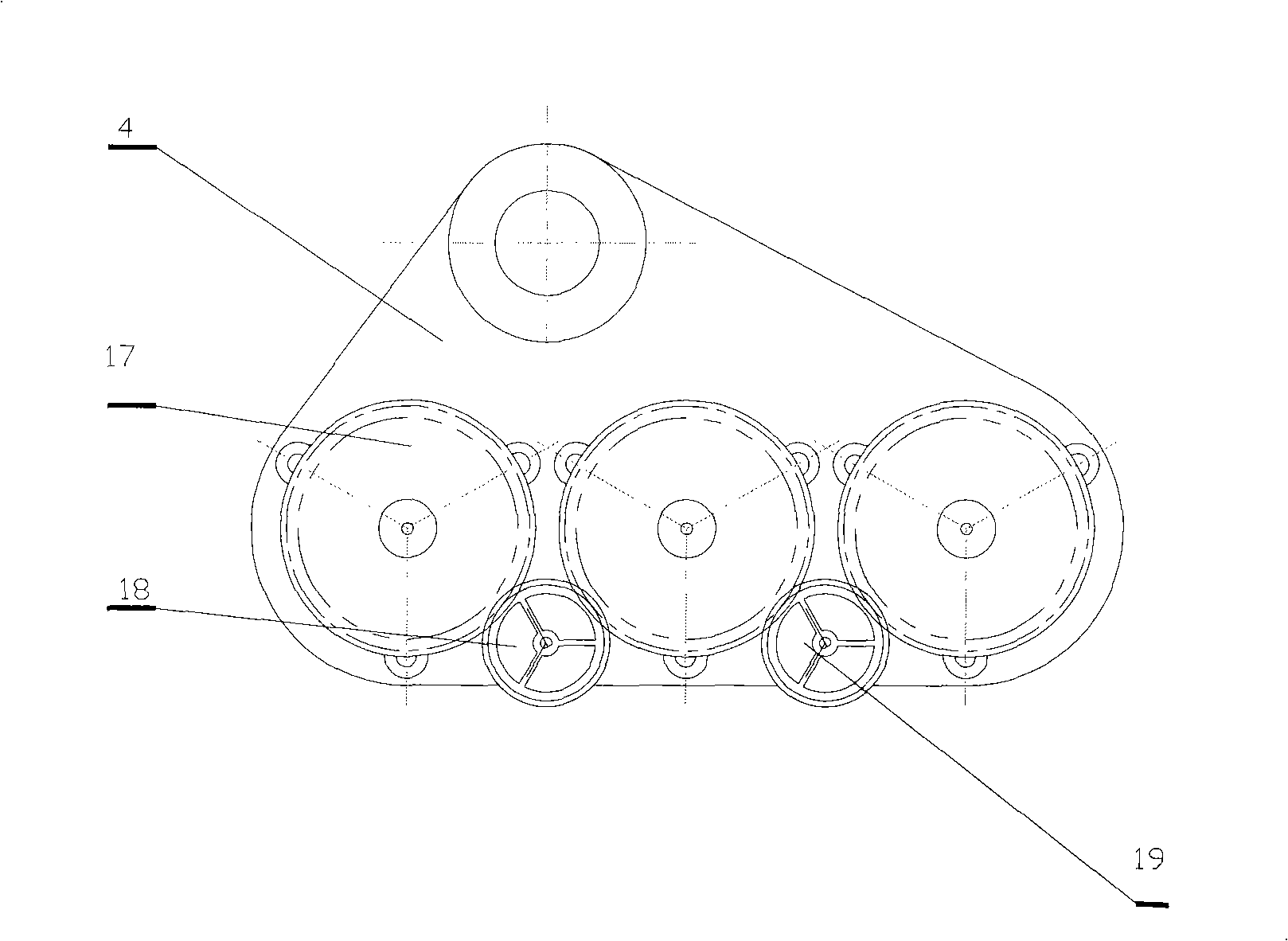

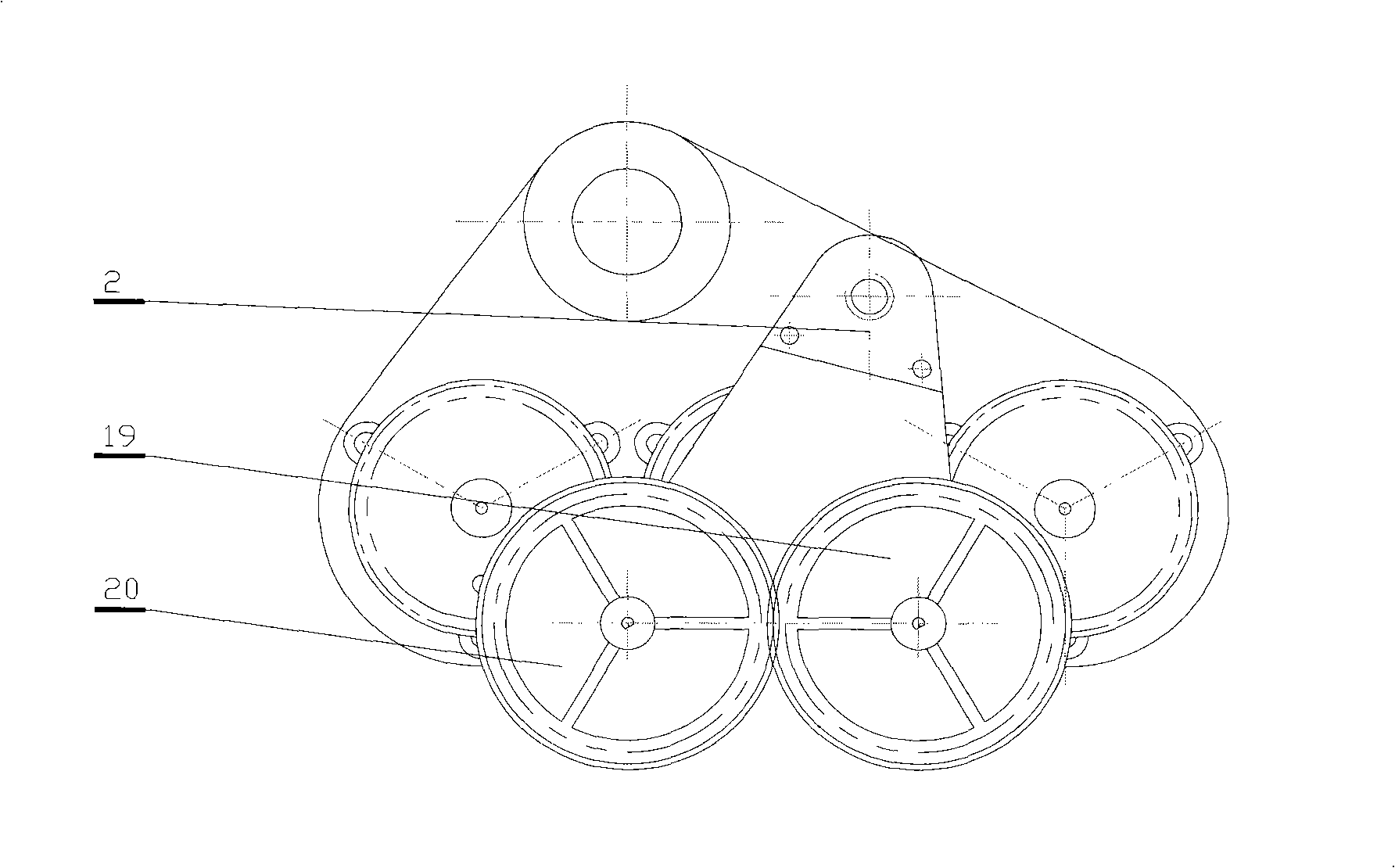

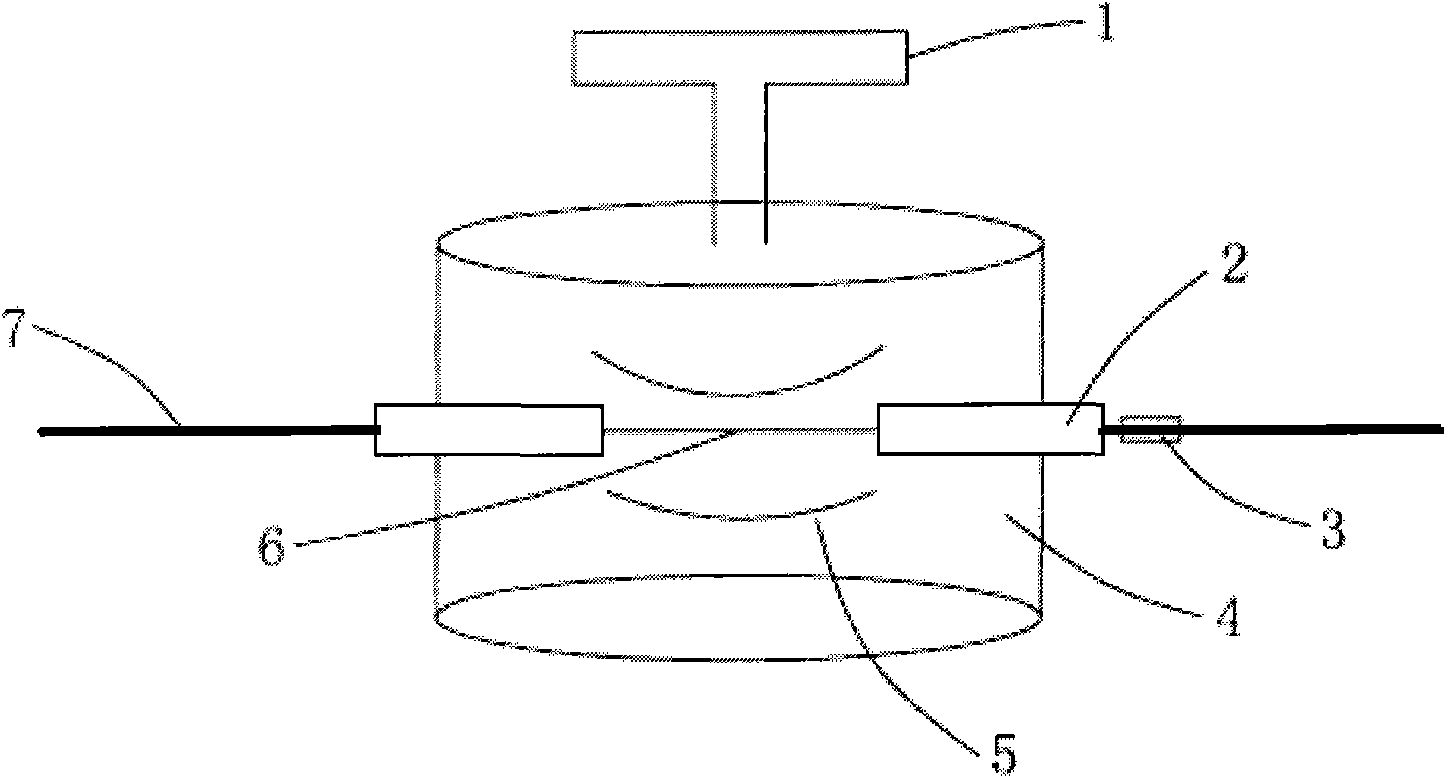

Constant-interface abstraction pool

InactiveCN101402002ANo joint gapEasy to washLiquid solutions solvent extractionDead volumeConstant interface

The invention discloses a small constant interfacial area extraction cell for extraction kinetics research. The constant interfacial area extraction cell comprises an upright post, a driving mechanism, an upper positioning plate, a lower positioning plate, an organic phase stirring paddle, an aqueous phase stirring paddle, a liquid bath tray, a central baffle plate, a bottom plate and so on, wherein the upright post is fixed on the bottom plate; the driving mechanism, the upper positioning plate, the lower positioning plate and the liquid bath tray are fixed on the upright post; a liquid bath is fixed on the liquid bath tray; the organic phase stirring paddle and the aqueous phase stirring paddle are arranged inside the liquid bath; the driving mechanism drives the organic phase stirring paddle and the aqueous phase stirring paddle to rotate respectively; the liquid bath provided with a liquid bath cover is cylindrical and is divided into an inner layer and an outer layer; a constant temperature water jacket is arranged between the inner layer and the outer layer; a baffle ring is designed on an interface of two phases in the liquid bath and consists of an interfacial baffle plate and a central baffle plate; the inner wall of the liquid bath is formed by overall mill processing; and the bottom and the interfacial baffle ring of the liquid bath adopt chamfered or circular design. By adoption of the design, the liquid bath is convenient to clean as the inner wall of the liquid bath is provided with no combined gap , and simultaneously dead volume is eliminated, and small constant interfacial area extraction cell is suitable for radioactive experiments.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

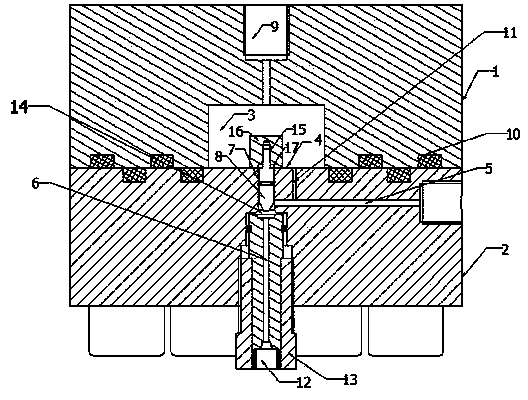

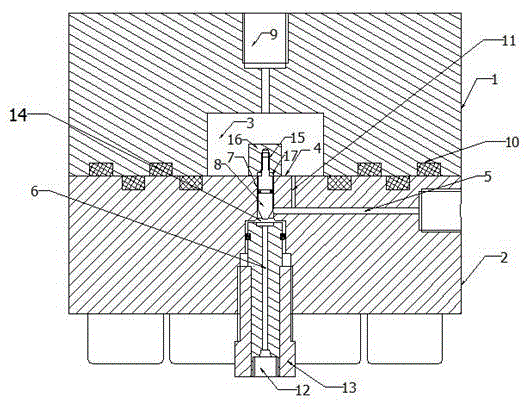

Ultrahigh-pressure high-temperature experimental back-pressure valve

ActiveCN103912700AImprove reliabilityEliminate dead volumeOperating means/releasing devices for valvesEqualizing valvesUltra high pressureDead volume

The invention discloses an ultrahigh-pressure high-temperature experimental back-pressure valve which mainly comprises an upper valve body, a lower valve body, an ultrahigh-pressure gas chamber, an alloy diaphragm, a horizontal fluid channel, a vertical fluid channel, a central hole and a valve needle. The alloy diaphragm 4 is located between the upper valve body 1 and the lower valve body 1 and forms a multistage combined soft seal 10 with the upper valve body and the lower valve body, the ultrahigh-pressure gas chamber 3 is located in the upper valve body and is connected with a back-pressure pipeline end 9, and a through hole 11 is formed between the ultrahigh-pressure gas chamber and the horizontal fluid channel 5; the central hole 7 is formed in the intersection point of the horizontal fluid channel 5 and the vertical fluid channel 6 which are located in the lower valve body, the central hole extends upwards to the ultrahigh-pressure gas chamber, the valve needle 8 is located in the central hole, the top of the valve needle is machined into a first threaded rod 15, the needle tip of the valve needle 8 is sealed in a sealing pad 14 at the tail end of the central hole 7, and the central hole moves downwards to be connected to a sample line end 12. The ultrahigh-pressure high-temperature experimental back-pressure valve is high in sealing performance, high in pressure control, high in stability and free of dead volume, and the gap in the prior art is filled up.

Owner:SOUTHWEST PETROLEUM UNIV

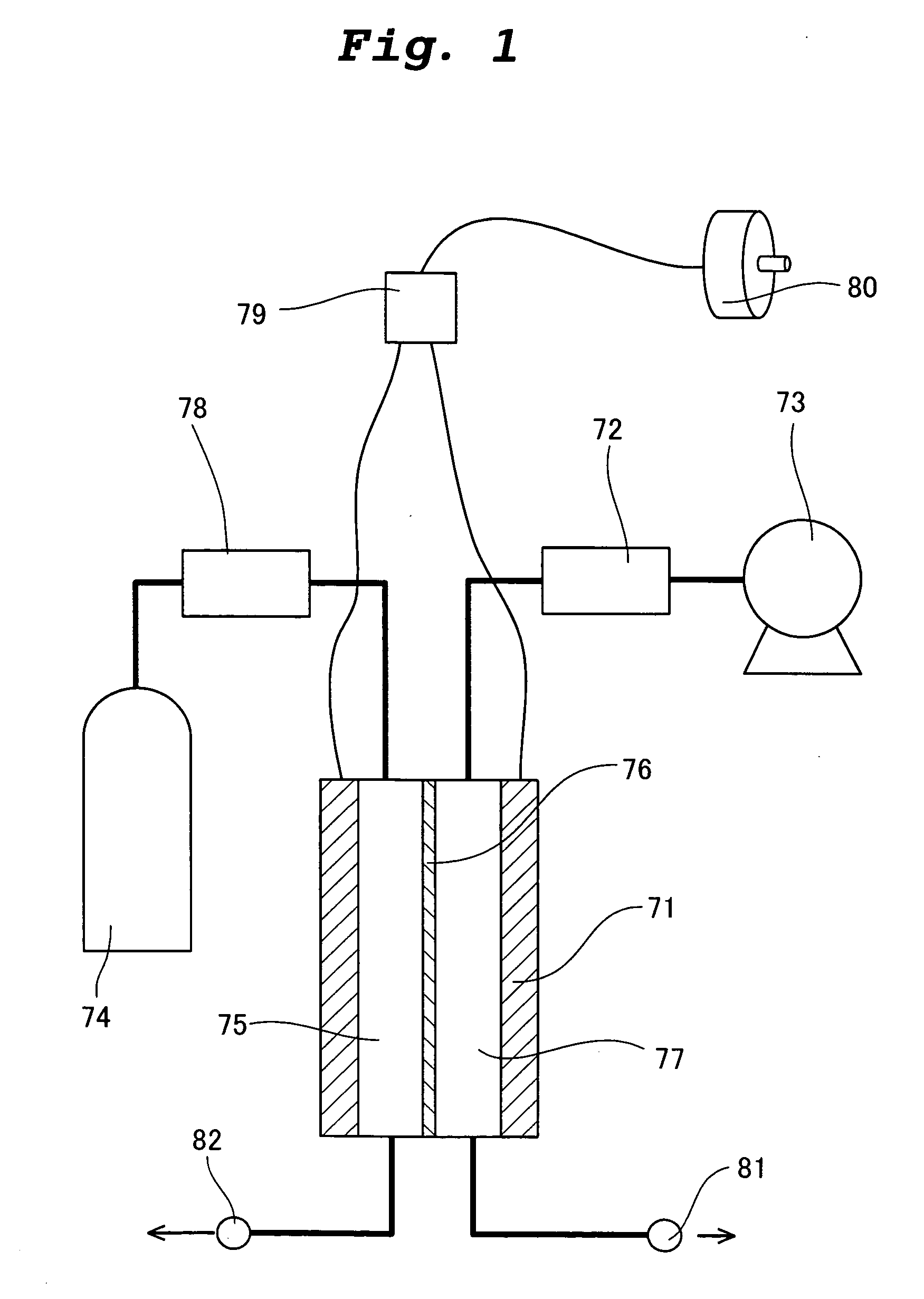

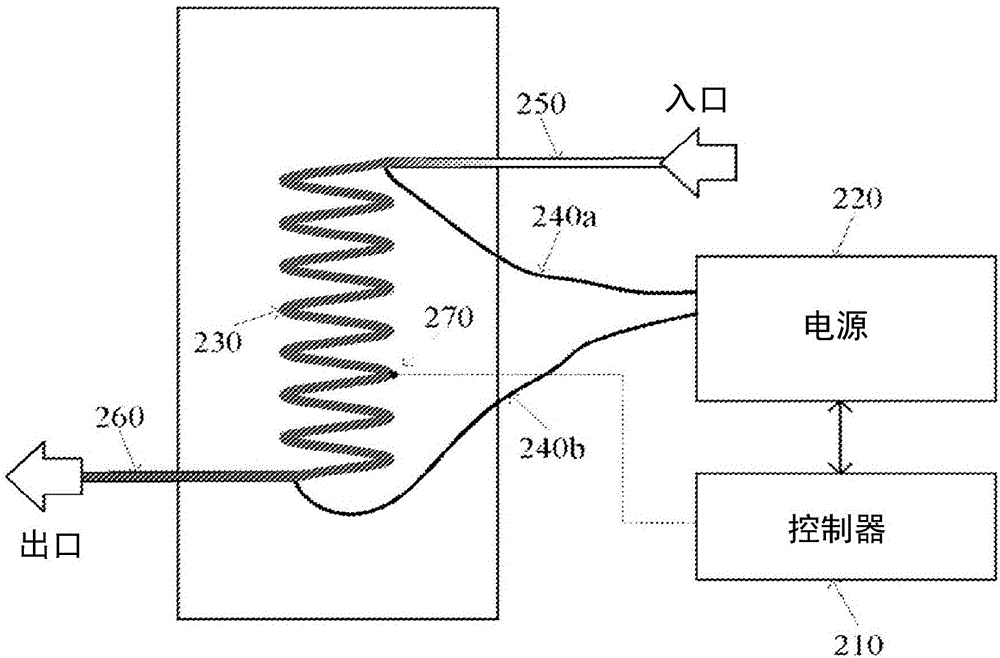

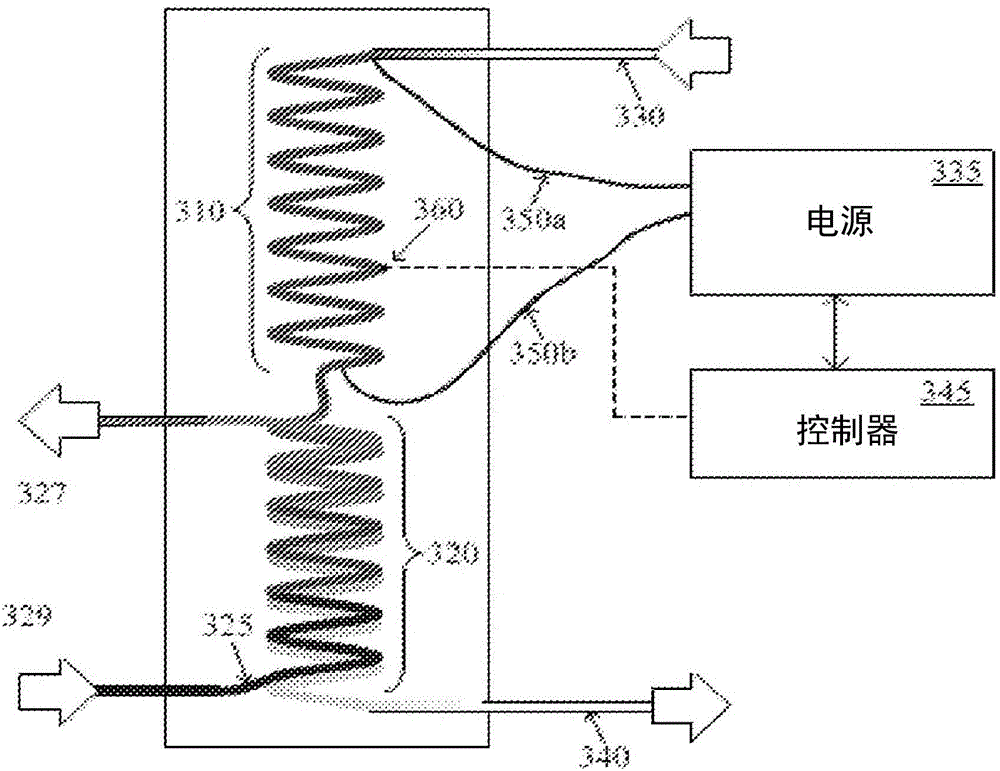

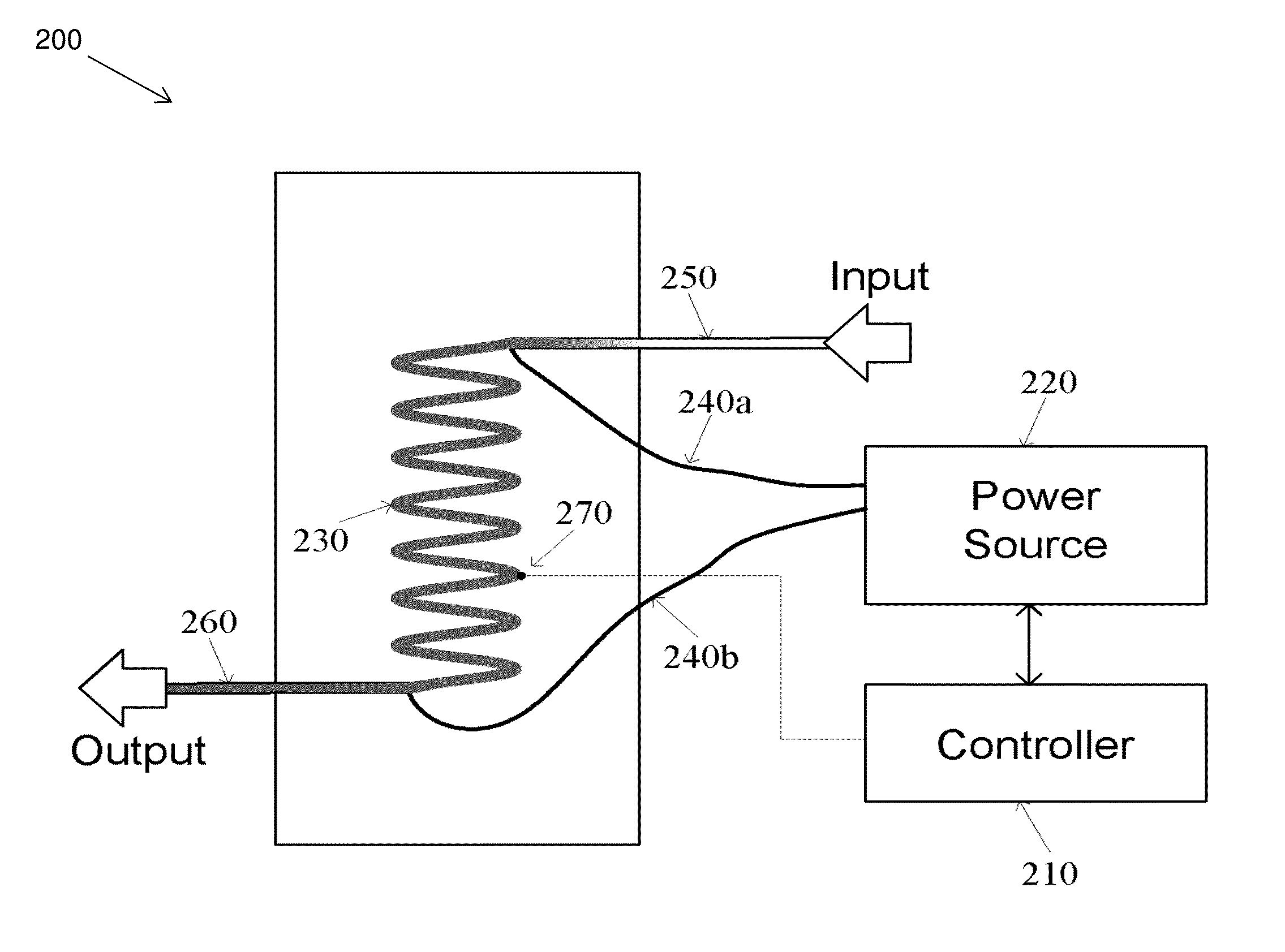

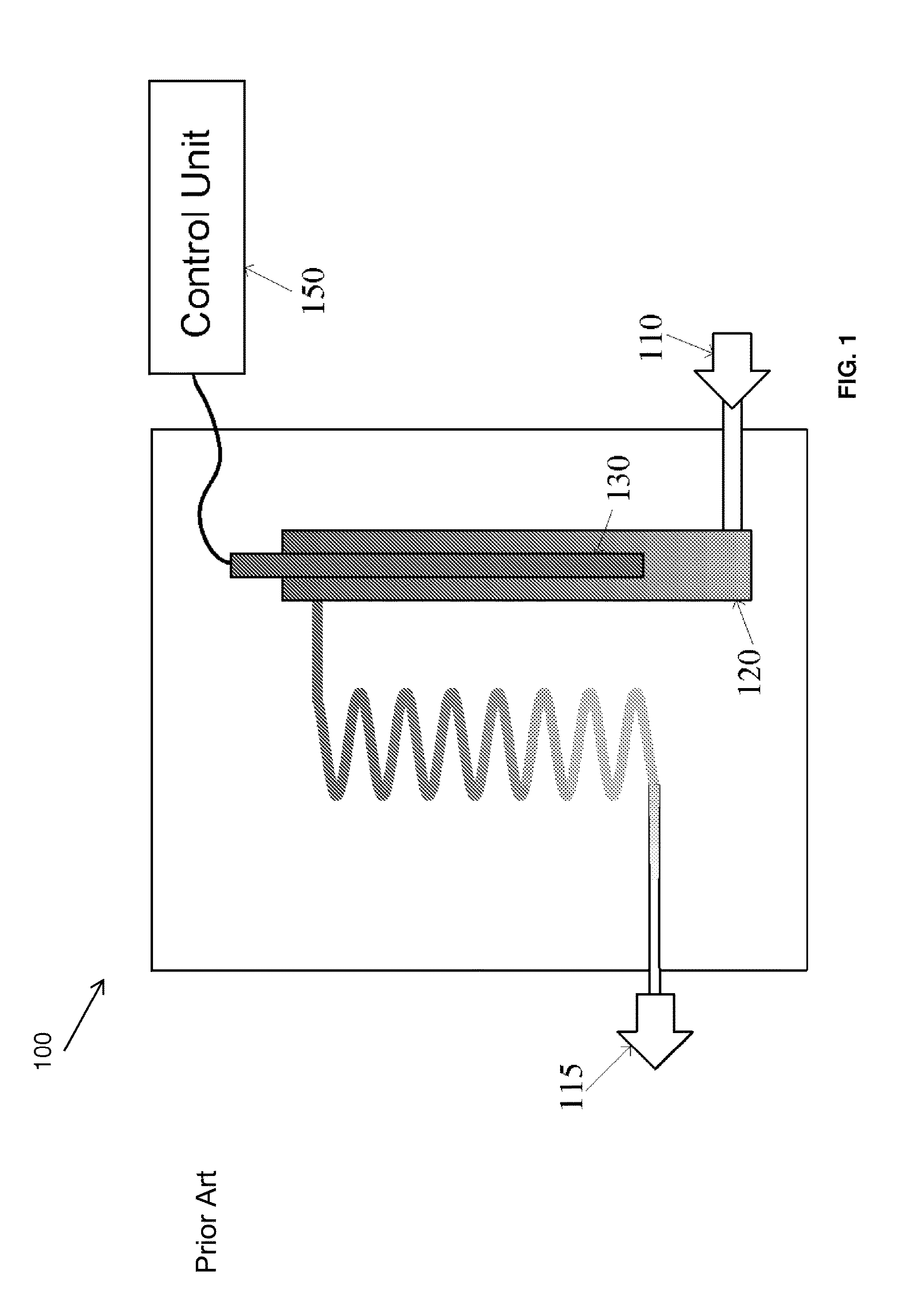

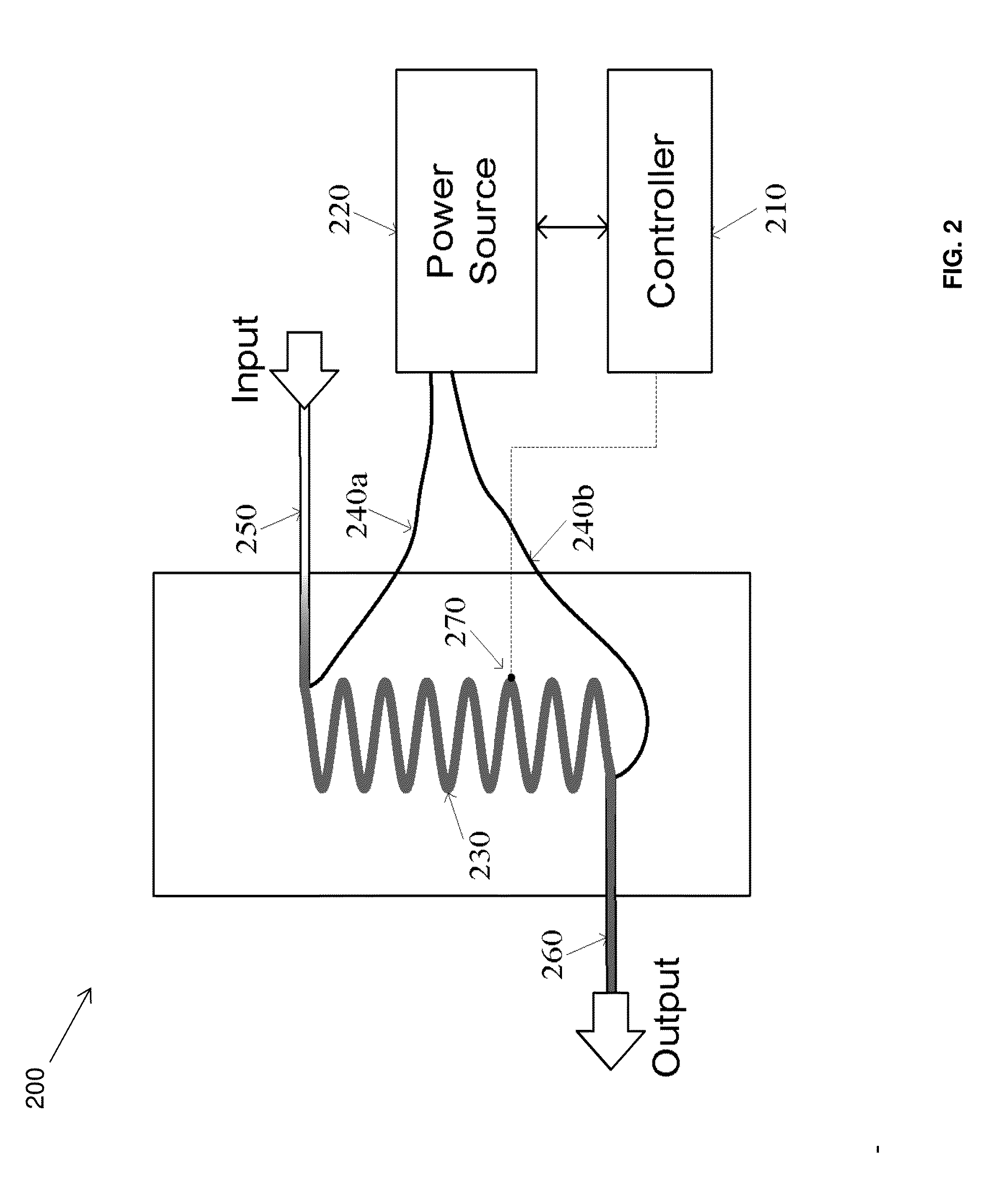

Method and Apparatus for a Directly Electrically Heated Flow-Through Chemical Reactor

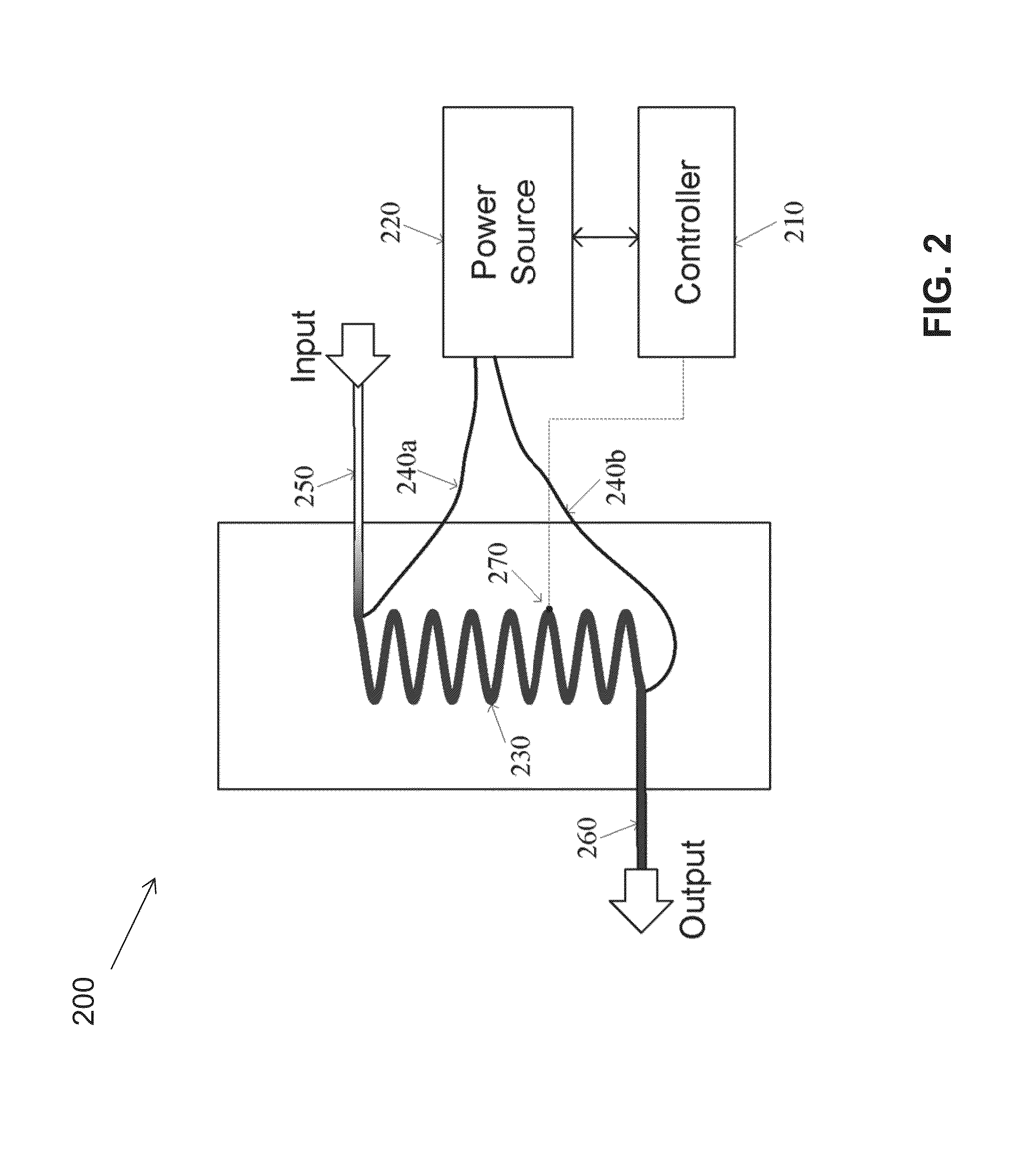

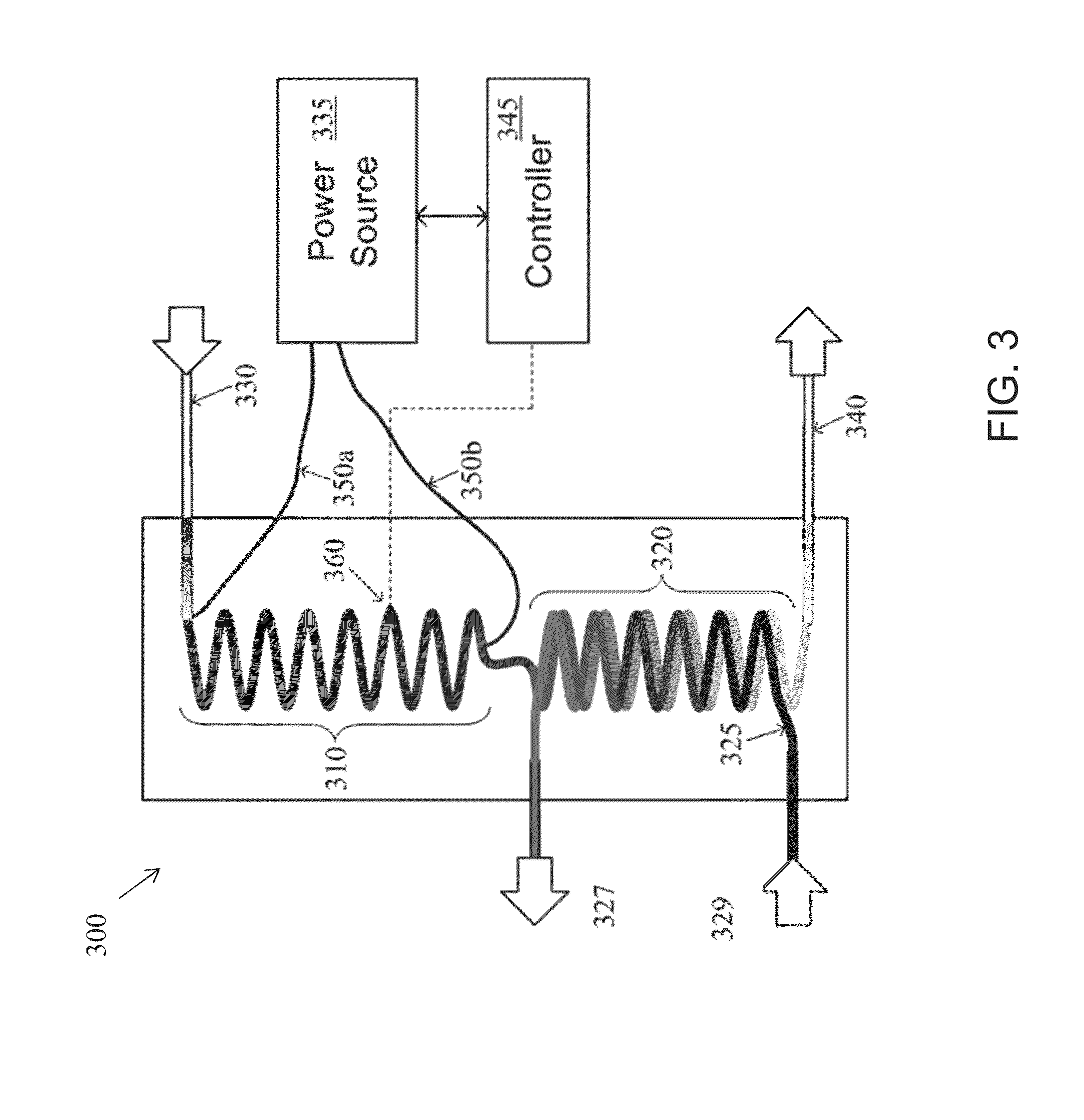

InactiveUS20160115025A1Small sizeLow costGas treatmentDispersed particle separationChemical mixturesChemical reaction

A system and method for facilitating a chemical reaction is provided. The system can have an electrically conductive member. The electrically conductive member is capable of holding a chemical mixture. The electrically conductive member is directly coupled to a power source and is heated when the power source is on. When a chemical mixture is within the electrically conductive member and the power source is on, the chemical mixture is heated such that a chemical reaction can occur.

Owner:MKS INSTR INC

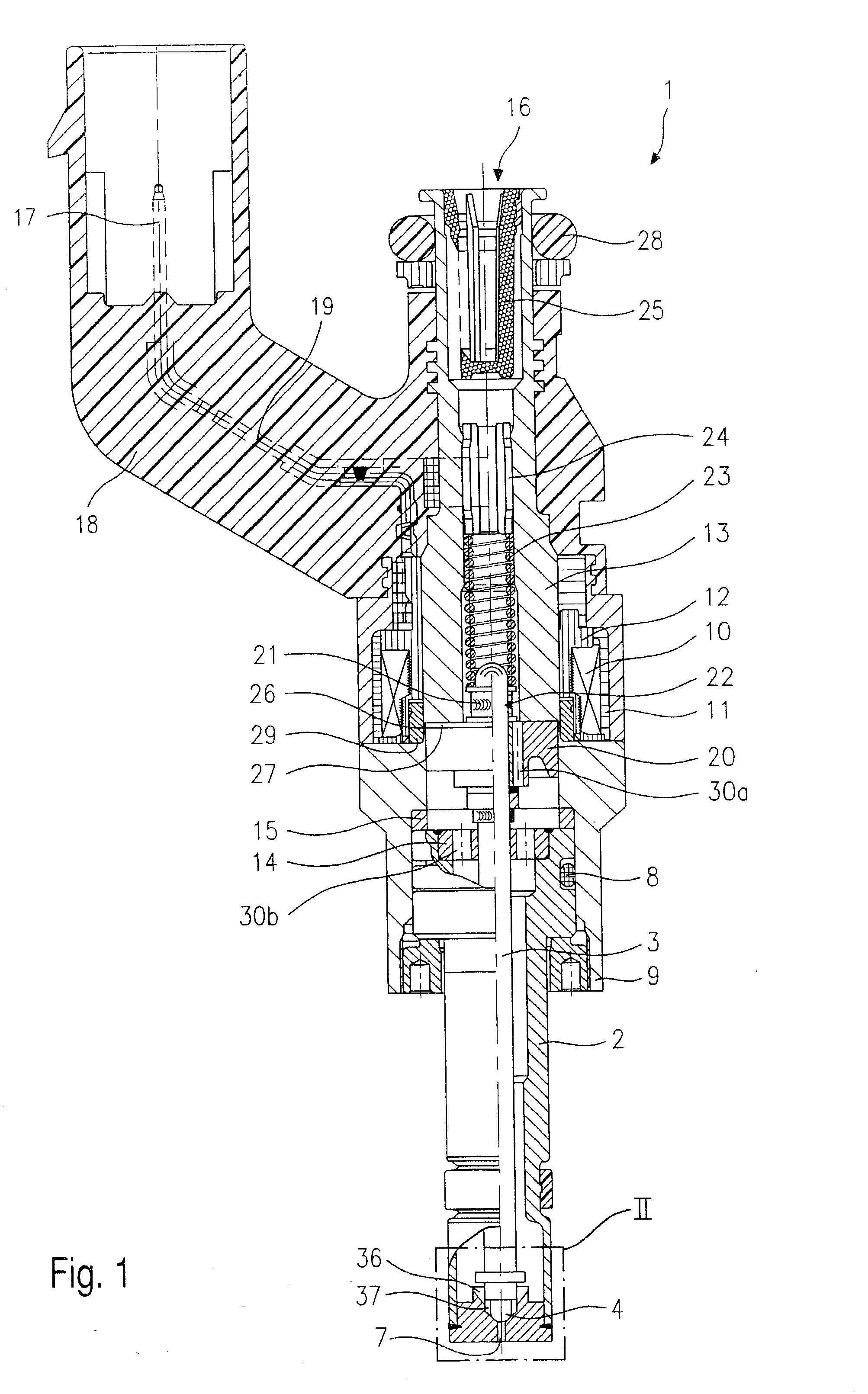

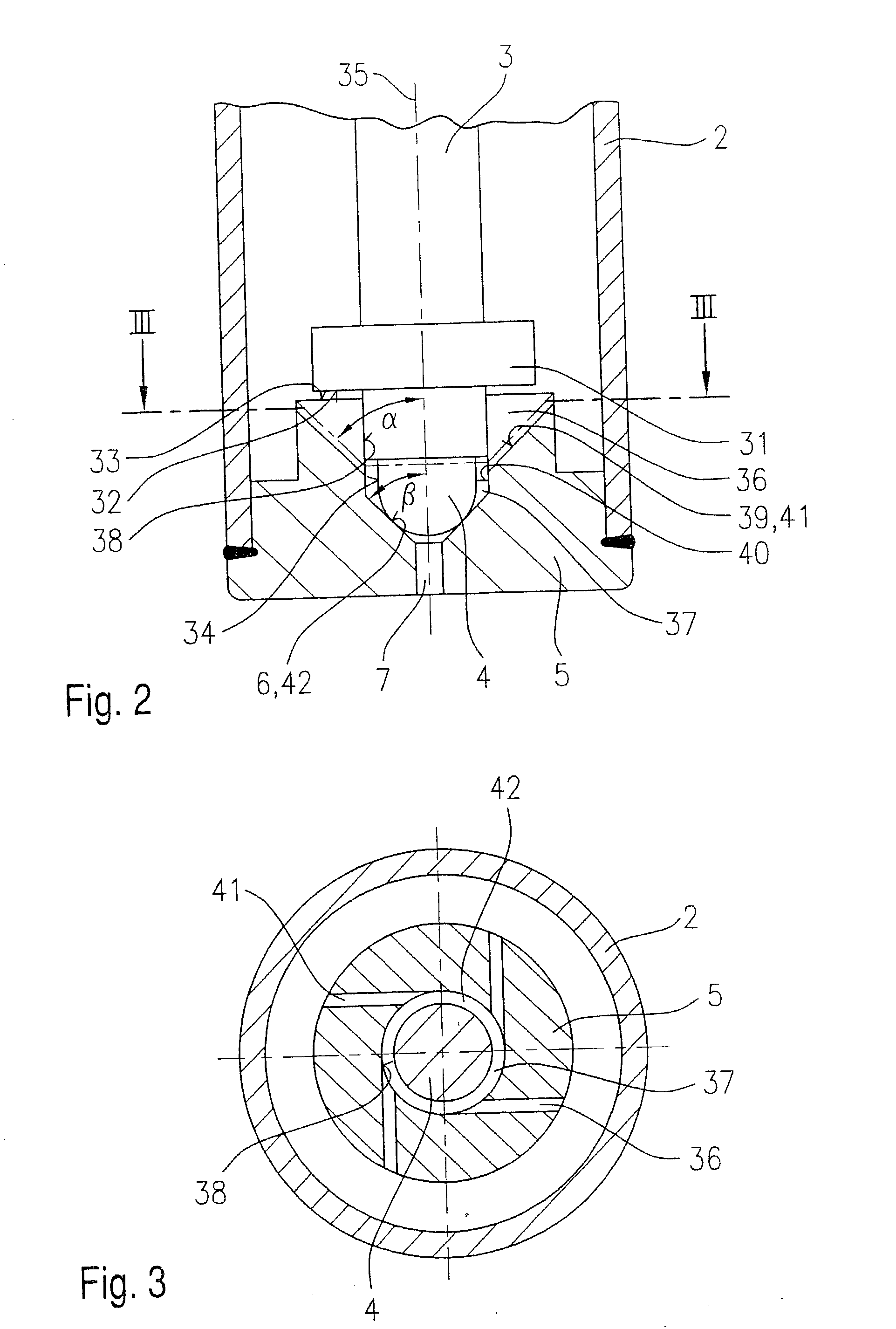

Fuel injection valve

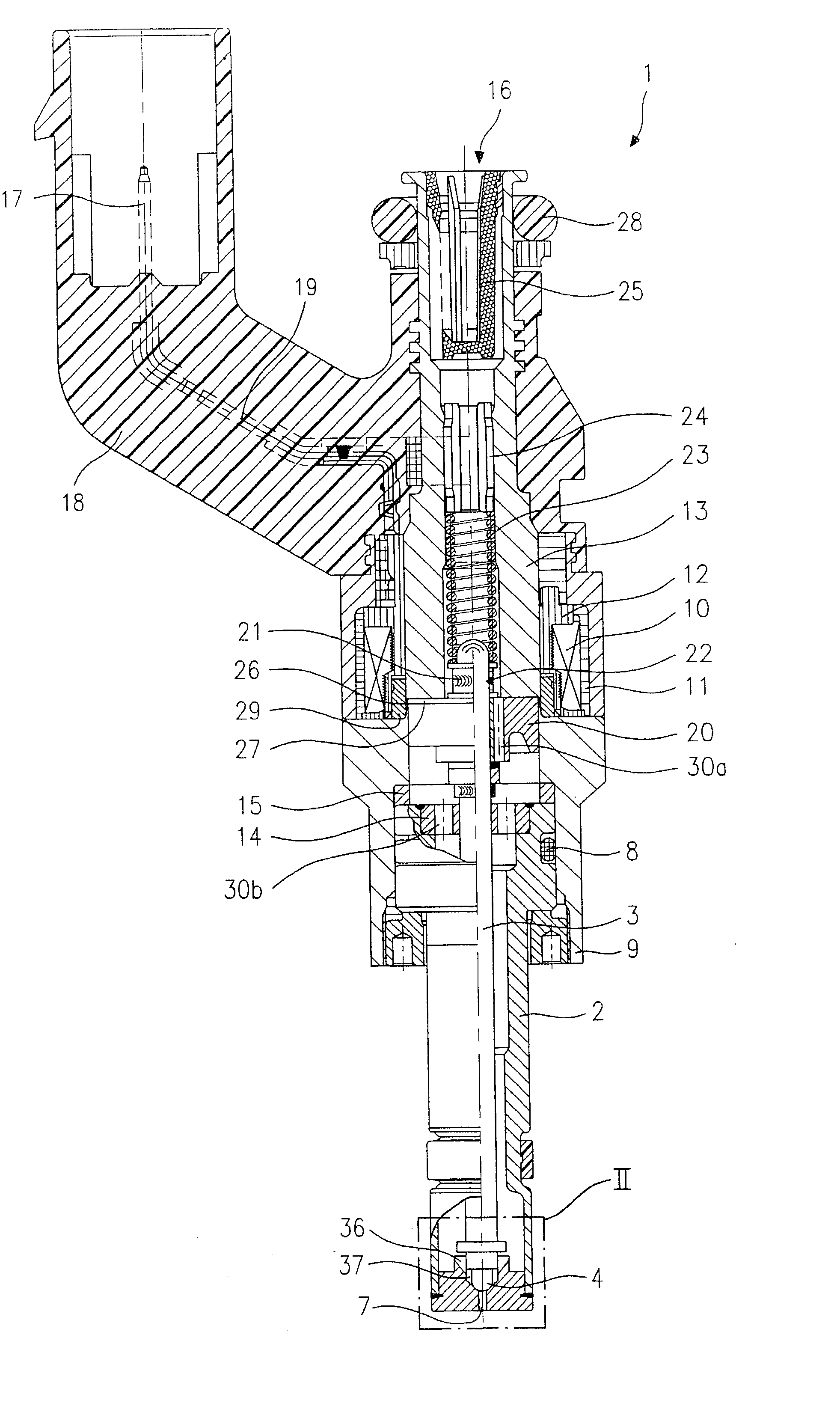

InactiveUS20030047623A1No loss in circumferential speedEmission reductionSpray nozzlesMachines/enginesCombustionEngineering

A fuel injector for fuel injection systems of internal combustion engines includes a valve needle and a valve-closure member mechanically linked to it, which cooperates with a valve-seat surface situated in a valve-seat member to form a sealing seat, and at least one swirl-producing element which is situated upstream from the sealing seat in the valve-seat member. One or more swirl channels which are open toward the upstream side of the valve-seat member are incorporated into the upstream side of the valve-seat member as a swirl-producing element.

Owner:ROBERT BOSCH GMBH

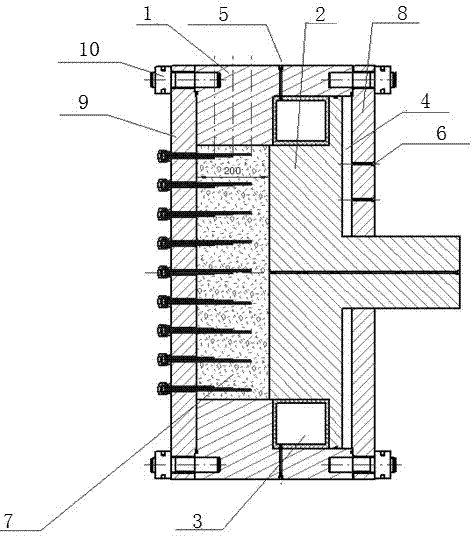

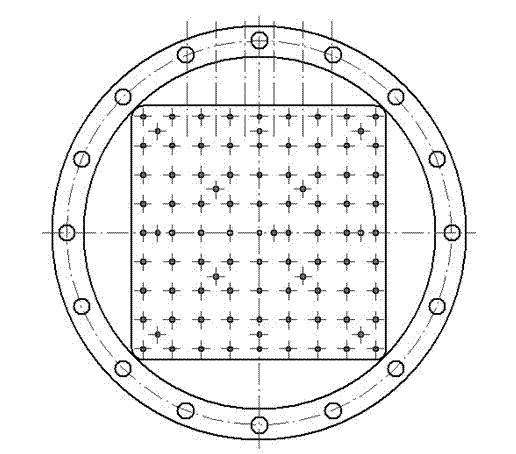

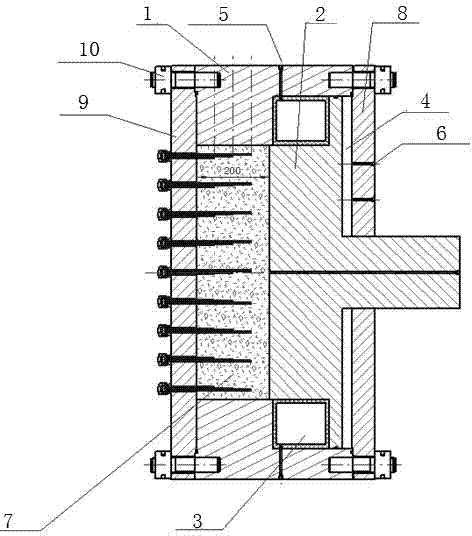

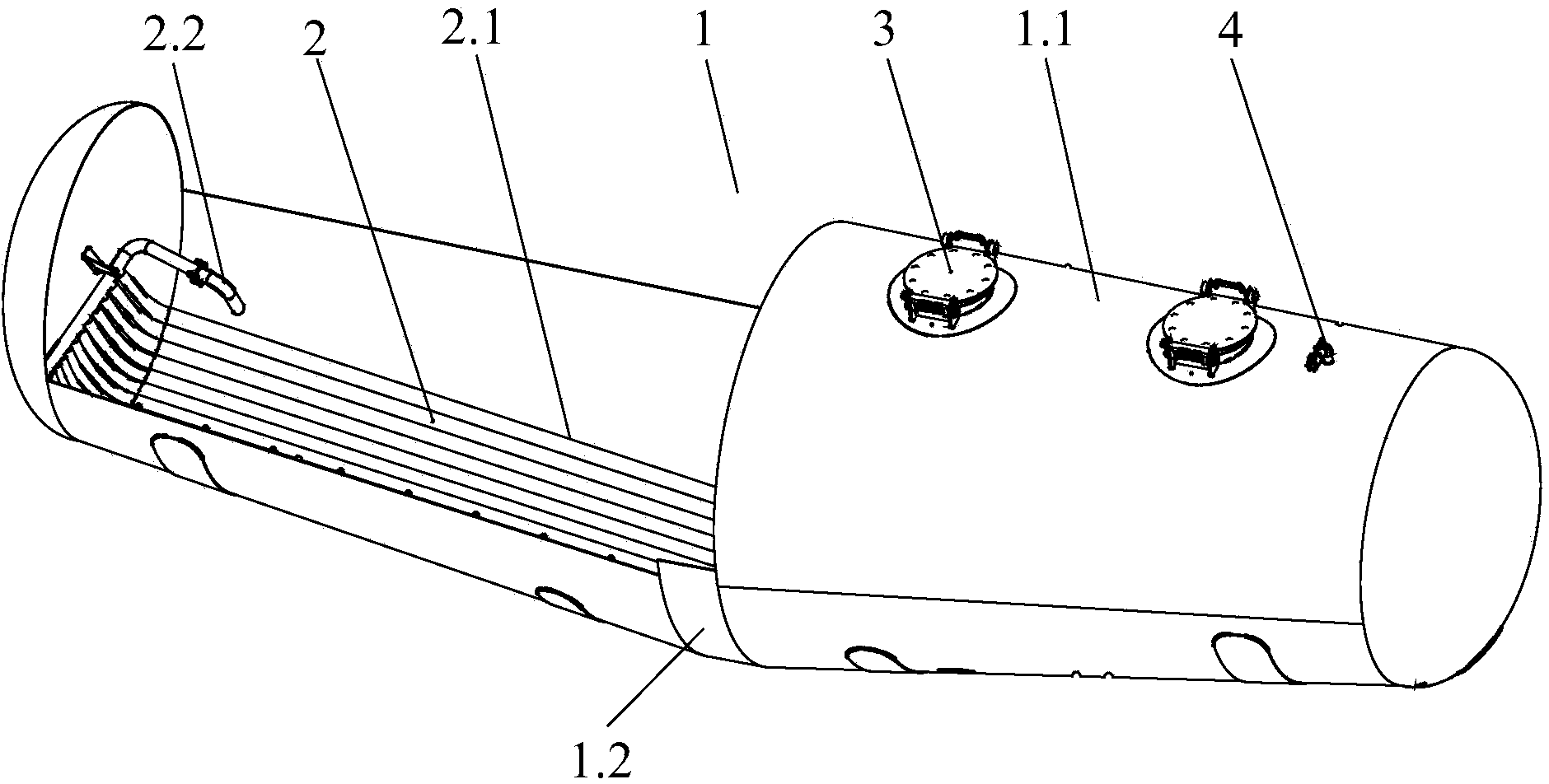

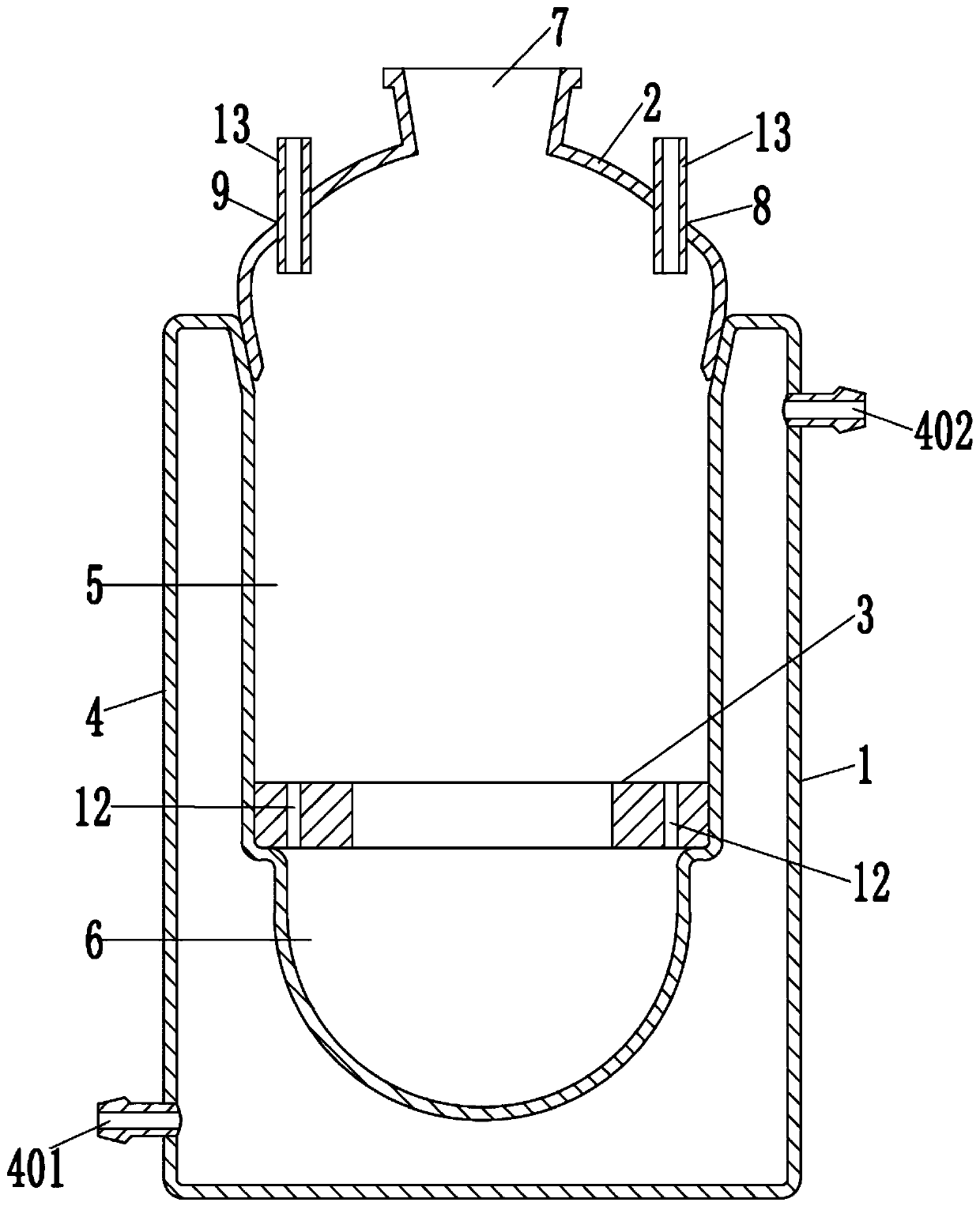

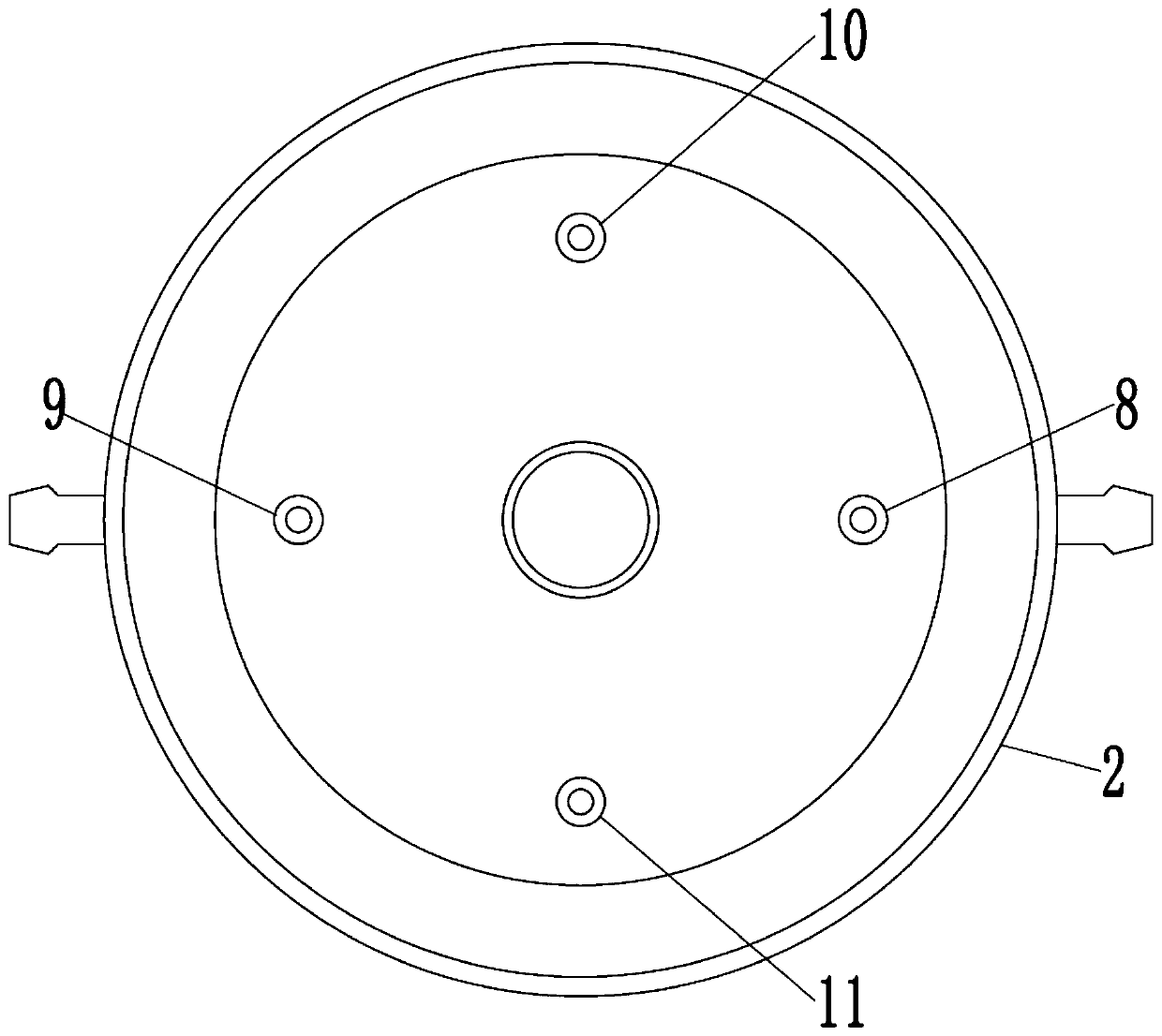

Overburden pressure system for three-dimensional model

InactiveCN102392622AWith overburden functionGuaranteed experimental accuracyFluid removalRubber materialDead volume

The invention provides an overburden pressure system for three-dimensional model, comprising a barrel body, a piston disposed in the barrel body and a sand filling layer connected with the piston; the piston is composed of a square piston and a round piston; a capsule chamber is disposed between the piston and the barrel body; the capsule chamber is located at the junction of the square piston and the round piston; one side of the barrel body is provided with a round overburden pressure chamber; the capsule chamber is connected with a capsule chamber injecting opening; the round overburden pressure chamber is connected with an overburden pressure chamber injecting opening. The invention has the following technical effects: 1, a round overburden pressure chamber is provided, a hydraulic pump is used for injecting liquid and pressurizing the overburden pressure chamber; the piston is used for pressing the sand filling layer, so that the sand filling layer has the overburden pressure function, then then experimental precision and accuracy are ensured; 2, four blocks of semilunar capsule chambers (rubber material) are arranged between the piston and the barrel body, when the piston is pressed down, liquid is injected into the capsule chamber by the capsule chamber injecting opening; the shape of the rubber capsule is changed by the liquid pressure, so as to fill the gap and remove the dead volume between the barrel body and the piston.

Owner:南通市飞宇石油科技开发有限公司

Gas/liquid separator comprising a capacitive level sensor

ActiveUS7895891B2Accurate responseCooling is possibleThermo-electric condensationMachines/enginesLevel sensorEngineering

The invention relates to a gas / liquid separator comprising a capacitive level sensor, which is particularly suitable for systems that employ reduced volumes of fluids at high pressures. The inventive separator includes a metal part comprising a borehole which is closed at the lower end thereof, such as to form a container. The aforementioned container comprises at least one gas inlet, one liquid outlet and one gas outlet. A cooling system in the form of a Peltier cell that is in contact with the walls of the metal part, generates the condensation of the liquid which is collected at the bottom of the container until the introduction of a probe, which is electrically isolated from the system and which forms an electric condenser with the walls of the part. The capacity of the condenser varies according to the level of liquid in the container. In addition, a frequency signal is generated by means of an oscillator output signal that is proportional to the response from the sensor and, consequently, the height of the liquid in the container.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

Capillary monolithic column spray needle and preparation method and application thereof

The invention relates to an interface for microcolumn liquid chromatogram and mass spectrum, in particular to a capillary monolithic column spray needle. The capillary monolithic column spray needle comprises a capillary pipe, the capillary pipe is filled with monolithic material, a needle head used for electron spray extend at one end of the capillary pipe to form a capillary monolithic column spray needle, then the capillary monolithic column spray needle is connected to the tail end of a capillary separating column through a two-way pipe and the voltage used for electron spray is applied to the two-way pipe. The invention has the main advantages that because the dead volume existing in an electron spray needle in the combined use of the microcolumn liquid chromatography and the mass spectrum and the electron spray needle is eliminated, the capillary monolithic column spray needle eliminates the disturbance and the mixing action of the dead volume to the microcolumn liquid chromatography is eliminated, greatly enhances the separating capacity and the repeatability of the microcolumn liquid chromatography and represents superior performance to the commercial capillary electron spray needle in the quantitative proteomics; and in addition, because the monolithic column material exists in the capillary monolithic column spray needle, the problem that the electron spray needle is easy to be blocked during the separation and the analysis process is solved and the service life of the electron spray needle is greatly prolonged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

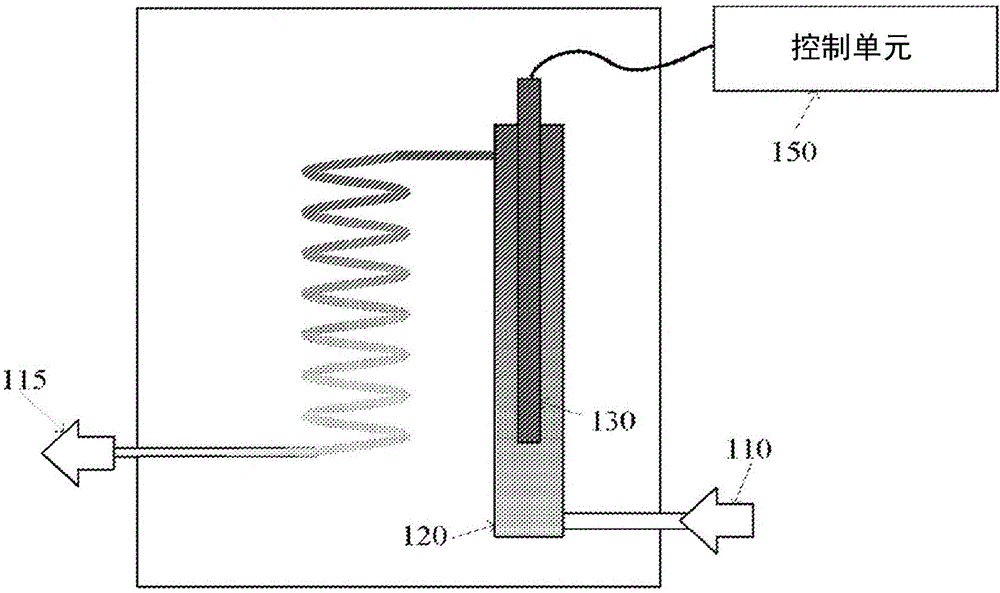

Method and apparatus for a directly electrically heated flow-through chemical reactor

InactiveCN105992643AEven heat distributionShort heating timeGas treatmentDispersed particle separationChemical mixturesChemical reaction

A system and method for facilitating a chemical reaction is provided. The system can have an electrically conductive member. The electrically conductive member is capable of holding a chemical mixture. The electrically conductive member is directly coupled to a power source and is heated when the power source is on. When a chemical mixture is within the electrically conductive member and the power source is on, the chemical mixture is heated such that a chemical reaction can occur.

Owner:MKS INSTR INC

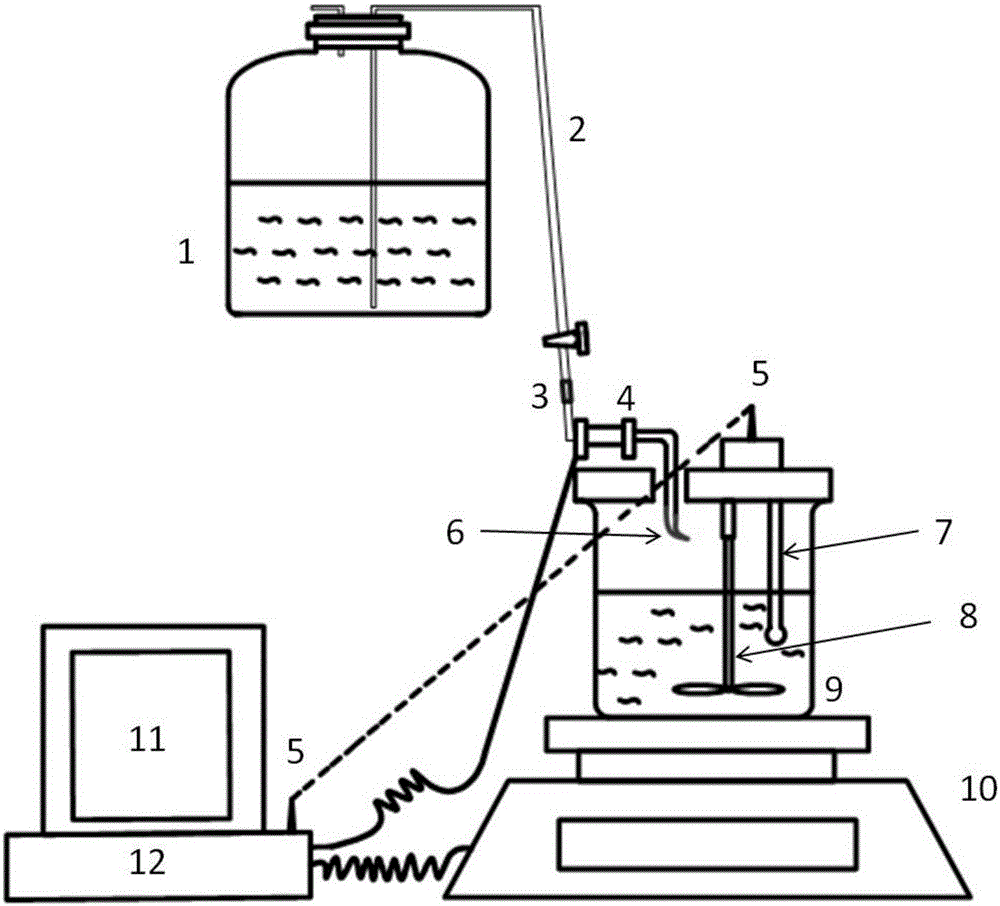

Electrically-controlled dropwise adding system for inductive gravity metering

InactiveCN106391156ASimple structureLow failure rateChemical analysis using titrationBurettes/pipettesFailure rateWireless transmission

The invention relates to an electrically-controlled dropwise adding system for inductive gravity metering. The electrically-controlled dropwise adding system comprises a liquid storage flask (1), a liquid discharge tube (2), an electromagnetic valve (4), a titrating head (6), a wireless transmission module, a titrating cup (9), a balance (10) and a controller (12); the liquid storage flask (1) is connected with the titrating head (6) through the liquid discharge tube (2) and the electromagnetic valve (4), the titrating head (6) is arranged on the titrating cup (9), the wireless transmission module is fixed to a lid of the titrating cup (9), the titrating cup (9) is arranged on the balance, and the controller (12) is connected with the electromagnetic valve (4), the balance (10) and the wireless transmission module separately. Compared with the prior art, the electrically-controlled dropwise adding system has the advantages of being simple in structure, low in failure rate, higher in precision, small in dead volume, capable of saving a standard titrating solution for washing and replacing and the like.

Owner:SHANGHAI RES INST OF CHEM IND +1

Interface unit containing capillary electrophoresis of hollow-fiber membrane and chemoluminescence combination

InactiveCN101782504AEliminate dead volumeSmall dead volumeChemiluminescene/bioluminescenceEpoxyInjection port

The invention relates to an interface unit containing capillary electrophoresis of a hollow-fiber membrane and chemoluminescence combination, which at least comprises a hollow-fiber membrane. The hollow-fiber membrane is arranged between an injection port of a capillary and a detection window, both ends of the hollow-fiber membrane are respectively inserted into a Teflon tube, and the edges for connecting the Teflon tube with the hollow-fiber membrane are bonded and sealed by epoxide resin; chemiluminescence reagent is mixed with a sample through the hollow-fiber membrane, the chemiluminescence reaction is carried out, and a chemiluminescence detector is used for further detection. The interface unit has the advantages of high column efficiency and detection sensitivity, simple structure,convenient operation, easy control and wide application range.

Owner:EAST CHINA UNIV OF SCI & TECH

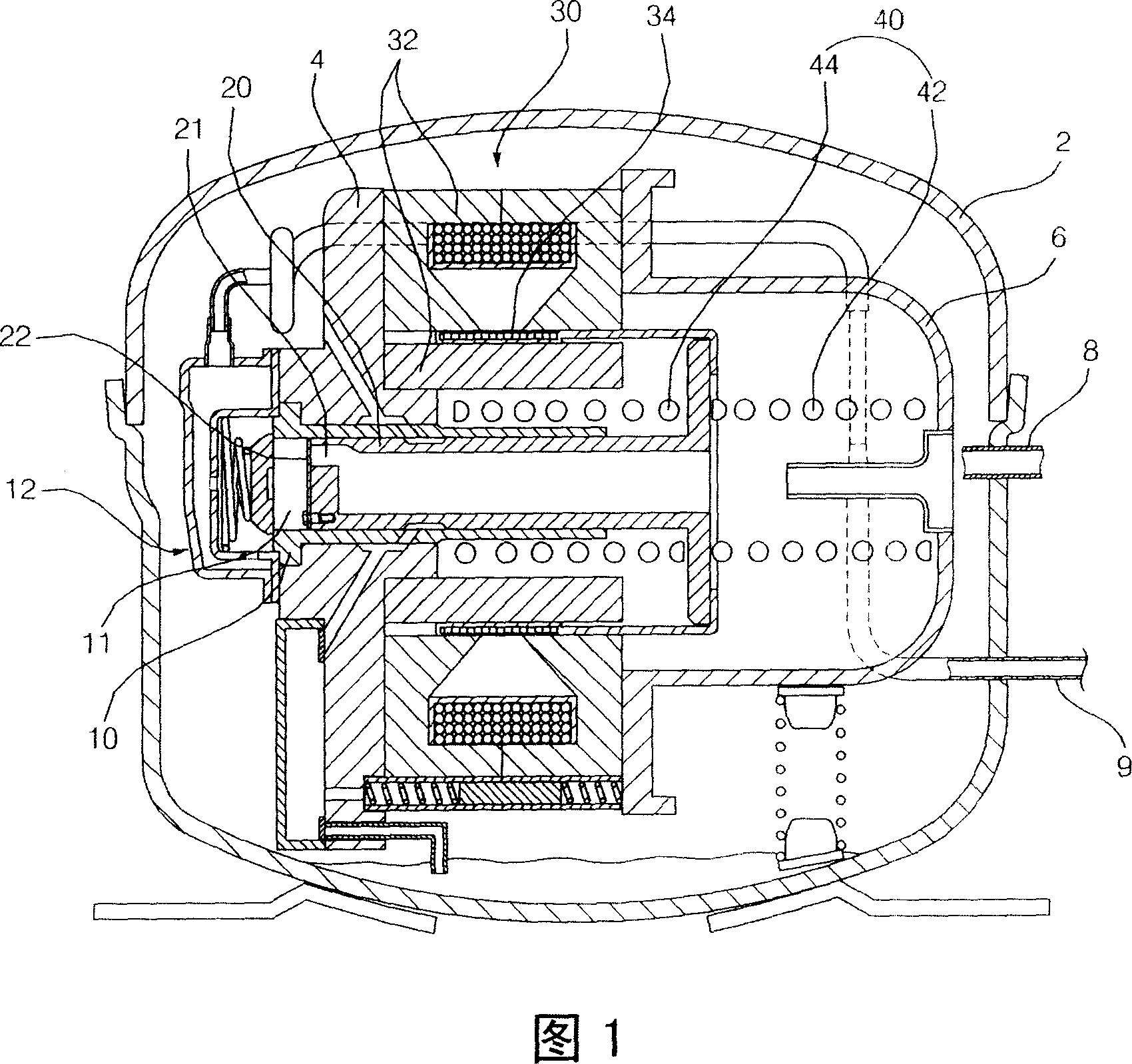

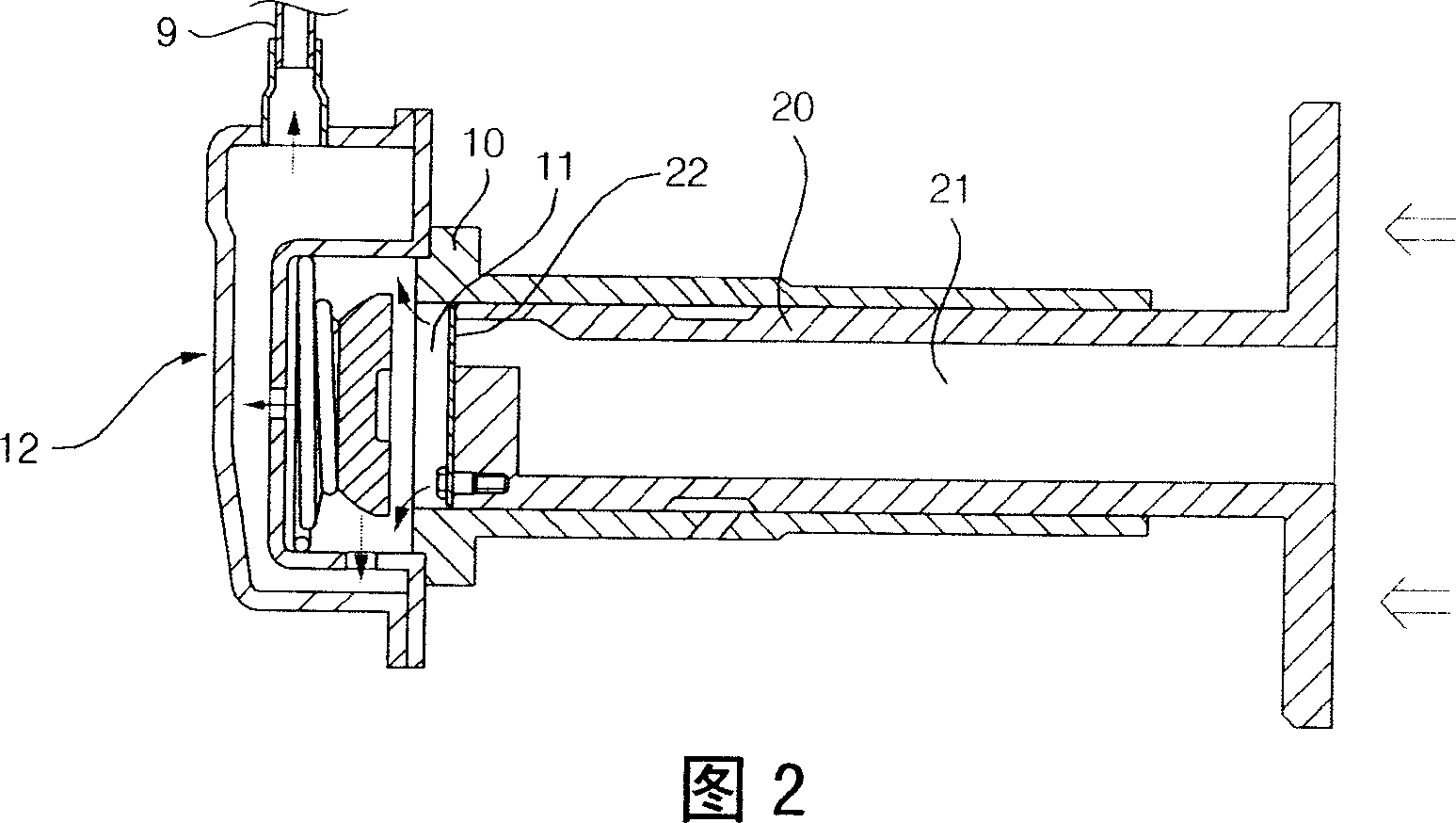

Linear compressor

InactiveCN1966979AUniform opening/closing strokeImprove responsePositive displacement pump componentsPiston pumpsWorking fluidReciprocating motion

Disclosed herein is a linear compressor in which a piston reciprocally moves in a cylinder upon receiving a reciprocating drive force of a linear motor to compress working-fluid, for example, refrigerant, received in the cylinder. The linear compressor comprises a piston adapted to reciprocally move in a cylinder, the piston being internally formed with a suction path, and a suction valve inserted in the suction path of the piston to move relative to the suction path, the suction valve performing opening / closing operations as it moves relative to the piston when the piston reciprocally moves. With this configuration, the suction valve always exhibits an even stroke, achieving an improvement in response and durability and minimizing vibration and noise due to the opening / closing operations thereof.

Owner:LG ELECTRONICS INC

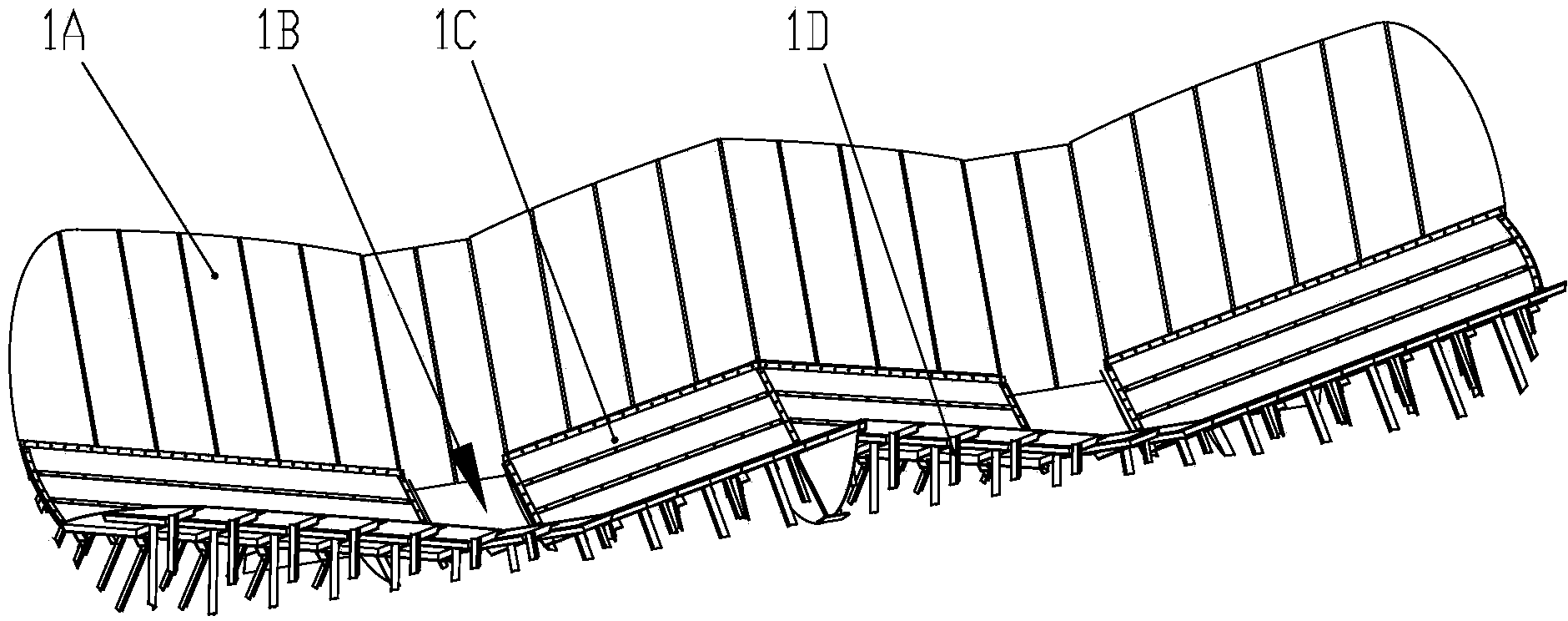

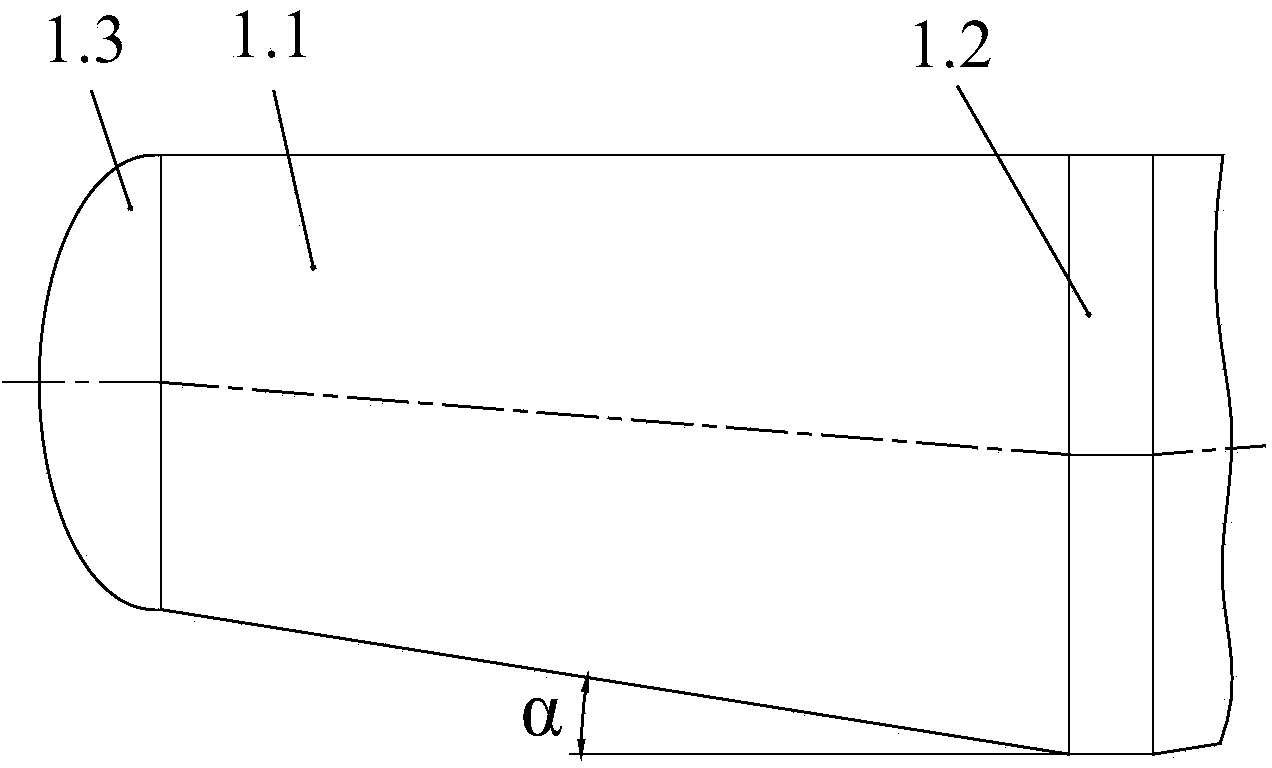

Non-mezzanine bulk cement tanker tank for railroad

The invention relates to a non-mezzanine bulk cement tanker tank for the railroad. The tank comprises a horizontal tank, wherein the horizontal tank is of a segmented combined structure and consists of a middle short cylindrical section, a pair of right-angle oblique cone cylinders and a pair of tank heads, and the upper generatrix of the right-angle oblique cone cylinders and the upper generatrix of the middle short cylindrical section horizontally coincide; the lower generatrix of the right-angle oblique cone cylinders and the lower generatrix of the middle short cylindrical section form a slope, and a curved fluidized bed is arranged at the bottom of the inner cavity of the right-angle oblique cone cylinders in an adherence way and is provided with a plurality of juxtaposed breathable weaving tube belts which are connected with an external compressed gas source through an intake manifold. The design eliminates the complex internal structure of the existing cement tanker, utilizes the radian and the slope of the bottom of the tank to arrange the fluidized beds, so that the internal structure of the tank is simplified, the invalid volume is eliminated, the weight of the tank is reduced, and the height of the center of gravity is reduced, thus the vehicle load is increased, a series of inertia problems brought by ash leakage are solved, and the maintenance and the overhaul are more time-saving and convenient.

Owner:CRRC YANGTZE CO LTD

Method and Apparatus for a Directly Electrically Heated Flow-Through Chemical Reactor

InactiveUS20150232333A1Low costSmall sizeChemical/physical/physico-chemical processesOxygen preparationChemical mixturesChemical reaction

A system and method for facilitating a chemical reaction is provided. The system can have an electrically conductive member. The electrically conductive member is capable of holding a chemical mixture. The electrically conductive member is directly coupled to a power source and is heated when the power source is on. When a chemical mixture is within the electrically conductive member and the power source is on, the chemical mixture is heated such that a chemical reaction can occur.

Owner:MKS INSTR INC

Composite electrical steel material

InactiveCN102975424AImprove insulation performanceImprove rust resistanceInorganic material magnetismMetal layered productsElectrical steelMaterials science

The invention discloses a composite electrical steel material which is characterized by comprising two magnetic materials, namely an amorphous soft magnetic alloy material and an electrical steel base material, wherein the amorphous soft magnetic alloy material is compounded to two surfaces or one surface of the electrical steel base material; and the amorphous soft magnetic alloy material is metal glass. According to the composite electrical steel material, the amorphous soft magnetic alloy material and the electrical steel base material are compounded; due to high insulativity and high rust resistance of the layered amorphous soft magnetic alloy material, the insulation and rust resistance functions of an organic, inorganic or semiorganic coating layer coated on the surface of the conventional electrical steel material are replaced, so that the material completely gets rid of the problem of low environment friendliness during production, coating and use of an organic and / or inorganic insulative coating; furthermore, since the amorphous soft magnetic alloy material has high magnetic performance, the ineffective volume of the conventional insulative coating layer is eliminated, the stacking coefficient of the material is effectively increased; and the magnetic performance of the material is greatly improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

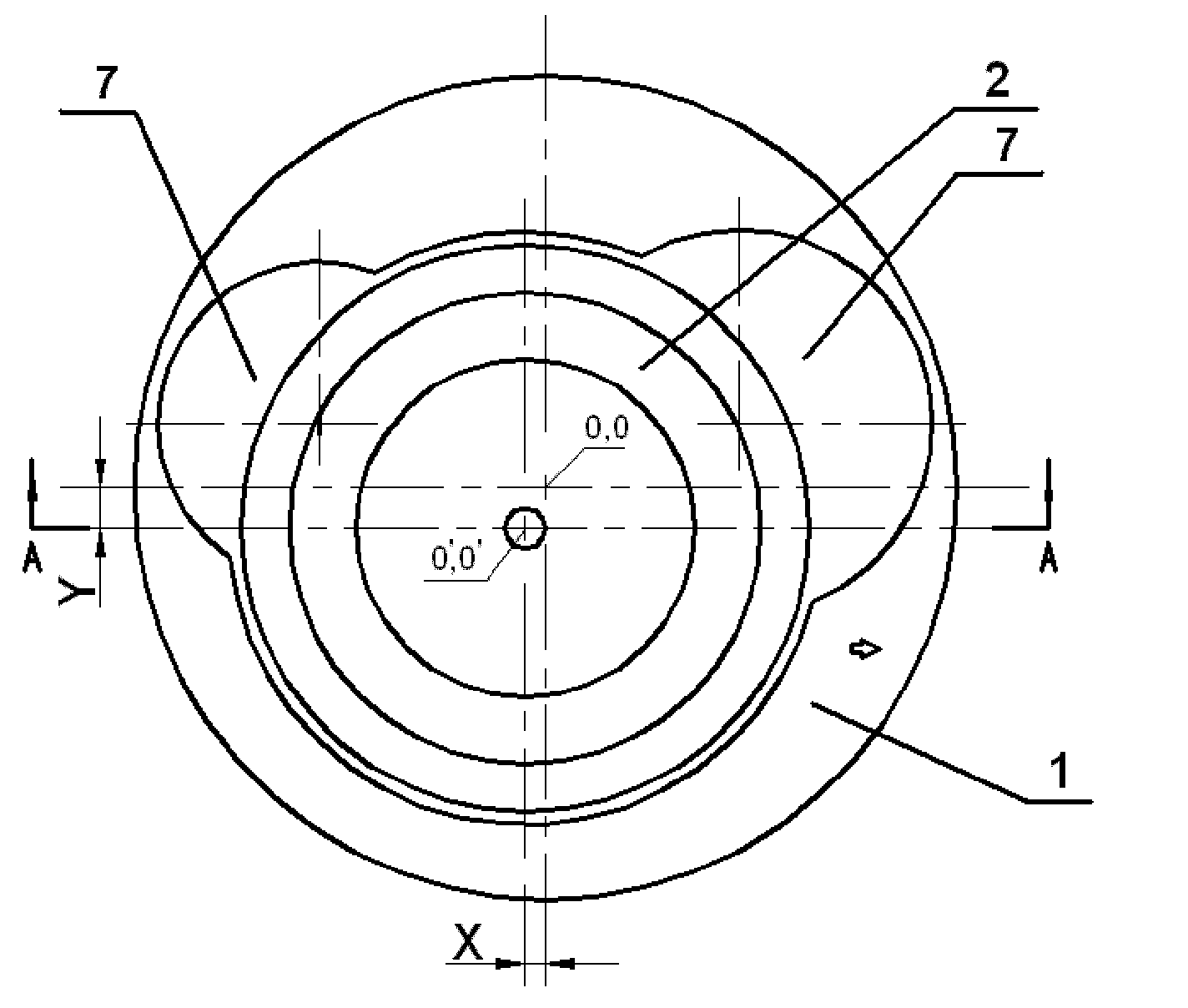

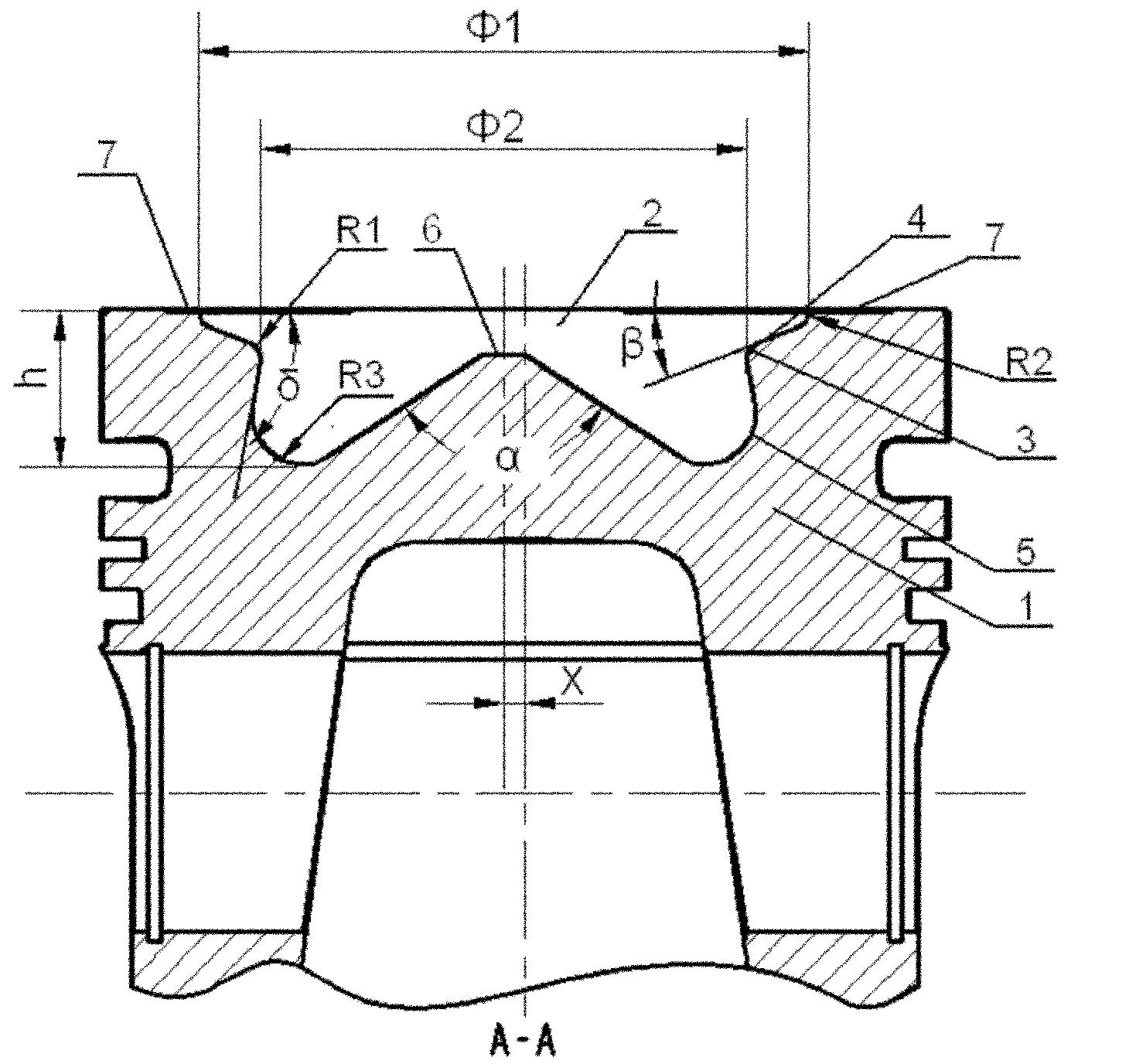

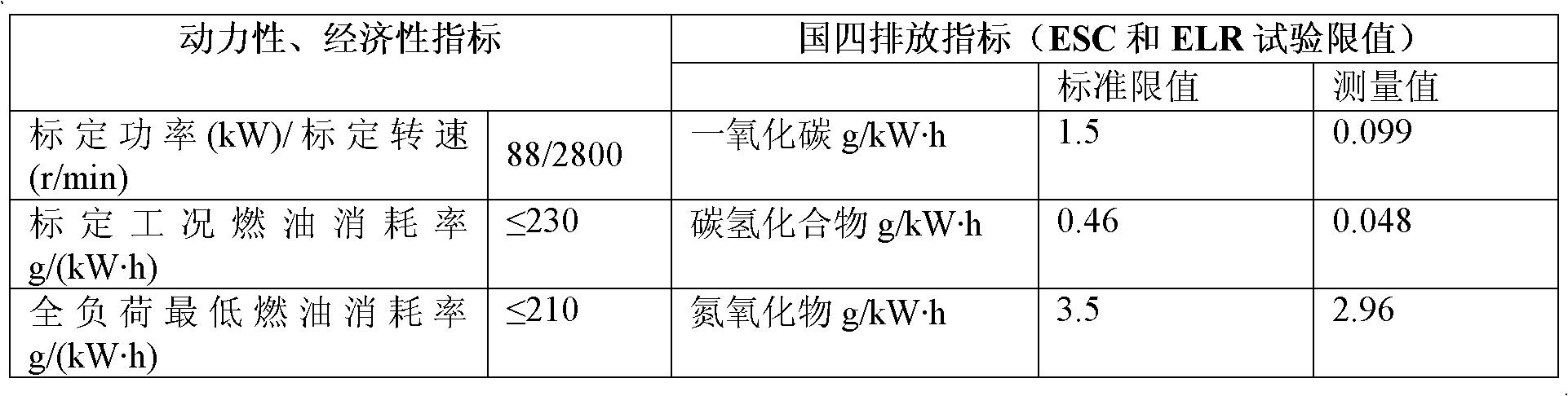

Combustion chamber of diesel engine

InactiveCN102062014AImprove powerEmission reductionMachines/enginesPistonsCombustion chamberDead volume

The invention discloses a combustion chamber of a diesel engine. The combustion chamber arranged at the upper part of a piston body is designed into an eccentric type, the offset X' equals to 2.5mm, and the offset Y' equals to 5mm. The inner periphery of the combustion chamber is an annular necking which divides the inner periphery of the combustion chamber into two parts, i.e. a slope and a concave, the first part and the second part are in transition connection by an angle beta and a circular arc of R1, R2 is combined with the piston top surface; a punch insert platform is arranged in the center of the combustion chamber, the included angle beta between the slope and a horizontal line of the top surface of the piston body is 21 degrees; the arc length R1 of the transition segment between the slope and the concave equals to 2mm; and the circular arc radius R3 of the concave is tangential to the end lines of an included angle alpha of the punch insert and the transition surface of the concave, and the arc length R2 of the transition segment between the outer edge of the slope and the piston top surface is 2mm. The structural design of the combustion chamber is favorable for reasonably controlling the strength and the form of a vortex to fully mix fuel and air for combustion, and preventing the fuel from being stuck on the walls of the combustion chamber, and a large-angle punch insert is favorable for eliminating the dead volume to promote more sufficient combustion and improve the dynamics of the diesel engine and reduce the emission.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

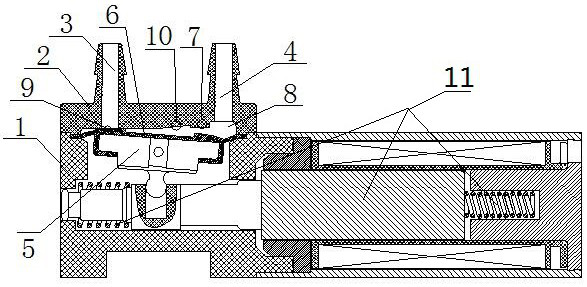

Dead-volume-free rocker arm two-way electromagnetic valve

PendingCN113090784AEliminate flow dead endsEliminate dead volumeDiaphragm valvesOperating means/releasing devices for valvesRocker armEngineering

The invention relates to a dead-volume-free rocker arm two-way electromagnetic valve which comprises a valve body, a valve seat, a fluid inlet, a fluid outlet, a rocker arm and a diaphragm. The valve seat covers the valve body, the valve body, the valve seat, the fluid inlet, the fluid outlet and the diaphragm jointly form a flow channel for fluid circulation, and a flow sweeping structure capable of eliminating the fluid dead volume is arranged on the flow channel. The flow sweeping structure comprises a first inclined surface and a flow guide wing, the first inclined surface is an inclined surface on the left part of the diaphragm and is close to the fluid inlet, the flow channel inclines upwards in the horizontal direction from the fluid inlet to the fluid outlet, and the fluid outlet is located in the farthest end of the flow channel; and the flow guide wing forms a flow guide structure for controlling fluid in the flow channel not to rotate so as to prevent formation of the dead volume. After the structure is adopted, the following effects can be achieved: the circulation condition of fluid in the valve is thoroughly changed, the dead volume in the valve is eliminated, the experiment accuracy and precision are improved, and the economic benefit and the experiment effect are very remarkable.

Owner:SHENZHEN JINGGAN TECH DEV CO LTD

A back pressure valve for ultra-high pressure and high temperature experiments

ActiveCN103912700BImprove reliabilityEliminate dead volumeOperating means/releasing devices for valvesEqualizing valvesUltra high pressureDead volume

The invention discloses an ultrahigh-pressure high-temperature experimental back-pressure valve which mainly comprises an upper valve body, a lower valve body, an ultrahigh-pressure gas chamber, an alloy diaphragm, a horizontal fluid channel, a vertical fluid channel, a central hole and a valve needle. The alloy diaphragm 4 is located between the upper valve body 1 and the lower valve body 1 and forms a multistage combined soft seal 10 with the upper valve body and the lower valve body, the ultrahigh-pressure gas chamber 3 is located in the upper valve body and is connected with a back-pressure pipeline end 9, and a through hole 11 is formed between the ultrahigh-pressure gas chamber and the horizontal fluid channel 5; the central hole 7 is formed in the intersection point of the horizontal fluid channel 5 and the vertical fluid channel 6 which are located in the lower valve body, the central hole extends upwards to the ultrahigh-pressure gas chamber, the valve needle 8 is located in the central hole, the top of the valve needle is machined into a first threaded rod 15, the needle tip of the valve needle 8 is sealed in a sealing pad 14 at the tail end of the central hole 7, and the central hole moves downwards to be connected to a sample line end 12. The ultrahigh-pressure high-temperature experimental back-pressure valve is high in sealing performance, high in pressure control, high in stability and free of dead volume, and the gap in the prior art is filled up.

Owner:SOUTHWEST PETROLEUM UNIV

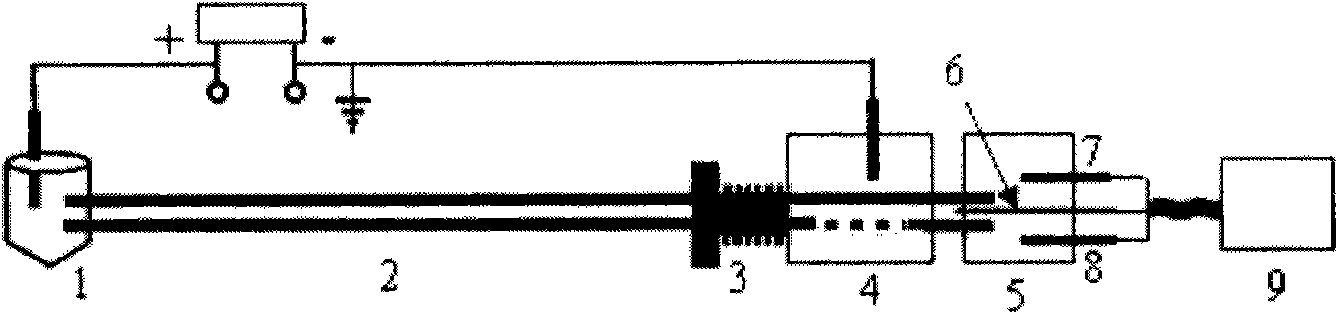

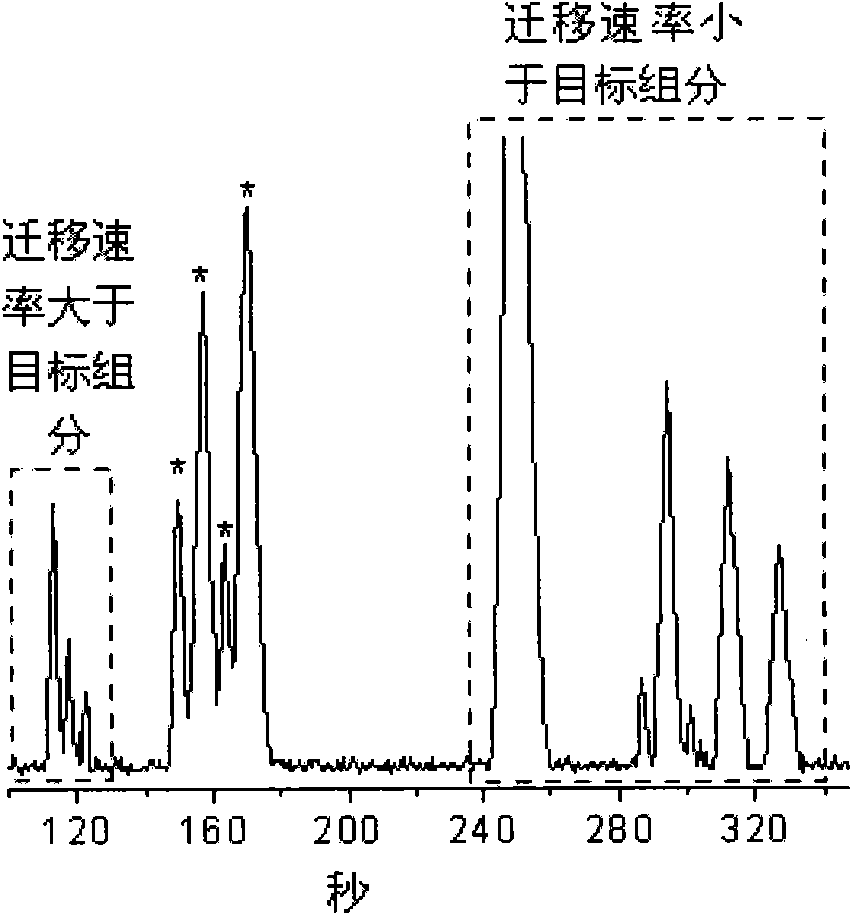

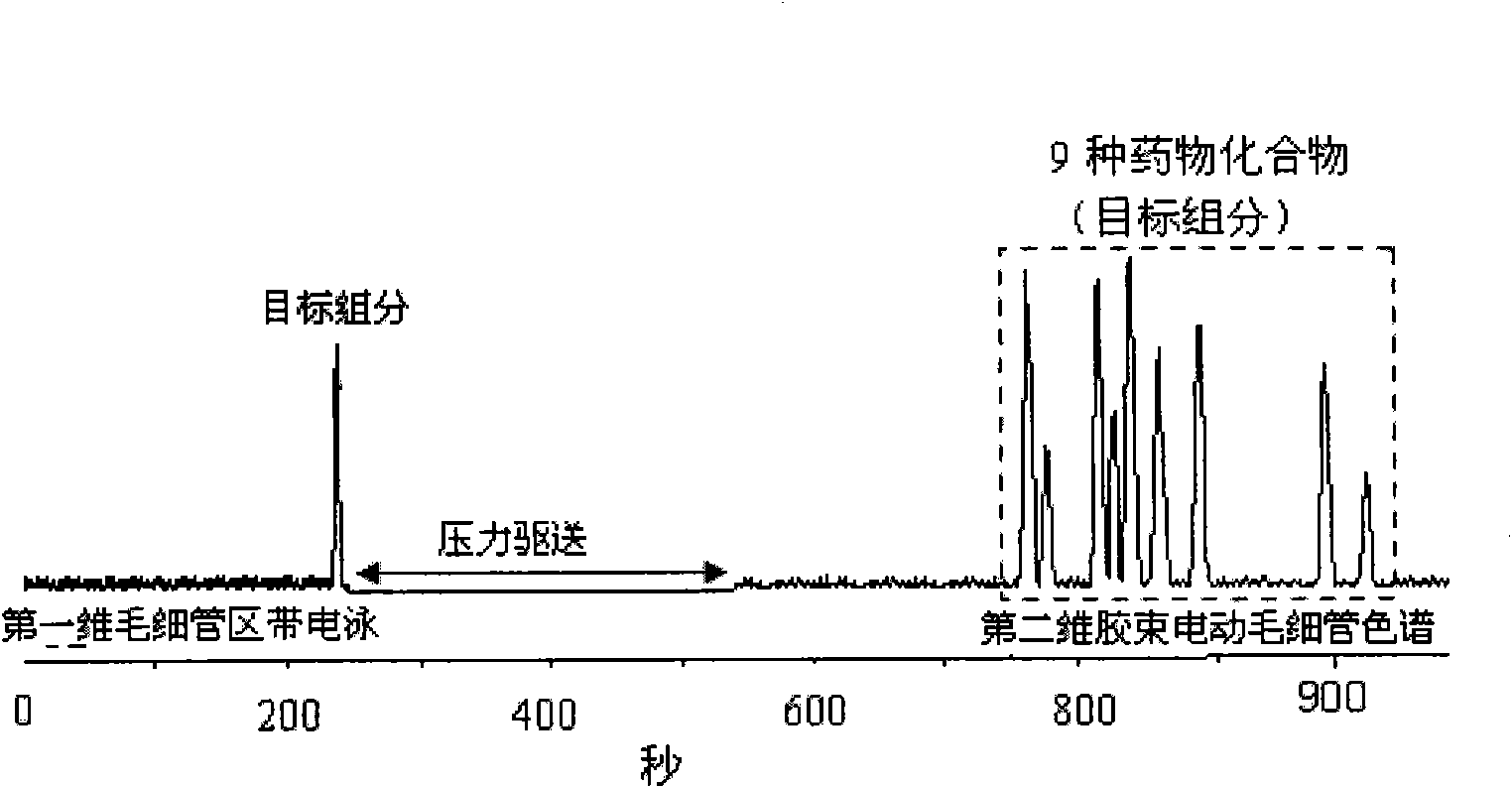

Heart-cutting two-dimensional capillary electrophoresis on-column electrochemical device and application thereof

InactiveCN101852764AReduce usageHigh column efficiencyMaterial analysis by electric/magnetic meansElectrochemical detectorOn column

The invention relates to a capillary tube electrophoretic technique, in particular to a heart-cutting two-dimensional capillary electrophoresis on-column electrochemical device and application thereof. The device comprises a capillary column, an electrochemical detection pool, an electrochemical detector and a high-voltage power supply, wherein a segment of polyimide coating is removed from a position with a distance of 0.5 to 3 cm away from the outlet end of the capillary; the capillary wall with the coating removed is corroded into a porous shape by using hydrofluoric acid; a layer of cellulose acetate pulp is coated on the position uniformly to form a field insulating joint which can only allow current to pass through and avoid leakage of solution; and a working electrode, an auxiliary electrode and a reference electrode are inserted into the electrochemical detection pool. The application comprises the following steps of: separating a complicated sample in first dimension buffer solution; when the working electrode detects a signal of a target component, applying pressure at a detection end to drive the target component to the inlet end of the capillary; allowing second dimension separation buffer solution to enter the capillary from the tail end of the capillary; and further performing separation and detection on the target component in the second dimension separation buffer solution. The device has the advantages of high column efficiency of heart-cutting two-dimensional capillary electrophoresis separation, no loss of samples and suitability for on-line separation and detection of target components in complicated samples.

Owner:QINGDAO UNIV OF SCI & TECH

Two-phase integral column as well as preparation and application thereof

InactiveCN101413932BEliminate dead volumeRealize "zero dead volume" connectionOther chemical processesComponent separationChromatographic separationMicro column

The invention relates to a monolithic capillary column, in particular to a two-phase monolithic column which is characterized in that two fixed phases with different separation mechanisms exist in the same column pipe; the two phases exist in the form of a front section and a rear section. The two-phase monolithic column has the main advantages of basically eliminating dead volume which is generated when two monolithic columns with different separation mechanisms are connected in a micro-column liquid phase chromatographic separation system, carrying out automatic online multi-dimensional separation and having extremely strong capability of separating complex samples such as protein zymolyte; furthermore, the monolithic column has good permeability and low operation pressure, and is easy to be operated on a normal liquid chromatography and can obtain high-efficiency separation results.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Quiescent interface extraction tank, quiescent interface extraction device and extraction method

PendingCN110652747AImprove sealingGuaranteed tightnessWithdrawing sample devicesLiquid solutions solvent extractionLiquid tankExtraction methods

The invention relates to the technical field of extraction kinetics, and discloses a quiescent interface extraction tank, a quiescent interface extraction device and an extraction method. The quiescent interface extraction tank comprises a tank body, a tank cover and a phase interface ring; the tank body comprises a jacket layer, and a light-phase liquid tank and a heavy-phase liquid tank which are sequentially connected from top to bottom, the upper end of the light-phase liquid tank is open, the bottom end of the heavy-phase liquid tank is gradually shrunk and extends downwards to be closed,the jacket layer is arranged at the peripheries of the light-phase liquid tank and the heavy-phase liquid tank, a sealed accommodating space is formed between the jacket layer and the light-phase liquid tank wall and the heavy-phase liquid tank wall, a quiescent-temperature water inlet is formed at the lower end of one side of the jacket layer, and a quiescent-temperature water outlet is formed at the upper end of the other side of the jacket layer; and the tank cover is detachably connected with the upper end of the light-phase liquid tank, and the phase interface ring is mounted in the tankbody and is located at the junction of the light-phase liquid tank and the heavy-phase liquid tank. The quiescent interface extraction tank has the advantages of good sealing performance, controllable temperature, and convenience in phase interface ring replacement and sampling.

Owner:SOUTH CHINA UNIV OF TECH

Proximal degas driven microfluidic actuation

ActiveUS9737888B2High porosity and air solubilityReduce internal pressureLaboratory glasswaresLiquid degasification by filtrationEngineeringPre treatment

An apparatus with a self-contained, tunable, microfluidic pumping system that utilizes the high air permeability of the matrix material to actuate fluid flow in a network of fluidic microchannels and microstructures is provided. The pumping relies upon partial evacuation of degas / vacuum channels that are located next to the fluid channels to degas air from the fluid channels or structures producing a reduction of pressure in the fluidic channel leading to the flow of fluid from an inlet at atmospheric pressure through the device. The solution is isolated from the pumping apparatus since the liquid does not pass through the diffusion barriers. The apparatus and method can also provide bubble-free microfluidic pumping, without any auxiliary equipment or device pre-treatment, and can fill dead-end channels and chambers, providing a powerful liquid handling tool for a broad range of applications.

Owner:RGT UNIV OF CALIFORNIA

System for on-line desalinization, enrichment and mass spectrum of Double tap upgrade liquid chromatogram

InactiveCN101206197BEliminate dead volumeReduce the effects of ionizationComponent separationDead volumeSystem pressure

The invention relates to a double splitflow nano upgrade liquid phase chromatogram online desalting, enrichment and mass spectrum combination system which comprises a pump, a first splitter, a second splitter, a sample valve, a switching valve, a backpressure valve, a capillary tube separation column and a mass spectrometer, wherein, the pump, the first splitter, the sample valve, the second splitter, the capillary tube separation column and the mass spectrometer are connected in series in turn through pipelines; the split ports of the first splitter and the second splitter are respectively connected with the two inlets of the switching valve through the pipelines; moreover, the outlet of the switching valve is connected in series with the backpressure valve and then is communicated with a waste fluid pool through the pipeline. The system has the advantages that: during the sampling and separation of sample, the system has less pressure fluctuation; with small pre-column dead volume, the system overcomes the gradient delay effect caused by large-volume sampling adopted in the prior nano upgrade liquid phase separation system; with excellent separation repeatability, the system is particularly suitable for gradient separation; meanwhile, the system can be used in online desalting, enrichment and mass spectrum combination of sample with high salinity and low concentration; moreover, the system has a simple structure, convenient operation and easily realized automation.

Owner:徐州脉析医疗技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com