System for on-line desalinization, enrichment and mass spectrum of Double tap upgrade liquid chromatogram

A liquid chromatography and desalting technology, which is applied in the field of enrichment and mass spectrometry combined system, double-split nano-upgrade liquid chromatography on-line desalination, can solve the problems of poor separation effect, poor system repeatability, unfavorable automation, etc., and achieves the application scope Wide, good versatility, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

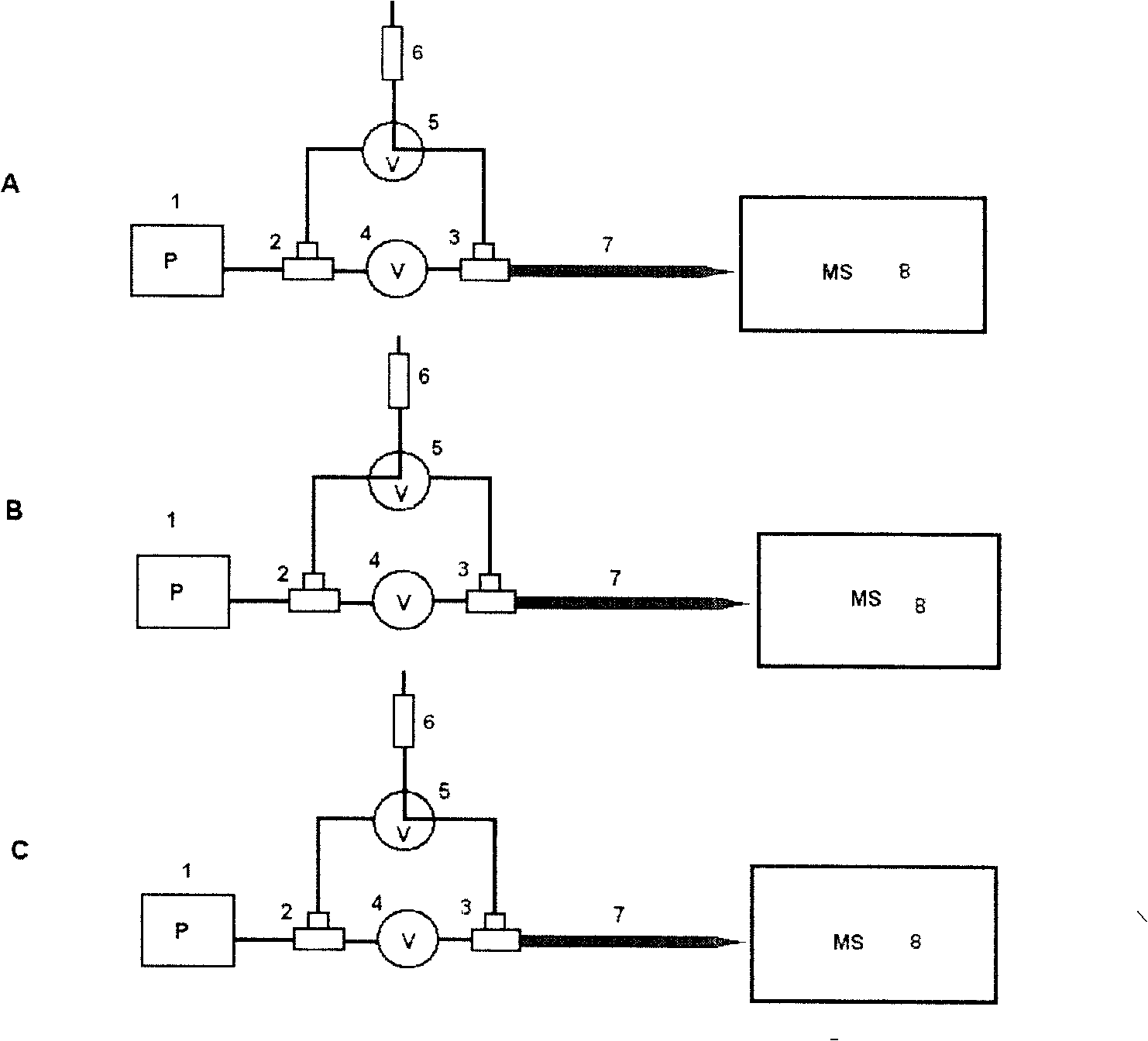

[0026] see figure 1 , the system consists of a pump 1, a first splitter 2, a second splitter 3, an injection valve 4, a switching valve 5, a back pressure valve 6, a (capillary) separation column 7 and a mass spectrometer 8. The mobile phase transported from the pump 1 can be split through the first splitter 2 and the second splitter 3; the injection valve 4 is connected between the first splitter 2 and the second splitter 3, and the two splitters are respectively Connected to switching valve 5. Finally, the passage leads through the back pressure valve 6 to waste. One end of the capillary separation column 7 becomes tapered after heating and stretching, not only can fix the stationary phase in the separation column directly, but also can be connected with the mass spectrometer; the other end is directly connected with the second splitter 3 .

[0027] When equilibrating the separation column as figure 1 -a, by controlling the switching valve 5, the mobile phase is split at ...

Embodiment 2

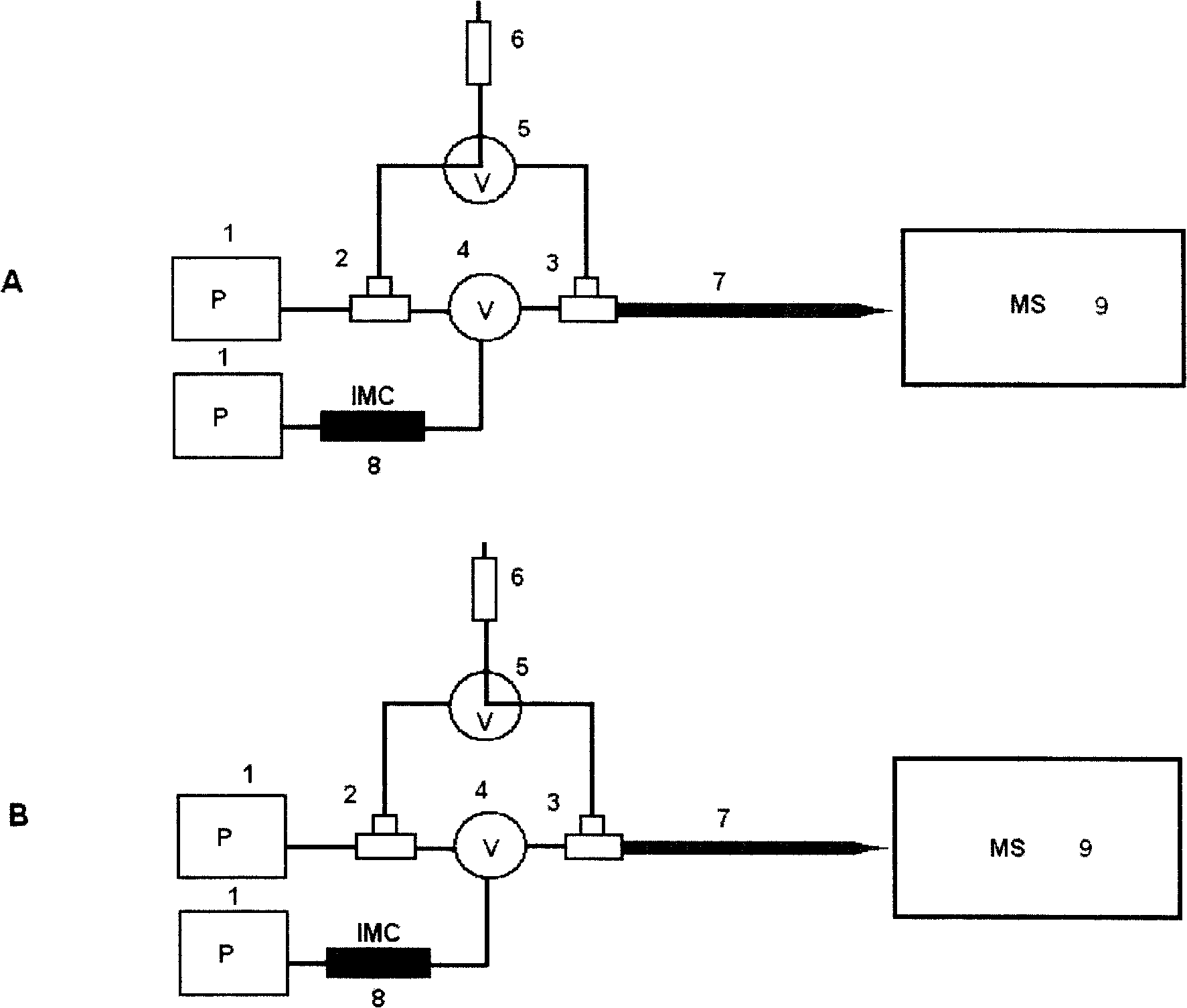

[0033] see image 3 , the system consists of pump 1, first splitter 2, second splitter 3, injection valve 4, switching valve 5, back pressure valve 6, (capillary) separation column 7, immobilized metal affinity chromatography monolithic column (IMC) 8 and mass spectrum 9 composition. The mobile phase transported from the pump 1 can be split through the first splitter 2 and the second splitter 3 . The sampling valve 4 is connected between the first flow divider 2 and the second flow divider 3 , and the two flow dividers are respectively connected with the switching valve 5 . Finally, the passage leads through the back pressure valve 6 to waste. One end of the capillary separation column 7 becomes tapered after heating and stretching, not only can fix the stationary phase in the separation column directly, but also can be connected with the mass spectrometer; the other end is directly connected with the second splitter 3 .

[0034] The sample is pumped into the immobilized me...

Embodiment 3

[0037] see figure 1 , the system consists of a pump 1, a first splitter 2, a second splitter 3, an injection valve 4, a switching valve 5, a back pressure valve 6, a (capillary) separation column 7 and a mass spectrometer 8. The mobile phase transported from the pump 1 can be split through the first splitter 2 and the second splitter 3 . The sampling valve 4 is connected between the first flow divider 2 and the second flow divider 3 , and the two flow dividers are respectively connected with the switching valve 5 . Finally, the passage leads through the back pressure valve 6 to waste. One end of the capillary separation column 7 becomes tapered after heating and stretching, not only can fix the stationary phase in the separation column directly, but also can be connected with the mass spectrometer; the other end is directly connected with the second splitter 3 .

[0038] When equilibrating the separation column as figure 1 -a, by controlling the switching valve 5, the mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com