Quiescent interface extraction tank, quiescent interface extraction device and extraction method

An extraction device and constant interface technology, applied in the field of constant interface extraction pool, can solve the problems of increased experimental error, uneven concentration distribution in the phase, large experimental error, etc., to avoid solvent volatilization, ensure sealing, and eliminate dead volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

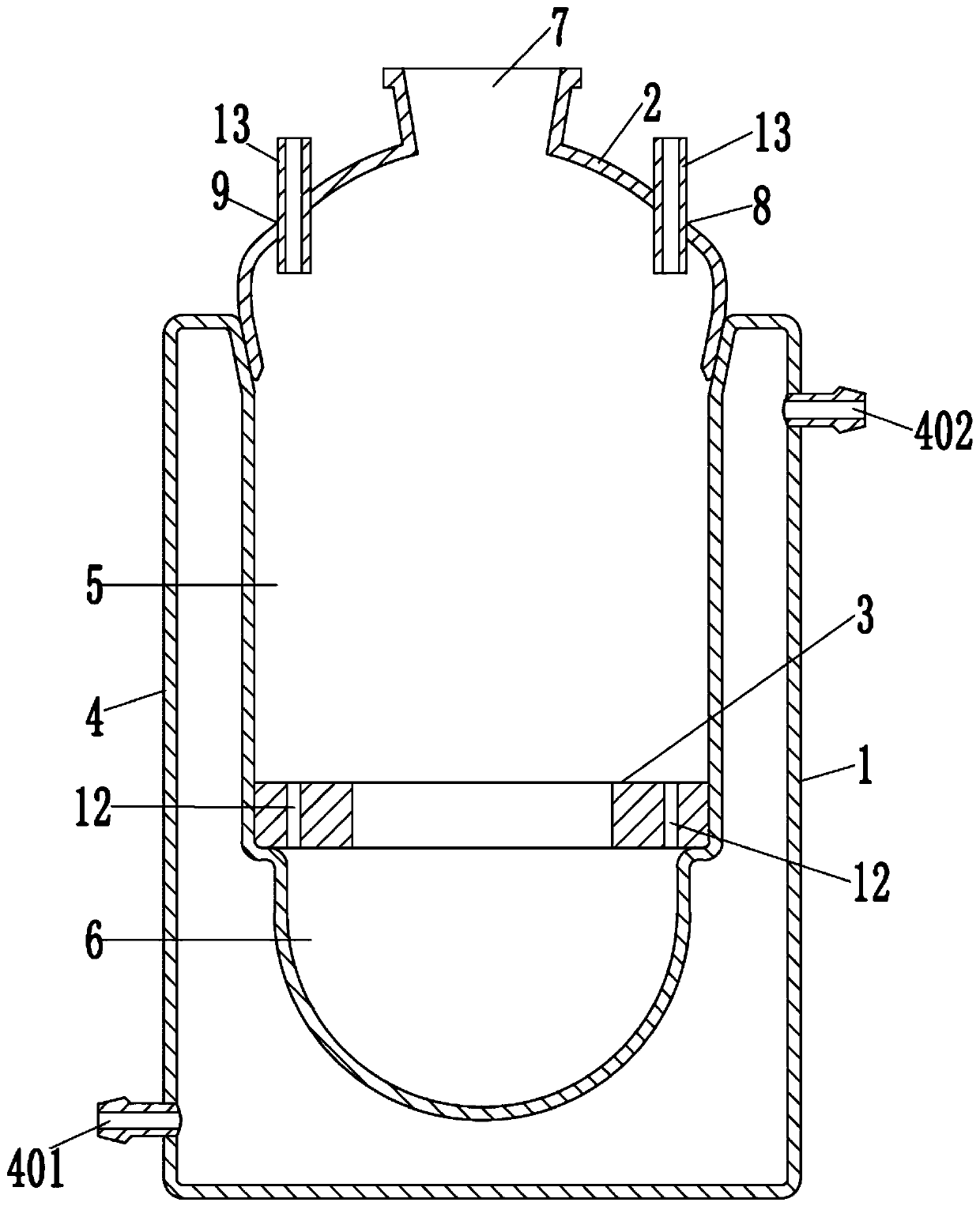

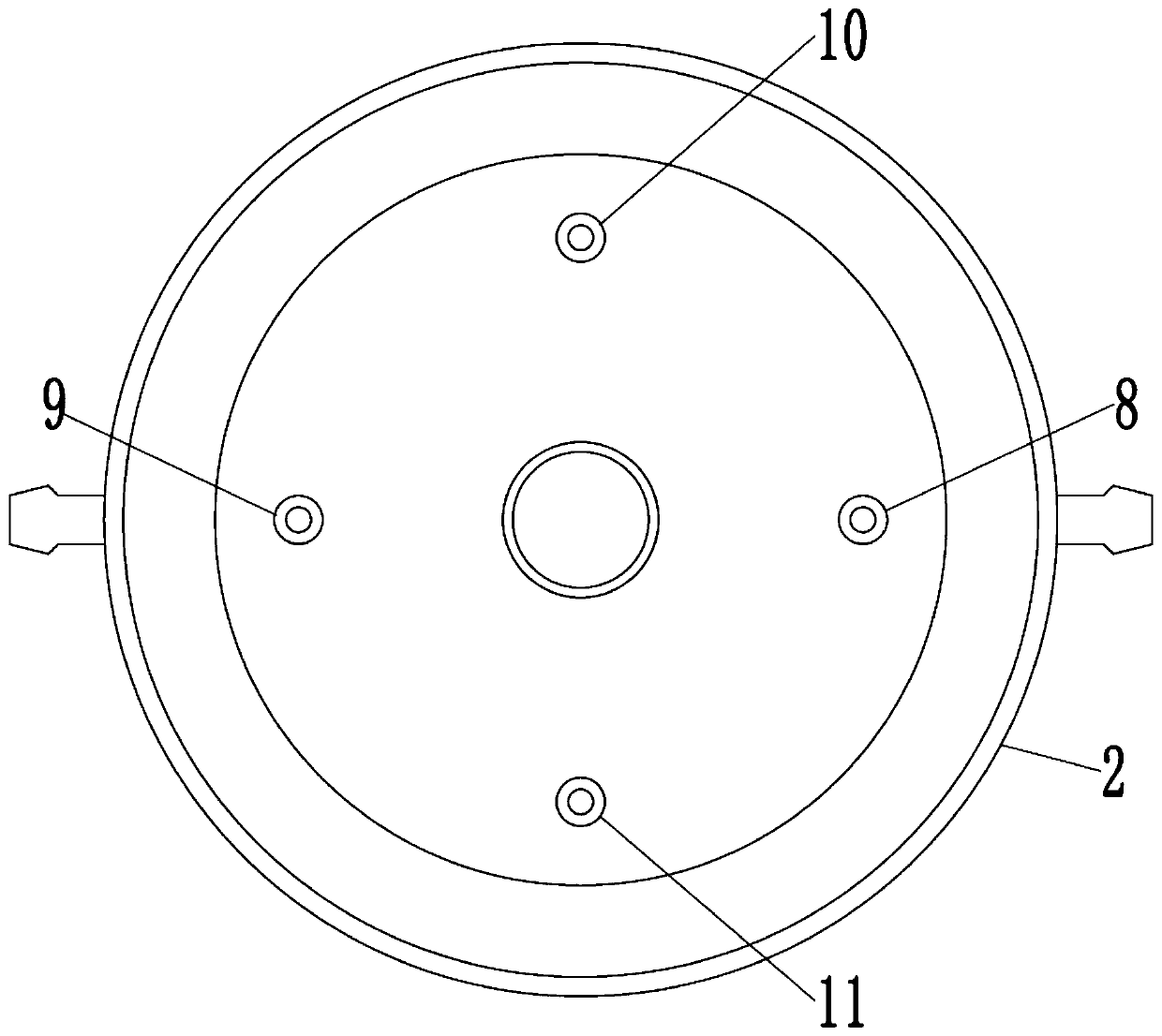

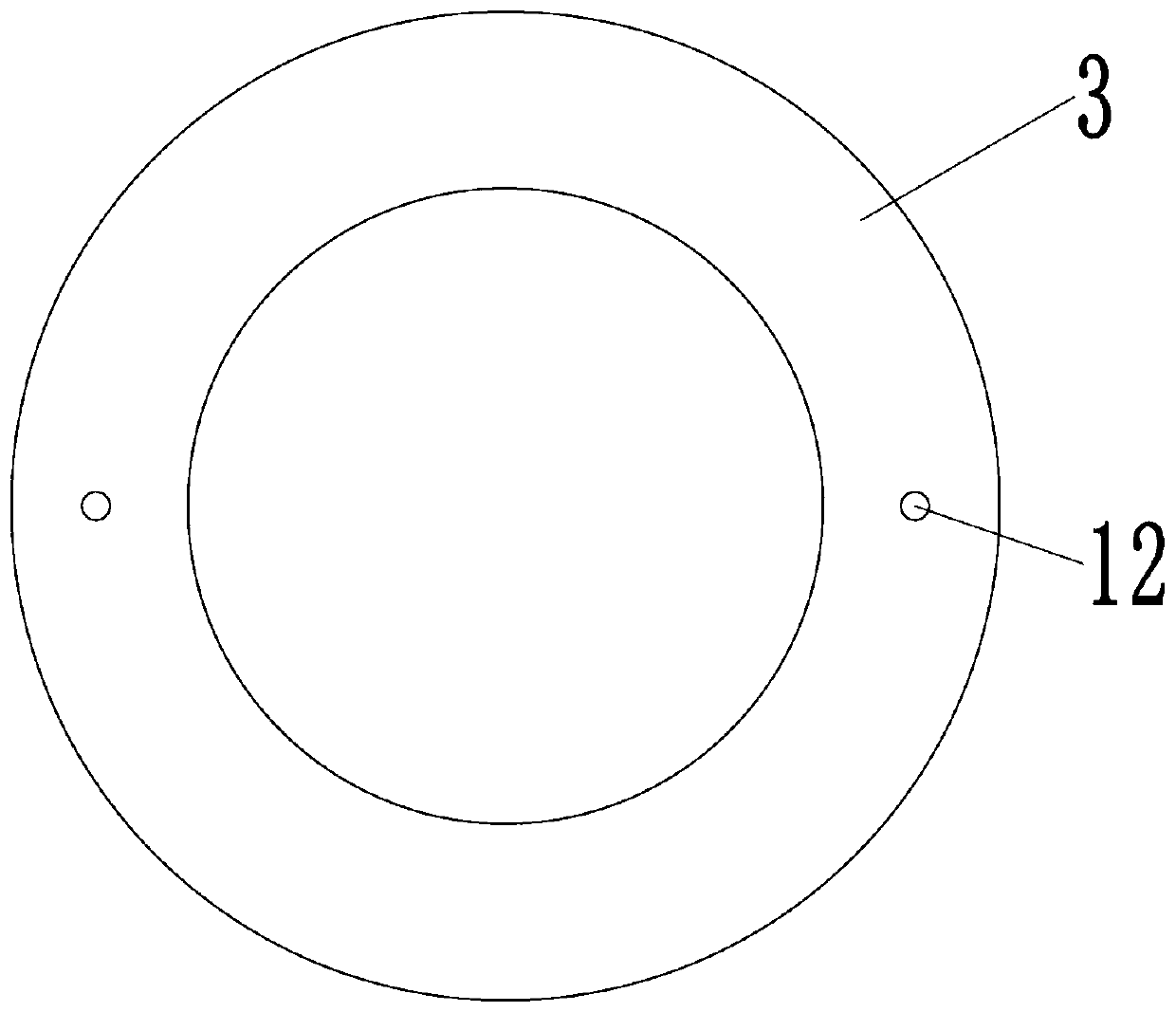

[0037] Such as Figure 1-Figure 3 A constant interface extraction cell shown includes a cell body 1, a cell cover 2 and a phase interface ring 3; the cell body 1 includes a jacket layer 4 and a light phase liquid pool 5 and a heavy phase liquid pool 6 connected up and down in sequence , the upper end of the light phase liquid pool 5 is open, the bottom end of the heavy phase liquid pool 6 is tapered downwards and extends to close, and the jacket layer 4 is arranged between the light phase liquid pool 5 and the heavy phase liquid pool 6 Periphery, there is a sealed accommodation space between the jacket layer 4 and the outer wall of the light phase liquid pool 5 and the outer wall of the heavy phase liquid pool 6 wall, and a constant temperature water inlet 401 is opened at the lower end of one side of the jacket layer 4, The upper end of the other side of the jacket layer 4 is provided with a constant temperature water outlet 402, wherein both the constant temperature water in...

Embodiment 2

[0061]This embodiment is the same as embodiment 1 except the following technical features:

[0062] Using the constant interface extraction device with the above structure, study the extraction kinetics of 2-octanone from water with a concentration of 20000ppm xylenol, the inner diameter of the light phase liquid pool is 70mm, the diameter of the heavy phase liquid pool is 60mm, and the flow rate is 300mL / min. The pump pumps constant temperature water at 40°C from the constant temperature water bath to the jacket layer. Select a phase interface ring with an appropriate inner diameter, the thickness of the phase interface ring is 10mm, and the maximum sampling volume calculated based on the thickness does not exceed 12.56mL. The inner diameter of the through hole is 1mm, and the tested stirring paddle can keep the two-phase contact surface stable at the fastest speed of 300 rpm. The inner diameters of the light and heavy phase sampling needles are both 0.7mm, the length of the...

Embodiment 3

[0064] This embodiment is the same as embodiment 1 except the following technical features:

[0065] The constant interface extraction device with the above structure was used to study the extraction kinetics of 2-hexanone from water with a concentration of 10000ppm xylenol, the inner diameter of the light phase liquid pool was 70mm, and the diameter of the heavy phase liquid pool was 60mm, using a peristaltic flow rate of 500mL / min The pump pumps constant temperature water at 80°C from the constant temperature water bath to the jacket layer. Select a phase boundary ring with an appropriate inner diameter, and calculate the maximum sampling volume based on the thickness to be no more than 12.56mL. The inner diameter of the through hole is 1mm, and the tested stirring paddle can keep the two-phase contact surface stable at the fastest speed of 250 rpm. The inner diameters of the light and heavy phase sampling needles are both 0.7mm, the length of the heavy phase liquid samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com