Constant-interface abstraction pool

A technology of extraction pool and constant interface, applied in the field of separation, can solve the problems of complex internal structure, large amount of waste liquid, unsuitable radioactive experimental operation, etc., to achieve the effect of eliminating dead volume and facilitating washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

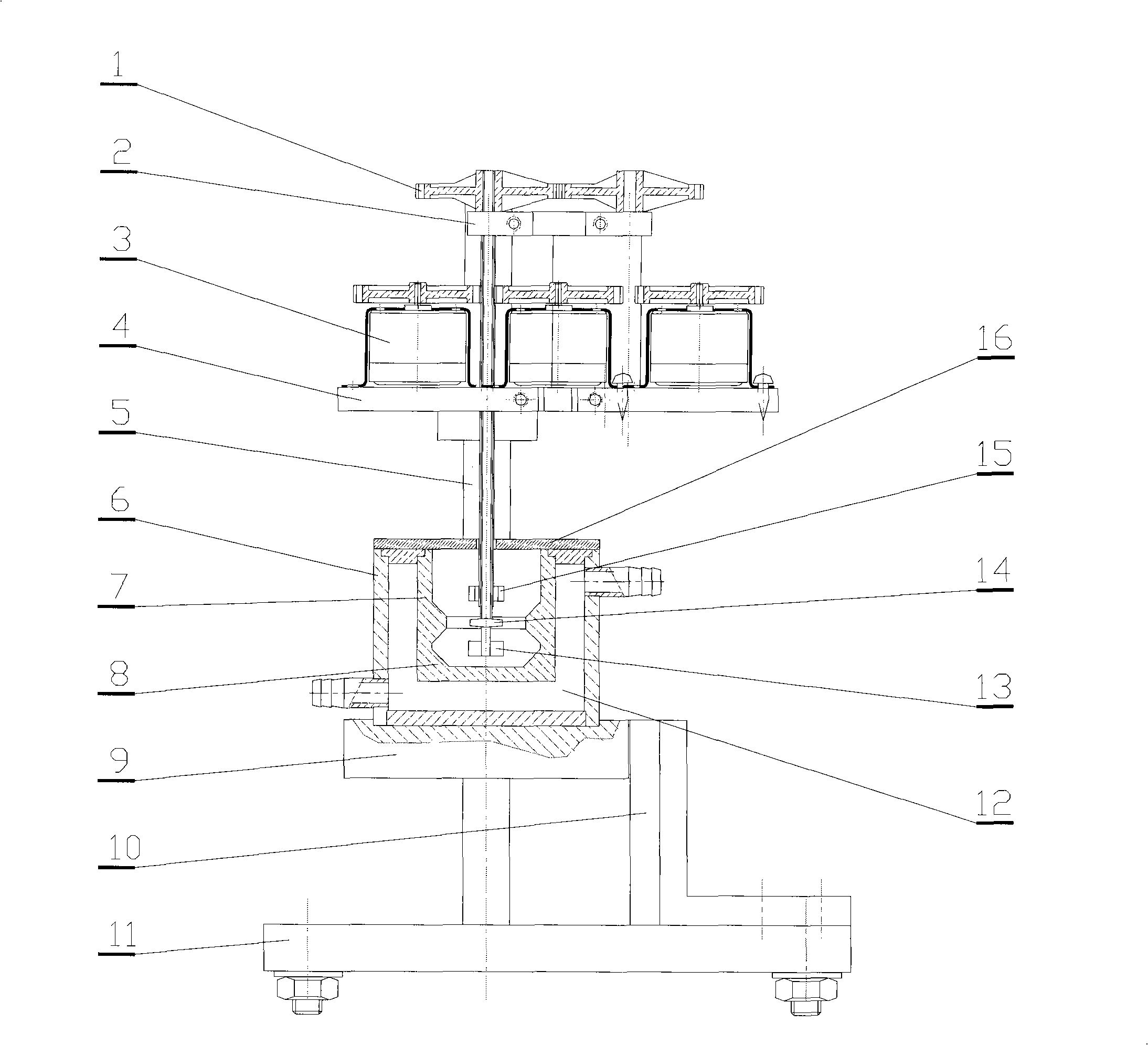

[0017] Such as figure 1 As shown, a constant interface extraction tank, the column 5 is fixed on the bottom plate 11, and the upper positioning plate 2 and the lower positioning plate 4 are respectively fixed on the column 5. The transmission mechanism is fixed on the upper positioning plate 2 and the lower positioning plate 4.

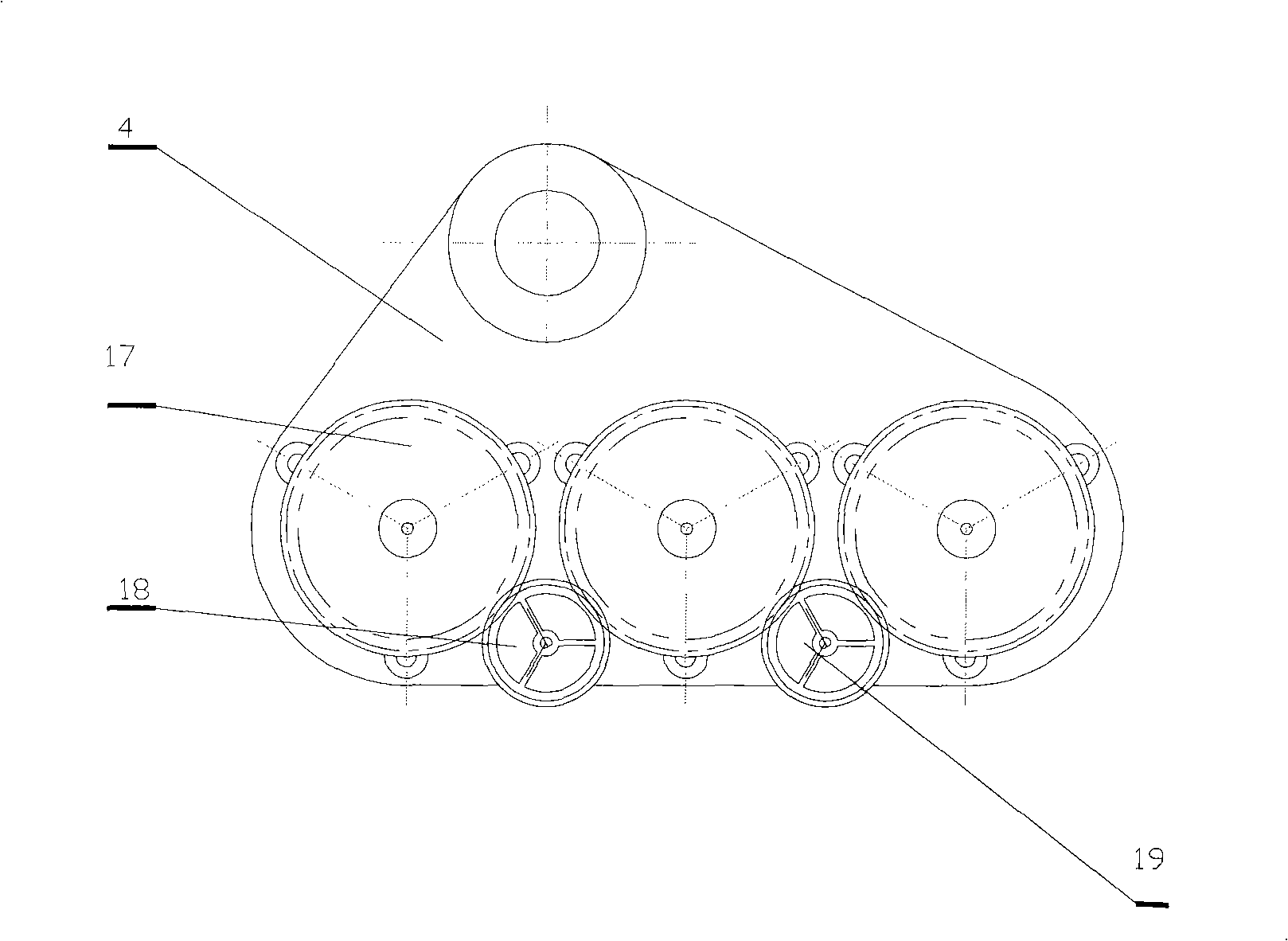

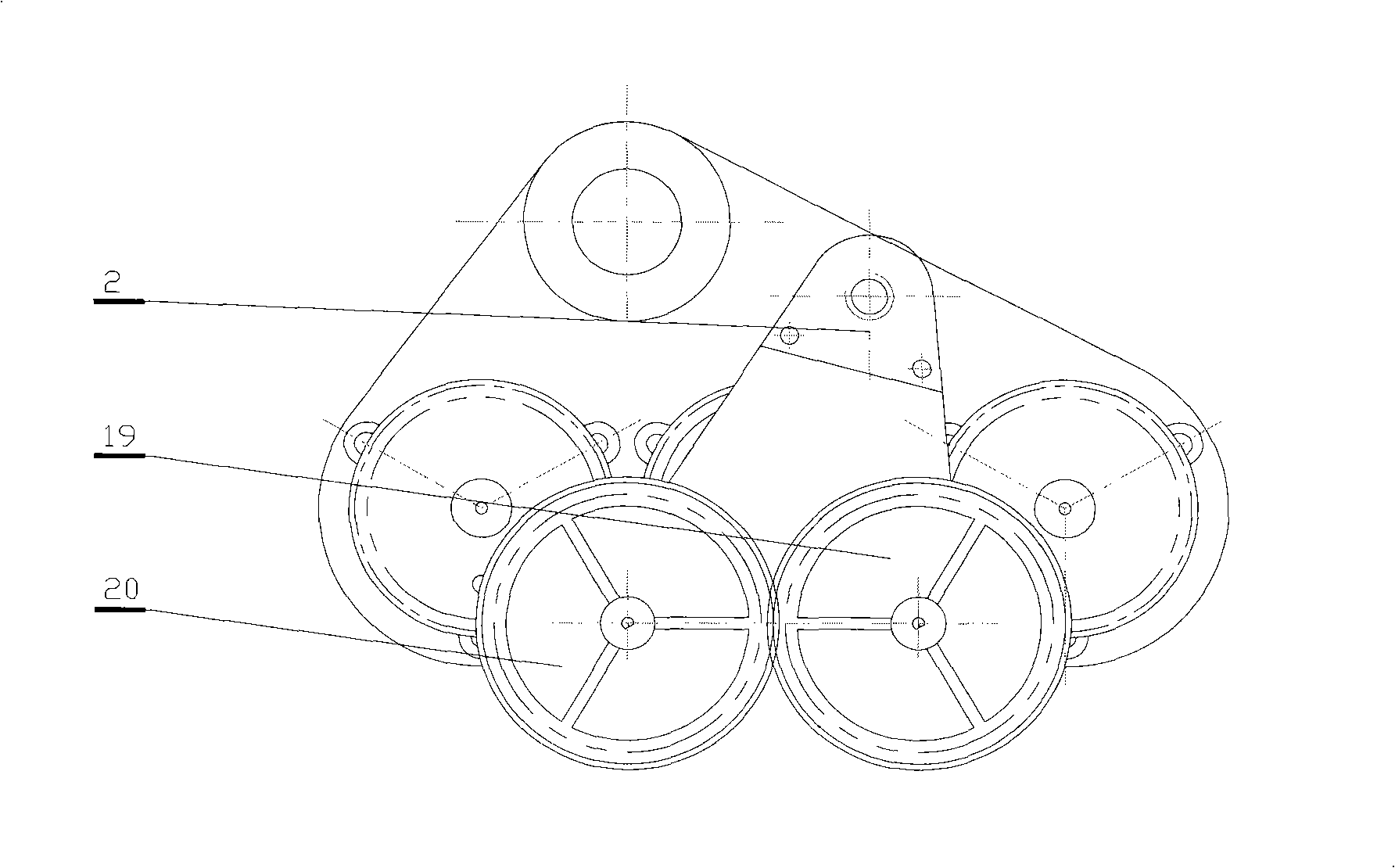

[0018] Such as figure 2 As shown, the DC motor 3 is fixed on the lower positioning plate 4 . Since the inner shaft 21 and the outer shaft 23 are required to rotate in opposite directions synchronously, and the rotating speed can be precisely controlled, the present embodiment adopts three micromotors 3 as drives, and the micromotor gear 17 is coupled with the outer shaft gear 18 and the transmission gear 19 respectively. Such as image 3 As shown, on the upper positioning plate 2, the transmission gear 19 is cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com