Combustion chamber of diesel engine

A diesel engine and combustion chamber technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as complex gas distribution structure, increased failure frequency and maintenance, difficulties, etc., to simplify the structure, improve emission control level, The effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

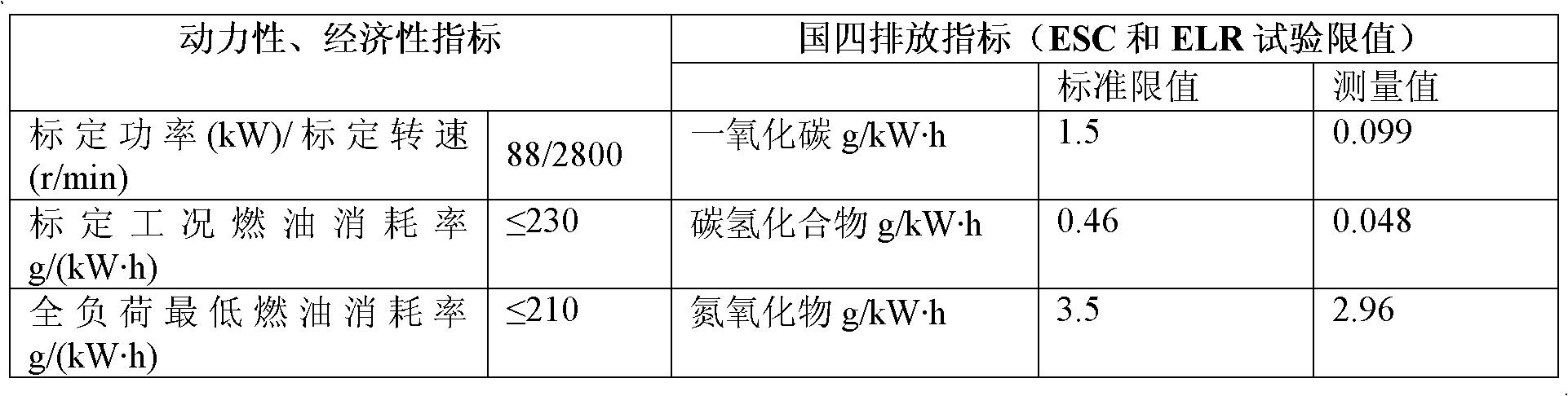

[0008] The structure and principle of the present invention will be further described by taking the combustion chamber of the National IV diesel engine 4102-CE4C diesel engine as an example, but the content covered by the present invention is not limited to the following examples.

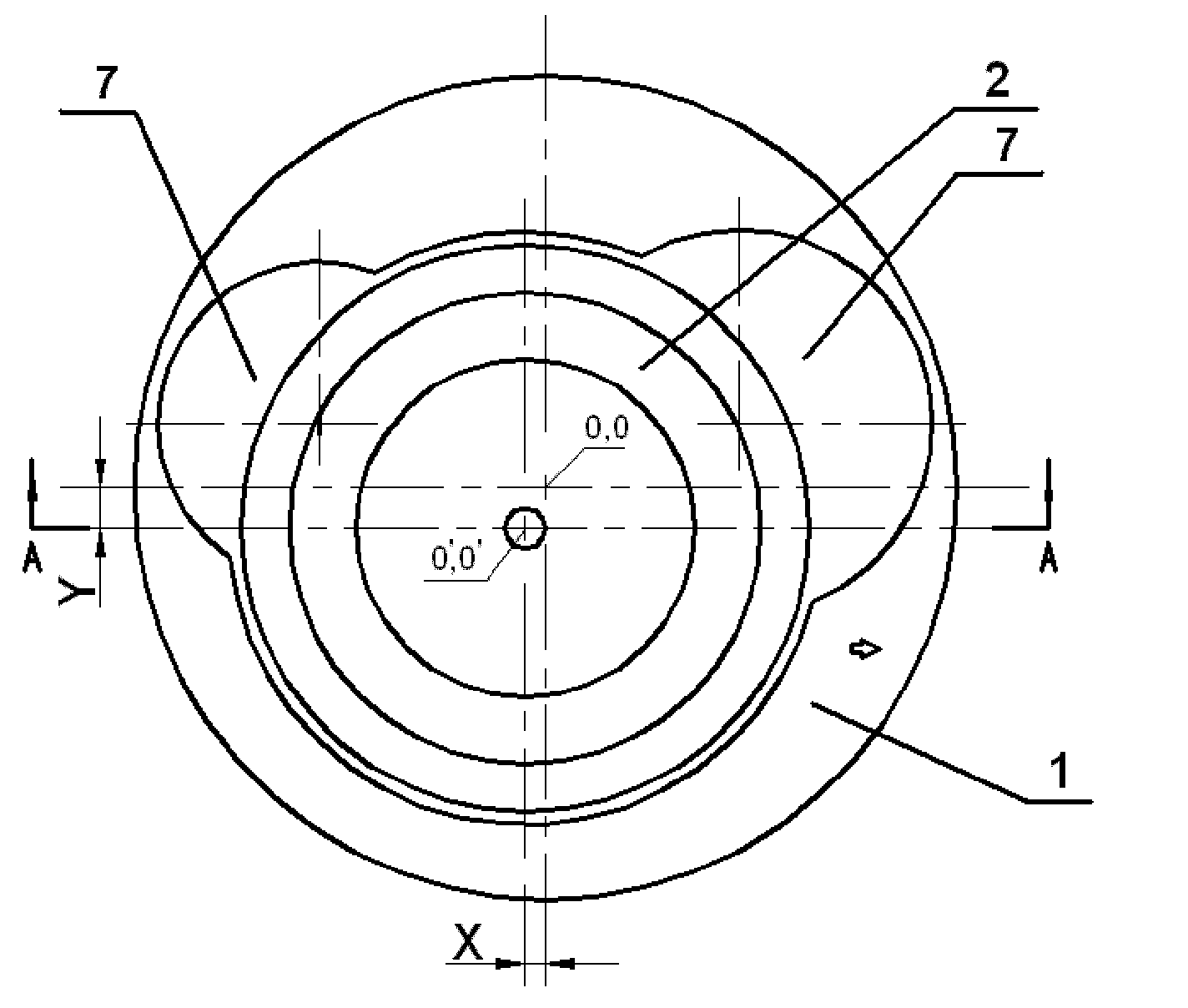

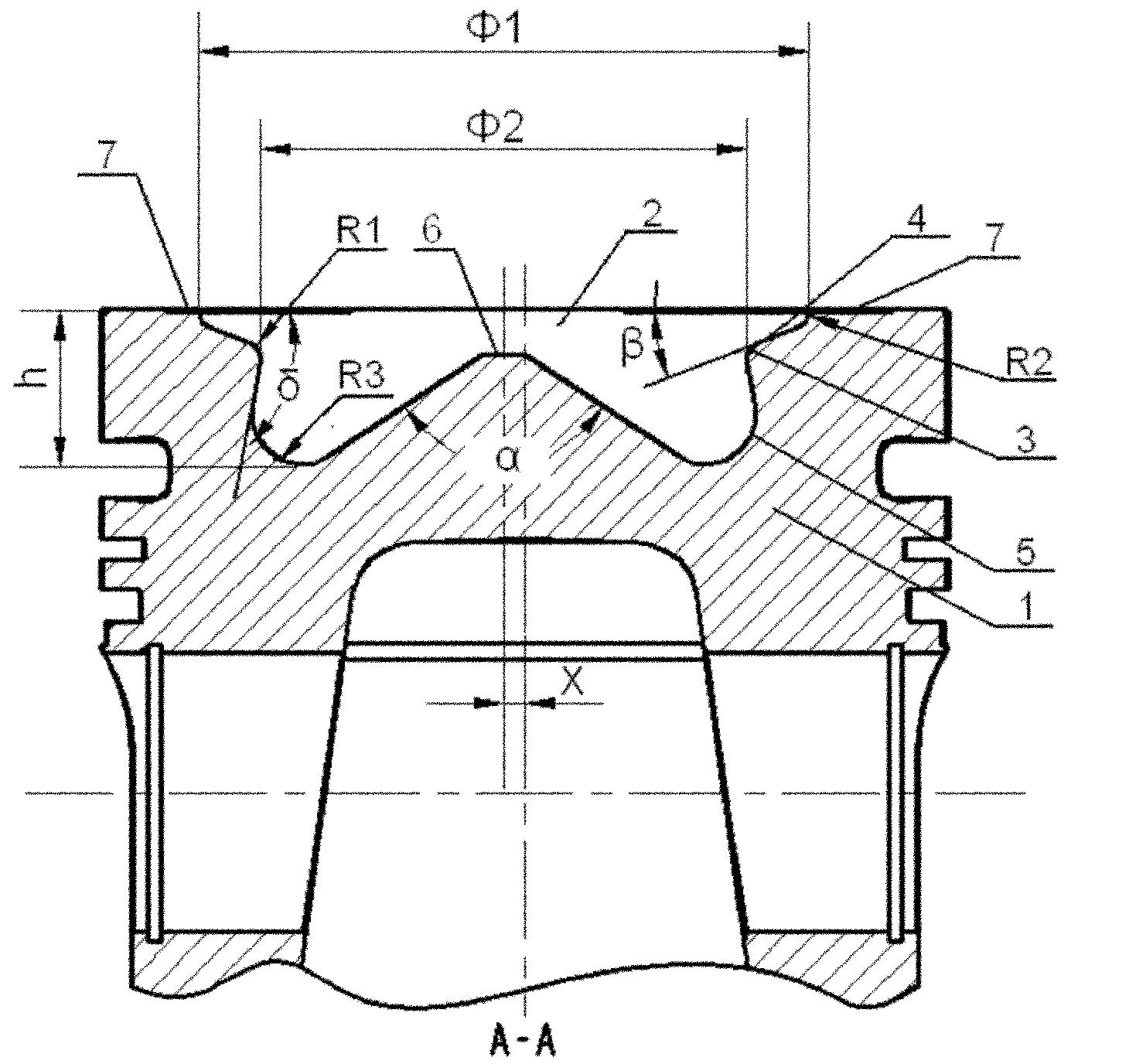

[0009] The specific structure of the diesel engine combustion chamber is as follows: the combustion chamber 2 located on the upper part of the piston body 1 is designed as an eccentric shape, with the center of the piston (X=0, Y=0) as the base point, and the combustion chamber (X'=0', Y' =0') as the center, the offset position is X'=-2.5mm, Y'=-5mm (such as figure 1 ). The inner periphery of the combustion chamber 2 is an annular constriction 3, which divides the periphery of the combustion chamber into two parts, a slope surface 4 and a concave surface 5. The center of the combustion chamber is a convex core platform 6, and the top surface of the piston is provided with intake and exhaust valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com