Interface unit containing capillary electrophoresis of hollow-fiber membrane and chemoluminescence combination

A technology of capillary electrophoresis and chemiluminescence, which is applied in the fields of chemiluminescence/bioluminescence, measuring devices, and analysis by making materials react chemically, and can solve the problem of limiting the application range of chemiluminescence capillary electrophoresis detectors and the mixing of luminescent reagents and analytes Insufficient uniformity and stability, capillary electrophoresis cut-off and other problems, to achieve separation analysis, improve column efficiency and detection sensitivity, and eliminate dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

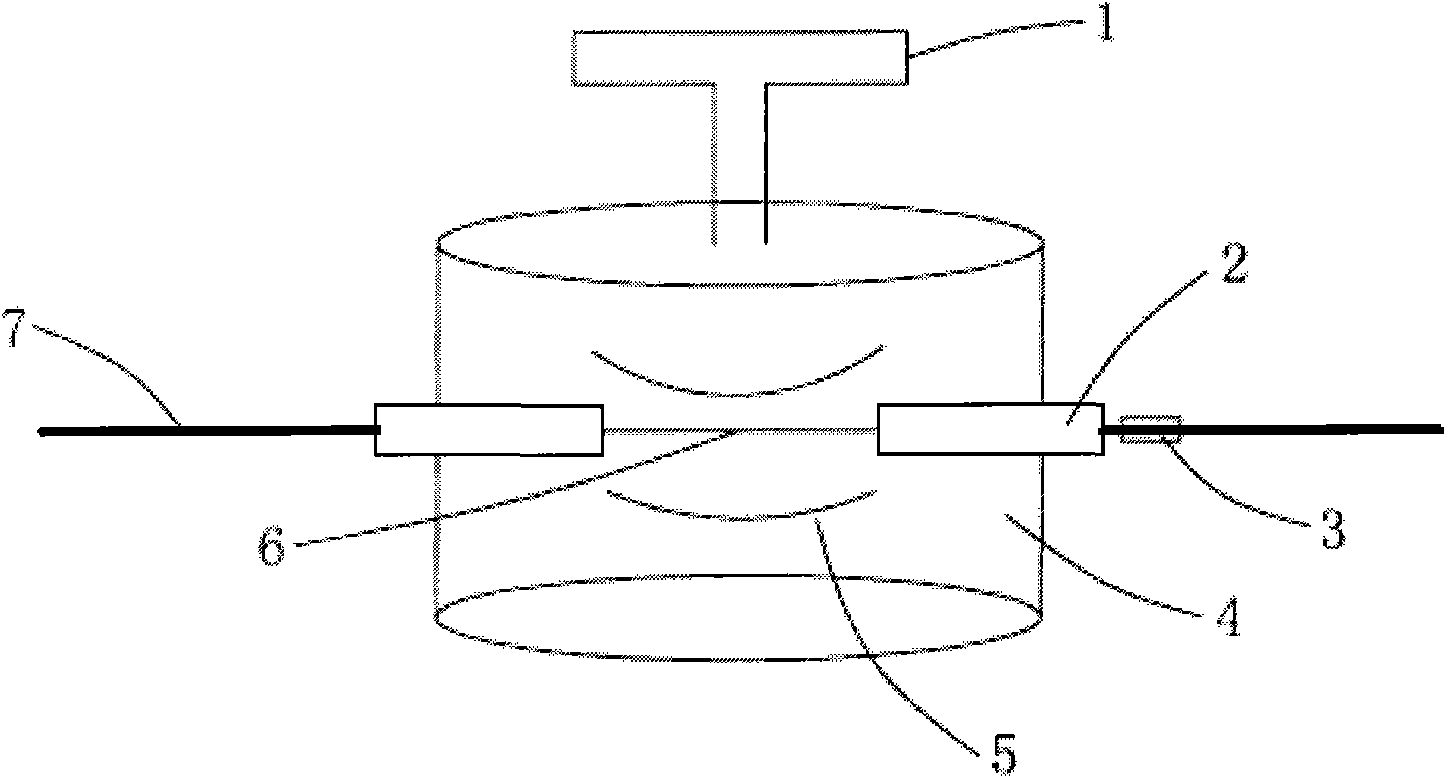

[0027] Please see attached figure 1 , an interface device for combined use of capillary electrophoresis and chemiluminescence containing a hollow fiber membrane. Take a hollow fiber membrane 6 with a length of about 10-15 mm, insert its two ends into a Teflon tube 2 with a length of 5-10 mm, and expose it to the tube. The hollow fiber membrane 6 of the outer part is about 3 to 5 mm long, and the edge of the connection between the Teflon tube 2 and the hollow fiber membrane 6 is tightly sealed with epoxy resin; hole, and the above-mentioned connected hollow fiber membrane 6 passes through the holes on both sides of the plastic box 4, and is installed in the plastic box 4, and the pores on both sides of the plastic box 4 are sealed with epoxy resin; the plastic box 4 contains chemical For the luminescent reagent 5, in order to speed up the penetration of the chemiluminescent reagent 5 in the hollow fiber membrane 6, a pressure-driven device 1 is added on the top of the plastic b...

Embodiment 2

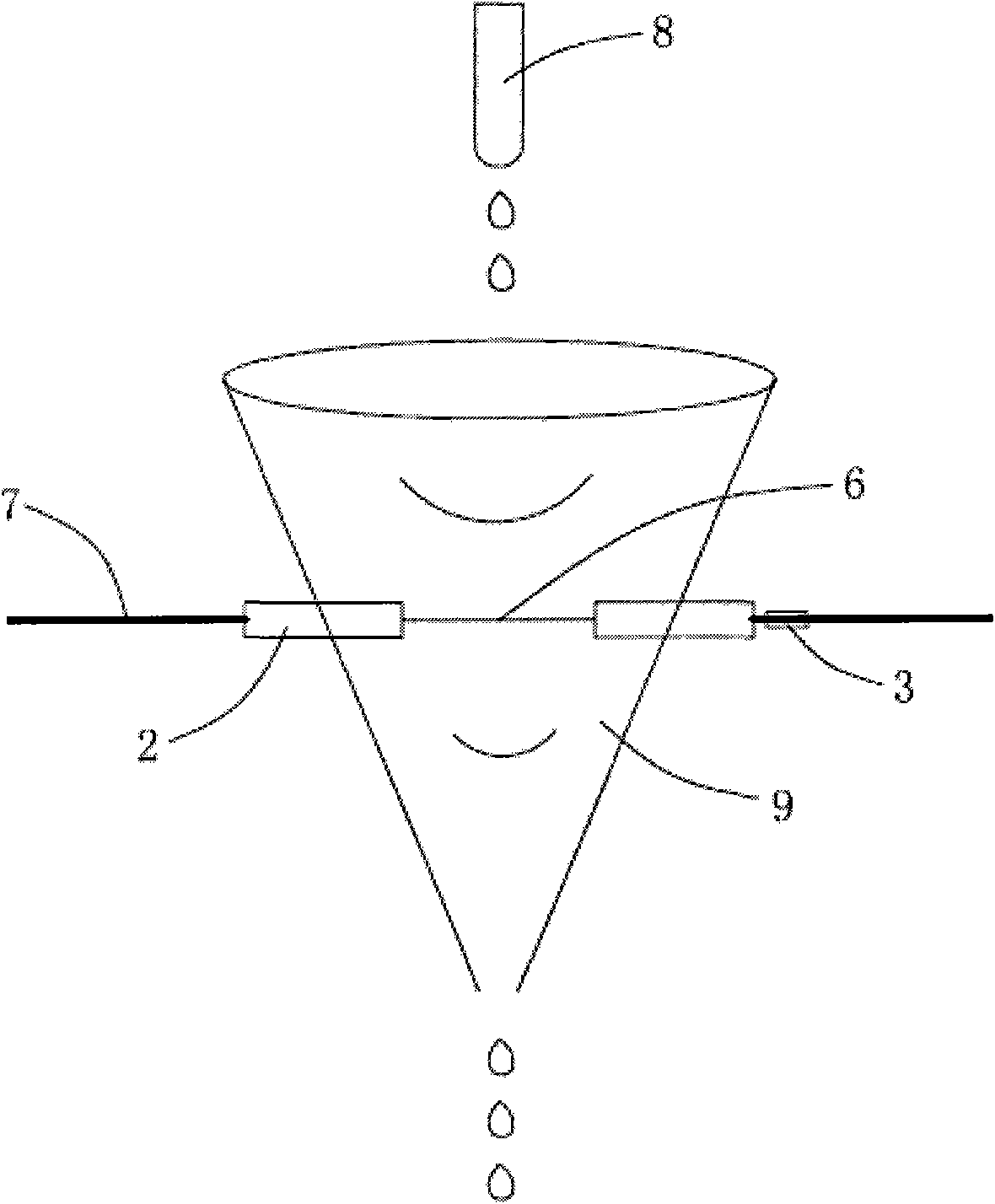

[0030] Please see attached figure 2, an interface device for combined use of capillary electrophoresis and chemiluminescence containing a hollow fiber membrane. Take a hollow fiber membrane 6 with a length of about 10-15 mm, insert its two ends into a Teflon tube 2 with a length of 5-10 mm, and expose it to the tube. The hollow fiber membrane 6 of the outer part is about 3-5mm long, and the edge connecting the Teflon tube 2 and the hollow fiber membrane 6 is tightly sealed with epoxy resin. Get a pipette tip 9, punch two holes equivalent to the outer diameter of the Teflon tube 2 on both sides, pass the above-mentioned connected hollow fiber membrane 6 through the holes on both sides of the pipette tip 9, and install it on the In the pipette tip 9, the pores on both sides are sealed with epoxy resin; Add the chemiluminescent reagent 5 dropwise with the dropper 8 to the top of the pipette 8, and the bottom flows out, that is, the chemiluminescent reagent 5 is flowing in the p...

Embodiment 3

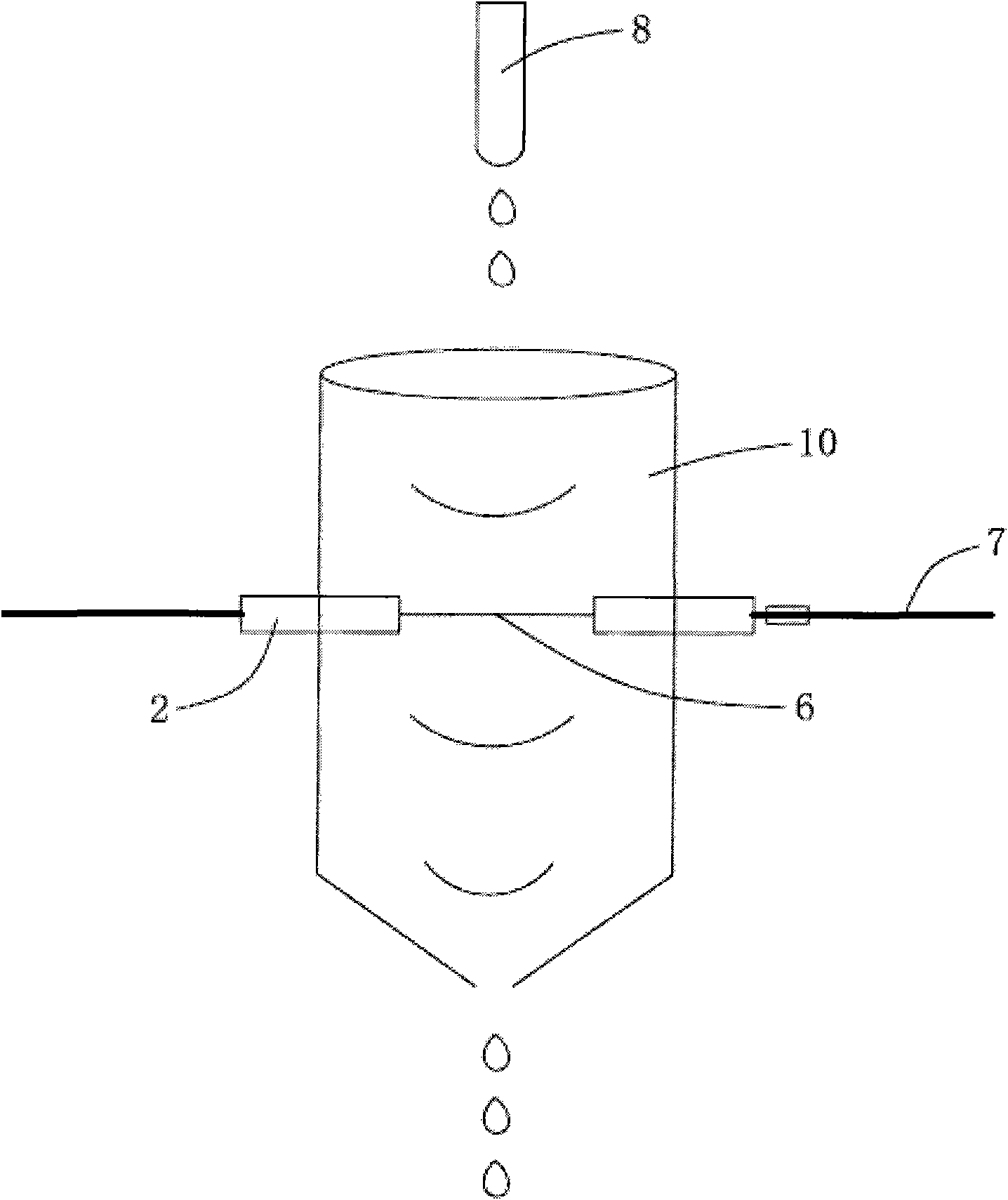

[0033] Please see attached image 3 , an interface device for combined capillary electrophoresis and chemiluminescence containing a hollow fiber membrane. Take a hollow fiber membrane 6 with a length of 10-15 mm, insert its two ends into a Teflon tube 2 with a length of 5-10 mm, and expose it to the outside of the tube. Part of the hollow fiber membrane 6 is about 3 to 5 mm long, and the edge of the connection between the Teflon tube 2 and the hollow fiber membrane 6 is tightly sealed with epoxy resin; Teflon tube 2 has a suitable hole in the external diameter, and the above-mentioned connected hollow fiber membrane 6 is passed through the holes on both sides of the centrifuge tube 10, and is installed in the centrifuge tube 10, and the pores on both sides are sealed with epoxy resin; the centrifuge tube 10 Built-in chemiluminescent reagent 5, in order to speed up the penetration of chemiluminescent reagent 5 in the hollow fiber membrane 6, so drop the chemiluminescent reagent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com