Method for operating dishwasher

A dishwasher and household technology, applied in the application of dishwashers, tableware washing machines/rinsing machines, applications, etc., can solve problems such as danger and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

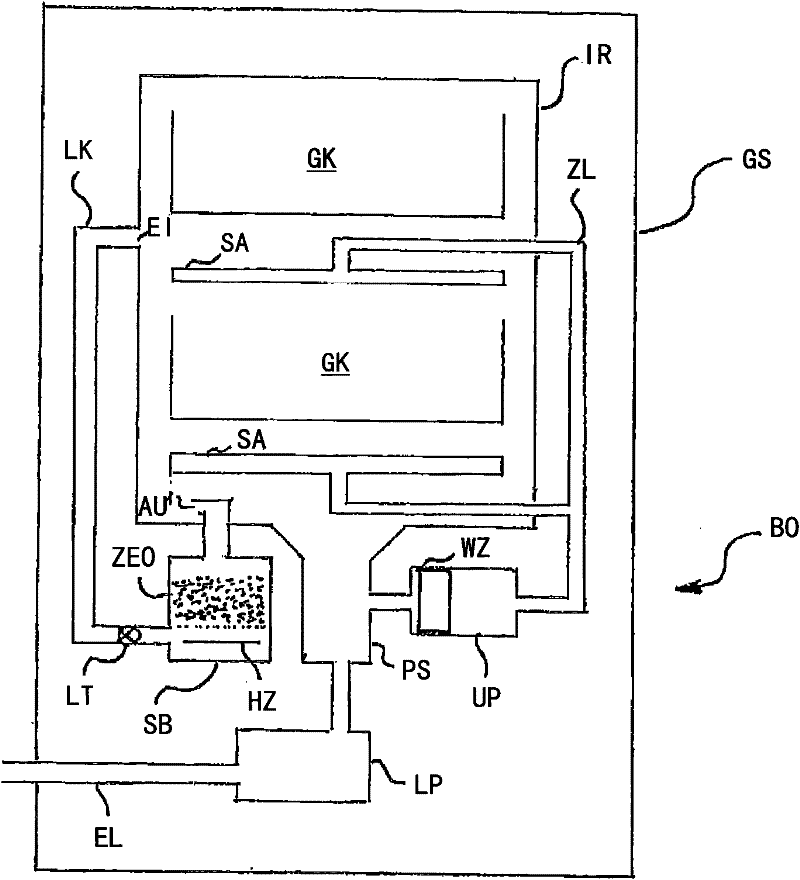

[0022] First refer to the attached figure 1 .

[0023] In this exemplary embodiment, the dishwasher GS implemented as a household dishwasher has an inner cavity IR used as a washing container, and a door for picking and placing tableware can be hinged on the dishwasher GS by swinging (in the figure) Not shown) Open or close the cavity. The inner cavity IR of the dishwasher GS is provided with a cutlery basket GK for holding items to be washed, and these cutlery baskets can be removed from the inner cavity IR of the dishwasher GS to facilitate picking and placing of the cutlery.

[0024] In order to clean the items to be washed placed in the tableware basket GK, a spray arm SA is provided in the inner cavity IR of the dishwasher GS for spraying fluid to the items to be washed. The fluid may be It is water mixed with detergent or rinse aid so as to have a cleaning effect and / or dryness without traces. The fluid flowing down from the items to be washed collects in the sump PS arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com