Active cooling of a motor

An electronic and stator technology, which is applied in the direction of cooling/ventilation devices, connection with control/drive circuits, electromechanical devices, etc., can solve problems such as hindering the circulation of motors and electronic housings, and difficulties in effective cooling of motors or electronic components. sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

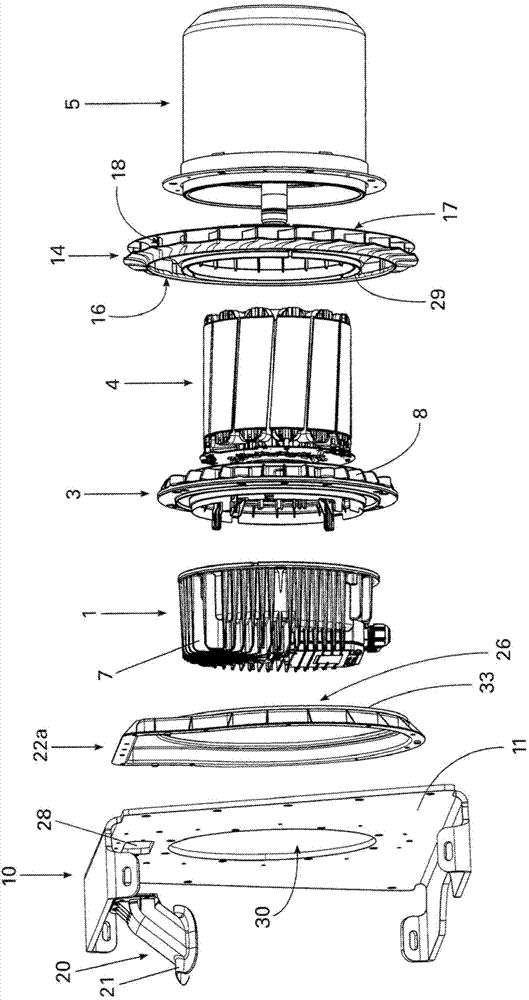

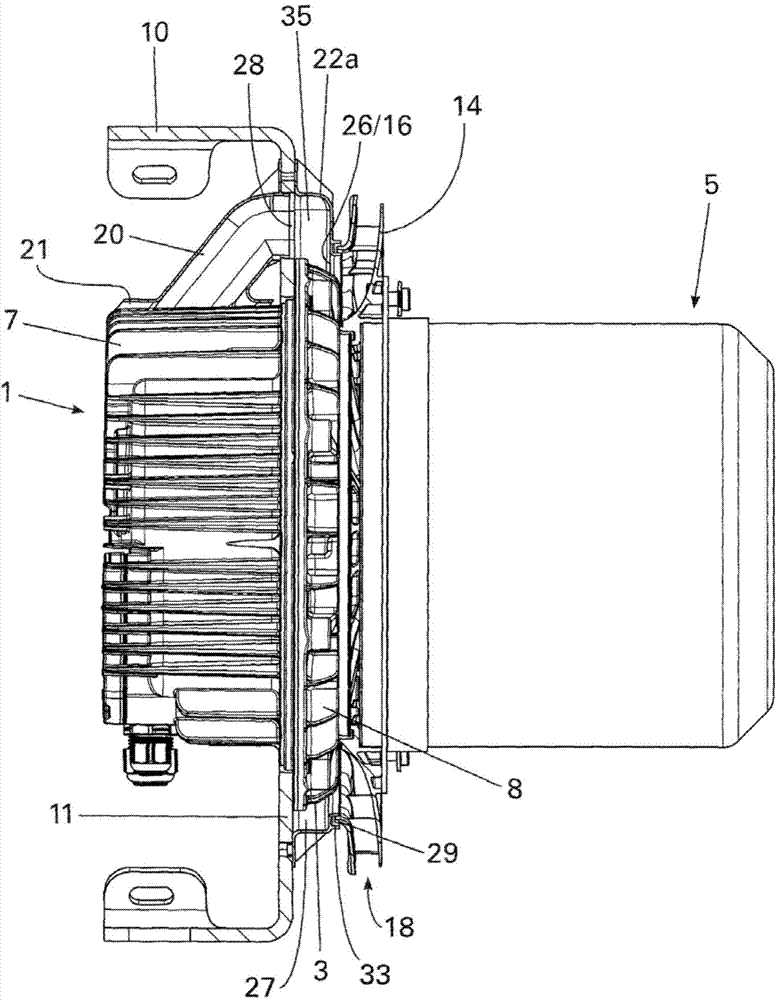

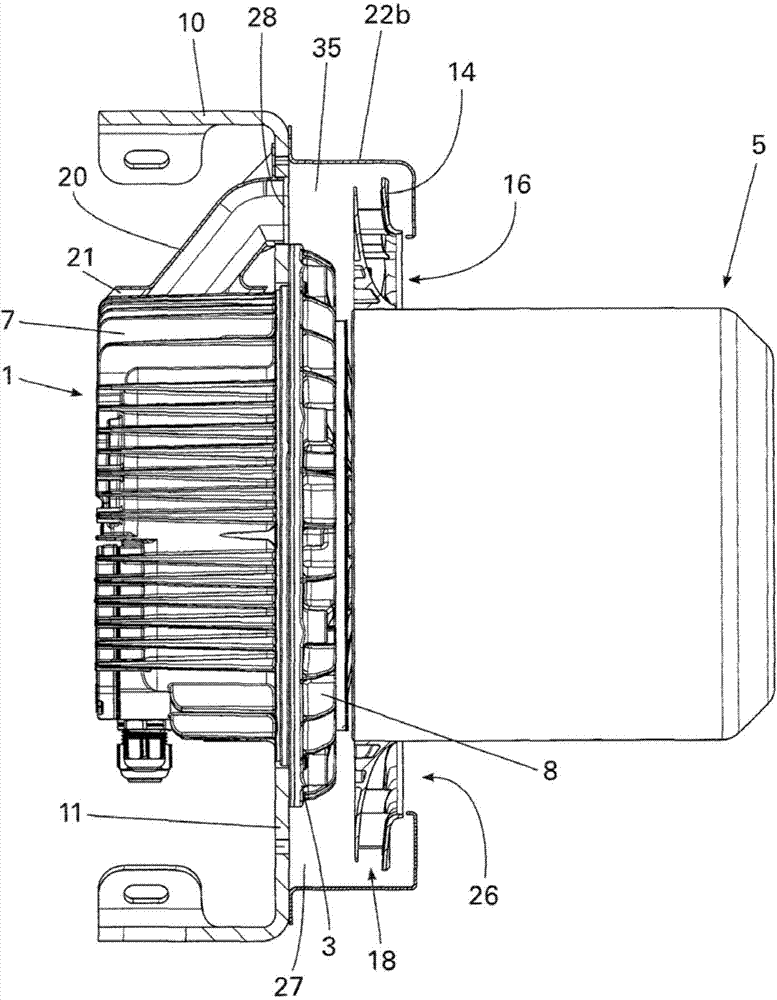

[0022] figure 1 , figure 2 and image 3 An electric machine according to the invention, in particular an external rotor electric machine, is shown in each case. The electric machine comprises an electronics housing 1 , a stator comprising a stator bushing 3 and a stator laminated core 4 with motor coils, and a rotor 5 (in particular an outer rotor). The stator bushing 3 and the electronics housing 1 consist in particular of metal. Furthermore, electromechanical electronics for driving and controlling the electric motor, in particular commutation electronics with electrical power components such as output stages, are located in the electronics housing 1 . The electronics housing 1 has housing cooling fins 7 on its outer wall for cooling electronic components (not shown) inside the electronics housing 1 . The stator bush 3 has on its outer wall radially extending stator cooling fins 8 which dissipate the heat generated by the stator, in particular by ball bearings (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com