Automatic high-frequency needle burning machine

A high-frequency, automatic technology, applied in the direction of improving energy efficiency, process efficiency, furnace type, etc., can solve the problems of large amount of scrapped needles, difficult processing of high-end knitting needles, and increased scrap rate of products, etc., to meet the cleanliness requirements Requirements and environmental protection requirements, reduce labor intensity, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

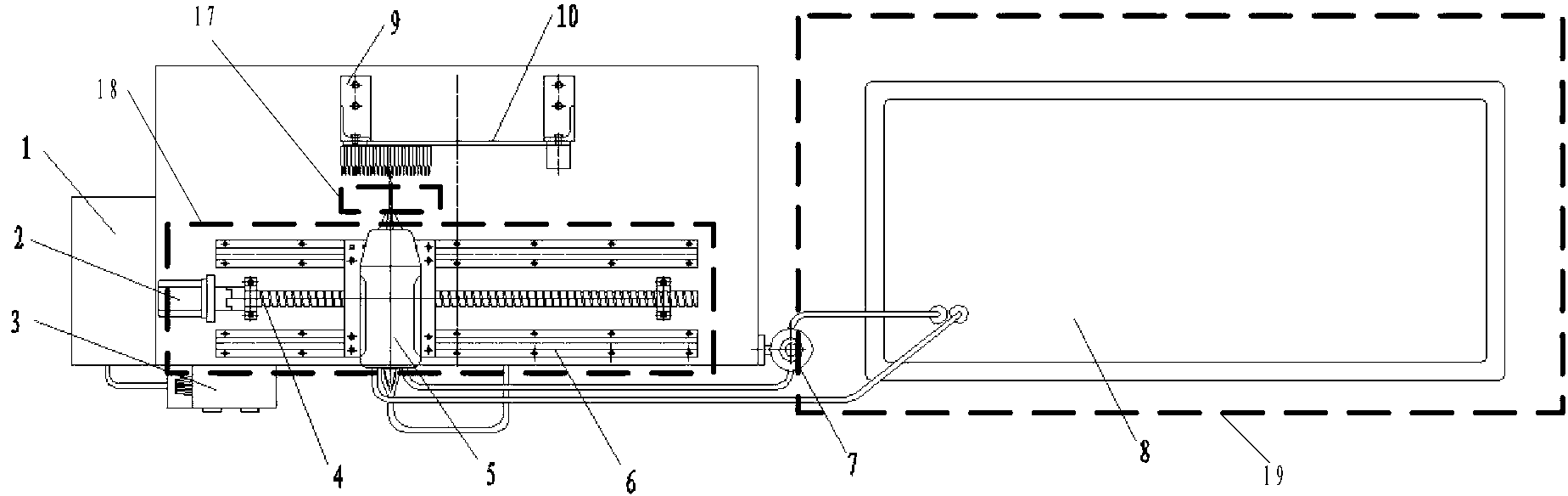

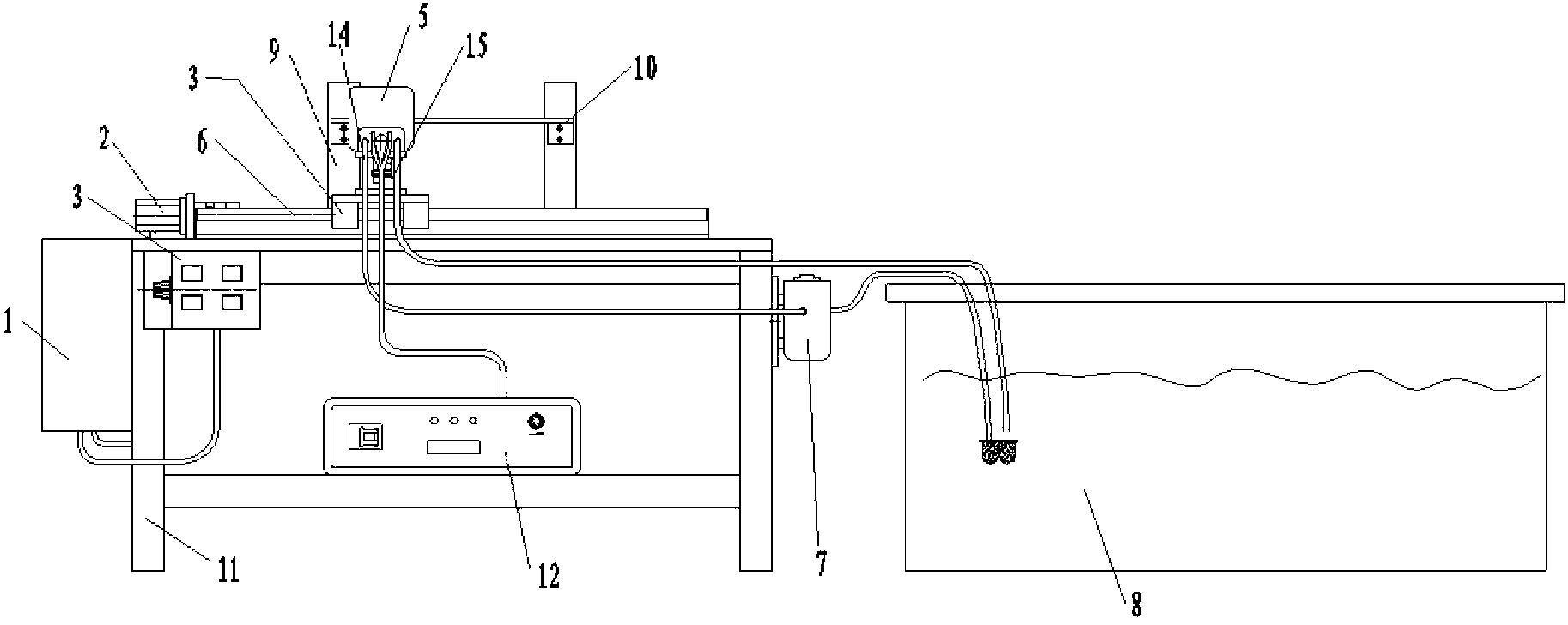

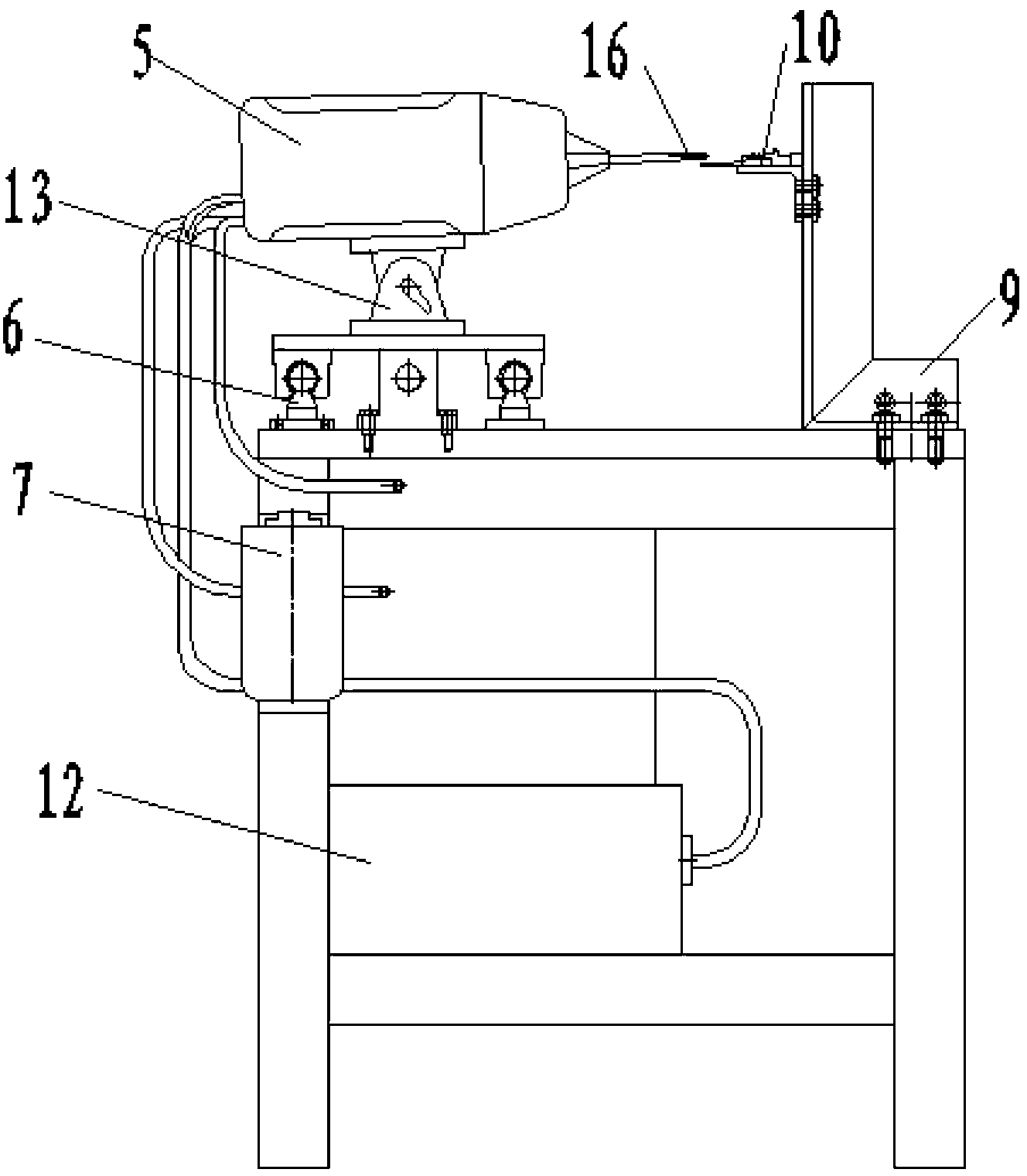

[0033] An automatic high-frequency needle burning machine, comprising a high-frequency probe 5, a heating unit 17, a traveling unit 18, a cooling unit 19 and an electrical box 1;

[0034] The bottom of the high frequency probe 5 is fixed to the movable connection end of the traveling unit 18, the needle of the high frequency probe 5 is fixed to the heating end of the heating unit 17, and the cooling connection end of the cooling unit 19 is connected to the high The high-frequency probe 5 is internally connected, and the electrical box 1 supplies power for the high-frequency probe 5, the heating unit 17, the traveling unit 18 and the cooling unit 19 respectively.

[0035] The heating unit 17 includes a high-frequency probe controller 12 and a high-frequency heating head 16, the high-frequency probe controller 12 is electrically connected to the high-frequency heating head 16, and the high-frequency heating head 16 is connected to the high-frequency heating head 16. The needle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com