Large-scale multifunctional frozen soil-structure contact surface cyclic direct shearing instrument and its test operation method

A multi-functional, contact surface technology, applied in the direction of applying stable shear force to test the strength of materials, to achieve the effect of precise stress application and displacement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

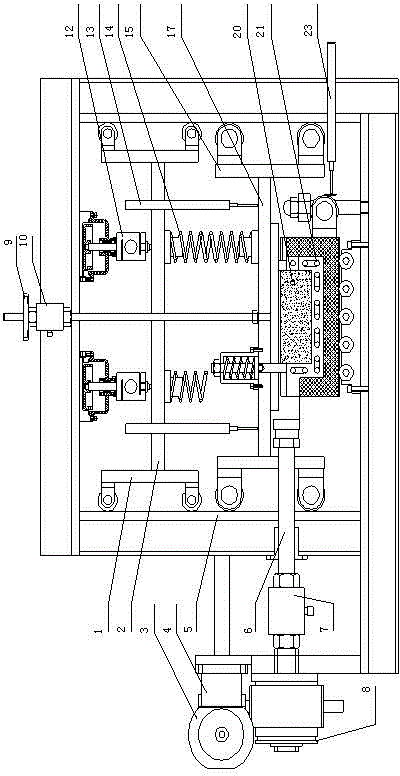

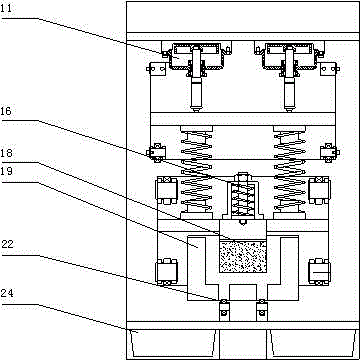

[0023] 1) Overall dimensions of the instrument: Bracket dimensions: length 2000×height 700×width 800mm, instrument dimensions: length 1500×height 900×width 500mm.

[0024] 2) Horizontal reciprocating shearing is completed by servo motor 3, worm gear reducer 4, tension pressure sensor 7, dowel 6, horizontal displacement sensor 23 and elevator 8. The power of the horizontal reciprocating shearing source is realized by a servo motor (power 1.1kW). To ensure the shearing speed set in the test, a reducer (reduction ratio of 1:15) is installed between the servo motor and the connecting rod of the soil box. A tension and pressure sensor is installed between the connecting rod and the reducer to realize real-time monitoring of the horizontal shear load, and the elevator (with a driving speed ratio of 1:24) is installed at the bottom of the servo motor to realize the precise position of the servo motor in the vertical direction For control, the horizontal displacement sensor is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com