A high temperature gas-cooled reactor reactor pressure vessel inspection device

A technology for high-temperature gas-cooled reactors and pressure vessels, which is applied to the monitoring of reactors and nuclear reactors and the reduction of greenhouse gases, etc., to achieve the effect of simple movement and precise displacement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

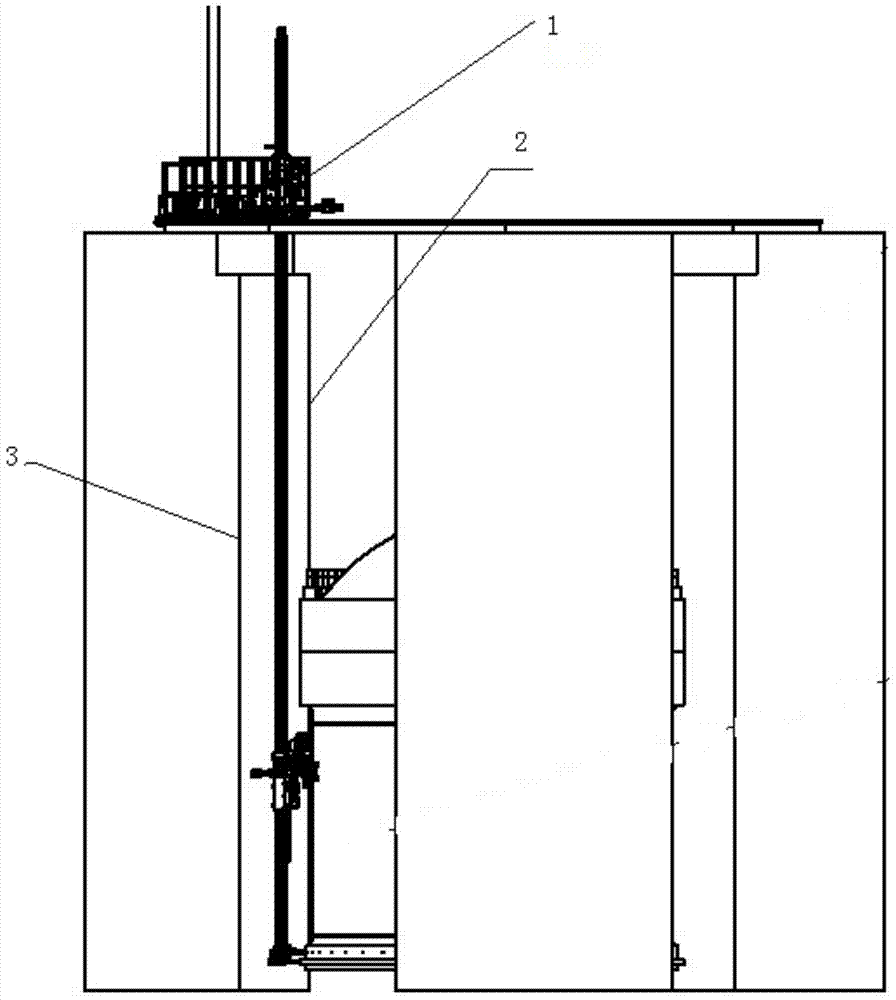

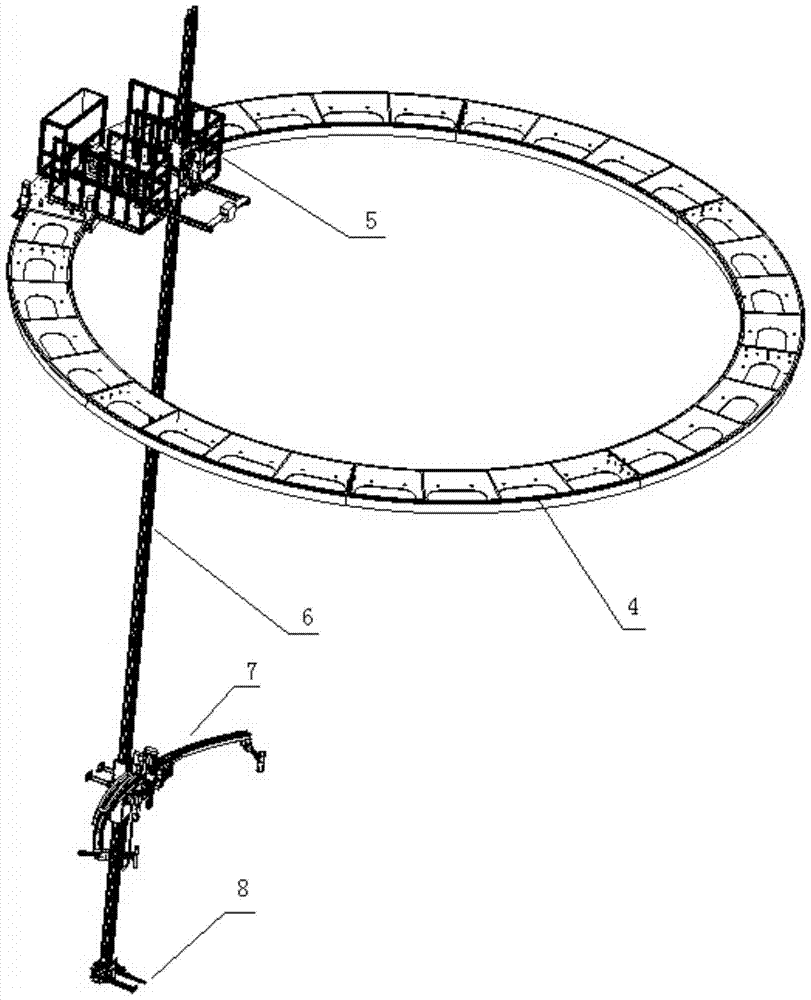

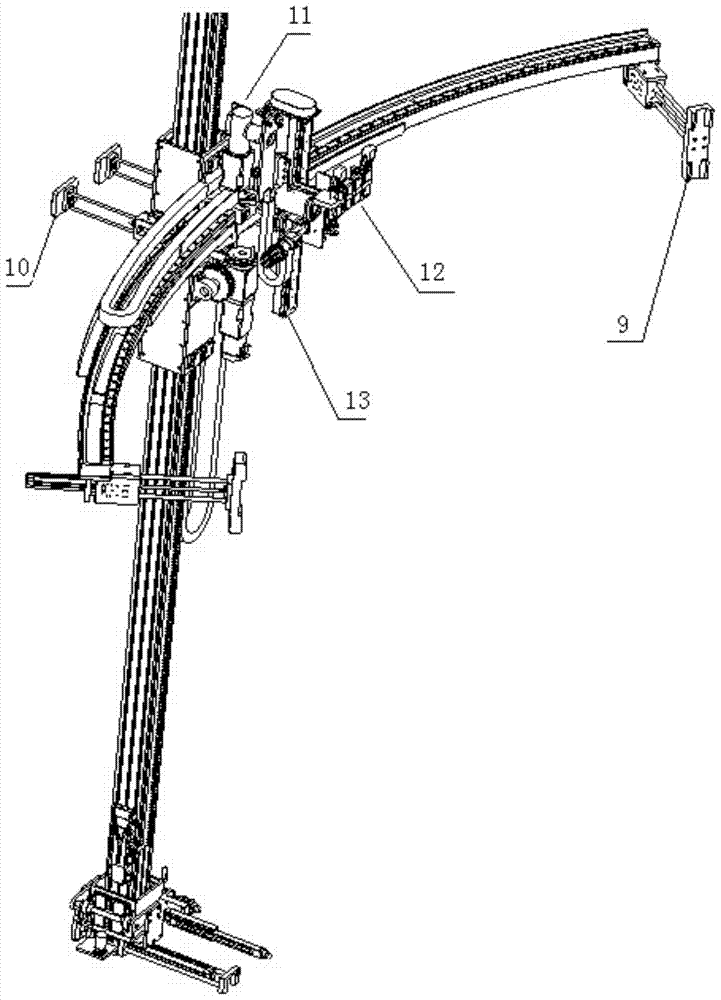

[0016] Such as figure 1 As shown, a high-temperature gas-cooled reactor reactor pressure vessel inspection device, the inspection device 1 is located between the outer cylinder wall 2 of the pressure vessel and the cabin cylinder wall 3 during the inspection, and the inspection device 1 includes a ring guide rail 4, a track running trolley 5, and a lifting rod 6. Two-axis scanner 7, positioning pin pointing mechanism 8, the ring guide rail 4 is a whole ring made of multiple pieces of circular arc guide rails; the track running trolley 5 is located on the ring guide rail 4 and can move along the track; it runs on the track The lifting rod 6 is installed on the trolley 5. The lifting rod 6 is made of quadrilateral columnar aluminum profile and assembled from multiple sections, thus forming a long rack guide column from the top of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com