Non-impeller rotor valveless pump for artificial heart

A technology of impeller rotor and artificial heart, which is applied in the direction of drug equipment, hypodermic injection equipment, and other medical equipment, and can solve the problems of centrifugal heart pump miniaturization, thrombus or hemolysis, deterioration and degeneration, etc., so as to reduce the difficulty of surgery and infection risk, simple exercise form, and good stress status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

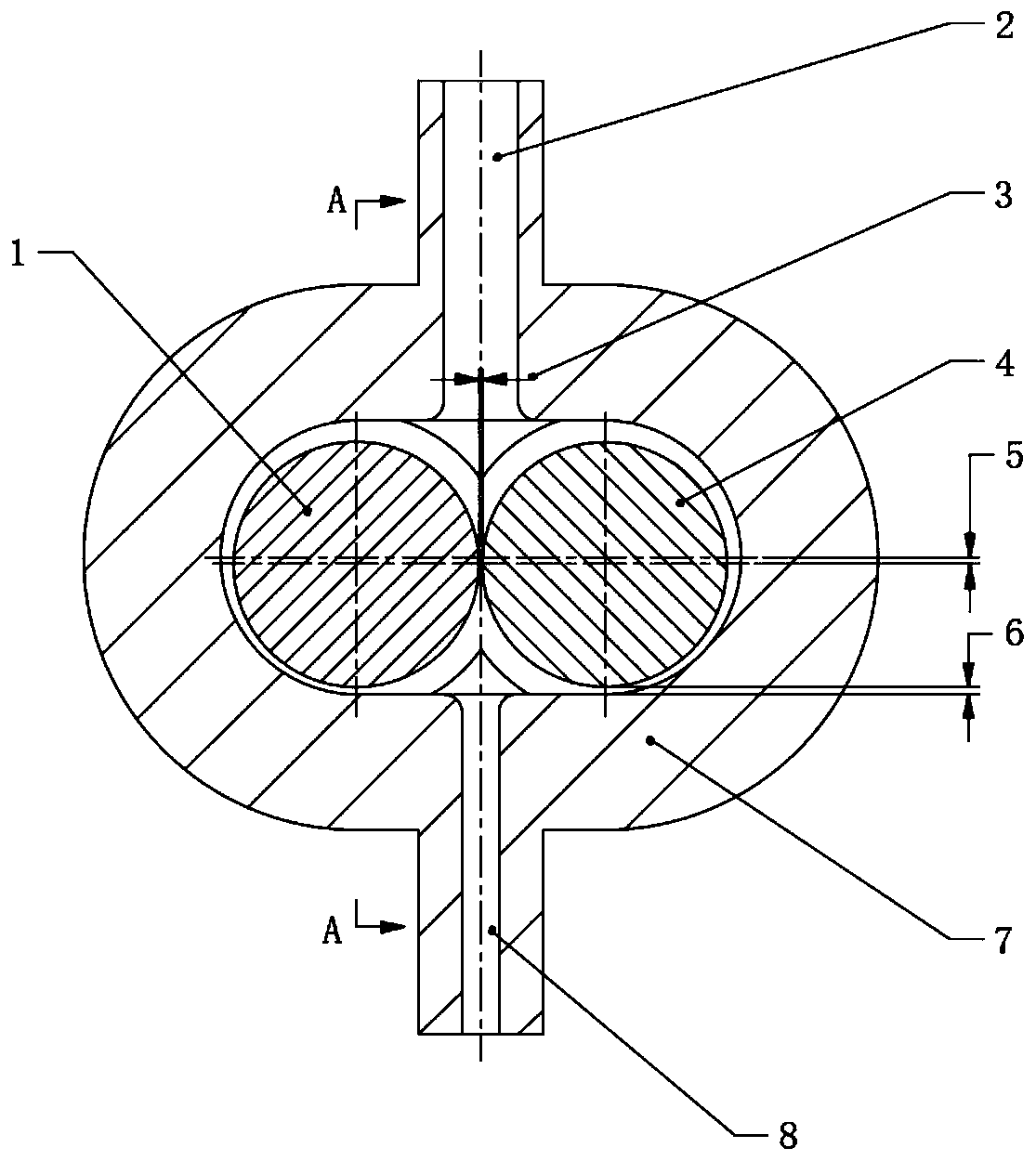

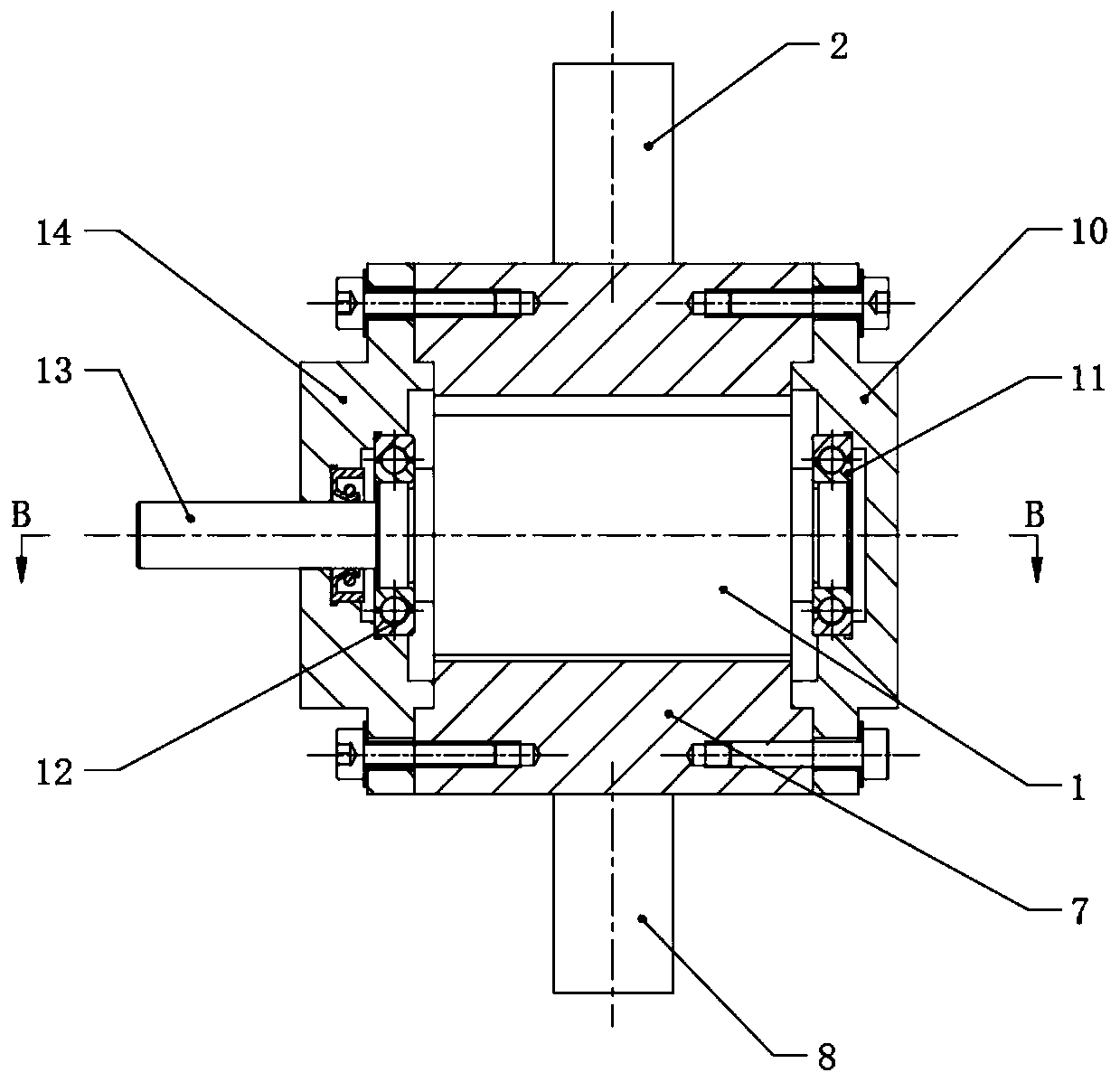

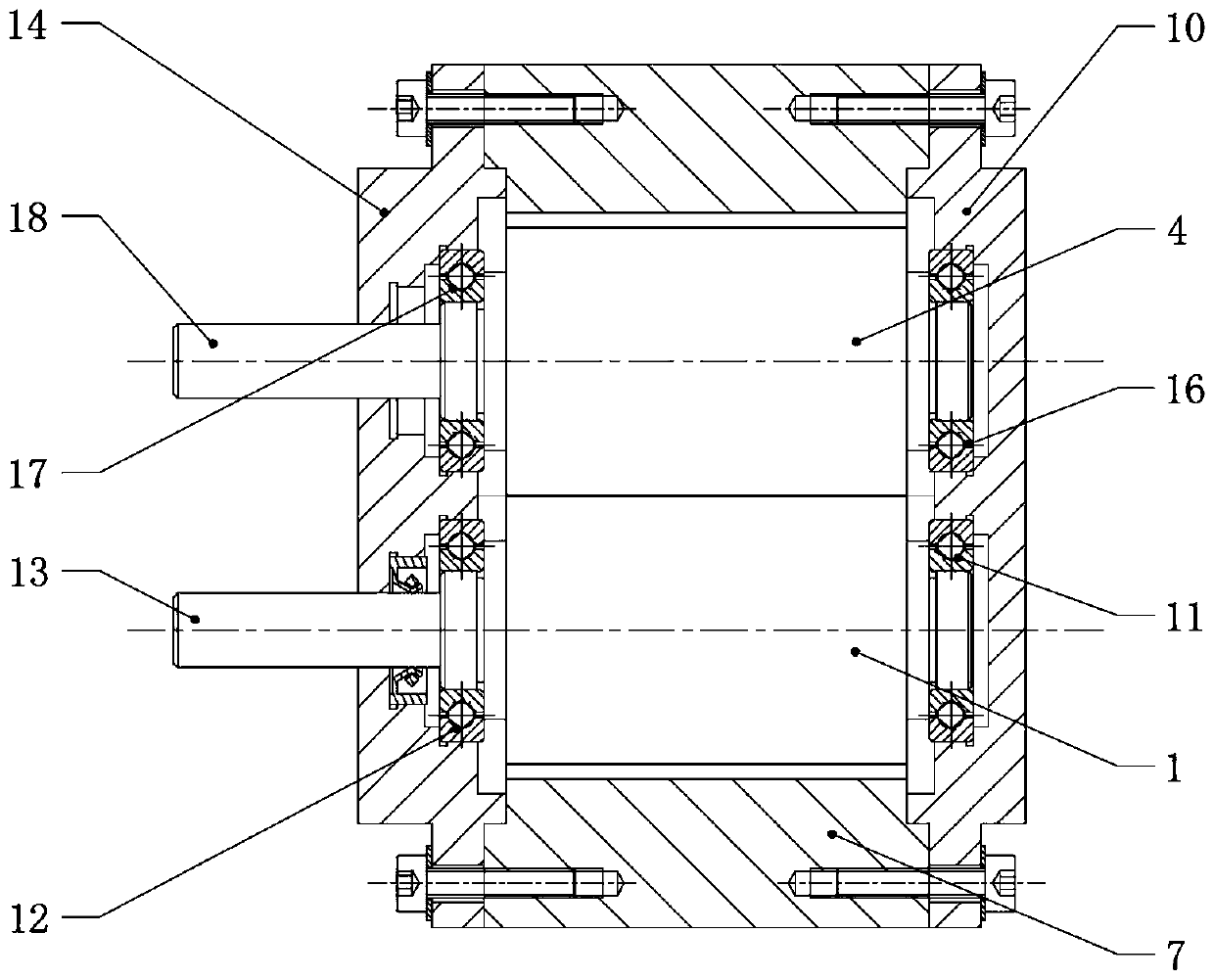

[0023] refer to figure 1 and Figure 4 , a non-impeller rotor valveless pump for an artificial heart, comprising a pump housing 7, the cross-sectional profile of the inner wall of the housing is oblong, and the oblong outline is defined by the first semicircle 20 and the first straight line of the inner wall of the housing. The line segment 15, the second semicircle 23 of the inner wall of the housing and the second straight segment 19 are connected end to end. The first semicircle 20 of the inner wall of the housing and the second semicircle 23 of the inner wall of the housing are two semicircles of equal diameter. The first straight segment 15 and The second straight line 19 is two parallel straight lines equal in length, and the two ends of the first straight line 15 and the second straight line 19 are respectively tangent to the first semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com