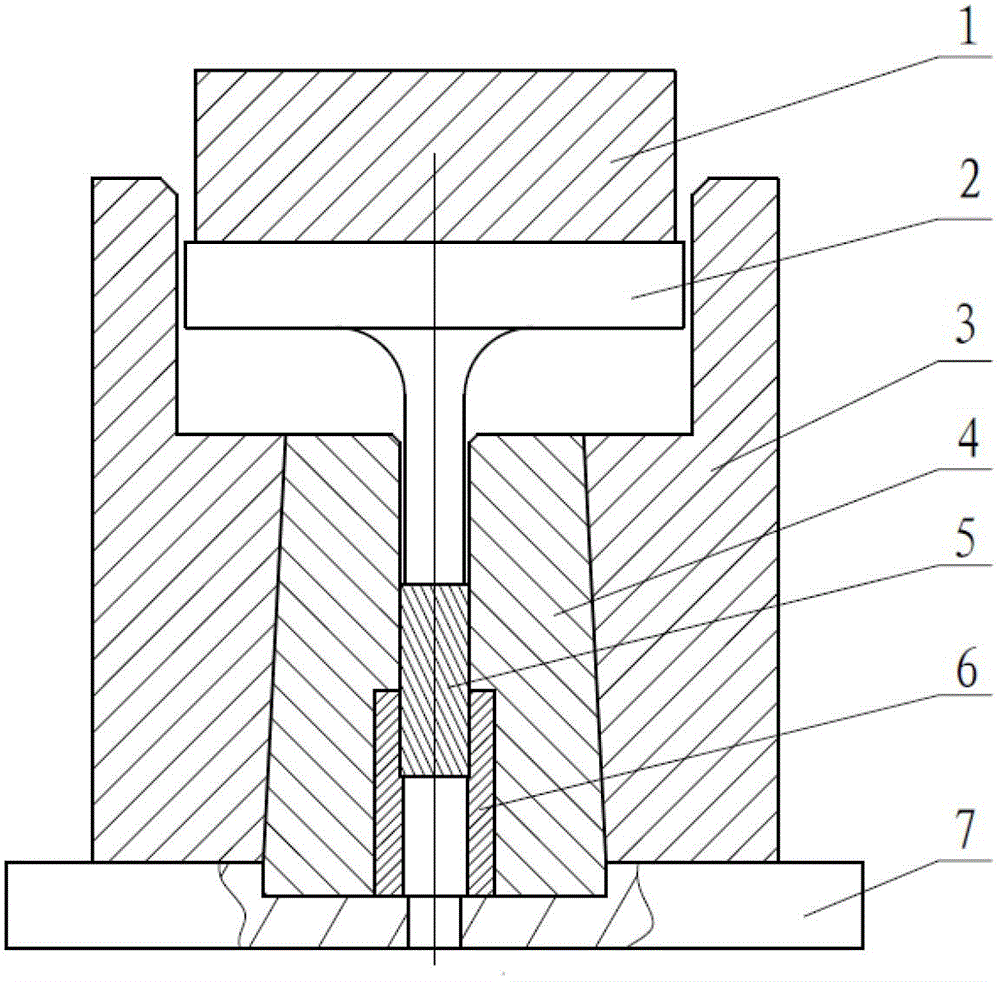

Preparation method and preparation mold of amorphous alloy-copper laminated composite material

A technology of amorphous alloys and composite materials, applied in manufacturing tools, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large deformation, insufficient removal of oxide film at the connection interface, and uneven longitudinal distribution of core materials. To achieve the effect of ensuring accuracy, good interface bonding, and precise displacement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

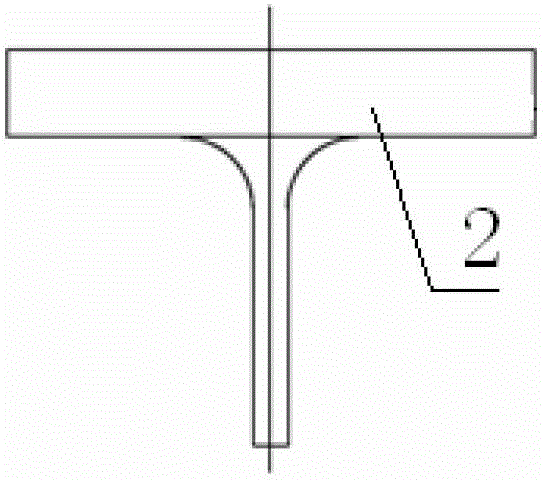

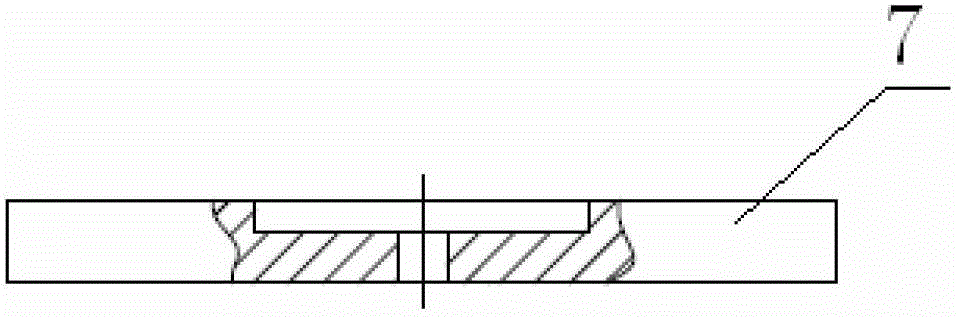

Image

Examples

Embodiment 1

[0034] The present embodiment is a kind of preparation method of the layered composite material of amorphous alloy-copper, and described amorphous alloy is made of Zr 41.25 Ti 13.75 Cu 12.5 Ni 10 be22.5 A bar with a diameter of Φ5mm is produced; the copper is a T2 copper tube of Φ6mm×1mm. The concrete process of this embodiment is:

[0035] Step 1, surface treatment: Pass the amorphous alloy rod through the lathe to Φ4.2mm, and the outer surface of the amorphous alloy rod and the inner wall of the T2 copper tube are successively passed through 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper Sand until the surface is smooth without scratches. Use 5% hydrochloric acid alcohol treatment to remove the oxide film on the surface of the T2 copper tube. The surface-treated amorphous alloy rods and T2 copper tubes were ultrasonically cleaned with acetone by a conventional method and placed in a mold.

[0036] Step 2, vacuum pre-pressing: place the assembled mold in a vacuum diffu...

Embodiment 2

[0041] The present embodiment is a kind of preparation method of the layered composite material of amorphous alloy-copper, and described amorphous alloy is made of Zr 41.25 Ti 13.75 Cu 12.5 Ni 10 be 22.5 A bar with a diameter of Φ5mm is produced; the copper is a T2 copper tube of Φ6mm×1mm. The concrete process of this embodiment is:

[0042] Step 1, surface treatment: Pass the amorphous alloy rod through the lathe to Φ4.2mm, and the outer surface of the amorphous alloy rod and the inner wall of the T2 copper tube are successively passed through 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper Sand until the surface is smooth without scratches. Use 5% hydrochloric acid alcohol treatment to remove the oxide film on the surface of the T2 copper tube. The surface-treated amorphous alloy rods and T2 copper tubes were ultrasonically cleaned with acetone by a conventional method and placed in a mold.

[0043] Step 2, vacuum pre-pressing: place the assembled mold in a vacuum dif...

Embodiment 3

[0048] The present embodiment is a kind of preparation method of the layered composite material of amorphous alloy-copper, and described amorphous alloy is made of Zr 41.25 Ti 13.75 Cu 12.5 Ni 10 be 22.5 A bar with a diameter of Φ5mm is produced; the copper is a brass tube with a diameter of Φ6mm×1mm. The concrete process of this embodiment is:

[0049] Step 1, surface treatment: pass the amorphous alloy rod through the lathe to Φ4.2mm, the outer surface of the amorphous alloy rod and the inner wall of the brass tube are passed through 240#, 400#, 800#, 1000#, 1500#, 2000# sandpaper in sequence Sand until the surface is smooth without scratches. Use 5% hydrochloric acid alcohol treatment to remove the oxide film on the surface of the brass tube. The surface-treated amorphous alloy rods and brass tubes were ultrasonically cleaned with acetone by a conventional method and placed in a mold.

[0050] Step 2, vacuum pre-pressing: place the assembled mold in a vacuum diffusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com