Automatic pipe connection and arranging device based on full-automatic winding machine

A winder, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, transportation of filamentous materials, etc., can solve the problem of impractical high-speed transmission and take-up device of automatic winder, increase labor intensity of employees, exercise Difficult to control and other problems, to achieve the effect of good device stability, simple and convenient design and installation, and simple movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

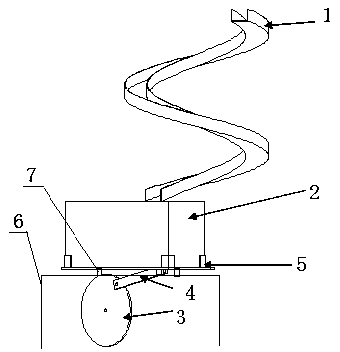

[0021] Such as figure 1 As shown, an automatic takeover and swing pipe device based on a fully automatic winder includes a sand pipe slideway 1 for accepting fine sand pipes, a swing pipe box 2 and a reciprocating mechanism; the sand pipe slideway 1 is installed and connected to the network On the straight slideway of the barrel machine, the swing tube box 2 is located below the sand tube slideway 1, and the swing tube box 2 is used to accept the fine sand tubes falling from the sand tube slideway 1; the reciprocating mechanism and the swing tube The boxes are connected, and the reciprocating mechanism drives the swing tube box to reciprocate laterally. The empty spun bobbin from the automatic winding machine is slid into the bobbin slideway 1 by the straight slide of the winding machine, and then slides into the swinging bobbin box 2 by utilizing its motion inertia. The bobbin box 2 reciprocates under the drive of the reciprocating mechanism, and then places the spun bobbins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com