Reciprocating piston type internal combustion engine of crankless connecting rod mechanism

A technology of crank connecting rod mechanism and reciprocating piston is applied in the field of internal combustion engine device and reciprocating piston internal combustion engine device, which can solve the problems of complex inertia effect and noise, complex motion state of connecting rod, complex crank structure, etc., and achieves low processing requirements and noise. Small, simple form of motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

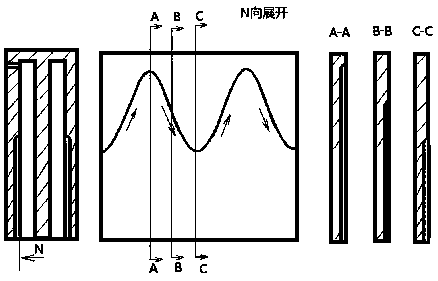

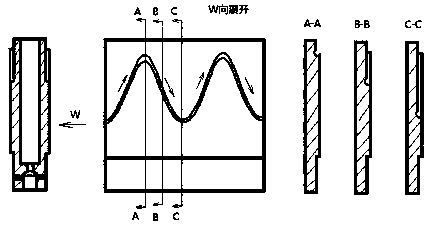

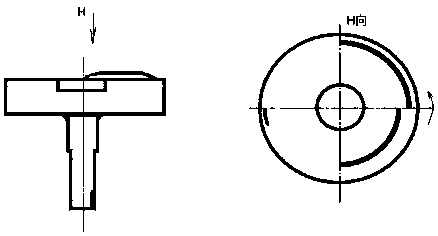

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , the reciprocating piston type internal combustion engine without crank connecting rod mechanism of the present invention is formed by the inner ring 7, steel ball 18 and outer ring 6 raceways of the curved groove ball bearing without cage to form a mechanism with two cycles and four strokes per revolution , the two strokes are used for compression and exhaust respectively, and the two return strokes are used for combustion work and air intake respectively; wherein, the push stroke is to use the rising slope of the curved groove to push the piston 9 to move upward; the combustion work stroke of the return stroke uses The expansion of gas pushes the piston 9 to move downward; the suction stroke of the return stroke lacks power; therefore, a plunger cylinder is arranged in the piston, and the upward movement during the push stroke is used to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com