Capacity changing device for vortex type compressor

A scroll compressor and changing device technology, applied in the direction of rotary piston machinery, pumping device components for elastic fluid, rotary piston type/swing piston type pump components, etc., can solve the manufacturing cost of compressors Increase and other issues, to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows in conjunction with the drawings:

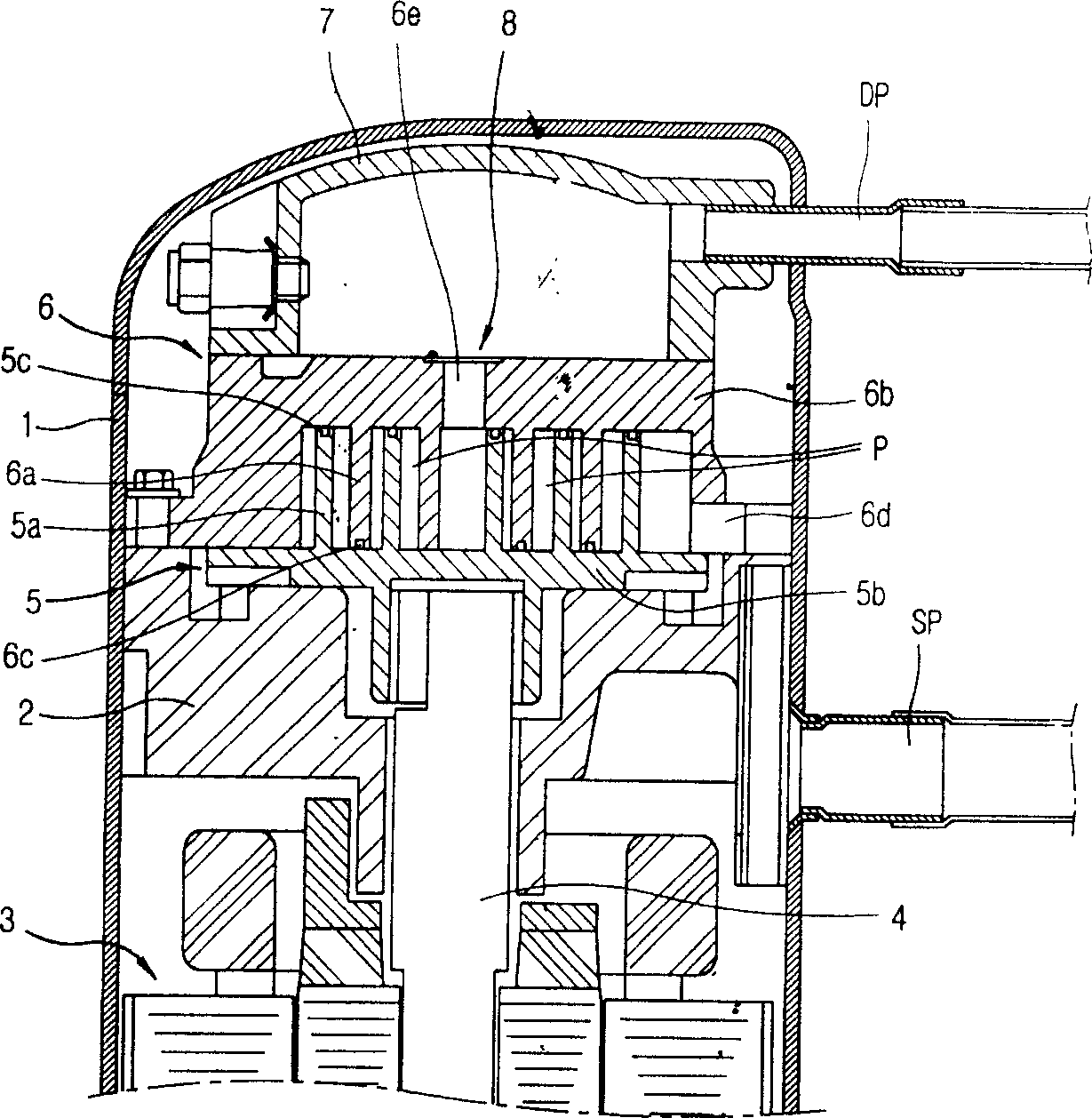

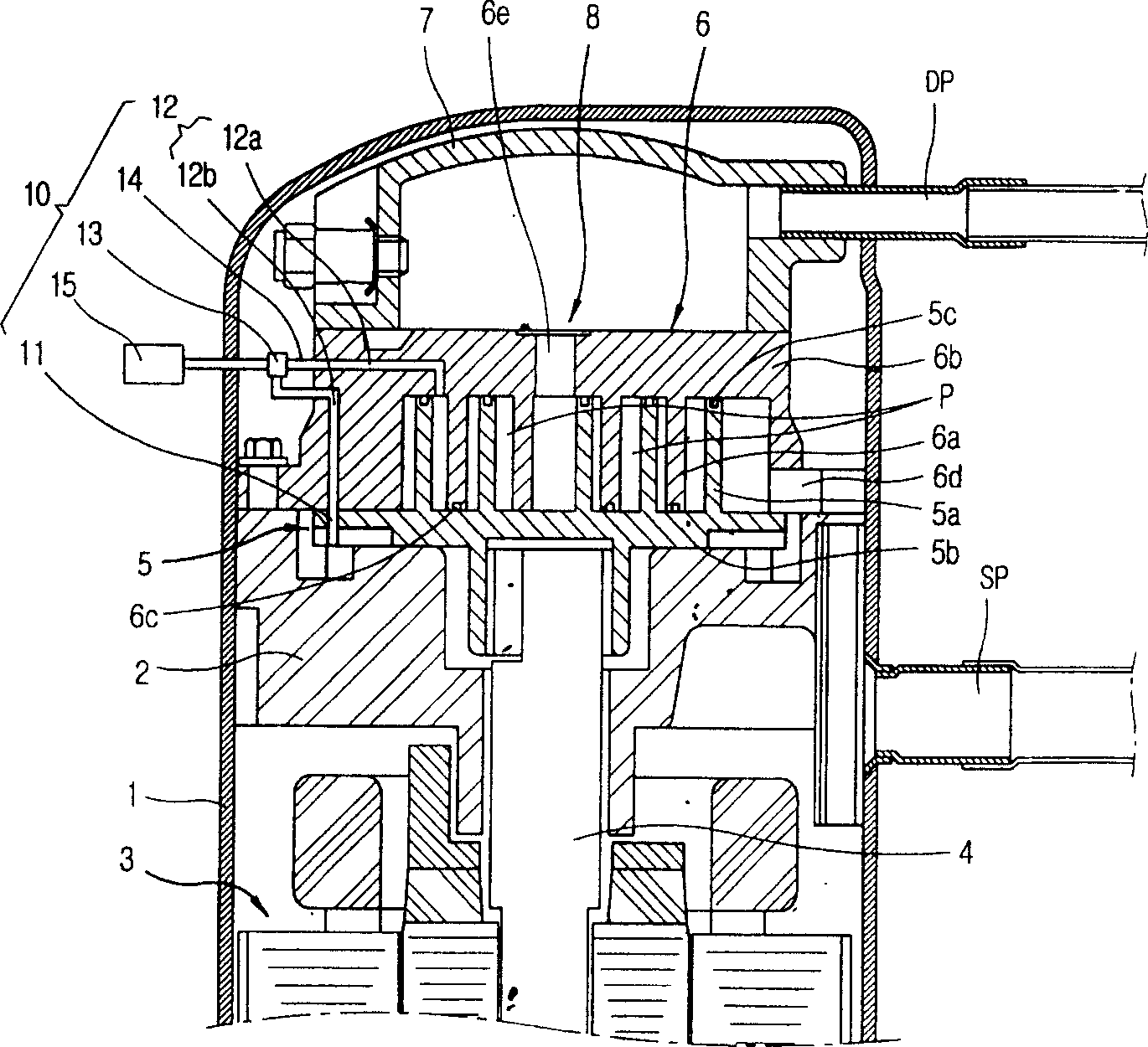

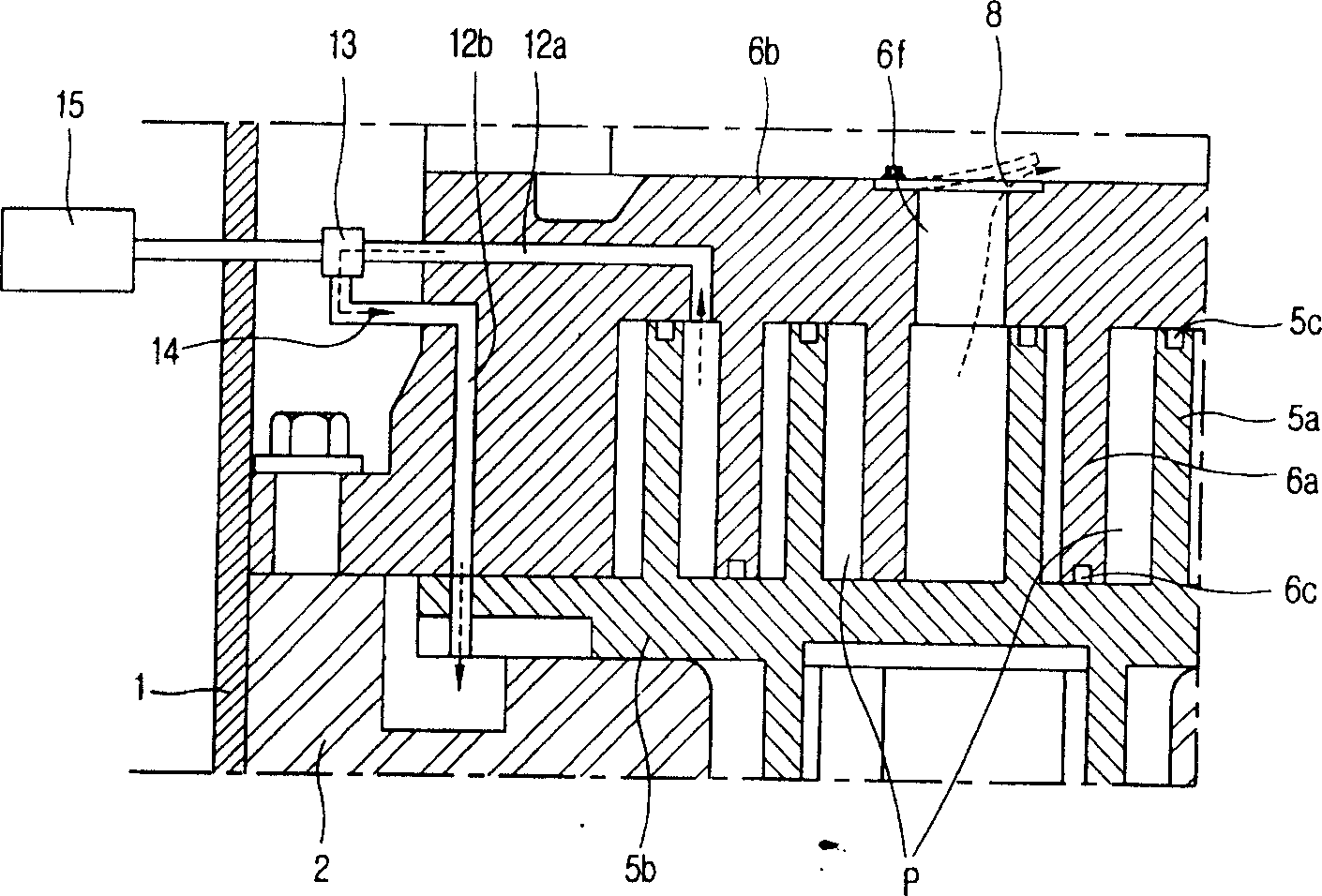

[0028] figure 2 It is a longitudinal cross-sectional view showing an example of the scroll compressor of the present invention. image 3 It is an exploded perspective view showing the fixed scroll and the movable scroll of the scroll compressor of the present invention. Fig. 4 is a schematic diagram illustrating the operating state of the main part of the capacity changing device of the scroll compressor of the present invention. Fig. 5 is a detailed diagram illustrating the discharge state of compressed gas during low-capacity operation of the scroll compressor of the present invention.

[0029] As shown in the figure, the capacity changing device of the scroll compressor according to the present invention is composed of a casing (1) equipped with a gas sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com