Variable-capacity metering tube for tobacco shred blending

A metering tube and variable capacity technology, which is applied in the field of tobacco processing, can solve problems such as unadjustable metering tube capacity, material blockage or disconnection, and affecting debugging results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

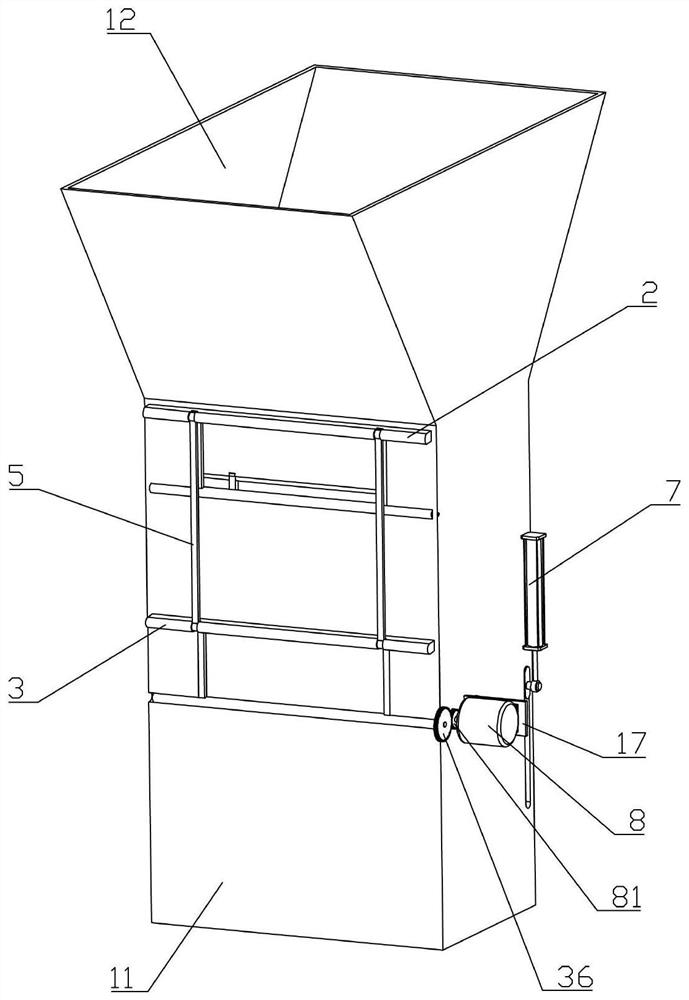

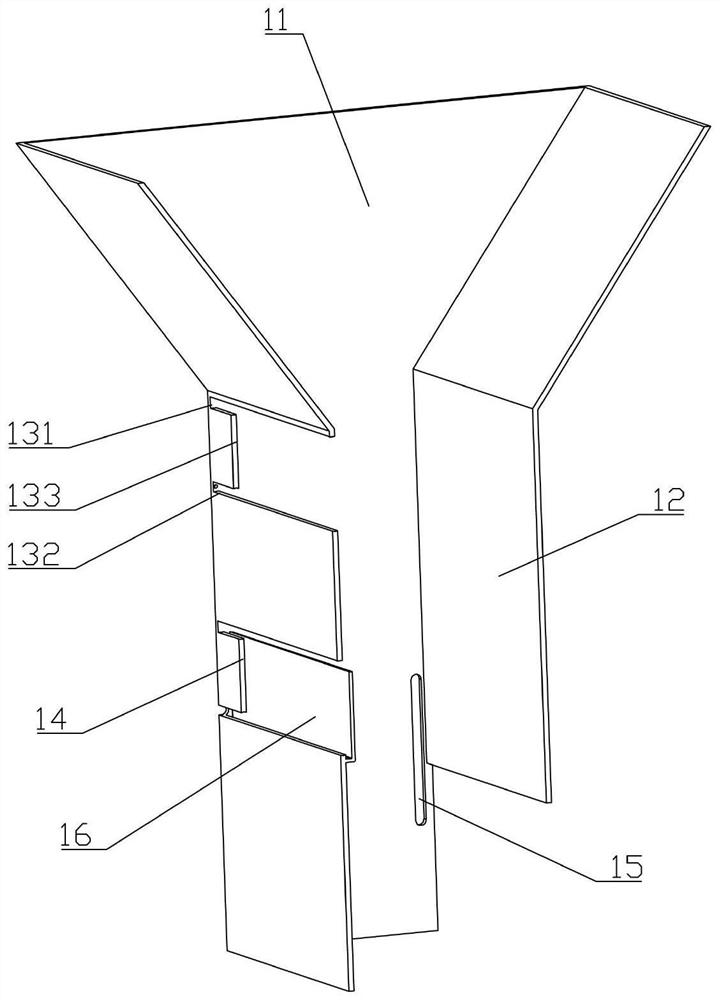

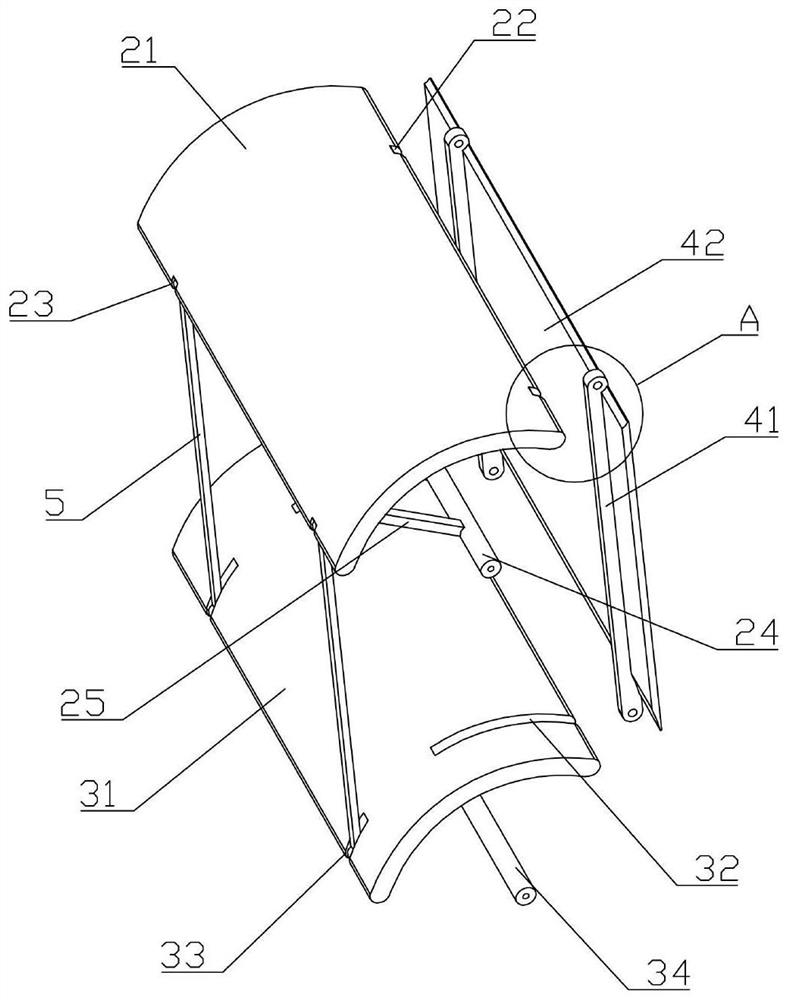

[0027] Such as Figure 1 to Figure 7 As shown, a variable volume metering tube for shredded tobacco blending according to the present invention includes a metering tube body 11 and a hopper 12 located above the metering tube body 11. The metering tube body 11 is provided with a first installation groove and a second Two mounting grooves 14, the first mounting groove includes a first slide groove 131, a rotating shaft groove 132 and an escape groove 133, the second mounting groove 14 has the same structure as the first mounting groove, and the first adjusting member 2 is installed in the first mounting groove, The second adjusting member 3 is installed in the second installation groove 14, the first adjusting member 2 includes the first arc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com