Cloth rolling device and method for producing glue canvas

A technology of rubber canvas and detection device, which is applied in the directions of winding strips, transportation and packaging, and sending objects, etc., can solve the problems such as the rubber layer deviates to one side of the cloth and the edge of the rubber canvas is not neat, so as to improve product quality, The effect of neat glue layer and quick action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

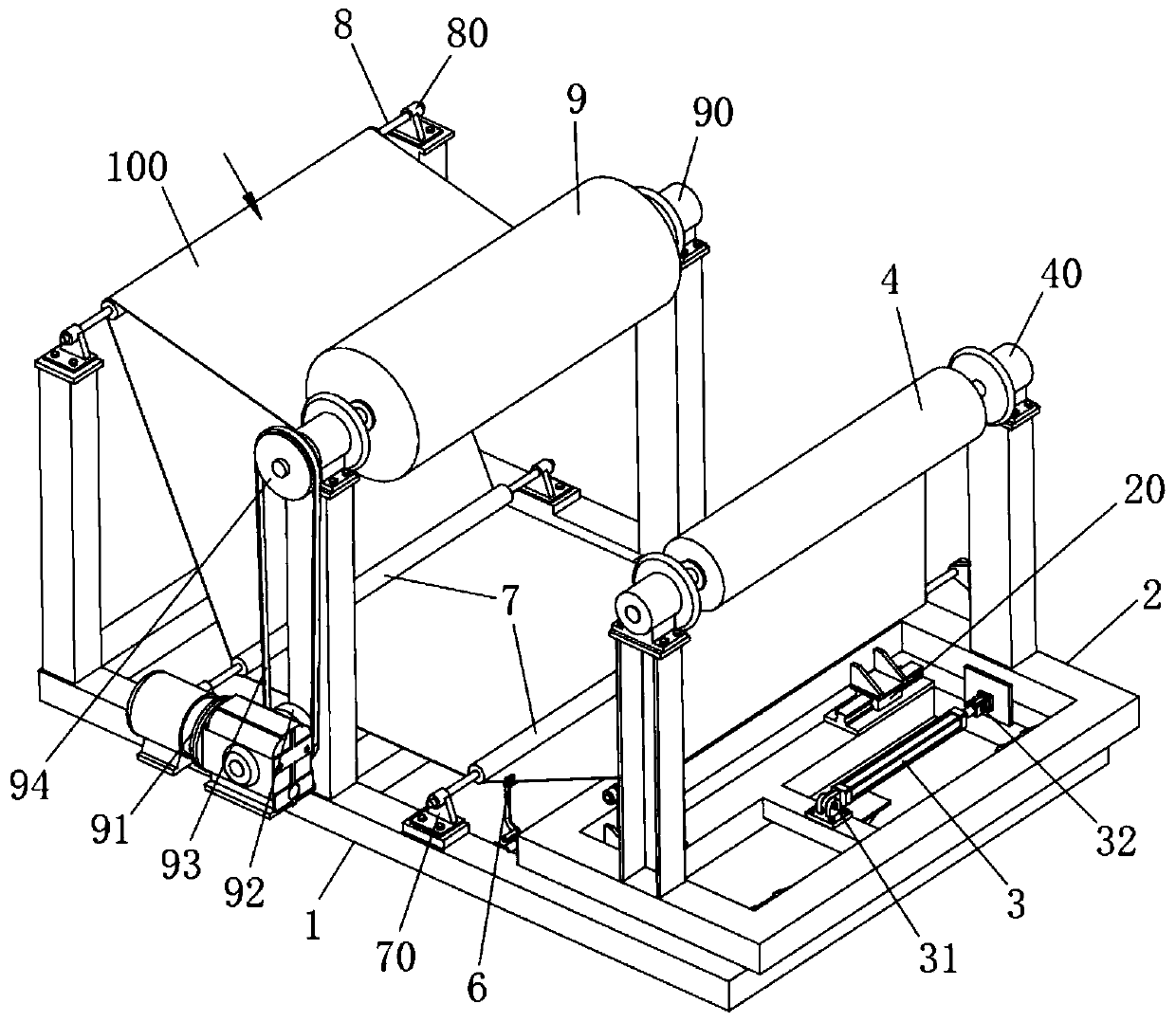

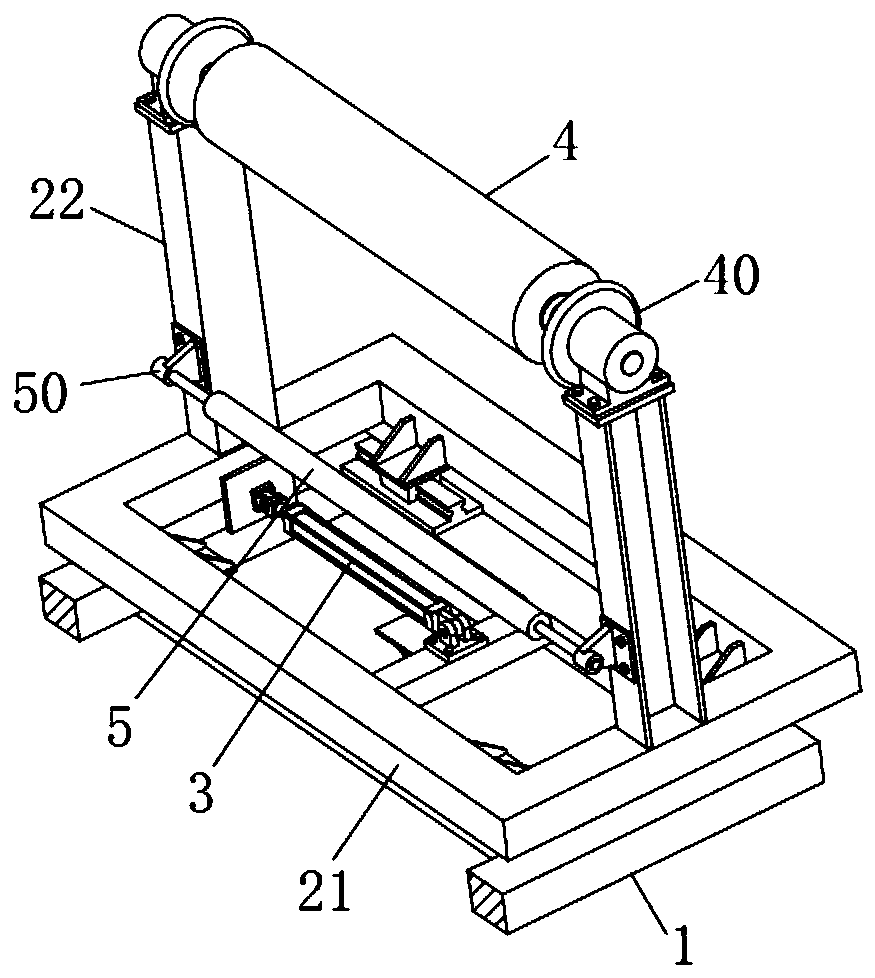

[0049] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

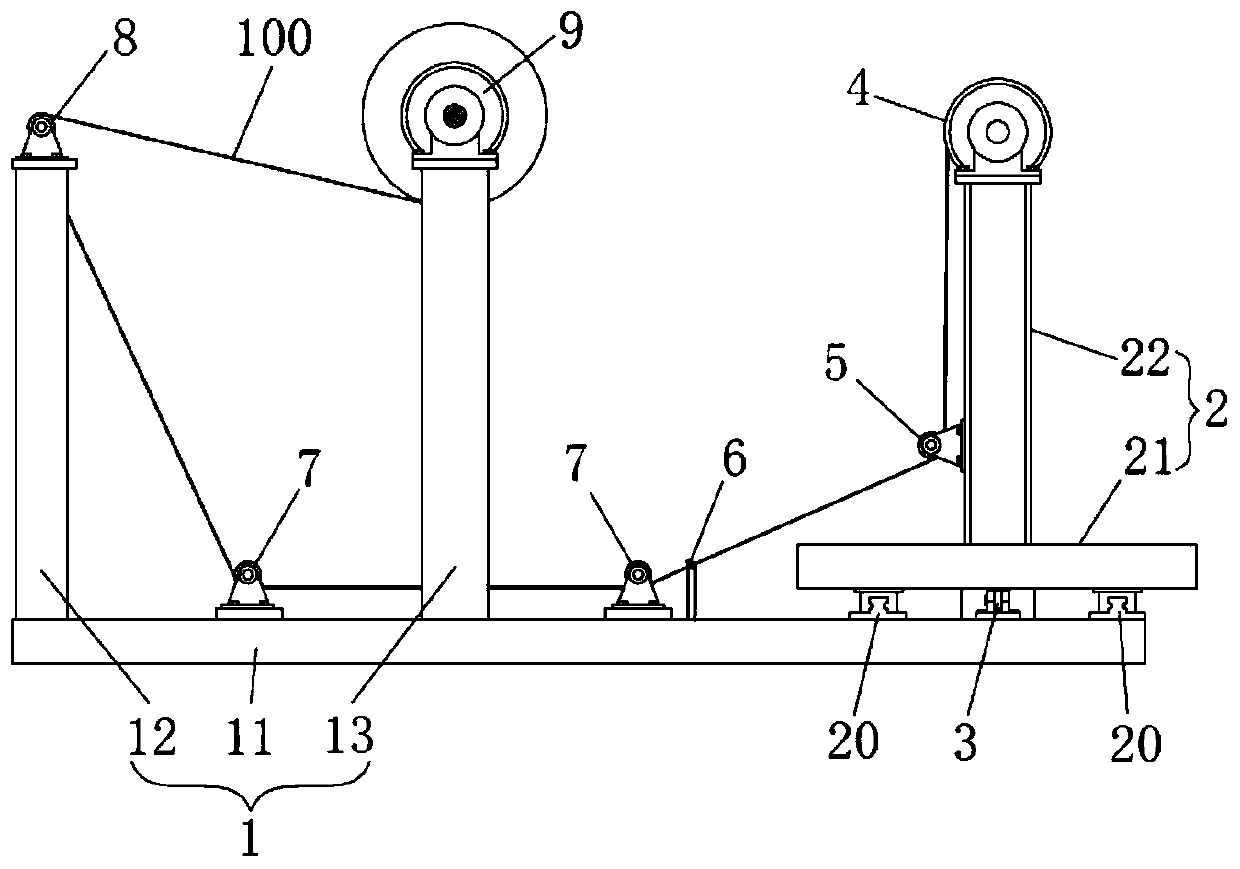

[0050] In the production process of rubber canvas, due to uncertain factors such as production and transportation, the cloth winding will be irregular when the cloth roller 4 is incoming, and the gap between the cloth roller 4 and the winding roller 90 in the traditional cloth rolling device Relatively still, the output of the fabric 100 from the fabric roller 4 to the take-up roller 90 will be shifted left and right, and the glue layer continuously input will not move back and forth with the fabric 100, which leads to the S-shaped glue layer on the produced glue canvas. The irregular edge or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com