Patents

Literature

40results about How to "Fast collection processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

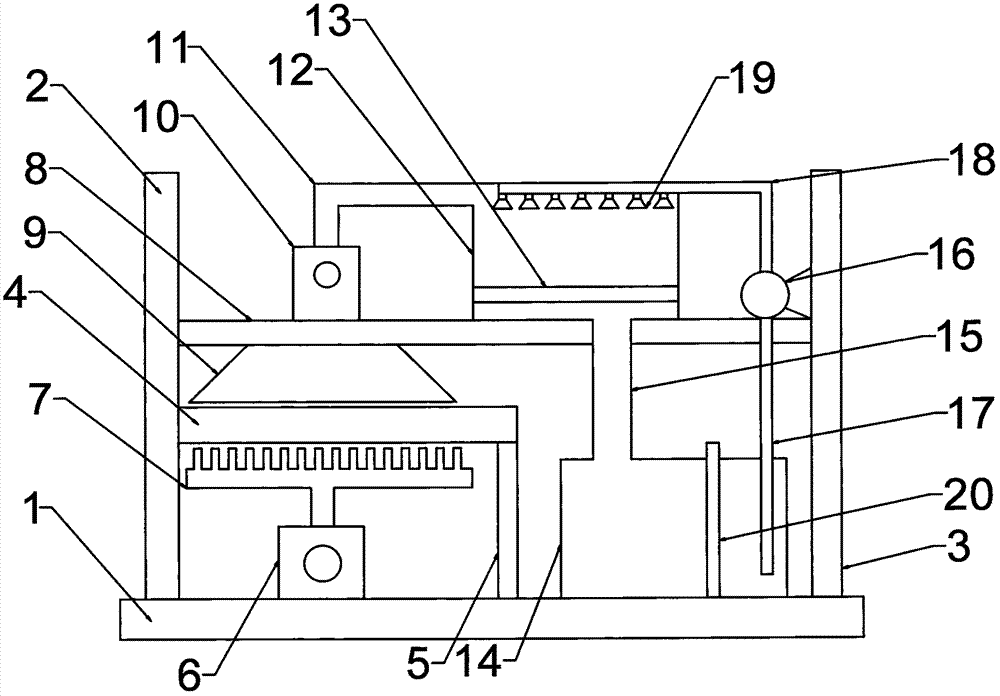

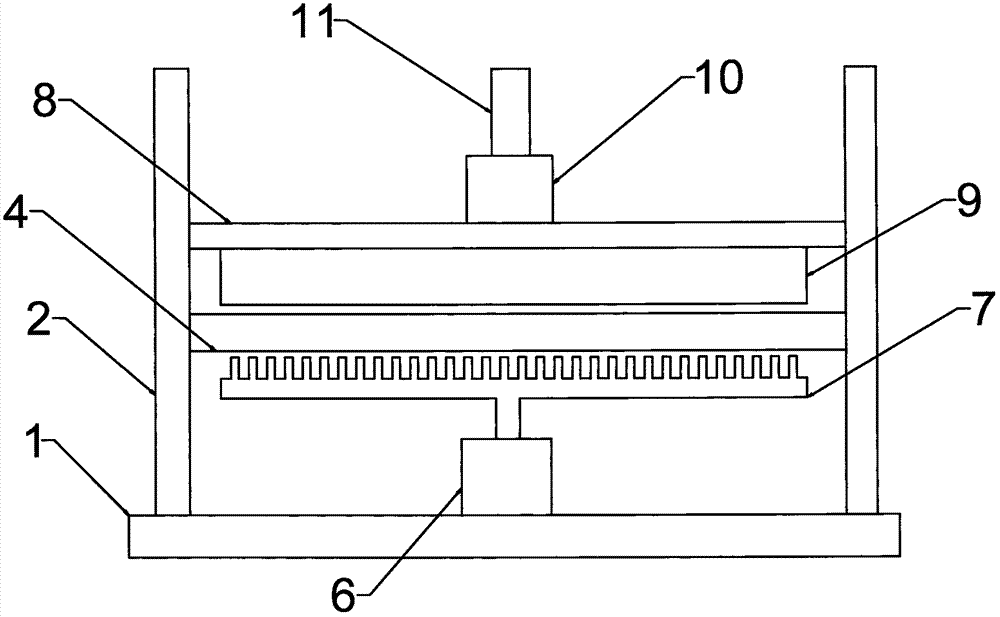

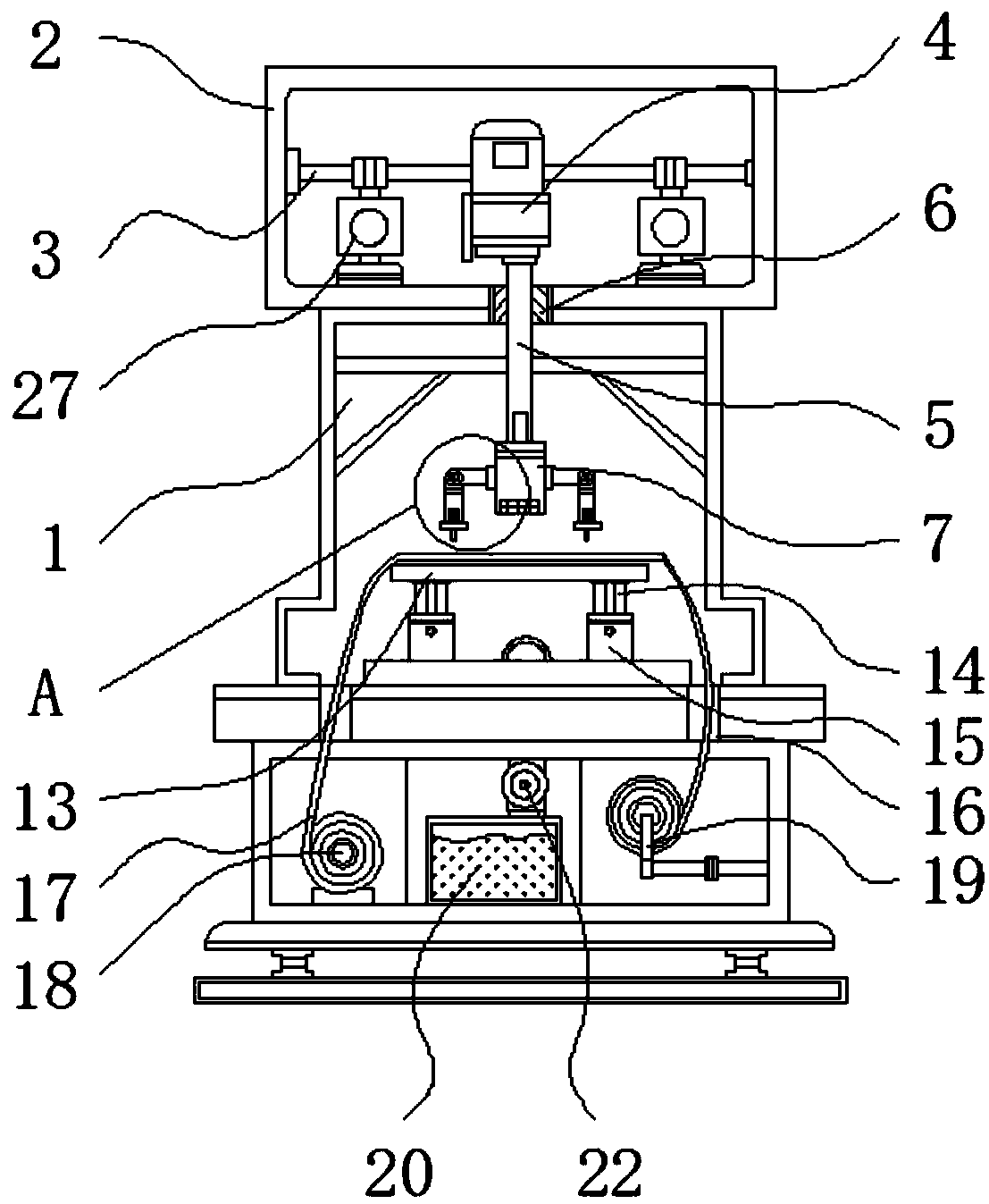

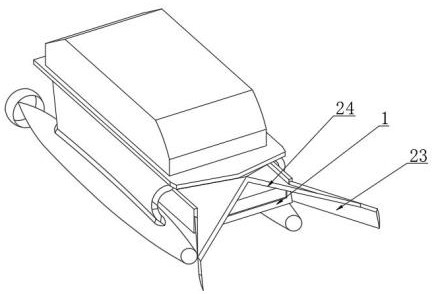

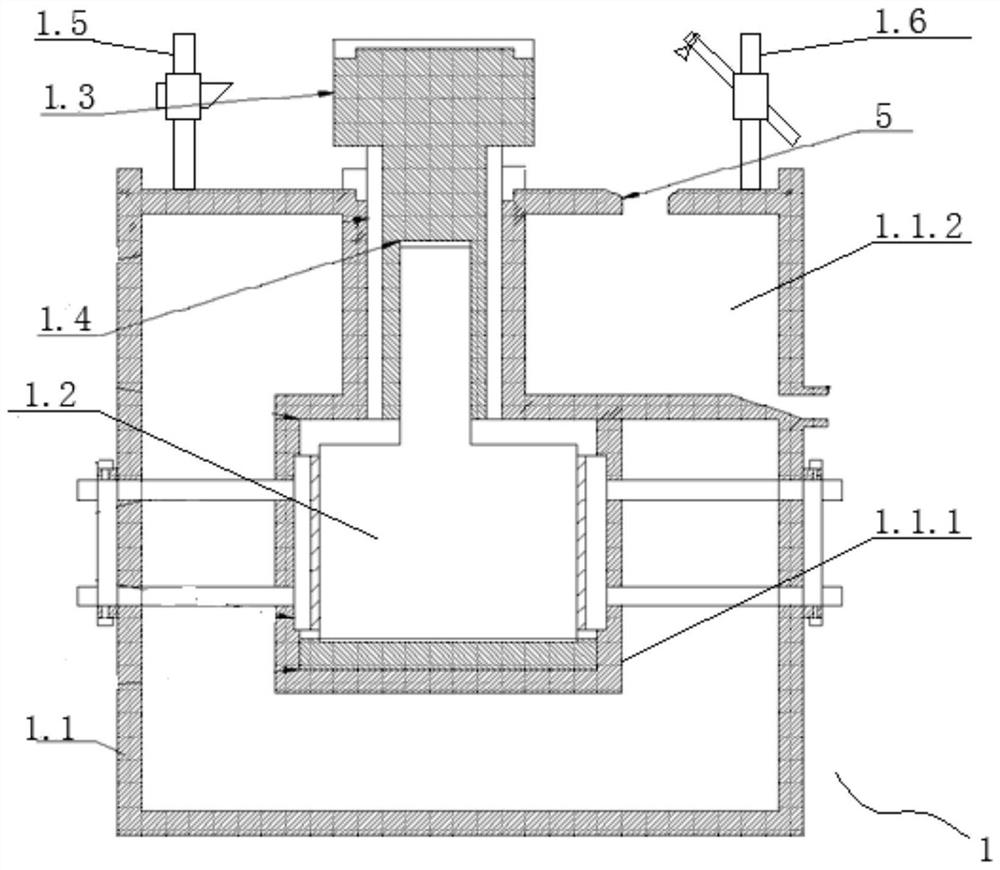

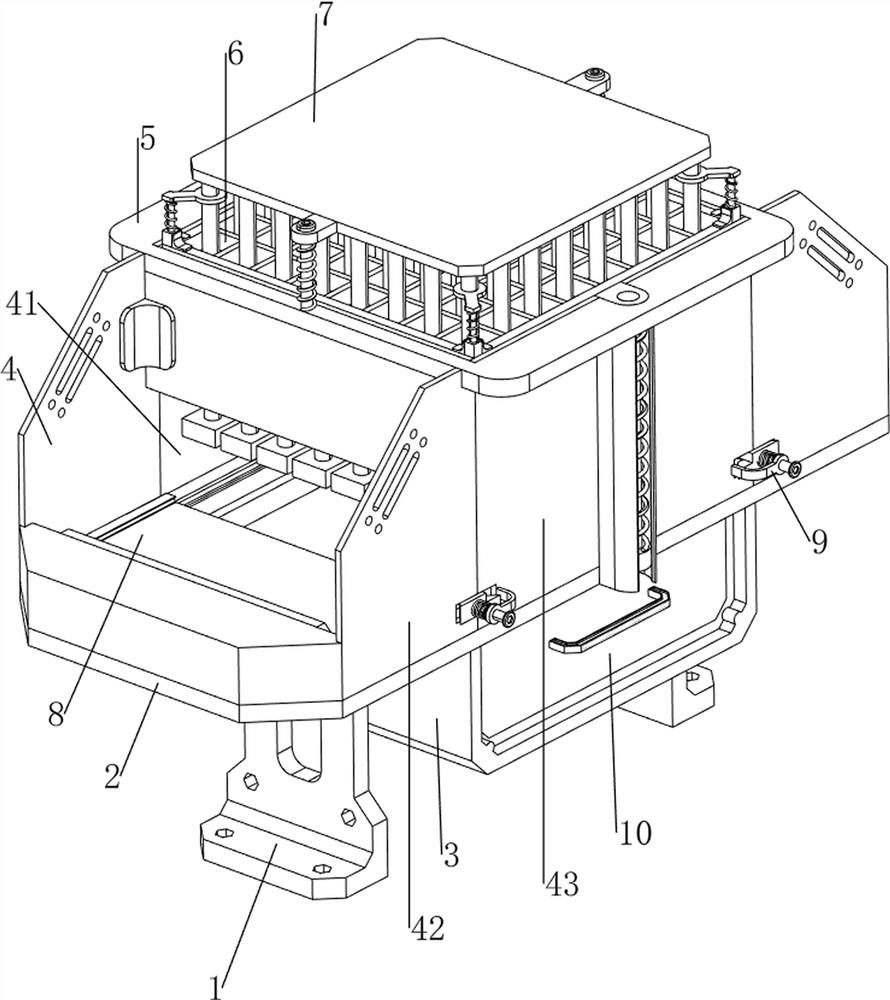

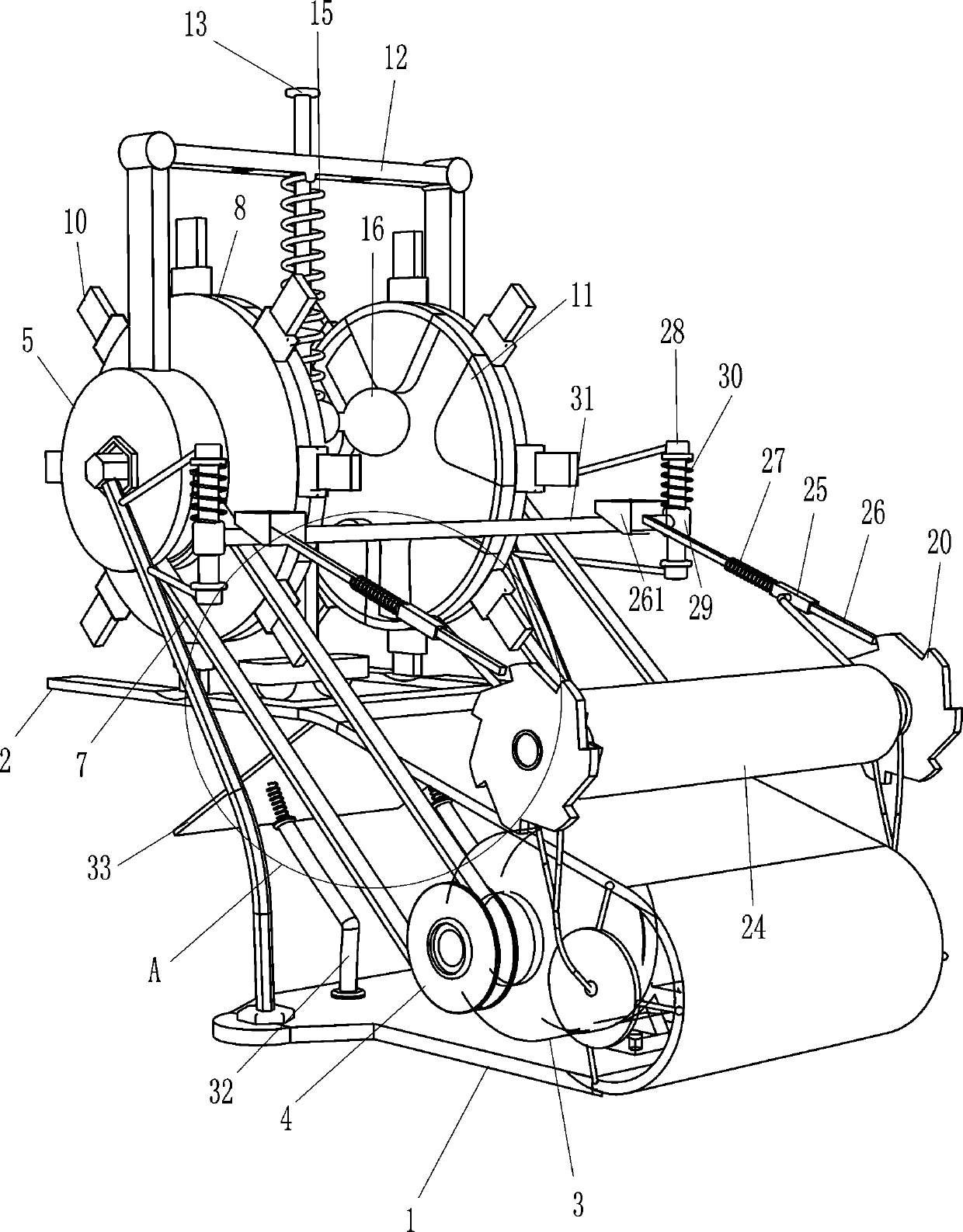

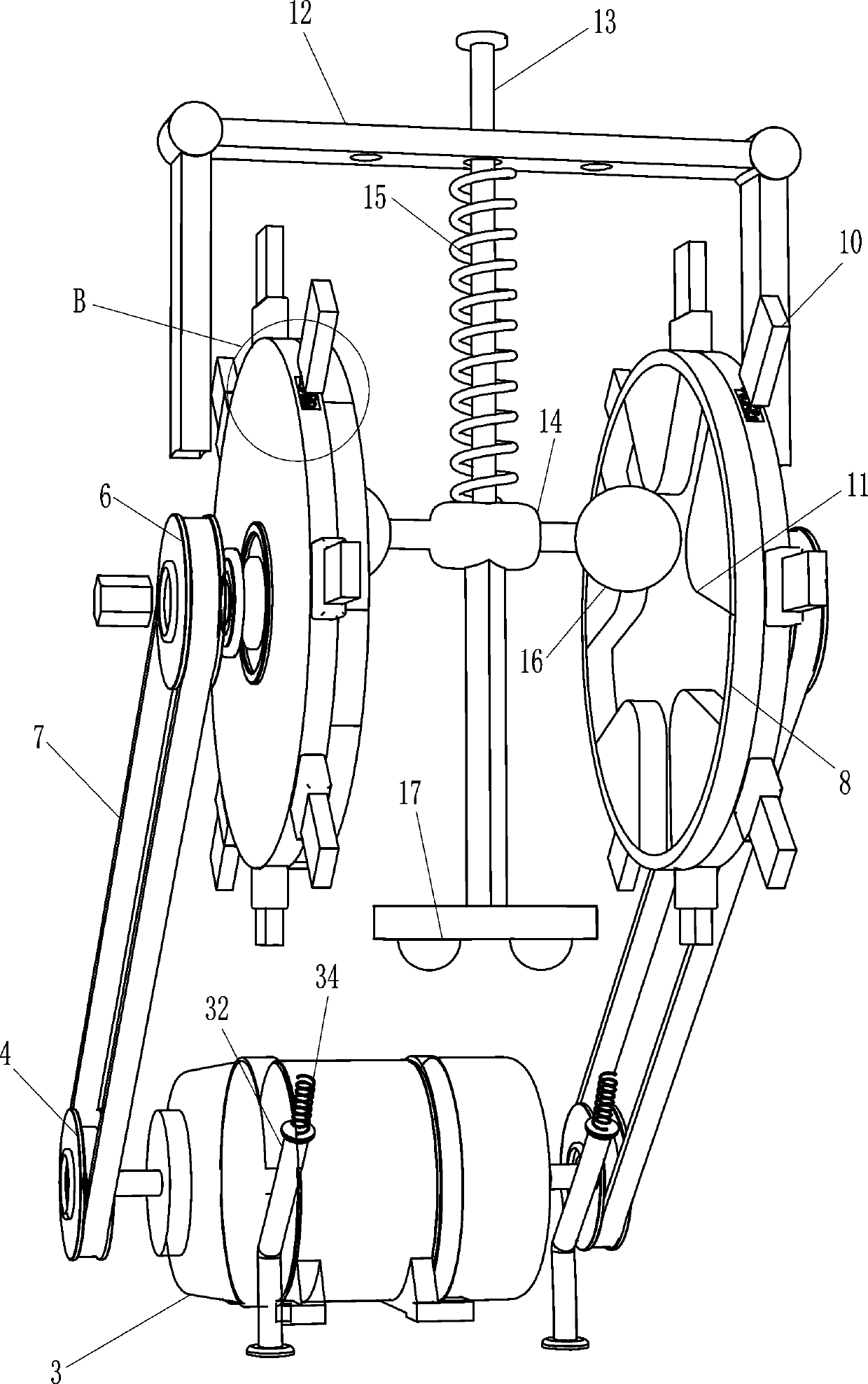

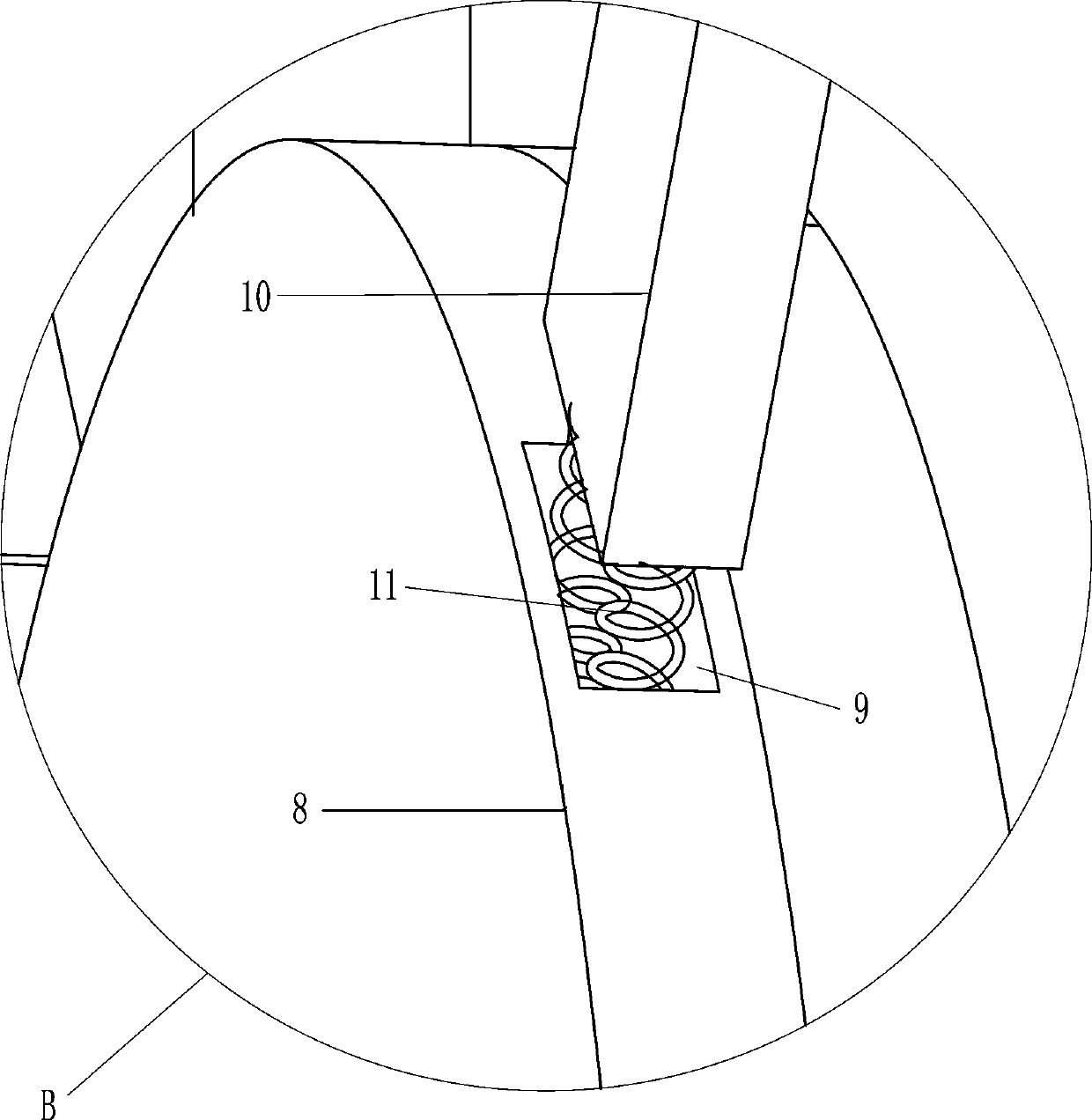

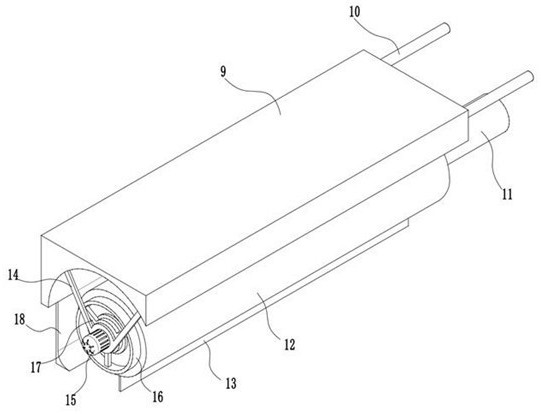

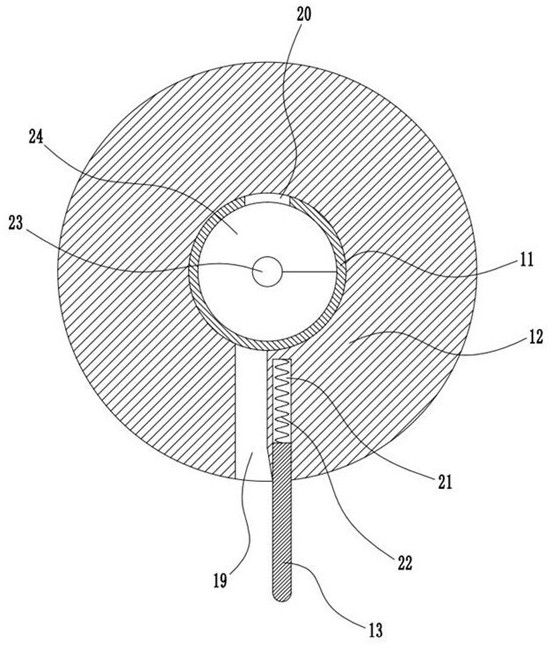

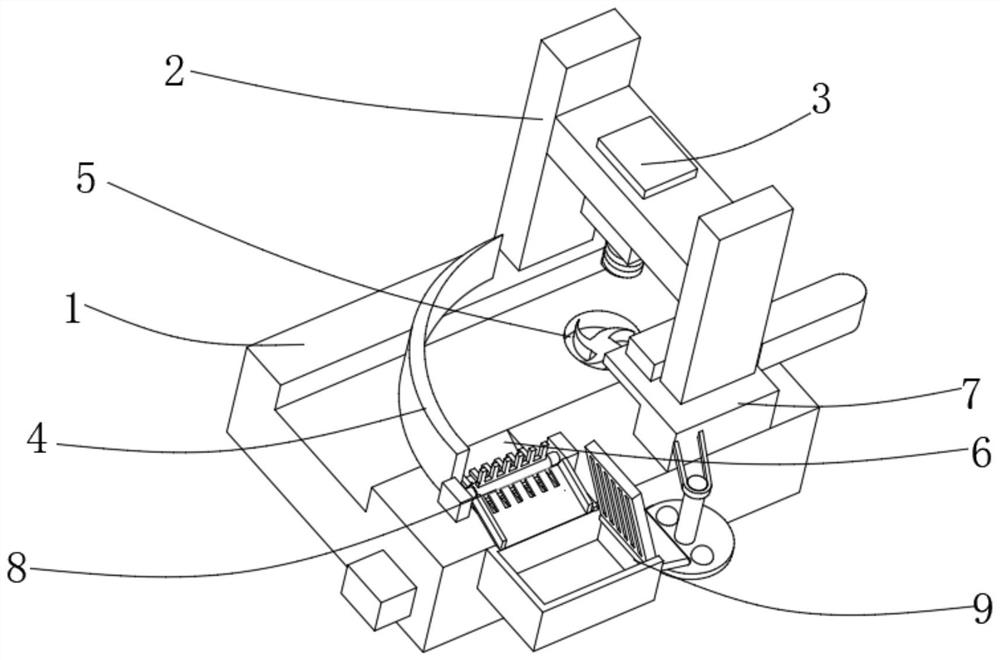

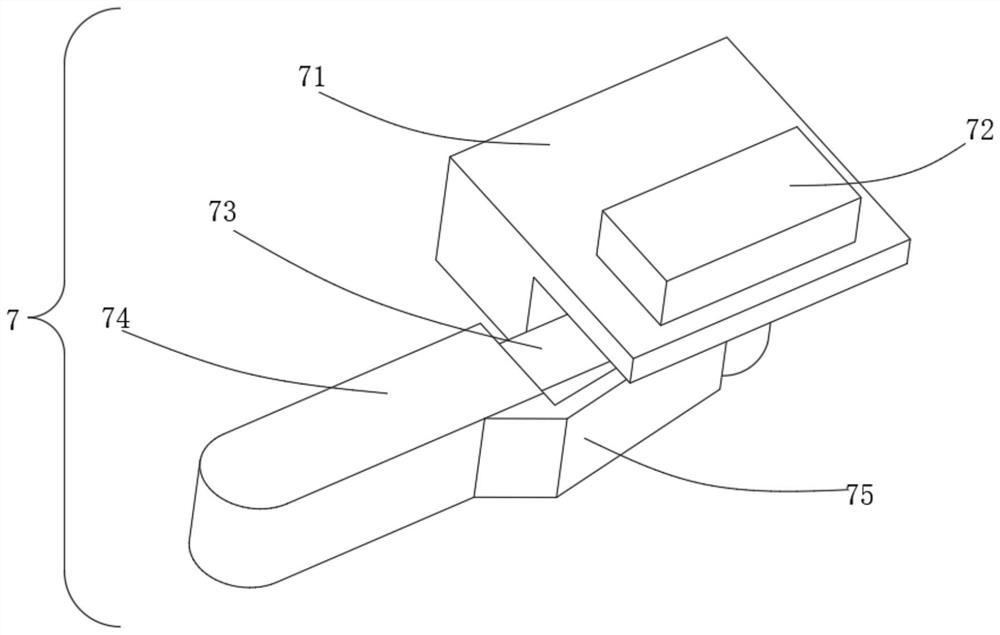

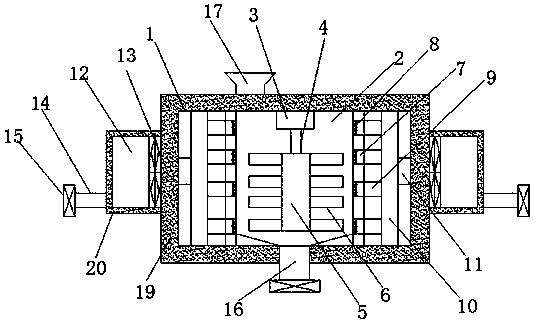

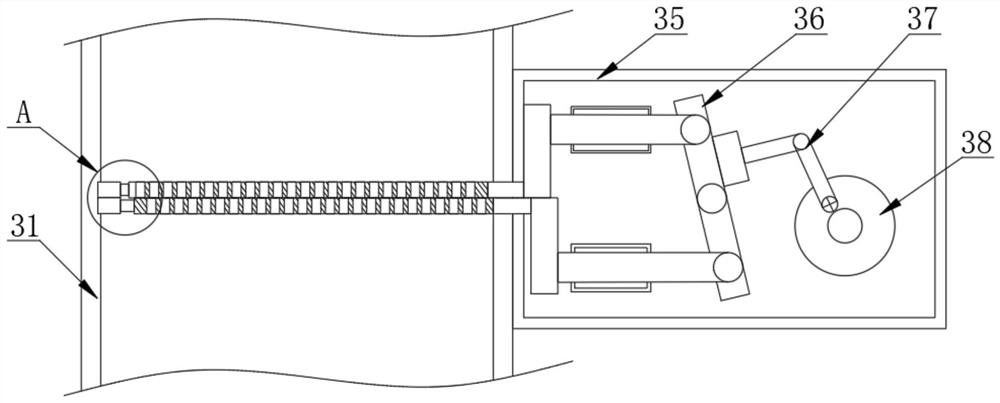

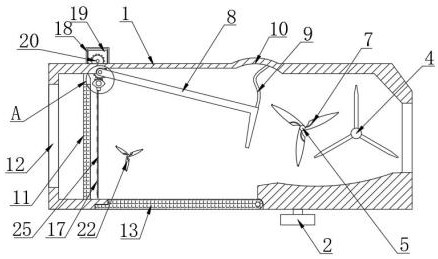

Yarn combing and impurity removing mechanism for textile machine that facilitates collection of impurities

ActiveCN111270383AEasy to collectFast collection processingFibre cleaning/openingYarnHydraulic cylinder

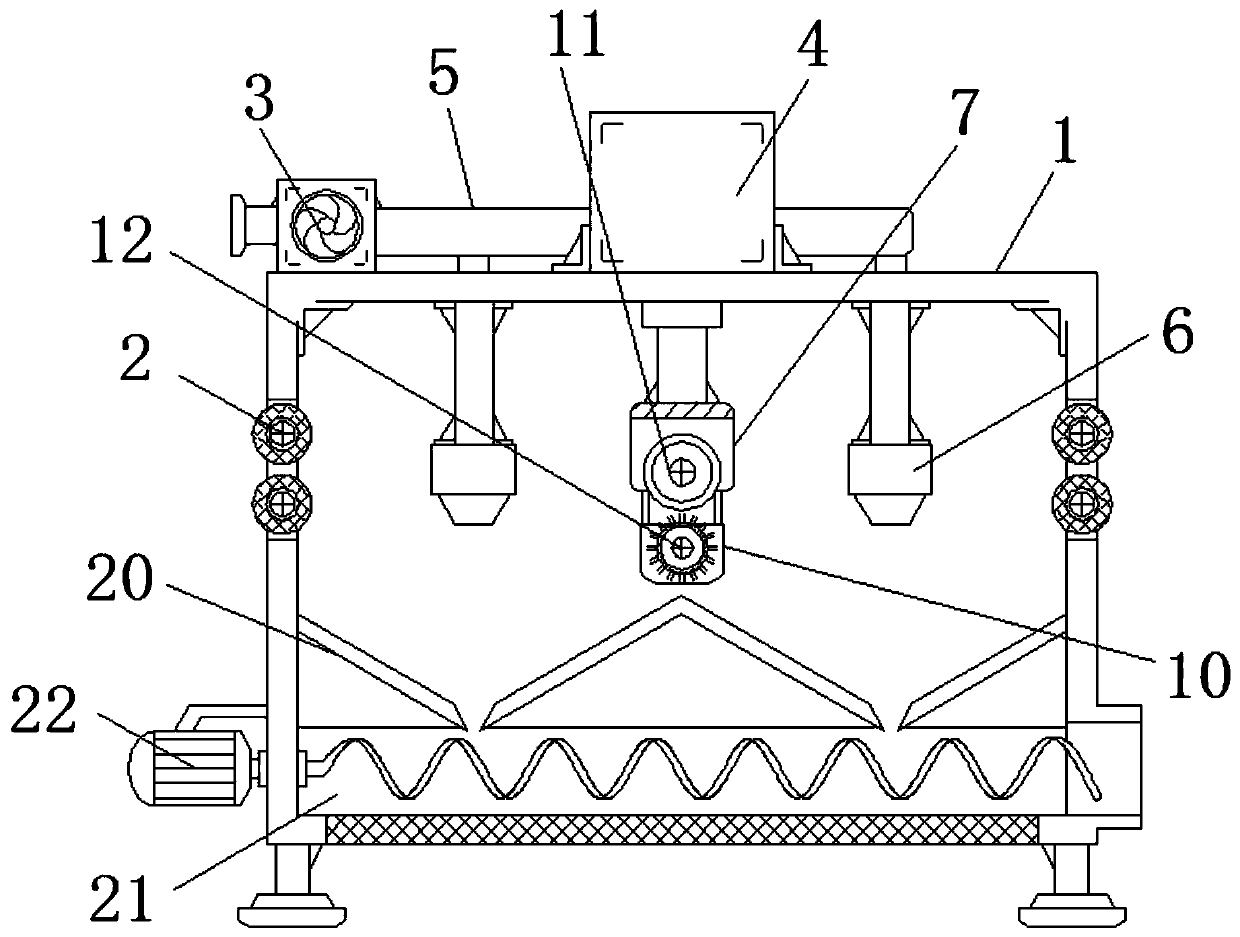

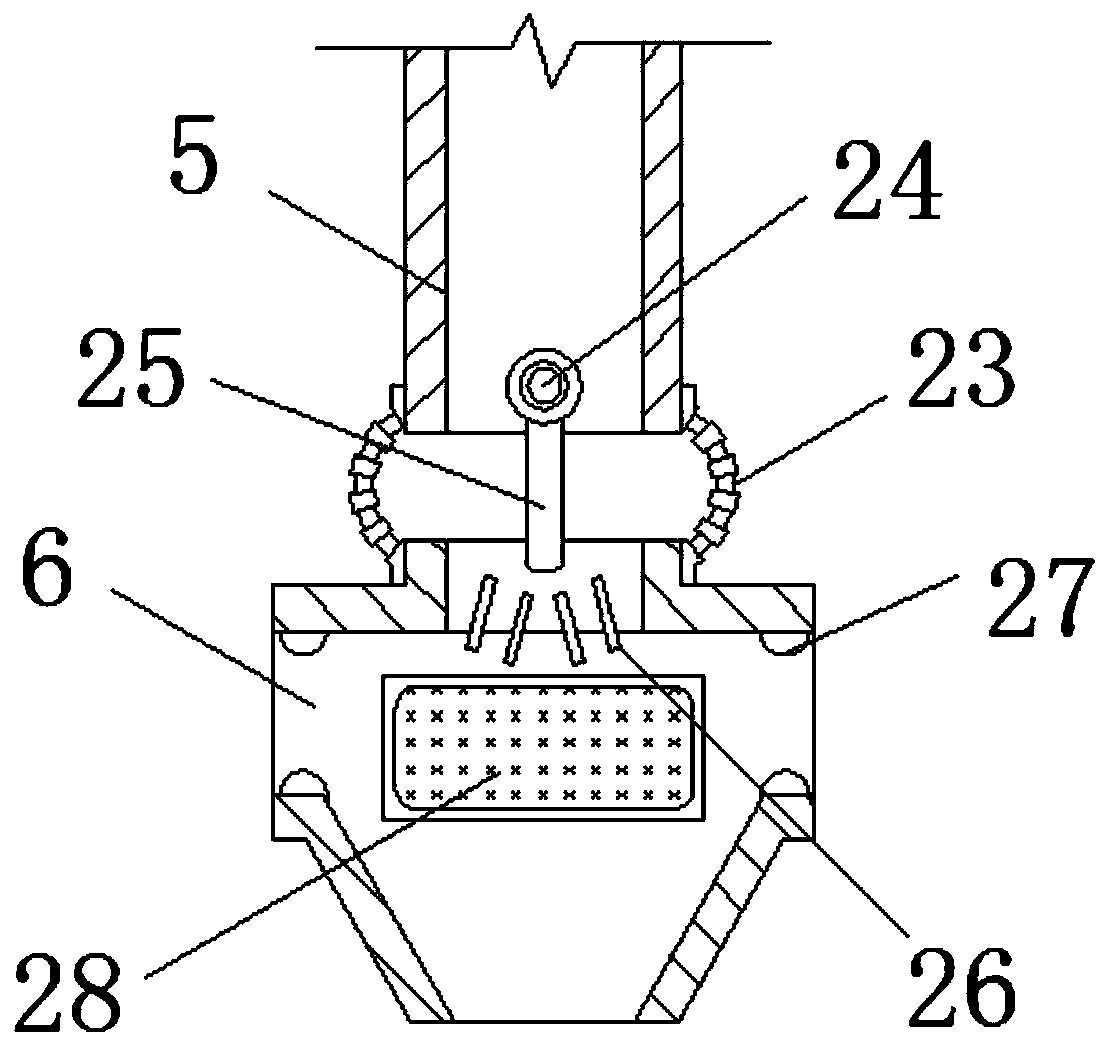

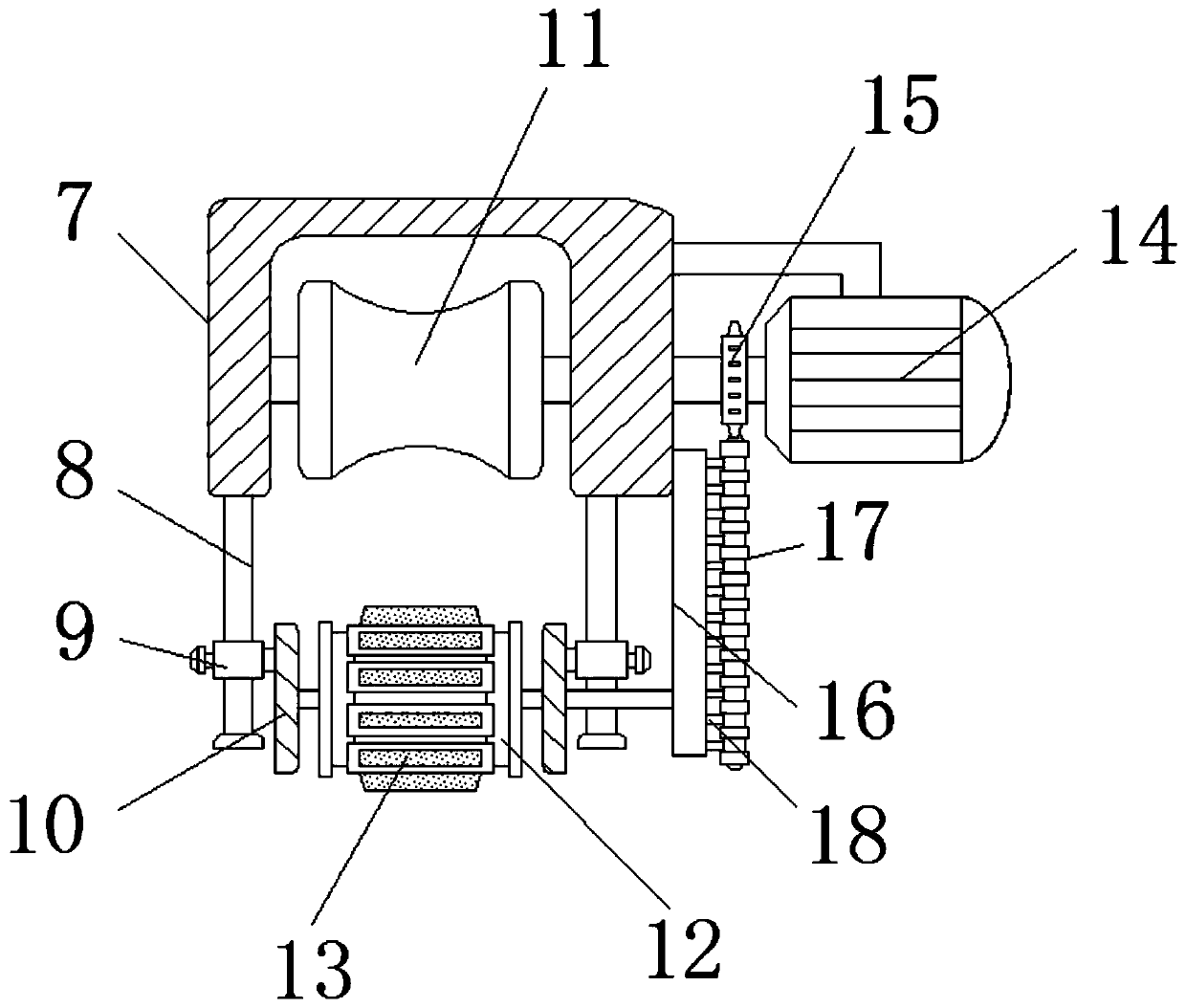

The invention discloses a yarn combing and impurity removing mechanism for a textile machine that facilitates collection of impurities. The yarn combing and impurity removing mechanism comprises an impurity removing cavity, an air pump, a hydraulic cylinder and a motor; guide pulleys are rotatably installed at the left and right sides of the impurity removing cavity, and the air pump and the hydraulic cylinder are respectively fixedly installed at the top edge and the middle part of the impurity removing cavity; the output end of the hydraulic cylinder penetrates through the top of the impurity removing chamber and is fixedly connected with a guide frame; an inner rotating shaft of the guide frame is provided with a take-up pulley; the motor is fixedly installed on the outer wall of the guide frame; a fixing frame is fixed on the outer wall of the guide frame leaning towards one side of the motor, and a chain belt is slidably installed on the fixing frame; and a guide plate is fixed ata lower position of the inner wall of the impurity removing chamber. According to the yarn combing and impurity removing mechanism for the textile machine that facilitates the collection of the impurities provided by the invention, yarns of different thicknesses and materials can be conveniently subjected to impurity removal, the working efficiency of carding fluff impurities on the yarns is improved, and the overall rapid collection and processing of the fluff impurities can be facilitated.

Owner:浙江永红纺织有限公司

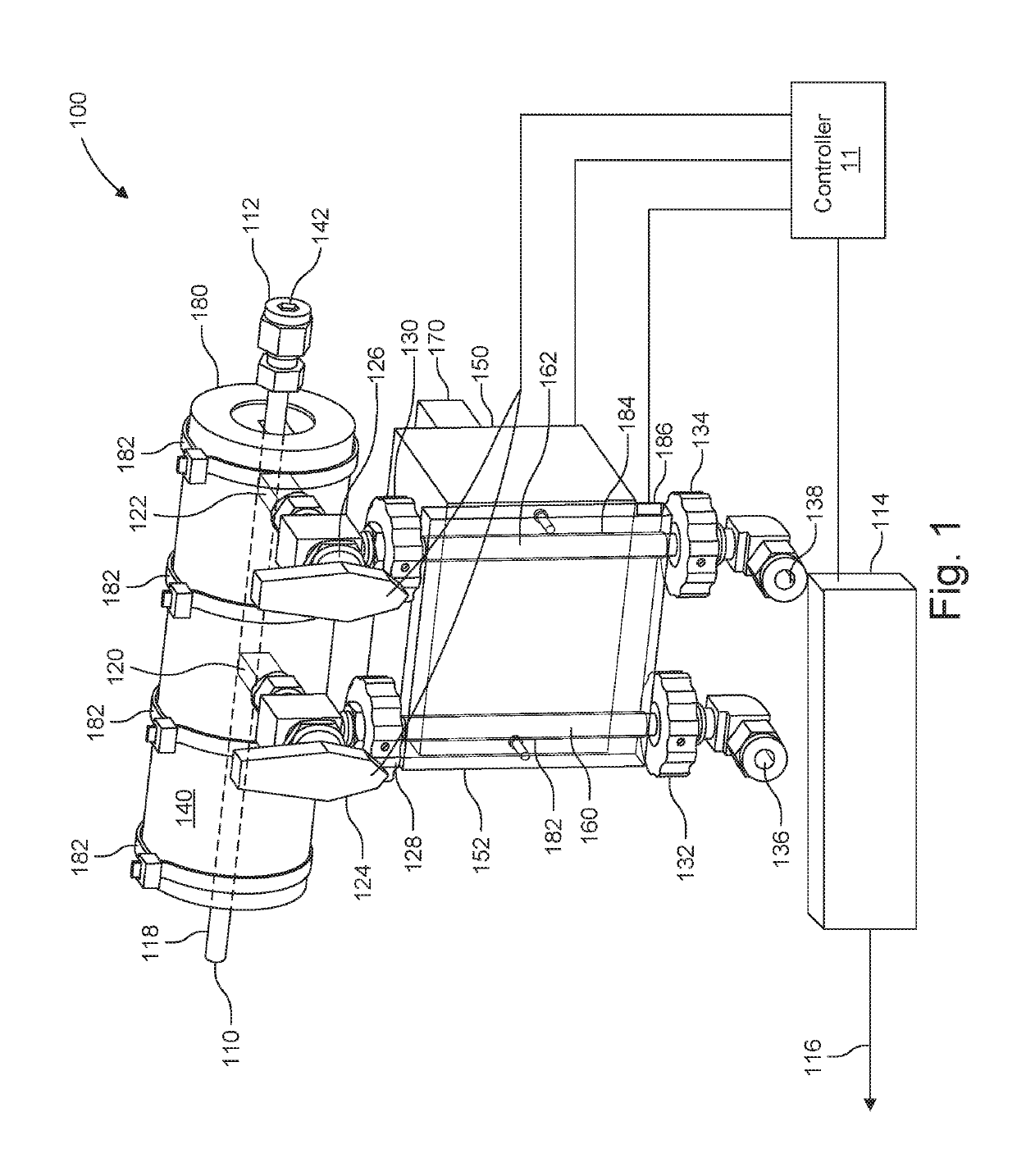

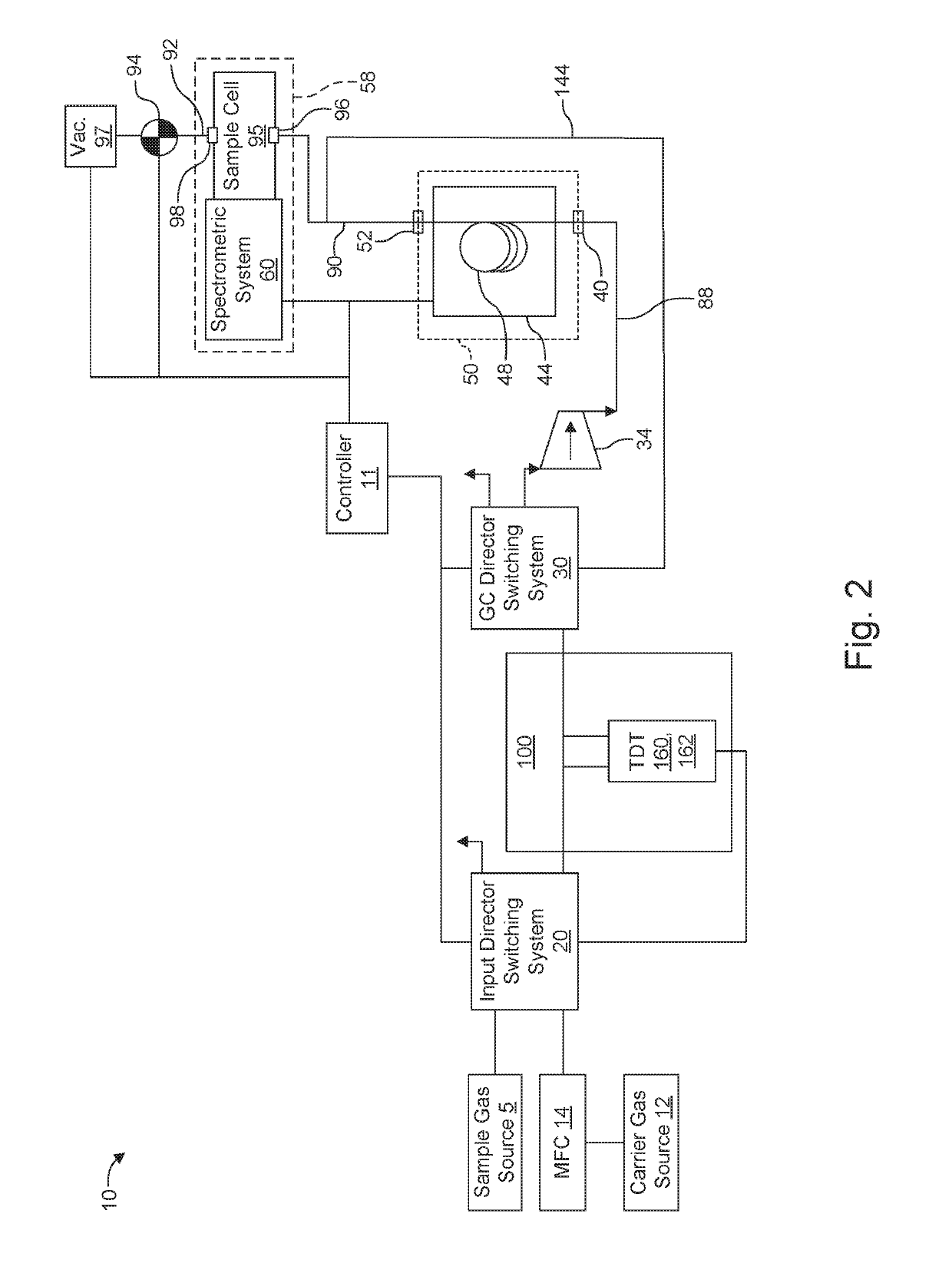

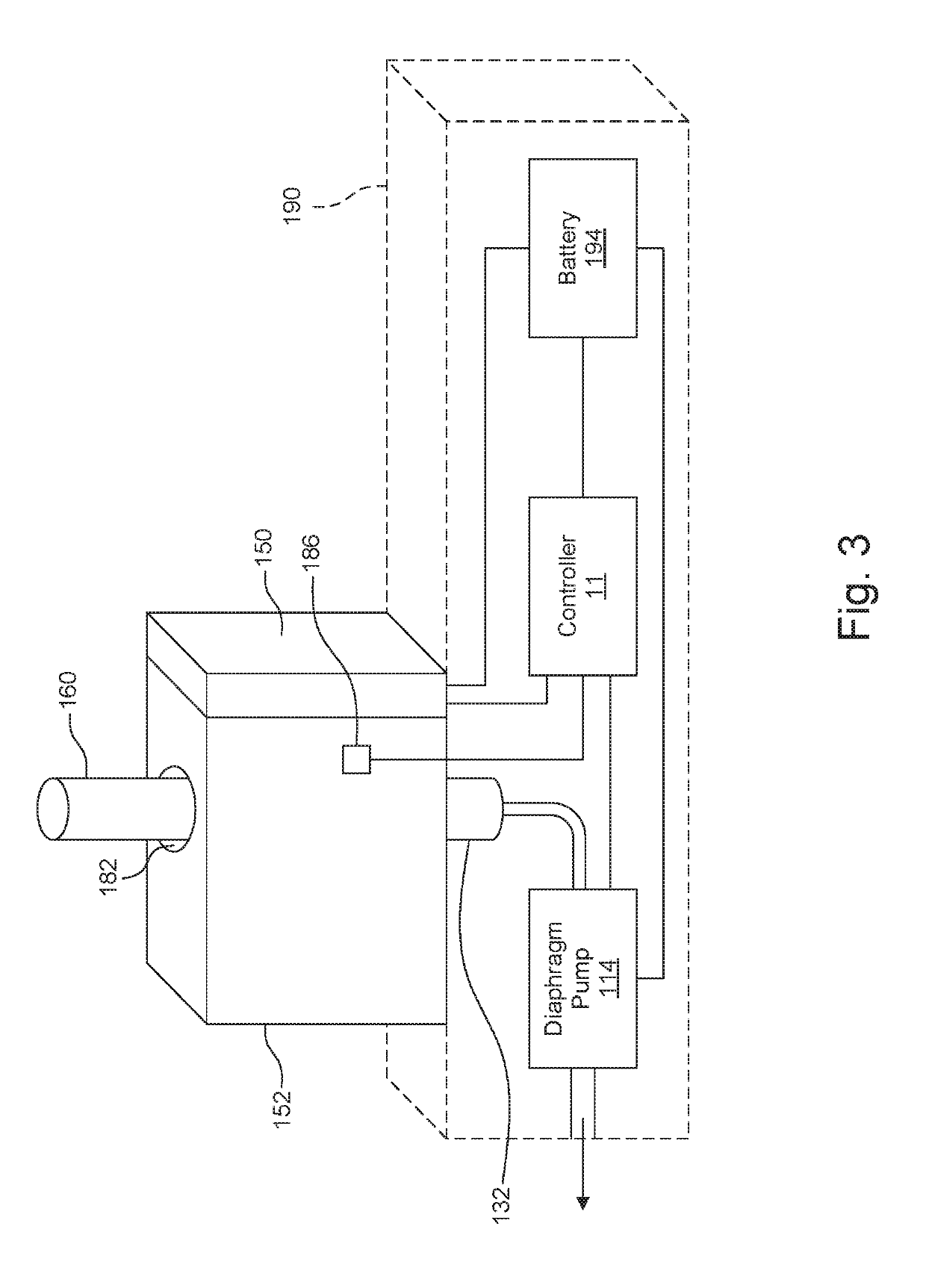

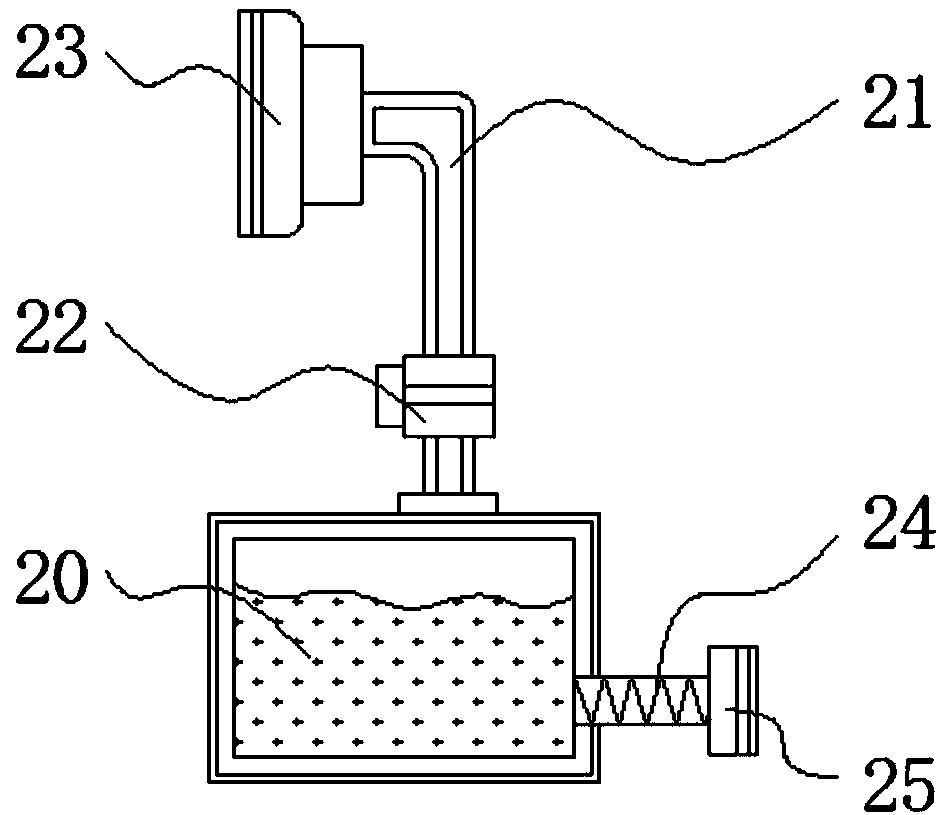

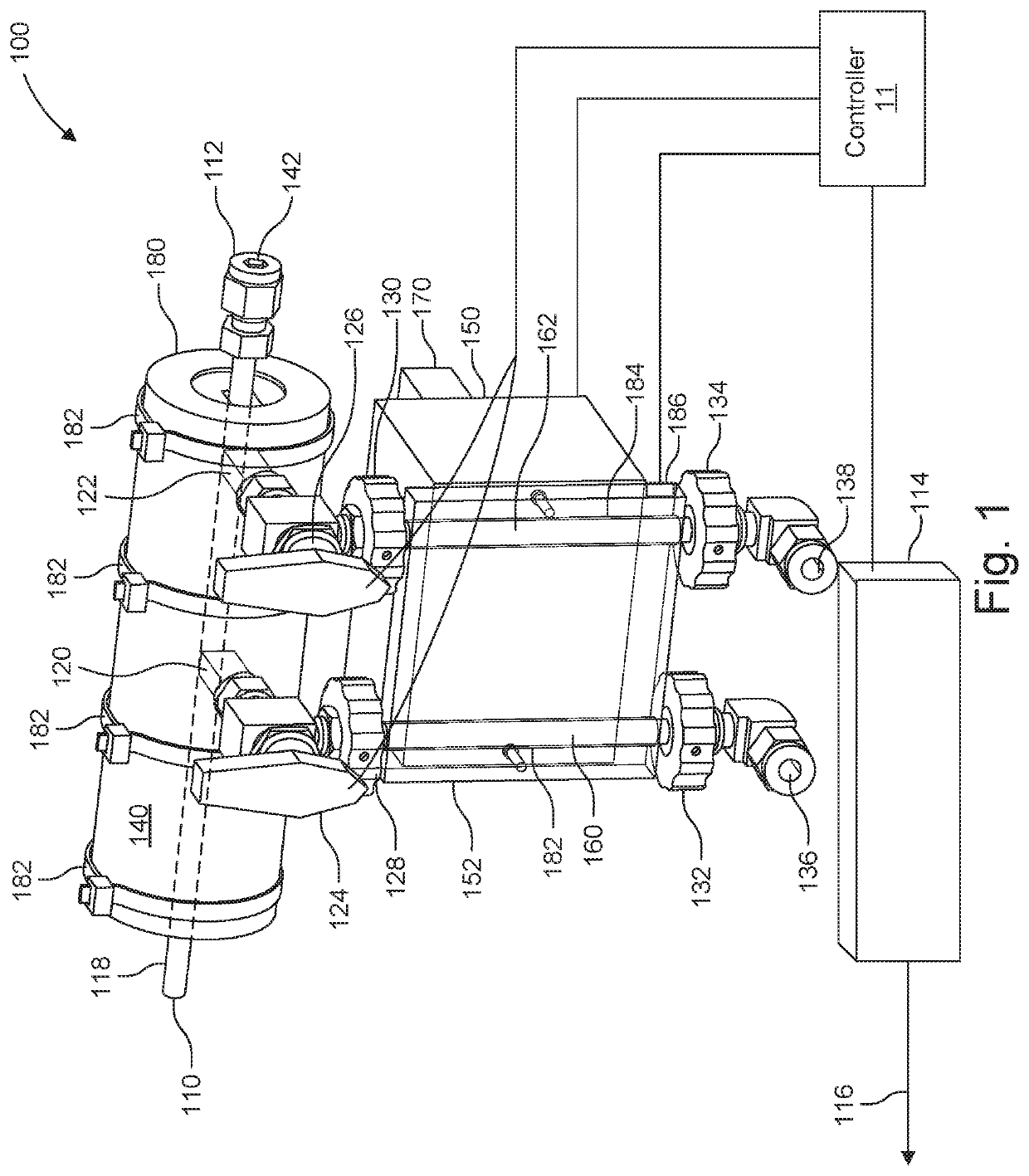

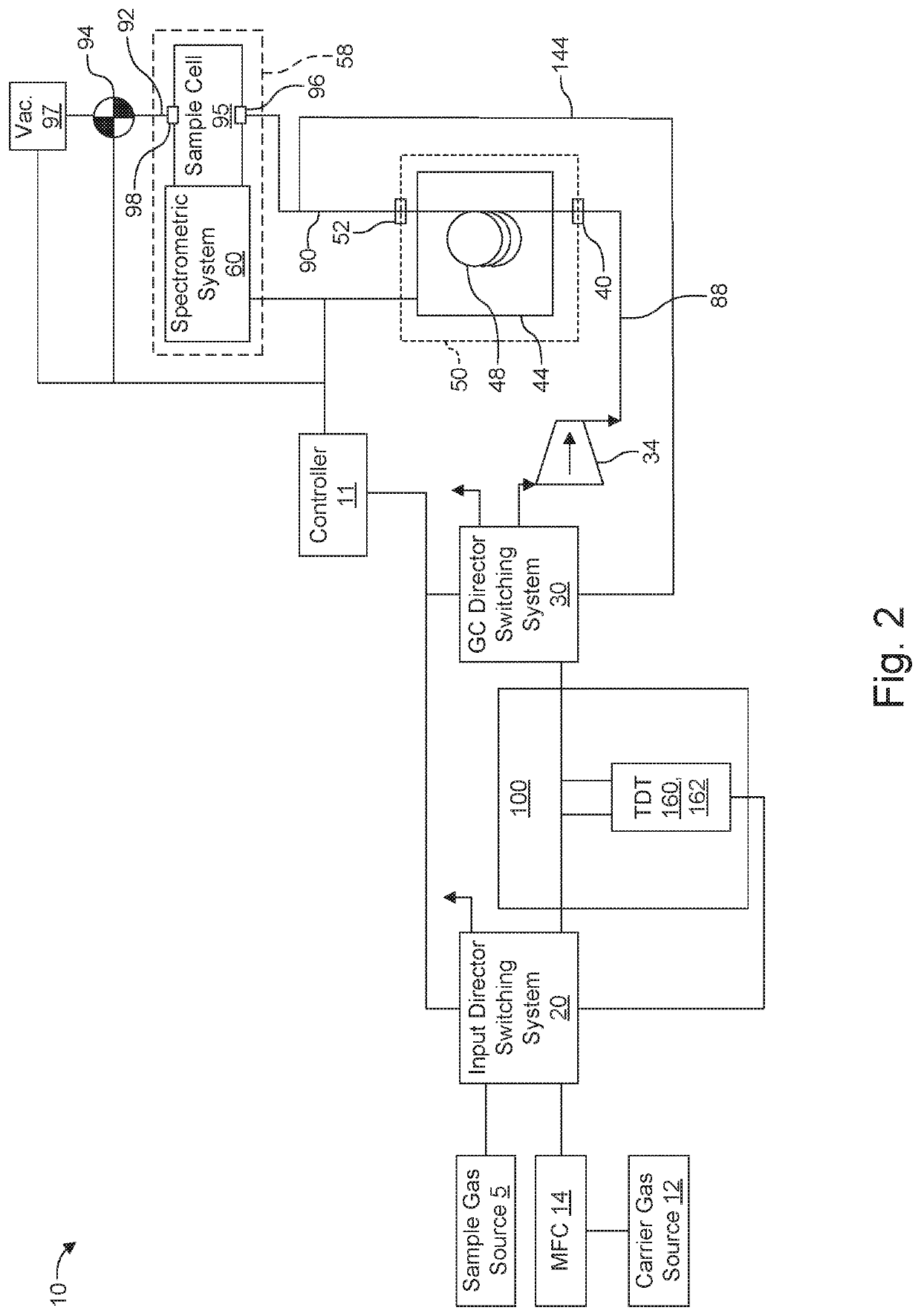

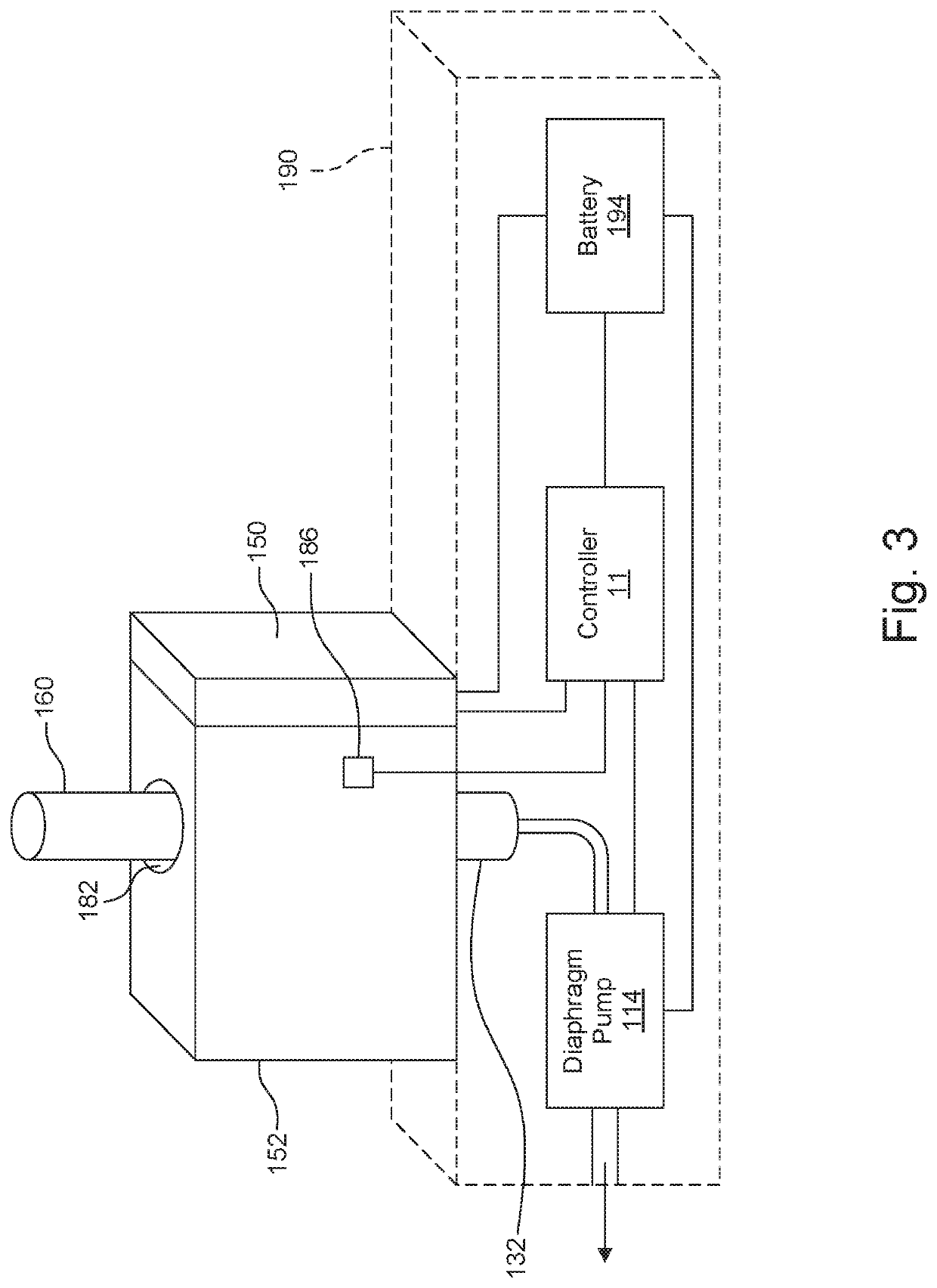

Thermal desorption tube collection system and method

ActiveUS20190265205A1Increase the amount of materialLow detection limitSamplingComponent separationGas phaseCollection system

A thermal desorption tube collection system uses a thermoelectric cooler to collect and concentrate gas samples. In some modes, the operation of the cooler is reversed to flow the concentrated sample directly into a separator such as a gas chromatography system. Components resolved in time by a thermal desorption separator accumulate in a sample cell and are analyzed by electromagnetic radiation-based spectroscopic techniques. Also presented are methods for analyzing biogas samples.

Owner:MLS ACQ INC

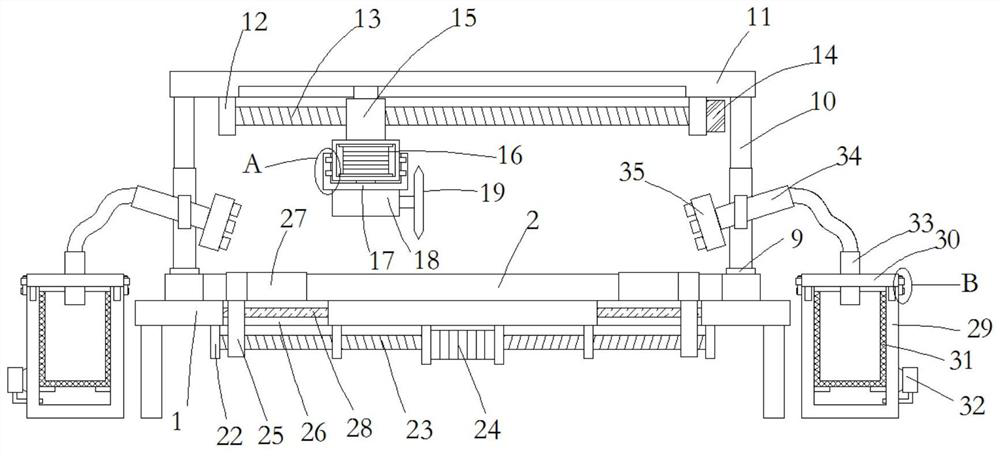

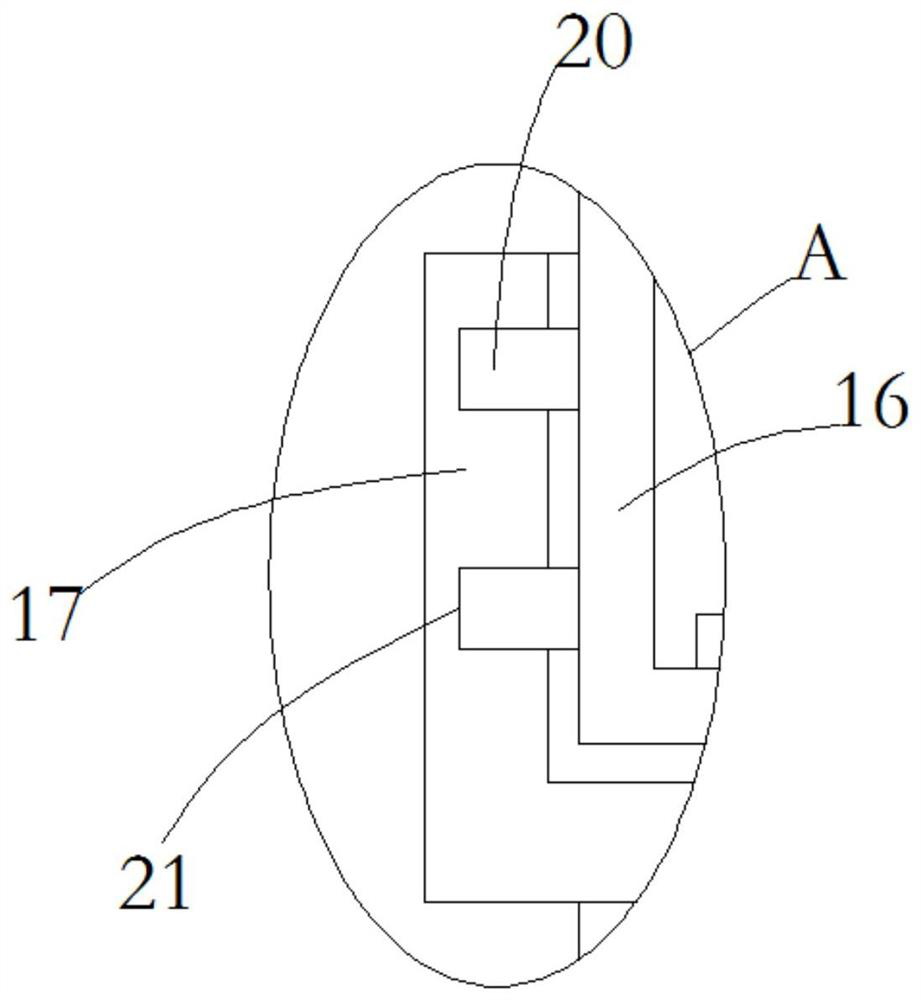

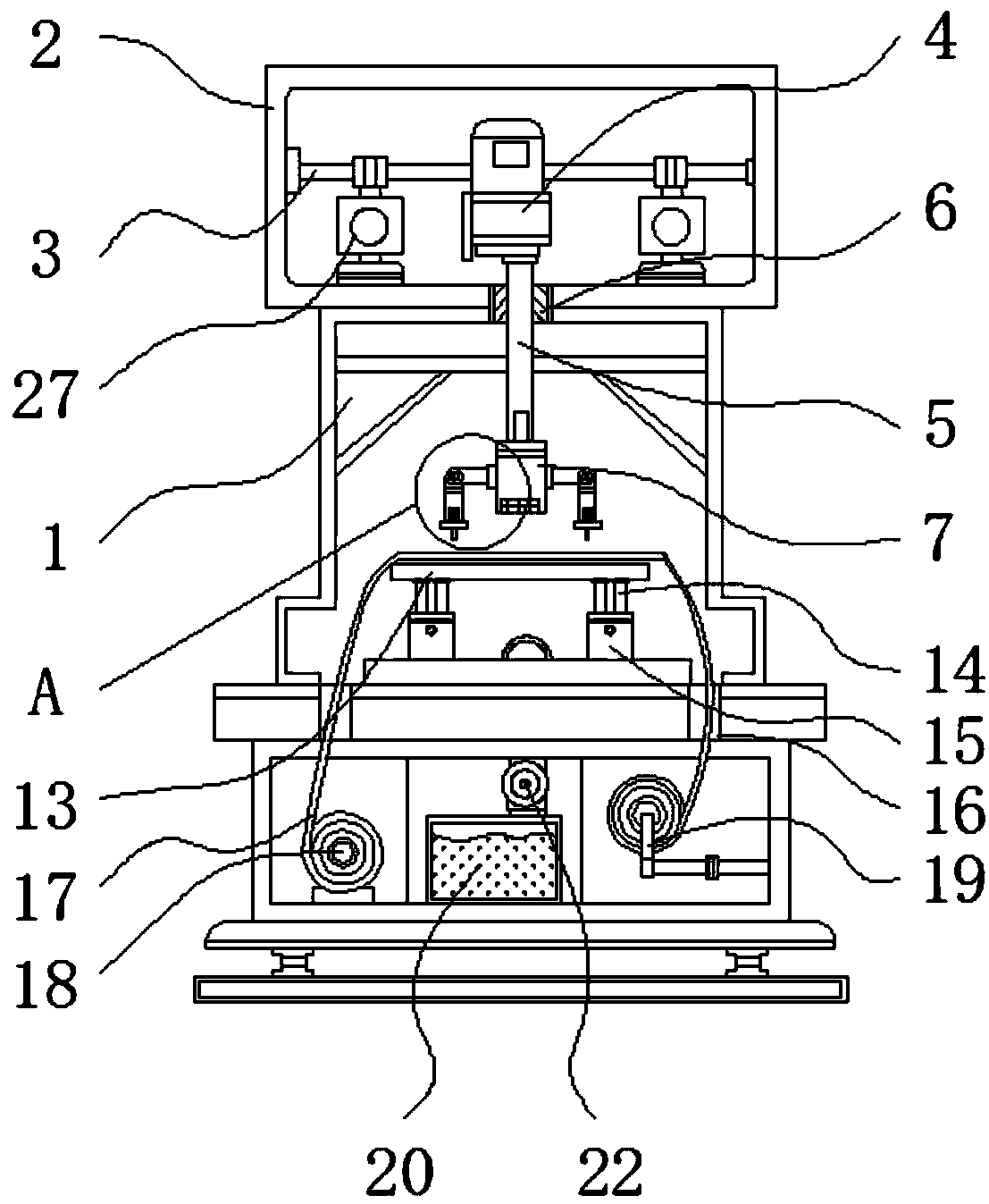

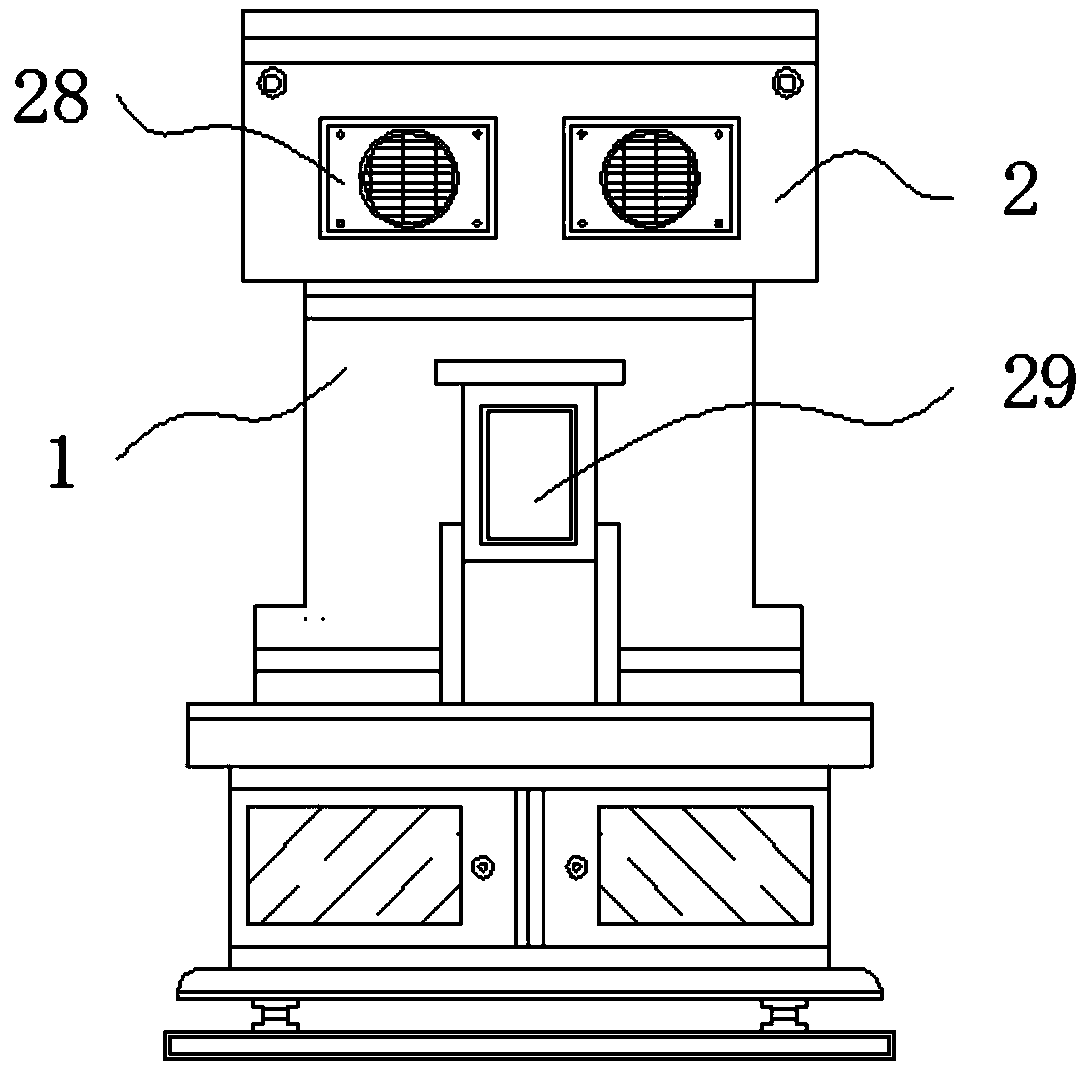

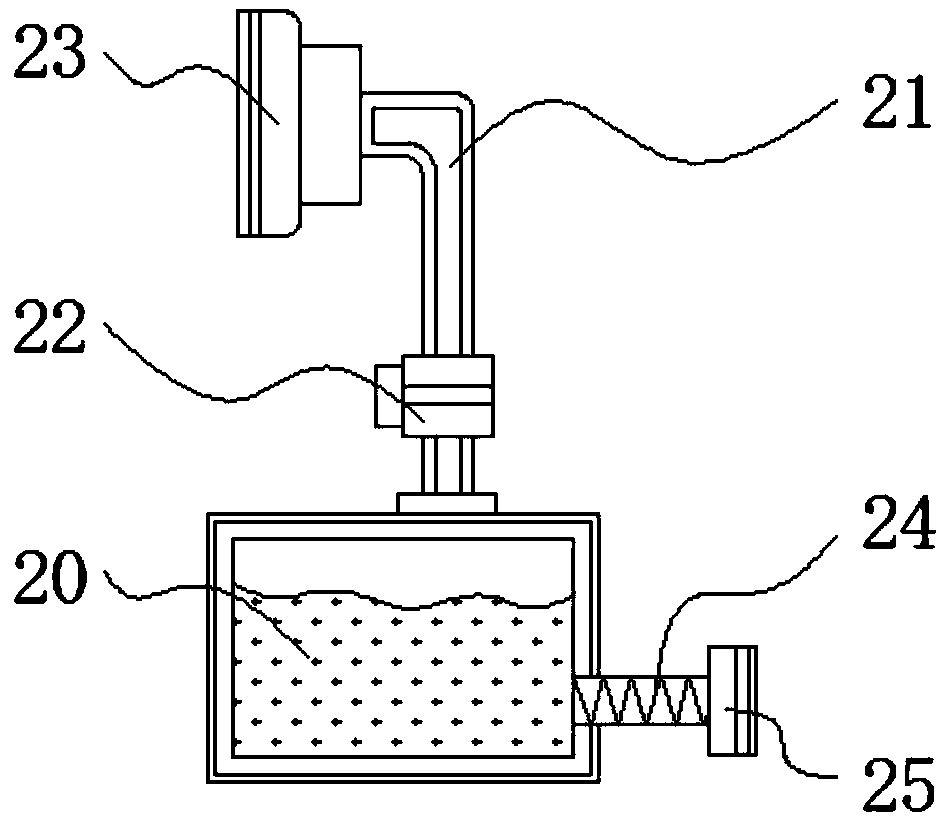

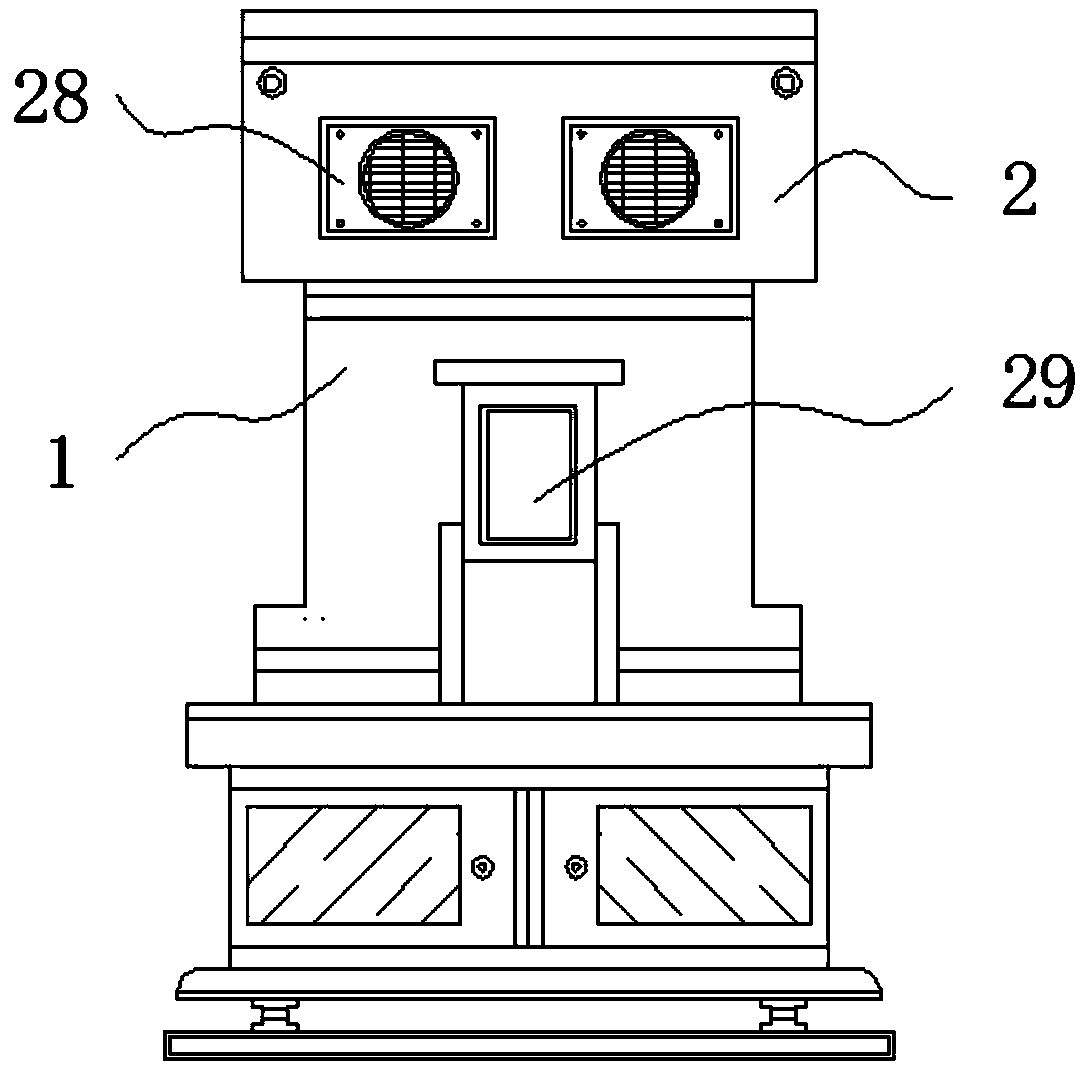

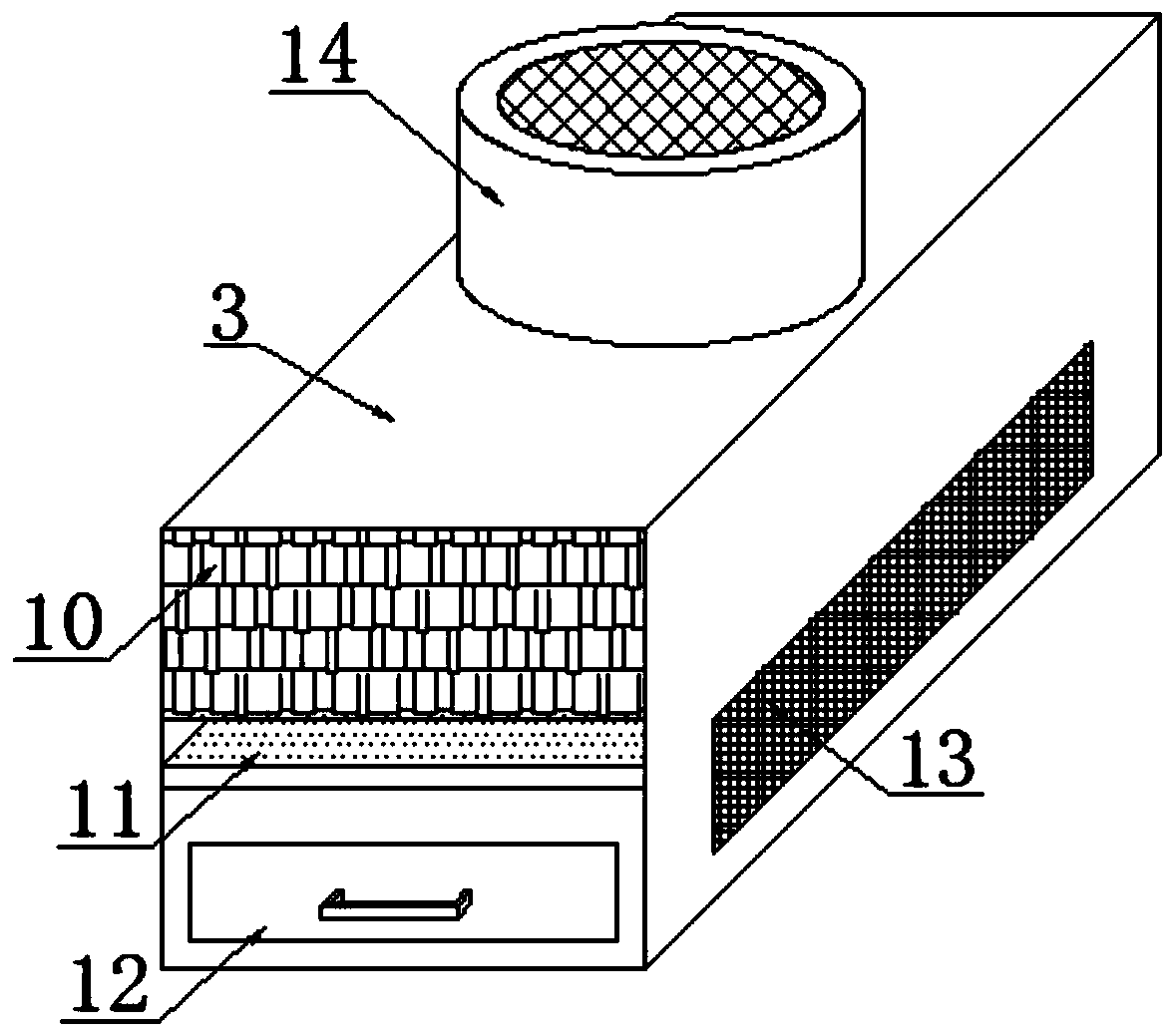

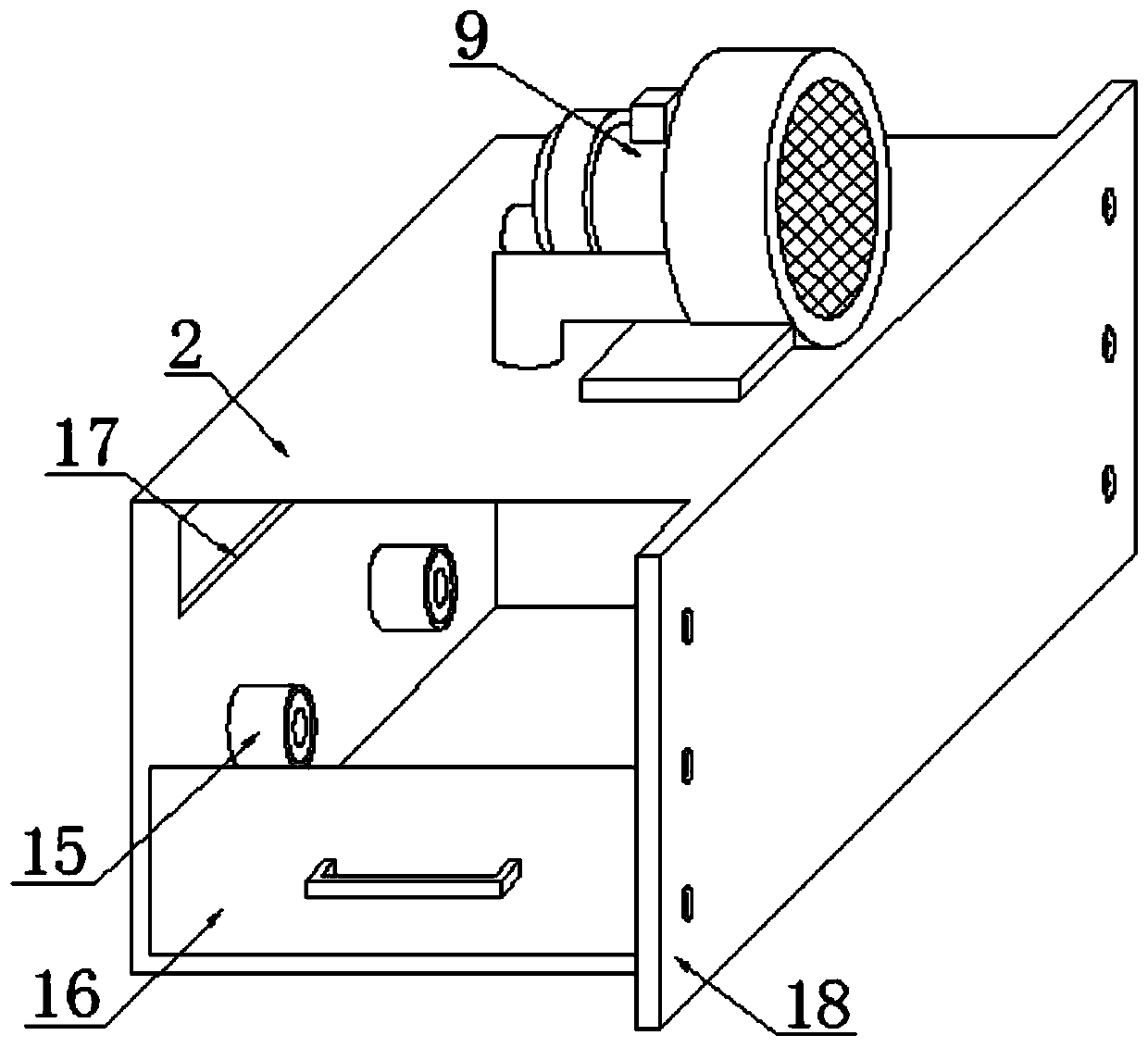

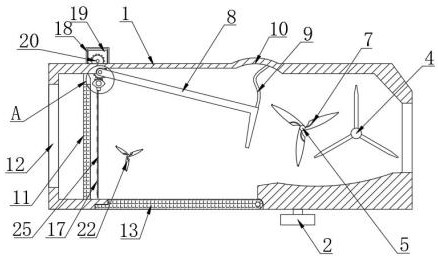

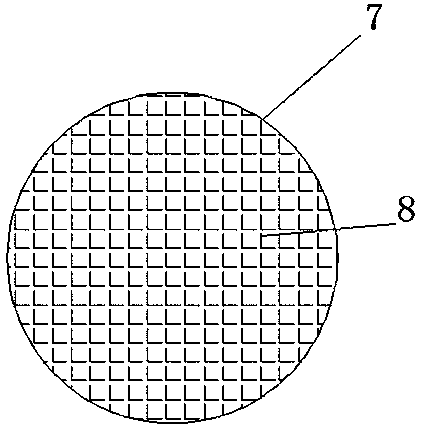

Textile mechanical dust removal device

InactiveCN106994275AImprove production qualityGood for collection and cleaningGas treatmentUsing liquid separation agentAerospace engineeringWater tanks

The invention discloses a textile mechanical dust removal device which comprises a base, a left upright column, a right upright column, a textile workbench, a horizontal platform and a water pump; a supporting column is arranged at the lower part of the right end of the textile workbench; an air blower is arranged on the left side of the upper part of the base; a blowhole platform is arranged at the upper part of the air blower; an air suction opening is formed in the left side of the lower end of the horizontal platform; an exhaust fan is arranged on the left side of the upper end of the horizontal platform; a ventilation pipe is arranged at the air outlet end of the upper end of the exhaust fan; the right end of the ventilation pipe is provided with a dust accumulation tank in a connecting manner; a filter screen is arranged at the lower part in the dust accumulation tank; a water tank is arranged on the right side of the upper part of the base; and a double-layer filter plate is vertically arranged in the water tank. According to the textile mechanical dust removal device, by matching densely distributed air blowing pipelines with the exhaust fan at the upper end, thread ends, fluffs and dust generated in the textile process can be rapidly and effectively eliminated, and the quality of production can be effectively improved.

Owner:杨露萍

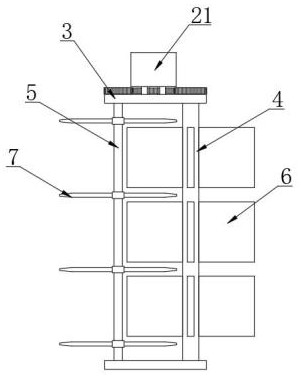

Trash collecting net device

InactiveCN105442509AFast collection processingGood dirt collection effectWater cleaningFiberWater flow

The invention discloses a trash collecting net device and relates to the technical field of floating-type trash holding devices applied to trash holding of water conservancy and water intake engineering. The trash collecting net device comprises a trash holding net, a plurality of pontoons and a plurality of hanging drooping chains. High-strength and high-modulus polyethylene fiber ropes are arranged on the upper edge of the trash holding net. The circumference of each pontoon is provided with a groove. The circumference of each pontoon is tightly bound by a high-strength low-malleability rope along the corresponding groove. Each pontoon is connected with the corresponding high-strength and high-modulus polyethylene fiber rope through the corresponding high-strength low-malleability rope. The hanging drooping chains are bound on the lower edge of the trash holding net through ropes and located under the pontoons respectively. The length of the hanging drooping chains is as same as that of the pontoons. The trash collecting net device can be used for collecting and cleaning away floating objects in a common river, a city river and the water inflow upstream part of a hydropower station. The trash collecting effect is good, using is convenient, and the safety is high. The maneuverability is high, and the floating objects are collected and disposed fast. The trash collecting net device can be arranged under the circumstance that riverway traffic is not affected. The cleanliness and sanitation of water flow is ensured, and the requirements of environment and working conditions are met.

Owner:JIULI ROPE

Cutting equipment for shaving board processing

InactiveCN112223442AEasy to adjustImprove cutting efficiencyProfiling/shaping machinesBall bearingElectric machinery

The invention relates to the technical field of shaving board processing, and discloses cutting equipment for shaving board processing. The cutting equipment comprises a workbench, wherein the upper end of the workbench is fixedly connected with a U-shaped fixing block; two grooves are symmetrically formed in the upper end of the U-shaped fixing block; the inner walls of the opposite sides of thegrooves in the front and in the rear are rotatably connected with the same rotating screw through ball bearings; the rear end of the rotating screw penetrates through the rear side of the U-shaped fixing block and is fixedly connected with a driven bevel gear; the rear side of the U-shaped fixing block is fixedly connected with a first double-shaft motor; and output shafts at the two ends of the first double-shaft motor are fixedly connected with driving bevel gears engaged with the driven bevel gear through rotating shafts. The cutting equipment for shaving board processing has the advantagesthat the relative position of a cutting knife can be quickly adjusted in all directions, the cutting efficiency is greatly improved, and the cutting quality is guaranteed.

Owner:河南佳诺威木业有限公司

Pole piece punching device capable of automatically removing leftover materials for battery production

ActiveCN109570324AIncrease frictionGood stamping effectStripping-off devicesCleaning using gasesPunchingHydraulic pump

The invention relates to a pole piece punching device capable of automatically removing leftover materials for battery production. The pole piece punching device comprises a device body, a friction pad and a placing table. A top layer is fixed to the upper end of the device body, and the top layer is internally provided with a fixing rod. A hydraulic pump is connected to the front end of the fixedrod in a welded mode, and a hydraulic rod is fixed to the lower end of the hydraulic pump. The outer part of the hydraulic rod is wrapped with a moveable groove, and a punching block is arranged at the lower end of the hydraulic rod. The friction pad is disposed at the lower end of the punching block, and rotating rods are fixed to the left end and the right end of the punching block. Rotating shafts are mounted on the outer sides of the rotating rods, and springs are disposed at the lower ends of the rotating shafts. According to the pole piece punching device capable of automatically removing the leftover materials for the battery production, the hydraulic pump and the punching block constitute a telescopic structure through the hydraulic rod, the hydraulic rod and the movable groove constitute a movable structure, the hydraulic pump in the top layer is started to enable the hydraulic pump to drive the rod to extending downwards, and at the same time, the hydraulic rod slides in themovable groove.

Owner:SHANGHAI QINXUAN INFORMATION TECH CO LTD

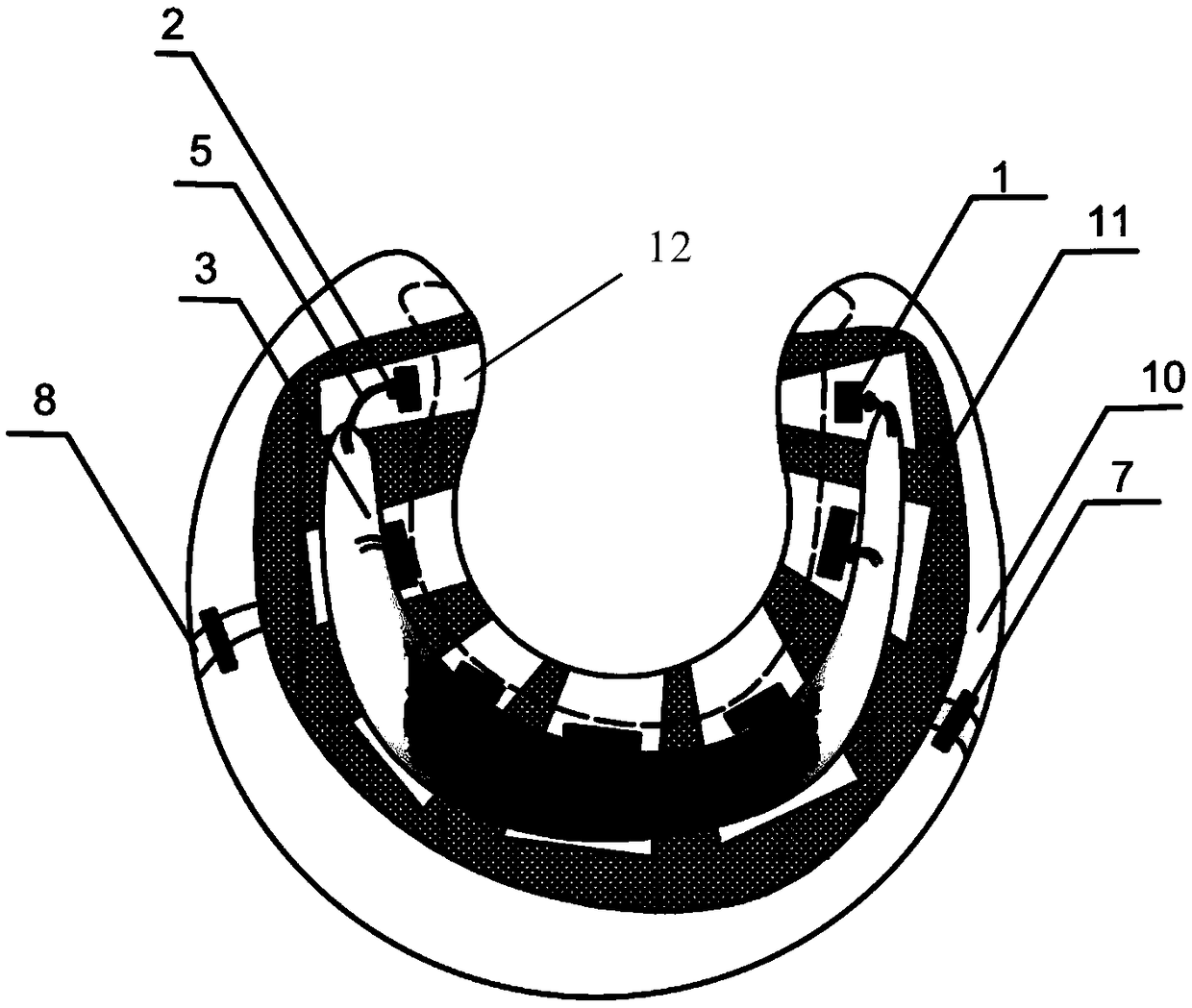

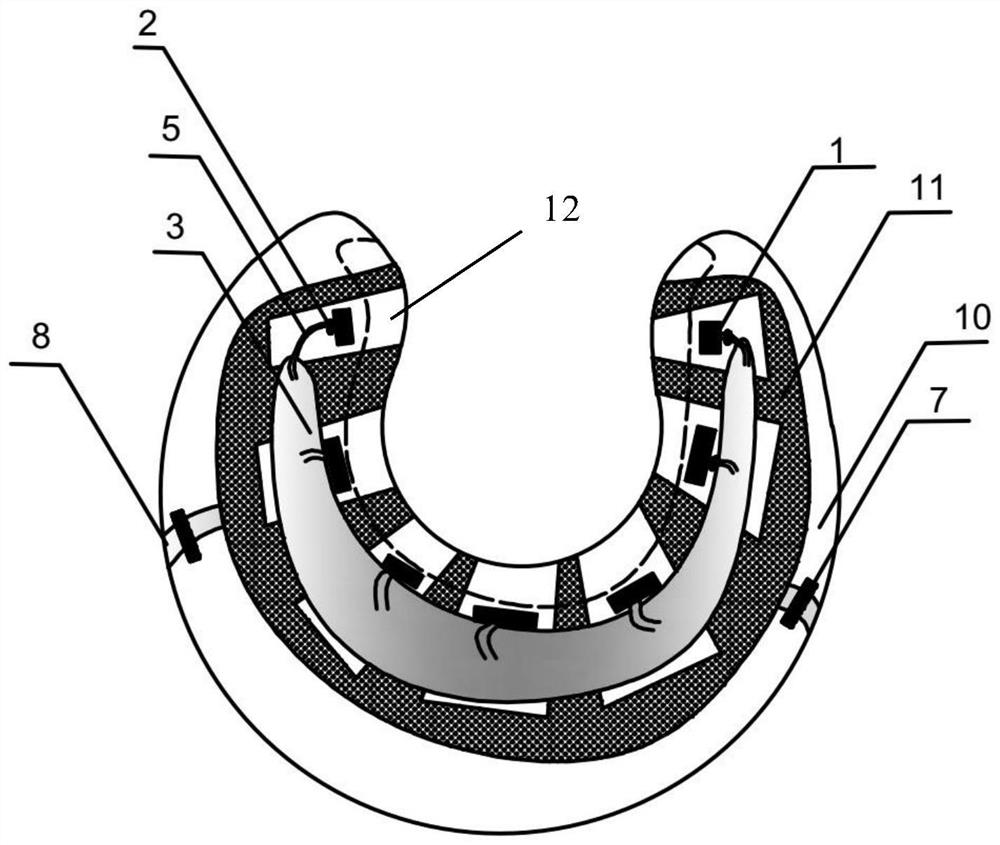

Sea surface oil stain collection and recovery integrated device

ActiveCN109339017APrevent deep contaminationEasy to handleWater cleaningWaterborne vesselsFiltrationEngineering

The invention provides a sea surface oil stain collection and recovery integrated device. The whole device is crescent, and achieves an effect of an oil surrounding fence to surround the sea surface oil stains from the end part; a mixture collecting port is formed in a crescent cabin body; oil-water mixtures are quickly absorbed in the device through an electric pump in the mixture collecting port; through a separation effect of a centrifuge, the oil stains are collected into an oil tank by an oil pipeline at the upper part of the device, and water is leaded out by a water pipeline at the lower part; and after multi-layer filtration, clean seawater is directly drained into the sea.

Owner:DALIAN UNIV OF TECH

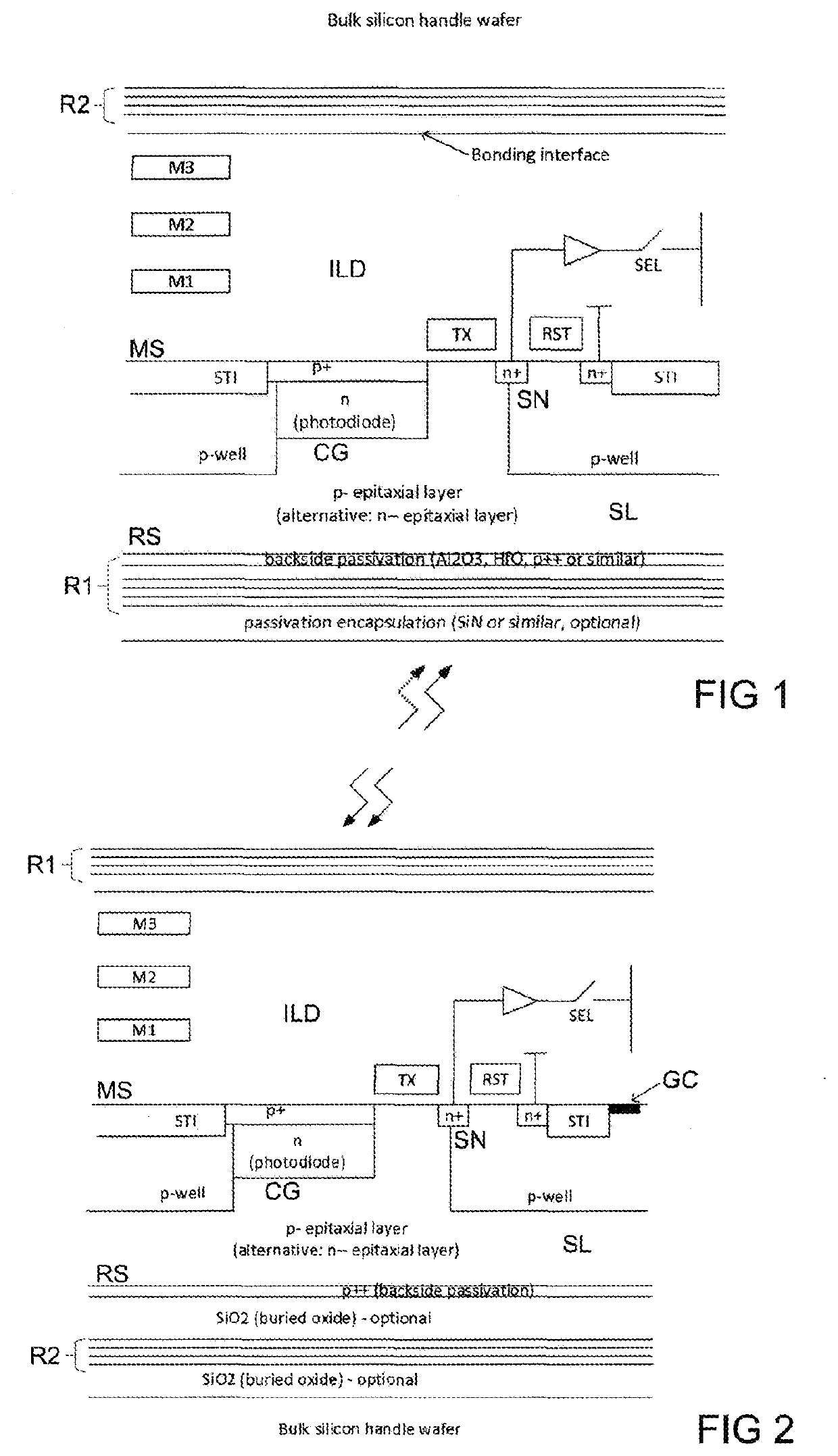

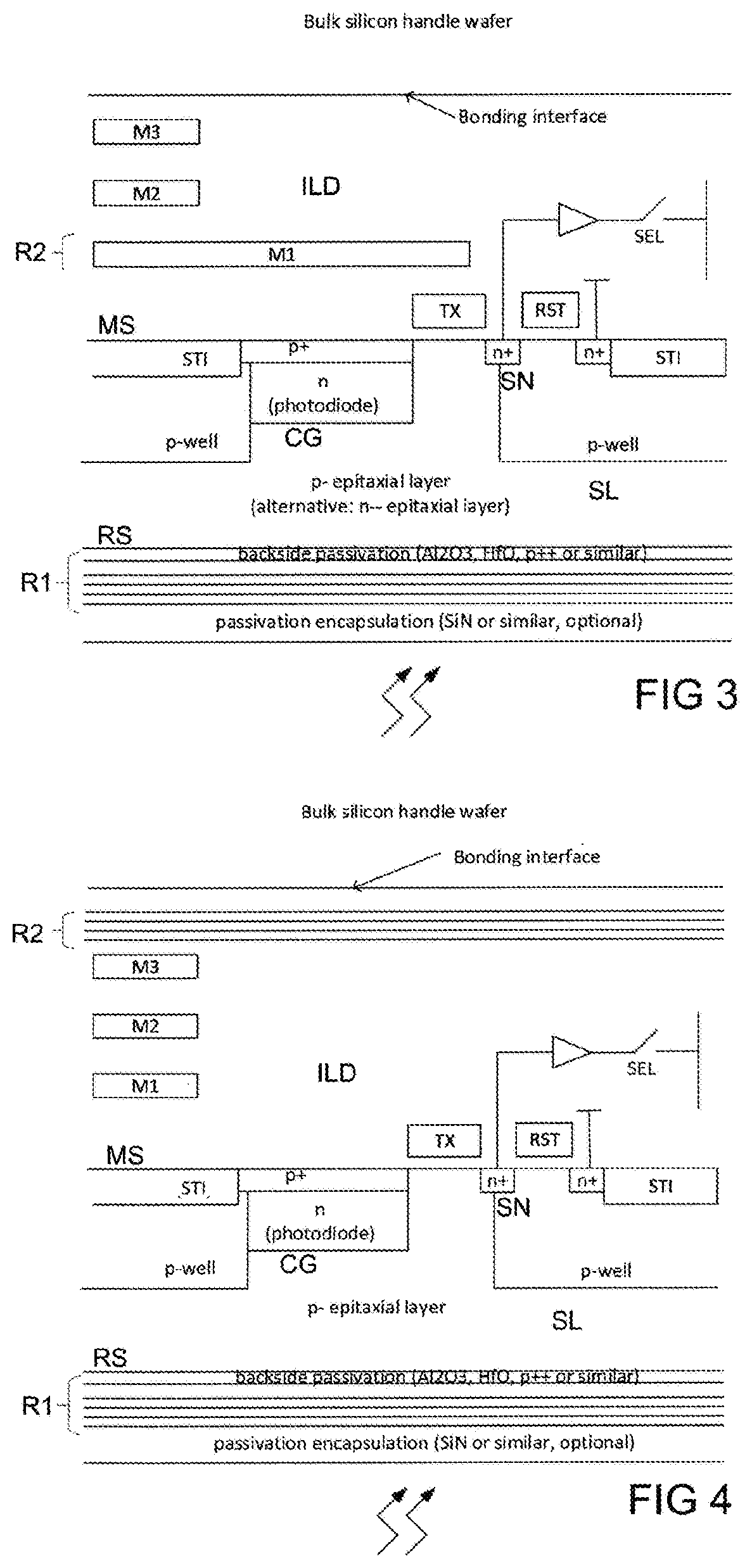

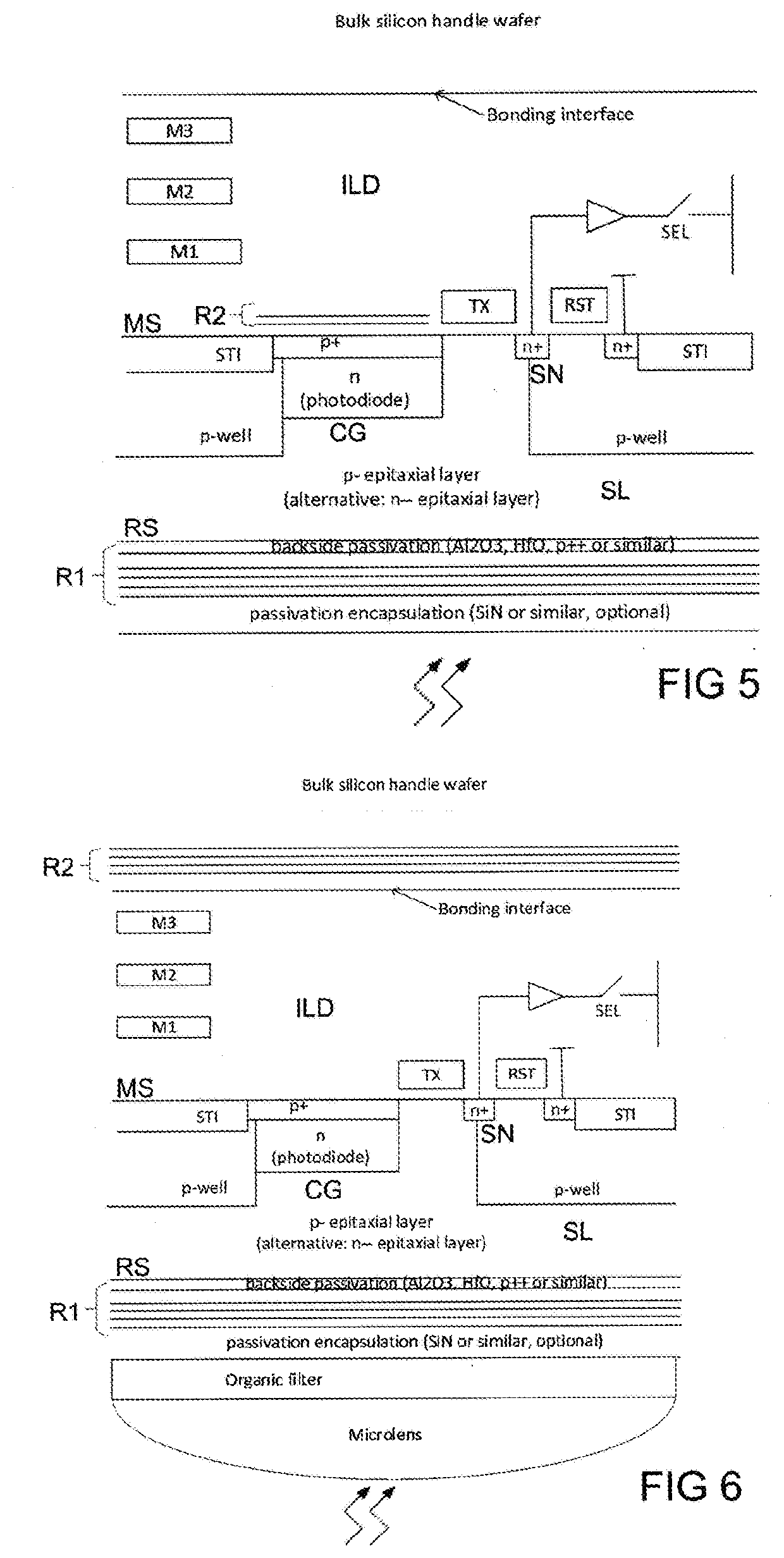

Resonant cavity enhanced image sensor

ActiveUS20200194474A1Improve quantum efficiencyReduce depthSolid-state devicesDiodeResonant cavityCharge carrier

The semiconductor image sensor device comprises a semiconductor layer having a main surface and an opposite rear surface, and a charge carrier generating component at the main surface. The charge carrier generating component is arranged between a top reflecting layer and a bottom reflecting layer, which are arranged outside the semiconductor layer.

Owner:AMS AG

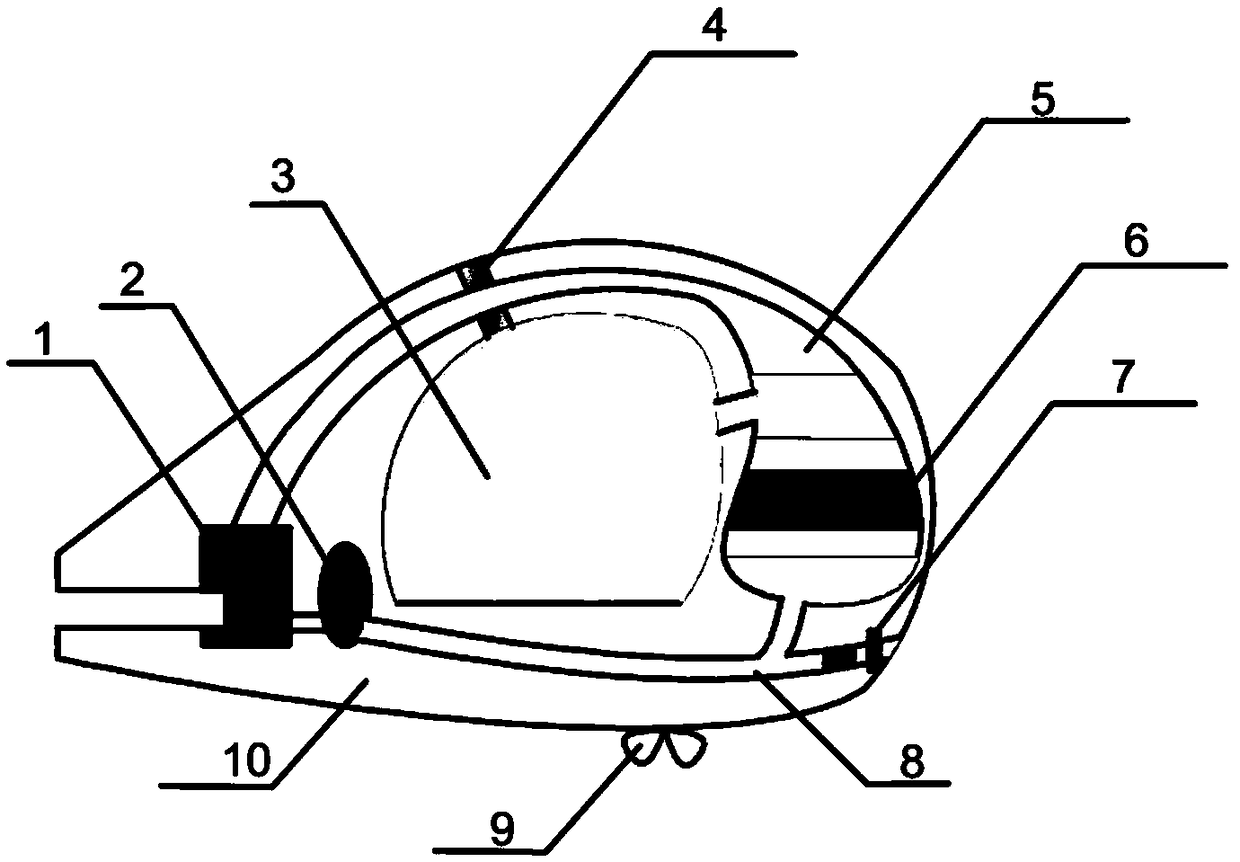

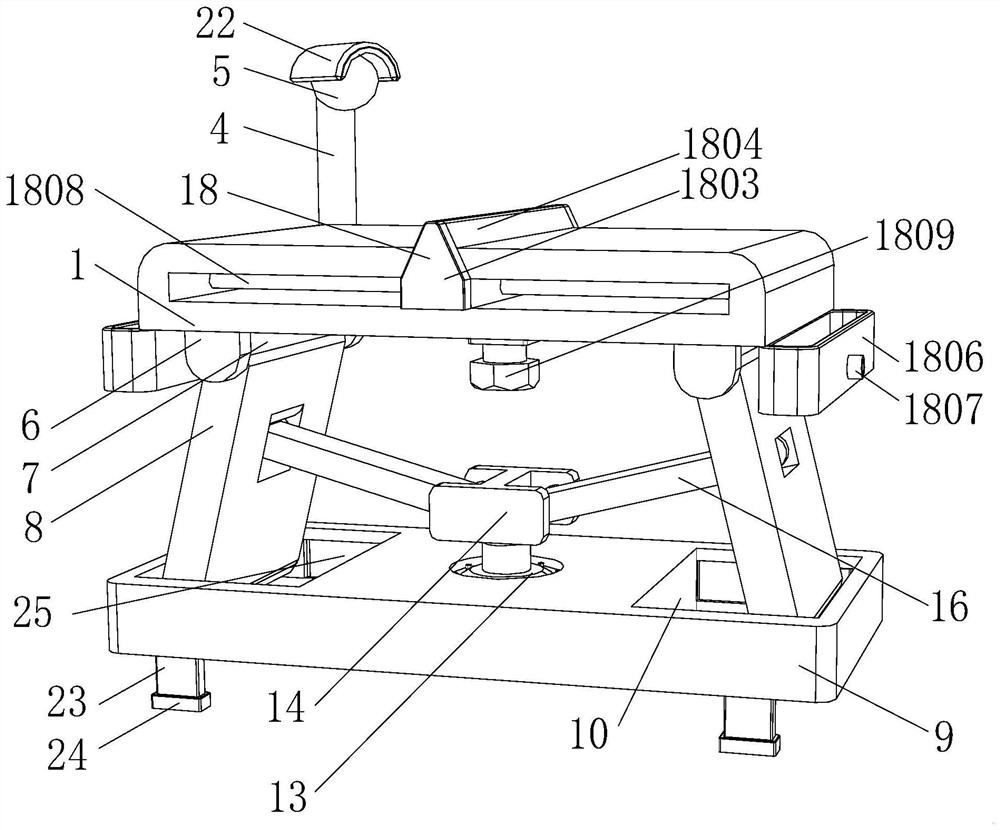

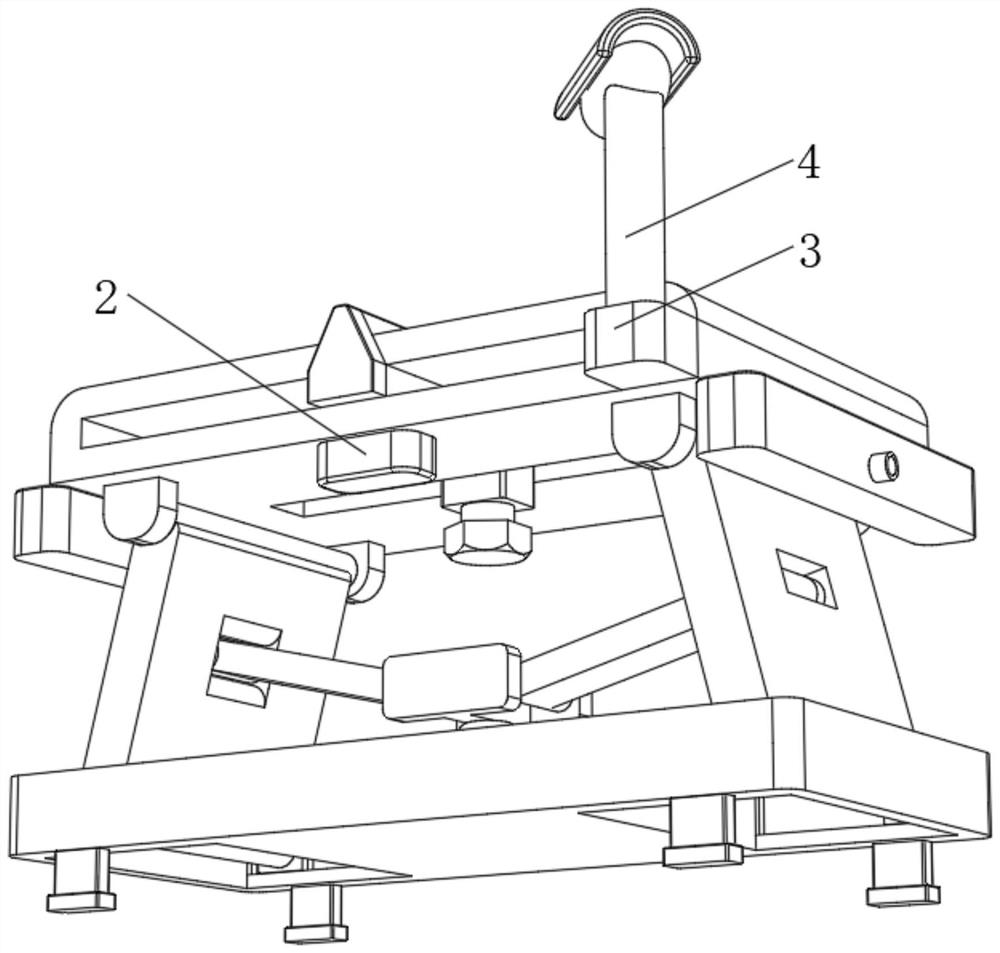

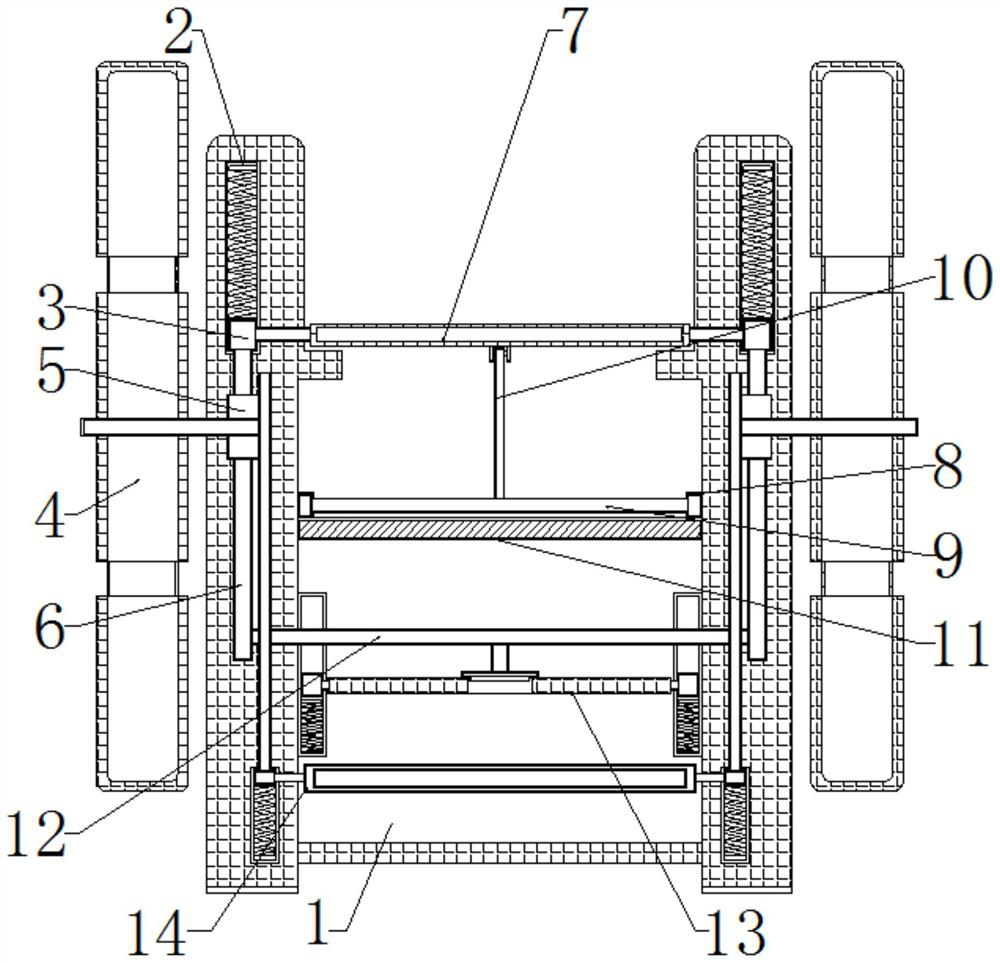

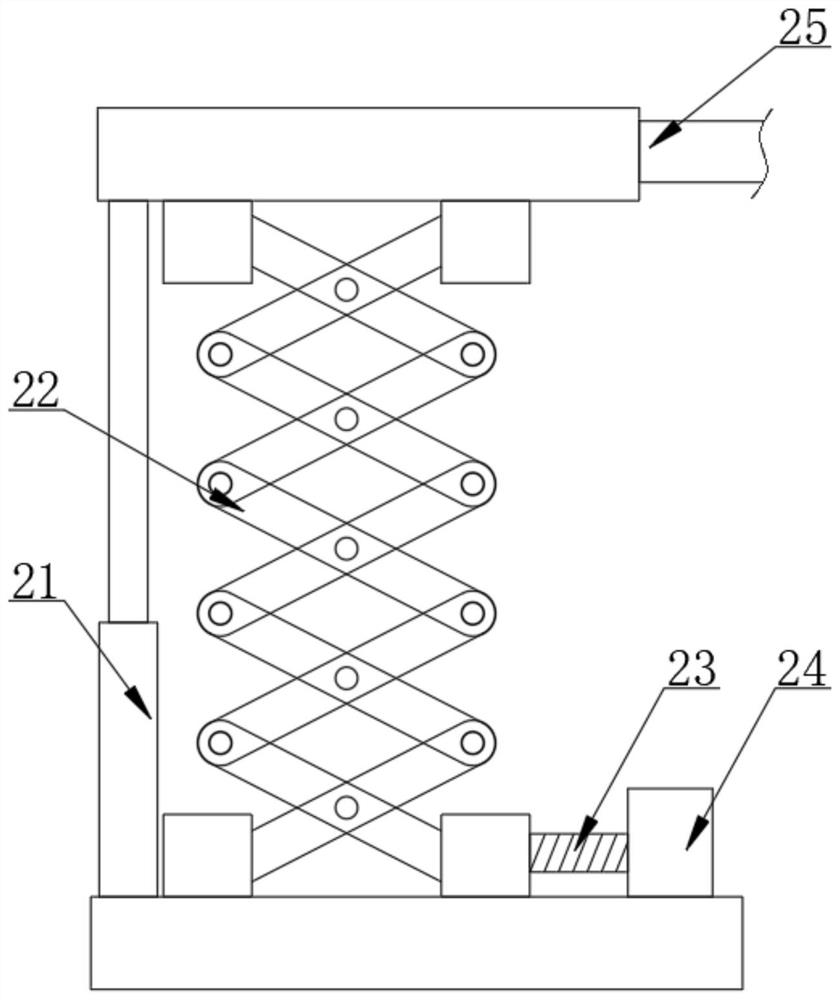

Intelligent control medical device for trauma surgery in general surgery department

The invention relates to the technical field of medical treatment, and discloses an intelligent control medical device for trauma surgery in the general surgery department. The intelligent control medical device comprises a working plate; auxiliary plates are fixedly connected to the four corners of the lower surface of the working plate; a bottom plate is arranged below the working plate; a hydraulic cylinder is fixedly connected to the bottom side wall of an inner cavity of the bottom plate; the hydraulic cylinder is arranged in a storage groove; a control block is fixedly connected to the output end of the hydraulic cylinder; both the interior of the left end and the interior of the right end of the control block are each rotatably connected with a control shaft; connecting plates are fixedly connected to the outer side walls of the control shafts; auxiliary holes are formed in the middle portions of supporting plates; connecting shafts are rotatably connected to the middle portionsof the supporting plates; and the outer side surfaces of the connecting plates are fixedly connected with the outer side walls of the connecting shafts. According to the intelligent control medical device for the trauma surgery in the general surgery department in the invention, due to cooperation of the hydraulic cylinder, the control block, the control shafts, the connecting shafts, the connecting plates, the auxiliary plates, an auxiliary shaft, a supporting shaft, a first sliding block and a first sliding groove, the height of the device can be adjusted.

Owner:广州极诣科技有限公司

Pole piece punching device used for battery production and capable of automatically eliminating offcuts

The invention relates to a pole piece punching device used for battery production and capable of automatically eliminating offcuts. The pole piece punching device used for battery production and capable of automatically eliminating the offcuts comprises a device body, a friction pad and a placement table, wherein a top layer is fixed to the upper end of the device body, and a fixed rod is arrangedin the top layer; a hydraulic pump is connected to the front end of the fixed rod in a welding manner, and a hydraulic rod is fixed to the lower end of the hydraulic pump; the hydraulic rod is externally wrapped with a movable groove, and a punching block is arranged at the lower end of the hydraulic rod; the friction pad is installed at the lower end of the punching block, and rotary rods are fixed to the left end and the right end of the punching block separately; and a rotary shaft is installed at the outer side of each rotary rod, and a spring is arranged at the lower end of each rotary shaft. According to the pole piece punching device used for battery production and capable of automatically eliminating the offcuts, the hydraulic pump forms a telescopic structure with the punching block through the hydraulic rod, and the hydraulic rod forms a movable structure with the movable groove; the hydraulic pump in the top layer is started and enabled to drive the rod to extend downwards;and meanwhile, the hydraulic rod slides in the movable groove.

Owner:俞杰

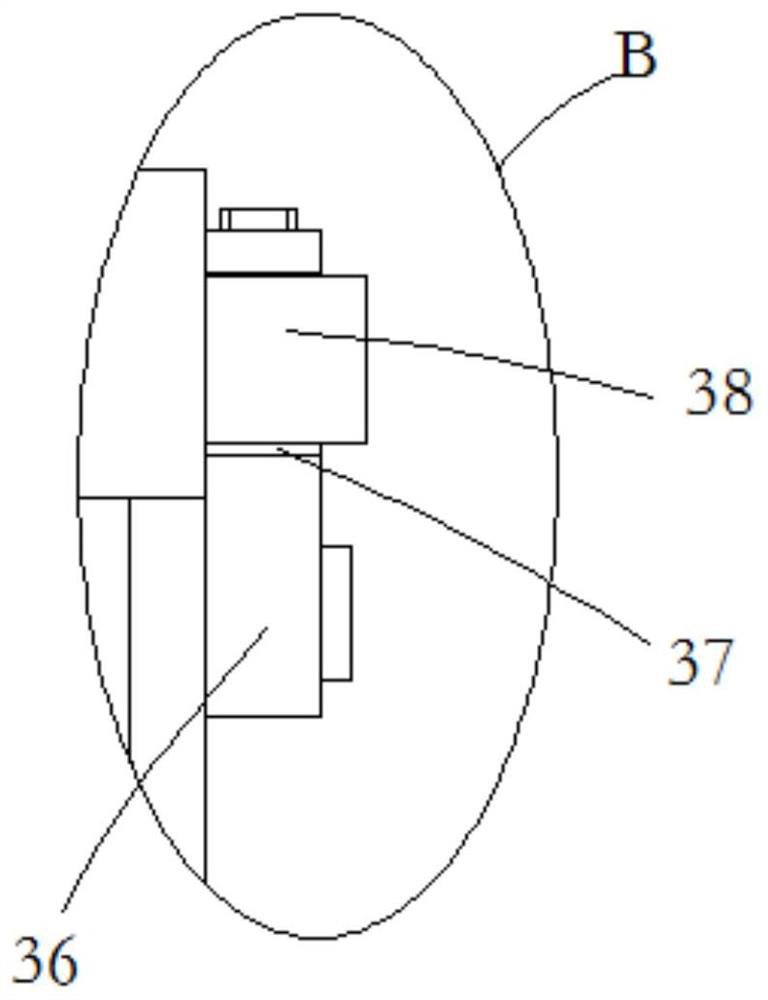

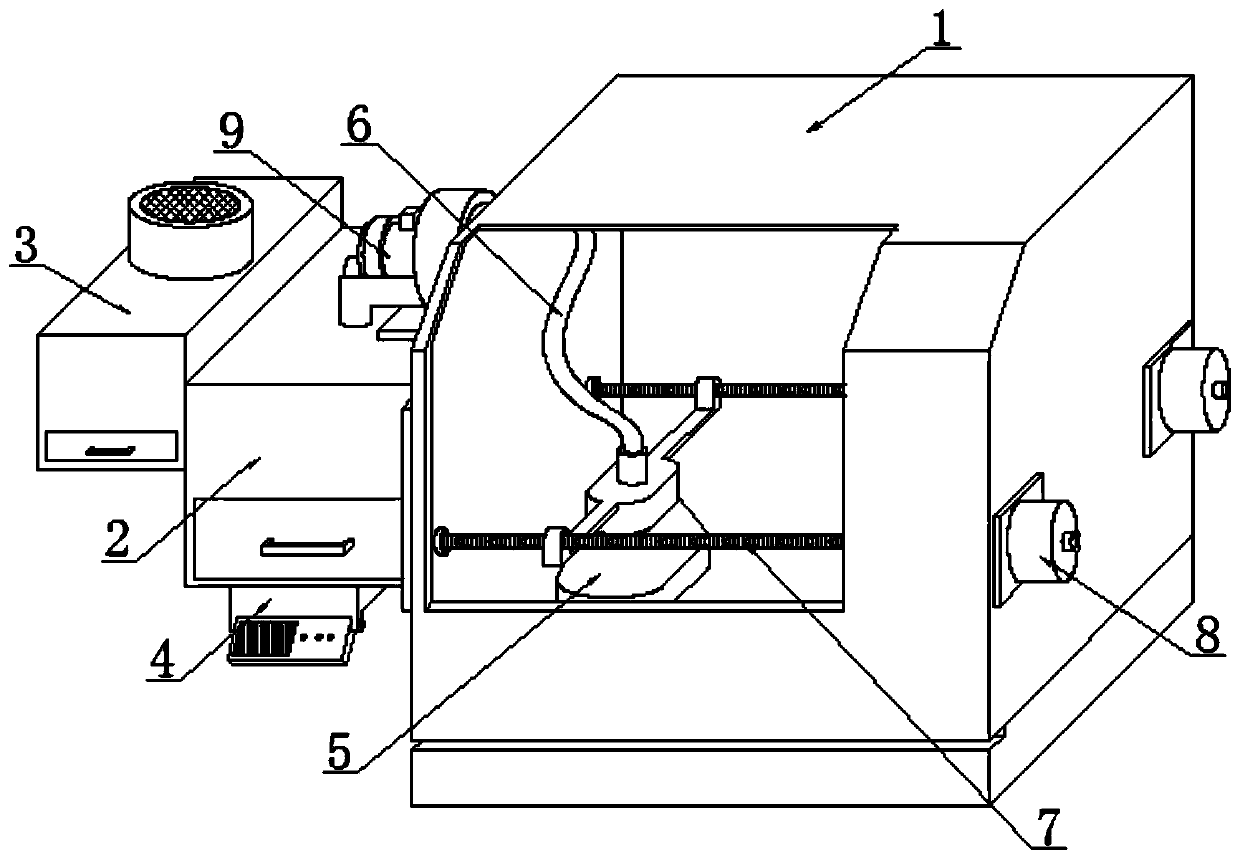

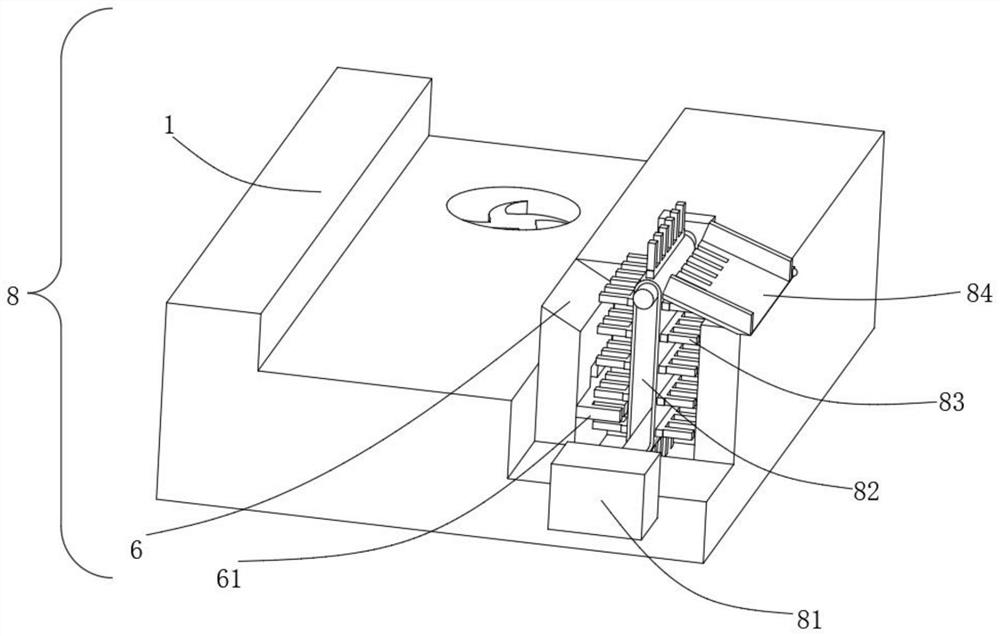

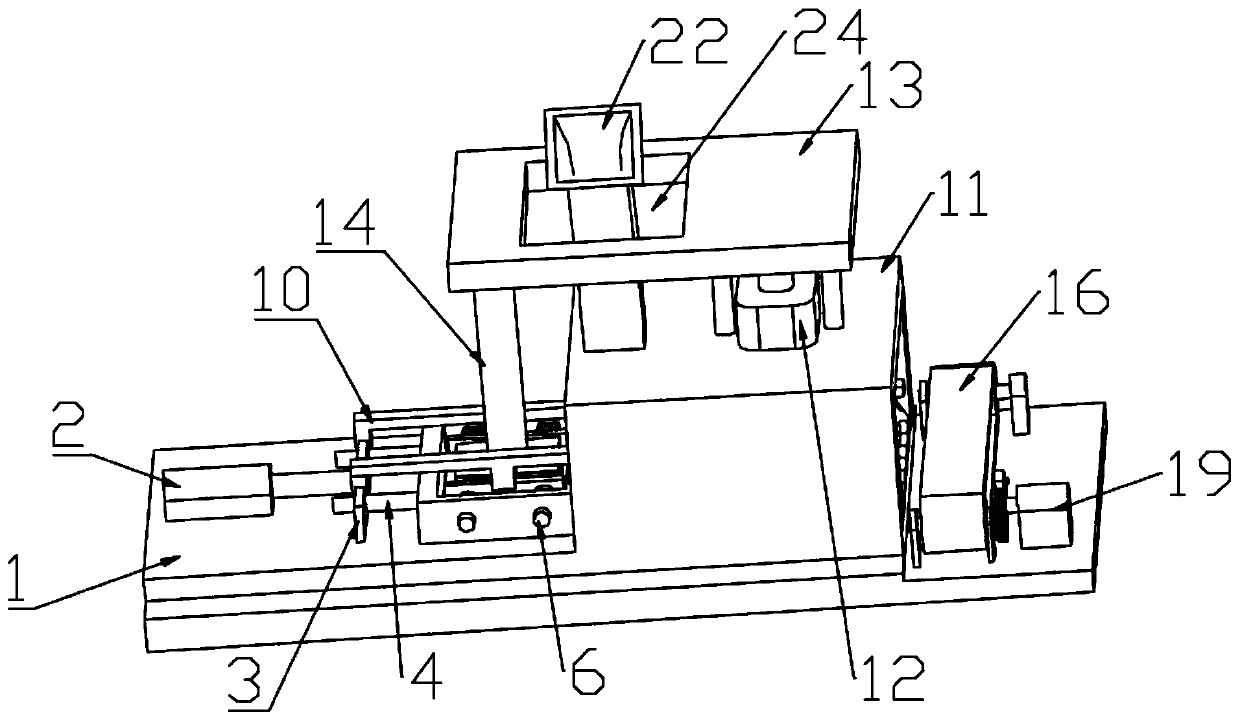

Efficient sweeping mechanism for numerical control machining center

InactiveCN110961975AAvoid driftingFast collection processingMaintainance and safety accessoriesNumerical controlElectric machine

The invention discloses an efficient sweeping mechanism for a numerical control machining center and particularly relates to the technical field of numerical control machining. The mechanism comprisesa numerical control machining device, wherein a moving motor is mounted on one side of the numerical control machining device, a threaded rod is welded to the position, penetrating through one side of the numerical control machining device, of one side of the moving motor, a sweeping mechanism is rotationally mounted on an outer surface of the threaded rod, a scrap pipe is mounted on an upper surface of the sweeping mechanism in a penetrating manner, a first waste scrap collecting box is fixed to an outer surface of one side of the numerical control machining device, a vacuum pump is installed on an upper surface of the first waste scrap collecting box, a second waste scrap collecting box is welded to an upper end of one side of the first waste scrap collecting box in a penetrating mode,and a control box is installed on a lower surface of the first waste scrap collecting box. The mechanism is advantaged in that air suction type sweeping is adopted, sweeping is carried out through a brush, the vacuum pump is arranged, the scrap collecting boxes are provided with electromagnets, independent operation can be carried out, and left-right translation operation can be carried out in thenumerical control machining process.

Owner:嘉兴致信精密零部件股份有限公司

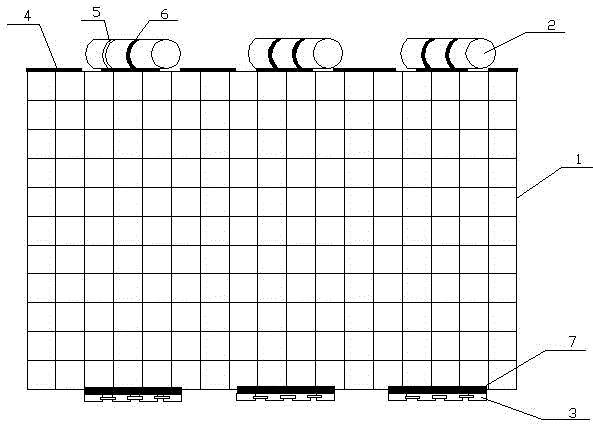

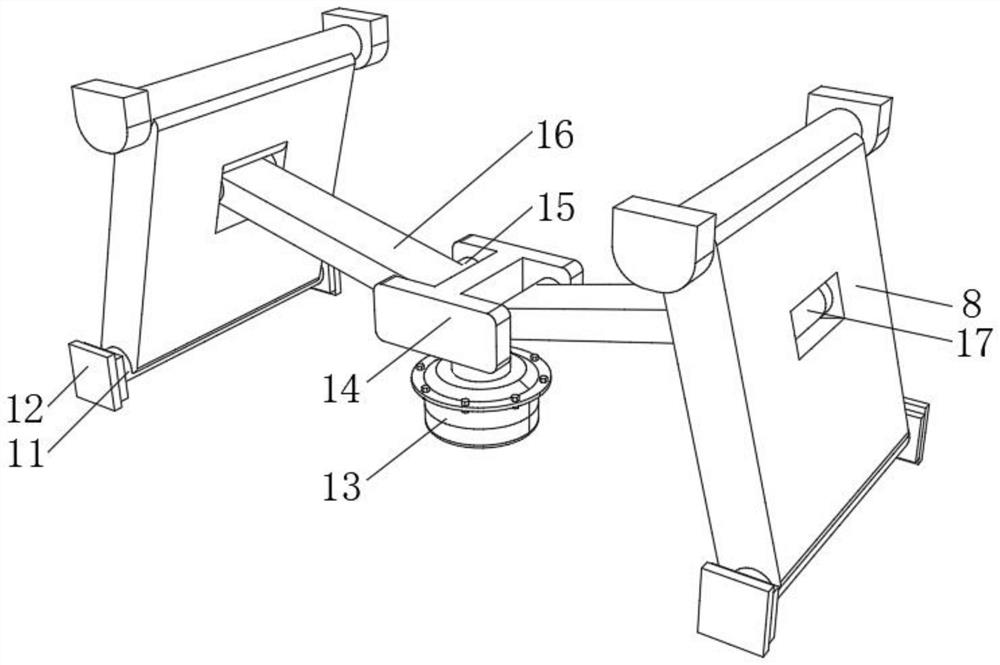

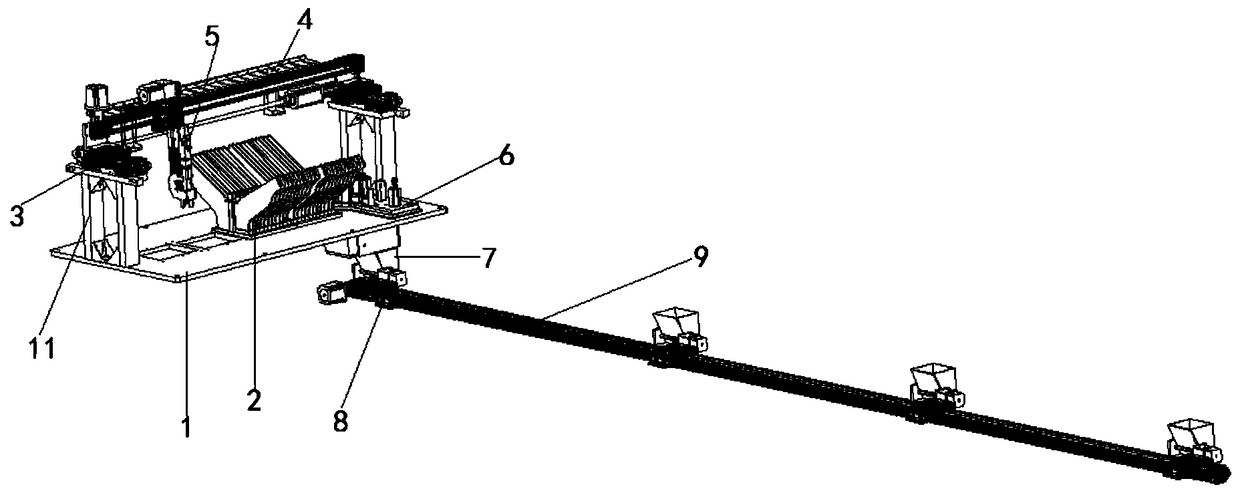

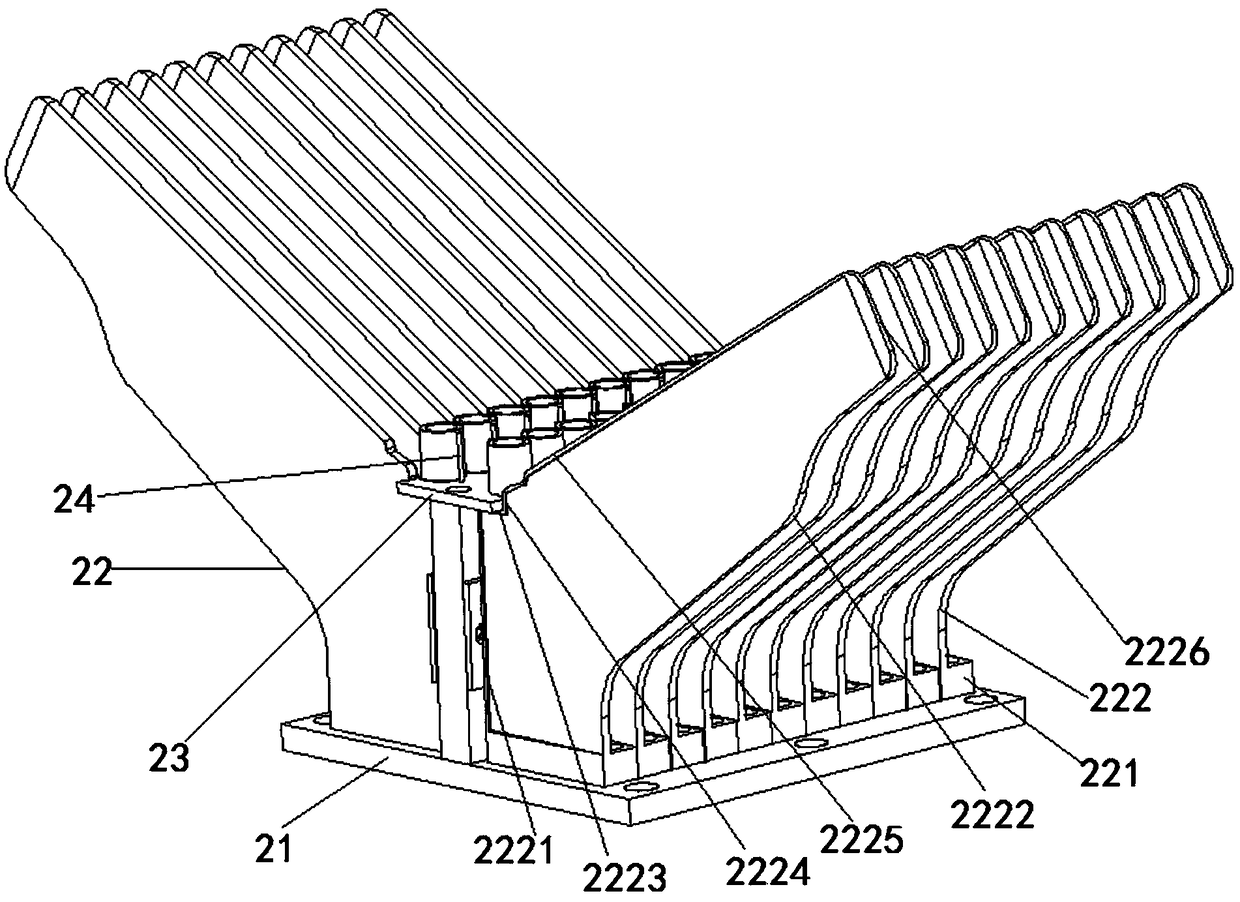

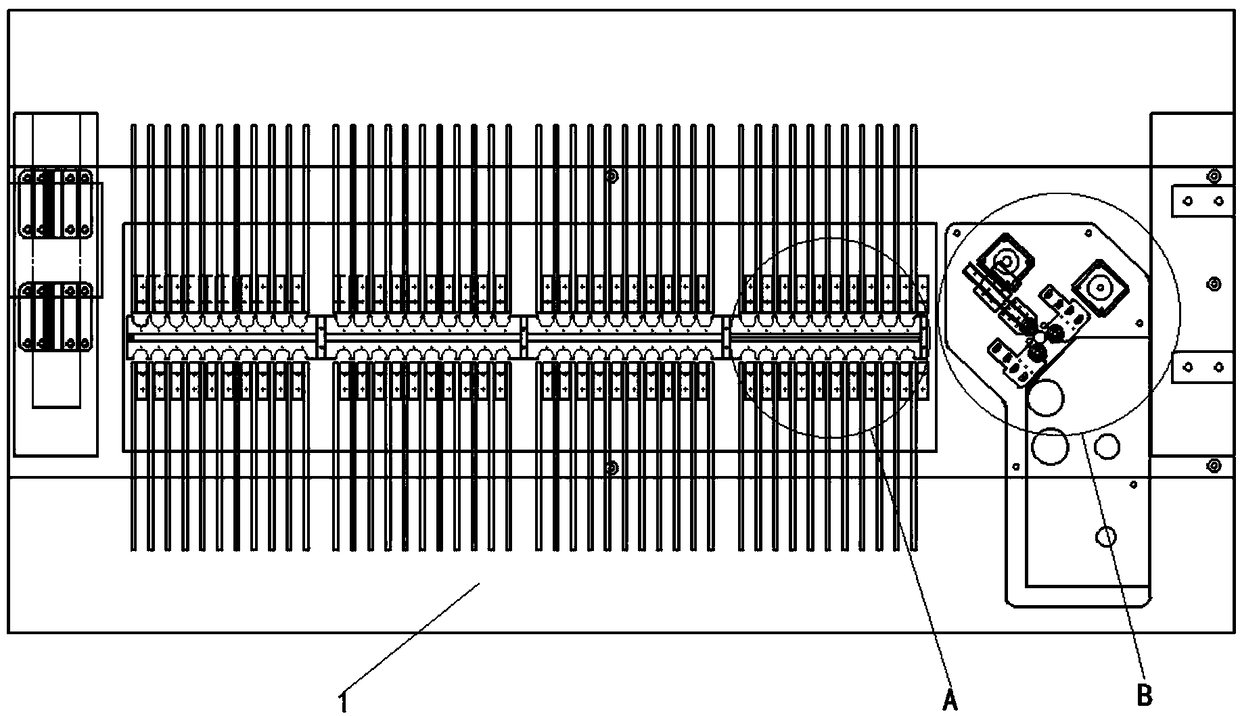

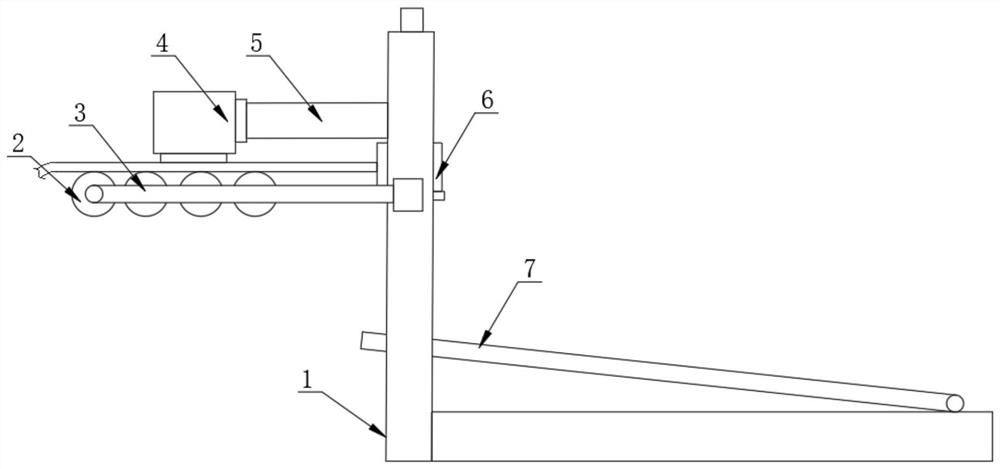

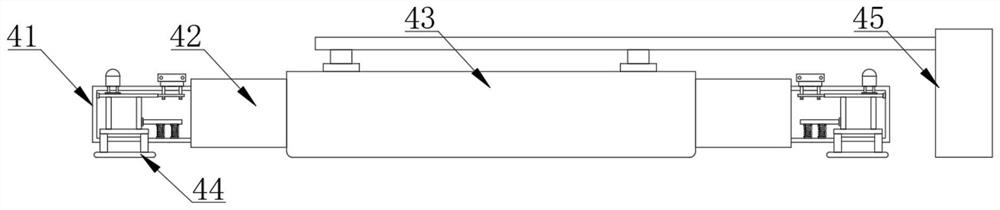

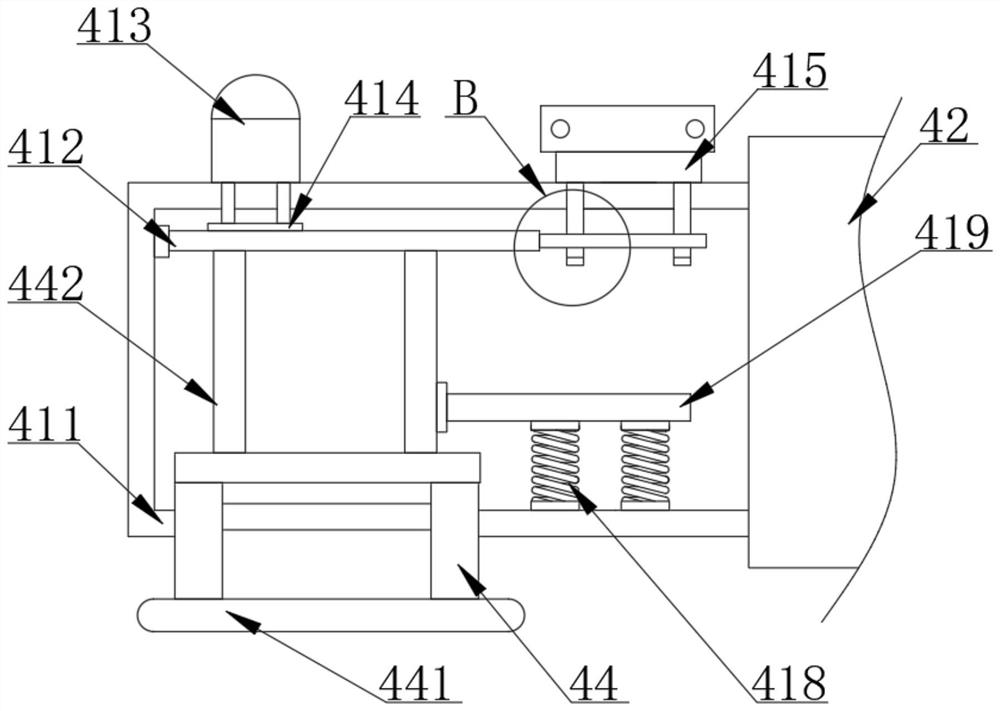

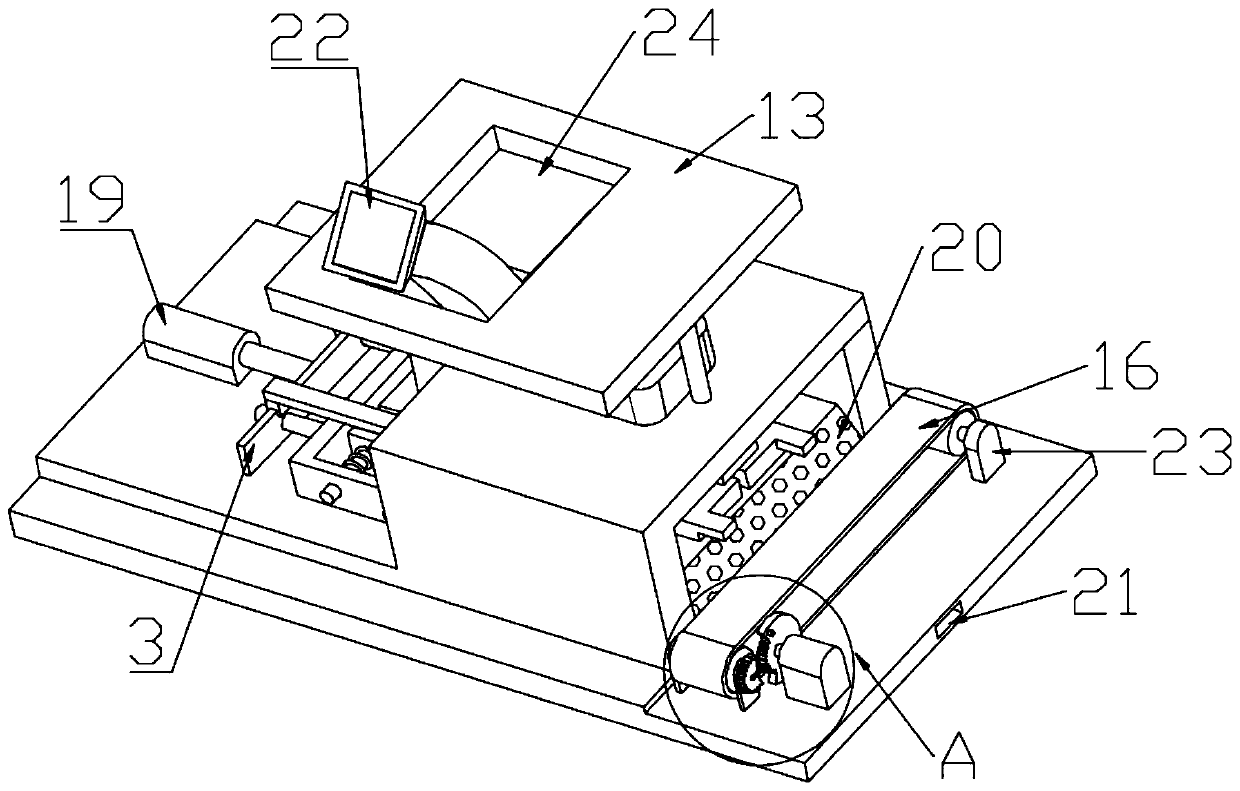

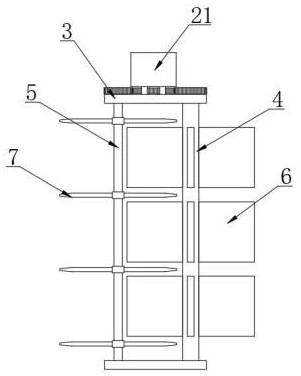

Blood collecting tube information marking and multi-point blood collecting window in-place conveying system

ActiveCN108657779AEasy to addArrange neatlyConveyor partsMechanical conveyorsBlood Collection TubeAutomation

The invention discloses a blood collecting tube information marking and multi-point blood collecting window in-place conveying system. The system comprises a mounting substrate, and support frames symmetrically mounted at the two ends of the mounting substrate; left-right sliding mechanisms are mounted at the tops of the two support frames; left-right sliding cross beams are mounted between the two left-right sliding mechanisms; vacuum blood collecting tube clamping and conveying devices are vertically mounted in middles of the left-right sliding cross beams; vacuum blood collecting tube taking and positioning devices are uniformly distributed in middle of the mounting substrate in the linear direction; a vacuum blood collecting tube vertical information marking device is mounted on one side of the mounting substrate; a vacuum blood collecting tube rail conveying mechanism is mounted under the vacuum blood collecting tube vertical information marking device; and the vacuum blood collecting tube rail conveying mechanism conveys vacuum blood collecting tubes in place to a multi-point blood collecting window through rail slide blocks and slide rails. Through scientific and reasonablestructural design, the system is quick and convenient to feed and take the tubes, high in automation degree and convenient for doctors to quickly collect the blood collecting tubes.

Owner:合肥妙思智能医疗科技有限公司

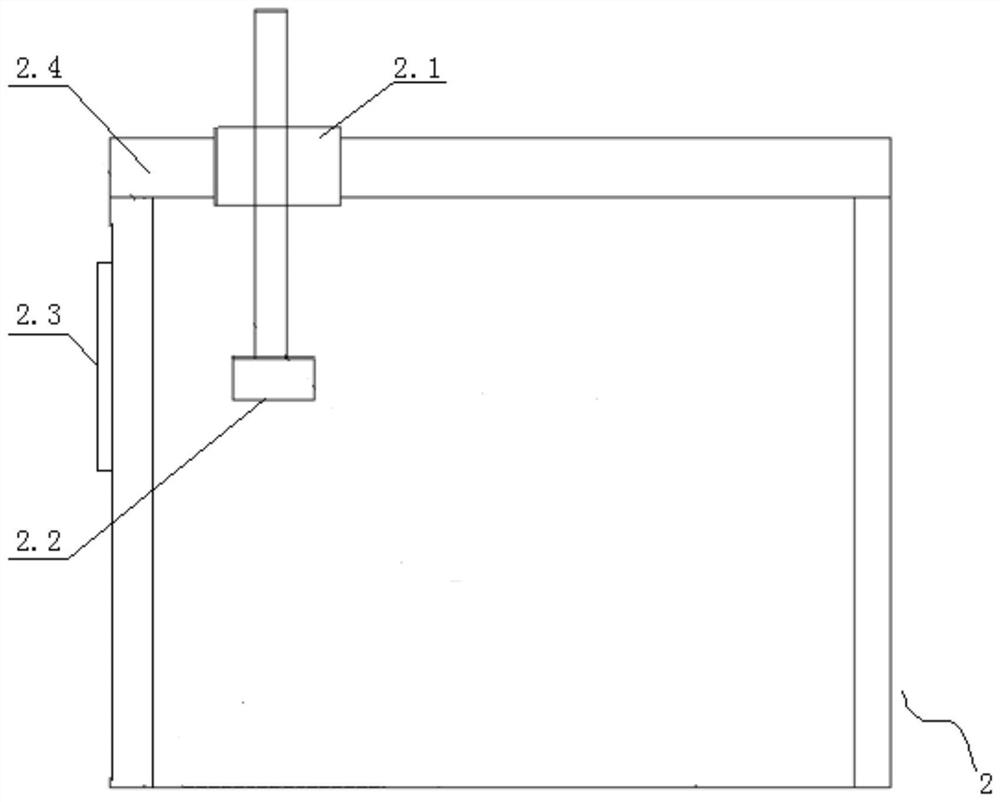

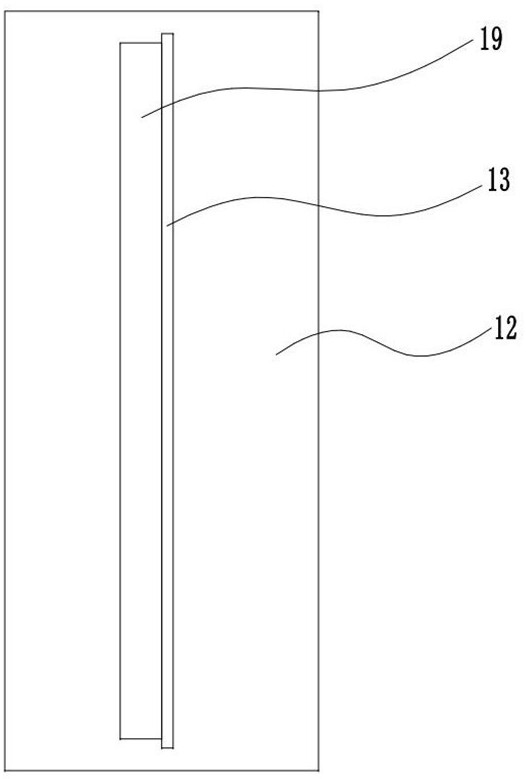

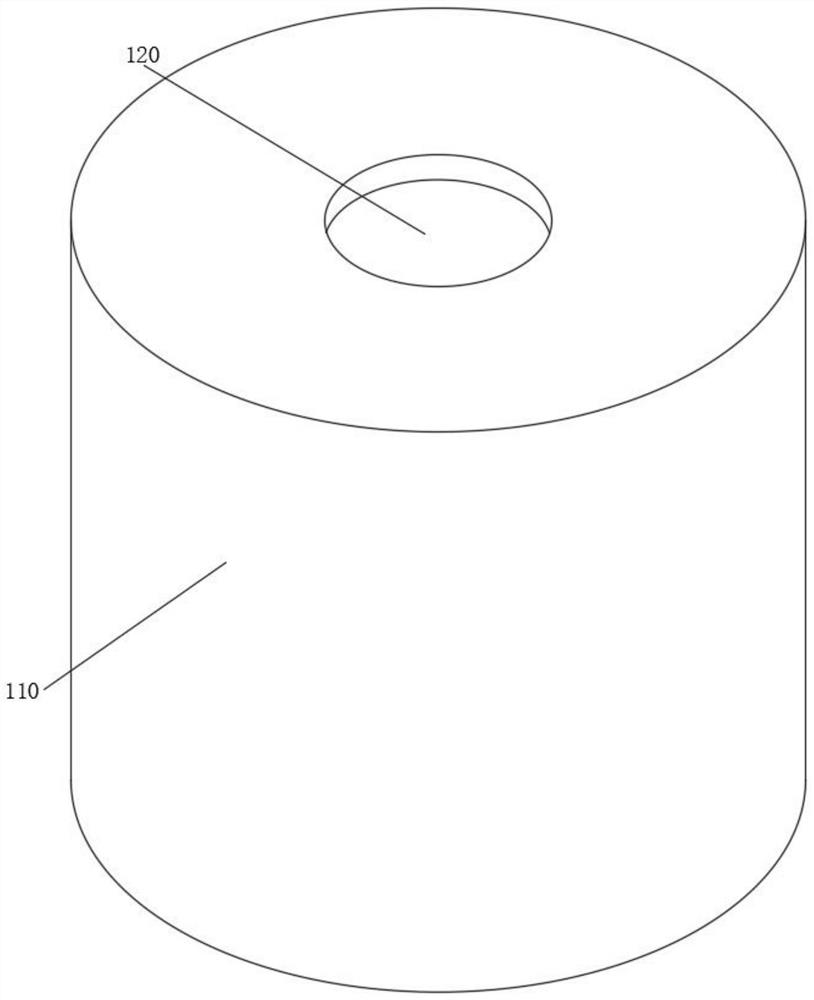

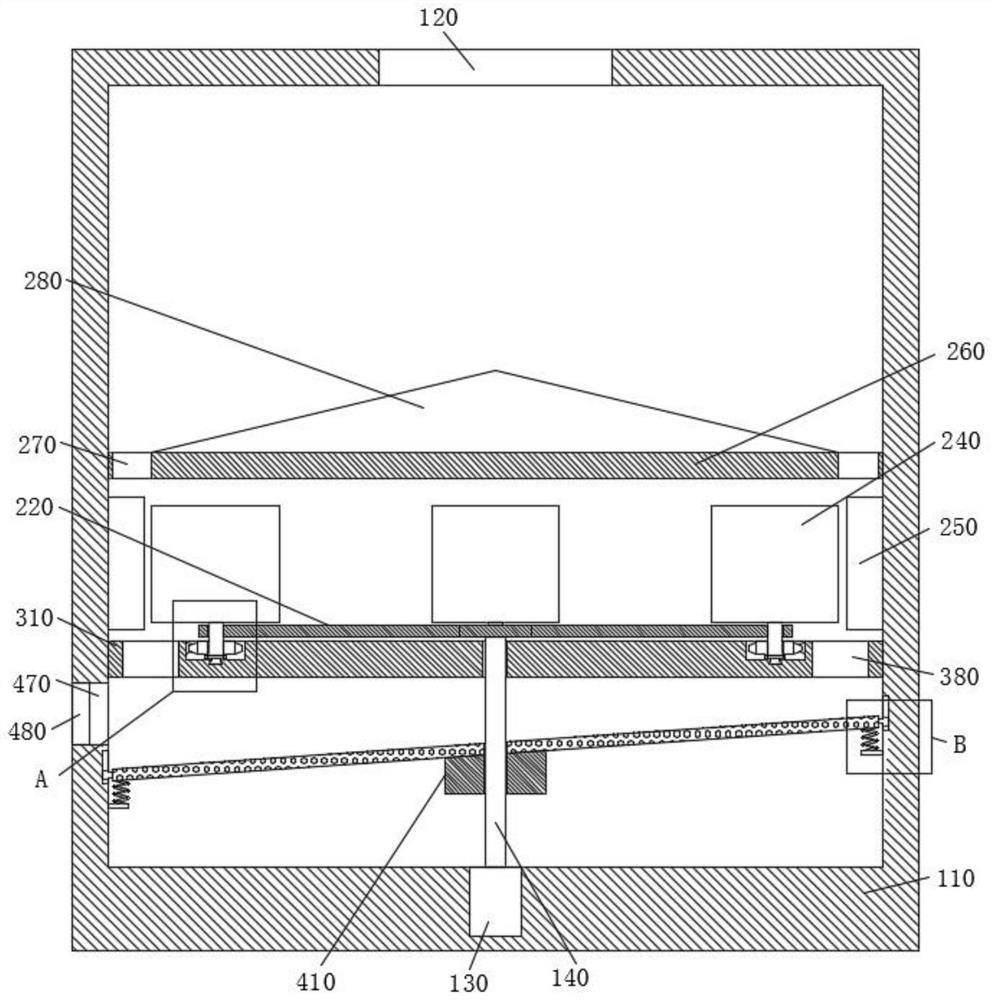

Detachable winding equipment for heavy fabric textile production and processing line

The invention discloses detachable winding equipment for a heavy fabric textile production and processing line, and particularly relates to the field of spinning. The detachable winding equipment comprises mounting brackets, a roller group connecting frame is fixedly connected to the two mounting brackets, a transmission roller group is rotatably mounted on the inner side of the roller group connecting frame, and a textile fabric is slidably connected to the top surface of the transmission roller group. Supporting connecting frames are fixedly mounted on one sides of the mounting brackets, leveling mechanisms are fixedly mounted on the other sides of the supporting connecting frames, and the bottom surfaces of the leveling mechanisms are in sliding connection with the top surface of the textile fabric. According to the scheme of the detachable winding equipment for the heavy fabric textile production and processing line, through the effect of the leveling mechanisms, the fabric can be leveled through the leveling mechanisms in the transportation process before being rolled, the outer surface of the fabric is prevented from wrinkling, when the fabric is wrinkled, a leveling plate and the fabric are separated from each other, a buzzer sounds, and the whole equipment stops running, the situation that wrinkles are generated after the fabric is rolled is effectively prevented, and the level degree of fabric rolling is improved.

Owner:嘉兴鼎澳纺织科技有限公司

Unmanned ship device with garbage cleaning and full-spectrum water quality monitoring functions

ActiveCN114261485AFast collection processingImprove collection effectWater cleaningWaterborne vesselsRefuse collectionStructural engineering

The invention discloses an unmanned ship device with garbage cleaning and full-spectrum water quality monitoring functions, which comprises a ship body, a water quality detector is arranged at the bottom of the ship body, and a garbage leading-in mechanism, a garbage extrusion mechanism and a filtering mechanism are arranged in an inner cavity of the ship body; and the garbage guiding-in mechanism comprises a connecting plate fixed to an inner cavity of the ship body, one side of the connecting plate is rotationally connected with a guiding-in shaft and a crushing shaft, the surface of the guiding-in shaft is fixedly connected with a scraping plate, the surface of the crushing shaft is fixedly connected with a crushing plate, and the scraping plate and the crushing plate are arranged in a staggered mode. According to the unmanned ship device with the garbage sweeping and full-spectrum water quality monitoring functions, garbage is guided in through the garbage guiding-in mechanism to be preliminarily smashed, the garbage is compacted through the garbage extrusion mechanism, water is automatically discharged and the garbage flows down in the ship body movement process, large-batch garbage collection and treatment can be rapidly conducted, and the labor intensity of workers is reduced. The collection effect is good.

Owner:安徽新宇环保科技股份有限公司

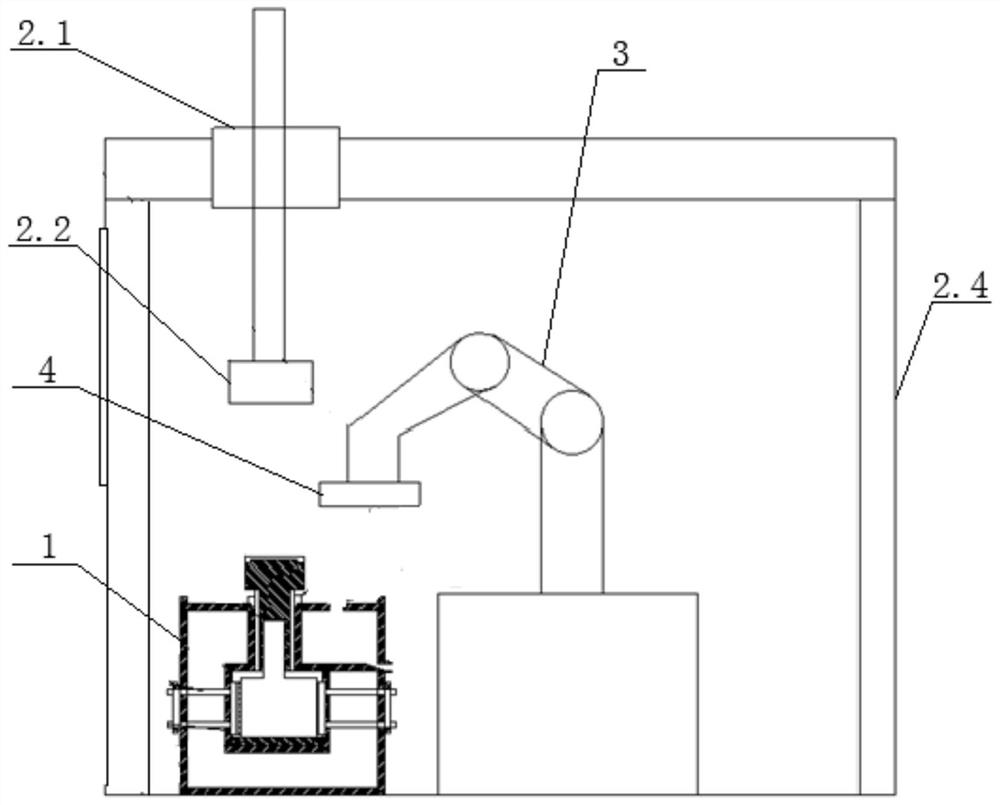

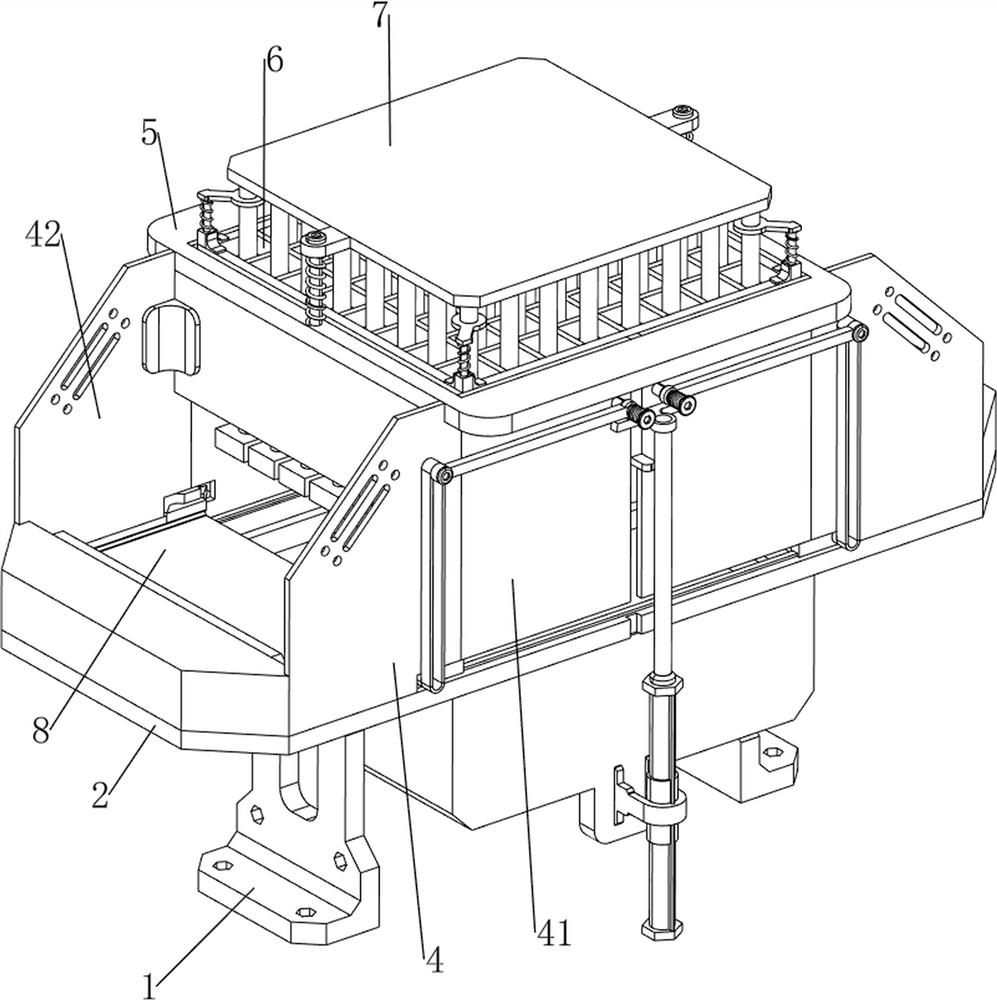

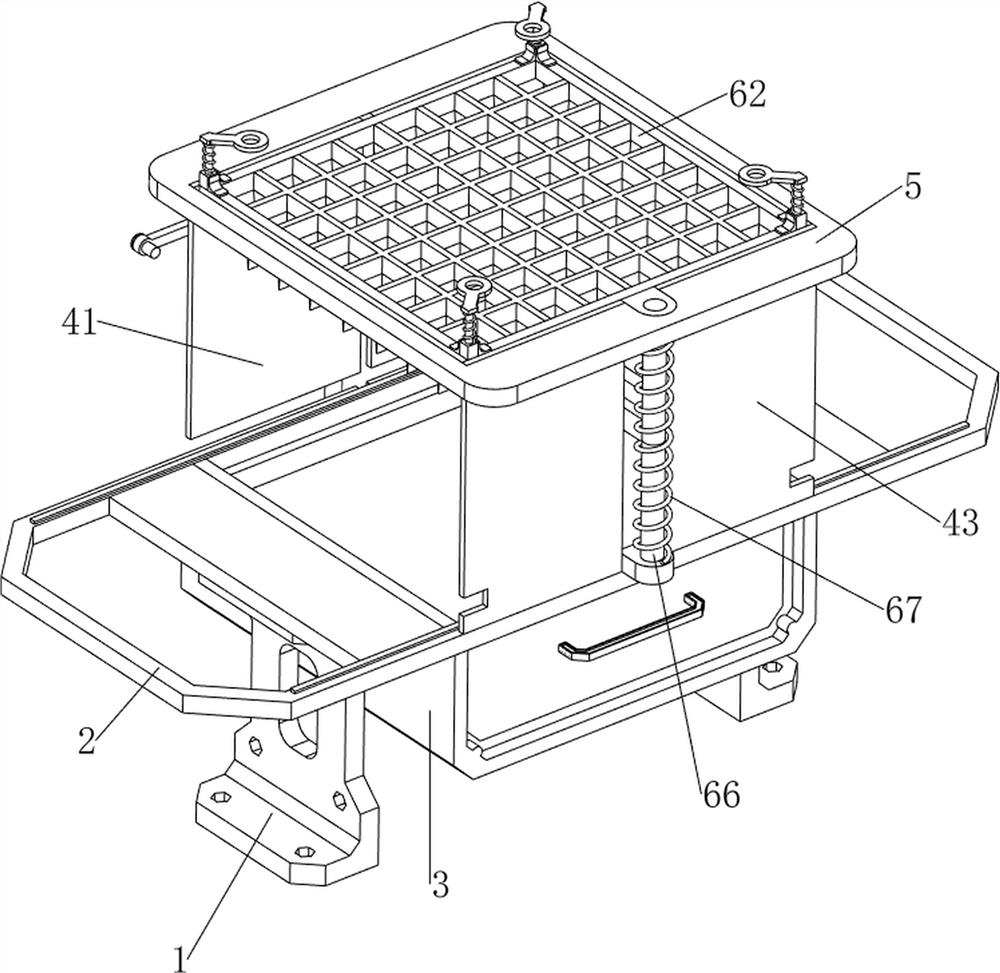

Self-adaptive control platform for grinding

InactiveCN113245988AEasy extractionFast collection processingGrinding feed controlGrinding machinesMachined surfaceImage manipulation

The invention discloses a self-adaptive control platform for grinding. The self-adaptive control platform for grinding comprises a pressure control device, a picture recognition processing device, a machining robot and a grinding head, the pressure control device comprises a box body, a press machine, a machining table, a sensor, a hot air blowing device and a flushing device, the picture recognition processing device comprises a sliding table, a camera, a picture processing device and a support, the pressure control device is fixed to the left end of the inner bottom end face of the support, the camera is located right above the machining table, the machining robot is fixed to the right end of the inner bottom end face of the support, and the grinding head is fixed to the end part of a robot arm of the machining robot. According to the self-adaptive control platform for grinding, the position of the camera can be adjusted, extraction is advantageously carried out on surface features of a machined surface, and rapidly collecting and processing are carried out on the machined surface, and the machining table is lifted through the press machine, the machining contact force is changed, and the grinding contact force is accurately adjusted.

Owner:HEBEI UNIV OF TECH

Slicing device for soap processing and production

ActiveCN114347140AQuick cut operationEasy to collectNon-rotating vibration suppressionMetal working apparatusEngineeringMechanical engineering

The invention relates to a dicing device, in particular to a dicing device for soap processing and production. The invention provides the dicing device for soap processing and production, which can cut more soaps at the same time, can quickly cut the soaps into blocks, and is convenient to collect after the soaps are cut into blocks. The dicing device for soap processing and production comprises supporting legs, a fixing frame, a box body and the like, the supporting legs are connected to the left side and the right side of the bottom of the fixing frame, and the box body is connected to the middle of the lower side of the fixing frame. The soap can be quickly diced through the two placing frames, and the soap is conveniently collected after being diced through the box body.

Owner:深圳市宁泰科技实业有限公司

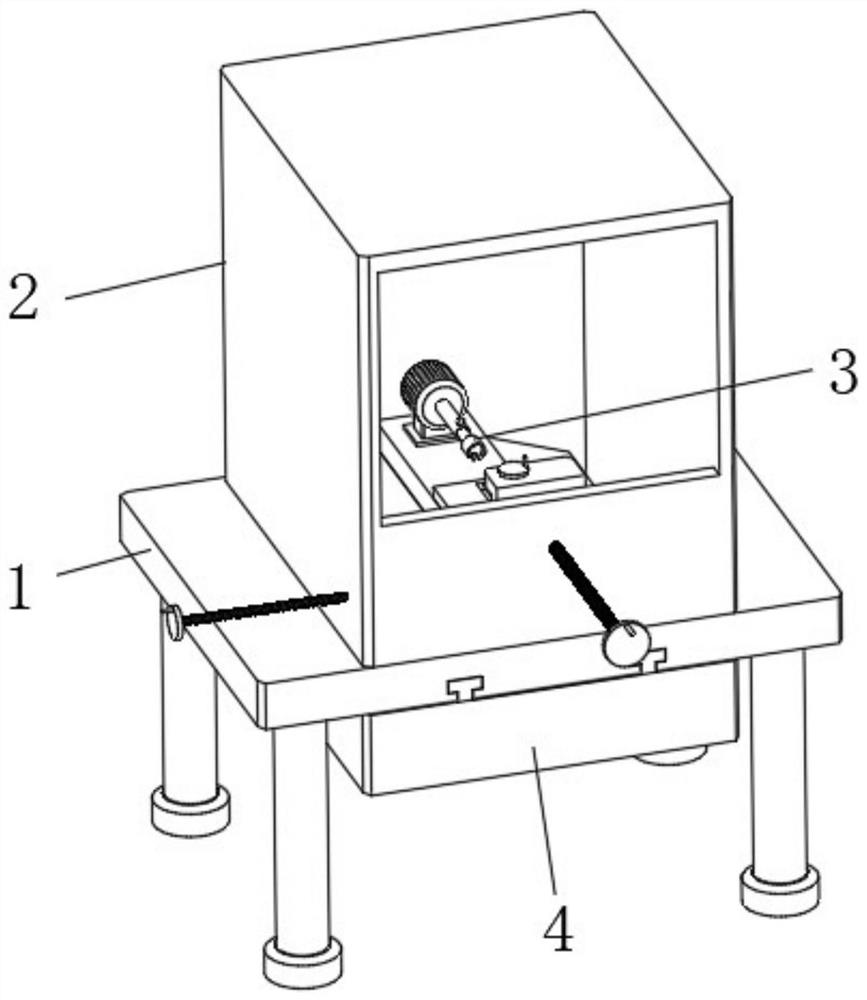

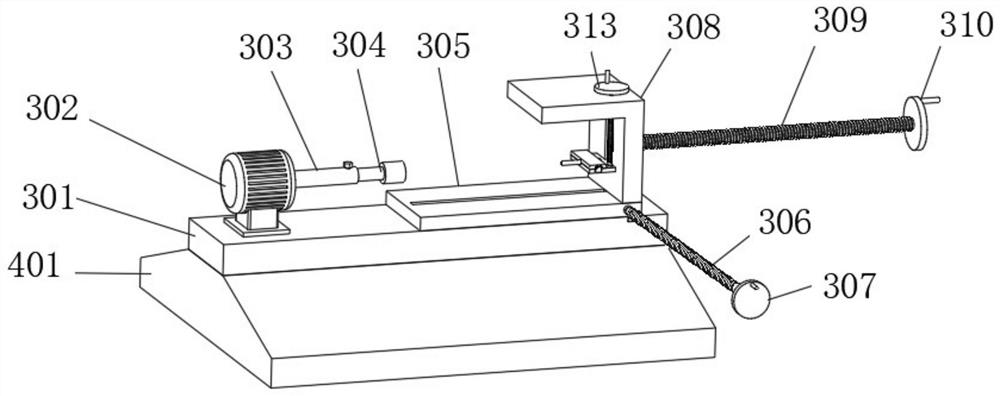

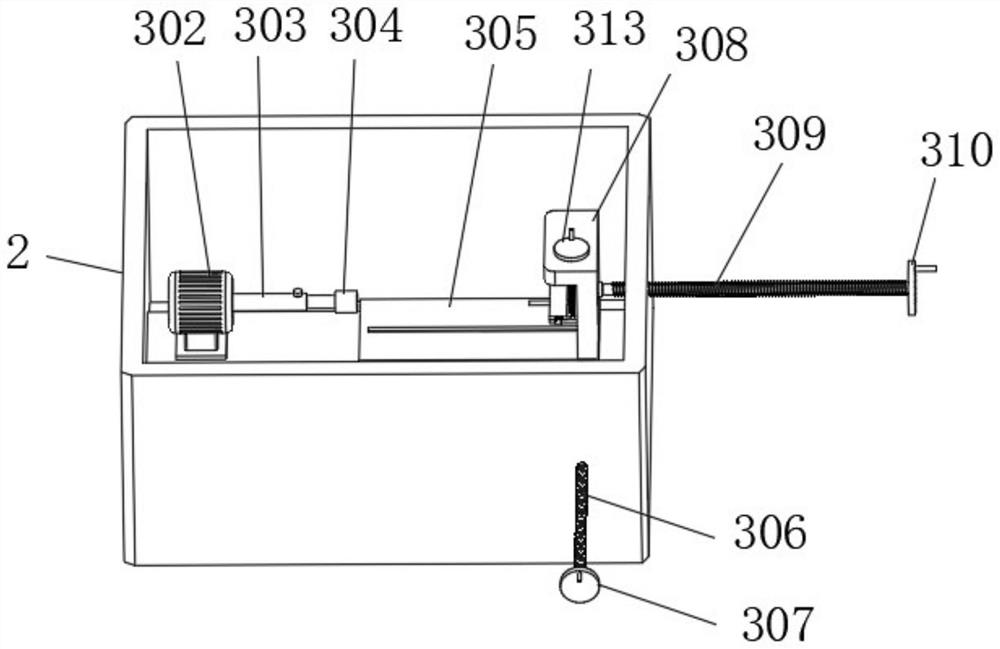

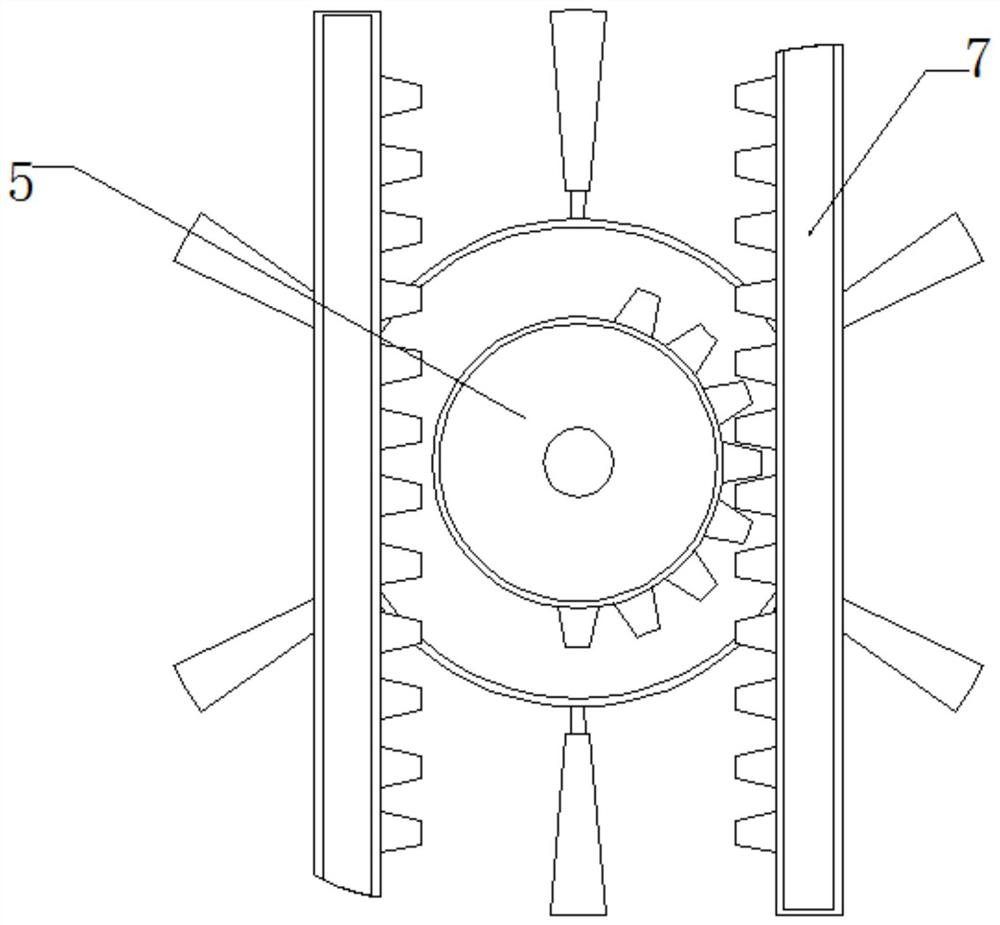

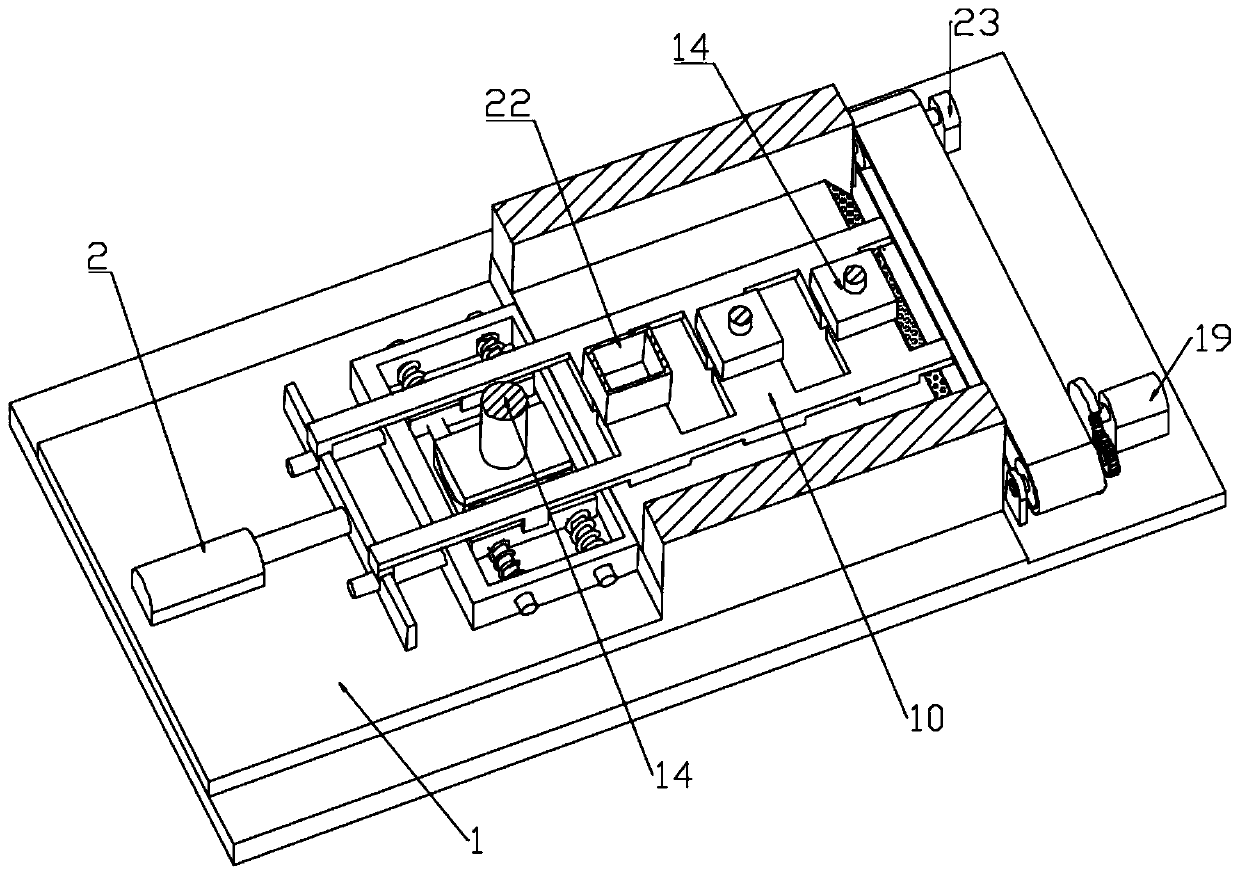

Spring end deburring treatment device for spring machining

InactiveCN113084259AImprove processing efficiencyFast collection processingWork clamping meansLarge fixed membersElectric machineryEngineering

The invention discloses a spring end deburring treatment device for spring machining. The spring end deburring treatment device for spring machining comprises a base table, wherein a machining box is arranged at the upper end of the base table, a burr removing mechanism is arranged in the machining box, and the burr removing mechanism comprises a first sliding groove plate, a motor, a shaft sleeve, a cutter cylinder, a second sliding groove plate, a first screw rod, a first rotating disc, a first sliding plate, a second screw rod, a second rotating disc, a second sliding plate, a third screw rod, a third rotating disc, a hinge, a pressing plate, a limiting buckle, a telescopic column and a limiting block, and the first sliding groove plate is arranged at the position, close to the lower end, in the machining box. According to the spring end opening deburring device for spring machining, deburring treatment can be conducted on various spring end openings, the machining efficiency is high, machined metal filings can be rapidly collected, the cleaning work of the whole device is reduced, and the use requirement is better met.

Owner:黄淑卿

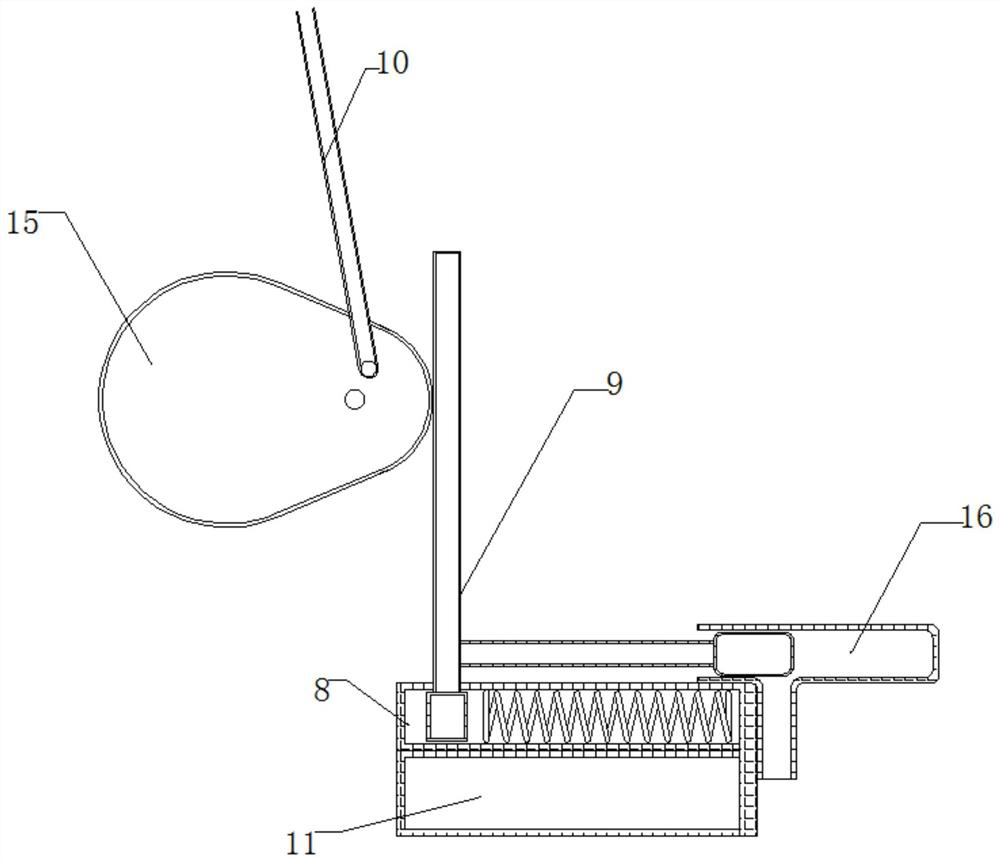

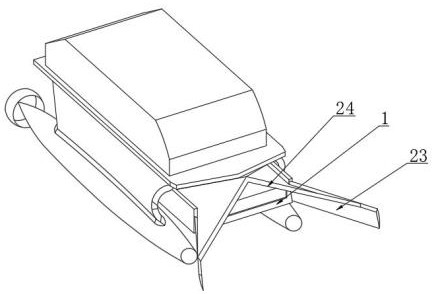

Automatic mold taking device for mold

ActiveCN111113744AFast collection processingPlay a buffer roleElectric machineryIndustrial engineering

The invention relates to a mold taking device, in particular to an automatic mold taking device for a mold. According to the automatic mold taking device for the mold, the mold can be automatically taken down, the manufacturing cost can be reduced, and the the production efficiency can be improved. The automatic mold taking device for the mold comprises a tray, a carrying plate, a double-shaft gear motor, a transmission assembly, a mold taking assembly and the like; and the carrying plate is arranged at the top of the tray, the double-shaft gear motor is arranged at the top of the tray, the double-shaft gear motor is located between the tray and the carrying plate, and the transmission assembly powered by the motor is arranged on the left side of the top of the tray. According to the automatic mold taking device for the mold, by means of the transmission assembly and the mold taking assembly, the mold can automatically move rightwards, meanwhile, in the rightward moving process of themold, mold taking can be automatically carried out, after mold taking of the mold is completed, the remaining mold plates can be wound and collected, and therefore the mold plates can be rapidly collected and treated.

Owner:南京君平智造科技有限公司

Livestock breeding excrement treatment device

InactiveCN114600777ABreak up evenlyFacilitate subsequent centralized processingAnimal housingBird housingsAnimal scienceCrop livestock

The invention discloses a livestock breeding excrement treatment device, and relates to the related technical field of animal husbandry, the livestock breeding excrement treatment device comprises a treatment outer box, one end of the treatment outer box is provided with an excrement collection device, and the treatment outer box is internally provided with an excrement dispersion device; the excrement collecting device comprises a top cover arranged on one side of the treatment outer box, a mounting rod is fixedly connected between one end of the top cover and the treatment outer box, a side plate is arranged at the bottom of one end of the top cover, a first conveying pipe is arranged below the top cover, and one end of the first conveying pipe extends into the treatment outer box; by arranging the excrement collecting device, excrement can be pushed and automatically collected in a mechanical collecting mode, the collected excrement enters the treatment outer box to be subjected to dispersion treatment, the excrement can be uniformly dispersed by arranging the excrement dispersing device, subsequent centralized treatment of the excrement is facilitated, and the treatment efficiency is improved. According to the device, excrement generated in the livestock breeding process can be rapidly collected and treated, manual collection operation is not needed, the automation degree is high, and use is easy.

Owner:诸城市中裕机电设备有限公司

High-precision grinding equipment for fluorocarbon resin coating production

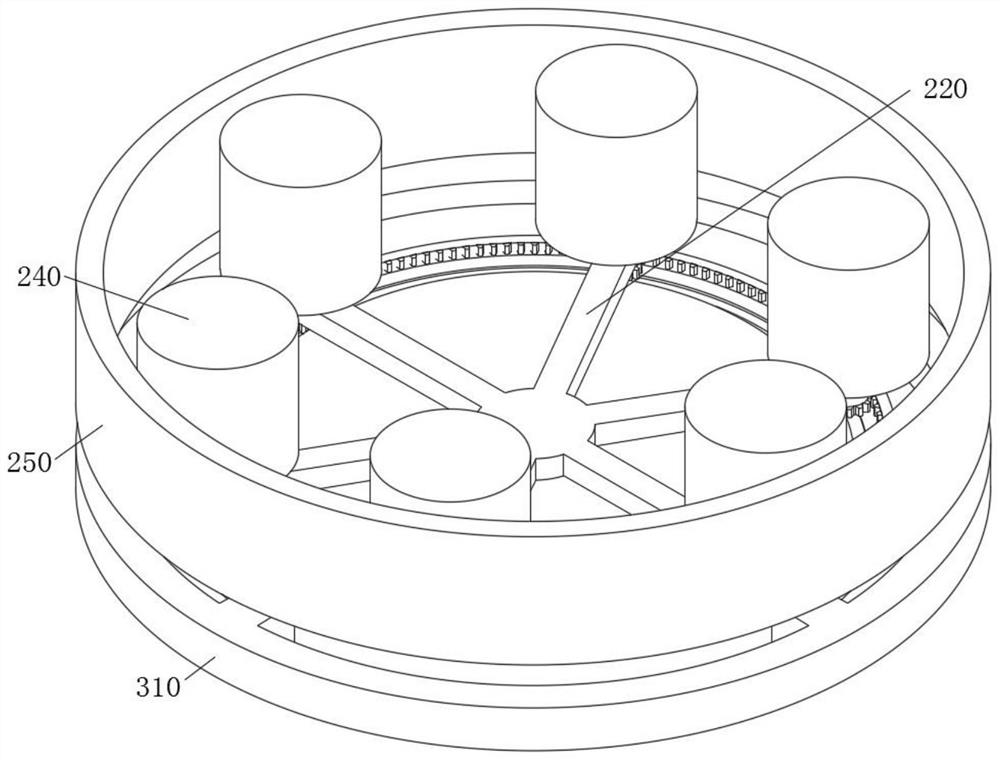

PendingCN114130464AGuaranteed grinding effectGrind fullySievingScreeningElectric machineryEngineering

The invention relates to the technical field of grinding, in particular to high-precision grinding equipment for fluorocarbon resin coating production, which comprises an equipment outer shell, a feeding port is formed in the top end of the equipment outer shell, an output motor is mounted in the equipment outer shell, and an output shaft is fixedly connected to the top end of the output motor. A revolution mechanism is arranged above the output shaft and comprises a rotating plate, the top end of the output shaft is fixedly connected with the rotating plate, six sets of connecting rods are evenly arranged on the outer wall of the rotating plate, the ends, away from the rotating plate, of the six sets of connecting rods penetrate through rotating shafts, and the top ends of the rotating shafts are fixedly connected with grinding rollers. According to the grinding device, the rotating plate, the connecting rod and the grinding roller can rotate, raw materials can be ground through the grinding roller, and meanwhile, the grinding effect is guaranteed through mutual extrusion of the inner ring and the grinding roller.

Owner:广德衡峰新型建材有限公司

A device that uses river water flow as power to generate negative pressure to collect floating objects

ActiveCN110952518BEasy to collectFast collection processingWater cleaningStationary filtering element filtersDrive wheelWater flow

The invention relates to the technical field of water pollution treatment, and discloses a device that uses river water flow as power to generate negative pressure to collect floating objects, including a processing machine, and the inside of the processing machine is movably connected with a cover slide rail, and the cover The inside of the board slide rail is movably connected with a movable slider, the exterior of the processor is movably connected with a power fan wheel, the bottom of the cover slide rail is movably connected with a driving wheel, and the bottom of the movable slider is fixedly connected with a drive wheel. A water rack, a water retaining cover plate is fixedly connected between the two movable sliders, and a moving slide rail is movably connected inside the processor. The water on the surface of the river flows into the processor through the water inlet. When the water flows through the filter, the floating objects remain on the filter, thus ensuring that the floating objects in the river water entering the processor will be isolated on the filter. The floating objects are separated from the river water, which is convenient for collecting the floating objects.

Owner:山东博泓信息科技有限公司 +1

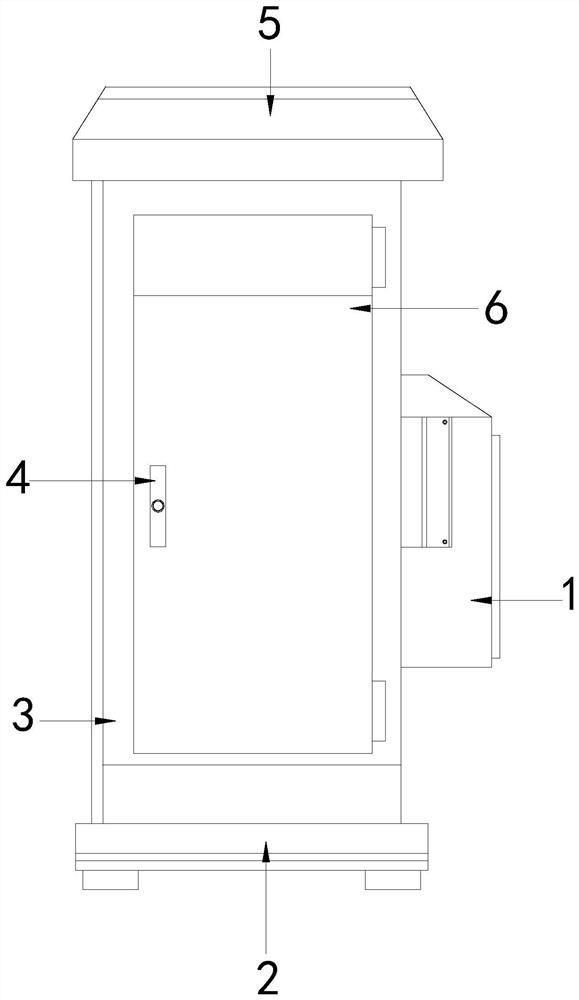

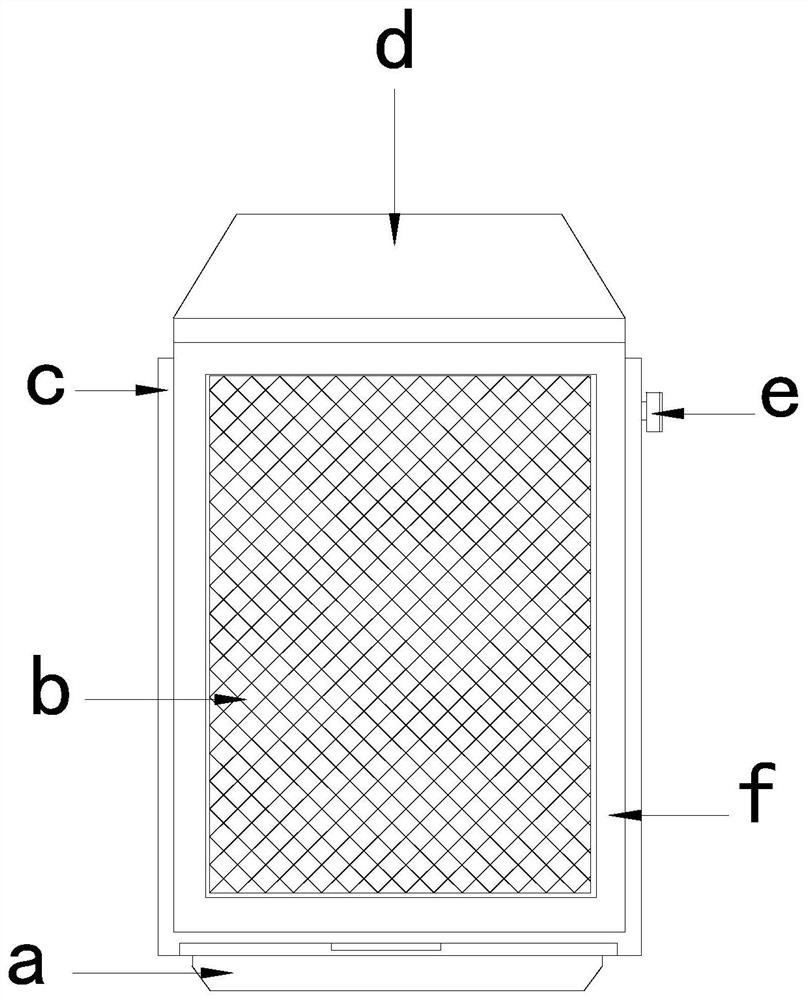

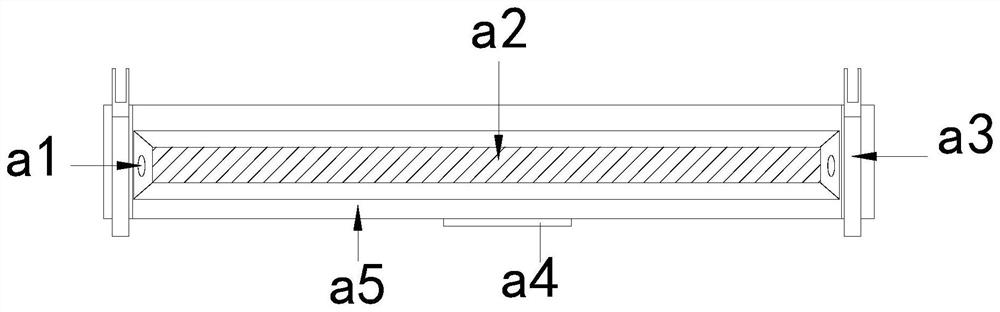

Safety fireproof communication equipment cabinet

PendingCN113423204AFast collection processingDispersed particle filtrationClosed casingsEquipment useScreen filter

The invention discloses a safety fireproof communication equipment cabinet which structurally comprises a heat dissipation box device, a supporting base, a main cabinet body, a door lock, an upper cover bin and a movable door body, wherein the upper cover bin is installed above the main cabinet body and connected with the main cabinet body in a locked mode. When equipment is used, through the arranged mechanisms, the problem that a heat dissipation box on the side edge of the equipment cabinet usually utilizes a heat dissipation fan to convert internal hot air to the outside, dust is continuously attached to a filter screen at the front end in the process, and cleaning and collection are inconvenient and fast can be solved; the equipment is matched with a sliding block plate through an arranged sliding rod set, then a contact shaft pipe is driven to do displacement motion along the filter screen, at the moment, extrusion contact can be formed on the inner surface of the filter screen through a special contact shaft tube structure, then dust attached to the surface of the filter screen is scraped off, a side supporting device is used for assisting reset fit, and finally rapid collection treatment is conducted through a collecting tank device, so that more convenience is achieved.

Owner:郑焕彬

Drilling machine with waste recovery function

InactiveCN114309700AEasy to cleanWith recycling functionMaintainance and safety accessoriesBoring/drilling machinesElectric machineryWaste material

The invention discloses a drilling machine with a waste recovery function, and relates to the technical field of drilling machines. The drilling machine with the waste recycling function comprises a drilling machine body, a material moving groove is formed in the upper surface of the drilling machine body, a movable drilling machine support is fixed to the upper surface of the drilling machine body, a drilling machine is fixedly embedded in a movable plate of the movable drilling machine support, and a second collecting groove is formed in the position, located at one end of an arc-shaped plate, of the upper surface of the drilling machine body. A surface waste cleaning device is fixed to the upper surface of the drilling machine body. According to the drilling machine with the waste recycling function, a to-be-machined material is placed in a material moving groove, then drilling operation is conducted on the to-be-machined material through the drilling machine, after drilling is finished, a first motor in a surface waste cleaning device is started to control a cleaning rod to rotate, surface waste is driven to move, and then the waste is concentrated through an arc-shaped plate; therefore, the purpose of conveniently treating the waste materials on the surfaces of the materials is achieved.

Owner:张智

Thermal desorption tube collection system and method

ActiveUS11346821B2Reduce the amount of solutionLow detection limitComponent separationWithdrawing sample devicesThermoelectric coolingGas liquid chromatographic

Owner:MLS ACQ INC

Waste treatment device for acetamide production

InactiveCN108253753AAvoid wasting resourcesImprove resource utilizationDrying gas arrangementsDrying machines with non-progressive movementsScrapWaste treatment

The invention discloses a waste treatment device for acetamide production. The waste treatment device comprises a treatment box. The outer wall of the treatment box is connected with a first heat preservation plate. A fixing box is connected to the top end and the bottom end of the treatment box. A rotation motor is connected to the inner wall of the top end of the fixing box. The output end of the rotation motor is connected with a rotation shaft. A connecting plate is vertically welded to the end, away from the rotation motor, of the rotation shaft. Stirring plates are vertically welded to the two side walls of the connecting plate. Symmetrically-arranged through holes are formed in the two side walls of the fixing box. The end, close to the connecting plate, of each through hole is internally connected with a filter net. One end of each through hole is connected with a first air suction pipe, wherein the first air suction pipe communicates with the through hole, the end, away from the through hole, of the first air suction pipe is vertically connected with a second air suction pipe, and the end, away from the first air suction pipe, of the second air suction pipe is connected with a fixing pipe. By means of the waste treatment device, heat of the waste can be rapidly collected and treated, the collected heat is used for acetamide production or other aspects, and resource waste is prevented.

Owner:XIANGSHUI MODERN CHEM CO LTD

Environmental protection and comprehensive recovery processing device of waste garbage

InactiveCN111531938AFast collection processingNot easy to breedClimate change adaptationOrganic fertilisersAgricultural scienceAgricultural engineering

The invention discloses an environmental protection and comprehensive recovery processing device of waste garbage. An electric telescopic rod is fixedly installed at the left end of the upper surfaceof a base, a push plate is fixedly installed at the rod end of the electric telescopic rod, limiting columns are in transverse clearance fit with the two ends of the push plate, the right ends of thelimiting columns are fixedly installed on the left surface of a groove, a cylinder is vertically in clearance fit with the front view face of the groove, an inclined block is fixedly installed at therear end of the front view face of the cylinder, a limiting plate is fixedly arranged at the middle end of the cylinder, a spring is installed in the cylinder in a penetrating mode, one end of the spring makes contact with the inner wall of the groove, the other end of the spring makes contact with the surface of the limiting plate, the upper end of the limiting plate is in transverse clearance fit with a clamping plate, and the left end of the clamping plate is in vertical clearance fit with the upper end of the push plate. secondary utilization and environment-friendly treatment of the vegetable and fruit garbage can be achieved, the vegetable and fruit garbage with water squeezed out can serve as fertilizer, and the vegetable and fruit garbage with water squeezed out is not prone to breeding bacteria and decaying to generate unpleasant gas.

Owner:项开梅

Sea surface oil pollution collection, treatment and recovery integrated device

ActiveCN109339017BPrevent deep contaminationEasy to handleWater cleaningWaterborne vesselsFiltrationOil water

The invention provides a sea surface oil stain collection and recovery integrated device. The whole device is crescent, and achieves an effect of an oil surrounding fence to surround the sea surface oil stains from the end part; a mixture collecting port is formed in a crescent cabin body; oil-water mixtures are quickly absorbed in the device through an electric pump in the mixture collecting port; through a separation effect of a centrifuge, the oil stains are collected into an oil tank by an oil pipeline at the upper part of the device, and water is leaded out by a water pipeline at the lower part; and after multi-layer filtration, clean seawater is directly drained into the sea.

Owner:DALIAN UNIV OF TECH

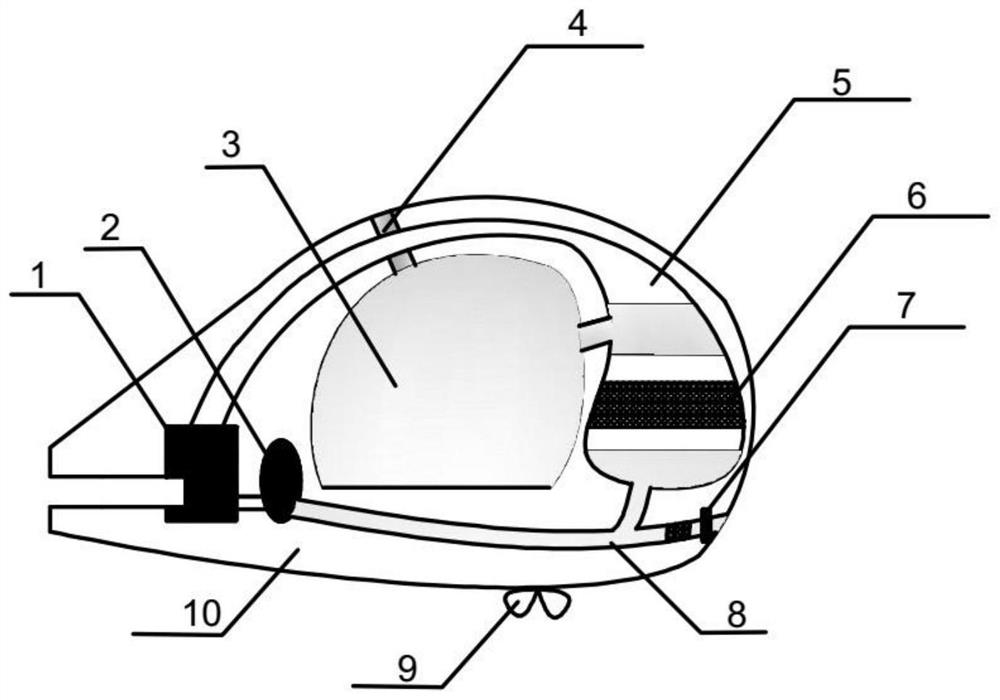

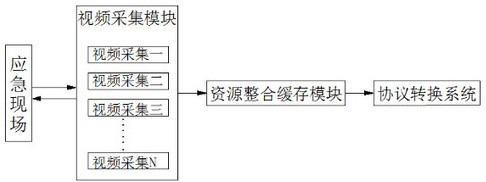

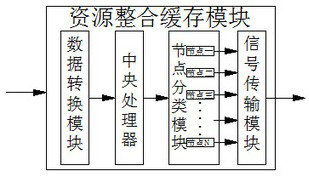

A video resource integration and protocol conversion system based on emergency scenarios

ActiveCN112153353BReduce recording timeAvoid lossTelevision system detailsColor television detailsVideo optimizationElectrical connection

The invention discloses a video resource integration and protocol conversion system based on an emergency scene, which includes a video acquisition module, a resource integration buffer module and a protocol conversion system. The output end of the video acquisition module and the input end of the resource integration buffer module pass through the internal The power line is electrically connected, the video acquisition module is electrically connected to the electronic equipment on the emergency site in two directions through electrical signals, the output end of the resource integration buffer module is electrically connected to the input end of the protocol conversion system, and multiple video acquisition and aggregation are adopted At the scene of an emergency, the video recording time can be shortened in a timely and effective manner, and all the evidence on the scene can be collected and processed in a timely and effective manner to avoid changes due to time factors. At the same time, the video can be optimized simultaneously while collecting and sorting , filtering of interference factors and reintegration of video, multiple lines are performed synchronously, which can greatly shorten and reduce the memory resources occupied by video.

Owner:南京创科信息科技有限公司

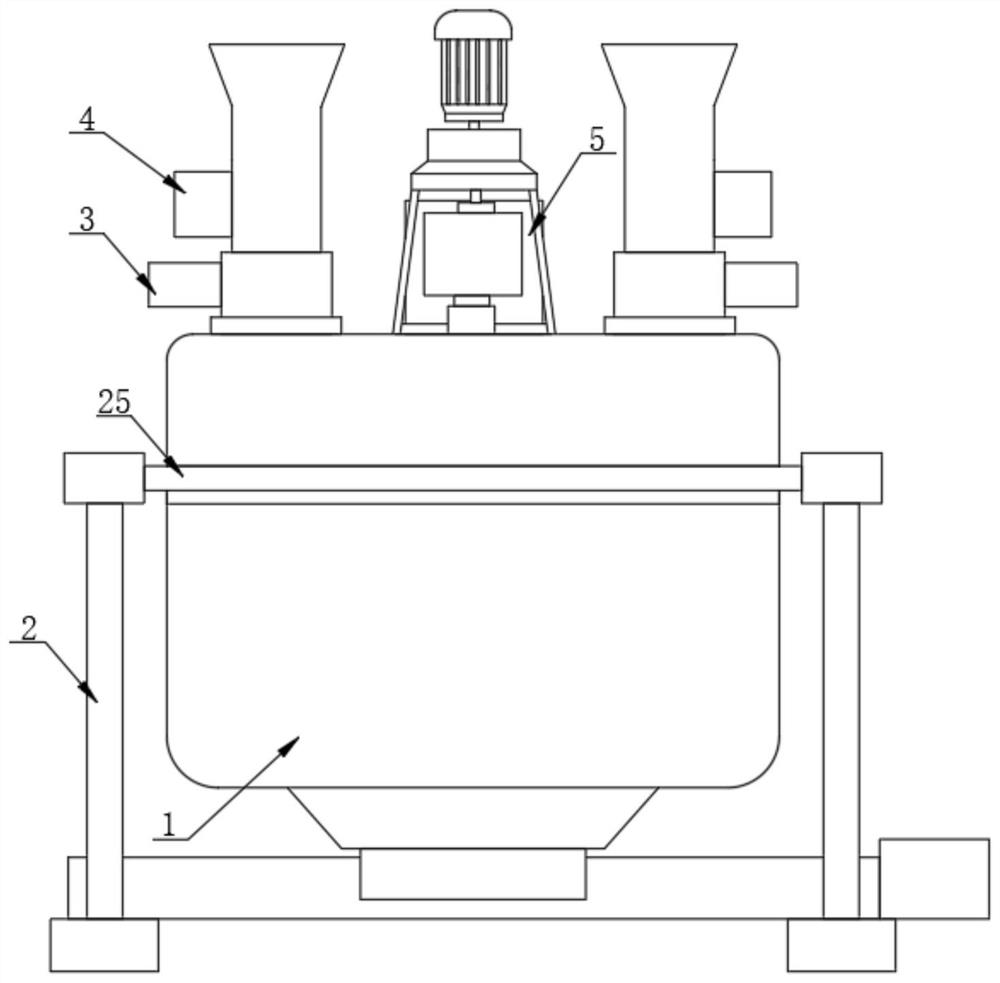

Efficient reaction kettle for mixing nitrogen, phosphorus and potassium fertilizers for pretreatment work of agricultural paddy fields

InactiveCN113351092AAvoid cloggingImprove mixing uniformityDispersed particle separationMixer accessoriesAgricultural engineeringEnvironmental engineering

The invention discloses an efficient reaction kettle for mixing nitrogen, phosphorus and potassium fertilizers for pretreatment of agricultural paddy fields, and particularly relates to the field of agriculture. The efficient reaction kettle comprises a reaction kettle body, a hoisting mechanism is fixedly mounted on the outer side of the reaction kettle body, and a staggered friction mechanism is fixedly mounted on the top surface of the reaction kettle body; a feeding control mechanism is fixedly mounted on the top surface of the staggered friction mechanism, a smell eliminating mechanism is fixedly mounted on the top surface of the reaction kettle body, and a mixing motor is fixedly mounted on the top surface of the reaction kettle body. According to the scheme, under the action of the staggered friction mechanism, caked parts in a nitrogen fertilizer, a phosphate fertilizer and a potash fertilizer can be independently separated in the feeding process, and then separation treatment of the caked fertilizer is achieved through staggered friction between a first metal partition net and a second metal partition net; the conditions that the caking part blocks a feeding pipe and the nitrogen fertilizer, the phosphate fertilizer and the potash fertilizer are not uniformly mixed are prevented, and the mixing uniformity is improved.

Owner:桐乡市常新农机专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com