Safety fireproof communication equipment cabinet

A communication equipment and safety technology, applied in electrical equipment shell/cabinet/drawer, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of large heat dissipation requirements, inconvenient cleaning and collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

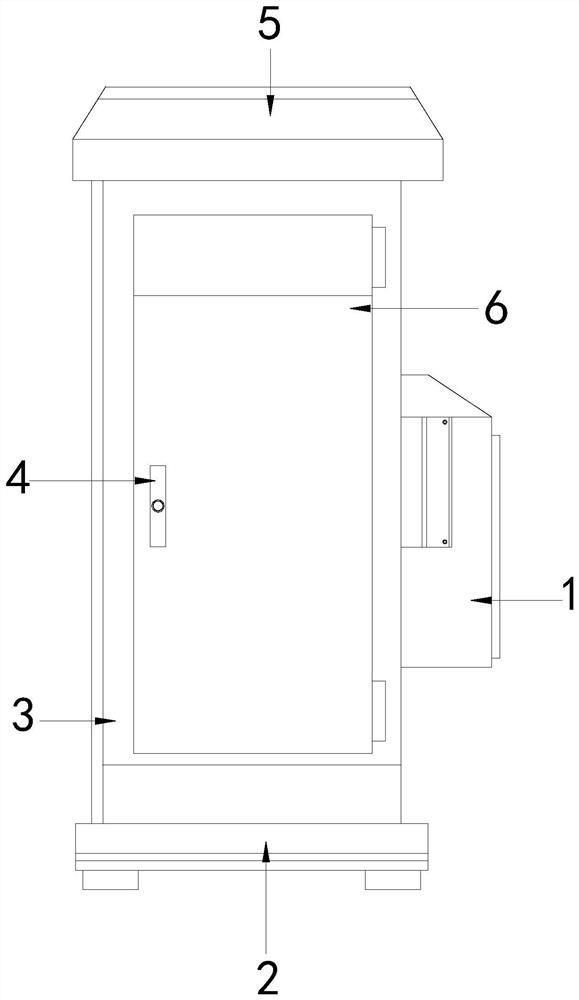

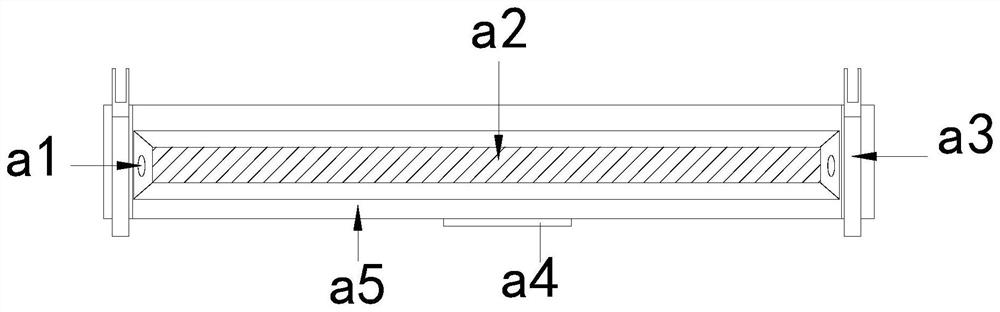

[0026] see Figure 1-Figure 3 , the present invention provides a technical solution for a safe and fireproof communication equipment cabinet: its structure includes: a heat dissipation box device 1, a support base 2, a main cabinet body 3, a door lock 4, an upper cover warehouse 5, and a movable door body 6, and the upper cover The warehouse 5 is installed above the main cabinet body 3 and is locked with the main cabinet body 3. A support base 2 is provided below the main cabinet body 3. The support base 2 is welded to the main cabinet body 3. The front of the main cabinet body 3 is The side is provided with a movable door body 6, and the movable door body 6 is buckled with the main cabinet body 3, and the side of the main cabinet body 3 is provided with a door lock 4, and the door lock 4 is buckled with the main cabinet body 3, so that The right side of the main cabinet body 3 is provided with a cooling box device 1, the cooling box device 1 is locked with the main cabinet bo...

no. 2 example

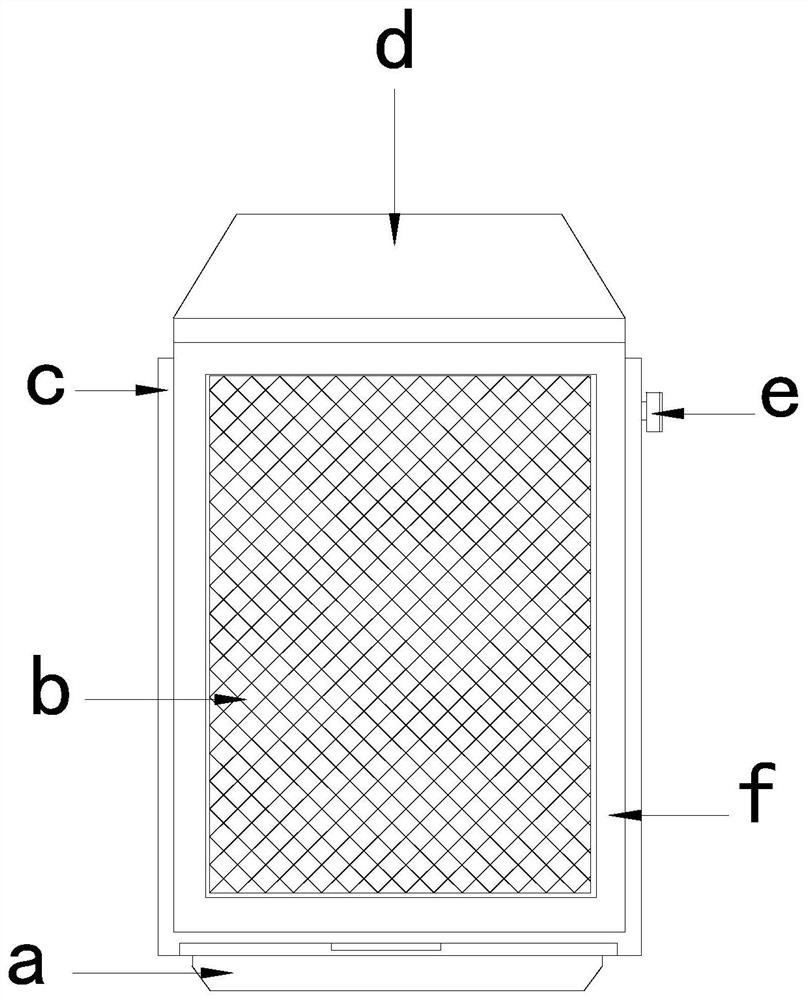

[0030] see Figure 4-Figure 6 , the present invention provides a technical solution for a safe and fireproof communication equipment cabinet: its structure includes: the scraper device e includes a contact shaft tube e1, an inner shaft rod e2, a slide bar group e3, a slider plate e4, and a side support device e5, The slider group e3 is installed on the outside of the slider plate e4 and fastened with the slider plate e4. The slider plate e4 is flexibly connected to the contact shaft tube e1 through the inner shaft rod e2. The left end of the contact shaft tube e1 is provided with The side support device e5, the side support device e5 is fastened with the contact shaft tube e1.

[0031] The contact shaft tube e1 includes a support tube e11, an inner hollow groove e12, a buffer collar e13, and a contact sleeve e14. A support tube e11 is provided inside the ring e13, and an inner hollow groove e12 runs through the inside of the support tube e11.

[0032] The side support device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com