Efficient reaction kettle for mixing nitrogen, phosphorus and potassium fertilizers for pretreatment work of agricultural paddy fields

A reaction kettle and paddy field technology, applied in the agricultural field, can solve problems such as uneven fertilizer mixing, difficult fertilizer ratio, difficult removal of ammonia gas, etc., to achieve the effects of preventing damage, rapid collection and processing, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

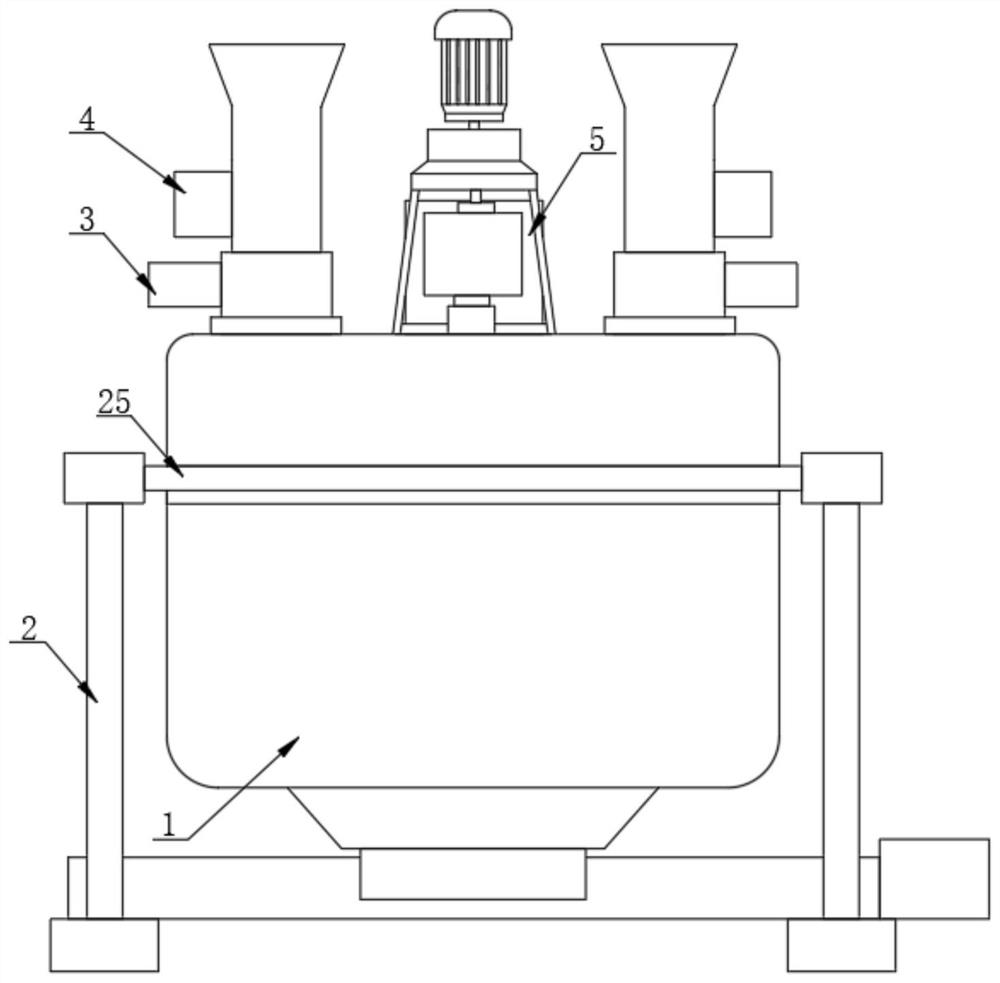

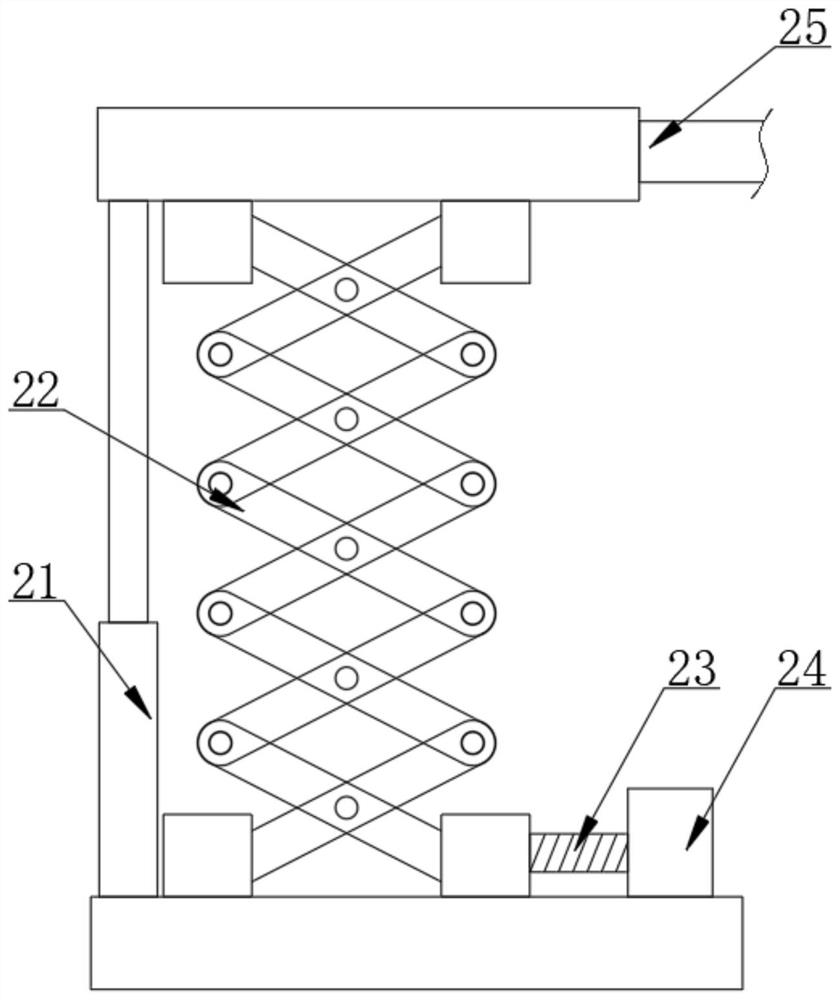

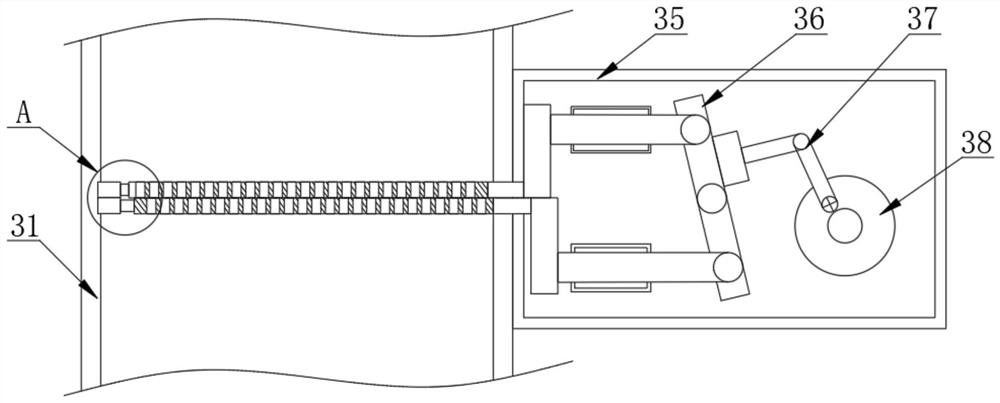

[0033] as attached figure 1 to attach Figure 8Embodiments of the present invention provide a high-efficiency reactor for mixing nitrogen, phosphorus, and potassium fertilizers for agricultural paddy field pretreatment, a high-efficiency reactor for mixing nitrogen, phosphorus, and potassium fertilizers for agricultural paddy field pretreatment, including a reactor body 1, A lifting mechanism 2 is fixedly installed on the outside of the reaction kettle body 1, a staggered friction mechanism 3 is fixedly installed on the top surface of the reaction kettle body 1, and a feed control mechanism 4 is fixedly installed on the top surface of the staggered friction mechanism 3. An odor elimination mechanism 5 is fixedly installed on the top surface, a mixing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com