Automatic mold taking device for mold

An automatic and mold technology, applied in the field of automatic mold taking device, can solve the problems of labor consumption, increase production cost, low work efficiency, etc., and achieve the effect of reducing labor consumption, increasing work efficiency, and quickly collecting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

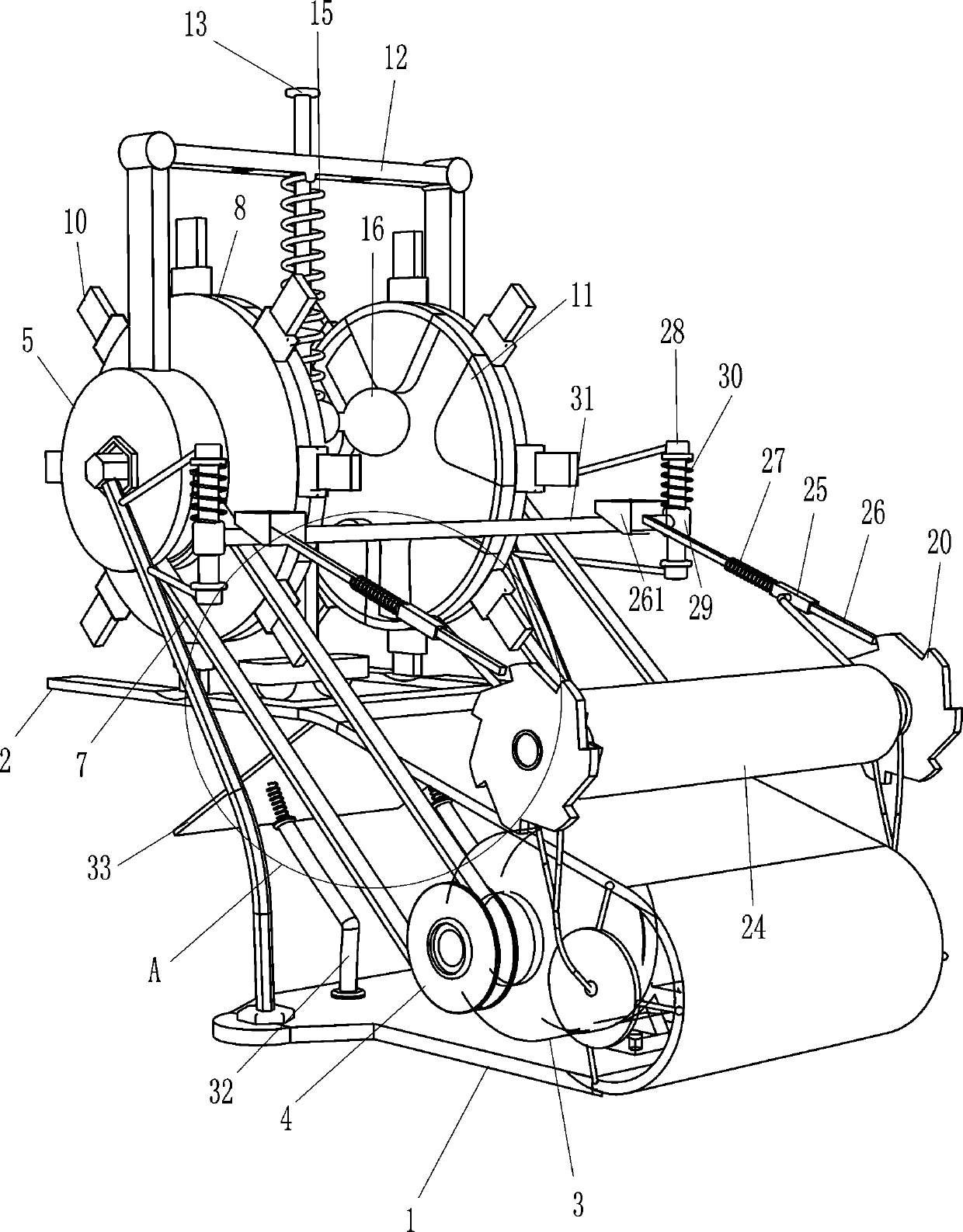

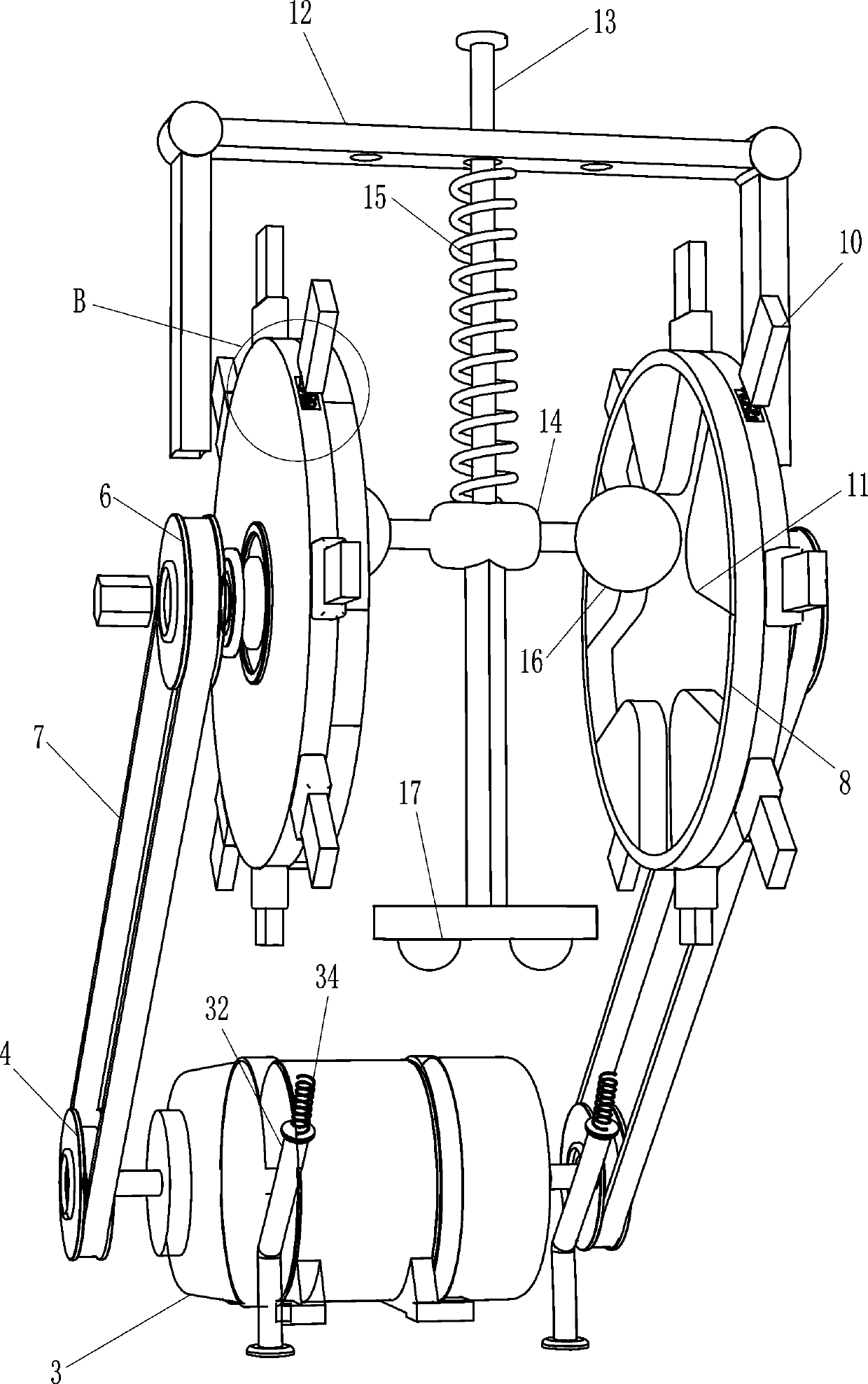

[0020] A kind of mold automatic mold taking device, such as figure 1 , 2 As shown in and 5, it includes a tray 1, a loading plate 2, a double-axis reduction motor 3, a transmission assembly and a mold taking assembly. The top of the tray 1 is provided with a loading plate 2, and the top of the tray 1 is provided with a double-axis reduction motor 3. The double-axis deceleration motor 3 is located between the tray 1 and the loading plate 2, and the left side of the top of the tray 1 is provided with a transmission assembly powered by the motor, and a mold-taking assembly for taking the mold by knocking is provided between the transmission assemblies. The transmission assembly cooperates with the mold taking assembly.

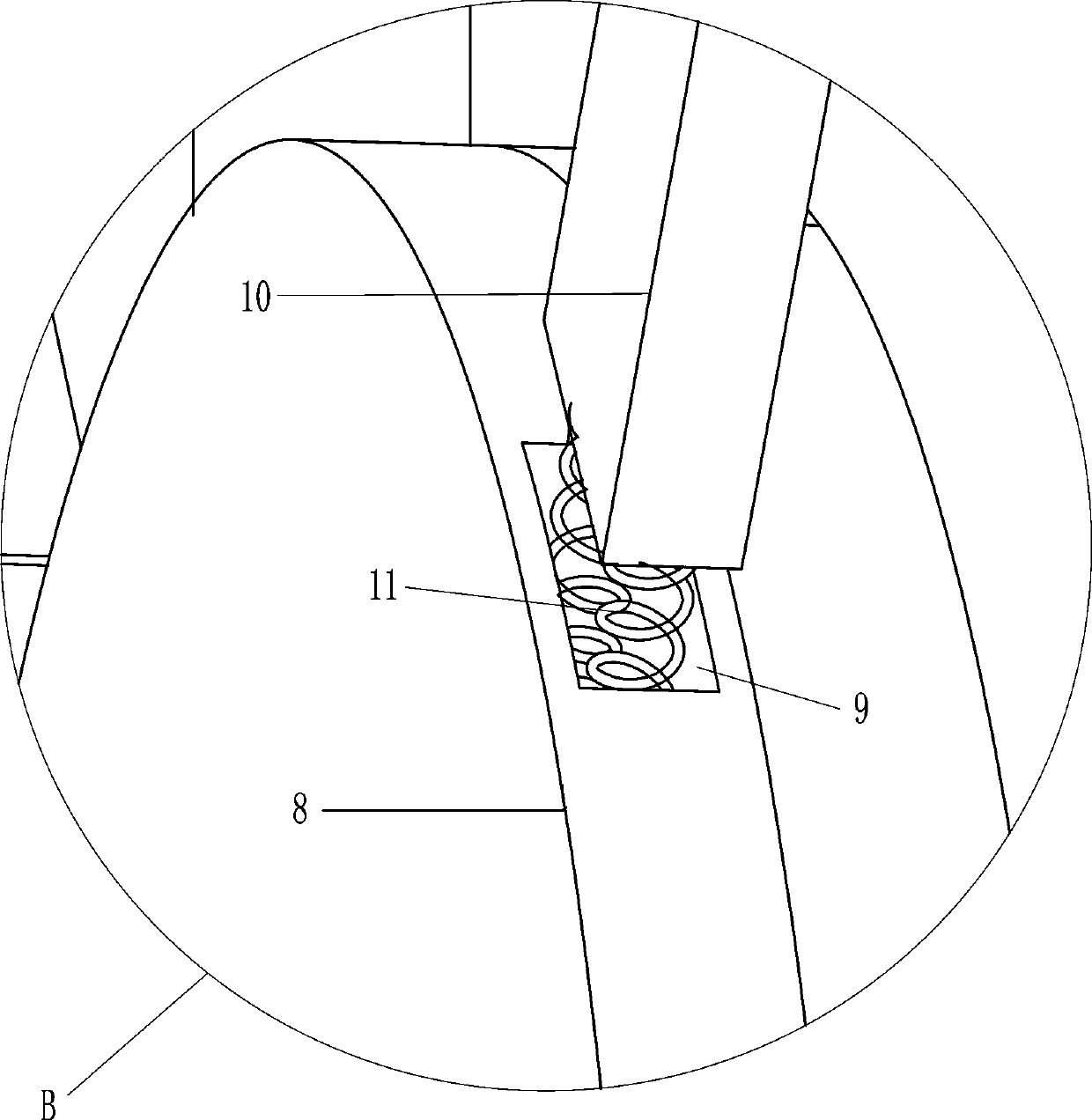

[0021] Such as figure 1 , 2 As shown in and 5, the transmission assembly includes a first pulley 4, an installation housing 5, a second pulley 6, a flat belt 7, a turntable 8, a slider 10 and a first spring 11, and the output shaft of the biaxial reduction mot...

Embodiment 2

[0027] On the basis of Example 1, such as figure 1 , 3 As shown in and 4, in order to improve the practicability of the equipment, it also includes a rotating shaft 18, a second mounting block 19, a ratchet 20, a star block 21, a third spring 22, a roller 24, a guide sleeve 25, and a second slide bar 26. Wedge block 261, fourth spring 27, guide rod 28, sliding sleeve 29, fifth spring 30 and cross bar 31, the front and rear parts of the top right side of the tray 1 are welded with the second mounting block 19, the second mounting block 19 The inner uniform rotation type is provided with a rotating shaft 18, the inner side of the rotating shaft 18 is provided with a star-shaped block 21, the outer end of the rotating shaft 18 is provided with a ratchet 20, and a third spring 22 is arranged between the star-shaped block 21 and the second mounting block 19. The three springs 22 are in contact with the second mounting block 19, and a roller 24 is arranged between the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com