Granulate machine screen and screen mechanism of swing type granulate machine with screen

A granulator and screen technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of reducing work efficiency, time-consuming, pollution, etc., and achieve the effect of ensuring safety, not easy to break or break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

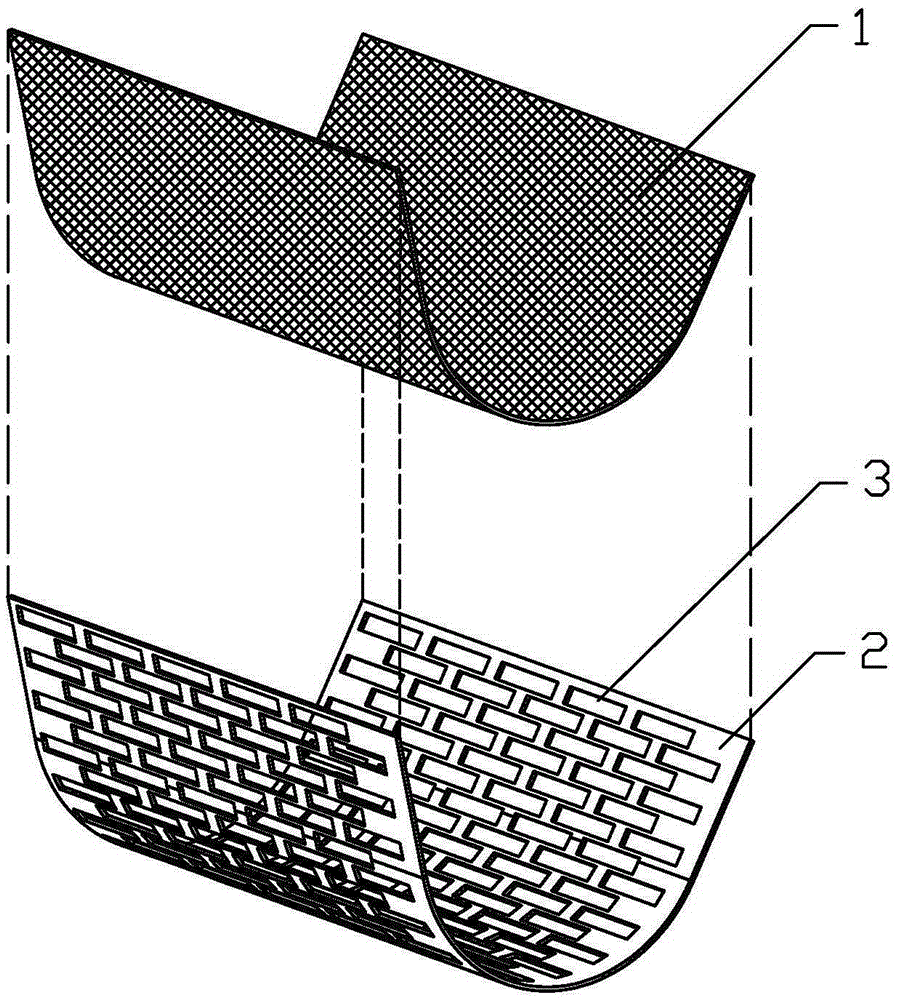

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of sizing machine screen mesh of this embodiment comprises stainless steel wire mesh 1 and stainless steel plate 2, and stainless steel plate 2 is densely covered with a plurality of through holes 3 that penetrate up and down, and stainless steel wire mesh 1 and stainless steel plate 2 are made of Heat-sealing from top to bottom forms a screen 4, and the heat-bonded screen 4 is usually U-shaped.

[0022] The sieve of the granulator in this embodiment adopts a double-layer structure and is thermally combined into one, which effectively combines the flexibility of the upper layer of stainless steel wire mesh and the rigidity of the lower layer of stainless steel plate densely covered with through holes, so that the sieve can effectively realize the screening of drugs. The granulation of the material controls the size of the granules after granulation, and has a certain degree of stretch re...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the multiple through holes on the stainless steel plate 2 of this embodiment are opened in a strip shape and arranged in a rectangular array. Among the multiple through holes in each row, the gap between two adjacent through holes is The spacing is 3-10mm, such as: 3mm, 4mm, 5mm, 8mm or 10mm. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 This embodiment will be described. In this embodiment, a plurality of via holes in adjacent rows are distributed in a dislocation manner. In this way, the parts (ribs) between adjacent through holes are also dislocated, which can better provide support and heat-sealing fulcrums for the upper stainless steel wire mesh, and make the heat-sealing fulcrums uniformly dislocated, further ensuring the broken The stainless steel wire mesh is bonded to the lower stainless steel plate, so it will not fall into the pharmaceutical material and cause pollution to it. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com