Preparation method of curable silicon-based hybrid resin

A technology of resin and polysiloxane, applied in coatings, adhesives, etc., can solve the problems of mechanical properties, hardness, and product status cannot be fully assembled, and achieve excellent adhesion, fast surface drying, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

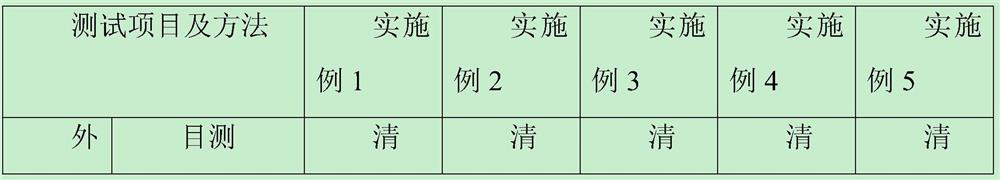

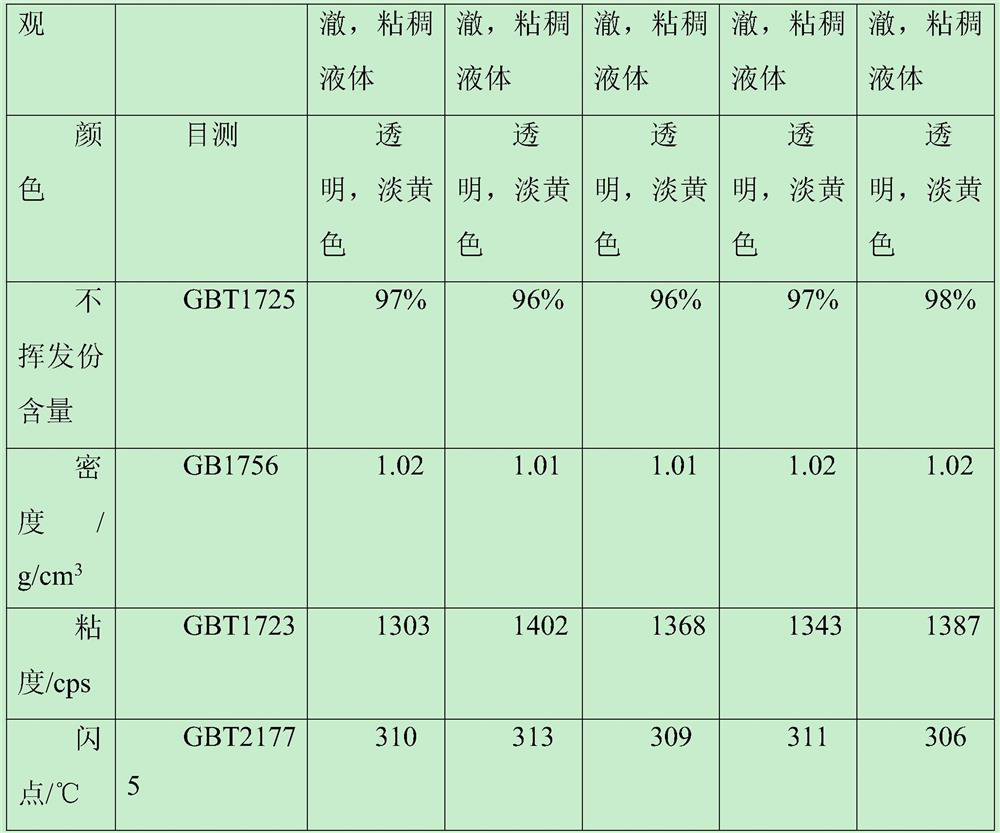

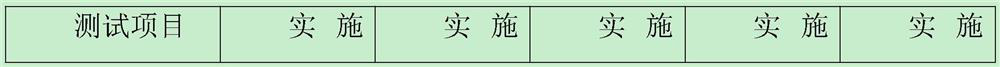

Examples

Embodiment 1

[0024] The preparation method of curable silicon-based hybrid resin comprises the following steps:

[0025] Step 1. Add amino-terminated linear polysiloxane with a number average molecular weight of 4000 into a three-necked flask, dehydrate under vacuum at 110°C for 1 hour, then pass in nitrogen gas, add hexamethylene diisocyanate dropwise while stirring, and obtain intermediate Product I;

[0026] Step 2. Diallyl isocyanurate is added to a three-necked flask, nitrogen is introduced, heated and melted, and isocyanate propyltriethoxysilane is added dropwise while stirring, and the intermediate product II is obtained after the reaction is completed;

[0027] Step 3, mixing the intermediate product I, the intermediate product II and the photoinitiator TPO according to the mass ratio of 90:10:3 to obtain a curable silicon-based hybrid resin;

[0028] In said step 1, the molar ratio of amino group to isocyanate group is 1:1.1;

[0029] In the second step, the molar ratio of diall...

Embodiment 2

[0031] The preparation method of curable silicon-based hybrid resin comprises the following steps:

[0032] Step 1. Add amino-terminated linear polysiloxane with a number-average molecular weight of 2000 into a three-necked flask, vacuum dehydrate at 110°C for 1 hour, then pass in nitrogen, add toluene diisocyanate dropwise while stirring, and obtain intermediate product I after the reaction is completed;

[0033] Step 2. Diallyl isocyanurate is added to a three-necked flask, nitrogen is introduced, heated and melted, and isocyanate propyltriethoxysilane is added dropwise while stirring, and the intermediate product II is obtained after the reaction is completed;

[0034] Step 3, mixing the intermediate product I, the intermediate product II and the photoinitiator TPO-L according to the mass ratio of 80:20:1 to obtain a curable silicon-based hybrid resin;

[0035] In said step 1, the molar ratio of amino group to isocyanate group is 1:1.05;

[0036] In the second step, the mo...

Embodiment 3

[0038] The preparation method of curable silicon-based hybrid resin comprises the following steps:

[0039] Step 1. Add amino-terminated linear polysiloxane with a number average molecular weight of 6000 into a three-necked flask, dehydrate under vacuum at 110°C for 1 hour, then blow in nitrogen, add isophorone diisocyanate dropwise while stirring, and obtain intermediate Product I;

[0040] Step 2. Diallyl isocyanurate is added to a three-necked flask, nitrogen is introduced, heated and melted, and isocyanate propyltriethoxysilane is added dropwise while stirring, and the intermediate product II is obtained after the reaction is completed;

[0041] Step 3, mix the intermediate product I, the intermediate product II and the photoinitiator 1173 according to the mass ratio of 90:10:5 to obtain the curable silicon-based hybrid resin;

[0042] In said step 1, the molar ratio of amino group to isocyanate group is 1:1.25;

[0043] In the second step, the molar ratio of diallyl iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com