Adsorbent for removing endotoxin by blood perfusion and preparation method thereof

A blood perfusion and adsorbent technology, applied in the field of biomedicine, can solve the problems of reducing the biological activity of ligands, complicated preparation process, leakage of ligands, etc., and achieves the effects of good safety, simple preparation method and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

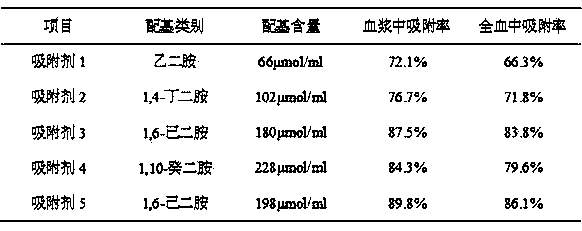

Image

Examples

Embodiment 1

[0040] (1) Preparation of carrier materials

[0041] Add 10g of vinyl acetate, 20g of triallyl isocyanurate, 3ml of ethyl acetate and 3ml of n-heptane into a 500ml three-necked flask, heat up to 40°C, stir well and add 0.3g of azobisisobutyronitrile After dissolving, add 1000ml of aqueous solution (containing 1.5% polyvinyl alcohol and 3% sodium chloride), adjust the stirring speed to disperse the droplets evenly, raise the temperature to 65°C, heat-preserve and polymerize for 1h, then raise the temperature to 75°C and maintain for 5h, filter A white spherical copolymer was obtained, washed with water, fully washed with ethanol, and dried in the air. The above-mentioned copolymer microspheres were added to a solution composed of 12g NaOH and 500ml methanol, and the transesterification reaction (or alcoholysis reaction) was carried out at 40°C for 18h. After the reaction was completed, it was filtered with suction, washed with methanol, and dried in the air to obtain the carrie...

Embodiment 2

[0048] (1) Preparation of carrier materials

[0049] Add 20g of vinyl acetate, 10g of triallyl isocyanurate, 15ml of ethyl acetate and 15ml of n-heptane into a 500ml three-necked flask, heat up to 40°C, stir well and add 0.3g of azobisisobutyronitrile After dissolving, add 450ml of aqueous solution (containing 1.5% polyvinyl alcohol and 3% sodium chloride), adjust the stirring speed to disperse the droplets evenly, raise the temperature to 65°C, keep warm for 2h, then raise the temperature to 75°C for another 3h, filter A white spherical copolymer was obtained, washed with water, fully washed with ethanol, and dried in the air. The above-mentioned copolymer microspheres were added to a solution composed of 12g NaOH and 500ml methanol, and the transesterification reaction (or alcoholysis reaction) was carried out at 40°C for 18h. After the reaction was completed, it was filtered with suction, washed with methanol, and dried in the air to obtain the carrier. The hydroxyl conten...

Embodiment 3

[0055] (1) Preparation of carrier materials

[0056] Add 24g of vinyl acetate, 6g of triallyl isocyanurate, 60ml of ethyl acetate and 60ml of n-heptane into a 500ml three-necked flask, heat up to 40°C, stir well and add 0.3g of azobisisobutyronitrile After dissolving, add 750ml of aqueous solution (containing 1.5% polyvinyl alcohol and 3% sodium chloride), adjust the stirring speed to disperse the droplets evenly, raise the temperature to 65°C, keep warm for 5h, then raise the temperature to 75°C and maintain for 1h, filter A white spherical copolymer was obtained, washed with water, fully washed with ethanol, and dried in the air. The above-mentioned copolymer microspheres were added to a solution composed of 12g NaOH and 500ml methanol, and the transesterification reaction (or alcoholysis reaction) was carried out at 40°C for 18h. After the reaction was completed, it was filtered with suction, washed with methanol, and dried in the air to obtain the carrier. The hydroxyl co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com