Modified PETG material with multilayer structure and preparation method of modified PETG material

A multi-layer structure and modification technology, applied in chemical instruments and methods, layered products, flat products, etc., can solve problems such as unfavorable PETG multilayer structure preparation, unfavorable preparation performance, unfavorable compound modification of PETG and other materials, etc. , to achieve the effect of improving degradable performance, improving environmental protection performance, and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

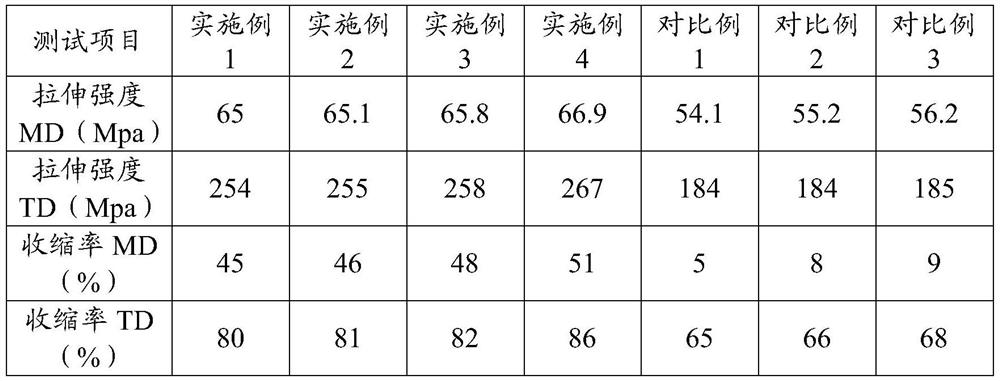

Examples

Embodiment approach

[0028] In one embodiment, a modified PETG material with a multi-layer structure includes a PP layer and two modified PETG layers, and the PP layer is arranged between the two modified PETG layers.

[0029] It should be noted that, by setting a PP layer and two modified PETG layers, a modified PETG material with a multilayer structure is formed. Specifically, the PP layer is arranged as an inner layer between the two modified PETG layers, and the two modified PETG layers PETG is set as the surface layer on the two sides of the PP layer respectively, and the two modified PETG materials are arranged symmetrically to obtain a multi-layer modified PETG material with good shrinkage performance and mechanical properties. PP is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, and good corrosion resistance. The PP layer is placed between two modified PETG layers, which is conducive to obtaining a multi-layer structure modified PETG material ...

Embodiment 1

[0050] Add PETG, silicon dioxide, toluene diisocyanate, ethylene-propylene rubber and bamboo powder into the reaction kettle in proportion, carry out stirring and mixing operation, and then carry out extrusion granulation operation through an extruder to obtain PETG pellets;

[0051] Using 200,000 Ci 60 The Co-γ-ray source irradiates the PETG pellets at a dose rate of 50Gy / min to obtain modified PETG pellets;

[0052] PP, triallyl isocyanurate, PP-g-MAH, PP-g-ST, PP-g-GMA, sorbitol-based polypropylene transparent nucleating agent, dodecylbenzenesulfonic acid Add sodium and carboxymethyl cellulose into the reaction kettle, perform stirring and mixing operation, and then perform extrusion granulation operation through an extruder to obtain PP pellets, wherein the PP-g-MAH, the PP-g- The mass ratio of ST and the PP-g-GMA is 1:1:1, and the mass ratio of the sodium dodecylbenzenesulfonate and the carboxymethyl cellulose is 0.75:1;

[0053] The modified PETG pellets and PP pellets...

Embodiment 2

[0055] Add PETG, silicon dioxide, toluene diisocyanate, ethylene-propylene rubber and bamboo powder into the reaction kettle in proportion, carry out stirring and mixing operation, and then carry out extrusion granulation operation through an extruder to obtain PETG pellets;

[0056] Using 200,000 Ci 60 The Co-γ-ray source irradiates the PETG pellets at a dose rate of 50Gy / min to obtain modified PETG pellets;

[0057] PP, triallyl isocyanurate, PP-g-MAH, PP-g-ST, PP-g-GMA, sorbitol-based polypropylene transparent nucleating agent, dodecylbenzenesulfonic acid Add sodium and carboxymethyl cellulose into the reaction kettle, perform stirring and mixing operation, and then perform extrusion granulation operation through an extruder to obtain PP pellets, wherein the PP-g-MAH, the PP-g- The mass ratio of ST and the PP-g-GMA is 1:1:1, and the mass ratio of the sodium dodecylbenzenesulfonate and the carboxymethyl cellulose is 0.75:1;

[0058] The modified PETG pellets and PP pellets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com