Fuel Cell Separating Plate And Method Of Manufacturing The Same

A fuel cell and manufacturing method technology, applied in the direction of fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complex manufacturing process and long manufacturing time, and achieve good air tightness and injection molding Excellent, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

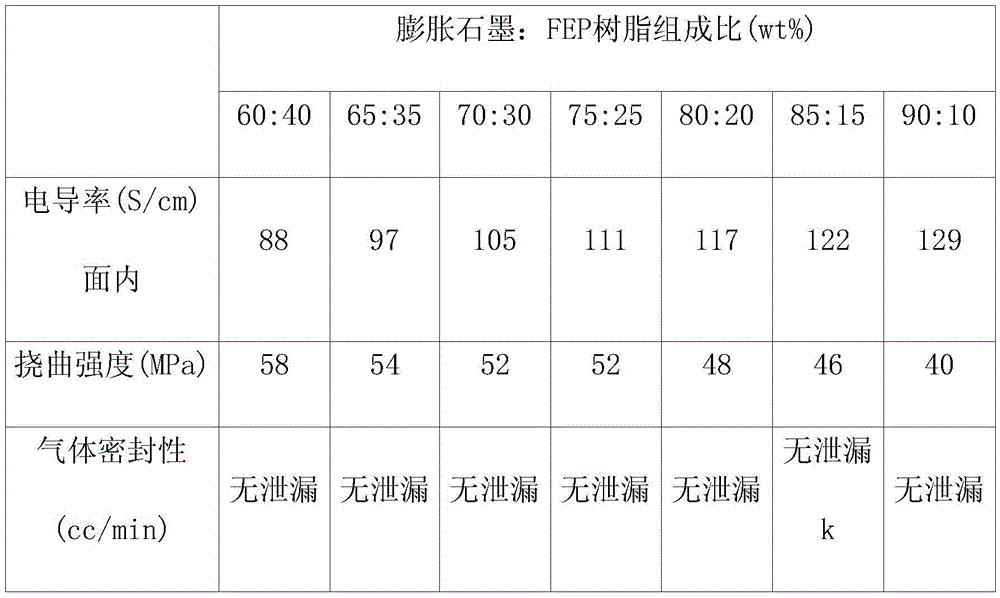

[0064] The molded body for the fuel cell separator was manufactured using the expanded graphite and FEP resin composition, and the electrical conductivity, flexural strength and gas tightness were tested according to the composition changes of the expanded graphite and the FEP resin. The results are shown in Table 1.

[0065] 【Table 1】

[0066]

[0067] As shown in Table 1, although the electrical conductivity increased and the flexural strength decreased as the FEP content decreased, it remained at a level usable as a corrosion-resistant fuel cell separator for high temperature use. In particular, even when the content of the FEP resin is around 10w%, the gas-tightness is maintained by virtue of the combined characteristics of the expanded graphite and the FEP resin.

[0068] In the carbon composites with the compositions shown in Table 1, even when the amount of expanded graphite was about 60 wt%, it was confirmed that they had electrical conductivity sufficient for use i...

experiment example 2

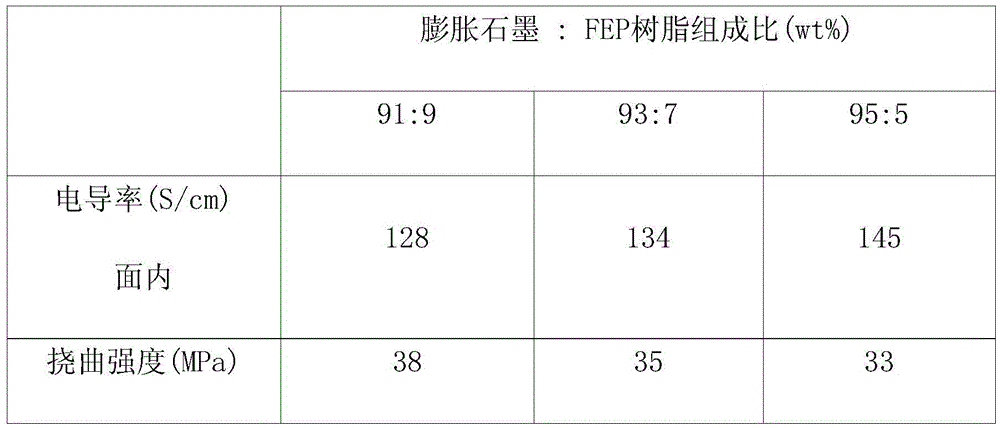

[0073] After fabricating the carbon composites for the production of porous separator plates, their electrical conductivity, flexural strength, and gas-tightness were measured. Table 2 is the result of an experimental example where the composition of expanded graphite and expanded graphite in FEP resin is manufactured at a ratio of 91-95%, and Table 3 is the result of an experimental example where the composition of natural graphite flakes is manufactured at a ratio of 85-92%.

[0074] 【Table 2】

[0075]

[0076]

[0077] 【table 3】

[0078]

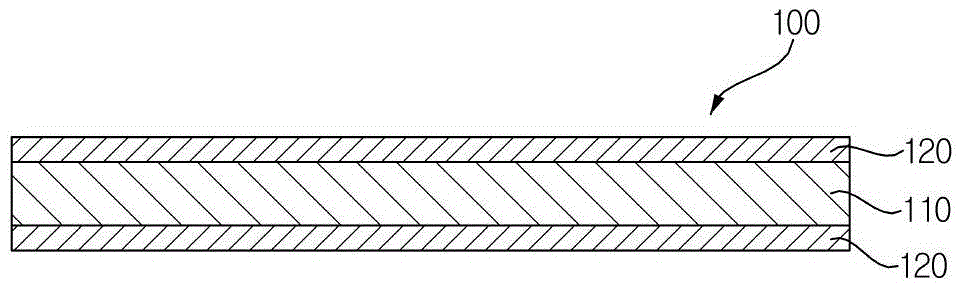

[0079] It was confirmed that a fuel cell separator plate having a porosity of 0.1 to 10 cc / min or more can be manufactured by molding the above-mentioned carbon composite. Carbon composites produced as above can be used as figure 1 The high graphite containing layer of the fuel cell separator plate is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com