Anti-corrosion coating for power grid overhead conductor

A technology of overhead wires and anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of reduced electrical conductivity and restrictions on wide application, and achieve the effects of long service life, good economic benefits, and good anti-corrosion and anti-rust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

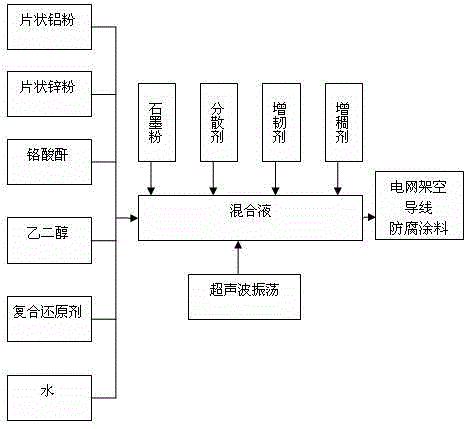

[0018] The specific embodiment of the present invention is as figure 1 As shown, the following is a detailed description of the new anti-corrosion paint coating process for power grid overhead wires of the present invention.

[0019] The technological process of the anti-corrosion coating coating of the new type power grid overhead wire in the embodiment of the present invention is as follows:

[0020] Coating liquid configuration--degreasing and degreasing of coating base materials-mechanical shot blasting to remove scale-coating-preheating and baking-sintering and curing-cooling-coating-preheating and baking-sintering and curing-cooling-inspection.

[0021] (1) Preparation of coating solution

[0022] The preparation of the coating solution is different from the general multi-component coatings, which can be mixed and dispersed in proportion. The coating mixing and preparation process is a redox reaction process, so in the coating mixing and dispersing process, a suitable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com