Plastic injection mold

A technology for injection molds and plastics, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems affecting the health of workers, single exhaust function, etc. Ensure the effect of ventilation and material resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

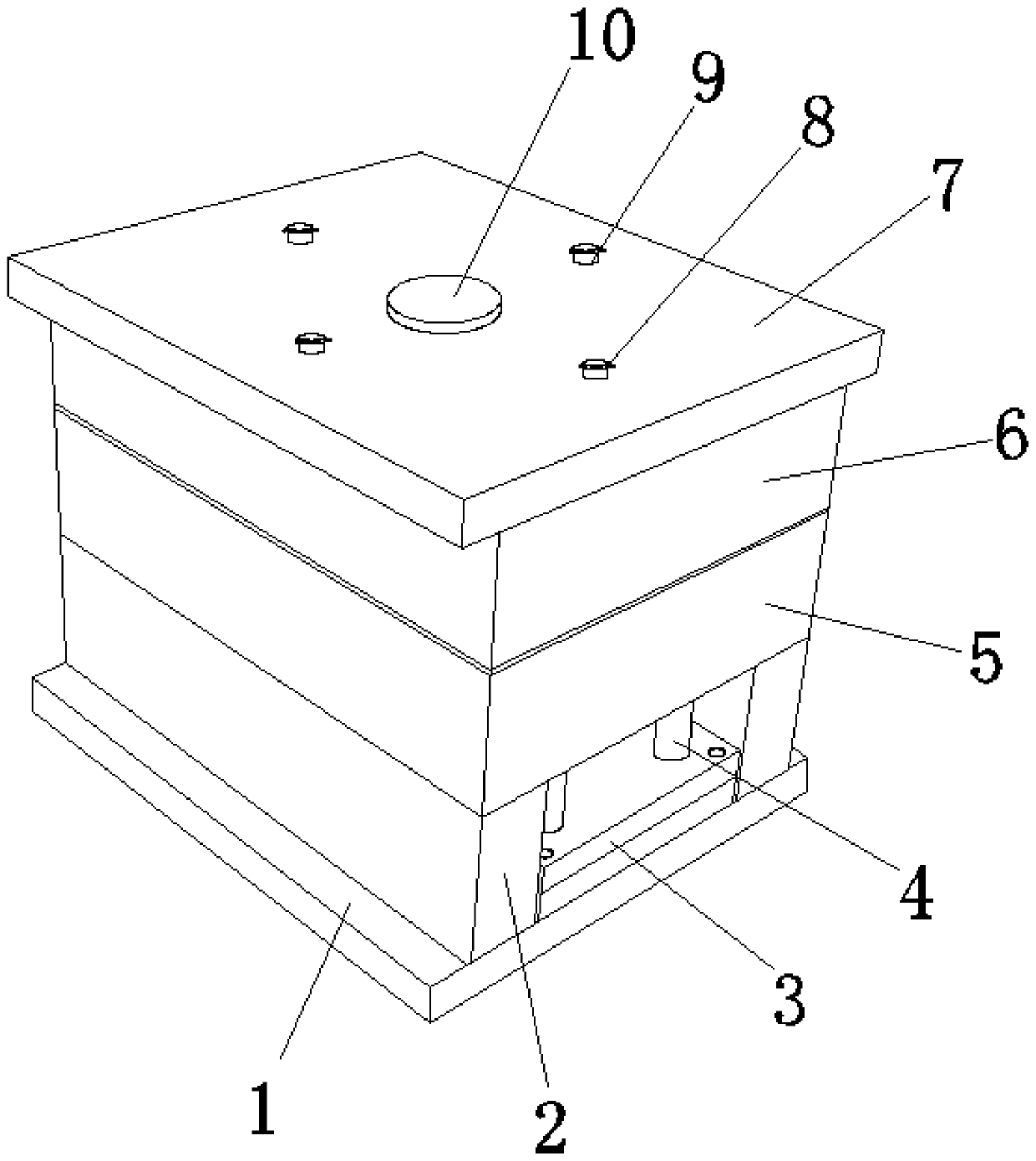

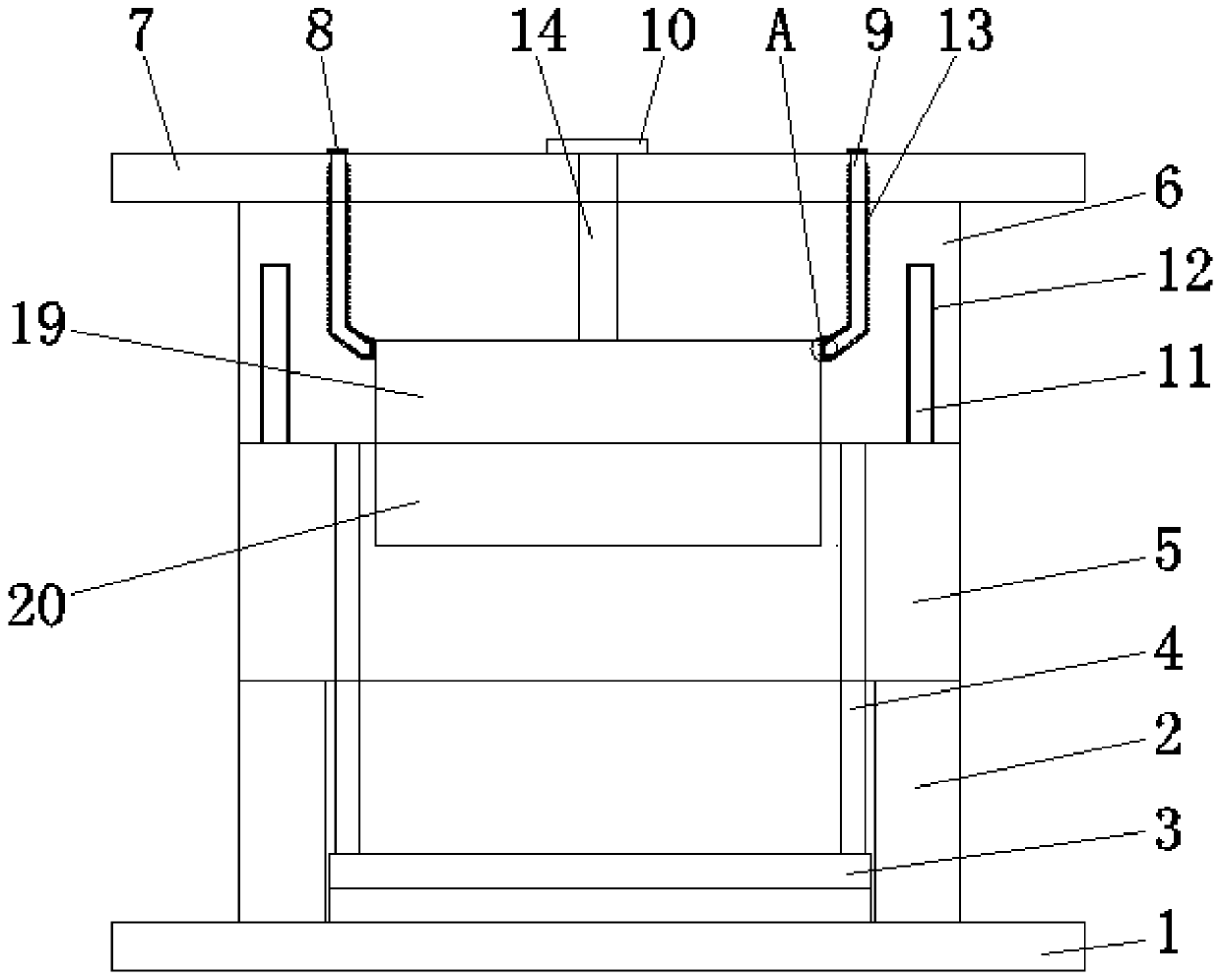

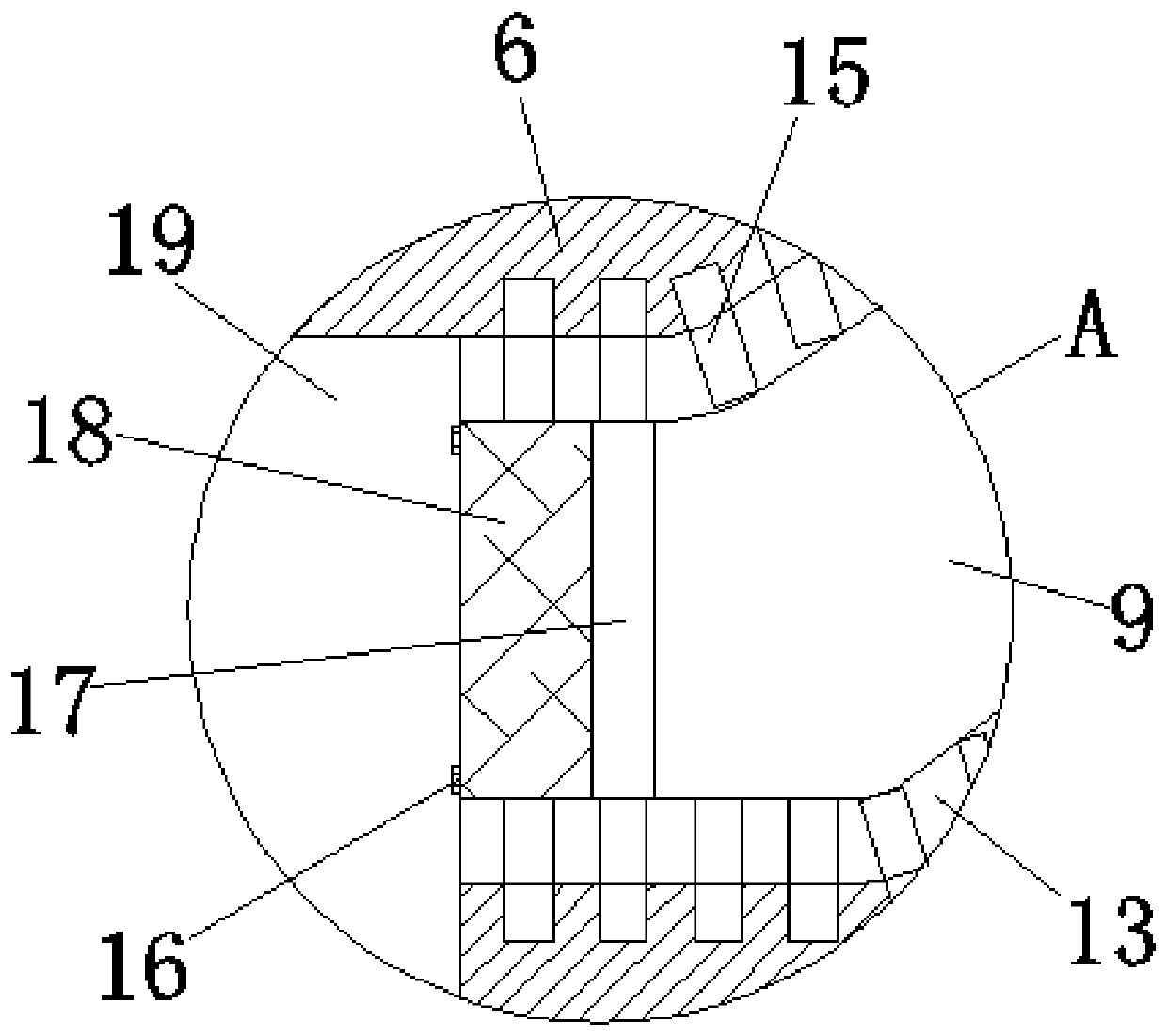

[0024] see Figure 1~5 , in an embodiment of the present invention, a plastic injection mold includes a rear formwork base plate 1, square irons 2 arranged symmetrically and in parallel are fixedly connected to both sides of the upper surface of the rear formwork base plate 1, and the two square irons 2 The bottom plate 1 of the rear formwork between them is fixedly connected with a thimble fixing plate 3, and the two sides of the upper surface of the thimble fixing plate 3 are fixedly connected with a plurality of symmetrically arranged thimble guide rods 4, and the top ends of the thimble guide rods 4 penetrate and slide into the rear mold In the holes on the corresponding surface of the frame 5, the positioning and docking of the rear mold frame 5 is realized, and the upper surface of the thimble fixing plate 3 is fixed with symmetrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com